General-purpose Limit Switch

D4A-@N

The Limit Switch with Better Seal, Shock

Resistance, and Strength

• A double seal on the head, a complete gasket cover, and other

features ensure a better seal (meets UL NEMA 3, 4, 4X, 6P, 12, 13).

• Wide standard operating temperature range:

−40°C to +100°C (standard type).

• Models with fluoro-rubber available for greater resistance to

chemicals.

• Block mounting method also reduces downtime for maintenance.

• DPDT, double-break models available for complex operations.

• Approved by UL, CSA, and CCC (Chinese standard).

(Ask your OMRON representative for information on approved model.)

Be sure to read Safety Precautions on page 14 to 15 and

Safety Precautions for All Limit Switches.

Model Number Structure

CSM_D4A-_N_DS_E_4_1

Model Number Legend (Not all combinations are possible. Ask your OMRON representative for details.)

D4A-@@@@N (Set model number)

(1) (2) (3)

(1) Receptacle box

1 : 1/2-14 NPT conduit (SPDT, double-break)

2 : 1/2-14 NPT conduit (DPDT, double-break)

3 : G 1/2 conduit (SPDT, double-break)

4 : G 1/2 conduit (DPDT, double-break)

(2) Switch Box

1 : SPDT, double-break, without indicator

3 : SPDT, double-break, neon lamp

E : SPDT, double-break, LED (24 VDC, leakage current: 1.3 mA)

5 : DPDT, double-break, simultaneous operation, without indicator

7 : DPDT, double-break, sequential operation, without indicator *1

9 : DPDT, double-break, center neutral operation, without indicator *2

L : DPDT, double-break, simultaneous operation, neon lamp

P : DPDT, double-break, simultaneous operation, LED

*1. Use the D4A-0017N Special Head.

*2. Use the D4A-0018N Special Head.

Note: Fluoro-rubber sealed type is also available.

(3) Head

01 : Roller lever, standard

02 : Roller lever, high-sensitivity

03 : Roller lever, low torque

04 : Roller lever, high-sensitivity, low torque

05 : Roller lever, maintained

17 : Roller lever, sequential operation

18 : Roller lever, center neutral operation

06 : Side plunger, standard

07-V : Side plunger, vertical roller

07-H : Side plunger, horizontal roller

08 : Side plunger, adjustable

09 : Top plunger, standard

10 : Top plunger, roller

11 : Top plunger, adjustable

12 : Flexible rod, spring wire

14 : Flexible rod, plastic rod

15 : Flexible rod, cat whisker

16 : Flexible rod, coil spring

1

Ordering Information

Set model number

SPDT, Double-break Switches

Actuator

Standard D4A-3101N UL, CSA D4A-3301N UL, CSA D4A-3E01N

High-sensitivity D4A-3102N UL, CSA D4A-3302N UL, CSA D4A-3E02N

Receptacle box G 1/2 Conduit

Indicator Without indicator With neon lamp indicator (AC)

Model

Approved

standards

Model

Approved

standards

D4A-@N

With LED indicator (DC)

Model

Roller lever *1

Side plunger

Top plunger

Flexible rod

Low-torque D4A-3103N UL, CSA --- --- ---

High-sensitivity,

Low-torque

Maintained *2 D4A-3105N UL, CSA D4A-3305N UL, CSA D4A-3E05N

Standard D4A-3106N UL, CSA --- --- ---

Vertical roller D4A-3107-VN UL, CSA D4A-3307-VN UL, CSA D4A-3E07-VN

Horizontal roller D4A-3107-HN UL, CSA D4A-3307-HN UL, CSA ---

Adjustable D4A-3108N UL, CSA D4A-3308N UL, CSA D4A-3E08N

Standard D4A-3109N UL, CSA D4A-3309N UL, CSA ---

Roller D4A-3110N UL, CSA D4A-3310N UL, CSA ---

Adjustable D4A-3111N UL, CSA D4A-3311N UL, CSA ---

Spring wire D4A-3112N UL, CSA D4A-3312N UL, CSA D4A-3E12N

Plastic rod D4A-3114N UL, CSA D4A-3314N UL, CSA D4A-3E14N

Cat whisker D4A-3115N UL, CSA D4A-3315N UL, CSA D4A-3E15N

D4A-3104N UL, CSA D4A-3304N UL, CSA ---

Coil spring D4A-3116N UL, CSA D4A-3316N UL, CSA D4A-3E16N

Note: 1. Switches are also available with @1/2-14 NPT conduits. The model numbers correspond as follows:

(Examples) G 1/2 Conduits 1/2-14 NPT Conduits

2. Switches are also available with fluoro-rubber seals for higher resistance to chemicals. (The operating temperature range for these Switches, however,

is −10 to +120°C.) Add “-F” to the model number. (Example: D4A-3101N becomes D4A-3101N-F.) Ask your nearest OMRON representative for details.

*1. The lever is not included with the Roller Level Models. Select the lever from those listed in this data sheet and order it separately (refer to Levers on page 12).

*2. The Maintained Switches have a lock mechanism for the switch operation and thus use a Fork Lever Lock.

D4A-3@@@N D4A-1@@@N

D4A-4@@@N D4A-2@@@N

2

D4A-@N

DPDT, Double-break Switches

Receptacle box G 1/2 Conduit

Indicator Without indicator

Actuator Model Approved standards Model Model

Standard D4A-4501N UL, CSA D4A-4L01N D4A-4P01N

High-sensitivity D4A-4502N UL, CSA --- ---

Low-torque D4A-4503N UL, CSA --- ---

Roller lever *1

High-sensitivity,

Low-torque

Maintained *2 D4A-4505N UL, CSA --- ---

Sequential operation D4A-4717N UL, CSA --- ---

Center neutral

operation

Standard D4A-4506N UL, CSA --- ---

D4A-4504N UL, CSA --- ---

D4A-4918N UL, CSA --- ---

With neon lamp indicator (AC)

With LED indicator (DC)

Side plunger

Top plunger

Flexible rod

Note: 1. Switches are also available with @1/2-14 NPT conduits. The model numbers correspond as follows:

(Examples) G 1/2 Conduits 1/2-14 NPT Conduits

2. Switches are also available with fluoro-rubber seals for higher resistance to chemicals. (The operating temperature range for these Switches, however,

is −10 to +120°C.) Add “-F” to the model number. (Example: D4A-4501N becomes D4A-4501N-F.) Ask your nearest OMRON representative about delivery

times and prices.

*1. The lever is not included with the Roller Level Models. Select the lever from those listed in this data sheet and order it separately (refer to Levers on page 12).

*2. The Maintained Switches have a lock mechanism for the switch operation and thus use a Fork Lever Lock.

Vertical roller D4A-4507-VN UL , C SA --- ---

Horizontal roller D4A-4507-HN UL, C SA --- ---

Adjustable D4A-4508N UL, CSA --- ---

Standard D4A-4509N UL, CSA --- ---

Roller D4A-4510N UL, CSA D4A-4L10N D4A-4P10N

Adjustable D4A-4511N UL, CSA --- ---

Spring wire D4A-4512N UL, CS A --- ---

Plastic rod D4A-4514N UL, CSA --- ---

Cat whisker D4A-4515N UL, CSA --- ---

Coil spring D4A-4516N UL, CSA --- ---

D4A-3@@@N D4A-1@@@N

D4A-4@@@N D4A-2@@@N

Individual Parts

Receptacle box

SPDT double-break

DPDT double-break

Type G1/2 conduit *1 1/2-14NPT conduit *2

Appearance Model

D4A-3000N UL, CSA D4A-1000N UL, CSA

D4A-4000N UL, CSA D4A-2000N UL, CSA

Approved standards

Model

Approved standards

*1. M6-screw mounting

(standard mounting)

*2. 10-32UNF-screw mounting

(standard mounting)

3

Switch Box

Indicator Without indicator With neon lamp indicator (AC)

Appearance Model

Approved

standards

Model

Approved

standards

D4A-@N

With LED

indicator (DC)

Model

SPDT doublebreak

DPDT doublebreak

Heads

Appearance

Roller lever *1

(Without indicator lamp)

Simultaneous

operation

Sequential

operation

Center neutral

(Without indicator lamp)

Standard D4A-0001N UL, CSA

High-sensitivity D4A-0002N UL, CSA

Low-torque *2 D4A-0003N UL, CSA

Sequential operation: *3

Center neutral

operation: *3

Maintained D4A-0005N UL, CSA

Standard D4A-0006N UL, CSA

operation

Model

D4A-0017N UL, CSA

D4A-0018N UL, CSA

Approved

standards

D4A-0100N UL, CSA D4A-0300N UL, CSA D4A-0E00N

D4A-0500N UL, CSA D4A-0L00N --- D4A-0P00N

D4A-0700N UL, CSA --- --- ---

D4A-0900N UL, CSA --- --- ---

Appearance Type

Top plunger

Model

Standard D4A-0009N UL, CSA

Roller D4A-0010N UL, CSA

Adjustable D4A-0011N UL, CSA

Approved

standards

Vertical roller

Side plunger

*1. Levers for Roller Lever Switches are optionally available. Select the lever

from those listed in this data sheet and order (refer to Levers on page 12).

*2. The D4A-C00 adjustable roller lever is too heavy and long for these heads

and it should not be used or mechanical malfunction will result.

*3. These heads cannot be used for double break operations.

Horizontal roller

Side adjustable D4A-0008N UL, CSA

D4A-0007-VN

D4A-0007-HN

UL, CSA

UL, CSA

Spring wire D4A-0012N UL, CSA

Plastic rod D4A-0014N UL, CSA

Flexible rod

Cat whisker D4A-0015N UL, CSA

Coil spring D4A-0016N UL, CSA

4

Levers

Actuator Model

D4A-A00

D4A-A10

Roller Lever

Adjustable Roller Lever

Resin Loop Lever D4A-F00

Fork Lever Lock

Note: Refer to page 12 for Lever shapes and applicable models.

D4A-A20

D4A-A30

D4A-B06

D4A-C00

D4A-D00

D4A-E30

D4A-E20

D4A-E10

D4A-E00

Specifications

Approved Standards

Agency Standard File No.

UL UL508 E76675

CSA CSA C22.2 No.14 LR45746

CCC (CQC) GB14048.5 2003010305077615

Note: Ask your OMRON representative for information on approved models.

D4A-@N

Ratings

Non-inductive load (A)

Type

SPDT

doublebreak

(with/

without

indicator)

DPDT

doublebreak

(without

indicator)

DPDT

doublebreak

(with indicator)

* For those with indicators, refer to the following rated voltages.

Item Type

Inrush

current

Note: 1. The above current ratings are for steady-state current.

2. Inductive loads have a power factor of 0.4 min. (AC) and a time

3. Lamp loads have an inrush current of 10 times the steady-state current.

4. Motor loads have an inrush current of 6 times the steady-state current.

Rated

voltage

125 VAC *

250 VAC *

480 VAC

600 VAC

8 VDC

14 VDC

30 VDC

125 VDC *

250 VDC *

125 VAC

250 VAC

480 VAC

600 VAC

14 VDC

30 VDC

125 VDC

250 VAC

125 VAC

250 VAC

12 VDC

24 VDC

48 VDC

Normally closed

Normally open 20 A max.

constant of 7 ms max. (DC).

Resistive

load

NC NO NC NO NC NO NC NO

10

10

10

3

10

10

5

31--- --- --- ---

SPDT, Double-break DPDT, Double-break

Without

indicator

30 A max.

6

0.8

0.4

5

3

1.5

1

5

3

0.4

0.2

5

3

10

10

10

1

Lamp load

3

2

1.5

1

6

6

4

0.2

0.1

2

1

0.5

0.4

2

1

0.1

0.05

2

1

With indi-

cator

Inductive load (A)

Inductive

1.5

1

0.8

0.5

3

3

3

0.2

0.1

Without

indicator

load

10

10

3

1.5

10

10

6

0.8

0.4

4

2

1

0.7

4

2

0.4

0.2

4

2

Motor load

5

2.5

3

1.5

1.5

0.8

1

0.5

6

6

4

0.2

0.1

3

1.5

0.8

0.5

3

1.5

0.1

0.05

3

1.5

With indi-

cator

Ratings for Indicators

Classi-

fication

SPDT

doublebreak

DPDT

doublebreak

Indicator Model

Neon lamp D4A-0300N

LED D4A-0E00N 24 VDC

Neon lamp D4A-0L00N

LED D4A-0P00N 48 VDC

Rated

voltage

125 VAC,

250 VAC

125 VAC,

250 VAC

Leakage

current

Approx.

0.47 mA

Approx.

1.3 mA

Approx.

0.28 mA

Approx.

1.4 mA

Internal

resistance

150 kΩ

15 kΩ

240 kΩ

---

5

D4A-@N

Approved Standard Ratings

UL/CSA

A600

D4A-@1@@N (SPDT, Double-break, Without Indicator)

Rated

voltage

120 VAC

240 VAC

480 VAC

600 VAC

Carry

current

10 A

A300

D4A-@3@@N (SPDT, Double-break, With Neon Lamp)

Rated

voltage

120 VAC

240 VAC

Carry

current

10 A

B600

D4A-@5@@N (DPDT, Double-break, Simultaneous

Operation)

D4A-@7@@N (DPDT, Double-break, Sequential Operation)

D4A-@9@@N (DPDT, Double-break, Center Neutral

Operation)

Rated

voltage

120 VAC

240 VAC

480 VAC

600 VAC

Carry

current

5 A

CCC (GB14048.5)

Applicable category and ratings

AC-15 2 A/125 VAC

Current (A) Volt-amperes (VA)

Make Break Make Break

60

30

15

12

Current (A) Volt-amperes (VA)

Make Break Make Break

60

30

Current (A) Volt-amperes (VA)

Make Break Make Break

30

15

7.5

6.0

6

3

1.5

1.2

6

3

3

1.5

0.75

0.6

7,200 720

7,200 720

3,600 360

Characteristics

Degree of protection

(reference standards)

Mechanical: *1

Durability

*2

Electrical:

Operating speed

Operating

frequency

Rated frequency 50/60 Hz

Insulation resistance

Contact resistance 25 mΩ max. (initial value)

Temperature rise 50°C max.

Dielectric

strength

Pollution degree

(operating environment)

Protection against electric shock Class I (with grounding terminal)

Vibration

resistance

Shock resistance

Ambient operating humidity 35% to 95%RH (with no icing)

Weight Approx. 290 g (in case of D4A-3101N)

Note: The above figures are initial values.

*1. Excluding maintained models.

*2. The values are calculated at an operating temperature of +5°C to +35°C,

and an operating humidity of 40% to 70%RH. Contact your OMRON sales

representative for more detailed information on other operating

environments.

*3. 1,500 VAC is applied to the indicator lamp type.

*4. Not including Flexible rods (cat whisker, plastic rod, coil spring, and spring

wire types).

Item Type Roller lever *1

Ambient temperature

*1. Excluding low-torque and high-sensitivity models.

*2. Including roller lever low-torque and high-sensitivity operating models.

Mechanical: 300 operations/minute

Electrical: 30 operations/minute

Between terminals of

same polarity

Between current-carrying metal parts and

ground

Between each terminal and non-currentcarrying metal part

Malfunction: *4 10 to 55 Hz, 1.5-mm double amplitude

Destruction: 1,000 m/s2 min.

Malfunction: *4

−40°

C to +100°C−20°C to +100°C

IP67 and NEMA 1, 2, 3, 4X, 5, 6P, 12,

and 13

SPDT, double-break, roller lever:

50,000,000 operations min.

DPDT, double-break, roller lever:

30,000,000 operations min.

SPDT, double-break: for 125 VAC,

10 A resistive load: 1,000,000 operations min.

DPDT, double-break: for 125 VAC, 5 A

resistive load: 750,000 operations min.

1 mm/s to 2 m/s (in case of D4A-3101N

roller lever model)

100 MΩ min. (at 500 VDC) between

terminals of the same polarity, between current-carrying metal parts and

ground, and between each terminal

and non-current-carrying metal part

1,000 VAC, 50/60 Hz for 1 min.

2,200 VAC, 50/60 Hz for 1 min. *3

2,200 VAC, 50/60 Hz for 1 min. *3

3

SPDT, double-break, roller lever:

2

min.

600 m/s

DPDT, double-break, roller lever:

2

min.

300 m/s

Plunger, flexible rod *2

With indicator

−10°C to +80°C

6

Engineering Data

)

)

)

)

Electrical Durability (SPDT Double-break) (Ambient temperature: +5°C to +35°C; ambient humidity: 40% to 70%RH)

500

300

operations)

4

100

Durability (x 10

50

30

125 VAC

250 VAC

480 VAC

Operating frequencies:

30 operations/min,

cosφ = 1

500

300

operations)

4

100

Durability (x 10

50

30

125 VAC

250 VAC

480 VAC

Operating frequencies:

30 operations/min,

cosφ = 1

D4A-@N

10

0

2 4 6 8 10 12

Switching current (A

10

0

2 4 6 8 10 12

Switching current (A

Electrical Durability (DPDT Double-break)

500

300

operations)

4

100

Durability (x 10

50

30

10

0

Operating frequencies:

125 VAC

250 VAC

480 VAC

123456

30 operations/min,

cosφ = 1

Switching current (A

500

300

operations)

4

100

Durability (x 10

50

30

10

0

Operating frequencies:

30 operations/min,

125 VAC

250 VAC

480 VAC

123456

cosφ = 1

Switching current (A

Structure and Nomenclature

Structure (DPDT Double-break)

Head

With the Roller Lever and Side Plunger Switches, the

direction of the switch head can be varied to any of the four

directions by loosing the roller lever switch screws at the

four corners of the head.

The Roller Lever Switch

employs a system which

allows selection of the

operation of only one side

(left or right) or both sides

without use of any tools.

Operating Position

Mark (arrow)

Bearings

The copper-alloy bearings ensure long life

expectancy.

Receptacle

The plug-in type receptacle provides adequate

space for wiring.

Conduit Opening *1, *2

G 1/2 conduit threads featuring high sealing

property are used. (Refer to Limit Switch

Connectors for details on SC connectors).

A terminal box with 1/2-14NPT conduit threads

is also available on request.

Sealed Gasket

The employed full-cover

method prevents the gasket

from direct exposure to oil

or water spray.

Roller

The roller actuator is made of hardened

stainless steel and excels in resistance to

wear.

Lever

With the Roller Lever Switch, the lever can

be installed anywhere in a 360° range (180°

if the lever is reversed and attached to

the shaft).

Oil Seal

Improved sealing property is ensured with a

double-seal construction (a oil seal plus an

X-ring seal).

Switch Box

Boasts long life expectancy (50 million

mechanical operations or more with the

2-pole Double-break Switches and

30 million mechanical operations or more

with the DPDT Double-break Switches).

Ground Terminal Screw

A ground terminal is provided to enhance

safety.

Switch Box Screw

A Phillips screw is used to secure the switch

housing for ease of use, and features a

measure to prevent the screw from coming off.

Note: 1. NBR is used in rubber components.

Fluoro-rubber sealed types use fluoro-rubber.

2. For Roller Levers, there is some lever play in the free position (about 2 mm), but this is due to the structure of the head and does not interfere with performance.

*1. A Receptacle and Terminal Box with 1/2-14NPT conduit threads are also available for the North America market.

*2. The conduit thread indication has been changed from “PF1/2” to “G1/2” accompanying the JIS B 0202 revision.

This changes applies only to the indication; thread sizes and pitches have not been affected.

Easy-maintenance Block Mounting

Block mounting makes it possible to easily assemble

or disassemble the head, switch body, and

receptacle of the D4A-

@N by tightening or loosening

the attached screws.

Actuator

Switch

box

Head

Receptacle

7

Contact Forms (Switch Boxes)

STDP Double-break Switches

Type

Without indicator With neon lamp indicator * With LED indicator *

D4A-0100N D4A-0300N

4

Za

D4A-@N

Contact model

D4A-0E00N

Lamp

unit

3

4

Za

3

4

Lamp

unit

Za

3

Operating pattern

Resistor

2

1

Lamp

unit

Lamp Unit Internal Circuits

Rectifier stack

LEDs

Resistor

2

1-2

3-4

Energized

1NC/1NO

snap-action

1

2

1

Lamp

unit

Lamp Unit Internal Circuits

Neon lamp

* Switches with indicators are factory-set to light when the switch is not operated.

DTDP Double-break Switches

Each of these Switches can be used to replace two limit switches in applications, such as high-speed control in machine tools and

switching motors between forward and reverse, that previously required 2 limit switches. This simplifies wiring, saves space, and reduces

costs.

Type

2NC/2NO snap-action,

simultaneous operation

Without indicator

D4A-0500N D4A-0L00N D4A-0P00N

2NC/2NO snap-action,

sequential operation

(2-step operation)

D4A-0700N --- ---

2NC/2NO snap-action,

central neutral operation

D4A-0900N --- ---

Item Without indicator With neon lamp indicator * With LED indicator *

D4A-0500N

D4A-0700N

D4A-0900N

Contact

form

4

1

Za

3

2

Contact model

With neon lamp

indicator *

With LED indicator *

Operating pattern Remarks

1-2

3-4

5-6

7-8

Stroke

1-2

3-4

5-6

7-8

Stroke

1-2

3-4

5-6

7-8

Left

operation

D4A-0L00N D4A-0P00N

Lamp

unit

4

Za Za

3

8

Lamp

unit

4

7

Energized

Energized

Energized

Free

Right

position

operation

Lamp

unit

Za Za

Head is compatible with

double-break head. Can

be switched for operation

on both sides of actuator.

Use the D4A-0017N Special Head.

Use the D4A-0018N Special Head.

3

8

Lamp

unit

7

8

5

7

1

6

Lamp

unit

2

5

Neon lamp

Lamp

unit

1

6

Lamp

unit

Rectifier stack

2

5

Constant

current diode

Lamp unit

internal

circuit

----

Resistor

LED

* Switches with indicators are factory-set to light when the switch is not operated, but the setting can be changed to light for operation (dotted lines).

Lamp

unit

6

8

D4A-@N

r

S

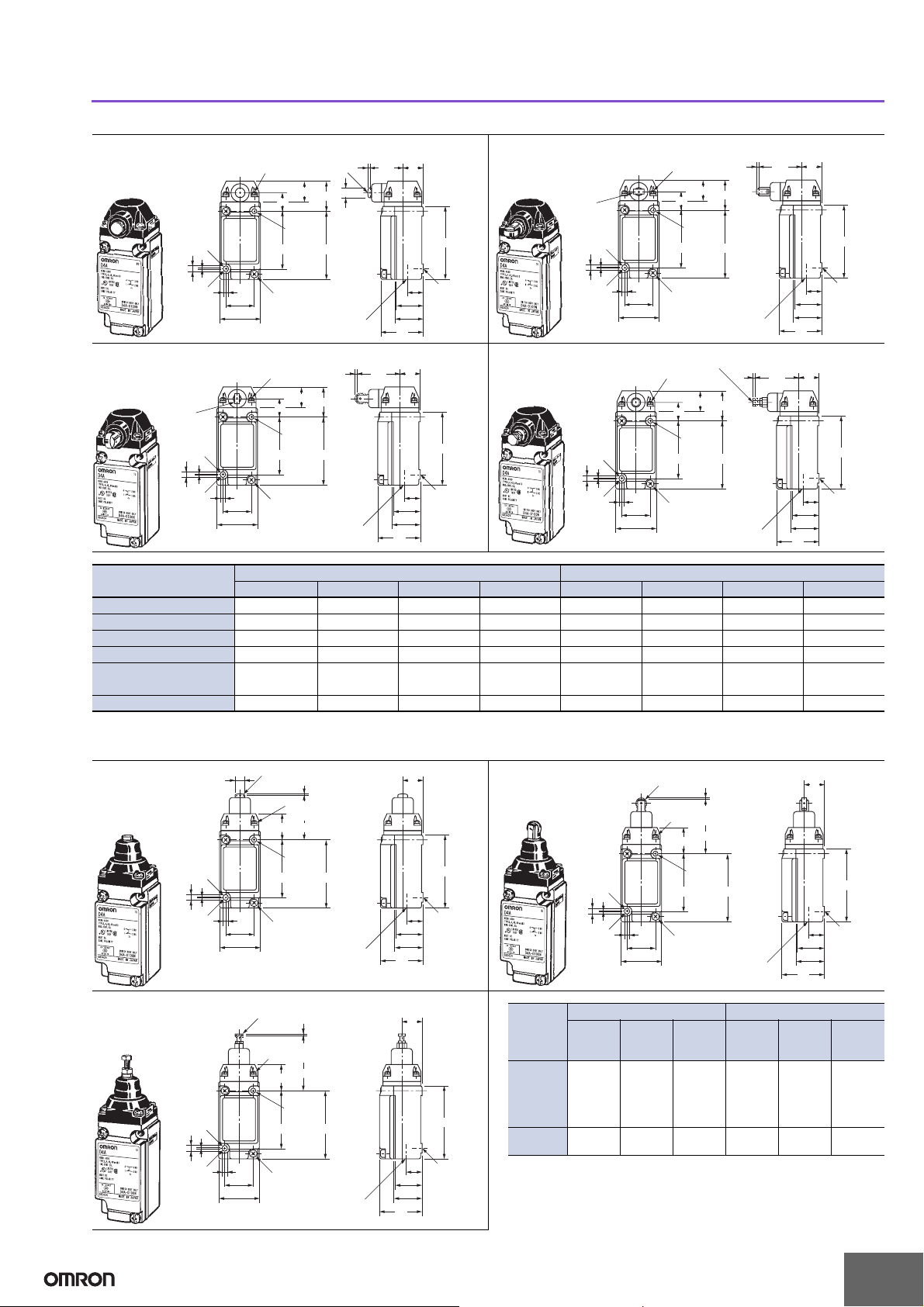

r

Dimensions and Operating Characteristics (Unit: mm)

Set Model Numbers

(The box in a model number indicates the switch box type.)

Roller Lever Switches Note: Levers of the side rotary type are optionally available.

tandard

D4A-3@01N, D4A-4@01N

High-sensitivity

D4A-3@02N, D4A-4@02N

Low-torque

D4A-3@03N, D4A-4@03N

High-sensitivity/Low-torque

D4A-3@04N, D4A-4@04N

Sequential Operation

D4A-4@17N

R2.6

6

0.8

R2.6

5.2

29.4±0.2

42

Four, M4 (length: 12)

screws for head

19

5.2 dia.

mounting

holes

59.5±0.2

Two, M5 (length: 20)

screws for box

Center Neutral Operating

D4A-4@18N

Maintained

D4A-3

@05N, D4A-4@05N

R2.6

6

0.8

R2.6

5.2

29.4±0.2

42

Four, M4 (length: 12)

screws for head

19.1

5.2 dia.

mounting

holes

59.5±0.2

Two, M5 (length: 20)

screws for box

24.5

38.1

62.5

48

62

47.5

44

44

28

29.5

28

29.5

21

16.5

21

16.5

75.5

Two, M6

(depth: 10) screws fo

back-mounting

75.5

Two, M6

(depth: 10) screws fo

back-mounting

7.25 dia.

34

+0.2

0

70.5

G1/2

conduit

7.25 dia.

+0.2

0

70.5

G1/2

conduit

Note: Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

Model SPDT Double-break DPDT Double-break

Operating characteristics

Operating force

OF max. 0.39 N·m 0.39 N·m 0.2 N·m 0.2 N·m 0.39 N·m 0.39 N·m 0.39 N·m 0.2 N·m 0.2 N·m 0.39 N·m 0.39 N·m 0.39 N·m

D4A3@01N

D4A3@02N

D4A3@03N

D4A3@04N

D4A3@05N

D4A4@01N

D4A4@02N

D

4A-

4@03N

D4A4@04N

D4A4@05N

D4A4@17N

Release force RF min. 0.05 N·m 0.05 N·m --- --- --- 0.05 N·m 0.05 N·m --- --- --- 0.05 N·m 0.02 N·m

Pretravel PT max. 15° (12°) 7° (6°) 15° (12°) 7° (6°) 65° (60°) 15° (12°) 7° (6°) 15° (12°) 7° (6°) 65° (60°)

12° (10°)

20° (17°)

Overtravel OT min. 70° 75° 70° 75° 20° 70° 75° 70° 75° 20° 65° 65°

Movement Differential

MD max.

5° (4°) 4° (3°) 5° (4°) 4° (3°) 35° (30°) 7° (6°) 5° (4°) 7° (6°) 5° (4°) 35° (30°) 6° (5°) 5° (4°)

Note: The figures in the parentheses are average values.

1-stage:

2-stage:

D4A4@18N

19° (15°)

9

Side Plunger Switches

D4A-@N

Standard

D4A-3

@06N

D4A-4@06N

Vertical Roller

D4A-3

@07-VN

D4A-4@07-VN

11 dia.x 5

stainless

steel roller

Four, M4 (length: 12)

screws for head

R2.6

6

0.8

R2.6

R2.6

6

0.8

R2.6

5.2

29.4±0.2

42

Four, M4 (length: 12)

screws for head

5.2

29.4±0.2

42

Stainless

steel plunger

21.5

19

+0.2

5.2 dia.

0

mounting

holes

59.5±0.2

Two, M5 (length: 20)

screws for box

21.5

31.1

19

+0.2

5.2 dia.

0

mounting

holes

59.5±0.2

70.5

Two, M5 (length: 20)

screws for box

31.1

70.5

10 dia.

G1/2

conduit

G1/2

conduit

PT

21

OP

75.5

16.5

Two, M6

(depth: 10) screws

28

for back-mounting

29.5

44

21

OPPT

75.5

Two, M6

(depth: 10) screws

16.5

for back-mounting

28

29.5

44

Horizontal Roller

D4A-3

@07-HN

D4A-4@07-HN

11 dia.x 5

stainless

steel roller

R2.6

6

R2.6

Adjustable

D4A-3

@08N

D4A-4@08N

R2.6

6

0.8

R2.6

0.8

Four, M4 (length: 12)

screws for head

59.5±0.2

5.2

29.4±0.2

42

Four, M4 (length: 12)

screws for head

59.5±0.2

5.2

29.4±0.2

42

21.5

31.1

19

+0.2

5.2 dia.

0

mounting

holes

70.5

Two, M5 (length: 20)

screws for box

M5 x 0.8 (length:14)

Allen-head bolt

21.5

31.1

19

+0.2

5.2 dia.

0

mounting

holes

70.5

Two, M5 (length: 20)

screws for box

G1/2

conduit

G1/2

conduit

21

OPPT

75.5

Two, M6

(depth: 10) screws

16.5

for back-mounting

28

29.5

44

21

OPPT

75.5

Two, M6

(depth: 10) screws

16.5

for back-mounting

28

29.5

44

Model SPDT Double-break DPDT Double-break

Operating characteristics D4A-3@06N

Operating force

OF max. 19.61 N 19.61 N 19.61 N 19.61 N 19.61 N 19.61 N 19.61 N 19.61 N

D4A-3@07-HN D4A-3@07-VN

D4A-3@08N D4A-4@06N

D4A-4@07-HN D4A-4@07-VN

D4A-4@08N

Release force RF min. 4.90 N 4.90 N 4.90 N 4.90 N 4.90 N 4.90 N 4.90 N 4.90 N

Pretravel PT max. 2.4 mm 2.4 mm 2.4 mm 2.4 mm 2.4 mm 2.4 mm 2.4 mm 2.4 mm

Overtravel OT min. 5.1 mm 5.1 mm 5.1 mm 5.1 mm 5.1 mm 5.1 mm 5.1 mm 5.1 mm

Movement Differential

MD max.

0.6 mm 0.6 mm 0.6 mm 0.6 mm 1.0 mm 1.0 mm 1.0 mm 1.0 mm

OP * 34±0.8 mm 44±0.8 mm 44±0.8 mm 41 to 47.5 mm 34±0.8mm 44±0.8 mm 44±0.8 mm 41 to 47.5 mm

* Operating position

Top Plunger Switches

Stainless steel plunger

Standard

D4A-3

@09N

D4A-4@09N

Adjustable

D4A-3

@11N

D4A-4@11N

10 dia.

R2.6

6

0.8

R2.6

R2.6

6

0.8

R2.6

5.2

29.4±0.2

42

M5 x 0.8 (length:14)

Allen-head bolt

5.2

29.4±0.2

42

PT

Four, M4 (length: 12)

screws for head

27

OP

+0.2

5.2 dia.

0

mounting

holes

59.5±0.2

59.5±0.2

70.5

Two, M5 (length: 20)

screws for box

PT

Four, M4 (length: 12)

screws for head

OP

27

+0.2

5.2 dia.

0

mounting

holes

70.5

Two, M5 (length: 20)

screws for box

G1/2

conduit

G1/2

conduit

44

44

28

29.5

28

29.5

21

16.5

21

16.5

75.5

Two, M6

(depth: 10) screws

for back-mounting

75.5

Two, M6

(depth: 10) screws

for back-mounting

Roller Plunger

D4A-3

@10N

D4A-4@10N

R2.6

6

R2.6

Model SPDT double-break DPDT double-break

Operating

characteristics

OF max.

RF min.

PT max.

OT min.

MD max.

OP *

* Operating position

Note: A Fork Lever Lock can be used with D4A-@@05N models only.

D4A

-3@09N

17.65 N

4.90 N

1.6 mm

5.1 mm

0.4 mm

46±0.8 mm56±0.8 mm55.5 to

0.8

11 dia.x 5 stainless

steel roller

Four, M4 (length: 12)

screws for head

59.5±0.2

5.2

Two, M5 (length: 20)

29.4±0.2

D4A

-3@10N

17.65 N

1.6 mm

5.1 mm

0.4 mm

screws for box

42

4.90 N

OP

27

+0.2

5.2 dia.

mounting

holes

D4A

-3@11N

17.65 N

4.90 N

1.6 mm

5.1 mm

0.4 mm

62 mm

PT

0

70.5

G1/2

conduit

D4A

-4@09N

17.65 N

4.90 N

1.6 mm

5.1 mm

1.0 mm

29.5

44

D4A

-4@10N

17.65 N

4.90 N

1.6 mm

5.1 mm

1.0 mm

46±0.8 mm56±0.8 mm55.5 to

21

Two, M6

(depth: 10) screws

16.5

for back-mounting

28

75.5

D4A

-4@11N

17.65 N

4.90 N

1.6 mm

5.1 mm

1.0 mm

62 mm

10

Flexible Rod

r

g

D4A-@N

Spring wire

D4A-3

@12N

D4A-4@12N

6

Cat Whisker

D4A-3

@15N

@15N

D4A-4

(see note 1)

PT

(see note 2)

(287)

Four, M4 (length: 12)

screws for head

R2.6

0.8

R2.6

Note: 1. The stainless rod can be operated from any direction except the

axial direction (i.e., from the top).

2. The optimum operating range of the stainless rod is within 1/3

of the entire length from the top end.

(124)

R2.6

6

0.8

R2.6

Note: 1. The stainless rod can be operated from any direction except the

axial direction (i.e., from the top).

2. The optimum operating range of the stainless rod is within 1/3

of the entire len

5.2

29.4±0.2

42

(see note 1)

29.4±0.2

42

59.5±0.2

PT

Four, M4 (length: 12)

screws for head

5.2

330

88

27

+0.2

5.2 dia.

0

mounting

holes

70.5

Two, M5 (length: 20)

screws for box

G1/2

conduit

(see note 2)

170.5

93.5

27

+0.2

5.2 dia.

0

mounting

holes

59.5±0.2

Two, M5 (length: 20)

screws for box

70.5

th from the top end.

G1/2

conduit

21

16.5

28

29.5

44

28

29.5

44

8 dia. max.

1.8 dia.

Stainless steel

wire rod

21

16.5

75.5

Two, M6

(depth: 10) screws fo

back-mounting

1.4 dia.

Stainless steel

wire rod

75.5

Two, M6

(depth: 10) screws

for back-mounting

Plastic Rod

D4A-3

@14N

D4A-4@14N

6

Coil Spring

D4A-3

@16N

@16N

D4A-4

(see note 1)

44

6.5 dia.

28

29.5

7 dia.

Plastic rod

21

16.5

29.5

44

28

21

16.5

PT

(see note 2)

(106.5)

R2.6

0.8

R2.6

6

(106.5)

Four, M4 (length: 12)

screws for head

59.5±0.2

5.2

Two, M5 (length: 20)

42

(see note 1)

5.2

29.4±0.2

42

screws for box

PT

29.4±0.2

Note: 1. The plastic rod can be operated from any direction except the

axial direction (i.e., from the top).

2. The optimum operating range of the plastic rod is within 1/3

of the entire length from the top end.

R2.6

0.8

R2.6

Note: 1. The coil spring rod can be operated from any direction except the

axial direction (i.e., from the top).

2. The optimum operating range of the coil spring rod is within 1/3

of the entire length from the top end.

150

88.5

27

+0.2

5.2 dia.

0

mounting

holes

70.5

G1/2

conduit

(see note 2)

Four, M4 (length: 12)

screws for head

27

+0.2

5.2 dia.

0

mounting

holes

59.5±0.2

Two, M5 (length: 20)

screws for box

150

70.5

G1/2

conduit

75.5

Two, M6

(depth: 10) screws for

back-mounting

Stainless steel

coil spring

75.5

Two , M 6

(depth: 10) screws

for back-mounting

Note: Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

Model SPDT Double-break DPDT Double-break

Operating characteristics D4A-3@12N D4A-3@14N D4A-3@15N D4A-3@16N D4A-4@12N D4A-4@14N D4A-4@15N D4A-4@16N

Operating force

OF max. 0.98 N 1.47 N 0.98 N 1.47 N

Pretravel PT max. 15° (5°) 15° (5°) 15° (5°) 15° (5°)

Note: The figures in the parentheses are average values.

11

D4A-@N

Levers (for Roller Lever Switches)

Note: No D4A-0003N or D4A-0004N head should be used with the adjustable roller lever or mechanical malfunctioning could result because the total weight of the

adjustable roller lever is comparatively large. Use a standard-load head (D4A-0001N or D4A-0002N) instead.

Roller Lever

D4A-A00

38.1

M5 Allen bolt

Roller Lever

D4A-A10

38.1

M5 Allen bolt

Roller Lever

D4A-A20

38.1

M5 Allen bolt

Roller Lever

D4A-A30

38.1

M5 Allen bolt

Nylon Loop Lever

D4A-F00

19 dia.

18

19 dia.

18

19 dia.

18

19 dia.

18

Stainless

sintered roller

7.3 dia.

Stainless

sintered

roller

7.3 dia.

Stainless

sintered roller

7.3 dia.

Stainless

sintered

roller

7.3 dia.

25 max.

7.9

11.5

7.9

19.5

7.9

9 16.5

39.4

13.8

9

9

(23.6)

7.9

5.5

9

7.3 dia.

Roller Lever

D4A-B06

M5 Allen bolt

Adjustable Roller Lever

D4A-C00

19 dia.

33 to 91

(adjustable)

113

12.9

18

21.2

Adjustable Rod Lever

D4A-D00

3 dia.

150 max.

11

6

7.5

33

M5 Allen bolt

(adjustable)

160

M5 Allen bolt

150

±10

7.5

4 dia.

13

21.2

33.7

Stainless

sintered roller

6.4 graduation

7.3 dia.

7.3 dia.

Nylon

17.5 dia.

18

M5 Allen bolt

M5 Allen bolt

60

Stainless

sintered

roller

7.3 dia.

±10

Fork Lever Lock

D4A-E30

21

15

9

7.9

14

17

(2)

7.9

3.6

19 dia.

M5 Allen bolt

9

Fork Lever Lock

Stainless

sintered

roller

38.1

D4A-E20

17

(2)

19 dia.

Stainless

sintered

roller

38.1

3.6

7.9

4.5

2.5

M5 Allen bolt

9

Note: A Fork Lever

Lock can be

used with

D4A-@@05N

models only.

90

°

7.3 dia.

Stainless

38.1

Note: A Fork Lever

7.3 dia.

38.1

sintered

roller

Lock can be

used with

D4A-@@05N

models only.

°

90

Stainless

sintered

roller

Fork Lever Lock

20

10.5

4.5

Stainless rod

D4A-E10

26

22

(2)

6.2

7.9

3.6

19 dia.

M5 Allen bolt

9

Fork Lever Lock

D4A-E00

26

22

(2)

6.2

7.9

3.6

19 dia.

M5 Allen bolt

9

Stainless

sintered

roller

38.1

Stainless

sintered

roller

38.1

Note: A Fork Lever

Lock can be

used with

D4A-@@05N

models only.

°

90

7.3 dia.

Stainless

38.1

Note: A Fork Lever

7.3 dia.

38.1

sintered

roller

Lock can be

used with

D4A-@@05N

models only.

°

90

Stainless

sintered

roller

Note: Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

12

Head and Lever Positions

• The operating head can be positioned

and locked in any of four 90° positions

and a lever can lock in any position

through 360° around the shaft of the Limit

Switch. Furthermore, the lever can be

reversed and attached to the shaft (refer

to the figures below on the right hand

side). Therefore the roller is compatible

with a wide movement range of a dog.

• A Fork Lever Lock can be used with

maintained models (D4A-0005N) only.

Remove the head from the

Switch by loosening the screws

(the screws can be loosened

but not removed from the head).

Four, M4 x 12

The operating head can be

positioned and locked in

any of four 90° positions.

D4A-@N

The lever can lock in any position through 360° around

the shaft. The lever can be reversed and attached to the

shaft, in which case the switching operation should

complete in a range of 0° to 180°.

180° operating

position

360°

operating

position

There are four kinds of fork lever locks.

The position of each roller is different.

It is possible to use D4A-E00 through

D4A-E30 levers instead, if they are reversed

before attaching.

They can be used with D4Amodels only.

By loosening the Allen-head bolt on an adjustable roller lever

or rod lever, the length of the lever can be adjusted.

@@05N

D4A-C00 D4A-D00

D4A-D00 Loosen

the bolt to adjust

the length of the

lever.

Adjustable between

33 and 91 mm

Lever Position

D4A-A00 D4A-A10 D4A-A20 D4A-A30

59 to 64.5

52.9 to 58.4

67 to 72.5

44.9 to 50.4

73 to 78.5

38.9 to 44.4

D4A-E00 D4A-E10

D4A-E20 D4A-E30

Loosen the screw

to adjust the

length of the rod.

86.9 to 92.4

25 to 30.5

Nameplate

The whole switch model without

lever is printed.

The type of switch box is printed.

(The type is also indicated on the

head and receptacle.)

When ordering, do not confuse set model numbers and model

numbers for individual blocks.

Compatibility with D4A-@

The D4A-@N is compatible with the D4A-@ when the following

accessories are attached to the D4A-@N.

D4A-@

Receptacle box

The D4A-@N without the above accessories is not compatible with the

D4A-@.

D4A-@N

Switch box

D4A-@N

Head

13

Safety Precautions

Refer to Safety Precautions for All Limit Switches.

Precautions for Correct Use

Operating Environment

• Seal material may deteriorate if a Switch is used outdoor or where

subject to special cutting oils, solvents, or chemicals. Always

appraise performance under actual application conditions and set

suitable maintenance and replacement periods.

• Install Switches where they will not be directly subject to cutting

chips, dust, or dirt. The Actuator and Switch must also be protected

from the accumulation of cutting chips or sludge.

Not Suitable Suitable

D4A-@N

Lighting Mode Selection of Indicators (SPDT only)

The lighting mode of the operation indicator can be changed easily

between two modes: lighting when the Switch is operating and

lighting when the Switch is not operating.

Lights When Not Operating *1 Lights When Operating *2

• Constantly subjecting a Switch to vibration or shock can result in

wear, which can lead to contact interference with contacts,

operation failure, reduced durability, and other problems.

Excessive vibration or shock can lead to false contact operation or

damage.

Install Switches in locations not subject to shock and vibration and

in orientations that will not produce resonance.

• The Switches have physical contacts. Using them in environments

containing silicon gas will result in the formation of silicon oxide

(SiO

2) due to arc energy. If silicon oxide accumulates on the

contacts, contact interference can occur. If silicon oil, silicon filling

agents, silicon cables, or other silicon products are present near the

Switch, suppress arcing with contact protective circuits (surge

killers) or remove the source of silicon gas.

Changing the Operating Direction

Roller Lever Switch

The head of the side rotary type can be converted in seconds to CW,

CCW, or both-way operation. Follow the procedures on the right hand

side for conversion (not applicable to the Maintained, Sequential

Operating, Center Neutral Operating Switches).

Operating Part (Rear of Head) Procedures

Operating position arrow marks

1. Dismount the head by loosening the

four screws that secure it.

2. Turn over the head to set the desired

operation (CW, CCW, or both). The

desired side can be selected by setting the mode selector knob shown in

the figure. This knob is factory set to

the “CW+CCW” (both-way operation)

position.

3. When set to the CW position, the

head rotates in clockwise direction.

When set to the CCW position, the

head rotates in counterclockwise direction.

In either case, be sure to accurately

align the arrow mark to the setting position.

Power supply

Internal circuits

4

1

Built-in switch

*1. The lamp is lit when the actuator is at the free position.

The lamp will be off when the contacts of the Limit Switch have been

actuated and snapped to each other at the operating position.

*2. The lamp is lit when the contacts have been released and snapped only from

the operating position.

3

Load

2

Power supply

Built-in switch

1

Internal circuits

34

2

Load

Change the lighting mode as follows:

1. Push the claw securing

the lamp section to the

right (do not push

strongly).

2. Remove the lamp

section.

3. Mount the lamp section

so that legend “NC-ON”

or “NO-ON” will appear

in the display window.

In either case, the lamp will not light when the load is ON.

Mounting

Model

Front

Mounting

29.4±0.15

G1/2 Conduit

D4A-3@@@N

D4A-4@@@N

59.5±0.15

Two, 6.2 dia. holes

(Recommended mounting

screws: M6.

Switch Box depth: 10.)

+0.2

Two, 5.2 dia. holes

0

or M5 tapped holes

+0.2

0

Mounting lo-

cations

: Mounting

locations

Rear

Mounting

29.4

±0.15

59.5±0.15

: Mounting

locations

14

D4A-@N

Screw Tightening Torques for Heads and Switch Boxes

To maintain the high sealing capability of the Limit Switch, tighten the

screws for the head and switch box with the following torques:

Head (four 12-mm M4 screws): 1.2 to 1.4 N·m

Switch box (two 20-mm M5 screws): 2.4 to 2.7 N·m

Solderless Terminals

The D4A-@N with DPDT double-break incorporates solderless

terminals.

Operation

• The operating methods, cam and dog shapes, operating frequency,

and overtravel (OT) have a significant effect on the service life and

accuracy of the Limit Switch. The shape of the cam should be as

smooth as possible.

• A marginal overtravel (OT) value should be set. The ideal value is

the rated OT value x 0.7.

• The actuator should not be remodeled to change the operating

position.

Connectors

To satisfy IP67, apply sealing tape to the connector conduit.

Appropriate external diameter of cables is 5.5 to 14 dia.

Use OMRON’s SC-@M Series.

Tighten the Connectors to a torque of 1.8 to 2.2 N·m.

Maintenance and Repair

The user must not maintain or repair equipment incorporating any

D4A-N model. Contact the manufacturer of the equipment for any

maintenance or repairs required.

Appropriate Tightening Torque

A loose screw may cause malfunctions. Be sure to tighten each screw

to the proper tightening torque as shown in the table.

No. Type

Terminal screws (M3.5 screws) (in-

1

cluding grounding terminals)

Head mounting screws 1.18 to 1.37 N·m

2

Switch box mounting screws 2.35 to 2.75 N·m

3

Body mounting screws

4*

Connectors 1.77 to 2.16 N·m

5

Actuator mounting screws 2.45 to 2.65 N·m

6

* When using M5 Allen-head bolts, particularly when the head direction has

been changed, check the torque of each screw and make sure that the screws

are free of foreign substances, and that each screw is tightened to the proper

torque.

Appropriate tightening

torque

0.78 to 0.88 N·m

4.90 to 5.88 N·m

How to Order

The D4A-@N is compatible with the D4A-@

when the following accessories are

attached to the D4A-@N.

*The D4A-@N without the above

accessories is not compatible with

the D4A-@.

Individual model numbers

=

*

=

Receptacle

Set model numbers

Example: D4A- 3101N D4A- 3 000N D4A-0 1 00N D4A-00 01 N

Switch box

Head

Lever

D4A-A00

15

Read and Understand This Catalog

Please read and understand this catalog before purchasing the products. Please consult your OMRON representative if you have any questions or

comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or other period if specified)

from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT, MERCHANTABILITY, OR

FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS

IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE PRODUCTS UNLESS

OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT

SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of products in the customer's

application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying ratings and limitations of use that apply to the

products. This information by itself is not sufficient for a complete determination of the suitability of the products in combination with the end product,

machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not intended to be an exhaustive list of all possible

uses of the products, nor is it intended to imply that the uses listed may be suitable for the products:

•

Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not described in this catalog.

•

Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment, amusement machines, vehicles,

safety equipment, and installations subject to separate industry or government regulations.

•

Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE

SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any consequence thereof.

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when significant construction changes are made.

However, some specifications of the products may be changed without any notice. When in doubt, special model numbers may be assigned to fix or

establish key specifications for your application on your request. Please consult with your OMRON representative at any time to confirm actual

specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

PERFORMANCE DATA

Performance data given in this catalog is provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent the

result of OMRON’s test conditions, and the users must correlate it to actual application requirements. Actual performance is subject to the OMRON

Warranty and Limitations of Liability.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no responsibility is assumed for clerical,

typographical, or proofreading errors, or omissions.

In the interest of product improvement, specifications are subject to change without notice.

OMRON Corporation

Industrial Automation Company

http://www.ia.omron.com/

(c)Copyright OMRON Corporation 2010 All Right Reserved.

2010.10

Loading...

Loading...