Page 1

Small Safety Limit Switch

D4F

A Smaller Limit Switch than

Ever Previously Produced.

Ideal for Applications to

Small-scale Machinery and

Equipment

• A noticeable reduction to 1/4 the size of OMRON's

conventional model.

• High-sensitivity safety limit switch.

• Built-in switches with two- or four-contact construction

are available.

• Degree of protection: IP67 (EN60947-5-1)

• Patent and design pending.

Features

A Dramatic Reduction in Size

The volume is reduced to one quarter of the volume of our company's

conventional types of limit switches

(30 (W) × 18 (L) × 60 mm (H)).

Optimal for the downsizing of machinery and equipment.

High-sensitivity and Spacesaving

The conventional types of limit

switches with a direct opening

mechanism required 18 degrees for

a movement until operation because its direct opening point is long

(Our company's conventional types

of limit switches).

The D4F requires 6 degrees to respond.

On the table that allows machine

tools etc. to move at an increasing

speed, the moment the dog pushes

the actuator, the D4F responds.

With the development of smaller

versions of machines, the D4F

saves space and fits in a smaller

space.

Compared with conventional type

1

4

60 mm

18 mm

30 mm

18˚

6˚

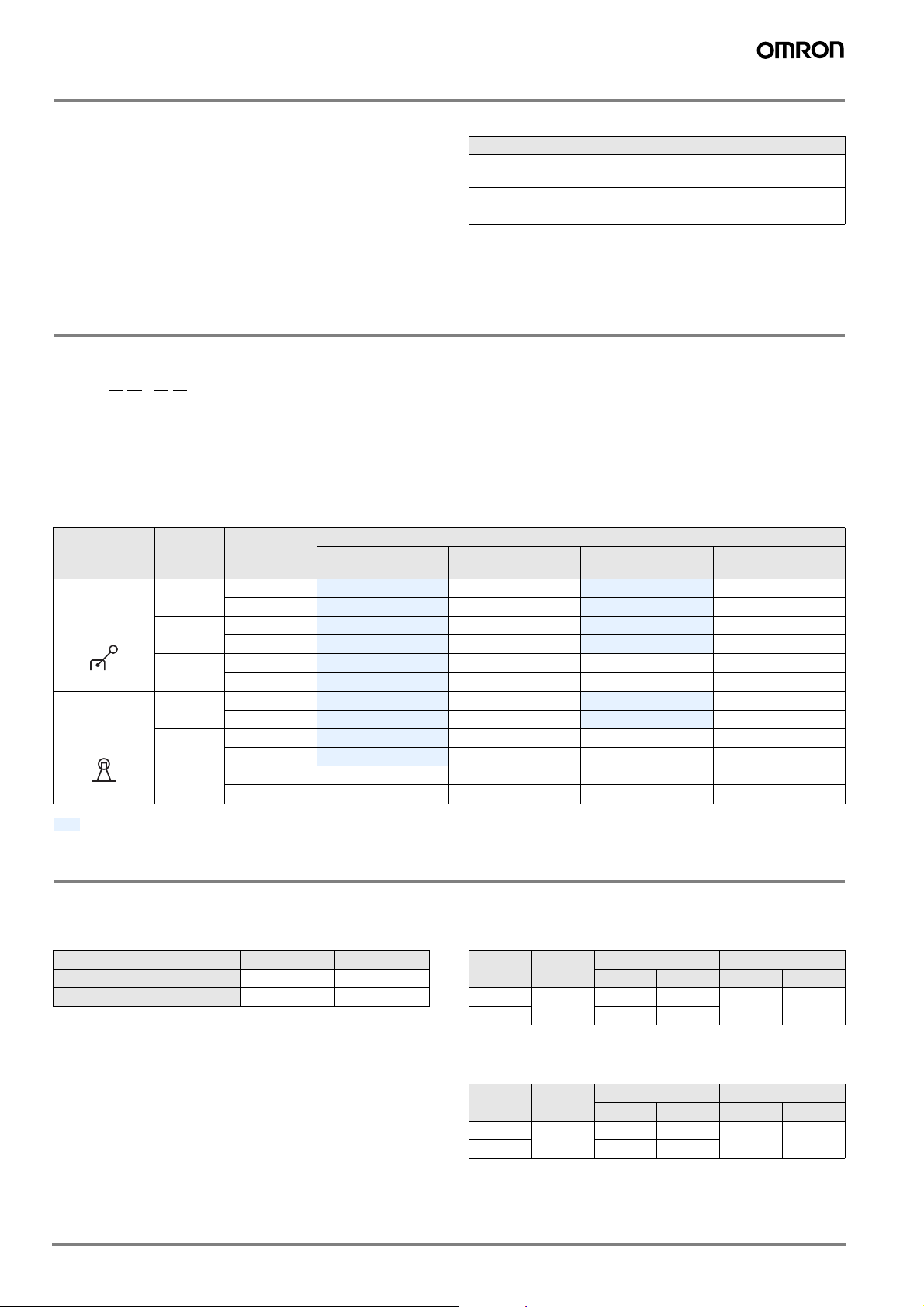

Four-contact Construction is Available

D4F models of two-contact construction (1NC/1NO and 2NC) and

those of four-contact construction

(2NC/2NO and 4NC) are available.

The auxiliary contact can be used

for monitoring input of control circuits and indicator lighting.

<2NC/2NO>

Safety contact 11

Safety contact 21

Auxiliary contact

Auxiliary contact

33

43

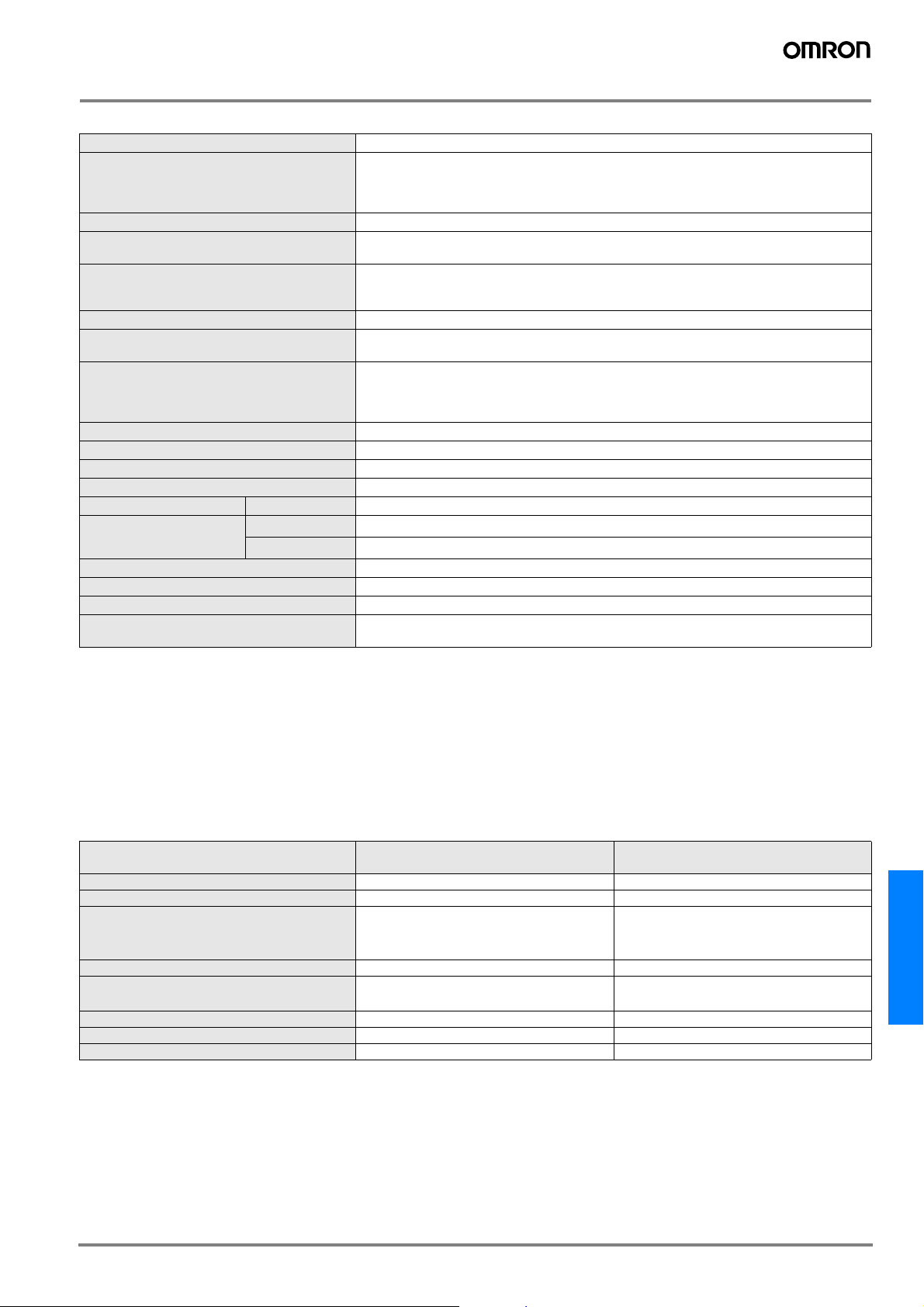

Positioning in Steps of 9 Degrees

For a roller lever type of switch,

grooves are incised on the body and

the cam of the actuator, to allow positioning in steps of 9 degrees.

Zb

12

22

34

44

9

˚

9

˚

9

˚

9

˚

D4F

G-259D4F

Page 2

Standards and EC Directives

• Conforms to the following EC Directives:

Machinery Directive

Low Voltage Directive

EN60204-1

EN1088

EN50047

EN81

EN115

GS-ET-15

JIS C 8201-5-1

Ordering Information

Model Number Legend

D4F-@@-@@

1 2 3 4

1. Built-in Switch

1: 1NC/1NO (slow-action)

2: 2NC (slow-action)

3: 2NC/2NO (slow-action)

4: 4NC (slow-action)

List of Models

2. Actuator

02: Roller plunger

(Metallic roller)

20: Roller lever

(Metallic lever, resin roller)

Approved Standards

Agency Standards File No.

TÜV Product

service

UL (See note 2.) UL508

Note: 1. Contact your Omron sales representative.

2. Approval has been obtained for CSA C22.2 No. 14

under UL.

3. Cable Length

1: 1 m

3: 3 m

5: 5 m

EN60947-5-1

(Direct opening: approved)

CSA C22.2 No.14

4. Pull-outing direction of cable

R: Horizontal

D: Vertical

(See note 1.)

E76675

Actuator Cable

Roller lever (Metallic lever, resin

roller)

Roller plunger

(Metallic roller)

length

1 m Horizontal

3 m Horizontal

5 m Horizontal

1 m Horizontal

3 m Horizontal

5 m Horizontal D4F-102-5R D4F-202-5R D4F-302-5R D4F-402-5R

Cable

direction

Vertical

Vertical

Vertical

Vertical

Vertical

Vertical D4F-102-5D D4F-202-5D D4F-302-5D D4F-402-5D

1NC/1NO

(slow-action)

D4F-120-1R D4F-220-1R D4F-320-1R D4F-420-1R

D4F-120-1D D4F-220-1D D4F-320-1D D4F-420-1D

D4F-120-3R D4F-220-3R D4F-320-3R D4F-420-3R

D4F-120-3D D4F-220-3D D4F-320-3D D4F-420-3D

D4F-120-5R D4F-220-5R D4F-320-5R D4F-420-5R

D4F-120-5D D4F-220-5D D4F-320-5D D4F-420-5D

D4F-102-1R D4F-202-1R D4F-302-1R D4F-402-1R

D4F-102-1D D4F-202-1D D4F-302-1D D4F-402-1D

D4F-102-3R D4F-202-3R D4F-302-3R D4F-402-3R

D4F-102-3D D4F-202-3D D4F-302-3D D4F-402-3D

Prefered items

Specifications

Approved Standard Ratings

TÜV (EN60947-5-1)

Item Utilization category AC-15 DC-13

Rated operating current (Ie) 0.75 A 0.27 A

Rated operating voltage (Ue) 240 V 250 V

Note: Use a 10-A fuse type gI or gG that conforms to IEC269 as a

short-circuit protection device.

Built-in switch

2NC

(slow-action)

2NC/2NO

(slow-action)

4NC

(slow-action)

UL/CSA (UL508, CSA C22.2 No. 14)

C300

Rated

voltage

120 VAC 2.5 A 15 A 1.5 A 1,800 VA 180 VA

240 VAC 7.5 A 0.75 A

Q300

Carry

current

Current Volt-amperes

Make Break Make Break

Rated

voltage

125 VDC 2.5 A 0.55 A 0.55 A 69 VA 69 VA

250 VDC 0.27 A 0.27 A

Carry

current

Current Volt-amperes

Make Break Make Break

G-260 Safety Sensors / Components

Page 3

Characteristics

Degree of protection (See note 1.) IP67 (EN60947-5-1)

Durability (See note 2.) Mechanical: 10,000,000 times min.

Operating speed 1 mm/s to 0.5 m/s

Operating frequency Mechanical: 120 operations/minute

Insulation resistance 100 MΩ min. (at 500 VDC) between terminals of the same polarities, between terminals of dif-

Minimum applicable load (See note 4.) 4-mA resistive load at 24 VDC, 4 circuits (Level N reference value)

Contact resistance (See note 5.) 300 mΩ max. (initial value with 1-m cable), 500 mΩ max. (initial value with 3-m cable),

Dielectric strength Between terminals of same polarities: Uimp 2.5 kV (EN60947-5-1)

Conditional short-circuit current 100 A (EN60947-5-1)

Pollution degree (operating environment) 3 (EN60947-5-1)

Conventional free air thermal current (Ith) 2.5 A (EN60947-5-1)

Protection against electric shock Class I (with a ground wire)

Vibration resistance Malfunction 10 to 55 Hz, 0.75-mm single amplitude

Shock resistance Destruction

Malfunction

Ambient temperature Operating: −30°C to 70°C (with no icing)

Ambient humidity Operating: 95% max.

Cable UL2464 No. 22 AWG, finishing O.D.: 8.3 mm

Weight Approx. 190 g (D4F-102-1R, with 1-m cable)

Electrical: 1,000,000 times min. (4-mA resistive load at 24 VDC, 4 circuits)

150,000 times min. (1-A resistive load at 125 VAC, 2 circuits / 4-mA resistive load at 24 VDC,

2 circuits) (See note 3.)

Electrical: 30 operations/minute

ferent polarities, between current-carrying metal parts and grounds, and between each terminal and non-current carrying metal parts

700 mΩ max. (initial value with 5-m cable)

Between terminals of different polarities: Uimp 4 kV (EN60947-5-1)

Between current-carrying metal parts and grounds: Uimp 4 kV (EN60947-5-1)

Between each terminal and non-current carrying metal parts: Uimp 4 kV (EN60947-5-1)

2

2

min.

min.

1,000 m/s

300 m/s

Approx. 220 g (D4F-120-1R, with 1-m cable)

Note: 1. The degree of protection shown above is based on the test method specified in EN60947-5-1. Be sure to confirm in advance the sealing

performance under the actual operating environment and conditions.

2. Durability values are calculated at an operating temperature of 5°C to 35°C, and an operating humidity of 40% to 70%. Contact your

OMRON sales representative for more detailed information on other operating environments.

3. When the ambient temperature is 35°C or higher, do not apply 1 A at 125 VAC to more than two circuits.

4. The value will vary depending on factors such as the switching frequency, the ambient environment, and the reliability level.

Be sure to confirm correct operation with the actual load before application.

5. The contact resistance was measured with 0.1 A at 5 to 8 VDC with a fall-of-potential method.

Operating Characteristics

Slow-action (1NC/1NO, 2NC, 2NC/2NO, and 4NC)

Operating Characteristics

Operating force max.: OF (See note 1.) 5 N 12 N

Release force min.: RF (See note 2.) 0.5 N 1.5 N

Pretravel: PT1 (11-12 and 21-22)

: PT1 (31-32 and 41-42)

: PT2 (See note 3.)

Overtravel min.: OT 40° 3.2 mm

Operating position: OP (11-12 and 21-22)

: OP (31-32 and 41-42)

Total travel: TT (See note 3.) (55°) (4.5 mm)

Min. direct opening travel: DOT (See note 4.) 18° 1.8 mm

Min. direct opening force: DOF 20 N 20 N

Note: 1. The OF value is the maximum load that opens an NC contact (11-12, 21-22, 31-32, 41-42).

2. The RF value is the minimum load that closes an NC contact (11-12, 21-22, 31-32, 41-42).

3. The PT2 and TT values are reference values.

4. The D4F is used in accordance with EN81 and EN115 at a minimum DOT of 30° and 2.8 mm.

Model

6±3° (NC)

9±3° (NC)

(12°) (NO)

——

——

D4F-@20-@R

D4F-@20-@D

D4F-@02-@R

D4F-@02-@D

1 mm max. (NC)

1.3 mm max. (NC)

(1.2 mm) (NO)

29.4±1 mm

29±1 mm

D4F

G-261D4F

Page 4

Nomenclature

Lever

Improved safety of the lever-setting (Form lock configuration).

Many grooves are incised on the lever and the rotating shaft

Head

The plunger type of actuator can be used in a

normal direction and reverse direction.

that mesh with each other to prevent a slip between the lever

and the rotating shaft.

The lever can be set for positioning in steps of 9 degrees.

Cable

Built-in Switch

Has a direct opening mechanism separating

The cable can be pulled out in a horizontal

direction or in a vertical direction.

the contacts when the NC contacts are welded.

Operation

Contact Form

Model Contact Diagram Remarks

D4F-1@-@@ 1NC/1NO

(slow-action)

D4F-2@-@@ 2NC

(slow-action)

D4F-3@-@@ 2NC/2NO

(slow-action)

D4F-4@-@@ 4NC

(slow-action)

Zb

11

33

Zb

11

21

Zb

11

21

33

43

Zb

11

21

31

41

11-12

12

33-34

34

11-12

12

21-22

22

11-12

12

21-22

22

33-34

43-44

34

44

11-12

12

21-22

22

31-32

41-42

32

42

Stroke

Stroke

Stroke

Stroke

Only NC contact 11-12 has an approved

ON

direct opening mechanism.

The terminals 11-12 and 33-34 can be used

as unlike poles.

NC contacts 11-12 and 21-22 have an

ON

approved direct opening mechanism.

The terminals 11-12 and 21-22 can be used

as unlike poles.

NC contacts 11-12 and 21-22 have an

approved direct opening mechanism.

The terminals 11-12, 21-22, 33-34 and

ON

43-44 can be used as unlike poles.

NC contacts 11-12, 21-22, 31-32 and 41-42

have an approved direct opening

mechanism.

ON

The terminals 11-12, 21-22, 31-32 and

41-42 can be used as unlike poles.

Direct Opening Mechanism

1NC/1NO Contact (slow-action)

Fixed contact (NC)

Contact spring

Return spring

Movable contact

Fixed contact (NO)

Plunger

Conforms to EN60947-5-1 Direct Opening .

(Only the NC contacts have a direct opening function.)

When metal weld occurs, the NC contacts are separated from each

other by pushing in the plunger.

G-262 Safety Sensors / Components

Page 5

Dimensions

Note: 1. All units are in millimeters unless otherwise indicated.

2. Each dimension has a tolerance of 0.4 mm unless otherwise specified.

Roller lever (Metallic lever, resin roller)

D4F-@20-@R

(30.8)

25.5

9

18.5

(42.7)

0.1

±

20

17.5-dia. × 6.8,

resin roller

R24.7

Two, 4.4-dia.

8-dia. countersinking,

depth 4

(14.4-dia.)

(35)

Roller plunger (Metallic roller)

D4F-@02-@R

Pretravel

Operating

27.5

30

position

8.8

(42.7)

12-dia. × 4.4,

Sintered stainless steel roller

Two, 4.4-dia.

8-dia. countersinking,

depth 4

0.1

±

20

(14.4-dia.)

(35)

30

(11.4)

UL2464

No. 22 AWG,

finishing O.D.: 8.3 mm

Roller lever (Metallic lever, resin roller)

D4F-@20-@D

17.5-dia. × 6.8,

resin roller

R24.7

Two, 4.4-dia.

±

20

(17.6)

30

0.1

8-dia. countersinking,

depth 4

(16.7)

UL2464

No. 22 AWG,

finishing O.D.: 8.3 mm

2

18.5

(42.7)

(7.9)

(30.8)

25.5

18

30

(11.4)

UL2464

No. 22 AWG,

finishing O.D.: 8.3 mm

18

Roller plunger (Metallic roller)

D4F-@02-@D

Pretravel

Operating

27.5

18

30

position

8.8

(42.7)

(7.9)

12-dia. × 4.4,

Sintered stainless steel roller

Two, 4.4-dia.

8-dia. countersinking,

depth 4

0.1

±

20

(16.7)

UL2464

No. 22 AWG,

finishing O.D.: 8.3 mm

(17.6)

30 2

18

D4F

G-263D4F

Page 6

Precautions

NOTICE

Be sure to connect a ground line, otherwise an electric shock may

occur.

If the D4F is to be used as a switch in an emergency stop circuit or in

a safety circuit for preventing accidents resulting in injuries or deaths,

use NC contacts with a forced release mechanism and set the D4F

so that it will operate in direct opening mode.

For safety, install the Switch using one-way rotational screws or other

similar means to prevent it from easily coming off. Protect the D4F

with an appropriate cover and post a warning sign near the D4F in

order to ensure the safety.

To prevent the D4F from damage due to circuit short-circuiting,

connect a fuse with a breaking current 1.5 to 2 times larger than the

rated current of the D4F in series to the D4F.

If the D4F is used under EN-approved conditions, use a gI or gG 10A fuse approved by IEC269.

Actuation of the Switch over a long time may deteriorate parts of the

Switch and a return failure may result. Be sure to check the

condition of the Switch regularly.

Do not supply electric power when wiring.

Do not use the Switch where explosive gas, flammable gas, or any

other dangerous gas may be present.

Keep the electrical load below the rated value.

Never wire to a wrong terminal.

Be sure to evaluate the Switch under actual working conditions after

installation.

Do not drop or disassemble the D4F.

Do not use in closely contacted mounting.

Do not use the Switch as a stopper.

Conduct periodic inspections.

Do not use it in an activating circuit. (Use it as a safety signal.)

Contacts of the D4F can be used both for ordinary load and

microload; however, once the contact is opened or closed with an

ordinary load, it cannot be used for a load smaller than that. The

contact surface may be rough, which impairs the reliability of

contacting.

Handling of cables

Cables cannot be flexed repeatedly.

The cable is fixed with sealing materials on the bottom of the switch.

When excessive force may be imposed on the cable, fasten the

cable with a fixing unit at a distance of 50 mm from the bottom of the

switch as shown.

Do not pull or press the cable at an excessive force (50 N max.).

When bending the cable, secure the cable with more than 45-mm

bending radius so as not to cause damage to the insulator or sheath

of the cable. Doing so may result in current leakage or burning.

Operating Environment

Keep the D4F away from oil and water, as these may enter the

casing. (Though the switch construction complies with IP67 and

prevents immersion of water even when held in water for a specified

time, its use is not guaranteed when it is immersed in a liquid.)

Make sure in advance that the environment is suitable, with the

presence of oil, water, or chemicals, as these may cause the seal to

deteriorate, resulting in faulty contact, faulty isolation, current

leakage, or burning.

Do not use the D4F in the following locations:

• Locations subject to corrosive gas

• Locations with severe changes in temperature

• Locations with excessive humidity that may cause condensation

• Locations with excessive vibration

• Locations that may be covered with processing chips or dust

• Locations subject to high temperature or excessive humidity

Correct Use

Operating Environment

The D4F is for indoor use only.

Do not use the D4F outdoors. Otherwise, the D4F may malfunction.

Durability

The life of the D4F will vary with the switching conditions. Before

applying the D4F, test the D4F under actual operating conditions and

be sure to use the D4F in actual operation within switching times that

will not lower the performance of the D4F.

Tightening Torque

Be sure to tighten each screw of the D4F properly, otherwise the

D4F may soon malfunction.

No. Type Proper tightening torque

1 Lever mounting screw (M5) 2.4 to 2.8 N·m

2 Body mounting screw (M4) 1.18 to 1.37 N·m

1

2

Mounting

Use two M4 screws and washers to mount the D4F securely. The

50 mm

Fixing unit

When wiring, be sure to prevent penetration of a liquid such as water

or oil through the cable end.

Bending radius

more than 45 mm

D4F can be mounted more securely with proper tightening torque.

Mounting Holes (Unit: mm)

Two, 4.2-dia. or M4 screw hole

0.1

±

20

G-264 Safety Sensors / Components

Page 7

Changing the lever angle

Unfasten the screw that holds the lever to set the position of the lever

at any angle through 360° (in steps of 9°).

After unfastening the screws that hold the lever, mount the lever the

other way (normal side or reverse side). Set an angle of the lever to

complete adjustment within a range in which the lever does not touch

the switch body.

<4NC>

Safety contact Brown 21

Auxiliary contact Orange 31

Auxiliary contact Pink 41

Safety contact Blue 11

Green/yellow ground

Zb

12 Blue/white

22 Brown/white

32 Orange/white

42 Pink/white

Wiring

Identifying Wires

Identify wires according to the color (with or without white lines) of

the insulation on the wire.

Cross section

Insulation

1

2

9

8 3

7

4

5

6

Core insulator (black)

Wire Colors

No. Color of insulation No. Color of insulation

1 Blue/white 6 Brown

2 Orange /white 7 Pink

3 Pink/white 8 Orange

4 Brown/white 9 Blue

5 Green/yellow

Note: "Blue/white, orange/white, pink/white, or brown/white" means

that the cover is blue, orange, pink, or brown with a white line.

Terminal Numbers

Identify terminal numbers based on the color (with or without white

lines) of the insulation on the wire.

The safety and auxiliary contacts of D4F models of four-terminal

contact construction and those of two-terminal contact construction

are described below.

The safety contacts are direct-opening NC contacts (11-12 and 21-

22); they are used for safety circuits, and each of them is indicated

with the appropriate mark .

Auxiliary contacts are used to check (to monitor) the operating state

of the switch, which are equivalent to NO contacts (33-34 and 43-44)

or NC contacts (31-32 and 41-42).

The NC contacts 31-32 and 41-42 of auxiliary contacts (orange or

pink) can be used as safety contacts.

<1NC/1NO>

Safety contact Blue 11

Auxiliary contact Orange 33

Green/yellow ground

External insulation sheath

Zb

12 Blue/white

34 Orange/white

Cut the black core insulator and all unused wires at the end of the

external insulation sheath when wiring the cable.

Operating

To set the plunger stroke correctly, press-fit the plunger until the top

of the pushing surface comes between two grooves on the plunger.

Pushing surface

Proper range

Grooves

To set the roller lever stroke correctly, push the dog and cam until the

the lance point comes within the range of the convex part that is the

correct setting position.

Lance point

Convex part

Proper range

Others

Actuating the switch from an angle other than 90 degrees to the

switch face may deform or damage the actuator, or deform or

damage the rotary spindle, so make sure that the dog is straight.

Dog

Dog

Dog

Dog

<2NC>

Auxiliary contact Brown 21

<2NC/2NO>

Safety contact Brown 21 22 Brown/white

Auxiliary contact Orange 33

Auxiliary contact Pink 43

Safety contact Blue 11

Green/yellow ground

Safety contact Blue 11

Green/yellow ground

Zb

Zb

12 Blue/white

22 Brown/white

12 Blue/white

34 Orange/white

44 Pink/white

Do not remove the head. Otherwise, a failure may occur.

To avoid telegraphing, take the following precautions.

1. Set the switch to operate in one direction.

2. Modify the rear end of the dog to an angle of 15° to 30° as shown

below or to a secondary-degree curve.

θ

θ≥30˚

θ

15˚≤θ≤30˚

3. Modify the circuit so as not to detect the wrong operating signals.

SI Units Conversion Table

To fully comply with international standards, this catalogue is based

on the International System of Units (SI).

G-265D4F

D4F

Page 8

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. C124-E1-Cat04-01A

In the interest of product improvement, specifications are subject to change without notice.

G-266 Safety Sensors / Components

Loading...

Loading...