Page 1

Safety,

Technology

& Innovation

D40ML Series

Operating Instructions for D40ML Series

IMPORTANT NOTE: Read and understand these instructions before installing, operating, or maintaining this equipment. The product is designed to

be a component of a safety oriented control system. It is the responsibility of each user to ensure the correct overall functionality of its systems and

machines. Omron STI its subsidiaries and affiliates, cannot guarantee all of the characteristics of a given system or product not supplied by Omron

STI.

WARNING: Do not defeat, tamper with, remove or bypass this unit. Severe injury to personnel could result.

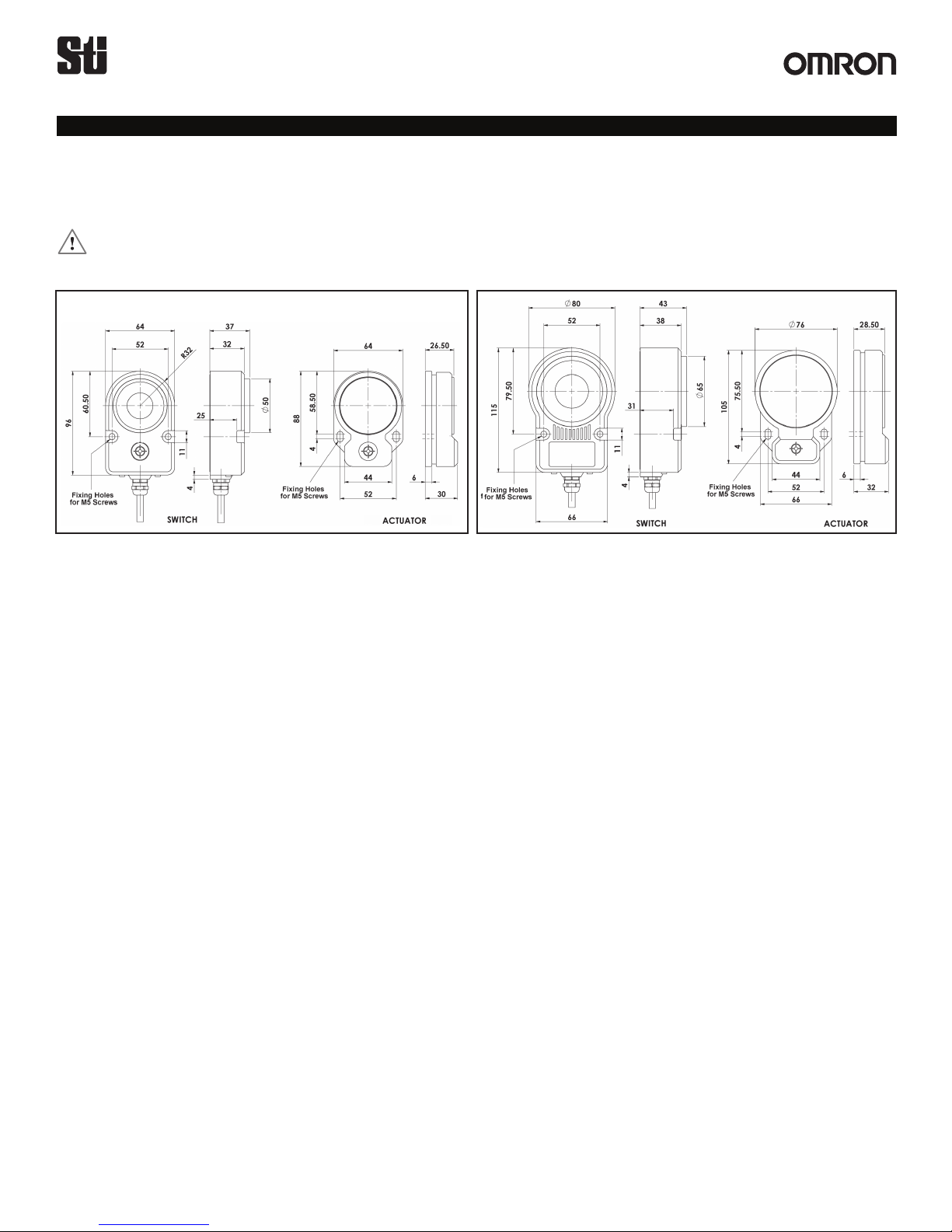

D40ML Medium Duty Switch Dimensions (mm)

D40ML Heavy Duty Switch Dimensions (mm)

Operation:

All D40ML series safety switches are designed to conform to EN60947-5-3 and be used as directed by ISO14119, EN ISO12100 and EN60204-1. They have

coded RFID sensing which provides a wide (>10mm) sensing distance and provide a high tolerance to misalignment after sensing. They can operate in extreme

environments of temperature and moisture. The switches are provided factory coded either uniquely or by series master code.

Installation:

• Installation of all D40ML series safety switches must be in accordance with a risk assessment for the individual application.

• The use of a safety relay is required for monitoring RFID coded switches. These relays monitor two redundant circuits as per ISO13849-1 for up to

PLe/Category 4 protection.

• D40ML series switches are designed to operate with most dual channel safety relays to satisfy EN60947-5-3.

• M5 mounting bolts must be used to mount the switches. Tightening torque for mounting bolts to ensure reliable fixing is 1.0 Nm. Always mount on non-ferrous

materials.

• Do not mount adjacent switches or actuators closer than 30mm.

• To achieve nominal holding force ensure face-to-face alignment of magnetic parts.

• After installation always check each switch function by opening and closing each guard individually in turn and ensuring that the Green LED on the switch and

the LEDs on the safety relay are illuminated when the switch is closed and are extinguished when the switch is open. Check that the machine stops and

cannot be re-started when each switch is open.

Maintenance/Safety Checks: Monthly: Check alignment of actuator and look for signs of mechanical damage to the switch casing or cables.

The safety functions and mechanics must be tested regularly. For applications were infrequent guard access is foreseeable, the system must have a manual

function test to detect a possible accumulation of faults at least once per month for PLe Cat3/4 or once per year for PLd Cat3 (ISO13849-1). Where possible it is

recommended that the control system of the machine demands and monitors these tests, and stops or prevents the machine from starting if the test is not done.

(ISO14119). Check that the machine stops and cannot be re-started when each switch is open.

NOTE: The safety outputs will only close when the actuator is in place and the lock magnet is energized. Forcing open of the lock will cause the safety outputs to

open.

IMPORTANT: The guard lock function is power-on applied and power-off released. It may not be used for person protection on machines with rundown. The Risk

Assessment for the particular application should include the risk of spare actuators. Spare actuators should not be readily available and must be securely

controlled. Record any RFID codes as required by factory rules or with reference to any risk assessment for the particular application and user location.

Page 2

D40ML Series

Operating Instructions for D40ML Series

Connection Colors

Quick Connect (QC)

250mm (10”)

M12 8 -Way

Male Plug

3 Blue 0VDC

2 Red 24VDC

8 Orange Lock Applied (+24VDC) 500mA max. (locked)

7 Black Safety Output 1

1 White Safety Output 1

4 Yellow Safety Output 2

6 Green Safety Output 2

5 Brown Auxiliary Signal +24 VDC 200mA

Insulation Resistance: 100 Mohms

Switching Frequency: 1.0 Hz maximum

Enclosure Protection: IP67 (Plastic or Metal)

Max. Switched Current (Outputs): 200mA (min. internal resistance 8.5 Ohms)

Conductor

Colors Function

Standards: ISO14119 EN60947-5-3 EN60204-1

ISO13849-1 UL508

:ataD ytilibaileR dna noitacifissalC ytefaS

Dielectric Withstand: 250VAC

Switching Distance: S

1mm Close

ao

10mm Open

S

ar

Approach Speed: 200mm/m to 1000mm/s

Body Material: D40ML-P__ = Plastic

D40ML-M__ = Die-Cast Metal

D40ML-SS__= 316 Stainless Steel

Temperature Range: -25C to +40C

Vibration: 10Hz to 55Hz, 1mm amplitude.

Shock: 11ms 30g

IP69K (Stainless Steel) with flying leads

Cable Type: PVC 8 core 6mm OD

Mounting Bolts: 2 x M5 Tightening torque 1.0 Nm

Mounting Position: Any

Power Supply: +24VDC ± 10% (selv / pelv)

Holding Force: SS2: F1max (typical): 600N Fzh: 450N

SS1: F1max (typical): 950N Fzh: 700N

P2 & M2 Version: F1max (typical): 900N Fzh: 675N

P1 & M1 Version: F1max (typical): 1500N Fzh: 1150N

50mA max. (sensing)

200mA max.

200mA max.

Power

Ratings

Actuator Operating

Direction:

LED Operation and Switch Status Indication:

The D40ML switch uses 2 LED to indicate all the different possible

switch states. The LED are in a clearly visible location at either side of

the cable exit point.

Switch Status Guard Green LED Yellow LED

Locked Closed Steady Off

Solenoid Power OFF (unlocked) Closed Flashing Off

Guard Open Open Off Steady

Door Forced Open Open Off Flashing

EU Declaration of Conformity

The manufacturer named below herewith declares that the product

fulfills the provisions of the directive(s) listed below and that the

related standards have been applied.

OMRON Scientific

Technologies Inc.

6550 Dumbarton Circle

Fremont, CA 94555, U.S.A.

Directives applied:

Machinery directive 2006/42/EC

EMC directive 2004/108/EC (valid until 19th April 2016)

EMC directive 2014/30/EU (valid from 19th April 2016)

RoHS Directive 2011/65/EC

Standards applied:

EN 60947-5-3:2013

EN 60947-5-1:2004+AC:2005+A1:2009

EN 60947-1:2007+A1:2011

EN ISO 13849-1:2008:+AC:2009

EN 62061:2005+AC:2010+A1:2013

EN ISO 14119:2013

Fremont, Date: August 12, 2015

Characteristic Data according to EN ISO13849-1:

Performance Level e If both channels are used in combination

with a SIL3/PLe control device

Category Cat. 4

MTTFd 1100a

Diagnostic Coverage DC 99% (high)

Number of operating days per year: dop = 365d

Number of operating hours per day: hop = 24h

B10d: Not mechanical parts implemented

When the product use deviates from these assumptions (different load, operating

frequency, etc.) the values must be adjusted accordingly.

Information with regard to UL508

Use LVLC or Class 2 supply. Type 1 enclosure.

WARNING: Hot surface – risk of burn if used at ambient temperature of +40C degrees.

Affix a warning label to the switch.

Marty Krikorian

Director, Quality Control

©2016 Omron Scientific Tetchnologies, Inc. All rights reserved.

Manual P/N 99983-0020 022016 Rev.C

Page 3

Printed on recycled paper.

OMRON AUTOMATION AMERICAS HEADQUARTERS • Chicago, IL USA • 847.843.7900 • 800.556.6766 • www.omron247.com

OMRON CANADA, INC. • HEAD OFFICE

Toronto, ON, Canada • 416.286.6465 • 866.986.6766 • www.omron247.com

OMRON ELECTRONICS DE MEXICO • HEAD OFFICE

México DF • 52.

OMRON ELECTRONICS DE MEXICO • SALES OFFICE

Apodaca, N.L. • 52.81.11.56.99.20 • 01-800-226-6766 • mela@omron.com

OMRON ELETRÔNICA DO BRASIL LTDA • HEAD OFFICE

São Paulo, SP, Brasil • 55.11.2101.6300 • www.omron.com.br

OMRON EUROPE B.V. •

55.59.01.43.00

Wegalaan 67-69, NL-2132 JD, Hoofddorp, The Netherlands.

• 01-800-226-6766 • mela@omron.com

Authorized Distributor:

OMRON ARGENTINA • SALES OFFICE

Cono Sur • 54.11.4783.5300

OMRON CHILE • SALES OFFICE

Santiago • 56.9.9917.3920

OTHER OMRON LATIN AMERICA SALES

54.11.4783.5300

•

+31 (0) 23 568 13 00

•

www.industrial.omron.eu

Controllers & I/O

• Machine Automation Controllers (MAC) • Motion Controllers

• Programmable Logic Controllers (PLC) • Temperature Controllers • Remote I/O

Robotics

• Industrial Robots • Mobile Robots

Operator Interfaces

• Human Machine Interface (HMI)

Motion & Drives

• Machine Automation Controllers (MAC) • Motion Controllers • Servo Systems

• Frequenc

y Inverters

Vision, Measurement & Identification

• Vision Sensors & Systems • Measurement Sensors • Auto Identification Systems

Sensing

• Photoelectric Sensors • Fiber-Optic Sensors • Proximity Sensors

• Rotary Enc

oders • Ultrasonic Sensors

Safety

• Safety Light Curtains • Safety Laser Scanners • Programmable Safety Systems

• Safety Mats and Edges • Safety Door Switches • Emergency Stop Devices

• Safety Switches & Operator Controls • Safety Monitoring/Force-guided Relays

Control Components

• Power Supplies • Timers • Counters • Programmable Relays

• Digital Panel Meters • Monitoring Products

Switches & Relays

• Limit Switches • Pushbutton Switches • Electromechanical Relays

• Solid Sta

te Relays

Software

• Programming & Configuration • Runtime

C434I-E-01 08/15

Note: Specifications are subject to change.

© 2017 Omron. All Rights Reserved.

Printed in U.S.A.

Loading...

Loading...