Page 1

Safety-door Switch

D4BS

Safety-door Switch’s Special

Operation Key Directly Pulls

Apart the Contacts from Each

Other and Contributes to the

Safety of the Production Site

• Conforms to EN (TÜV) standards corresponding to the CE marking.

• Approved by UL, CSA, BIA, and SUVA

standards.

• The switch contact is opened by a direct opening mechanism (NC contacts

only) when the protective cover is

opened. The EN-approved direct opening mechanism is indicated by on

the Switch.

• Degree of protection of the switch box:

IP67 (EN60947-5-1).

• Series includes models with gold-plated contacts for handling the micro-load

range.

• Metric conduit types available.

Model Number Structure

Model Number Legend

Switch

D4BS - S

123

1. Conduit

1: PG13.5 (1 conduit)

2: G1/2 (1 conduit)

3: 1/2-14NPT (1 conduit)

4: M20

5: PG13.5 (3-conduit)

6: G1/2 (3-conduit)

7: 1/2-14NPT (3-conduit)

8: M20 (3-conduit)

Ordering Information

List of Models

Switches

Type Mounting direction Conduit size

1-conduit

Front-side

mounting

3-conduit

Prefered stock item

5: 1NC/1NO (slow-action)

6: 1NC/NO (slow-action), gold-plated contacts

A: 2NC (slow-action)

B: 2NC (slow-action), gold-plated contacts

3. Head Mounting Direction

F: Four mounting directions pos-

sible (front-side mounting at

shipping)

Pg13.5

G1/2 D4BS-25FS D4BS-2AFS

M20

Pg13.5 D4BS-55FS

G1/2 D4BS-65FS D4BS-6AFS

M20 D4BS-85FS D4BS-8AFS

Operation Key

D4BS - K

1

1. Operation Key Type2. Built-in Switch

1: Horizontal mounting

2: Vertical mounting

3: Adjustable mounting (Horizontal)

1NC/1NO

(Slow-action)

D4BS-15FS D4BS-1AFS

D4BS-45FS D4BS-4AFS

2NC (Slow-action)

D4BS-5AFS

D4BS

G-143D4BS

Page 2

Operation Keys (Order Separately)

Type Model

Horizontal mounting

D4BS-K1

Vertical mounting

Adjustable mounting

(Horizontal)

D4BS-K2

D4BS-K3

Specifications

Approved Standards Standards and EC Directives

Agency Standard File No.

TÜV Rheinland EN60947-5-1

UL UL508 E76675

CSA CSA C22.2 No. 14 LR45746

BIA GS-ET-15 9303323

SUVA SUVA E6187.d

R9351022

(Direct opening: approved)

Conforms to the following EC Directives:

Machinery Directive

Low Voltage Directive

EN50041

EN1088

Approved Standard Ratings

TÜV (EN60947-5-1)

Utilization category AC-15

Rated operating current (Ie) 2 A

Rated operating voltage (Ue) 400 V

Note: Use a 10-A fuse type a gI or gG that conforms to IEC269 as a short-circuit protection device.

UL/CSA (UL508, CSA C22.2 No. 14)

A600

Rated voltage Carry current

120 VAC

240 VAC

480 VAC

600 VAC

10 A

Make Break Make Break

60 A 6 A

30 A 3 A

15 A 1.5 A

12 A 1.2 A

Current Volt-amperes

7,200 VA 720 VA

G-144 Safety Sensors / Components

Page 3

Characteristics

Degree of protection (see note 2) IP67 (EN60947-5-1)

Durability (see note 3)

Operating speed 0.1 m/s to 0.5 m/s

Operating frequency 30 operations/min max.

Rated frequency 50/60 Hz

Contact gap 2 x 2 mm min.

Direct opening force (see note 4) 19.61 N min. (EN60947-5-1)

Direct opening travel (see note 4) 20 mm min. (EN60947-5-1)

Full stroke 23 mm min.

Insulation resistance

Contact resistance 25 mΩ max. (initial value)

Rated insulation voltage (Ui) 600 V (EN60947-5-1)

Conventional enclosed thermal current (I

) 20 A (EN60947-5-1)

the

Dielectric strength (Uimp)

Switching overvoltage 1,500 V max. (EN60947-5-1)

Conditional short-circuit current 100 A (EN60947-5-1)

Pollution degree (operating environment) 3 (EN60947-5-1)

Insulation class Class I (with ground terminal)

Vibration resistance Malfunction: 10 to 500 Hz, 0.65-mm single amplitude

Shock resistance

Ambient temperature Operating:-40°C to 80°C (with no icing)

Ambient humidity Operating:95% max.

Weight Approx. 285 g (in the case of D4BS-15FS)

Mechanical:1,000,000 operations min.

Electrical:500,000 operations min. (10 A at 250 VAC, resistive load)

100 MΩ min. (at 500 VDC) between terminals of same or different

polarity, between each terminal and ground, and between each terminal and non-current-carrying metal part

Impulse dielectric strength (U

) 4 kV (EN60947-5-1) between ter-

imp

minals of same or different polarity, between current-carrying metal

parts and ground, and between each terminal and non-current-carrying metal part

2

Destruction:1,000 m/s

Malfunction:300 m/s

min. (IEC68-2-27)

2

min. (IEC68-2-27)

Note: 1. The above values are initial values.

2. Although the switch box is protected from dust, oil, or water penetration, do not use the D4BS in places where dust, oil, water, or chemicals

may penetrate through the key hole on the head, otherwise Switch damage or malfunctioning may occur.

3. The durability is for an ambient temperature of 5° C to 35° C and an ambient humidity of 40% to 70%. Contact your OMRON sales rep-

resentative for more detailed information on other operating environments.

4. These figures are minimum requirements for safe operation.

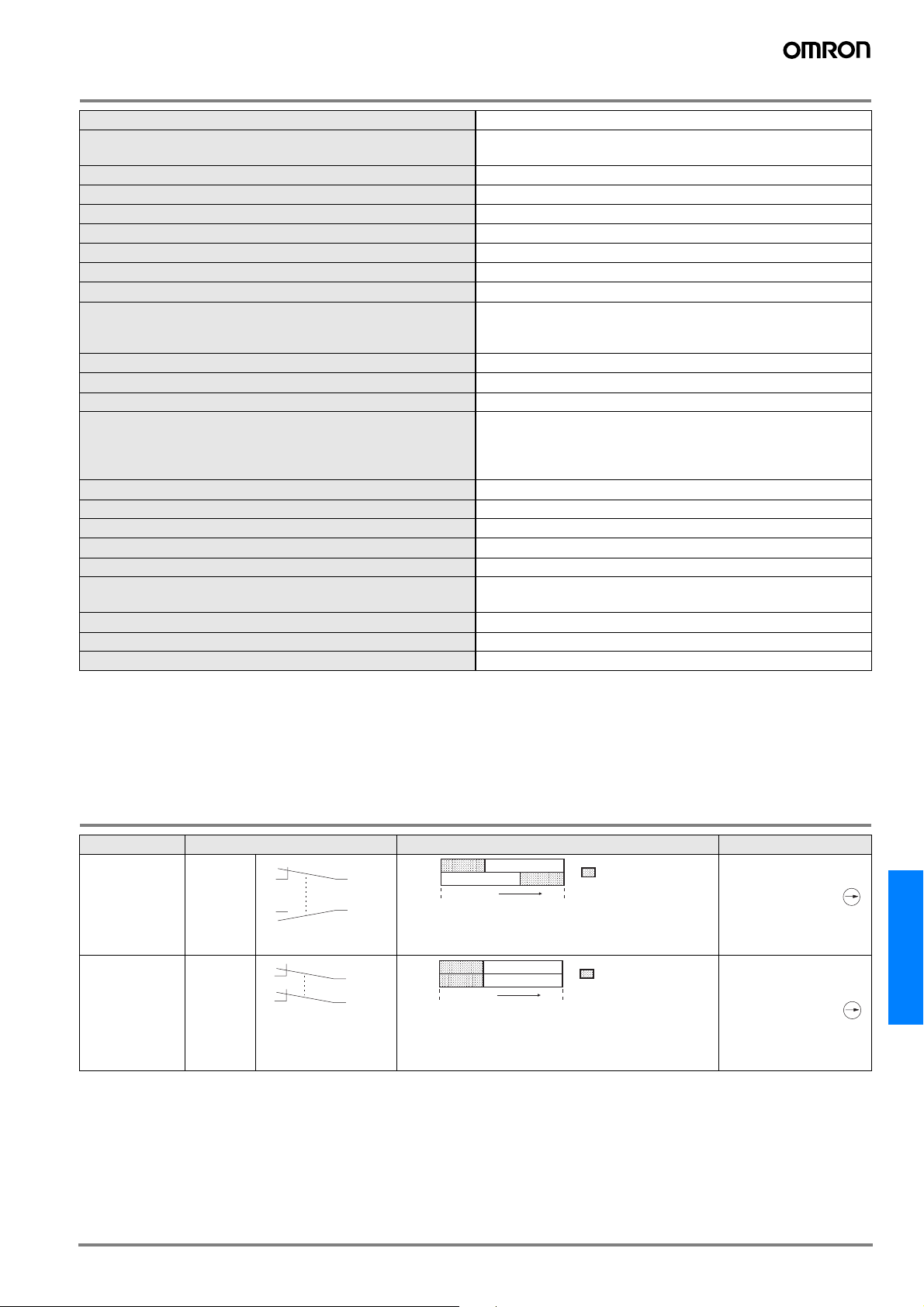

Contact Form (Diagrams Show State with Key Inserted)

Model Contact form Diagram Remarks

D4BS-#5#S 1NC/1NO

D4BS-#A#S 2NC

Zb

11

23

Zb

11

21

12

24

12

22

11 - 12

23 - 24

Operation Key

insertion completion position

11 - 12

21 - 22

Operation Key

insertion completion position

ON

Stroke

Extraction

completion

position

ON

Stroke

Extraction

completion

position

Note: The terminal numbers are in accordance with EN50013, and the contact symbols are in accordance with IEC947-5-1.

Only NC contact 11-12

has an approved direct

opening mechanism.

Terminals 11-12 and

23-24 can be used as

unlike poles.

NC contacts 11-12 and

21-22 have an

approved direct

opening mechanism.

Terminals 11-12 and

21-22 can be used as

unlike poles.

D4BS

G-145D4BS

Page 4

Nomenclature

Operation Key

D4BS's exclusive-use Operation Key is provided

to assure accurate switching operation.

Set Zone Mark

A triangular Set Zone Mark makes it

easy to adjust the operating position

when inserting the Operation Key.

Head

The switch head is coated with easy-to-see red

paint. The mounting direction of the switch head can

be varied to any of the four directions.

Seal Ring (NBR)

Oil Seal (NBR)

The operation plunger employs an oil seal, with

which the switch box meets the requirements of

IP67 (the sealing capability of the Operation Key's

insertion mouth is IP00).

Built-in Switch

A shearing force contact separating mechanism (NC

contact) is employed, which positively pulls apart the

contacts from each other by using shearing force if

any abnormality such as contact welding should occur

in the contact area.

There is a difference in level between the NC and NO

terminal, which assures easy wiring.

Seal Packing (NBR)

Conduit Opening

Available in four different types of conduit

threads: Pg 13.5, G1/2, or 1/2-14NPT, M20.

Ground Terminal Screw

A ground terminal is provided to

improve safety. (Built into the

Unit.)

G-146 Safety Sensors / Components

Page 5

Dimensions

Note: 1. All units are in millimeters unless otherwise indicated.

2. Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

3. The conduit thread varies with the model as follows:.

Conduit thread Model

Pg 13.5 D4BS-1##S, D4BS-5##S

G1/2 D4BS-2##S, D4BS-6##S

M20 D4BS-4##S, D4BS-8##S

Switches

1-conduit

D4BS-1##S

D4BS-2##S

D4BS-4##S

3-conduit

D4BS-5##S

D4BS-6##S

D4BS-8##S

Red

Red

(110)

(111.5)

66.4

60±0.2

50.9

31.4

17

7

35

Two, 5.3 dia.

mounting holes

Two, M4 cover

clamping screws

7.3

5.3

8

30±0.1

+1

40

0

31.4

17

7

5.3

Six, 5.3 dia.

30±0.2

mounting holes

Four, M3.5 x 10 cover

clamping screws

Two caps

Cover

Cover

41

Four, M3.5 head

16

clamping screws

D4BS-1##S: Pg13.5

15

D4BS-2##S: G1/2

31.5

D4BS-4##S: 1/2-14NPT

43

41

16

34.5

77

Four, M3.5 head

clamping screws

34.5

75.4

71.4

Operating

characteristics

Key insertion force

Key extraction force

Pretravel (PT)

Direct opening force

Direct opening stroke

Operating

characteristics

Key insertion force

Key extraction force

Pretravel (PT)

Direct opening force

Direct opening stroke

D4BS-1##S

D4BS-2##S

D4BS-4##S

19.61 N max.

19.61 N max.

10±5 mm

19.61 N min.

20 mm min.

D4BS-5##S

D4BS-6##S

D4BS-8##S

19.61 N max.

19.61 N max.

10±5 mm

19.61 N min.

20 mm min.

Operation Keys

D4BS-K1

D4BS-K3

Black

Red

26 15

11.4

5

Black

5.3 dia.

mounting hole

4 dia.

30±0.15

40.7

40

19.5±0.15

17.2

35.7

38.3

Black

(37.8)

51

28.5

78.7

20±0.15

12

Two, 2.65R

5.3 5.3

36

26

11.4

5

30

D4BS-5##S: 3-Pg13.5

D4BS-6##S: 3-G1/2

57

D4BS-8##S: 3-1/2-14NPT

63

D4BS-K2

7.3 15

7.5

2.5

20

40

15

4 dia. M4 Allen-head bolt

2012

(80.7)

36

2.5

17.5

34.6

+0.15

Two, 5

dia. holes (6 mm deep)

-0

15

26

11.4

5

4 dia.

53.7

36

5.3 ¥ 7.3 mounting long hole

13

52.4

40±0.15

12 7.5

5.3

2.5

20

D4BS

G-147D4BS

Page 6

With Operation Key Inserted

Horizontal Mounting

D4BS-1##S +D4BS-K1

D4BS-2##S +D4BS-K1

D4BS-4##S +D4BS-K1

Red

53.5 min.

58 max.

Operation Key insertion

radius in horizontal

direction: R ≥ 1200 53.5 min.

58 max.

Operation Key insertion

radius in horizontal

direction: R ≥ 1000

Vertical Mounting

D4BS-1##S +D4BS-K2

D4BS-2##S +D4BS-K2

D4BS-4##S +D4BS-K2

Red

54.5 min.

59 max.

Adjustable Mounting (Horizontal)

D4BS-1##S +D4BS-K3

D4BS-2##S +D4BS-K3

D4BS-4##S +D4BS-K3

Red

81.5 min.

86 max.

Operation Key insertion

radius in horizontal

direction: R ≥ 1200

Operation Key insertion

radius in horizontal

direction: R ≥ 150 81.5 min.

54.5 min.

59 max.

86 max.

Operation Key insertion

radius in horizontal

direction: R ≥ 1000

Operation Key insertion

radius in horizontal

direction: R ≥ 1000

Note: Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

Note: "R" is the Operation Key insertion radius.

G-148 Safety Sensors / Components

Page 7

Precautions

Do not dismount the Operation Key from the door intentionally and

insert it to the Switch with the door open. Machine may start operating and injury or death may be caused.

Mount the Operation Key at a location where it will not come in contact with users when the door is opened or closed.

When operating the D4BS as a part of a safety category circuit to

prevent injury, operate the NC contacts that have a direct opening

mechanism in direct opening mode. For safety purposes, tighten the

switch body and Operation Key with one-way screws or equivalents

or install a switch protection cover and warning label for safety purposes to prevent easy removal of the D4BS.

Connect the fuse to the D4BS in series to prevent it from short-circuit

damage. The value of the breaking current of the fuse must be calculated by multiplying rated current by 150% to 200%. When using the

D4BS with EN ratings, use 10-A fuse Type gI or gG that complies

with IEC60269.

Correct Use

Operating Environment

Make sure in advance that the environment is suitable, with no oil,

water, or chemicals, as these may cause the seal to deteriorate,

resulting in faulty contact, faulty isolation, current leakage, or burning.

Do not use the D4BS in the following locations:

• Locations subject to severe temperature changes

• Locations subject to high temperatures or condensation

• Locations subject to severe vibration

• Locations where the product may come into direct contact with pro-

cessing waste or dust

Securing the Door

If the Operation Key on the closed door is pulled outside the set zone

by a force caused by vibration, the door’s weight, or the door cushion

rubber, the switch contact may be opened (causing the machinery to

stop) or the D4BS may be damaged. Secure the door with hooks so

that it will remain within the set zone.

Extra space

Set zone

Mounting

Do not use the Switch as a stopper. Be sure to install a stopper as

shown in the following illustration when mounting the Switch. The

range of space “a” must be determined according to the available set

zone of the Operation Key.

Stopper

a

Operation Key

Be sure to use a special Operation Key only. Do not operate the

D4BS with anything other than the special Operation Key, otherwise

the D4BS may break or the safety of the system may not be maintained.

Do not impose excessive force on the Operation Key inserted into

the D4BS or drop the D4BS with the Operation Key inserted, otherwise the Operation Key may deform or break.

Excessive force

Drop

Secure the Operation Key with a one-way screw, or an equivalent, so

that the Operation Key cannot be easily removed.

Switch

Refer to Dimensions for the mounting dimension of the Operation

Key and mount the Operation Key correctly. The Operation Key will

soon become damaged or worn out if it is not mounted correctly.

Make sure that the Operation Key can be inserted properly with a tolerance of ±0.5 mm in the upward, downward, left, or right direction,

otherwise the D4BS may soon become damaged.

±0.5 min.

D4BS

±0.5 min.

G-149D4BS

Page 8

Other

Make sure that the D4BS is located outside the safety door and that

no metal dust, oil, or chemical will be sprayed onto the D4BS. Otherwise, the D4BS may soon fail to operate due to the penetration of

metal dust, oil, or chemical.

Tightening Torque

Be sure to tighten each screw of the D4BS properly, otherwise the

D4BS may malfunction.

Mounting Dimensions (M5)

Standard Model Three-conduit Model

30

40

42

60

59.3±0.1

Protruding portions

27±0.1

No. Type Torque

1

2

M3.5 terminal screw (including

ground terminal screw)

Cover mounting screw

(see note 1)

0.59 to 0.78 N·m

1.18 to 1.37 N·m

3 Head mounting screw 0.78 to 0.98 N·m

4

M5 body mounting screw

(see note 2)

4.90 to 5.88 N·m

5 Operation Key mounting screw 2.35 to 2.75 N·m

6 Connector 1.77 to 2.16 N·m

7 Cap screw 1.27 to 1.67 N·m

Note: 1. Apply a torque of 0.78 o 0.88 N·m if the D4BS is a three-con-

duit model.

2. Apply a torque of 4.90 to 5.88 N·m in the case of an Allen-

head bolt. If it is a pan head screw, apply a torque of 2.35 to

2.75 N·m.

30

Mounting hole

Mounting side

Insertion hole for protrusions

-0.05

5

-0.15

-0.05

5

dia. holes, max. height 5

-0.15

dia. holes, max. height 5

The D4BS can be mounted more securely by adding two protruding

portions, each of which is 5 mm maximum in height and

–0.05

/

5

mm in diameter as shown below.

–0.15

Operating Key Mounting Dimensions

Horizontal Mounting

Two, M5

±0.1

20

Vertical Mounting

Adjustable Mounting (Horizontal)

Changes in Head Mounting Direction

By removing the screws on the four corners of the head, the head

can be reset in any of four directions. The head direction can be

changed with or without the Operation Key inserted in the head.

Make sure that no foreign materials penetrate through the head and

that the head is tightened securely within the proper torque range.

Two, M5

±0.1

40

Two, M5

±0.1

30

G-150 Safety Sensors / Components

Page 9

Wiring

Do not connect the lead wires directly to the terminals. Connect the

lead wires through insulation tubes and M3.5 crimp terminals.

Tighten each terminal screw within the proper torque range.

The proper lead wire is AWG20 to AWG14 (0.5 to 2.5 mm

dz dia.: 3.7

D dia.: 4.5

B: 7.0

L: 20.2

F: 7.7

I: 9.0 (mm)

D dia.

2

) in size.

Connector

Tighten the connector to a suitable torque. Excessive tightening

torque may damage the casing.

When using a 1/2-14NPT conduit, apply sealing tape between connector and conduit opening so that the enclosure will confirm to IP67.

If using a Pg13.5 conduit, use an ABS-08 Pg13.5 connector or an

ABS-12 Pg13.5 connector (manufactured by Nippon Flex).

Use a connector (SC Series, sold separately) suitable for the outer

diameter of the cable.

When wiring a 3-conduit model, securely tighten the cap screw provided for unused conduit openings.

dz dia.

Make sure that all crimp terminals are correctly connected and

located within the casing or cover as shown below.

Casing

Incorrect

Incorrect

Terminal screw

Crimp terminal

Cover

Crimp terminal

Crimp terminal

Crimp

terminal

Casing

Correct

Terminal screw

Correct

Terminal screw

Cover

Crimp terminal

Maintenance and Repairs

The user must not maintain or repair equipment incorporating any

D4BS model. Contact the manufacturer of the equipment for any

maintenance or repairs required.

D4BS

G-151D4BS

Page 10

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. C094-E2-04A-X

In the interest of product improvement, specifications are subject to change without notice.

G-152 Safety Sensors / Components

Loading...

Loading...