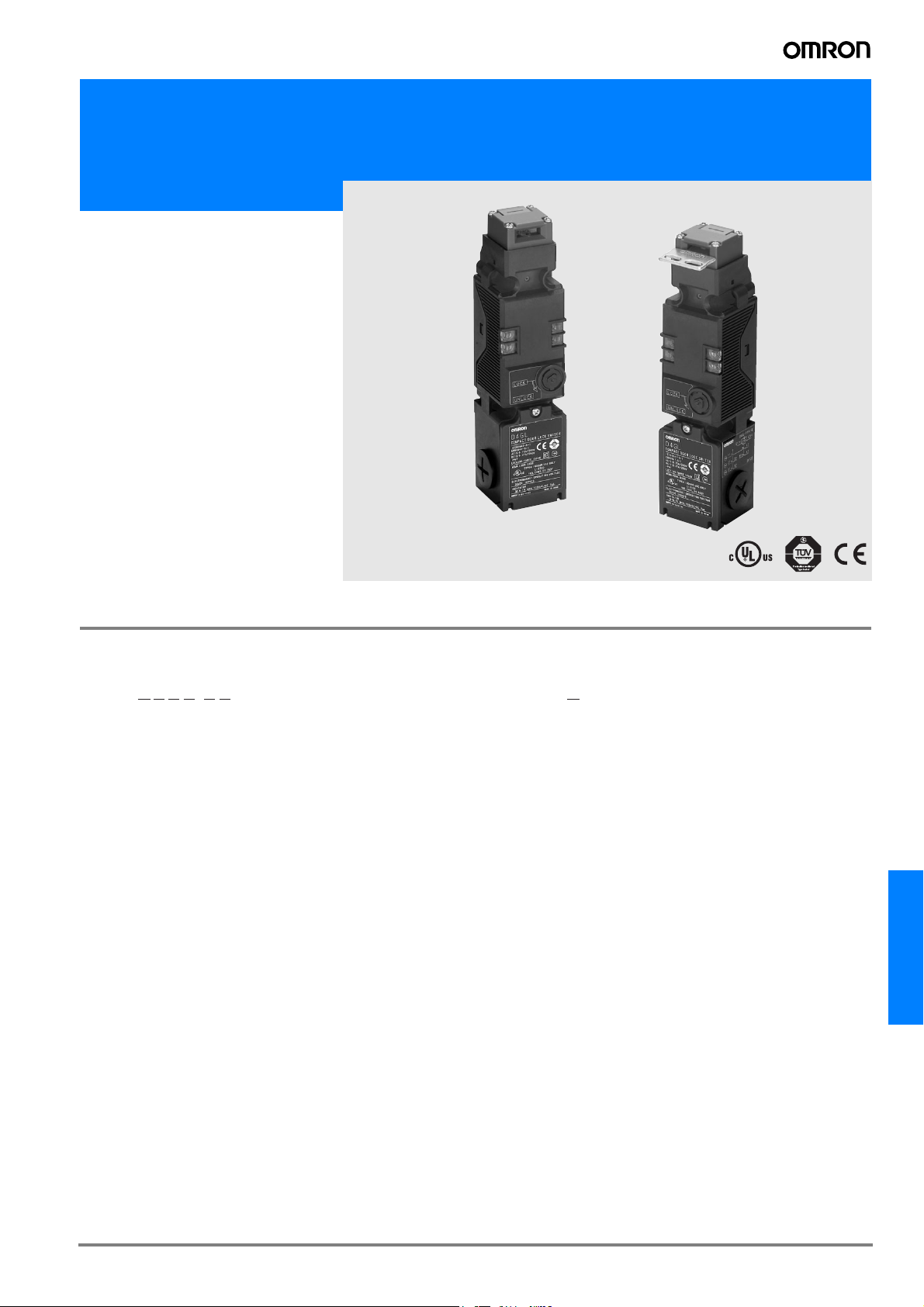

Guard Lock Safety-door Switch

D4GL

Environment-friendly

Switch with Direct

Opening Contacts

• Contains no harmful substances, such

as lead or cadmium, reducing the burden on the environment.

• Slim safety-door switch with an electromagnetic lock or unlock mechanism.

• Models with 4-contact and 5-contact

built-in switches are available.

• Capable of a holding force of 1,000 N

min.

• Can be used for either standard loads

or microloads.

• Lineup includes models with a conduit

size of M20.

• Patent and industrial design approval

pending.

Model Number Structure

Model Number Legend

Switch

D4GL-@@@@-@@

4 5

123

1. Conduit Size

1: Pg13.5

2: G1/2

4: M20

2. Built-in Switch (with Door Open/Closed Detection Switch and

Lock Monitor Switch Contacts)

A: 1NC/1NO slow-action contacts plus 1NC/1NO slow-action

contacts

B: 1NC/1NO slow-action contacts plus 2NC slow-action con-

tacts

C: 2NC slow-action contacts plus 1NC/1NO slow-action con-

tacts

D: 2NC slow-action contacts plus 2NC slow-action contacts

E: 2NC/1NO slow-action contacts plus 1NC/1NO slow-action

contacts

F: 2NC/1NO slow-action contacts plus 2NC slow-action con-

tacts

G: 3NC slow-action contacts plus 1NC/1NO slow-action con-

tacts

H: 3NC slow-action contacts plus 2NC slow-action contacts

3. Head Mounting Direction and Material

F: Four mounting directions possible (Front-side mounting at

time of delivery)/plastic

4. Door Lock and Release

A: Mechanical lock/24-VDC solenoid release

G: 24-VDC solenoid lock/mechanical release

5. Indicator

B: 24 VDC (orange/green LED indicator)

6. Release Key Type

Blank:Standard release key

4: Special release key

6

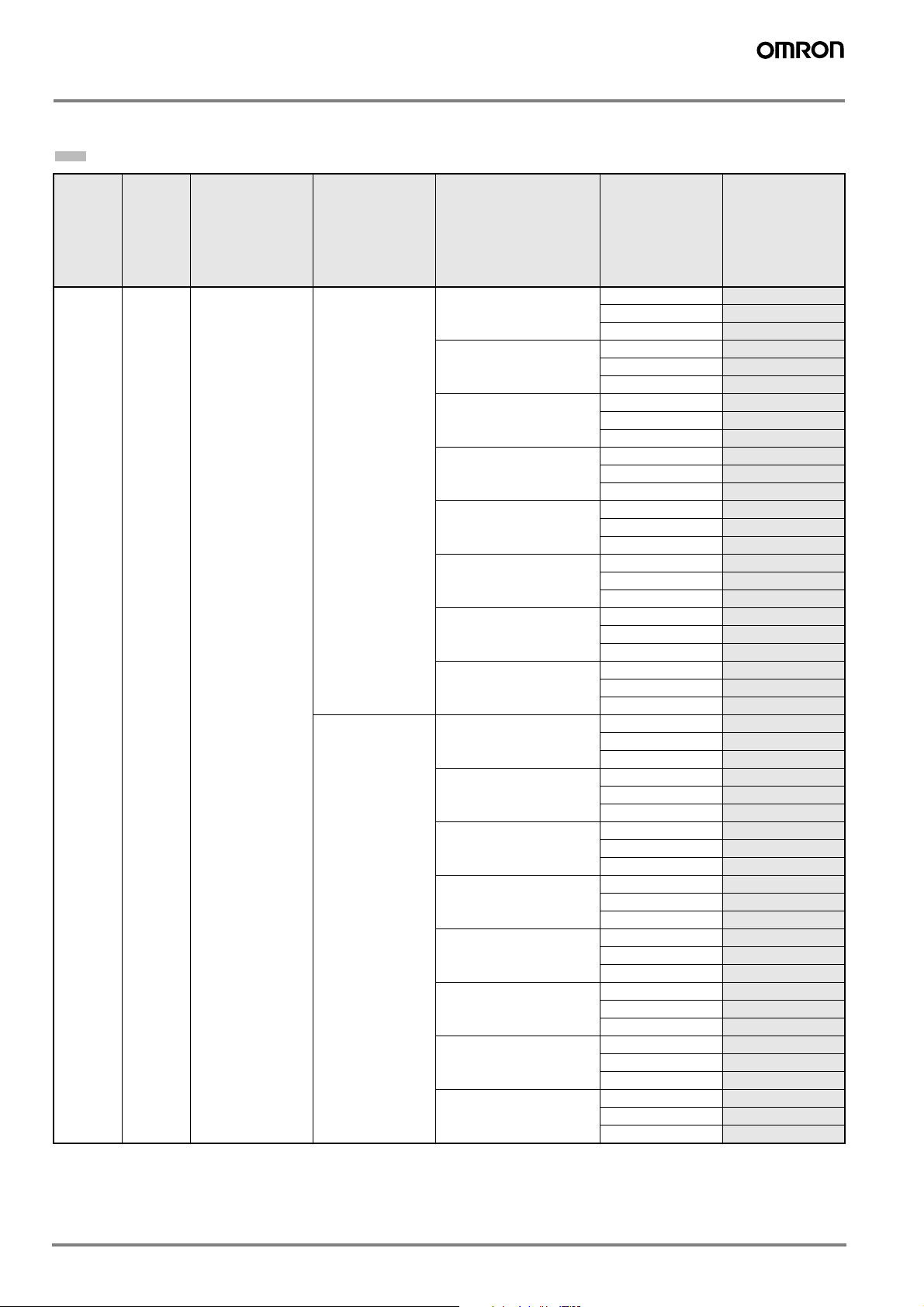

Operation Key

D4DS-K@

1

1. Operation Key Type

1: Horizontal mounting

2: Vertical mounting

3: Adjustable mounting (horizontal)

5: Adjustable mounting (horizontal/vertical)

\

D4GL

G-171D4GL

Ordering Information

List of Models

Switches (Operation Keys are sold separately.)

: Models with approved direct opening contacts. Prefered stock item*

Contact configuration

Head ma-

terial

Plastic Standard

Release

key type

Solenoid voltage/

indicator

Solenoid: 24 VDC

Orange/green LED:

24 VDC

Lock and release

types

Mechanical lock

Solenoid release

Solenoid lock

Mechanical release

detection switch and lock

monitor switch contacts)

Approved direct opening

1NC/1NO+1NC/1NO

1NC/1NO+2NC

2NC+1NC/1NO

2NC+2NC

2NC/1NO+1NC/1NO

2NC/1NO+2NC

3NC+1NC/1NO

3NC+2NC

1NC/1NO+1NC/1NO

1NC/1NO+2NC

2NC+1NC/1NO

2NC+2NC

2NC/1NO+1NC/1NO

2NC/1NO+2NC

3NC+1NC/1NO

3NC+2NC

(door open/closed

(slow-action)

NC contact

Conduit size Model

Pg13.5

G1/2

M20

Pg13.5

G1/2

M20

Pg13.5

G1/2

M20

Pg13.5

G1/2

M20

Pg13.5

G1/2

M20

Pg13.5

G1/2

M20

Pg13.5

G1/2

M20

Pg13.5

G1/2

M20

Pg13.5

G1/2

M20

Pg13.5

G1/2

M20

Pg13.5

G1/2

M20

Pg13.5

G1/2

M20

Pg13.5

G1/2

M20

Pg13.5

G1/2

M20

Pg13.5

G1/2

M20

Pg13.5

G1/2

M20

D4GL-1AFA-A*

D4GL-2AFA-A

D4GL-4AFA-A*

D4GL-1BFA-A

D4GL-2BFA-A

D4GL-4BFA-A

D4GL-1CFA-A*

D4GL-2CFA-A

D4GL-4CFA-A*

D4GL-1DFA-A

D4GL-2DFA-A

D4GL-4DFA-A

D4GL-1EFA-A

D4GL-2EFA-A

D4GL-4EFA-A*

D4GL-1FFA-A

D4GL-2FFA-A

D4GL-4FFA-A

D4GL-1GFA-A

D4GL-2GFA-A

D4GL-4GFA-A

D4GL-1HFA-A

D4GL-2HFA-A

D4GL-4HFA-A

D4GL-1AFG-A*

D4GL-2AFG-A

D4GL-4AFG-A*

D4GL-1BFG-A

D4GL-2BFG-A

D4GL-4BFG-A

D4GL-1CFG-A*

D4GL-2CFG-A

D4GL-4CFG-A*

D4GL-1DFG-A

D4GL-2DFG-A

D4GL-4DFG-A

D4GL-1EFG-A

D4GL-2EFG-A

D4GL-4EFG-A*

D4GL-1FFG-A

D4GL-2FFG-A

D4GL-4FFG-A

D4GL-1GFG-A

D4GL-2GFG-A

D4GL-4GFG-A

D4GL-1HFG-A

D4GL-2HFG-A

D4GL-4HFG-A

G-172 Safety Sensors / Components

Operation Keys (Order Separately)

Type Model

Horizontal mounting

D4DS-K1

Vertical mounting

Adjustable mounting

(Horizontal)

Adjustable mounting

(Horizontal/Vertical)

D4DS-K2

D4DS-K3

D4DS-K5

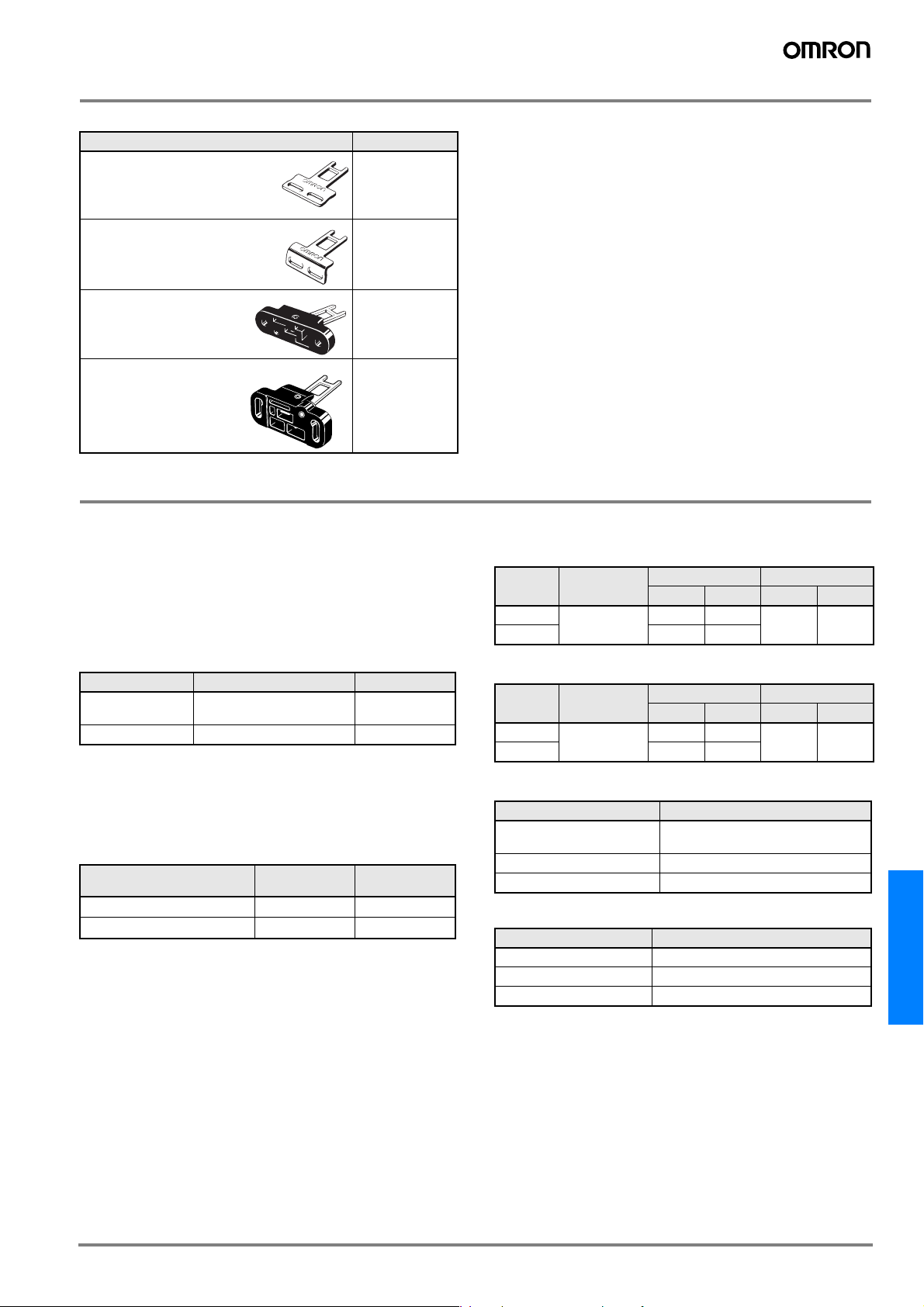

Specifications

Standards and EC Directives

Applicable EC Directives and Standards

• Machinery Directive

• Low Voltage Directive

• EN1088

• EN60204-1

• GS-ET-19

Approved Standards

Agency Standard File No.

TÜV Product

Service

UL (See note 2.) UL508, CSA C22.2 No.14 E76675

Note: 1. Consult your OMRON representative for details.

2. Approval for CSA C22.2 No. 14 is authorized by the UL

mark.

Approved Standard Ratings

TÜV (EN60947-5-1)

Item

Rated operating current (I

Rated operating voltage (U

Note: Use a 10-A fuse type gI or gG that conforms to IEC269 as a short-circuit

protection device.

EN60947-5-1 (approved

direct opening)

Utilization

category

) 0.75 A 0.27 A

e

e

AC-15 DC-13

) 240 V 250 V

(See note 1.)

UL/CSA (UL508, CSA C22.2 No. 14)

C300

Rated

voltage

120 VAC 2.5 A 15 A 1.5 A 1,800 VA 180 VA

240 VAC 7.5 A 0.75 A

Carry current Current Volt-amperes

Make Break Make Break

Q300

Rated

voltage

125 VAC 2.5 A 0.55 A 0.55 A 69 VA 69 VA

250 VAC 0.27 A 0.27 A

Carry current Current Volt-amperes

Make Break Make Break

Solenoid Coil Characteristics

Item 24 VDC

Rated operating voltage

(100% ED)

Current consumption Approx. 200 mA

Insulation Class F (130° C max.)

24 VDC ±10%

Indicator Characteristics

Item LED

Rated voltage 24 VDC

Current leakage Approx. 3 mA

Color (LED) Orange/Green

D4GL

G-173D4GL

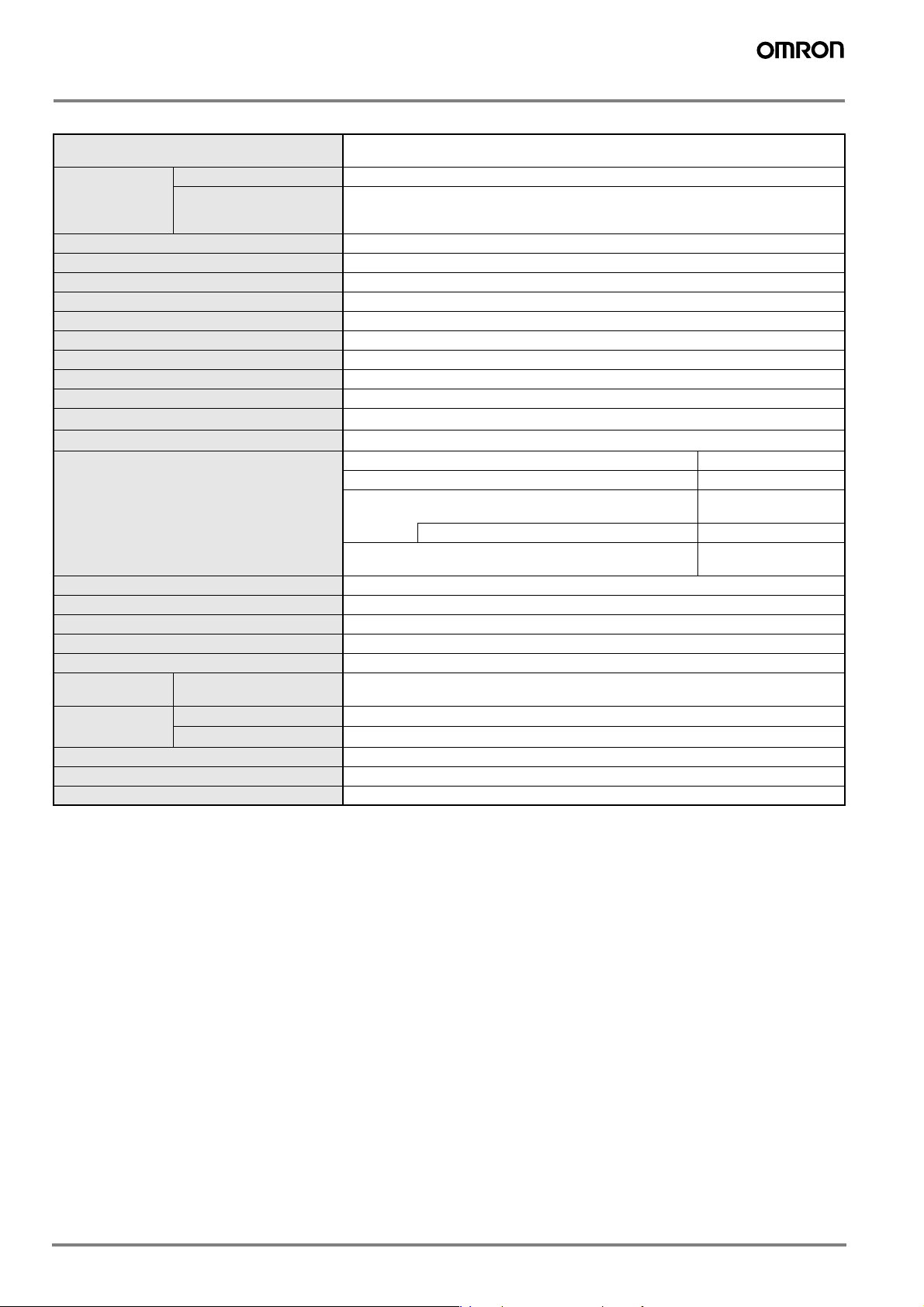

Characteristics

Degree of protection (See note 2.) IP67 (EN60947-5-1)

Durability

(See note 3.)

Mechanical 1,000,000 operations min.

Electrical 500,000 operations min. for a resistive load of 4 mA at 24 VDC;

Operating speed 0.05 to 0.5 m/s

Operating frequency 30 operations/minute max.

Rated frequency 50/60 Hz

Contact gap 2 x 2 mm min.

Direct opening force (See note 5.) 60 N min. (EN60947-5-1)

Direct opening travel (See note 5.) 10 mm min. (EN60947-5-1)

Holding force (See note 6.) 1,000 N min.

Insulation resistance 100 MΩ min. (at 500 VDC)

Minimum applicable load (See note 7.) Resistive load of 4 mA at 24 VDC (N-level reference value)

Rated insulation voltage (Ui) 300 V (EN60947-5-1)

Conventional enclosed thermal current (I

the

Impulse withstand voltage (EN60947-5-1) Between terminals of the same polarity 2.5 kV

Conditional short-circuit current 100 A (EN60947-5-1)

Pollution degree (operating environment) 3 (EN60947-5-1)

Protection against electric shock Class II (double insulation)

Closed-circuit counterelectromotive force 1,500 V max. (EN60947-5-1)

Contact resistance 25 mΩ max. (initial value)

Vibration resis-

Malfunction 10 to 55 Hz, 0.75-mm single amplitude

tance

Shock resistance Destruction

Malfunction

Ambient temperature Operating: −10° C to 55° C with no icing

Ambient humidity Operating: 95% max.

Weight Approx. 400 g (D4GL-1AFA-A)

Note: 1. The above values are initial values.

2. The degree of protection is tested using the method specified by the standard (EN60947-5-1). Confirm that sealing properties are suffi-

cient for the operating conditions and environment beforehand. Although the switch box is protected from dust or water penetration, do

not use the D4GL in places where foreign material may penetrate through the key hole on the head, otherwise Switch damage or malfunctioning may occur.

3. The durability is for an ambient temperature of 5°C to 35° C and an ambient humidity of 40% to 70%. For more details, consult your OM-

RON representative.

4. If the ambient temperature is greater than 35° C, do not pass the 1-A, 125-VAC load through more than 2 circuits.

5. These figures are minimum requirements for safe operation.

6. This figure is based on the GS-ET-19 evaluation method.

7. This value will vary with the switching frequency, environment, and reliability level. Confirm that correct operation is possible with the actual

load beforehand.

(This applies for the Switch only. The degree of protection for the key hole is IP00.)

150,000 operations min. for a resistive load of 1 A at 125 VAC in 2 circuits and 4 mA at

24 VDC in 2 circuits (See note 4.)

) 2.5 A (EN60947-5-1)

Between terminals of different polarities 4 kV

Between the solenoid and uncharged metallic parts and be-

---

tween the solenoid and ground

24-VDC solenoid 0.8 kV

Between other terminals and uncharged metallic parts and be-

4 kV

tween other terminals and ground

2

min.

2

min.

1,000 m/s

300 m/s

G-174 Safety Sensors / Components

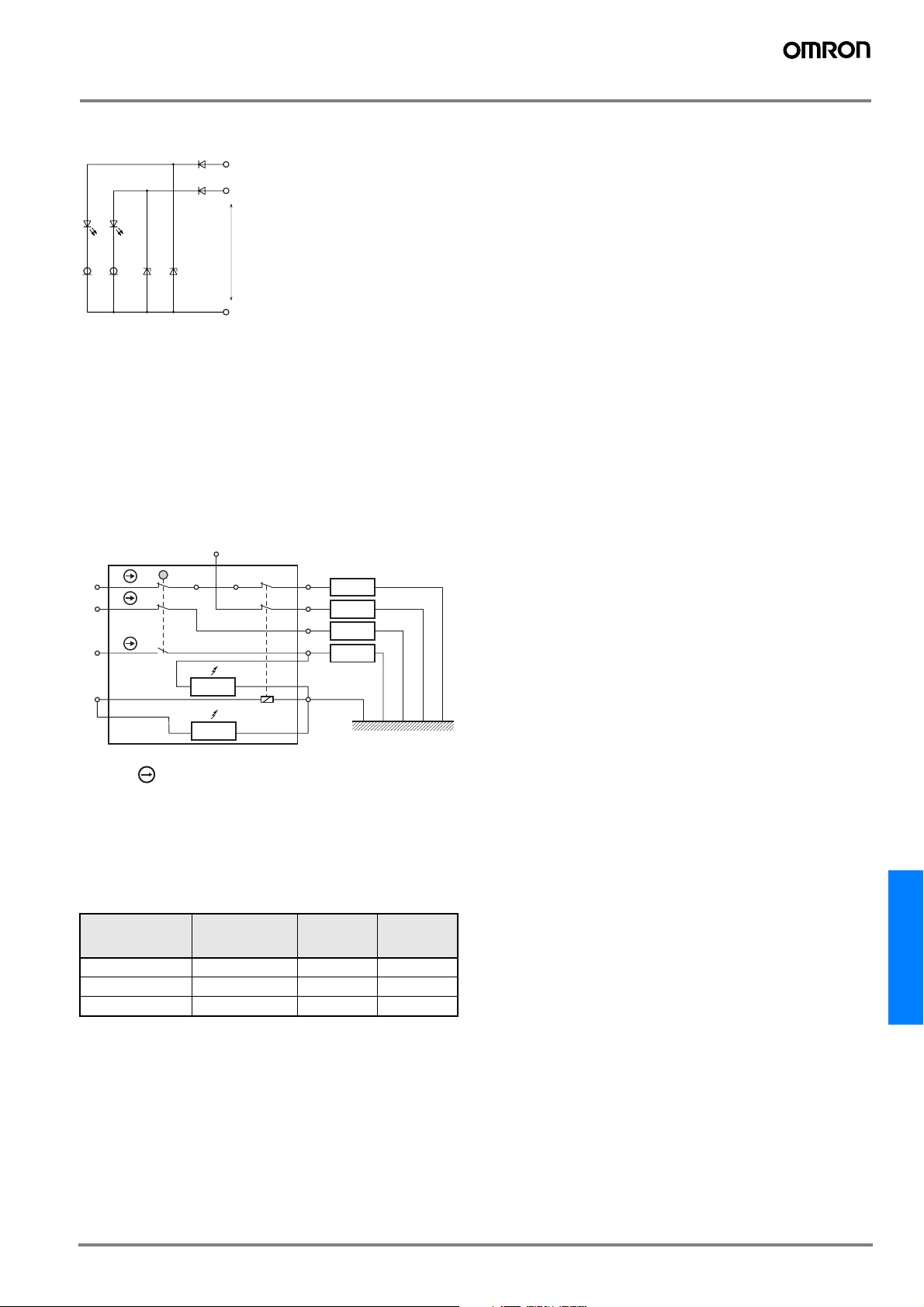

Connections

Indicator

Internal Circuit Diagram

D

D

LED

LED

(Green)

(Orange)

Green (+)

Orange (+)

CRD CRD ZD ZD

5 to 24V DC

COM (−)

Circuit Connection Example

• Terminals 12 and 41 are connected internally and so connect ter-

minals 11 and 42 for safety-circuit input. (BIA GS-ET-19)

• Connect terminals 21 and 22 and terminals 51 and 52 in series

when using as safety-circuit input (redundancy circuit for terminals

11 and 12 and terminals 41 and 42 above). Connect the terminals

individually when using as auxiliary-circuit input (e.g., terminals 21

and 22 for safety-door open/closed monitoring and terminals 51

and 52 for monitoring the lock status).

• In the following connection example, terminals 21 and 22 and ter-

minals 51 and 52 are used as auxiliary-circuit input.

Connection Example for D4GL-1HFA-A

51

11

21

31

O1 (Green)

E1

12 41

Indicator

(Green)

O2

(Green)

42

Safety

circuit

52

Auxiliary

circuit

22

Auxiliary

circuit

32

Auxiliary

circuit

E2

Indicator

O3 (Orange)

(Orange)

O4 (Orange)

• Direct opening contacts used as safety-circuit input are indicated

with the mark. Terminals 11 and 12 and terminals 21 and 22

are direct opening contacts.

• Connect the indicators in parallel to the auxiliary circuits or termi-

nals E1 and E2.

• Although the 3 lines are connected at the time of delivery, rewire

them as necessary for the application.

• The following table shows the connection configuration required to

make the green indicator light when the door is closed and the

orange indicator light when the solenoid turns ON.

Indicator Terminal

number

Lead wire

color

Connected

terminal

number

Green indicator O1 Green 32

Orange indicator O2 Orange E1

Common O3 Black E2

• If an indicator is connected in parallel to a direct opening contact,

when the indicator breaks, a short-circuit current will be generated,

possibly resulting in an installation malfunction.

• Do not switch standard loads for more than 2 circuits at the same

time. Otherwise, the level of insulation may decrease.

• The solenoid has polarity. Be sure to connect terminals with the

correct polarity.

D4GL

G-175D4GL

Loading...

Loading...