Page 1

Safety Limit Switch

D4B-#N

• Snap-action or slow-action contact for

accurate switching with safe operation

via a direct opening mechanism with

metal deposition between mating contacts.

• Two sets of contacts: one (NC) for safety category circuit and the other (NO)

for control circuit.

• Contacts opened by direct opening

mechanism (NC contacts only), thus

preventing faulty operation due to factors such as metal deposition.

• Wide standard operating temperature

range:

–40°C to 80°C (standard type).

• Safety of lever settings ensured using a

mechanism that engages a gear between the operating position indicator

plate and the lever.

• Equipped with a mechanism that indicates the applicable operating zone, as

well as push-button switching to control

left and right motion.

• Conforms to EN (TÜV) standards corresponding to the CE marking.

• 3-conduit switches are available.

• Metric conduit types available.

Model Number Structure

Model Number Legend

D4B-####N

1 2 3

1. Conduit

1: PG13.5 (1-conduit)

2: G1/2 (PF1/2) (1-conduit)

3: 1/2-14NPT (1-conduit)

4: M20

5: PG13.5 (3-conduit)

6: G1/2 (PF1/2) (3-conduit)

7: 1/2-14NPT (3-conduit)

8: M20 (3-conduit)

2. Built-in Switch

1: 1NC/1NO (snap-action)

3: 1NC/1NO (slow-action) gold-plated contacts

5: 1NC/1NO (slow-action) (see note)

A: 2NC (slow-action)

B: 2NC (slow-action) gold-plated contacts

Note: Excluding D4B-##81N and D4B-##87N models.

3. Actuator

00: Switch box (without head)

11: Roller lever (standard)

16: Adjustable roller lever

17: Adjustable rod lever

1R: Roller lever

(conventional D4B-compatible)

70: Top plunger

71: Top roller plunger

81: Coil spring

87: Plastic rod

N

@

D4B-

G-243D4B-@N

Page 2

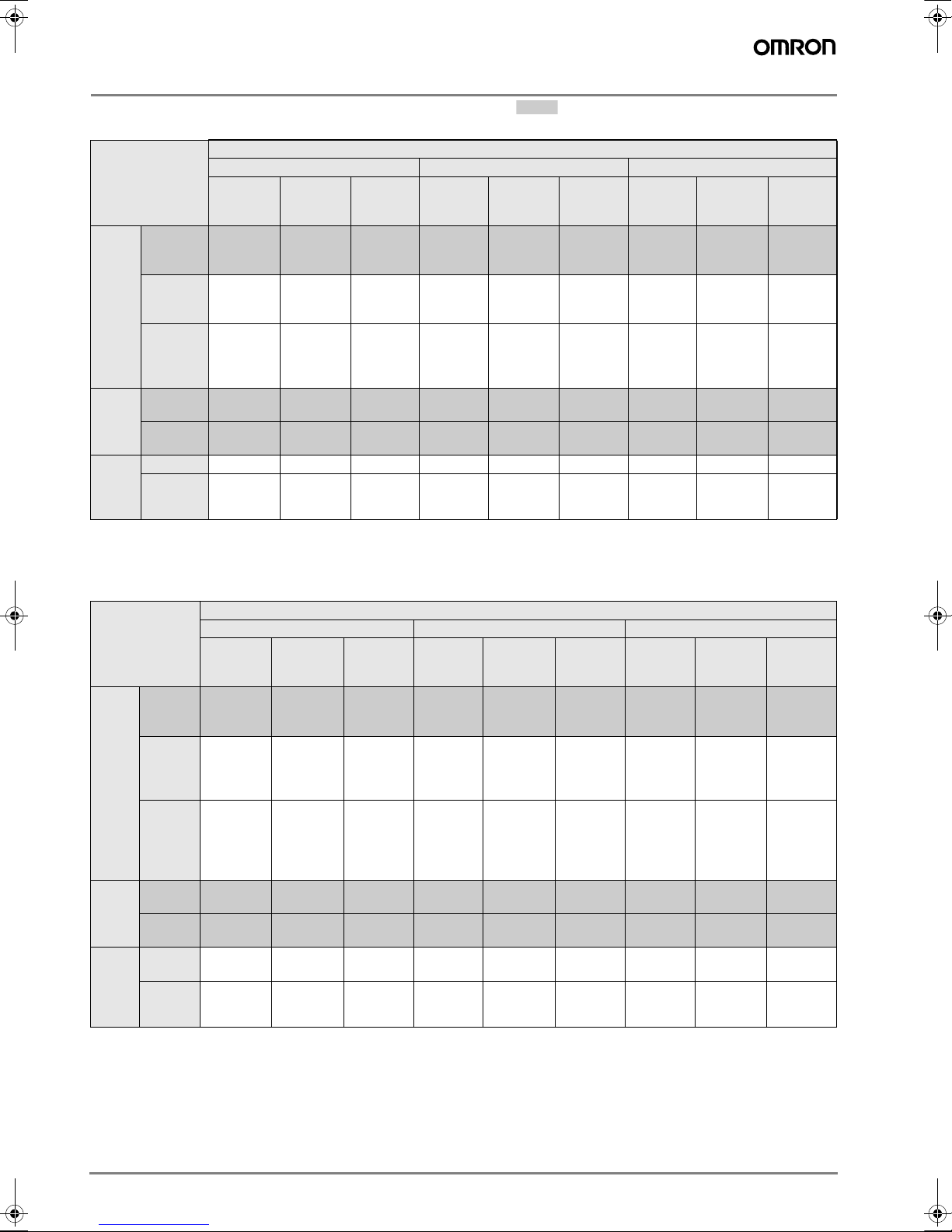

Ordering Information

List of Models Safety limit switch, mechanical form lock

Switches (EN50041)

Conduit size

PG13.5 (see note 2) G1/2 M20

1NC/1NO

(Snapaction)

D4B-1111N D4B-1511N

D4B-1116N D4B-1516N

D4B-1117N D4B-1517N

D4B-1170N D4B-1570N

D4B-1171N D4B-1571N

1NC/1NO

(Slow-

action)

2NC

(Slow-

action)

D4B-1A11N D4B-2111N

D4B-1A16N D4B-2116N

D4B-1A17N D4B-2117N

D4B-1A70N D4B-2170N

D4B-1A71N D4B-2171N

D4B-1A81N D4B-2181N

D4B-1A87N D4B-2187N

1NC/1NO

(Snapaction)

1NC/1NO

(Slow-

action)

D4B-2511N

D4B-2516N

D4B-2517N

D4B-2570N

D4B-2571N

---

---

2NC

(Slow-

action)

D4B-2A11N D4B-4111N

D4B-2A16N D4B-4116N

D4B-2A17N D4B-4117N

D4B-2A70N D4B-4170N

D4B-2A71N D4B-4171N

D4B-2A81N D4B-4181N

D4B-2A87N D4B-4187N

1NC/1NO

(Snapaction)

1NC/1NO

(Slow-

action)

D4B-4511N

D4B-4516N

D4B-4517N

D4B-4570N

D4B-4571N

---

---

2NC

(Slow-

action)

D4B-4A11N

D4B-4A16N

D4B-4A17N

D4B-4A70N

D4B-4A71N

Side

rotary

Top

plunger

Wobble

lever

(see

note 1)

Actuator

Roller

lever

(form A)

Adjustable

roller lever

(see note 1)

Adjustable

rod lever

(form D)

(see note 1)

Plain

(form B)

Roller

(form C)

Coil spring D4B-1181N ---

Plastic rod D4B-1187N ---

Note: 1. Mechanically speaking, these models are basic limit switches.

2. The D4B-#N is a Limit Switch conforming to European standards, and PG13.5 is commonly used in Europe.

3-conduit Switch

Conduit size

Actuator

Side

rotary

Top

plunger

Wobble lever

(see

note 1)

Roller

lever

(form A)

Adjustable roller

lever (see

note 1)

Adjustable

rod lever

(form D)

(see note

1)

Plain

(form B)

Roller

(form C)

Coil

spring

Plastic

rod

D4B-5111N D4B-5511N

D4B-5116N D4B-5516N

D4B-5117N D4B-5517N

D4B-5170N D4B-5570N

D4B-5171N D4B-5571N

D4B-5181N ---

D4B-5187N ---

PG13.5 (see note 2) G1/2 M20

1NC/1NO

(Snapaction)

1NC/1NO

(Slow-

action)

2NC

(Slow-

action)

D4B-5A11N D4B-6111N

D4B-5A16N D4B-6116N

D4B-5A17N D4B-6117N

D4B-5A70N D4B-6170N

D4B-5A71N D4B-6171N

D4B-5A81N D4B-6181N

D4B-5A87N D4B-6187N

1NC/1NO

(Snapaction)

1NC/1NO

(Slow-

action)

D4B-6511N

D4B-6516N

D4B-6517N

D4B-6570N

D4B-6571N

---

---

2NC

(Slow-

action)

D4B-6A11N D4B-8111N

D4B-6A16N D4B-8116N

D4B-6A17N D4B-8117N

D4B-6A70N

D4B-6A71N D4B-8171N

D4B-6A81N

D4B-6A87N

1NC/1NO

(Snapaction)

--- --- ---

--- --- ---

--- --- ---

1NC/1NO

(Slow-

action)

--- ---

--- ---

--- ---

---

2NC

(Slowaction)

D4B-8A71N

Note: 1. Mechanically speaking, these models are basic limit switches.

2. The D4B-#N is a Limit Switch conforming to European standards, and M20/PG13.5 is commonly used in Europe.

3. The wobble lever models are ordinary limit switches and are not approved under EN, GS, and SUVA’s Direct Opening Certificate.

G-244 Safety Sensors / Components

Page 3

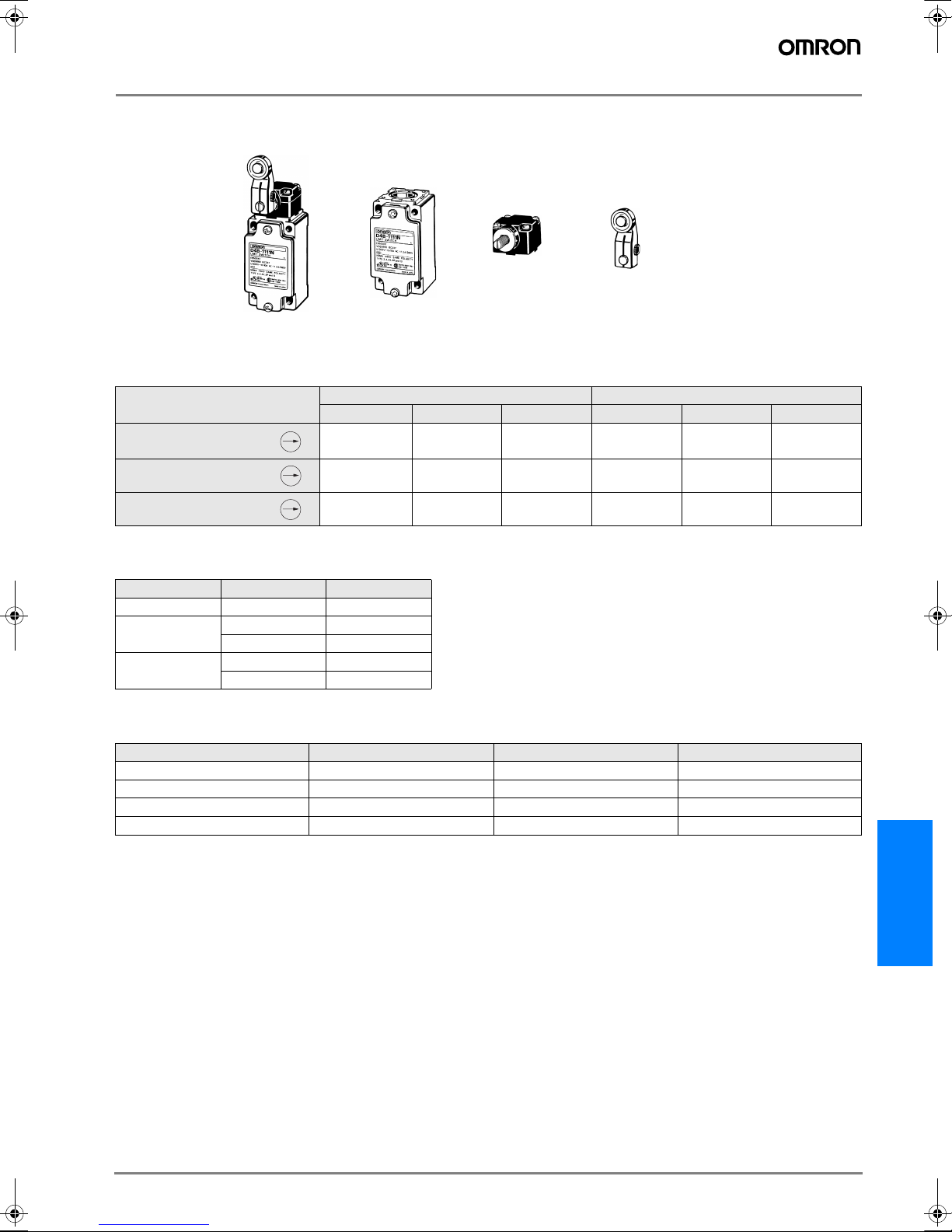

Replacement Part

Because the D4B-#N employs a block mounting construction, the switch box, operating head, and lever (side rotary type only) may be ordered as

a complete assembly or individually as replacement parts. (Replacement parts are not available as a switch box and head assembly or as a head

and lever assembly.)

Switch box

=++

D4B-2100Nex. D4B-2111N

=

Switch Box

PG13.5 G1/2 1/2-14NPT PG13.5 G1/2 1/2-14NPT

1NC/1NO

(Snap-action)

1NC/1NO

(Slow-action)

2NC

(Slow-action)

Operating Heads

Actuator Type Model

Side rotary Standard D4B-0010N

Top plunger

Wobble lever

Plain D4B-0070N

Roller D4B-0071N

Coil spring D4B-0081N

Plastic rod D4B-0087N

D4B-1100N D4B-2100N D4B-3100N D4B-5100N D4B-6100N D4B-7100N

D4B-1500N D4B-2500N D4B-3500N D4B-5500N D4B-6500N D4B-7500N

D4B-1A00N D4B-2A00N D4B-3A00N D4B-5A00N D4B-6A00N D4B-7A00N

Head

Lever (side rotary type only)

+ D4B-0010N D4B-0001N+

EN50041 3-conduit type

Levers (for Side Rotary Switches)

Actuator Length Diameter of roller Model

Standard 31.5 17.5 dia. D4B-0001N

Adjustable roller lever 25 to 89 19 dia. D4B-0006N

Adjustable rod lever 145 max. --- D4B-0007N

Interchangeable with D4B-0001 33.7 19 dia. D4B-000RN

Note: Other types of lever are also available.

N

@

D4B-

G-245D4B-@N

Page 4

Specifications

Approved Standards

Snap-action Models

Agency Standard File No.

R9851083

(Direct opening:

TÜV Rheinland EN60947-5-1

approved)

R9151372

(Direct opening:

approval pending)

(See note 1.)

UL UL508 E76675

CSA C22.2 No. 14 LR45746

BIA (See note 2.) GS-ET-15

Note: 1. Adjustable roller lever, adjustable rod lever, coil spring, and

plastic rod models only.

2. Not including adjustable roller lever, adjustable rod lever,

coil spring, and plastic rod models.

1-conduit: 9202158

3-conduit: 9309655

Approved Standard Ratings

TÜV Rheinland: EN60947-5-1

Utilization category AC-15

Rated operating current (I

Rated operating voltage (U

Note: As protection against short-circuiting, use either a gI-type or gG-type 10-A fuse that conforms to IEC269.

)2 A

e

) 400 V

e

Slow-action Models

Agency Standard File No.

TÜV Rheinland EN60947-5-1

UL UL508 E76675

CSA C22.2 No. 14 LR45746

BIA (See note.) GS-ET-15

SUVA (See note.) SUVA

Note: Not including adjustable roller lever, adjustable rod lever, coil spring, and

plastic rod models.

Standards and EC Directives

• Conforms to the following EC Directives:

Machinery Directive

Low Voltage Directive

EN1088

EN50041

R9151643

(Direct opening:

approved)

(See note)

1-conduit: 9202158

3-conduit: 9309655

1-conduit: E6188/

1.d

3-conduit: E6189/

1.d

UL/CSA: (UL508, CSA C22.2 No. 14)

A600

Rated voltage Carry current Current Volt-amperes

Make Break Make Break

120 VAC

240 VAC

480 VAC

600 VAC

10 A

60 A

30 A

15 A

12 A

6 A

3 A

1.5 A

1.2 A

7,200 VA 720 VA

G-246 Safety Sensors / Components

Page 5

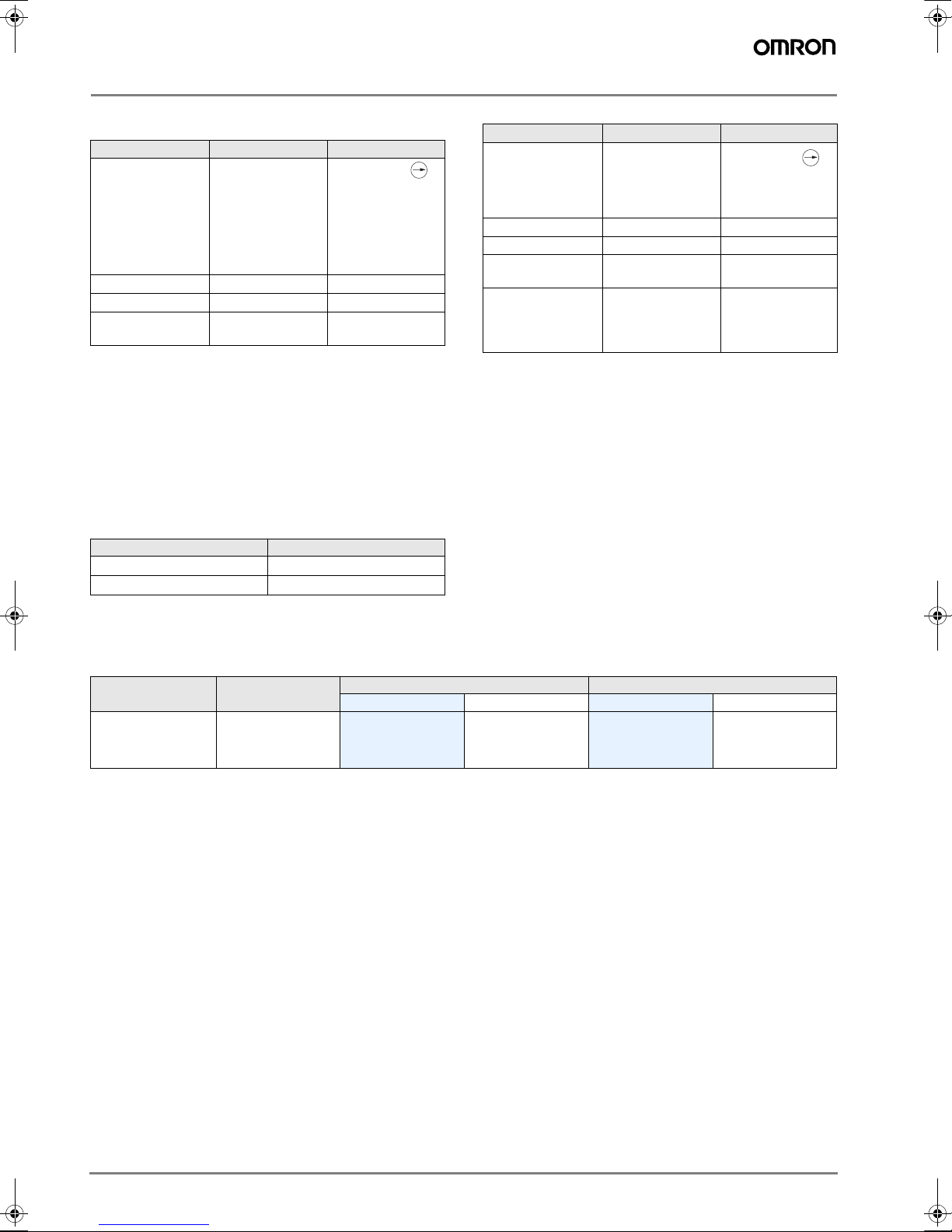

Characteristics

Item Snap-action Slow-action

Durability

(see note 3)

Operating speed 1 mm/s to 0.5 m/s

Operating frequency

Rated frequency 50/60 Hz

Insulation resistance

Contact resistance 25 mΩ max. (initial value)

Dielectric strength (U

Between terminals of same polarity U

Between terminals of different polarity --- U

Between current-carrying metal parts

and ground

Between each terminal and non-cur-

rent-carrying parts

Rated insulation voltage (Ui) 600 VAC (EN60947-5-1)

Counter electromotive voltage at switching 1,500 VAC max. (EN60947-5-1)

Operating environmental pollution level 3 (EN60947-5-1)

Conditional short-circuit current 100 A (EN60947-5-1)

Conventional enclosed thermal current (I

Electric shock protection class Class I (with ground terminal)

Vibration resistance Malfunction:10 to 55 Hz, 0.75 mm single amplitude

Shock resistance

Ambient temperature Operating:–40°C to 80°C (with no icing) (see note 4)

Ambient humidity Operating:95% max.

Degree of protection IP67 (EN60947-5-1)

Weight Approx. 250 g

Note: 1. The above values are initial values.

2. The above values may vary depending on the model. Consult your OMRON sales representative for details.

3. The durability is for an ambient temperature of 5°C to 35°C and ambient humidity of 40% to 70%. For further conditions, consult your

OMRON sales representative.

4. –25°C to 80°C for the flexible-rod type.

Mechanical 30,000,000 operations min. 10,000,000 operations min.

Electrical 500,000 operations min. (at a 250 VAC, 10-A resistive load)

Mechanical:120 operations/min

Electrical:30 operations/min

100 MΩ min. (at 500 VDC) between terminals of the same polarity and between each termi-

nal and non-current-carrying part

)

imp

2.5 kV U

imp

U

4 kV U

imp

U

4 kV U

imp

) 20 A (EN60947-5-1)

the

2

Destruction:1,000 m/s

Malfunction:300 m/s

2

min.

min.

imp

imp

imp

imp

4 kV

4 kV

4 kV

4 kV

Operating Characteristics

Model D4B-##11N

OF max. 9.41 N 2.12 N 18.63 N 1.47 N

RF min. 1.47 N 0.29 N 1.96 N --PT 21±3° 2.0 mm max. 15° max.

PT (2nd)

(see note 3)

(45°) (3.0 mm) ---

OT min. 50° 5.0 mm --MD max.

(see note 4)

DOT min.

12° 1.0 mm ---

35° (Slow-action models)

55° (Snap-action models)

DOF min. 19.61 N 49.03 N --TT (75°) 7.0 mm --FP max. --- 38 mm 51 mm --OP --- 35±1 mm 48±1 mm ---

Note: 1. The operating characteristics of these Switches were measured with the roller lever set at 31.5 mm.

2. The operating characteristics of these Switches were measured with the rod lever set at 140 mm.

3. Only for slow-action models.

4. Only for snap-action models.

D4B-##16N

(see note 1)

D4B-##17N

(see note 2)

D4B-##70N D4B-##71N D4B-##81N D4B-##87N

3.2 mm ---

N

@

D4B-

G-247D4B-@N

Page 6

Contact Form (EN50013)

Model Contact Diagrams Explanation

Za

D4B-#1#N

D4B-#5#N

D4B-#A#N

1NC/1NO

(Snap-action)

1NC/1NO

(Slow-action)

2NC

(Slow-action)

13

11

11 12

23

11

21

14

12

Zb

24

Zb

12

22

Direct Opening Mechanism

1NO/1NC Contact (Snap-action)

If metal deposition between mating contacts occurs on the NC contact side, they can be pulled apart by the shearing force and tensile force generated when part B of the safety cam or plunger engages part A of the movable contact blade. When the safety cam or plunger is moved in the

direction of the arrow, the Limit Switch releases.

11-12

13-14

11-12

23-24

11-12

21-22

Stroke

Stroke

Stroke

ON

ON

ON

Only NC contact 11-12 has an

approved direct opening

mechanism.

Terminal numbers 11-12 and

13-14 cannot be used as unlike

poles.

Only NC contact 11-12 has an

approved direct opening

mechanism.

Terminal numbers 11-12 or

23-24 can be used as unlike

poles.

Both NC contacts 11-12 and

21-22 have an approved direct

opening mechanism.

Terminal numbers 11-12 and

21-22 can be used as unlike

poles.

1. When metal deposition occurs. 2. When contacts are being pulled apart.

Movable contact

Movable contact

blade

A

B

Fixed contact (NC)

1NC/1NO Contact (Slow-action)

Contact spring

Return spring

2NC Contact (Slow-action)

Contact spring

Return spring

Plunger

Safety cam

Fixed contact (NC)

Movable contact

Plunger

Fixed contact (NO)

Fixed contact (NC)

Movable contact

Plunger

3. When contacts are completely

Safety cam directly

pushes up the

movable contact

blade.

pulled apart.

Conforms to EN60947-5-1 Direct Opening

When metal deposition occurs, the contacts

are separated from each other by the plunger

being pushed in.

Conforms to EN60947-5-1

When metal deposition occurs, the contacts

are separated from each other by the plunger

being pushed in.

is marked on the product to indicate approval of direct opening.

G-248 Safety Sensors / Components

Page 7

Engineering Data

Electrical Durability (Snap-action)

(cosj = 1) (cosj = 0.4)

10,000

5,000

125 VAC

3,000

)

3

250 VAC

480 VAC

1,000

500

300

Operations (x 10

100

Switching current (A) Switching current (A)

Operating frequencies:

30 times/min., cosf = 1

10,000

7,000

5,000

3,000

)

3

1,000

700

500

300

Operations (x 10

Nomenclature

Operating frequencies:

30 times/min., cosf = 0.4

250 VAC

500 VAC

Head

With roller lever models, the direction of the switch head can

be varied to any of the four directions by loosening the roller

lever switch screws at the four corners of the head.

Operating Position Mark

(arrow)

The roller lever switch employs a system which allows

selection of operation on only one side (left or right)

or both sides without the

use of any tools.

Conduit Opening

Available in four different types of conduit threads:

Pg 13.5, G1/2 or 1/2-14NPT, M20

Push and rotate

Switch Box Material

Aluminum die-cast

Safety-oriented Lever Setting

Grooves which engage the lever every 90∞ are cut in the

operating position indicator plate to prevent the lever from

slipping against the rotary shaft.

Equipped with Operating Position Indicator Plate

An optimum overtravel (OT) value may be secured by

setting a desired OT value with a projection.

Shearing Force Contact Separating Mechanism

(NC Contact Section Only)

Should any abnormality occur in the contact area, the

contacts are positively pulled apart from each other by

shearing force.

Ground Terminal Screw

A ground terminal is provided to improve safety.

Contact Material

Ag alloy

N

@

D4B-

G-249D4B-@N

Page 8

Dimensions

Note: 1. All units are in millimeters unless otherwise indicated.

2. Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

3. When placing your order, specify the conduit type by adding a code from the list below to the blank box of the following model numbers

as shown below.

Standard Switches 3-conduit Switches

1: PG 13.5 5: PG 13.5

2: G 1/2 6: G 1/2

3: 1/2-14NPT 7: 1/2-14NPT

4: M20 8: M20

Switches

Roller Lever

D4B-##11N

Adjustable Roller Lever

D4B-##16N

Adjustable Rod Lever

D4B-##17N

safety limit switch,

mechanical form lock

131.3±1.2

17.5 dia. x 6.6 resin roller

23

60±0.2

8

5.3

30±0.2

+1

40

0

25 to 89R

23

60±0.2

8

5.3

30±0.2

+1

40

0

5.4

145 max.

23

60±0.2

8

5.3

30±0.2

+1

40

0

PT 21∞ ±3∞

M5 x 12

Allen-head

31.5R

bolt

Set position

indicator

plate

Two, 5.3-dia.

mounting holes

Two, M4 x 12 cover

clamping screws

7.3

19 dia. x 7

resin roller

M5 x 16

Allenhead bolts

Two, 5.3-dia.

mounting holes

Two, M4 x 12

cover clamping

screws

7.3

3 dia. x 160

stainless steel

rod

M5 x 12

Allen-head

bolts

Two, 5.3-dia.

mounting holes

Two, M4 x 12 cover

clamping screws

7.3

11.5

Cover

Cover

Cover

62±1

28.3

71±1

64.4

66±1

56.8

28.3

56

43

53

46.8

31.5

31.5

43

31.5

43

16

15

1628.3

15

16

15

Four, M3.5 x 24.5 head

clamping screws

22.5

99.5

77

74

Conduit

Four, M3.5 x 24.5

head clamping screws

22.5

99.5

77

74

Conduit

Four, M3.5 x 24.5

head clamping screws

22.5

99.5

77

74

Conduit

G-250 Safety Sensors / Components

Page 9

Top Plunger

D4B-##70N

Top Roller Plunger

D4B-##71N

safety limit switch,

mechanical form lock

safety limit switch,

mechanical form lock

60±0.2

8

5.3

30±0.2

+1

40

0

12.7 dia. x 4.8

stainless steel roller

PT

OP

Two, 5.3-dia.

mounting holes

Two, M4 x 12 cover

clamping screws

PT

Stainless steel

plunger

Cover

7.3

9.2 dia.

9.2 dia.

16

Four, M3.5 x 24.5

head clamping screws

74

15

Conduit

31.5

43

16

Four, M3.5 x 24.5

head clamping screws

20

97

77

Coil Spring

Coil Spring

D4B-##81N

Plastic Rod

D4B-##87N

203.5±1.2

203.5±1.2

60±0.2

8

18.2 dia.

29.1

60±0.2

8

61.5

18.2 dia.

29.1

60±0.2

8

OP

Two, 5.3-dia.

mounting holes

Two, M4 x 12

cover clamping

screws

5.3

30±0.2

+1

40

0

Stainless steel coil spring

Rubber cap

Four, M3.5 x 7

clamping screws

Two, 5.3-dia.

mounting holes

Two, M4 x 12 cover

clamping screws

5.3

30±0.2

+1

40

0

Plastic rod

Seal cap

Four, M3.5 x 7

head mounting

screws

Two, 5.3-dia.

mounting holes

Two, M4 x 12 cover

mounting screws

5.3

30±0.2

+1

40

0

Cover

7.3

(see note 1)

Cover

7.3

The Switch can

be actuated to all

directions except

to the axis center.

Cover

7.3

15.7

15.7 16

43

31.5

43

31.5

15

16

15

31.5

43

74

Conduit

40 (see note 2)

6.6 dia.

2.7

77

74

Conduit

40 (see note)

6.6 dia.

74

Conduit

15

20

97

77

Note: 1.

The coil spring may be operated

from any directions except axial

directions (Ø).

2.

Be sure to adjust the dog to within

40 mm from the top end of the coil

spring.

2.7

Note: Be sure to adjust the dog to within 40 mm

77

from the top end of the plastic rod.

N

@

D4B-

G-251D4B-@N

Page 10

3-conduit Switches

Roller Lever

D4B-##11N

Adjustable Roller Lever

D4B-##16N

safety limit switch,

mechanical form lock

17.5 dia. x 6.6 resin roller

M5 x 12

Allen-head bolt

31.5R

Operating

position indicator

(see note)

40 to 42

Six, 5.3-dia.

mounting holes

Four, M3.5 x 10

cover mounting screws

Two, caps

Three, Conduit

19 dia. x 7 resin roller

Four, M3.5 x 24.5

head mounting screws

Cover

+0.15

-dia. holes (depth: 6)

/

Two, 5

0

Note: The lever can be set to any desired position

by turning the operating position indicator.

Adjustable Rod Lever

D4B-##17N

25 to 89R

66.4

145 max.

Operating position indicator

(see note)

40 to 42

M5 x 16

Allen-head

bolts

Six, 5.3-dia.

Mounting holes

Four, M3.5 x 10 Cover

mounting screws

Two, caps

Three, Conduit

3 dia. x 160

stainless steel rod

Operating position

indicator

(see note)

M5 x 12

40 to 42

Allen-head

bolts

Six, 5.3-dia.

mounting holes

Four, M3.5 x 10 cover

mounting screws

Two, caps

Four, M3.5 x 24.5 head

mounting screws

Cover

+0.15

Two, 5

/

-dia. holes (depth: 6)

0

Note: The lever can be set to any desired position

by turning the operating position indicator.

Four, M3.5 x 24.5

head mounting screws

Cover

G-252 Safety Sensors / Components

+0.15

Three, Conduit

Note: The lever can be set to any desired position

by turning the operating position indicator.

Two, 5

/

-dia. holes (depth: 6)

0

Page 11

Top Plunger

D4B-##70N

safety limit switch,

mechanical form lock

40 to 42

Stainless steel

plunger

Six, 5.3-dia.

mounting holes

Four, M3.5 x 10 cover

mounting screws

Two, caps

Cover

Three, Conduit

9.2 dia.

Four, M3.5 x 19.5

head mounting screws

+0.15

Two, 5

/

-dia. holes (depth: 6)

0

Top Roller Plunger

D4B-##71N

Coil Spring

D4B-##81N

safety limit switch,

mechanical form lock

12.7 dia. x 4.8

stainless steel roller

Stainless steel coil spring

18.2 dia.

40 to 42

9.2 dia.

40 to

42

Six, 5.3-dia.

mounting screws

Four, M3.5 x 10

cover mounting screws

Two, caps

Cover

Three, Conduit

The Switch can be actuated

to all directions except to

the axis center

Seal cap

Four, M3.5 x 7

head mounting screws

Six, 5.3-dia.

mounting holes

Four, M3.5 x 10 cover

mounting screws

Two, caps

Cover

Three, Conduit

Four, M3.5 x 19.5

head mounting screws

+0.15

/

Two, 5

(40) (see note)

6.6 dia.

Two , 5

-dia. holes (depth: 6)

0

+0.15

/

-dia. holes (depth: 6)

0

Note: Set the spring so that the dog comes in

contact at a point 40 mm from the tip.

Plastic Rod

D4B-##87N

201.9±1.2

18.2 dia.

40 to 42

Plastic rod

The Switch can be actuated to all

directions except to the axis center.

Seal cap

Four, M3.5 x 7

head mounting screws

Six, 5.3-dia.

mounting holes

Four, M3.5 x 10

cover mounting screws

Two, caps

Three, Conduit

Cover

(40) (see note)

6.6 dia.

+0.15

/

Two , 5

Note: Set the spring so that the dog comes in

-dia. holes (depth: 6)

0

contact at a point 40 mm from the tip.

G-253D4B-@N

N

@

D4B-

Page 12

Levers

8

p

Roller Lever Adjustable Roller Lever Adjustable Rod Lever

D4B-0001N

17.5 dia. x 6.8 nylon roller

31.5

15

Roller Lever (compatible with

previous D4B model)

D4B-000RN WL-1A118

19 dia. x 7 nylon roller

33.7

18

Roller Lever

WL-1A206

17.5 dia. ¥ 15

stainless steel roller

mechanical form lock

M5 hexagon

7.3 dia.

socket head

screw

mechanical form lock

7.3 dia.

mechanical form lock

M5 hexagon

socket head

screw

17

11.8

11.5

17.8

12

12

25.7

16.7

D4B-0006N

19 dia. x 7 nylon roller

Adjustable

range

(25 to 89)

97

6.4 adjusting scale

15.9

20

M5 hexagon

socket head

screw

Roller Lever

17.5 dia. ¥ 30

nylon roller

+0.1

7.3

dia.

0

Note: Reverse the indicator plate when mounting.

16

38

54.8

M5 hexagon socket

head screw (length: 12)

Roller Lever

WL-1A300

17.5 dia. ¥ 7

stainless steel roller

26

20.2

12.8

40.2±0.8

23.6

11.4

17.9

12.6

D4B-0007N

3 dia.

145 max.

160

3.2

Roller Lever

WL-1A106

M5 hexagon

socket head screw

Note: Reverse the indicator

Roller Lever

WL-1A400

17 dia. ¥ 6 bearing roller

Stainless rod

5.4

17

50 dia. ¥ 6 nylon roller

7.3 dia.

21.6

M5 hexagon

socket head

screw

20.1±0.8

late when mounting.

15.9

12.5

2

11

11.5

11.1

+0.1

dia.

7.3

0

16

Note: Reverse the indicator plate when mounting. Note: Reverse the indicator plate when mounting. Note: Reverse the indicator plate when mounting.

50

66.8

M5 hexagon socket

head screw (length: 12)

11.4

G-254 Safety Sensors / Components

63±0.3

+0.1

dia.

7.3

0

16

79.8

M5 hexagon socket

head screw (length: 12)

11.4

7.3 dia.

16

38

54.3

M5 hexagon

socket head

screw

11.5

Page 13

Adjustable Rod Lever

WL-3A100

7.3 dia.

12.8

611

M5 ¥ 16 hexagon

socket head screw

25.5

max.

13.4

5.5

Note: Reverse the indicator plate when mounting. Note: Reverse the indicator plate when mounting. Note: Reverse the indicator plate when mounting.

400±2

Adjustable range (350 to 380)

8.0±0.4

7.5

65±2

3.2 dia. stainless steel

operation rod

M5 hexagon socket head screw

Spring Rod Lever

WL-4A201

9

2 dia. stainless

steel spring

Adjustable

range

(290 max.)

13 dia.

Resin Loop Lever

D4A-F00

7.3 dia.

(23.6)

611

7.5

25 max.

13.8

5.5

M5 hexagon socket head screw

150±10

M5 hexagon socket head screws

33

4 dia.

Note: 1. Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

2. Safety Limit Switch specifications are satisfied with D4B-####AN Levers only.

60±10

Nylon

N

@

D4B-

G-255D4B-@N

Page 14

Precautions

If the D4B-#N is applied to a safety category circuit for prevention of

injury, use the D4B-#N model that has an NC contact equipped with

a direct opening mechanism, and make sure that the D4B-#N operates in the direct opening mode. Furthermore, secure the D4B-#N

with screws or equivalent parts that are tightened in a single direction so that the D4B-#N cannot be easily removed. Then provide a

protection cover for the D4B-#N and post a warning label near the

D4B-#N.

In order to protect the D4B-#N from damage due to short-circuiting,

connect a fuse breaking a current 1.5 to 2 times higher than the

rated current in parallel with the D4B-#N.

Correct Use

Operating Environment

The D4B-#N is for indoor use. The D4B-#N may malfunction if the

D4B-#N is used outdoors. Be sure to use a model with a lever-type

actuator for outdoor use instead.

Do not use the D4B-#N in the following locations:

• Locations subject to severe temperature changes

• Locations subject to high temperatures or condensation

• Locations subject to severe vibration

• Locations where the product may come in contact with metal dust,

oil, or chemicals

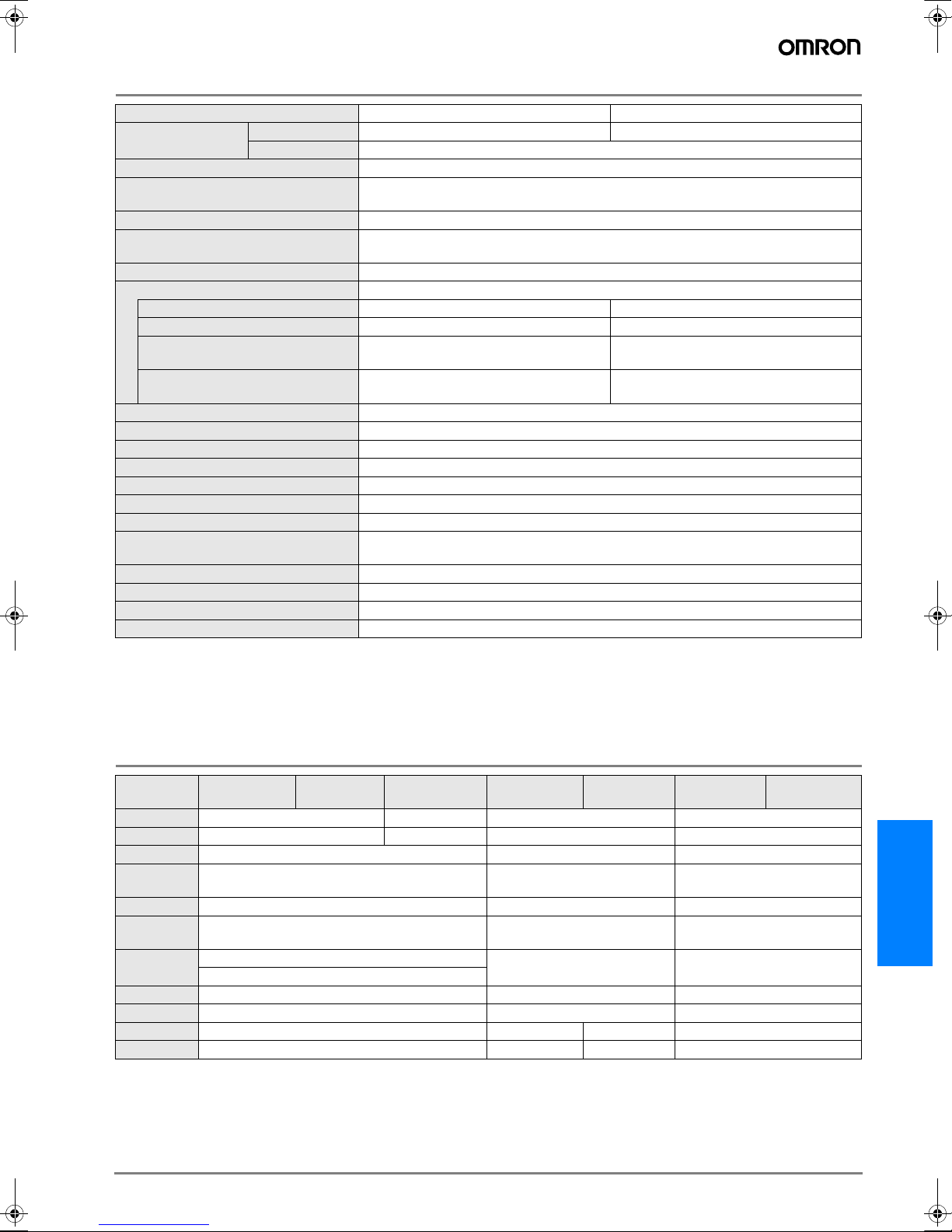

Tightening Torque

(3)

Be sure to tighten each

screw of the D4B-#N

properly, otherwise the

D4B-#N may malfunction.

(4)

(1)

If an application satisfying EN standards is to employ the D4BL,

apply the 10-A gI or gG fuse approved by IEC269.

Do not apply the D4B-#N to the door without applying a stopper to

the door.

If the D4B-#N is used with the actuator normally pressed, the

D4B-#N may malfunction or may soon have reset failures. Be sure to

check and replace the D4B-#N regularly.

Mounting

Use four M5 screws with washers to mount the standard model. Be

sure to apply the proper torque to tighten each screw. The D4B-#N

can be mounted more securely by using the four screws plus two

–0.05

5

/

-mm protruding parts, each of which has a maximum

–0.15

height of 4.8 mm as shown below.

Mounting Dimensions (M5)

Standard Model

60

30

3-conduit Model

59.3±0.1

30

40

42

Protruding portions

27±0.1

-0.05

5

dia. holes, max. 5 height

-0.15

(5) (2)

Type Torque

1 M3.5 terminal screw 0.59 to 0.78 N·m

Cover-mounting screw

2

(see note)

1.18 to 1.37 N·m

3 Head mounting screw 0.78 to 0.98 N·m

4 M5 body mounting screw 4.90 to 5.88 N·m

5 Connector 1.77 to 2.16 N·m

Cap screw

6

(for three-conduit models)

Note: Apply a tightening torque of 0.78 to 0.88 N·m to conduit models.

1.27 to 1.67 N·m

Changes in Actuator Mounting Position

To change the angle of the lever, loosen the Allen-head bolts on the

side of the lever.

The operating position indicator plate has protruding parts which

engage with the lever, thus allowing changes to the lever position by

90°.

The back of the operating position indicator plate has no protruding

parts. The lever can be set at any angle by attaching the operating

position indicator plate to the Switch so that this side will face the

lever. In this case, however, the D4B-#N will not be approved by

SUVA or BIA. Make sure that the lever engages with the operating

position indicator plate securely so that the lever will not slip.

Changes in Head Mounting Position

By removing the screws on the four corners of the head, the head

can be reset in any of four directions. Make sure that no foreign

materials will penetrate through the head.

G-256 Safety Sensors / Components

Page 15

CW, CCW or Two-way Operation

The head of Side Rotary Switches can be converted in seconds to

CW, CCW, or two-way operation. The conversion procedure follows.

Operating position mark (arrow)

Head cover (Push and rotate)

Procedure

1. Dismount the head by loosening the four screws that secure it.

2. Turn over the head to set the desired operation (CW, CCW, or

both). The desired operation can be selected by setting the mode

selector knob shown in the figure. This knob is factory set to the

“CW + CCW” (two-way operation) position.

3. Set the CW hole on the head at the operation position mark

(arrow) for clockwise operation or set the CCW hole right at the

arrow for counterclockwise operation. In either case, be sure to

set the hole position exactly at the arrow point.

Wiring

Do not connect the bare lead wires directly to the terminals but be

sure to connect each of them by using an insulation tube and M3.5

round crimp terminals and tighten each terminal screw within the

specified torque range.

The proper lead wire is 20 to 14 AWG (0.5 to 2.5 mm

dz dia.: 3.7

D dia.: 4.5

B: 7.0

L: 20.2

F: 7.7

l: 9.0 (mm)

D dia.

Make sure that all crimp terminals come into contact with the casing

or cover as shown below, otherwise the cover may not be mounted

properly or the D4B-#N may malfunction.

Crimp

terminal

Correct

Terminal screw

Crimp terminal

Correct

Terminal screw

Cover

Incorrect

Incorrect

2

dz dia.

Terminal screw

Cover

) in size.

Correct

Crimp terminal

Incorrect

Crimp terminal

Connector

Make sure that each connector is tightened within the specified

torque range. The casing may be damaged if the connector is tightened excessively.

If the 1/2-14NPT is used, cover the cable and conduit end with sealing tape in order to ensure IP67.

The Pg13.5 connector must be Nippon Flex’s ABS-08Pg13.5 or

ABS-12 Pg13.5.

Use OMRON’s SC-series connector which is suited to the cable in

diameter.

Properly attach the provided conduit cap to the unused conduit opening and securely tighten the cap screw within the specified torque

when wiring the D4B-#N.

Others

The load for the actuator (roller) of the Switch must be imposed on

the actuator in the horizontal direction, otherwise the actuator or the

rotating axis may be deformed or damaged.

Correct Incorrect

Dog

When using a long lever model like the D4B-##16N or

D4B-##17N, the Switch may telegraph. To avoid telegraphing, take

the following precautions.

1. Set the lever to operate in one direction. For details, see page G-

257, CW, CCW or Two-way Operation.

2. Modify the rear end of the dog to an angle of 15° to 30° as shown

below or to a secondary-degree curve.

θ

θ ≥ 30°

3. Modify the circuit so as not to detect the wrong operating signals.

Top View

Dog

θ

15° ≤ θ ≤ 30°

N

@

D4B-

Casing

Casing

Crimp terminal

G-257D4B-@N

Page 16

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. C005-E2-09A-X

In the interest of product improvement, specifications are subject to change without notice.

G-258 Safety Sensors / Components

Loading...

Loading...