Page 1

Cat. No. W418-E1-07

SYSMAC

CXONE-AL_C-V4/

CXONE-AL_D-V4

Face Plate Auto-Builder for NS

(Ver. 3.1)

OPERATION MANUAL

Page 2

Page 3

CXONE-AL@@C-V4/

CXONE-AL@@D-V4

Face Plate Auto-Builder for NS

(Ver. 3.1)

Operation Manual

Revised October 2010

Page 4

iv

Page 5

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

OMRON, 2003

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 6

vi

Page 7

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvi

SECTION 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Features of the Face Plate Auto-Builder for NS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-3 Application Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1-4 Upgrades Made for Version 2.0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-5 Upgrades Made for Version 3.0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-6 Upgrades Made for Version 3.1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SECTION 2

Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2-1 Installation Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-2 Uninstalling the Face Plate Auto-Builder for NS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

SECTION 3

Basic Operation Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3-1 Basic Operation Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SECTION 4

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4-1 Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4-2 Merging Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SECTION 5

Basic Specifications of Created Screens . . . . . . . . . . . . . . . . 25

5-1 Created Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5-2 Screen Titles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5-3 Tuning Screen Realtime Trends. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5-4 Engineering Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5-5 Percent Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5-6 Read Address and Write Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5-7 Work Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

vii

Page 8

TABLE OF CONTENTS

SECTION 6

Creation Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6-1 Basic PID (Block Model 011) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6-2 Advanced PID (Block Model 012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6-3 Two-position ON/OFF (Block Model 001) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6-4 Three-position ON/OFF (Block Model 002). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6-5 Indication and Operation (Block Model 032) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6-6 Indicator (Block Model 034) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6-7 Segment Program 2 (Block Model 157) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6-8 Indication and Setting (Block Model 031) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6-9 Ratio Setting (Block Model 033). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6-10 High/Low Alarm (Block Model 111) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6-11 Timer (Block Model 205) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

6-12 Counter (Block Model 208). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

6-13 ON/OFF Valve Manipulator (Block Model 221). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

6-14 Motor Manipulator (Block Model 222). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

6-15 Reversible Motor Manipulator (Block Model 223). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6-16 Motor Opening Manipulator (Block Model 224) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6-17 Blended PID (Block Model 013). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6-18 Batch Flowrate Capture (Block Model 014) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6-19 Segment Program 3 (Block Model 158) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

viii

Page 9

About this Manual:

This manual describes the installation and operation of the CXONE-AL@@C-V4/CXONE-AL@@D-V4

Face Plate Auto-Builder for NS. The Face Plate Auto-Builder for NS is a software package used to

automatically build project files for the CS1W-LC001 Loop Control Unit, the CS1W-LCB01 and CS1WLCB05 Loop Control Boards, CS1D-CPU@@P Process-control CPU Units, and CJ1W-CPU@@P Loop

Control CPU Units used with NS-series Programmable Terminals. These files are based on the tag

files created using CX-Process Tool.

The project files that are created are configured using the Face Plate Screens for the Loop Control

Unit.

Please read this manual carefully and be sure you understand the information provided before

attempting to install and operate the Face Plate Auto-Builder for NS. Please read the following manuals

carefully and be sure you understand the information provided before setting up the Loop Control Unit/

Board and NS-series PT System

Manuals Related to the Loop Control Unit/Board

Product Manual name Cat. No. Contents

CXONE-AL@@C-V4/

CXONE-AL@@D-V4

Face Plate AutoBuilder for NS

WS02-LCTC1-EV3

CX-Process Tool

CXONE-AL@@C-V4/

CXONE-AL@@D-V4

CX-One FA Integrated

Tool Package

WS02-LCTC1-E

CX-Process Monitor

WS02-LCMC1-E

CX-Process Monitor

Plus

CS1W-LC001

Loop Control Unit

CS1W-LCB01/05

CS1D-CPU

Loop Control Boards

CS1W-LC001

Loop Control Unit

CS1W-LCB01/05

CS1D-CPU

Loop Control Boards

@@P

@@P

Face Plate Auto-Builder

for NS

Operation Manual

CX-Process Tool

Operation Manual

CX-One

Setup Manual

CX-Process Monitor

Operation Manual

CX-Process Monitor Plus

Operation Manual

Loop Control Unit

Operation Manual

Loop Control Board

Operation Manual

Loop Control Unit

Function Block Reference

Manual

Loop Control Board

Function Block Reference

Manual

W418 (this manual) Installation and operation procedure for

Face Plate Auto-Builder for NS.

W372 Installation and operation procedures

for the CX-Process Tool.

W463 Provides an outline of the CX-One FA

Integrated Tool Package and the installation procedure. Refer to this manual

when installing software contained in

the CX-One FA Integrated Tool Package.

W373 Installation and operation procedures

for the CX-Process Monitor.

W428 Installation and operation procedures

for the CX-Process Monitor Plus.

W374 Installation and operation procedures

for the Loop Control Unit (except for

function blocks).

W406 Installation and operation procedures

for the Loop Control Boards (except for

function blocks).

W375 Detailed information on function blocks

for Loop Control Units.

W407 Detailed information on function blocks

for Loop Control Boards

ix

Page 10

Manuals Related to the NS-series PT

Product Manual name Cat. No. Contents

WS02-NSFC1-E

Face Plate Auto-

Builder for NS

WS02-LCTC1-EV3

CX-Process Tool

WS02-LCTC1-E

CX-Process Monitor

WS02-LCMC1-E

CX-Process Monitor

Plus

NS-CXDC1-V2

CX-Designer Ver. 2.0

NS12-series, NS10series, NS8-series,

NS5-series PT

NS12-series, NS10series, NS8-series,

NS5-series PT

Face Plate Auto-Builder

for NS

Operation Manual

CX-Process Tool

Operation Manual

CX-Process Monitor

Operation Manual

CX-Process Monitor Plus

Operation Manual

CX-Designer

User's Manual

NS-series PT

Setup Manual

NS-series PT

Programming Manual

W418 (this manual) Installation and operation procedure for

Face Plate Auto-Builder for NS.

W372 Installation and operation procedures

for the CX-Process Tool.

W373 Installation and operation procedures

for the CX-Process Monitor.

W428 Installation and operation procedures

for the CX-Process Monitor Plus.

V088 Operating procedures for the CX-

Designer.

V083 Setup procedures for NS-series PTs.

V073 Descriptions of NS-series PT functions.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

x

Page 11

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xi

Page 12

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xii

Page 13

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xiii

Page 14

xiv

Page 15

PRECAUTIONS

The information contained in this section is important for the safe and reliable application of the Face Plate AutoBuilder for NS. You must read this section and understand the information contained before attempting to set up or

operate the Face Plate Auto-Builder for NS and PLC system.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

xv

Page 16

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent) and

instrumentation systems.

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, petrochemical plants, and other systems,

machines, and equipment that may have a serious influence on lives and

property if used improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for using the Face Plate Auto-Builder for

NS. Be sure to read this manual before attempting to use the Face Plate AutoBuilder for NS and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units/Boards be used for the

specified purpose and under the specified conditions, especially in applications that can directly or indirectly affect human life. Your must consult with

your OMRON representative before applying a PLC System to the abovementioned applications.

3 Safety Precautions

!Caution When updating the CSV tag file generated by the CX-Process Tool Software

to use with the Face Plate Auto-Builder for NS, be sure to confirm that the

data is consistent with the program in the Loop Control Board/Unit. If the output project is not confirmed, unexpected operation may result.

4 Application Precautions

Observe the following points when using the Face Plate Auto-Builder for NS.

!Caution Confirm operation of any user programs that you develop before running the

programs.

!Caution Confirm the operation of screen data and host programs before using the pro-

grams for actual applications.

xvi

Page 17

1-1 Features of the Face Plate Auto-Builder for NS . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-2-1 Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-2-2 OS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-3 Application Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-3-1 Connection Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-4 Upgrades Made for Version 2.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-5 Upgrades Made for Version 3.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-6 Upgrades Made for Version 3.1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SECTION 1

Overview

1

Page 18

Features of the Face Plate Auto-Builder for NS Section 1-1

1-1 Features of the Face Plate Auto-Builder for NS

The Face Plate Auto-Builder for NS is a software package that automatically

builds project files for NS-series Programmable Terminals that are used for

monitoring and tuning CS1W-LC001 Loop Control Units, CS1W-LCB01,

CS1W-LCB05 Loop Control Boards, CS1D-CPU@@P Process-control CPU

Units, and CJ1W-CPU@@P Loop Control CPU Units.

Based on a CSV tag file created using the CX-Process Tool, the software

automatically builds a NS-series project file configured with Face Plate

Screens for the Loop Control Unit/Board and Process-control CPU Units.

1-1-1 Features

• By simply specifying the tag file created using the CX-Process Tool, the

software automatically builds a project file for an OMRON NS-series Programmable Terminal. The project file is configured with Face Plate

Screens of the Loop Control Unit/Board and Process-control CPU Units.

• When using a Loop Control Unit/Board and Process-control CPU Unit

containing NS system version 4 or later, up to 100 loops of function block

(e.g., PID Control) monitoring and tuning can be performed on an NSseries Programmable Terminal. With any other NS system version, up to

32 loops of function block monitoring and tuning can be performed.

• Face Plate Screens can be built for the following function blocks of Loop

Control Unit or Board.

2-position ON/OFF (Block Model 001)

3-position ON/OFF (Block Model 002)

Basic PID (Block Model 011)

Advanced PID (Block Model 012)

Indication and Operation (Block Model 032)

Indicator (Block Model 034)

Segment Program 2 (Block Model 157)

Segment Program 3 (Block Model 158)

Indication and Setting (Block Model 031)

Ratio Setting (Block Model 033)

High/Low Alarm (Block Model 111)

Timer (Block Model 205)

Counter (Block Model 208)

ON/OFF Valve Manipulator (Block Model 221)

Motor Manipulator (Block Model 222)

Reversible Motor Manipulator (Block Model 223)

Motor Opening Manipulator (Block Model 224)

Blended PID (Block Model 013)

Batch Flowrate Capture (Block Model 014)

2

Page 19

System Requirements Section 1-2

1-2 System Requirements

The following hardware and software is required to install and operate the

Face Plate Auto-Builder for NS.

1-2-1 Computer

■ Computer

IBM PC/AT or compatible

■ CPU

Intel CPU (Core, Pentium, or Celeron family)

For Windows Vista: 1 GHz min.

For any other OS: 333 MHz min. required, 1 GHz min. recommended

■ Memory

For Windows Vista: 1 GB min.

For any other OS: 256 MB min. required, 512 MB min. recommended

1-2-2 OS

Windows XP Professional (Service Pack 3) (see note), Windows Vista (Ultimate or Business), or Windows 7 is required.

Note: The 64-bit versions are not supported.

1-3 Application Environment

The Face Plate Auto-Builder for NS uses tag files created with the following

software.

CX-Process Tool

■ Using a Loop Control Board

CX-Process Tool Ver. 3.0 or later

■ Using a Loop Control Unit

CX-Process Tool Ver. 2.0 or later

Projects built with the Face Plate Auto-Builder for NS are used with the follow-

ing hardware and software.

Loop Control Unit,

Loop Control Board,

Loop Control CPU

Unit, or Processcontrol CPU Unit

Note 1. CX-Process Tool Ver. 3.2 or later must be used to output any EM banks

CS1W-LC001 Ver. 2.0 or later

CS1W-LCB01/05 Ver. 1.0 or later

CJ1G-CPU@@P Ver. 2.0 or later

CS1D-CPU@@P Ver. 1.0 or later

other than bank 0 to the area allocated for the Loop Control Board’s HMI.

2. Backup cannot be performed during operation with versions of the CS1WLCB01/05 Loop Control Boards earlier than version 1.5 or CS1W-LC001

Loop Control Units. With other Units/Boards, data can be backed up during

operation from the detail setting screens for the Segment Program 2 face

plate that is built.

NS-Designer NS-Designer Ver. 2.0 or later

3

Page 20

Upgrades Made for Version 2.0 Section 1-4

CX-Designer CX-Designer Ver. 1.0 or later

NS-series PT

(Programmable

Terminals)

The following models of NS-series PT, Ver. 2.0 or later:

NS12-TS00@/TS01@/-V1/-V2

NS10-TV00@/TV01@/-V1/-V2

NS8-TV00@/TV01@/-V1/-V2

NS7-SV00@/SV01@

1-3-1 Connection Methods

The project files built with the Face Plate Auto-Builder for NS can be used with

the following connection methods between the NS-series PT and PLC.

Communications

port

Serial port A 1:1 NT Link

Serial port B 1:1 NT Link

Ethernet FINS communications

Controller Link FINS communications

Note Other connection combinations not listed here may cause malfunctions.

Supported communications

1:N NT Links

1:N NT Links

1-4 Upgrades Made for Version 2.0

The functional changes made between version 1.1 and version 2.0 of the

Face Plate Auto-Builder for NS are described in this section.

methods

Maximum Number of

Loops Increased from 32

to 100

System Version Setting

for NS Project To Build

NS8 Support Project data can be built for the NS8.

EM Multi-bank Support With CS-Process Ver. 3.2 or later, EM banks 0 to C can be specified for output

Multi-node Support (Up to

32 Nodes)

Automatic Building of

Segment Program 2 Detail

Setting Screens

Accompanying upgrades to the NS-series PT system software, the number of

loops that can be used for monitoring and tuning on the NS-series PT has

been increased from 32 to 100 with Face Plate Auto-Builder for NS Ver. 2.0.

Note Set the NS-series project system to version 4 or later.

The output version of the project data after building can be specified.

to the Loop Control Board’s HMI. (Previously only bank 0 was supported.)

With version 2.0, function block data using EM banks 0 to C created with CXProcess Ver. 3.2 can be converted to NS-series projects.

An NS-series project file that monitors more than one Loop Control Unit/

Board from single NS-series PT can be built from and CS-Process project

using multiple nodes.

When a Segment Program 2 function block is used, detail setting screens to

set Segment Program 2 parameters (time width-output setting screen and

weight width setting screen) are automatically generated.

4

Page 21

Upgrades Made for Version 3.0 Section 1-5

1-5 Upgrades Made for Version 3.0

The functional changes made between version 2.0 and version 3.0 of the

Face Plate Auto-Builder for NS are described in this section.

Additional Support for

Function Blocks

Automatic Comments for

Unit and Scaling Settings

Face plates can be built for the following function blocks in addition to the

function blocks supported for version 2.0.

• Indication and Setting (Block Model 031)

• Ratio Setting (Block Model 033)

• High/Low Alarm (Block Model 111)

• Timer (Block Model 205)

• Counter (Block Model 208)

• ON/OFF Valve Manipulator (Block Model 221)

• Motor Manipulator (Block Model 222)

• Reversible Motor Manipulator (Block Model 223)

• Motor Opening Manipulator (Block Model 224)

• Blended PID (Block Model 013)

• Batch Flowrate Capture (Block Model 014)

Comments are automatically entered for automatically allocated unit and scaling settings when a project is generated. This prevents mistakes in editing

automatically allocated unit and scaling settings when editing projects.

1-6 Upgrades Made for Version 3.1

The functional changes made between version 3.0 and version 3.1 of the

Face Plate Auto-Builder for NS are described in this section.

Additional Support for

Function Block

Output in NS System

Version 6.6 and NSRuntime Version 1.0

Formats

Face plates can be built for the following function block in addition to the function blocks supported for version 3.0.

• Segment Program 3 (Block Model 158)

Projects can be output in NS System version 6.6 and NS-Runtime version 1.0.

5

Page 22

Upgrades Made for Version 3.1 Section 1-6

6

Page 23

2-1 Installation Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-1-1 Installation Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-1-2 Installing the Face Plate Auto-Builder for NS . . . . . . . . . . . . . . . . . 8

2-2 Uninstalling the Face Plate Auto-Builder for NS . . . . . . . . . . . . . . . . . . . . . . 11

SECTION 2

Setup

7

Page 24

Installation Method Section 2-1

2-1 Installation Method

Install the Face Plate Auto-Builder for NS from the installer of CX-One. Refer

to the included CX-One Setup Manual (W463) for details.

2-1-1 Installation Precautions

• Before installing the Face Plate Auto-Builder for NS, close all Windows

programs.

• Do not install on a compressed drive. If a file on a compressed drive is

corrupted, it cannot be recovered.

• Do not cancel installation during setup. Doing so may result in some files

already copied remaining in the installation directory.

• Do not turn OFF the power or reset the personal computer during installation. Doing so may damage data in the computer.

• If Windows 2000 is used, be user to use Service Pack 4 or later. To check

the Service Pack version number, from the Start Menu select Settings -

Control Panel - System. The System Properties Window will appear.

Click the General Tab. The Service Pack version is displayed under Sys-

tem. If the Service Pack version is not displayed, it is not installed. Refer

to the Microsoft Website for details on compatibility.

• For Windows login users, log in as the administrator or user with administrative authority. A filter preventing unauthorized users is provided and will

cause an access error to occur.

• After installation, Windows must be restarted. Use the Installation Wizard

Dialog Box to restart, if required.

2-1-2 Installing the Face Plate Auto-Builder for NS

Step 1: Execute the following setup wizard program from the CD.

<CD-ROM drive> \Face Plate Auto-Builder for NS\DISK1\SETUP.EXE.

Step 2: Start installation of the Face Plate Auto-Builder for NS by clicking the

Next Button.

8

Page 25

Installation Method Section 2-1

Step 3: Read the License Agreement thoroughly. If you agree with the terms,

select I accept the terms of the license agreement, and click the Next But-

ton to proceed.

Step 4: Specify the drive and directory in which the program files will be

installed.

The default setting is C: \Program Files\OMRON\CX-One\FP Auto-Builder.

To change the directory, click the Browse Button, and select the directory.

Check the installation directory and then click the Next Button.

9

Page 26

Installation Method Section 2-1

Step 5: Select the program folder.

Specify the location for the new shortcut to be added to the program folder

under the Start Menu. Check the setting and select the Next Button.

Step 6: Preparations for executing the installation have been completed.

10

Click the Install Button.

Installation will start from the install program.To check or change installation

details, click the Back Button. To cancel installation, click the Cancel Button.

Step 7: The following dialog box will be displayed when installation has been

completed. Click the Finish Button.

Page 27

Uninstalling the Face Plate Auto-Builder for NS Section 2-2

2-2 Uninstalling the Face Plate Auto-Builder for NS

Step 1: Select Add/Remove Programs from the Control Panel.

Select Face Plate Auto-Builder for NS from the list of applications, and

click the Change/Remove Button.

Step 2: Click the OK Button. The Face Plate Auto-Builder for NS will be uninstalled.

Step 3: When the uninstall process has been completed, the following screen

will be displayed. Click the Finish Button.

11

Page 28

Uninstalling the Face Plate Auto-Builder for NS Section 2-2

12

Page 29

Basic Operation Flow

3-1 Basic Operation Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SECTION 3

13

Page 30

Basic Operation Flow Section 3

3-1 Basic Operation Flow

This section describes the operation flow through execution of the project that

has been created using the Face Plate Auto-Builder for NS.

The following settings must be set from CX-Process Tool before executing

Face Plate Auto-Builder for NS.

Compile CSV Tag Files Using CX-Process Tool

(Refer to the CX-Process Tool Operation Manual (W372).)

Use the CX-Process Tool to compile (create) a CSV tag file for the Loop

Control Unit/Board.

1. Use the CX-Process Tool to create a program for the Loop Control Unit/Board.

Register and connect each function block, and register the Send/Receive All

Blocks block (for Loop Control Units only).

2. Set a CSV tag for each function block.

3. After setting the CSV tags, create the CSV tag file.

Note: Supported by CX-Process Tool Ver. 2.0 or later only.

Automatically Build NS Project Using Face Plate Auto-Builder for NS

(Refer to Section 4 Basic Operations.)

Specify the CSV tag file compiled using the CX-Process Tool to enable

the NS Face Plate Screen Project to be automatically built.

Note: Specify a new project for the project to be built automatically.

If an existing project is specified, the communications settings, numeric

unit and scale settings, and data log settings will be changed to the

default values when a new project is created.

Read Project and Transfer to the NS-series PT Using CX-Designer

Using as a New Project

Load the project file created by Face Plate Auto-Builder for NS to

the CX-Designer.

Loading Face Plates into an Existing Project

Refer to 4-2 Merging Projects.

Edit screens or create new screens, as required.

(Automatically built project files can be used as is.)

Set the initial settings for communications between the NS-series PT and PLC

in the CX-Designer System Settings.

After confirming project details, transfer the project file to the NS-series PT.

Start Operation of Loop Control Unit/Board + NS-series PT System

After connecting the Loop Control Unit/Board (CS series) and NS-series PT,

check operations, and then start operating the system.

14

Page 31

4-1 Basic Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4-2 Merging Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4-2-1 Merge Using the CX-Designer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4-2-2 Merging Using the NS Project Merge Tool . . . . . . . . . . . . . . . . . . . 22

SECTION 4

Operations

15

Page 32

Basic Operation Section 4-1

4-1 Basic Operation

Step 1: Start the Face

Plate Auto-Builder for

NS

Step 2: Make the

Required Settings

Start the Face Plate Auto-Builder for NS by selecting Programs\OMRON\CXOne/Face Plate Auto-Builder for NS\Face Plate Auto-Builder for NS from

the Windows Start Menu. The following parameter setting screen will be displayed, when the Face Plate Auto-Builder for NS starts.

CSV Tag File

Set the folder location and file name of the CSV tag file from which the project

will be built. Click the Browse (1) Button to display a dialog box for selecting

the CSV tag file.

Project Name

Set the name of the CX-Designer project file to be created (up to 38 characters).

Output Folder

Set the folder that will output the CX-Designer project file. Click the Browse

(2) Button to display a dialog box for selecting the folder that will output the

project.

■ Build Conditions

PT Model/Project Version

Select the model of the NS-series PT and the system version.

Model Project version

(system version)

NS7 NS System Version 2 32

NS8 NS System Version 4 or Version 6.6 100 (See note.)

NS10 NS System Version 2 32

NS System Version 4 or Version 6.6 100 (See note.)

NS12 (Default) NS System Version 2 32

NS System Version 4 or Version 6.6 100 (See note.)

NS-Runtime NS System Version 6.6 100 (See note.)

Number of changeable

function blocks

16

Page 33

Basic Operation Section 4-1

Note A maximum of 85 Segment Program 3 blocks can be created. Con-

version will not be possible if there are more than 85 Segment Program 3 blocks registered in the CSV tag file.

Enable for Making Detail Setting Screen of Segment Program 2 (Project

Version 4 or Later)

If this option is selected and a Segment Program 2 function block is used,

detail setting screens (time width-output setting screen and wait width setting

screen) to set the Segment Program 2 parameters will be built automatically.

Note The capacity of the NS-series PT may be exceeded if a large quantity of

screens are generated automatically. An error will occur when transferring the

project if the capacity is exceeded. If this occurs, delete the detail setting

screens and wait screens. When deleting detail setting screens and wait

screens, always delete the parts from the screen first and then delete the

screens using the screen maintenance function. (It will not be possible to

delete the screens using the screen maintenance function if there are parts

remaining on the screens.) Tool - Resource Report can be used from the

CX-Designer to see if the capacity has been exceeded.

Screen Number Offset

Set the first screen number in the NS-series PT.

Project version Version 2 Version 4 Version 6.6

Range 0 to 3799 0 to 3599 0 to 3599

Default 0

Starting from the specified screen number offset, screen numbers are

assigned to the Control Screens (up to 25 screens) and Tuning Screens (up to

100 screens) in that order.

Unit Number Offset

Set the first number allocated from the Unit and Scale No. data in the NSseries PT.

Project version Version 2 Version 4 Version 6.6

Range 12 to 800 12 to 700 12 to 700

Default 12

Unit and Scale No. data items for the NS-series PT Numeral Display and Input

objects are created automatically by the Face Plate Auto-Builder for NS from

the scaling upper/lower limit and unit characters.

If version 2 is selected, up to 69 Unit and Scale No. data items will be created

from the first number tag set here. If version 4 or version 6.6 is selected, up to

207 Unit and Scale No. data items will be created (when using Segment Program 3, up to 632 Unit and Scale No. data items will be created). (See note.)

Refer to the following illustration for details.

Note The number of data items shown here will be created when the

maximum of 85 Segment Program 3 blocks are registered in addition to 15 other blocks, making a total of 100 blocks.

17

Page 34

Basic Operation Section 4-1

The NS System uses

Allocation of Unit and Scaling Settings

Start of unit and scaling

settings to be set (default: 12)

These 100 are allocated regardless

of the number of registered

function blocks

These 100 are allocated regardless

of the number of registered

function blocks

Two allocated for Segment

Program 2. Numbers 999 and

1000 are always allocated

regardless of the start number

setting. (Applies only when the

detailed setting screen of

Segment Program 2 is used.)

the first 11.

Five are always

allocated.

One is allocated for each

registered function block

(PV scaling settings).

One is allocated for each

registered function block

(DV scaling settings).

The total number of freely set values for

bank data registered for Segment Program 3

(only in version 6.6 and NS-Runtime).

Refer to 5-4 Engineering Units for details on unit and scale settings.

Comments are automatically entered for unit and scaling settings automati-

cally allocated by the Face Plate Auto-Builder for NS. Unit and scaling settings

for which comments have been automatically entered are automatically generated by the Face Plate Auto-Builder for NS; do not change the settings

when constructing screens.

Data Log Number Offset

Specify the first number allocated to the data log group in the NS-series PT.

The maximum value of the data log used by the Face Plate Auto-Builder for

NS is 100 for NS system version 4 and higher and 32 for other versions.

18

Page 35

Basic Operation Section 4-1

Message ID Number Offset

Specify the first number allocated for confirmation messages in the NS-series

PT. There are two confirmation messages used by the Face Plate AutoBuilder for NS. These two messages are automatically created when a project

is generated.

■ Button

Build

Click this button to start automatic screen building.

Quit

Click this button to exit the Face Plate Auto-Builder for NS.

Version

Click this button to display the Version Information Dialog Box for the Face

Plate Auto-Builder for NS.

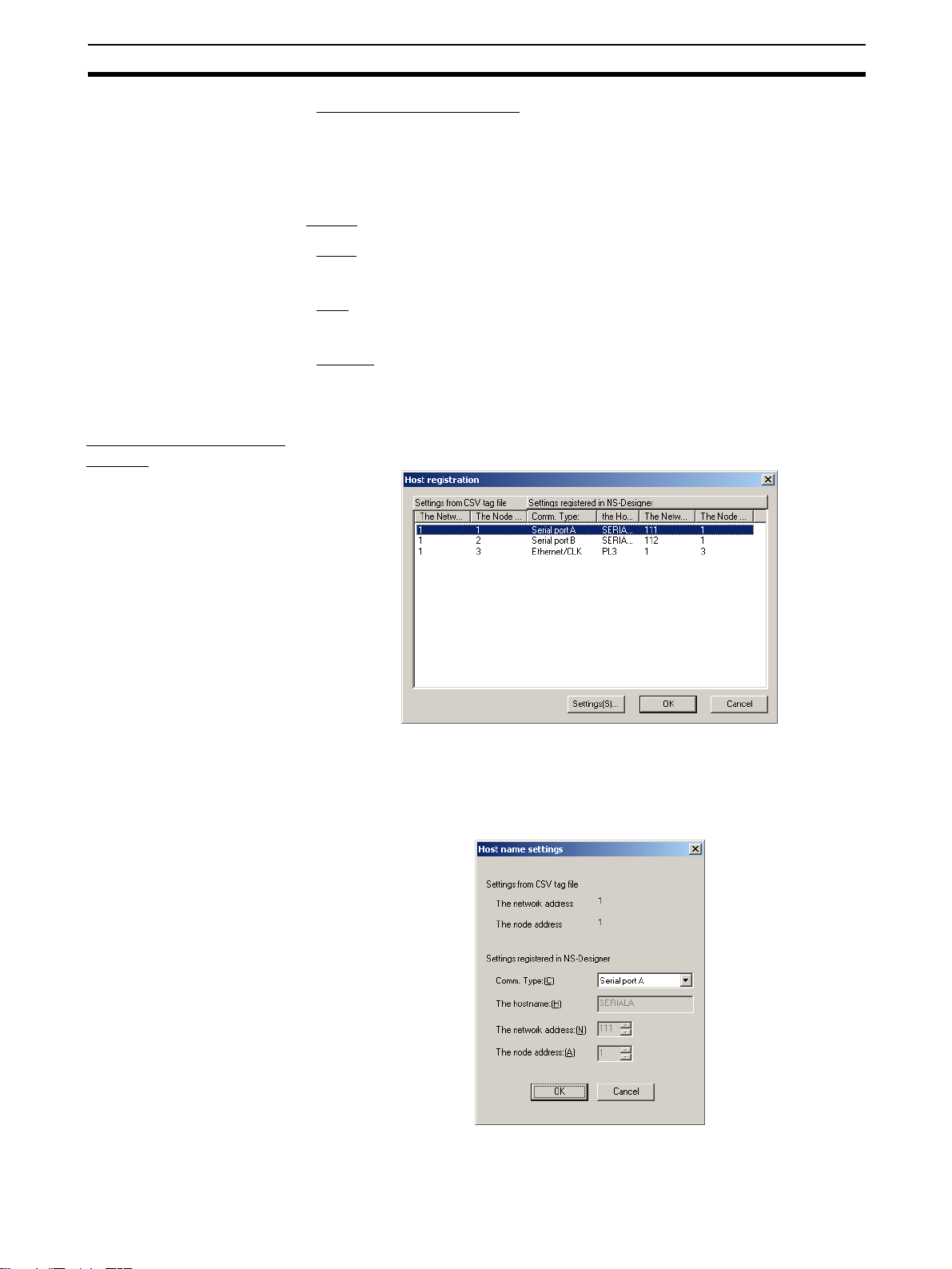

Step 3: Register Host

Names

1,2,3... 1. Select the host to be set in the Host Registration Dialog Box and click the

When all settings have been completed in step 2, click the Build Button. The

following dialog box will be displayed.

This window is used to make the host settings to create an NS-series project

file from a CX-Process project that uses multiple nodes. With the NS-series

PT, nodes are registered as hosts. Host settings are described next.

Settings Button. The following dialog box will be displayed.

19

Page 36

Basic Operation Section 4-1

2. Set the required items. The settings and display is described in the following table.

Item Meaning

CSV tag file

settings

Settings registered in

CX-Designer

Network

address

Node address Displays the node address given in the CSV tag file.

Communica-

tions connection method

Host name Set the host name.

Network

address

Node address Set the node address of the node (host) as viewed

Displays the network address given in the CSV tag

file.

Set the node (host) connection method.

Any of the following three methods can be set: Serial

port A, serial port B, Ethernet/CLK

Example: If the node is connected to serial port A,

select Serial port A.

Note: The host name, network address, and node

address cannot be set if serial port A or serial B is

selected.

• Serial Port A Settings

Host name: SERIALA

Network address: 111

Node address: 1

• Serial port B Settings

Host name: SERIALB

Network address: 112

Node address: 1

Note: When Ethernet/CLK is selected, the PLC type

registered in the CX-Designer will always be SYSMAC-CS1.

• The host name must be all-caps.

• The host name can be up to 16 characters long.

• The same host name can be used only once.

• The host name, network address, and node

address cannot be set if serial port A or serial B is

selected as the communications connection

method.

Set the network address of the node (host) as viewed

from the NS-series PT.

The network address will be 111 or 112 if serial port

A or serial B is selected as the communications connection method.

from the NS-series PT.

The node address will be 1 if serial port A or serial B

is selected as the communications connection

method.

Step 4: Load the

Project File

Step 5: Transfer the

Settings to the NSseries PT

20

Use CX-Designer to read the automatically built project files.

Use CX-Designer to edit the project files as required.

Transfer the settings from CX-Designer to the NS-series PT (or save the settings to a Memory Card and install the Memory Card in the NS-series PT).

Start the system, and perform monitoring/tuning of the Loop Control Unit/

Board from the NS-series PT.

Note An error message saying that the file is too large and to check the product

data (0088) may be displayed when transferring a project from the CXDesigner to the NS-series PT. If this message appears, clear the selection of

Page 37

Merging Projects Section 4-2

the Transfer with the symbol table Option in the Send Options of the CX-

Designer, and then resend the project.

4-2 Merging Projects

4-2-1 Merge Using the CX-Designer

Use the CX-Designer with the following procedure to merge an NS project

output using the Face Plate Auto-Builder for NS with an existing NS project.

Individually Copying

Screens

Selected screens can be copied. Screens can be copied from a project output

using Face Plate Auto-Builder for NS to an existing project by starting two

copies of the CX-Designer. Screens cannot be copied, however, if the system

version of the project copy destination is older than that of the project copy

source.

1,2,3... 1. Select the screen to be copied from the Project Workspace and press the

Ctrl+C Keys. Alternatively, right-click and select Copy from the pop-up

menu. Click the screens while pressing the Shift Key or Ctrl Key to select

multiple screens at the same time.

2. Select the category in which to paste in the Project Workspace.

3. Press the Ctrl + V Keys. Alternatively, right-click and select Paste from the

pop-up menu.

4. Specify the number of the first screen after pasting, then click the OK Button.

5. If the Reuse screen with sheet option has been set, specify the number of

the first sheet after pasting, and then click the OK Button. (This operation

is necessary only if the Reuse screen with sheet option has been set.)

Pasting Parts, Such As

Face Plates, into Separate

Projects

The screen will not be copied if the number of sheets after copying exceeds

ten.

Once copying has completed, a file in the format of projectname.txt will be

created in the folder where the project file (i.e., ipp file) is saved. The screen

numbers before copying and after copying can be checked.

Copied or cut parts can be pasted to separate projects. Common settings that

the part references are also copied at the same time. (Refer to the note below

regarding common settings.) Parts cannot be copied, however, if the system

version of the project copy destination is older than that of the project copy

source.

21

Page 38

Merging Projects Section 4-2

1,2,3... 1. Start two copies of the CX-Designer, and then open the copy source

project in one and the copy destination project in the other.

2. Copy or cut the part in the copy source CX-Designer project.

3. Paste the part into the copy destination CX-Designer project.

4. Alternatively, drag the part from the copy source CX-Designer project to

the copy destination CX-Designer project.

5. If multiple hosts are registered to the project at the reuse destination, select an appropriate host after copying for the communications addresses

used with the parts.

Note Common Settings

The following settings, which are referred to by function parts, are also copied

to the project of the copy destination.

• Alarm/event settings (alarm/event indication, alarm/event summary and

log)

• Data log settings (data log graph)

• Data block settings (data block tables)

• Unit and scale settings (unit-set value settings, inputs, and thumb rotary

switches)

• Dialog box settings (function parts for which specifying a confirmation

message has been set)

These settings will be added with numbers changed to not overlap settings

already at the copy source. Unused communications addresses at the copy

destination will be added to the symbol tables.

Note 1. Switch from the face plate on the Control Screen to the relevant Tuning

Screen by using the Command Button. The number of the screen switched

to may deviate depending on the method of screen copying.

2. When copying individual screens and parts, unit and scale settings except

for comments will be regarded as identical unit and scale settings if the settings are identical, and the allocation of unit and scale numbers will

change. To change the scaling information of function blocks, change the

scaling settings using the CX-Process Tool, and copy after again outputting the project with Face Plate Auto Builder for NS.

4-2-2 Merging Using the NS Project Merge Tool

22

The following settings are required for the Face Plate Auto-Builder for NS,

when merging the built project with other projects using the NS Project Merging Tool.

For details on merging projects, refer to the NS Project Merging Tool Opera-

tion Manual.

The NS Project Merge Tool is provided with the CX Designer.

Page 39

Merging Projects Section 4-2

Execute the “Setup.exe” file in \Utility\English\ProjectMergeTool\disk1 on the

CDROM to install it.

When merging projects, make the following settings when building the project

on the Face Plate Auto-Builder for NS so that the same resources are not

used by both projects. Confirm the build conditions in 4.1 Basic Operation for

details on settings.

• First screen number

• First unit number

• First data log number

• First confirmation message number

Note Observe the following precaution when merging projects with the NS Project

Merge Tool.

• The NS Project Merge Tool does not support version 6.6 projects. Follow

the procedure described in 4-2-1 Merge Using the CX-Designer to merge

version 6.6 projects.

• The SMART Active Parts will not function if a project (called project A)

that was output with the Enable for Making Detail Setting Screen of Seg-

ment Program 2 option selected is merged with a project (called project

B) in which SMART Active Parts were pasted.

Use the following procedure to successfully merge projects like these.

1,2,3... 1. Delete all of the SMART Active Parts from project B.

2. Save project B.

3. Merge the two projects with project A as the base project and project B as

the merge project.

4. Paste the SMART Active Parts into the merged project.

23

Page 40

Merging Projects Section 4-2

24

Page 41

SECTION 5

Basic Specifications of Created Screens

5-1 Created Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5-2 Screen Titles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5-3 Tuning Screen Realtime Trends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5-4 Engineering Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5-5 Percent Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5-6 Read Address and Write Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5-7 Work Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

25

Page 42

Created Screens Section 5-1

5-1 Created Screens

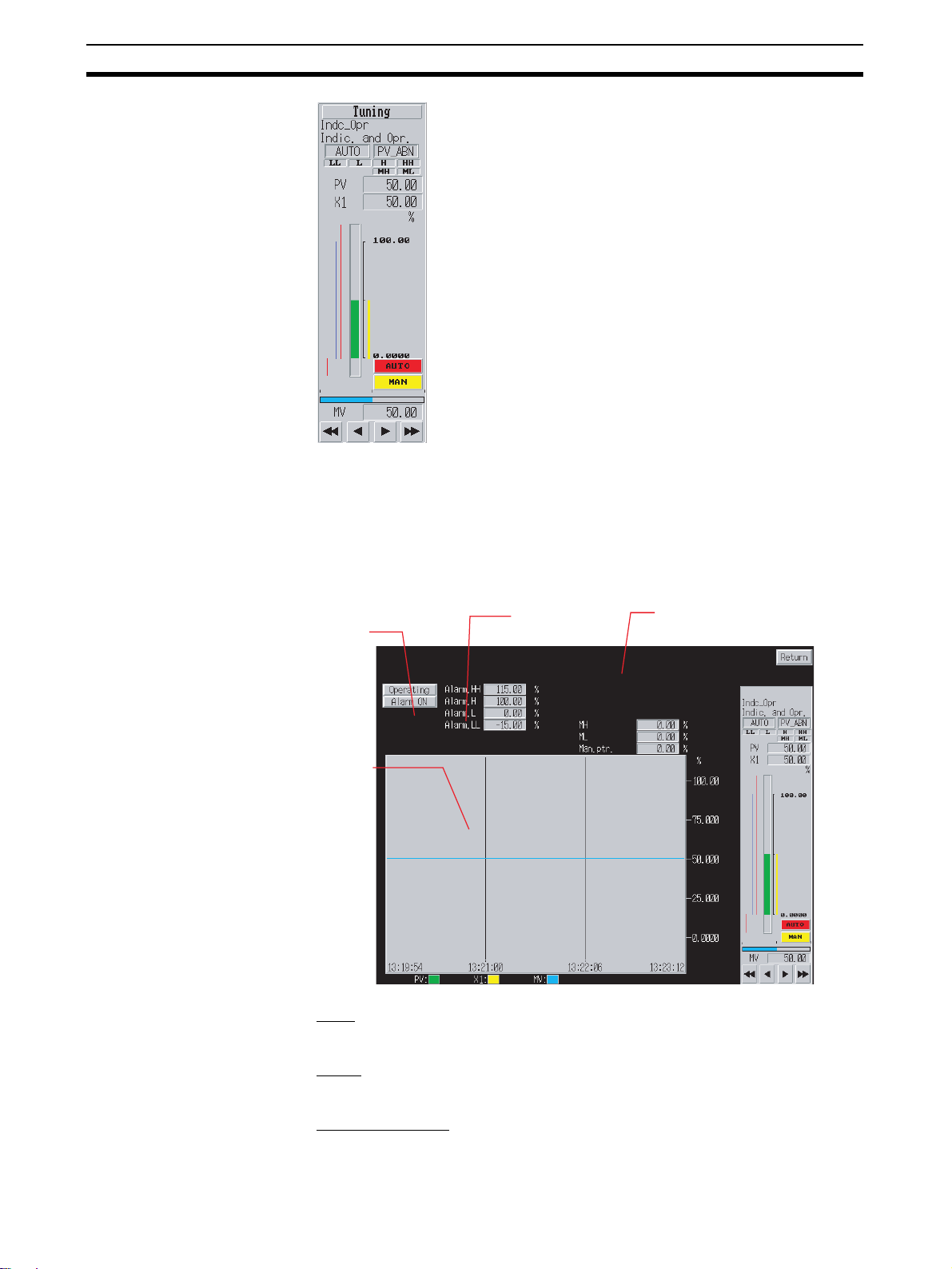

The Face Plate Auto-Builder for NS creates two types of screens: Control

Screens and Tuning Screens.

Control Screens Control Screens display a row of multiple face plates.

Control Screens are created from the beginning of the CSV tag file for up to

100 loops for system version 4 or later and for up to 32 loops for other system

versions.

For NS12 PTs, six face plates are created in a single screen, and for NS10,

NS8, and NS7 PTs, four face plates are created in a single screen.

The following screen is a Control Screen when using an NS12 PT.

Click the >> Button in the top right corner of the screen to move to the next

Control Screen page, and click the << Button to move to the previous page.

Tuning Screens Tuning Screens are adjustment screens for individual tag names (i.e., function

blocks) and are configured from the parameter settings, such as face plate,

realtime trend, and alarms.

Click the Tuning Button at the top of each face plate arranged in a row in the

Control Screens to move to the Tuning Screen of the corresponding tag name

(function block).

The following Tuning Screen is an example of when an NS12 PT is used.

Click the Back Button in the top right corner of the Tuning Screen to return to

the Control Screen.

26

Page 43

Created Screens Section 5-1

Screen Building

Order (Screen

Number Order)

Control Screens are built first, followed by Tuning Screens, as shown in the

following table. Building starts from the screen number specified as the screen

number offset, and continues in sequence without skipping any screen numbers. (The screen number offset can be specified between 0 and 3,799 (System Version 2), 0 and 3,599 (System Version 4 or later). The default is 0.)

Screen Details

A Control Screens

(up to 8 screens)

B Tuning Screens

(up to 32 screens)

Up to 100 face plates for system version 4 or later and up to

32 face plates for other system versions are built for the function blocks to be converted that are detected when searched

from the beginning of the CSV tag file.

The function blocks detected first are built with the smaller

numbers at the left of the screen, and are arranged in order to

the right. Six face plates are created for NS12 PTs and four

face plates are created for the NS10 and NS7 PTs, after which

building is shifted to the next screen.

The Control Screens are built for all the function blocks.

Up to100 face plates for system version 4 or later and up to 32

face plates for other system versions are built sequentially for

the function blocks to be converted that are detected when

searched from the beginning of the CSV tag file. The Tuning

Screens are built for all the function blocks.

Note In the screens built using the Face Plate Auto-Builder for NS, the face plates

(in both Control Screens and Tuning Screens) are built in groups. Parts other

than face plates are not grouped.

27

Page 44

Screen Titles Section 5-2

5-2 Screen Titles

Screen titles are assigned to each screen that is built, as shown in the following table.

Screen Screen title assignment method

Control Screens Control Screen <Sequential number from 1>

Example: Control Screen 1, Control Screen 2, etc.

Tuning Screens Tuning Screen - <Tag No. >

Tag No.

Example: Tuning Screen−TIC0000.

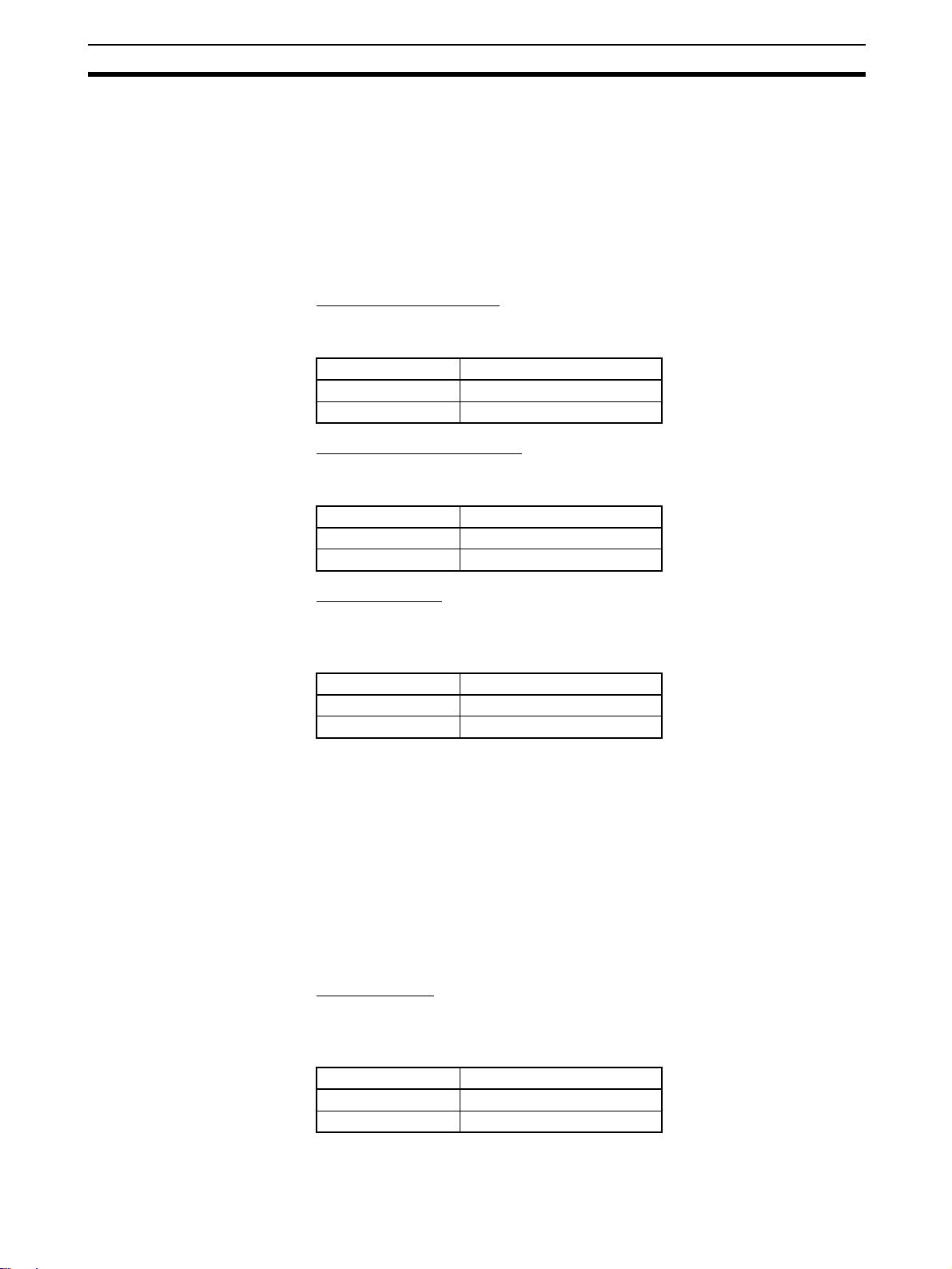

5-3 Tuning Screen Realtime Trends

Up to 100 Tuning Screens for system version 4 or later and up to 32 Tuning

Screens for other system versions can be built using the Face Plate AutoBuilder for NS. The NS-series data log is also generated for creating a realtime trend graph for the Tuning Screens. Up to 100 data logs for system version 4 or later and up to 32 data logs for other system versions are used and

data logs are created from the following details, according to the order the

face plates are built.

• Data log setting group name: Group (number) (Example: Group 1, Group

2, etc.)

• Data collection cycle: 1 s

• Log count: 533 records

• Log period: Logging is performed while data log object is displayed only.

(It is cleared when screens are switched.)

• Log address: (Refer to information on individual function blocks for details

on logging the SP, MV, and PV for the tag ITEM.)

Note The NS project file built with the Face Plate Auto-Builder for NS create build-

ing results after returning the communications settings, unit and scale setting,

and data log settings to the default values for creating new projects. Specify a

new project name in the name for the project file being built.

5-4 Engineering Units

Values such as the SP and PV for Basic PID must be scaled to engineering

units.

In the following explanations, places where engineering units are indicated

must be scaled as defined in this section.

With the data in tag ITEMs for engineering units, such as PV and SP for Basic

PID, the value stored and used in the PLC or in communications for the scaling lower limit (0%) is 0, and for the scaling upper limit (100%) is 10,000 (e.g.,

5,000 for scaling of 50%, −1,500 for −15%, etc.).

When the value of a tag ITEM for an engineering unit is displayed or set on

the PT screen, the value must be displayed or set as the actual amount (engineering unit value) after scaling.

Scaling is performed by referencing the CSV tag file's scaling upper limit, scaling lower limit, decimal point position (scaling decimal point position), and unit

characters.

28

Page 45

Percent Data Section 5-5

In a CSV tag file, the scaling upper limit, scaling lower limit, and decimal point

position are stored for every tag ITEM. The scaling upper limit, scaling lower

limit, and decimal point position are, however, the default values registered by

the user in for individual tag names (i.e., function blocks) from the CX-Process

Tool. Therefore, for the same tag name (function block), the scaling upper

limit, scaling lower limit, decimal point position, and unit characters are all the

same for the tag ITEM, i.e., the engineering unit is the same.

For example, when the scaling upper limit value=500, scaling lower limit

value=0, and decimal point position=1 the values in the PLC or communications are scaled to the values shown in the following table.

Value in PLC or communications Scaled value

−1,000 (−10%) −5.0

0 (0%) 0.0

5,000 (50%) 25.0

10,000 (100%) 50.0

11,000 (110%) 55.0

Scaling is based on the CSV tag file, according to the Integer Decimal setting

and Unit and Scale No. data for NS-series Numeral Display and Input objects.

The Integer Decimal is automatically set based on the decimal point position

in the CSV tag file.

Unit and Scale No. data items are created based on the scaling upper/lower

limit, and unit characters for tag names from the beginning of the CSV tag file.

Up to 66 sets of these items can be created for system version 2.0 and up to

207 can be created for system version 4.0 (632 if Segment Program 3 blocks

are set). When building, use the Unit Number Offset setting to specify which

of the Unit and Scale No. data items will be allocated. (System version 2 setting range: 12 to 800, System version 4 setting range: 12 to 700, System version 6.6 setting range: 12 to 700 (upper limit changes if Segment Program 3

blocks are set).

When the Tag ITEMs are required to display with the engineering units, the

units from the CSV tag file are used.

Note In NS project files built with the Face Plate Auto-Builder for NS, the following

5-5 Percent Data

two Unit and Scale settings are always registered: 0.01 multiplier, 0 offset,

and 0.1 multiplier, 0 offset.

Due to face plate design restrictions, when the decimal point position is 6 or

higher, only 5 decimal places will be displayed.

Data such as the MV for Basic PID is referred to as percent data, and is displayed using a base of 0.00% to 100.00%.

and used in the PLC or communications are 0 for 0%, and 10,000 for 100%

(e.g., the value for 50% is 5,000, and for −15% is −1,500).

When the values of tag ITEMs for percent data are displayed on the PT

screen or receive a set value, the values are displayed using two decimal

places and the percentage unit.

Value in device or communications Display value

−1,000 (−10%) −10.00%

0 (0%) 0.00%

5,000 (50%) 50.00%

29

Page 46

Read Address and Write Address Section 5-6

Value in device or communications Display value

10,000 (100%) 100.00%

11,000 (110%) 110.00%

Percent data is set by registering a setting in a Numeral Display and Input

objects with the integer set to four digits and the decimal to two digits. The

conversion rate/offset for the unit and scale setting is set to a multiplier of

0.01.

5-6 Read Address and Write Address

Even if the tag ITEM is the same for the read address that is read and displayed from the PLC to the NS-series PT and the write address that is written

to the PLC from the NS-series PT, the addresses are different.

For example, the following table shows the addresses when Basic PID is

used.

Tag ITEM Read address Write address

SP Determined by the I/O mem-

ory area type, address, and

bit position of SP in the CSV

tag file.

MV, R/L_SW, A/

M_SW, P, I, D,

HH_SP, H_SP, L_SP,

LL_SP, etc.

Determined by the I/O memory area type, address, and

bit position of each tag ITEM

in the CSV tag file.

Determined by the I/O memory area type, address, and

bit position of SP_W in the

CSV tag file, plus the offset

(write data).

Determined by the I/O memory area type, address, and

bit position of each tag ITEM

in the CSV tag file, plus the

offset (write data).

Note If any values in the receive area (i.e., I/O memory in the CPU Unit) have not

changed, Receive All Blocks in the Loop Control Unit will not receive any data

from the CPU Unit. Therefore, after changing the mode from MAN to AUTO

and then back to MAN mode, such as for Basic PID, and 2-position ON/OFF,

and after changes to the MV set values, the MV value change operation will

not function unless there is a change between the current MAN and previous

MAN mode in the MV write value (receive area value) from the NS-series PT.

In this case, perform an operation to change the MV write value (receive area

value) from the NS-series PT once, and then perform processing.

The following precaution is required for the Loop Control Unit.

When using an NS project file built with the Face Plate Auto-Builder for NS,

the NS-series PT communicates with the Loop Control Unit via the memory of

the CPU Unit, using the Send/Receive All Blocks block in the Loop Control

Unit. Therefore, compared with accessing the Loop Control Unit using the CXProcess Tool or CX-Process Monitor software, the communications response

is slower.

30

Page 47

Work Memory Section 5-7

5-7 Work Memory

The Face Plate Auto-Builder for NS creates the following macros using the

internal memory in the PT for purposes such as checking statuses of changed

SP data and changed MV data.

PT memory Application and places used

$B32760 Used to temporarily read tag ITEM R/L_SW.

Used in the macro for the SP Change Button in the face plate.

Used in the macro for the Numeral Display and Input object in

the Change SP Data Screen.

$B32761 Used to temporarily read tag ITEM A/M_SW.

Used in the macro for the MV Change Button in the face plate.

Used in the macro for the Numeral Display and Input object in

the Change MV Data Screen.

$B32762 Used to temporarily read tag ITEM CAS_SET.

Used in the macro for the SP Change Button in the face plate.

Used in the macro for the Numeral Display and Input object in

the Change SP Data Screen.

$B32763 Used to temporarily read tag ITEM MV (2-position ON/OFF).

Used in the macro for the MV Operation Button in the face

plate.

$B32764 Used to temporarily read tag ITEM MVH (3-position ON/OFF).

Used in the macro for the MV Operation Button in the face

plate.

$B32765 Used to temporarily read tag ITEM MVL (3-position ON/OFF).

Used in the macro for the MV Operation Button in the face

plate.

$B32766 Used to temporarily read tag ITEM S1 (Segment Program 2).

Used in the macro for the START/STOP Button in the face

plate.

$B32767 Used to temporarily read tag ITEM S2 (Segment Program 2).

Used in the macro for the CONT/PAUSE Button in the face

plate.

$W2047 Used to write word data.

Used for numeric settings such as those for SP, MV, alarm set

values, and PID.

$B32712, $B32720,

$B32728, $B32736,

$B32744, $B32752

$W32681 to

$W32686

$W32691 to

$W32694

$W32700 Used to display tag ITEMs Q1 and Q2 (for 013 Blended PID).

$W32706 Used to display tag ITEM B0 (for 014 Batch Flowrate Cap-

$W32708 Used to display tag ITEM BP (for 014 Batch Flowrate Cap-

$W32710 Used to display tag ITEM B1 (014 Batch Flowrate Capture).

Used to calculate tag ITEMs Q1, Q2, PR, BM, BMU, SM,

SMU, SP, and SPU (for 014 Batch Flowrate Capture). Used by

the macro when loading face plate screens.

Used to display tag ITEM SP (for 033 Ratio Setting). Used for

the Numerical Display and display objects of the face plate.

Used to calculate tag ITEMs SP and K1 (for 033 Ratio Setting). Used in the macro of the face plate Word Buttons.

Used for numerical input and display object of integrated values.

ture). Used for numerical input and display parts overshoot

amounts.

ture). Used for numerical input and display parts of pre-batch.

Used for numerical input and display parts of flow speed limit

amounts.

31

Page 48

Work Memory Section 5-7

PT memory Application and places used

$W32760 to

$W32762

$W32712 to

$W32759

$W32764 to

$W32767

Note Do not use the above areas of the internal memory in the PT for any other

purpose.

Used to calculate tag ITEMs Q1, Q2, PR, BM, BMU, SM,

SMU, SP, and SPU (for 014 Batch Flowrate Capture). Used by

the macro of the face plate Word Buttons.

Used to display tag ITEMs Q1, Q2, PR, BM, BMU, SM, SMU,

SP, and SPU. Used for the Numerical Display and input object

of the face plate.

Used to write tag ITEMs Q1, Q2, PR, BM, BMU, SM, SMU,

SP, and SPU (for 014 Batch Flowrate Capture). Used in the

macro for the Numeral Display and Input object of the face

plate.

32

Page 49

Creation Screens

6-1 Basic PID (Block Model 011). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6-1-1 Face Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6-1-2 Tuning Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6-2 Advanced PID (Block Model 012) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6-2-1 Face Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6-2-2 Tuning Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6-3 Two-position ON/OFF (Block Model 001). . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6-3-1 Face Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6-3-2 Tuning Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6-4 Three-position ON/OFF (Block Model 002) . . . . . . . . . . . . . . . . . . . . . . . . . 51

6-4-1 Face Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6-4-2 Tuning Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6-5 Indication and Operation (Block Model 032) . . . . . . . . . . . . . . . . . . . . . . . . . 55

6-5-1 Face Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6-5-2 Tuning Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6-6 Indicator (Block Model 034). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6-6-1 Face Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6-6-2 Tuning Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6-7 Segment Program 2 (Block Model 157) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6-7-1 Face Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6-7-2 Tuning Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6-7-3 Detail Setting Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6-8 Indication and Setting (Block Model 031) . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6-8-1 Face Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6-8-2 Tuning Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6-9 Ratio Setting (Block Model 033) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6-9-1 Face Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6-9-2 Tuning Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6-10 High/Low Alarm (Block Model 111) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6-10-1 Face Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6-11 Timer (Block Model 205) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6-11-1 Face Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6-12 Counter (Block Model 208) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6-12-1 Face Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6-13 ON/OFF Valve Manipulator (Block Model 221) . . . . . . . . . . . . . . . . . . . . . . 86

6-13-1 Face Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

6-14 Motor Manipulator (Block Model 222) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

6-14-1 Face Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

6-15 Reversible Motor Manipulator (Block Model 223) . . . . . . . . . . . . . . . . . . . . 93

6-15-1 Face Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

SECTION 6

33

Page 50

6-16 Motor Opening Manipulator (Block Model 224) . . . . . . . . . . . . . . . . . . . . . . 99

6-16-1 Face Plates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6-17 Blended PID (Block Model 013). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6-17-1 Face Plates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6-17-2 Tuning Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6-18 Batch Flowrate Capture (Block Model 014) . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6-18-1 Face Plates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6-18-2 Tuning Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

6-19 Segment Program 3 (Block Model 158) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

6-19-1 Face Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

6-19-2 Tuning Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

6-19-3 Program Setting Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

34

Page 51

Basic PID (Block Model 011) Section 6-1

6-1 Basic PID (Block Model 011)

6-1-1 Face Plates

The following diagram shows a face plate for Basic PID built using the Face

Plate Auto-Builder for NS in an 800×600 screen resolution.

The whole face is built using 580×133 dots.

2

3

4 5

7

9

13

14

25

20

21

22

1

6

8

10

1112

16

17

18

15

19

In the graphic display, 24 is

displayed as follows:

23

24

1: Tuning Screen Button

Touch this button to switch to the Tuning Screen for the corresponding tag

name. This button is created as a Command Button.

The Tuning Screen Button is not provided in the face plates in the Tuning

Screen.

2: Tag Name