Page 1

MX2/RX PROFIBUS Option Board

Model: 3G3AX-MX2-PRT-E

3G3AX-RX-PRT-E

USER’S MANUAL

Cat. No. I111E-EN-02

Page 2

Notice:

OMRON products are manufactured for use according to proper procedures

by a qualified operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this

manual. Always heed the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

OMRON Product References

All OMRON products are capitalized in this manual. The word "Unit" is also

capitalized when it refers to an OMRON product, regardless of whether or not

it appears in the proper name of the product.

Trademarks and Copyrights

PROFIBUS, PROFIBUS FMS and PROFIBUS DP are trademarks of PROFIBUS International.

Other product names and company names in this manual are trademarks or

registered trademarks of their respective companies.

The copyright of the Option Board Option Board belongs to OMRON Corporation.

Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

• Personnel in charge of maintaining FA systems.

About this Manual

This manual describes the:

• PROFIBUS 3G3AX-MX2-PRT-E Option Board for OMRON's MX2 Inverter.

• PROFIBUS 3G3AX-RX-PRT-E Option Board for OMRON’s RX Inverter.

It also describes how to install and operate the Unit.

Please read this manual carefully so that you understand the information provided before installing or using the Option Board. Start with the Safety Messages on page ix. They describe the operating environment and application

safety measures which must be observed prior to and when using the Option

Board Option Board.

OMRON, 2011

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written

permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless,

OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting

from the use of the information contained in this publication.

Page 3

For the remainder of this manual, both the 3G3AX-MX2-PRT-E PROFIBUS

Option Board as the 3G3AX-RX-PRT-E PROFIBUS Option Board will be

referred as Option Board or Unit. The MX2 and RX Inverters will be referred

as Inverter.

In case information is especially for the MX2 or for the RX Inverter, a clear

notification will be included for which the note is meant.

If information especially is meant for the MX2, this symbol is shown:

If information especially is meant for the RX, this symbol is shown:

Please be sure to read the related user manuals to use the

Option Board Option Board safely and properly. Be sure you are using the

most current version of the manual:

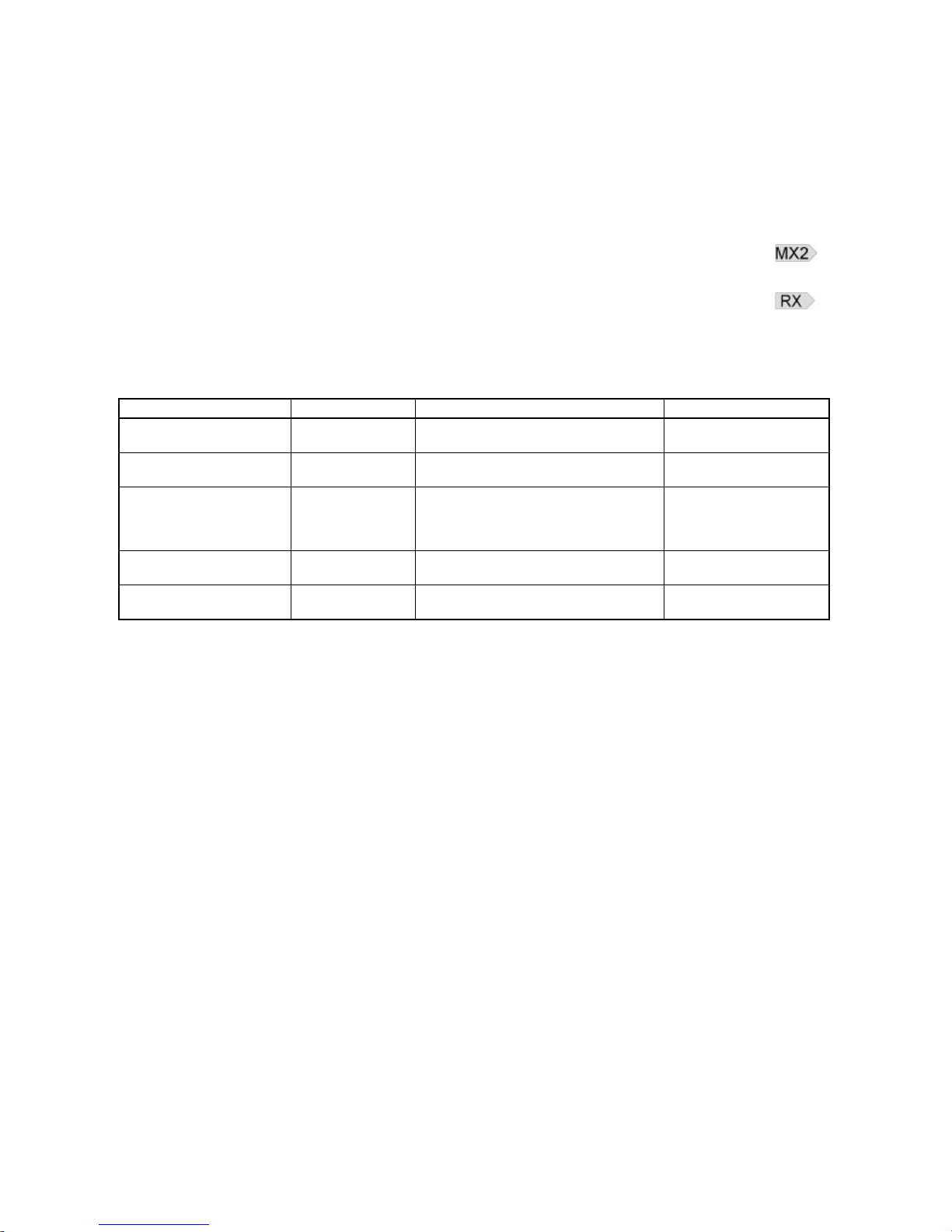

Manual Products Contents Cat No.

MX2 User's Manual MX2 Inverter Describes the installation and operation

of the MX2 Inverter

I570

RX User's Manual RX Inverter Describes the installation and operation

of the RX Inverter

I560

PROFIBUS Installation

Guideline for Cabling and

Assembly

PROFIBUS Provides information on how to properly

install PROFIBUS wiring and to provide

practical guidance on the best ways to

achieve this

PNO Order No. 8.022

PROFIBUS Profile for

Variable Speed Drives

PROFIdrive Provides information on the PROFIdrive

device profile and it's usage

PNO Order No. 3.072

PROFIBUS Master Units CS1W-PRM21

CJ1W-PRM21

Operation manual for PROFIBUS master

units

W409

Page 4

iv

Warranty and Limitations of Liability

Application Considerations

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials

and workmanship for a period of one year (or other period if specified) from date of

sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR

IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS

FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER

ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED

THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED

ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price

of the product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR,

OR OTHER CLAIMS REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED,

INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION,

ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of products in the customer's application or

use of the products.

At the customer's request, OMRON will provide applicable third party certification

documents identifying ratings and limitations of use that apply to the products. This

information by itself is not sufficient for a complete determination of the suitability of

the products in combination with the end product, machine, system, or other application or use.

The following are some examples of applications for which particular attention must

be given. This is not intended to be an exhaustive list of all possible uses of the

products, nor is it intended to imply that the uses listed may be suitable for the products:

o Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not described in this manual.

o Nuclear energy control systems, combustion systems, railroad systems, aviation

systems, medical equipment, amusement machines, vehicles, safety equipment,

and installations subject to separate industry or government regulations.

o Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS

RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A

WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE

OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED FOR THE

INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Page 5

v

Disclaimers

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable

product, or any consequence thereof.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on

improvements and other reasons. It is our practice to change model numbers when

published ratings or features are changed, or when significant construction changes

are made. However, some specifications of the products may be changed without

any notice. When in doubt, special model numbers may be assigned to fix or establish key specifications for your application on your request. Please consult with your

OMRON representative at any time to confirm actual specifications of purchased

products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent the result of

OMRON's test conditions, and the users must correlate it to actual application

requirements. Actual performance is subject to the OMRON Warranty and Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be

accurate; however, no responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

Page 6

vi

Page 7

vii

Table of contents

Table of contents

Notice: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

OMRON Product References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Trademarks and Copyrights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Warranty and Limitations of Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Application Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Disclaimers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

1 Hazardous High Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

2 General Precautions - Read These First! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

3 Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

4 Configuration Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

6 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

7 Handling, Storage and Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

8 Compliance with EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

SECTION 1

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-2 Option Board Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-3 Introduction to PROFIBUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SECTION 2

Option Board Mounting and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2-1 Orientation to Option Board Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2-2 Basic System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-3 How to mount the Option Board on the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

SECTION 3

Configuring Drive Parameters and Option Board . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3-1 Configuring the Option Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3-2 Configuring the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

SECTION 4

Operations and Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4-1 Source Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4-2 Operating the Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4-3 Customising the Process Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4-4 Faults and Trips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4-5 Accessing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4-6 Flexible Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4-7 Limitations Caused by Inverter Mode and Rating Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

SECTION 5

Troubleshooting and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5-1 Troubleshooting using the LED indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5-2 Troubleshooting Using PROFIBUS Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5-3 Maintenance and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5-4 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Page 8

viii

Table of contents

APPENDIX A

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

APPENDIX B

Parameter Process Data Object Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

B-1 I/O Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

B-2 Control and Status Words - STW/ZSW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

B-3 Frequency Reference and Output Frequency - HSW/HIW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

B-4 Parameter Processing Message Area - PKW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

APPENDIX C

Conventional Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

C-1 Basic Data I/O Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

C-2 Extended Data 1 I/O Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

C-3 Extended Data 2 I/O Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

C-4 Operation Command and Inverter Status Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

C-5 Extended Data 1 Digital Output Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

C-6 1 Digital Output Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

C-7 Modbus Message Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

APPENDIX D

Flexible Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

APPENDIX E

PROFIdrive DP-V1 Parameter Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

E-1 Read Parameter Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

E-2 Read Parameter Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

E-3 Change Parameter Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

E-4 Change Parameter Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

E-5 Parameter Value Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

APPENDIX F

Option Board Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

APPENDIX G

PROFIdrive Error Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

APPENDIX H

Slave_Diag Message (SAP60) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Table index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Page 9

ix

Hazardous High Voltage

Safety Messages

Read this manual and the warning labels attached to the Inverter carefully,

before you start to install and operate the Inverter.

Please follow the instructions exactly.

Keep this manual handy for quick reference.

Definitions and Symbols

A safety instruction (message) includes a "Safety Alert Symbol" and a signal

word or phrase such as WARNING or CAUTION. Each signal word has the

following meaning:

!HIGH VOLTAGE Indicates a potentially hazardous situation which, if not avoided, could result

in electric shock. It calls your attention to items or operations that could be

dangerous to you and other persons operating this equipment.

Read the message and follow the instructions carefully.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury, or property damage.

Step 1 Indicates a step in a series of action steps required to accomplish a goal. The

number of the step will be contained in the step symbol.

Note Notes indicate an area or subject of special merit, emphasizing either the

product's capability or common errors in operation or maintenance.

Tip Tips give a special instruction that can save time or provide other benefits

while installing or using the product. The tip calls attention to an idea that may

not be obvious if you are a first-time user of the product.

1 Hazardous High Voltage

!HIGH VOLTAGE Motor control equipment and electronic controllers are connected to hazard-

ous line voltages. When servicing drives and electronic controllers, there may

be exposed components with housing or protrusions at or above line potential.

Extreme care should be taken to protect against shock.

Stand on an insulating pad and make it a habit to use only one hand when

checking components. Always work with another person in case an emergency occurs. Disconnect power before checking controllers or performing

maintenance. Be sure equipment is properly grounded. Wear safety glasses

whenever working on electronic controllers or rotating machinery.

2 General Precautions - Read These First!

!WARNING Failure to read and understand the information provided in this manual may

result in personal injury or death, damage to the product, or product failure.

Please read each section in its entirety and be sure you understand the information provided in the section and related sections before attempting any of

the procedures or operations given.

Page 10

x

General Precautions - Read These First!

!WARNING This equipment should be installed, adjusted, and serviced by qualified elec-

trical maintenance personnel familiar with the construction and operation of

the equipment and the hazards involved. Failure to observe this precaution

could result in bodily injury.

!WARNING Wiring, maintenance or inspection must be performed by authorized person-

nel. Not doing so may result in electrical shock or fire.

!WARNING Hazard of electrical shock! Disconnect incoming power before working on the

Option Board or the Inverter!

!HIGH VOLTAGE Turn the power supply OFF and wait for the time specified on the Option

Board front cover before performing wiring, maintenance or inspection. Not

doing so may result in electrical shock.

The Option Board is attached to an Inverter.

Dangerous voltage exists until the Inverter power light is OFF.

!HIGH VOLTAGE Do not touch the conductive parts such as the internal PCB, terminals or con-

nector while power is being supplied. Doing so may result in electrical shock.

!WARNING Do not attempt to take an Option Board apart or touch any internal parts while

the power is being supplied. Doing so may result in electric shock.

!WARNING Do not attempt to disassemble, repair, or modify an Option Board. Any

attempt to do so may result in malfunction, fire, or electric shock.

!WARNING Provide emergency stop circuits, interlock circuits, limit circuits and similar

safety measures in external circuits (NOT in the Option Board). This ensures

safety in the system if an abnormality occurs due to malfunction of the Option

Board or another external factor affecting the Option Board operation. Not

doing so may result in serious accidents.

!WARNING Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes. Not doing so may result in

serious accidents.

!Caution Do not touch the Inverter during power on, and immediately after power off.

Hot surface may cause injury.

!Caution The product will be used to control an adjustable speed drive connected to

high voltage sources and rotating machinery that is inherently dangerous if

not operated safely. Interlock all energy sources, hazardous locations, and

guards in order to restrict the exposure of personnel to hazards. The adjustable speed drive may start the motor without warning. Signs on the equipment

installation must be posted to this effect. A familiarity with auto-restart settings

is a requirement when controlling adjustable speed drives. Failure of external

or ancillary components may cause intermittent system operation, i.e., the

system may start the motor without warning or may not stop on command.

Improperly designed or improperly installed system interlocks and permissives may render a motor unable to start or stop on command.

Page 11

xi

Installation Precautions

3 Installation Precautions

!WARNING Always connect the grounding cable to one of the ground terminals of the

Inverter. Failure to abide could lead to serious or possibly fatal injury.

!Caution Failure to observe these precautions could lead to faulty operation of the

Option Board or the Inverter, or could damage either of the two. Always read

these precautions.

• Install external breakers and take other safety measures against short-circuits in external wiring. Not observing this may result in burning.

• Be sure that all cable connector screws are tightened to the torque specified in the relevant manuals. Incorrect tightening torque may result in malfunction.

• Do not allow metal clippings to enter either Option Board or Inverter when

wiring or installing the unit.

• Follow "PROFIBUS Installation Guideline for Cabling and Assembly"

(PNO Order No. 8.022)

• Wire the PROFIBUS cables and connectors correctly. Incorrect wiring

may result in burning.

• Apply termination at both ends of a PROFIBUS cable segment. Do not

apply termination anywhere else.

• Be sure that the Option Board is mounted correctly. Improper mounting

may result in malfunction.

• Disconnect the grounding cable when performing withstand-voltage tests.

Not disconnecting the grounding cable may result in burning.

4 Configuration Precautions

!Caution Failure to observe these precautions could lead to unexpected operation of

the Option Board or the Inverter. Always read these precautions.

• Check the network related Inverter settings regarding PROFIBUS node

address and PROFIBUS map selection. Not doing so may result in unexpected operation.

• When replacing an Inverter be sure that all Inverter settings of the Inverter

being replaced are restored to the replacement.

• Restoring parameters stored in the remote operator also restores the

PROFIBUS node address. Always check the node address and other network related Inverter settings after restore.

5 Application Precautions

!WARNING Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

!WARNING It is extremely important that the Unit is used for its specified purpose and

under the specified conditions, especially in applications that can directly or

indirectly affect human life. You must consult your OMRON representative

before using it in a system in the above-mentioned applications.

Page 12

xii

Application Precautions

!WARNING Failure to observe these precautions could lead to serious or possibly fatal

injury. Always read these precautions.

• Check any user program in the system that acts as a PROFIBUS master

before actually running it. Not checking the program may result in unexpected operation.

• A revision AAAA Inverter allows the motor to run immediately if a trip condition is reset, and at the same time, a run command is active via PROFIBUS. For safe operation clear the run command via PROFIBUS as soon

as a trip condition is detected. Refer to section 1-1-2 Inverter Suppor t to

determine the Inverter revision.

!Caution Failure to observe these precautions could lead to faulty operation of the

Option Board or the Inverter, or could damage to either of the two. Always

read these precautions.

• Check the Inverter settings for proper Inverter behavior before actually

operating the Inverter remotely via the PROFIBUS network.

• Check the Inverter's EzSQ program and its interaction with the PROFIBUS master before actually running it on the Inverter. Not checking the

program may result in unexpected operation.

• Confirm that no adverse effect will occur at the moment the PROFIBUS

master stops communicating with the Inverter or at the moment the PROFIBUS master has not yet started communicating to the Inverter.

• Confirm that no adverse effect will occur in the Inverter before force-setting/force-resetting any bit in the system that acts as a PROFIBUS master.

Page 13

6 Operating Environment Precautions

!Caution Do not operate the Inverter with a mounted Option Board in the following loca-

tions (doing so may result in malfunction, electric shock or burning):

• Locations subject to direct sunlight

• Locations subject to temperatures or humidity outside the range specified

in the specifications

• Locations subject to condensation as the result of severe changes in temperature

• Locations subject to corrosive or flammable gases

• Locations subject to dust (especially iron dust) or salts

• Locations subject to exposure to water, oil, or chemicals

• Locations subject to shock or vibration

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations (doing so may result in malfunction):

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic fields

• Locations subject to possible exposure to radioactivity

• Locations close to power supplies

!Caution The operating environment of the Inverter with a mounted

Option Board can have a large effect on the longevity and reliability of the system. Improper operating environments can lead to malfunction, failure, and

other unforeseeable problems with the system. Make sure that the operating

environment is within the specified conditions at installation and remains

within the specified conditions during the life of the system.

7 Handling, Storage and Disposal

!Caution Failure to observe these precautions could lead to faulty operation of- or dam-

age to the Option Board. Always read these precautions.

• Before touching the Option Board or Inverter, be sure to first touch a

grounded metallic object in order to discharge any static built-up. Not

doing so may result in malfunction or damage.

• When transporting or storing the Option Board keep the product within the

specified storage temperature range.

!Caution Never dispose electrical components by incineration. Contact your state envi-

ronmental agency for details on disposal of electrical components and packaging in your area.

8 Compliance with EC Directives

This product complies with EC Directives when mounted to an Inverter with

the grounding cable connected.

Page 14

xiv

Compliance with EC Directives

Page 15

1

Introduction Section 1-1

SECTION 1

Getting Started

1-1 Introduction

1-1-1 Main Features

The Option Board 3G3AX-MX2-PRT-E and the 3G3AX-RX-PRT-E allow controlling, monitoring and parameterization of an Inverter via a PROFIBUS network.

The Option Board serves as a gateway that passes communicated register

values from the PROFIBUS network to the Inverter and vice versa.

The following functions are available via PROFIBUS communication by installing the Option Board:

Cyclic Data Exchange The PROFIBUS Master and Option Board can exchange data via a PROFI-

BUS DP-V0 message connection:

• Output data (from PROFIBUS Master to Option Board):

E.g. Run/stop, Reference frequency and Fault reset

• Input data (from Option Board to PROFIBUS Master):

E.g. Inverter status, Output frequency and Output current

Inverter Parameter Access The PROFIBUS Master can read and write parameter data via the

Option Board using the mailboxes provided by some modules, as well as a

PROFIdrive DP-V1 parameter channel.

Simplified Start-up The Option Board can be set up easily, just by wiring the Unit, setting the

PROFIBUS node address (P180) and device profile (P182) and restarting the

unit. The Unit's configuration is read automatically when the power is turned

ON. It is not necessary to make any settings with a special Programming

Device.

Simplified Replacement All parameters required by the Option Board are stored in the Inverter. The

Option Board can be replaced, requiring no re-configuration.

Automatic Baud Rate

Recognition

The Option Board automatically detects the Master's communication baud

rate, and no user configuration is required.

Note The PROFIdrive DP-V1 parameter channel is only available if the PROFIBUS

Master also provides DP-V1 Class 2 (MSAC2) Messaging to the user.

Note If the PROFIBUS Master's baud rate changes, the PROFIBUS Communica-

tion Unit must be turned OFF and then ON to detect the new baud rate.

Page 16

2

Introduction Section 1-1

1-1-2 Inverter Support

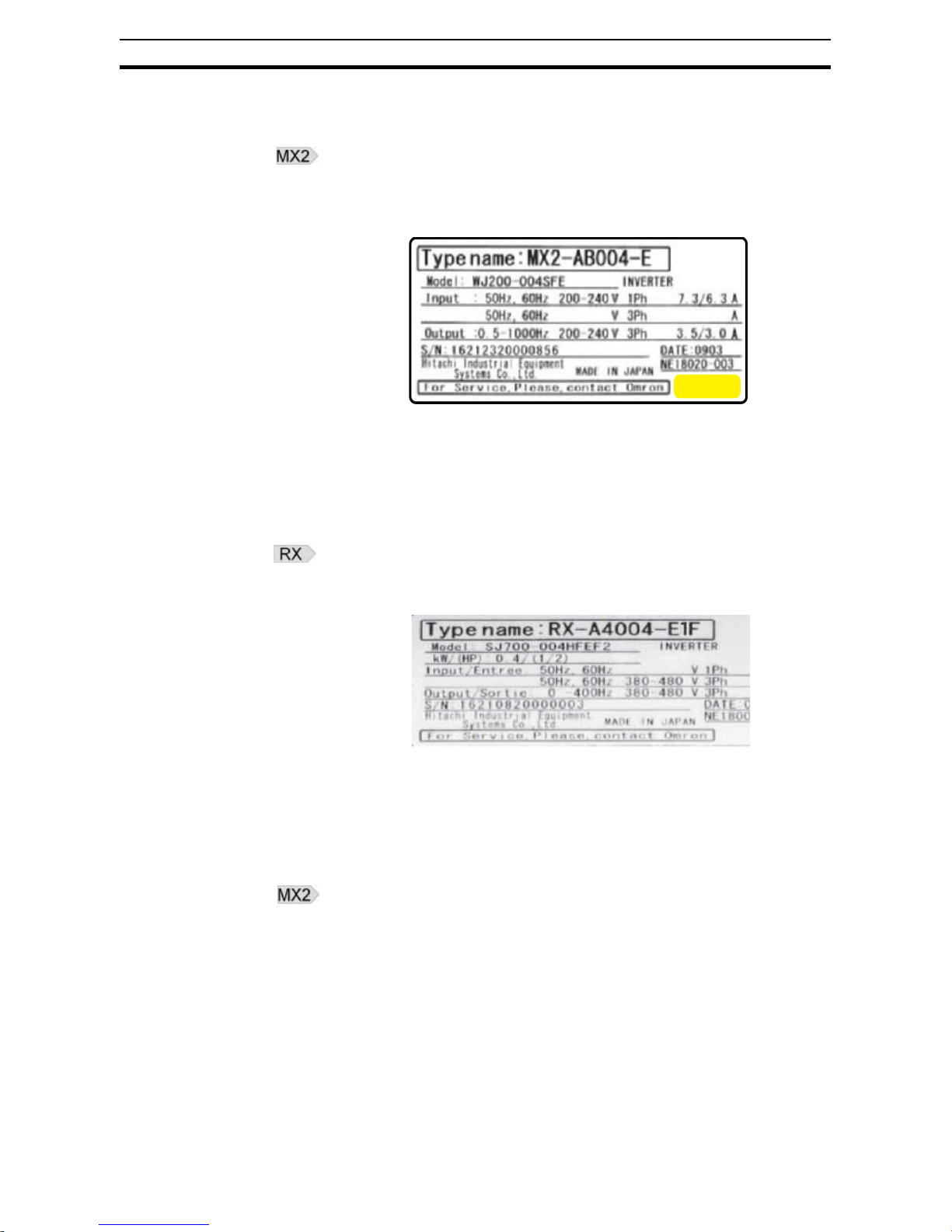

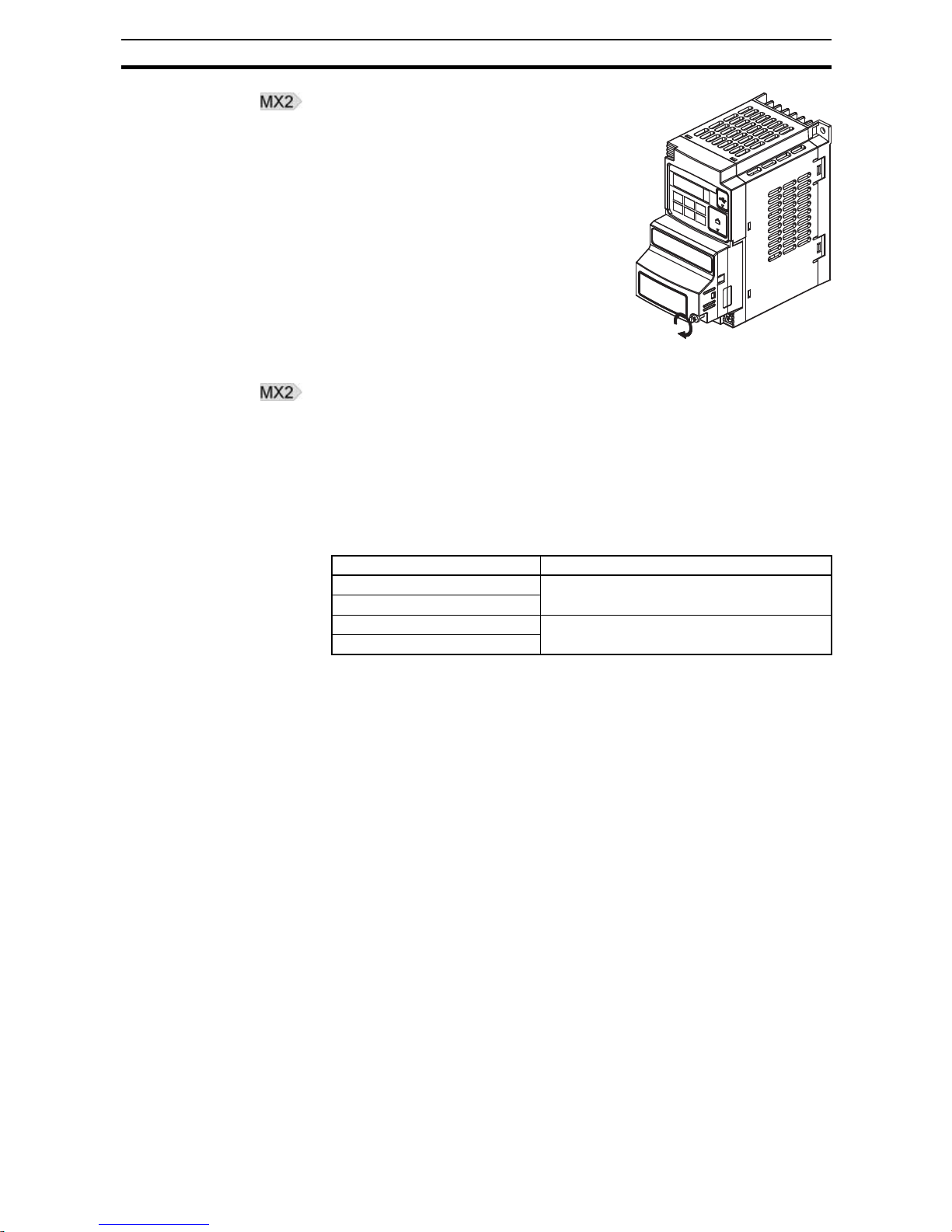

1-1-2-1 Inverter support for the MX2

The 3G3AX-MX2-PRT-E Option Board supports the MX2 Inverter with minimum revision of AAAA. An MX2 Inverter that supports the

3G3AX-MX2-PRT-E Option Board can be recognized from the Inverter type

label. Please check that your Inverter type label displays revision characters in

the bottom right corner where the is displayed in this illustration.

Please note if these characters are absent, your Inverter does not support the

3G3AX-MX2-PRT-E, so please contact your local OMRON representative.

1-1-2-2 Inverter support for the RX

The 3G3AX-RX-PRT-E Option Board supports the RX Inverter with minimum

revision of RX-@-E1F or RX-@-V1. An RX Inverter that supports the

3G3AX-RX-PRT-E Option Board can be recognized from the Inverter type

label.

Note If your RX Inverter has no postfix on type label (e.g.RX-A4004) or the EF post-

fix (e.g. RX-A4004-EF) the 3G3AX-RX-PRT-E option is not supported, so

please contact your local OMRON representative.

1-1-3 Inverter Safety (ISO 13849-1)

An Inverter provides a Gate Suppress function to perform a safe stop according to the EN60204-1, stop category 0. The Option Board has been designed

not to interfere with this safety function.

The Option Board is not a safety device and does not implement any safety

protocols.

Note The Option Board is not a safety device and does not implement any safety

protocols such as PROFIsafe.

@@@@

Page 17

3

Option Board Specifications Section 1-2

1-2 Option Board Specifications

Note 1 The derated- or ambient operating temperature of the Inverter takes prece-

dence over that of the Option Board.

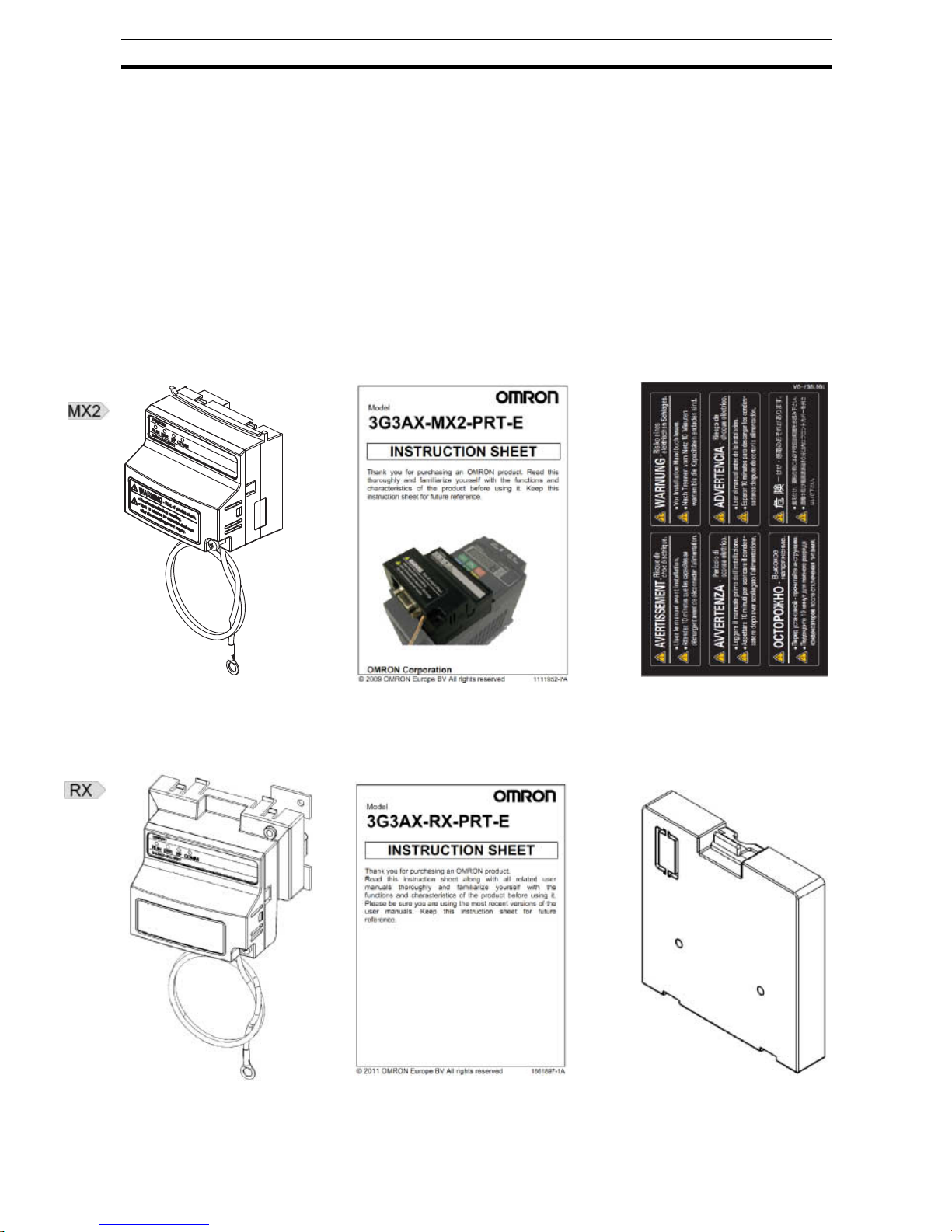

Table 1 Option Board Specifications

Item Specification

Installation MX2

Unit type MX2 Series Option Card

Model Option Board

Dimensions (W x H x D) 68 x 58 x 45 mm

Weight 170g (typical)

Installation RX

Unit type RX Series Option Card

Model 3G3AX-RX-PRT-E

Dimensions (W x H x D) 80 x 67 x 49 mm

Weight 170gram (typical)

Environment

Ambient operating temperature

*1

-10 to 55C (no icing or condensation)

Ambient operating humidity 20 to 90%RH

Ambient storage temperature -20 to 65C (no icing or condensation)

Vibration resistance

5.9m/s

2

(0.6G) at 10…55Hz

Dielectric strength 500 VAC (between isolated circuits)

Conformance to EMC and Electrical safety standards

EN61800-3: 2004 (2004/108/EC) Second environment, Category

C3

EN61800-5-1: 2007 (2006/95/EC) SELV

Enclosure rating IP 20

Front Case

Indicators 4 LEDs, indicating Option Board and PROFIBUS status:

Option Board Status: RUN (Green)

ERR(Red)

PROFIBUS Status: BF (Red)

COMM (Green)

PROFIBUS connector 9-pin sub-D female connector (#4/40 UNC thread)

PROFIBUS

Interface

Applicable standards IEC 61158 Industrial communication networks - Fieldbus specifi-

cations

Protocol type supported PROFIBUS DP

PROFIBUS DP-V1, Class 2 (MSAC2 acyclic messaging)

PROFIBUS Unit type PROFIBUS DP-V1 Slave

PROFIBUS Media type RS-485, galvanically isolated from the Inverter

PROFIBUS Connector 9-pin sub-D female connector (#4/40 UNC thread)

Termination according to EN50170 provided by the cable connector

Certificate Test Specification for PROFIBUS DP Slaves, Version 3.0

DP-V0 DP-V1 Physical Layer

Unit device address range 0 ~ 125, set with inverter parameter P180

Baud rates supported Automatically detected from:

9.6 kbit/s 19.2 kbit/s 45.45 kbit/s 93.75 kbit/s

187.5 kbit/s 500 kbit/s 1.5 Mbit/s 3 Mbit/s

6 Mbit/s 12 Mbit/s

Page 18

4

Introduction to PROFIBUS Section 1-3

1-3 Introduction to PROFIBUS

1-3-1 The Purpose of PROFIBUS

PROFIBUS (PROcess FIeldBUS) is an open fieldbus standard for a wide

range of applications in manufacturing, processing and building automation.

The Standard, IEC 61158 (Industrial communication networks), to which

PROFIBUS adheres, guarantees vendor independence and transparency of

operation. It enables devices of various manufacturers to intercommunicate

without having to make any special interface adaptations.

1-3-2 What is PROFIBUS DP

PROFIBUS DP (for Decentralized Periphery) is a variant optimized for high

speed and low-cost interfacing. It is specially designed for communication

between automation control systems and distributed I/O at the device level.

PROFIBUS DP uses the same transmission technology and uniform bus

access protocol as PROFIBUS FMS (for Fieldbus Message Specification).

Consequently, both versions can be operated simultaneously on the same

bus. DP field devices, however, cannot be controlled by FMS masters and

vice versa.

!Caution It is not possible to exchange a PROFIBUS DP device or master for a PROFI-

BUS FMS device or master. This will cause faulty operation.

Table 1 Option Board Specifications (continued)

Item Specification

PROFIBUS DP

Services and

Profiles

Master Class 1 – Slave

cyclic services

Set_Prm Chk_Cfg Slave_Diag Data_Exchange

Get_Cfg Rd_Inp Rd_Outp

Global-Control (SYNC/UNSYNC, FREEZE/UNFREEZE & CLEAR)

Master Class 1 – Slave

acyclic services

Not supported

Master Class 2 – Slave

acyclic services

MSAC2_Initiate MSAC2_Read MSAC2_Write MSAC2_Abort

Profiles supported PROFIdrive V2 (If P182 = 0)

Conventional (If P182 = 1)

Flexible (If P182 = 2)

Supported I/O modules PROFIdrive V2

(If P182 = 0)

PPO Type 1 (4 words PKW + 2 words PZD)

PPO Type 2 (4 words PKW + 6 words PZD)

PPO Type 3 (2 words PZD)

PPO Type 4 (6 words PZD)

PPO Type 5 (4 words PKW + 10 words PZD)

Conventional

(If P182 = 1)

Basic Data

Extended Data 1

Extended Data 2

Flexible

(If P182 = 2)

Flexible (10 words output and input)

I/O Data

I/O data 28 bytes max. input data using PPO Type 5

28 bytes max. output data using PPO Type 5

Diagnostics data size 11 bytes

MX2 GSD file

OC_0C6A.gsd

RX GSD file

OC_0D2F.gsd

Page 19

5

Introduction to PROFIBUS Section 1-3

1-3-3 What is PROFIdrive

The PROFIdrive device profile supplements the PROFIBUS standard. It

defines a unified behavior and technique to access Inverter and drive device

data. All drives supporting the PROFIdrive profile respond the same way to

control instructions.

!Caution For backward compatibility and direct use of the Inverter registers, the Option

Board offers two additional device profiles that are NOT PROFIdrive compliant. For PROFIdrive compliance, ensure that P182 = 0.

Page 20

6

Introduction to PROFIBUS Section 1-3

Page 21

7

Orientation to Option Board Features Section 2-1

SECTION 2

Option Board Mounting and Installation

2-1 Orientation to Option Board Features

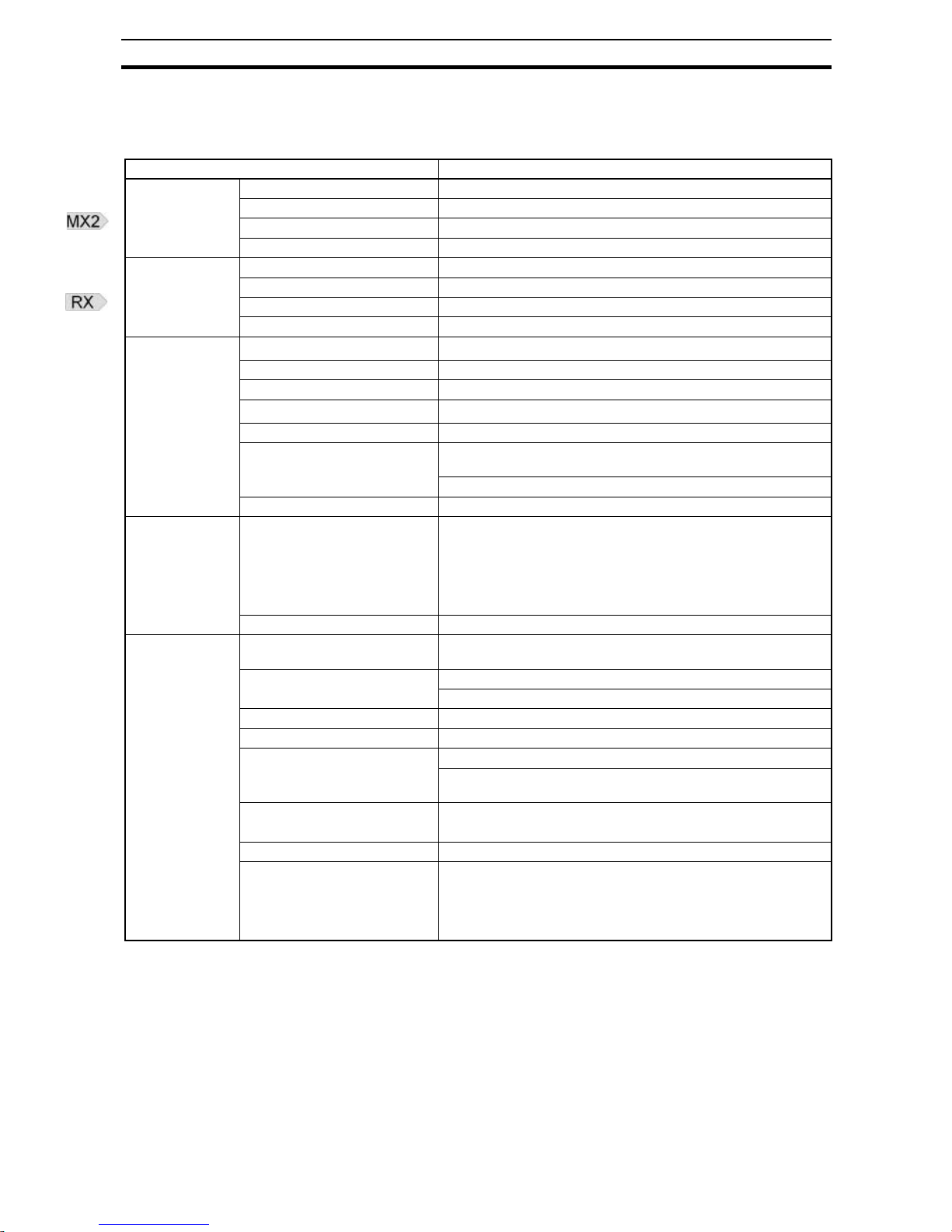

2-1-1 Unpacking and Inspection

Take a few moments to unpack your new Option Board and perform these

steps:

1. Look for any damage that may have occurred during transportation.

2. Verify the contents of the box

3. Inspect the markings on the Option Board. Make sure it matches the product part number you ordered:

Option Board

with Grounding

Instruction Sheet

Warning Labels

Instruction Sheet

Blind cover

Option Board

with Grounding

Cable and Profibus connector

Page 22

8

Orientation to Option Board Features Section 2-1

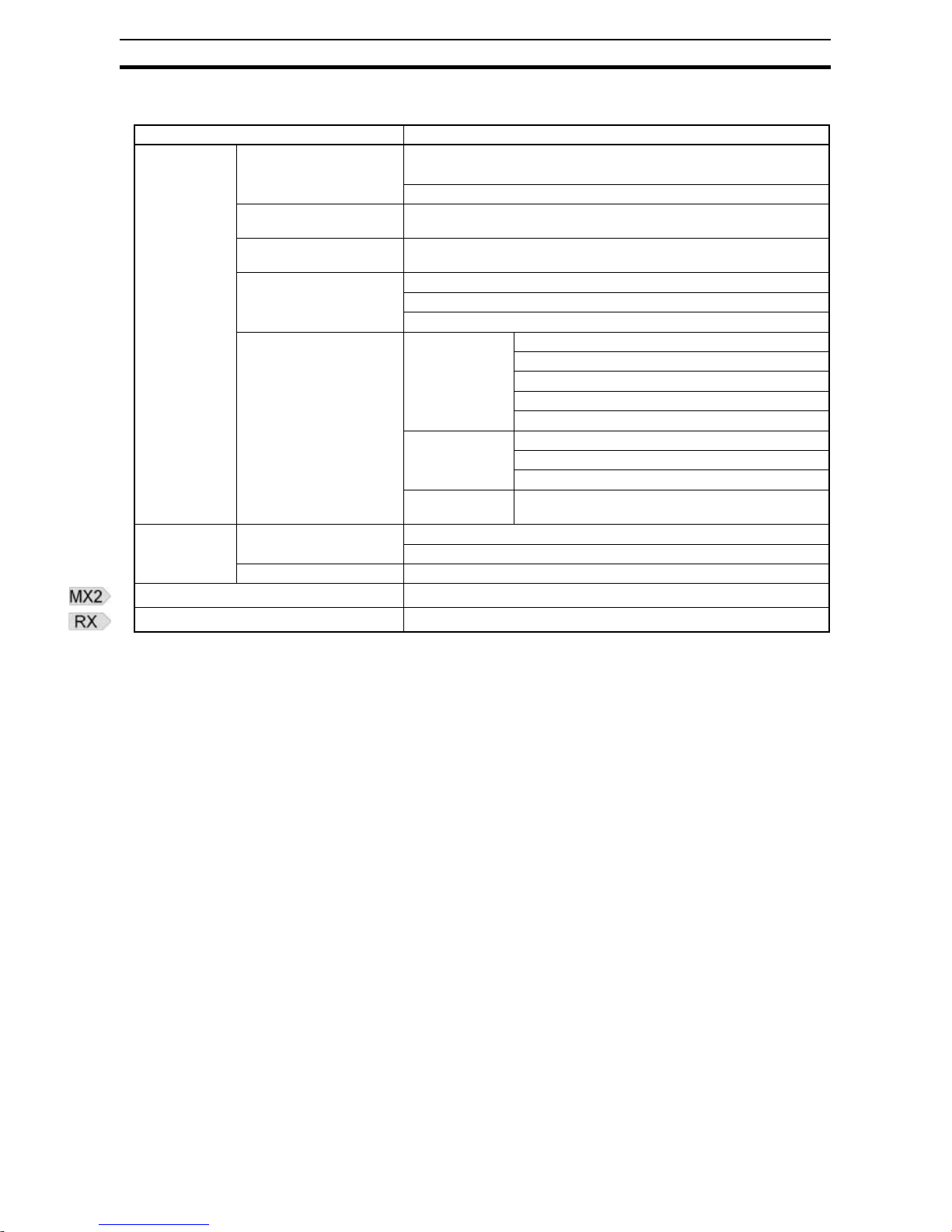

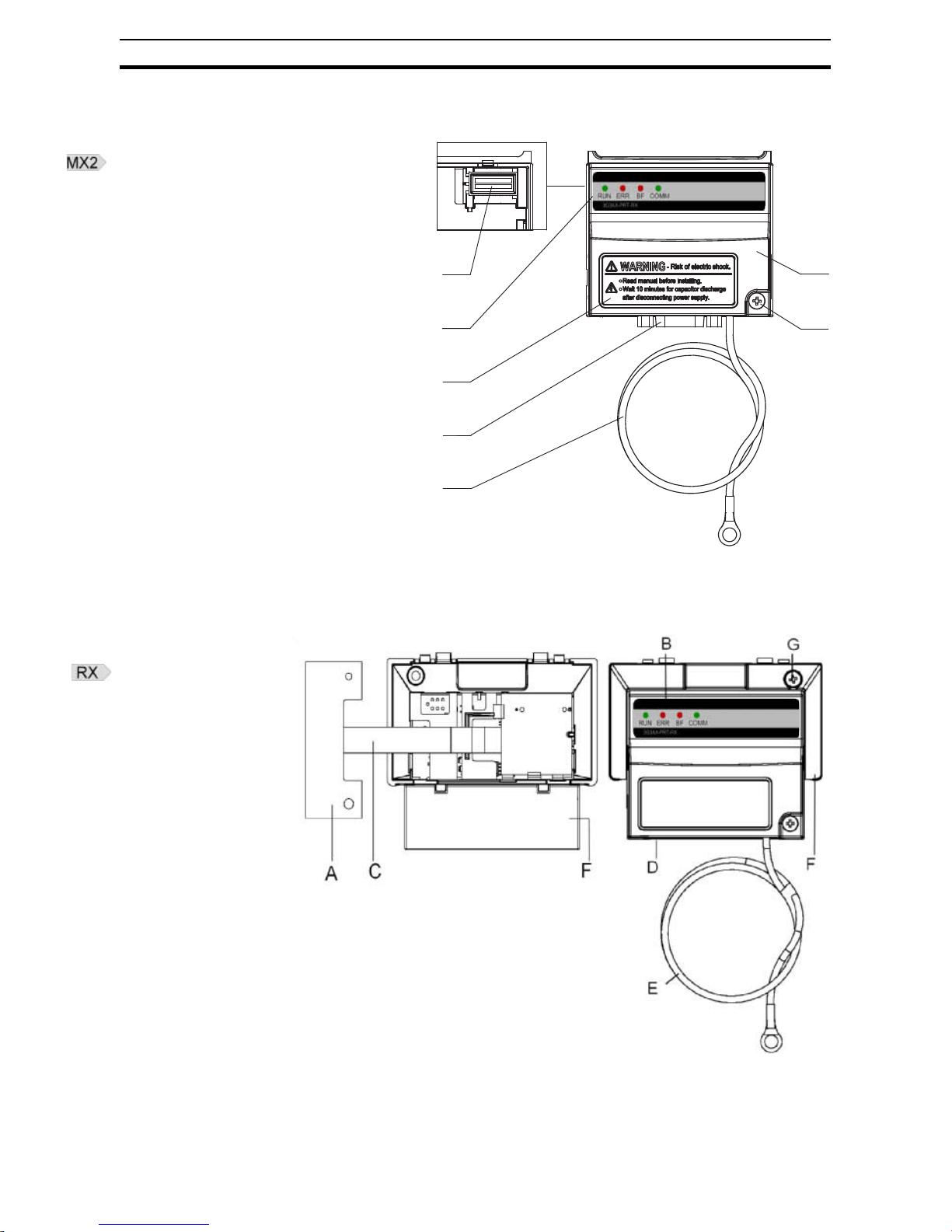

2-1-2 Main Physical Features

G

D

F

B

E

C

A

underside

A - Option board connector

B - LED indicators (RUN, ERR, BF, COMM)

C - Warning label

D - Fieldbus connector

E - Grounding cable

F - Housing

G - Mounting screw

A - Option Board Inverter connector

B - LED indicators (RUN, ERR, BF, COMM)

C - Option Board Cable

D - Fieldbus connector

E - Grounding cable

F- Housing

G - Mounting screw

Page 23

9

Basic System Description Section 2-2

Four LED indicators (B) allow easy diagnosis. An attached grounding cable

(E) is sized to reach the ground terminals on all Inverter models. A feature in

the housing (F) will retain the mounting screw (G) when the Option Board is

not mounted to the Inverter. The orientation of the Fieldbus connector (D)

allows unstrained connection and removal of the PROFIBUS connector.

Please pay special attention to the Option Board connector: It must be properly connected with the Inverter when the Option Board is mounted.

2-1-3 LED Indicators

The LED indicators on the front indicate the operational mode and status of

the Option Board and the network.

Refer to Section 5-1 for Troubleshooting using the LED indicators on page 57

2-2 Basic System Description

The Option Board connects to the Master via a PROFIBUS network cable.

Inverter I/O data is generally shared with the Master's I/O memory through the

PROFIBUS DP network. Every PROFIBUS communication cycle, Inverter I/O

data is collected by the Option Board and exchanged with the Master. The

Engineering Station allows you to configure, monitor, program, diagnose and

operate the system.

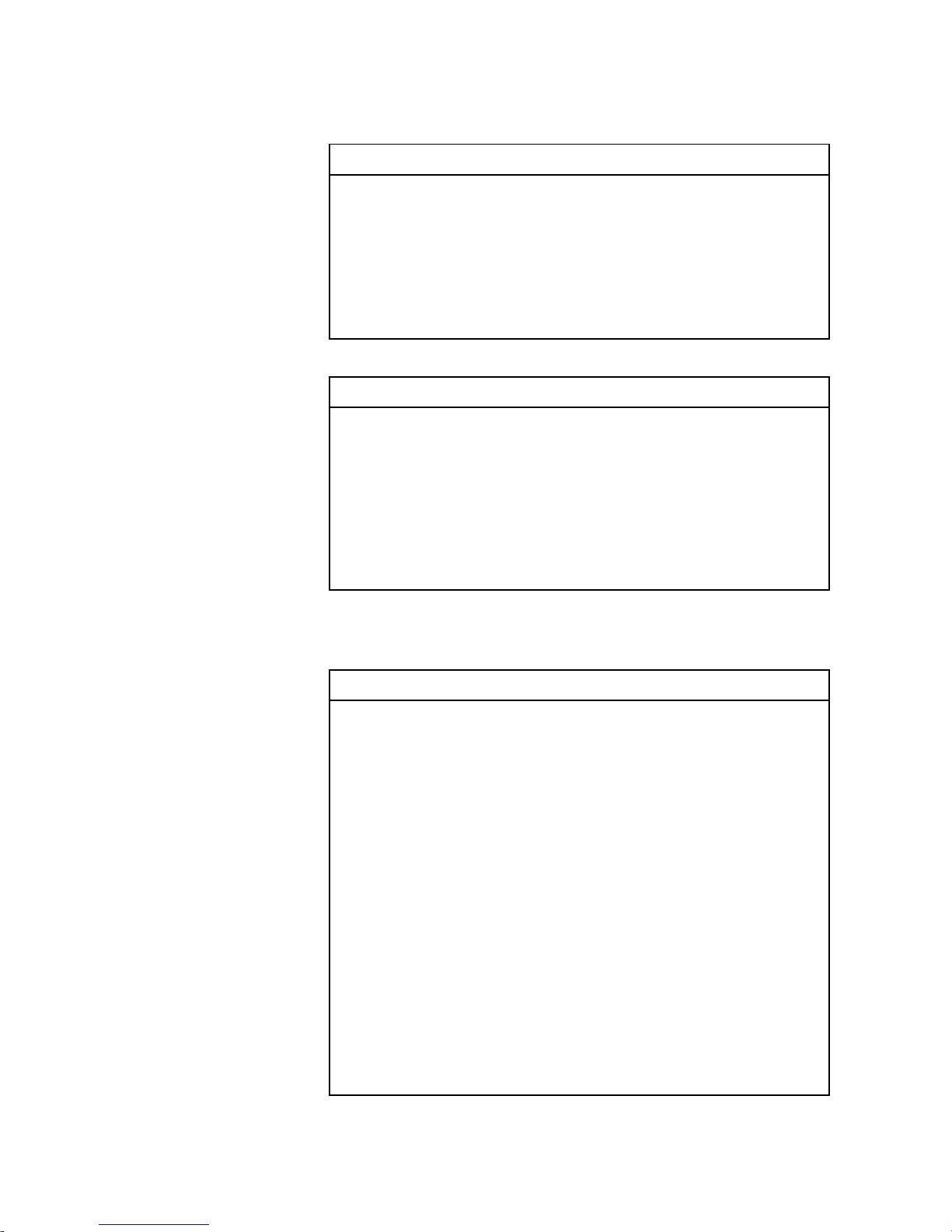

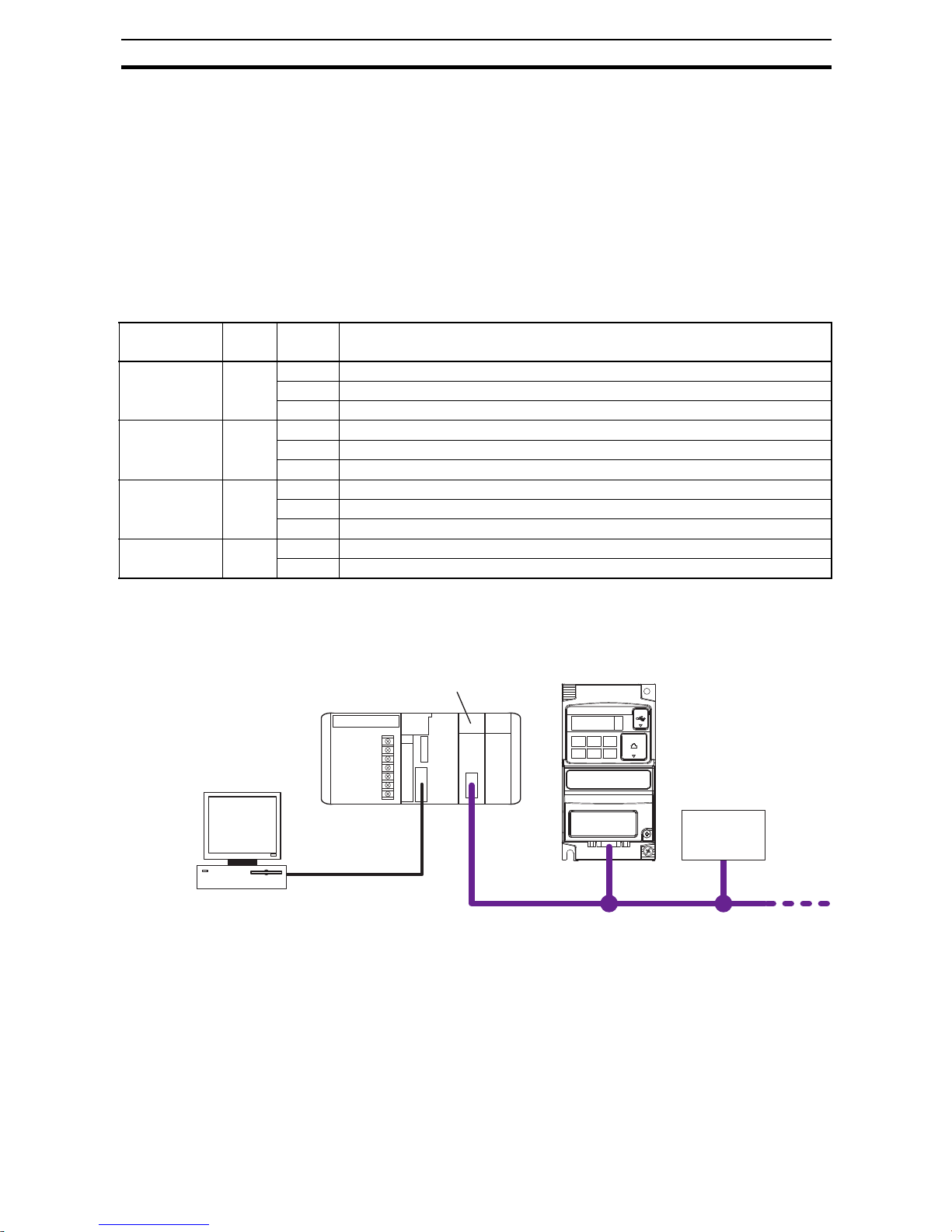

Table 2 LED Indicators

Indicator Colour Status Meaning

RUN

(Unit status)

Green OFF No power or not yet ready for operation

Flashing Operating in commissioning mode

ON Normal operation

ERR

(Unit error)

Red ON Fatal error

Flashing Operational error

OFF No error

BF

(Bus Fail)

Red ON No communication with PROFIBUS Master

Flashing Unsupported parameters or module configuration received from PROFIBUS Master

OFF Communicating with PROFIBUS Master

COMM

(Comms status)

Green ON Cyclic data exchange or PROFIBUS diagnostics operational

OFF No cyclic data exchange or PROFIBUS diagnostics

Slave

PLC

PROFIBUS DP-V1 Master

MX2-A@ Inverter +

Option Board

PROFIBUS

Engineering Station

(For setting, monitoring and operation)

Inverter + Option Board

PROFIBUS

Slave

PROFIBUS DP-V1 Master

PLC

Engineering Station

For setting, monitoring and operation)

Page 24

10

How to mount the Option Board on the Inverter Section 2-3

2-3 How to mount the Option Board on the Inverter

!HIGH VOLTAGE Always Switch OFF the mains power supply to the Inverter before removing

any covers. Wait for the time specified on the Inverter front cover for the

capacitors to discharge. Not doing so may result in electrical shock.

!HIGH VOLTAGE Never operate the Inverter with the terminal block cover or backing plate

removed.

!WARNING Provide emergency stop circuits, interlock circuits, limit circuits and similar

safety measures in external circuits (NOT in the Option Board). This ensures

safety in the system if an abnormality occurs due to malfunction of the Option

Board or another external factor affecting the Option Board operation. Not

doing so may result in serious accidents.

!WARNING Always connect the grounding cable to one of the ground terminals of the

Inverter. Failure to abide could lead to serious or possibly fatal injury.

!Caution Never touch the heat sink during or just after operation; it can be very hot.

!Caution Be sure that the Option Board is mounted correctly. Improper mounting may

result in malfunction.

!Caution Be sure that all cable connector screws are tightened to the torque specified

in the relevant manuals. Incorrect tightening torque may result in malfunction.

Note Illustrations are only provided for one Inverter size. The instructions however

are generic, and may be followed for all Inverter sizes.

Please refer to the MX2 Inverter manual (Cat. No. I570) section 2-1-3 for

details on assembly and disassembly of the Inverter.

Please refer to the RX Inverter manual (Cat. No. I560) section 2 for details on

assembly and disassembly of the Inverter.

Page 25

11

How to mount the Option Board on the Inverter Section 2-3

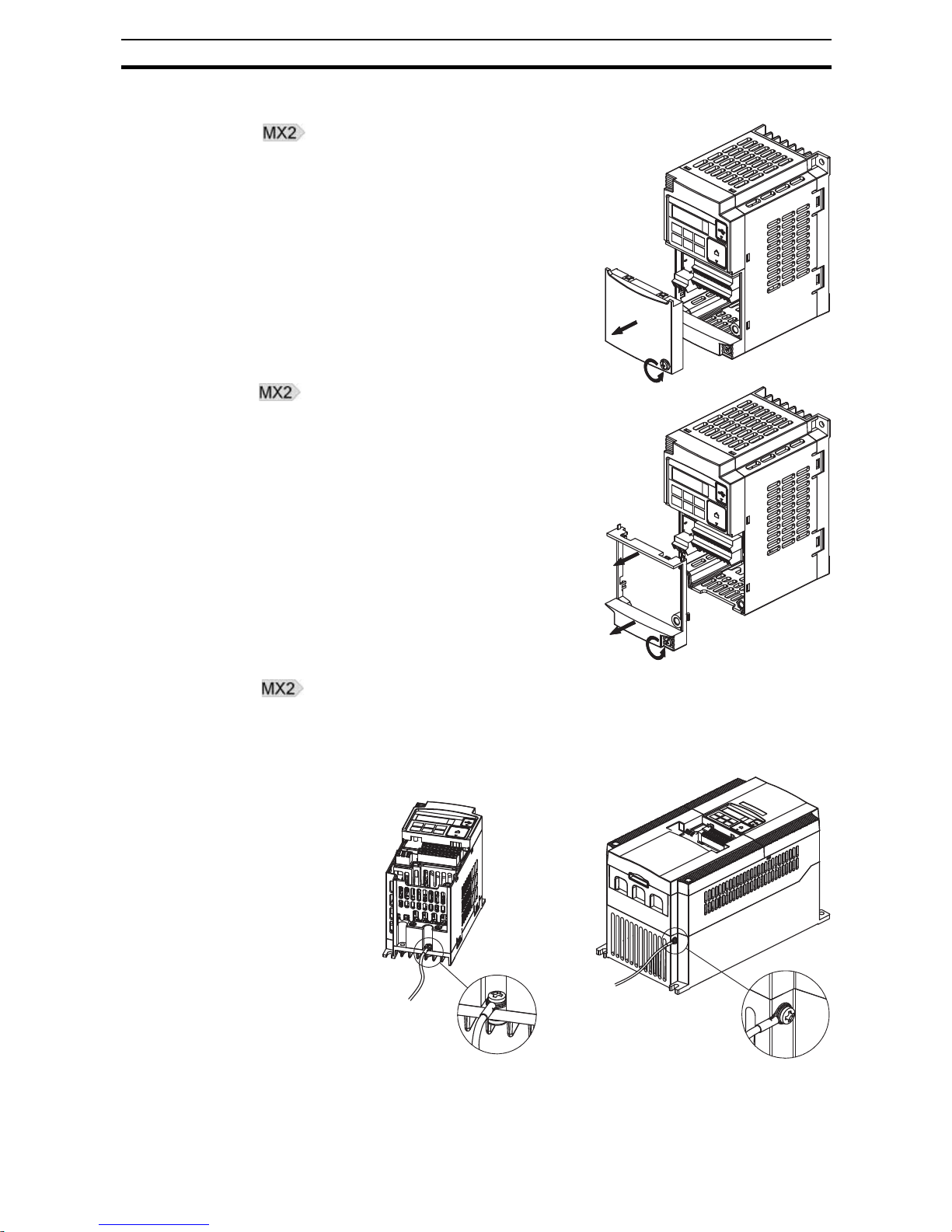

2-3-1 Mounting sequence of the Option Board on the MX2 Inverter

Step 1 Loosen the screw of the option board

cover, remove the cover and put the

cover aside.

Step 2 For Inverters up to 4.0 kW only:

loosen the screws of the terminal

block cover and remove the cover to

enable access to the chassis ground

terminal screws.

Step 3 Secure the Option Board grounding cable to the Inverter with a mounting

screw.

3-phase 200 V 0.1 - 3.7 kW

3-phase 400 V 0.4 - 4.0 kW

1-phase 200 V 0.1 - 2.2 kW

3-phase 200 V 5.5 - 15 kW

3-phase 400 V 5.5 - 15 kW

Page 26

12

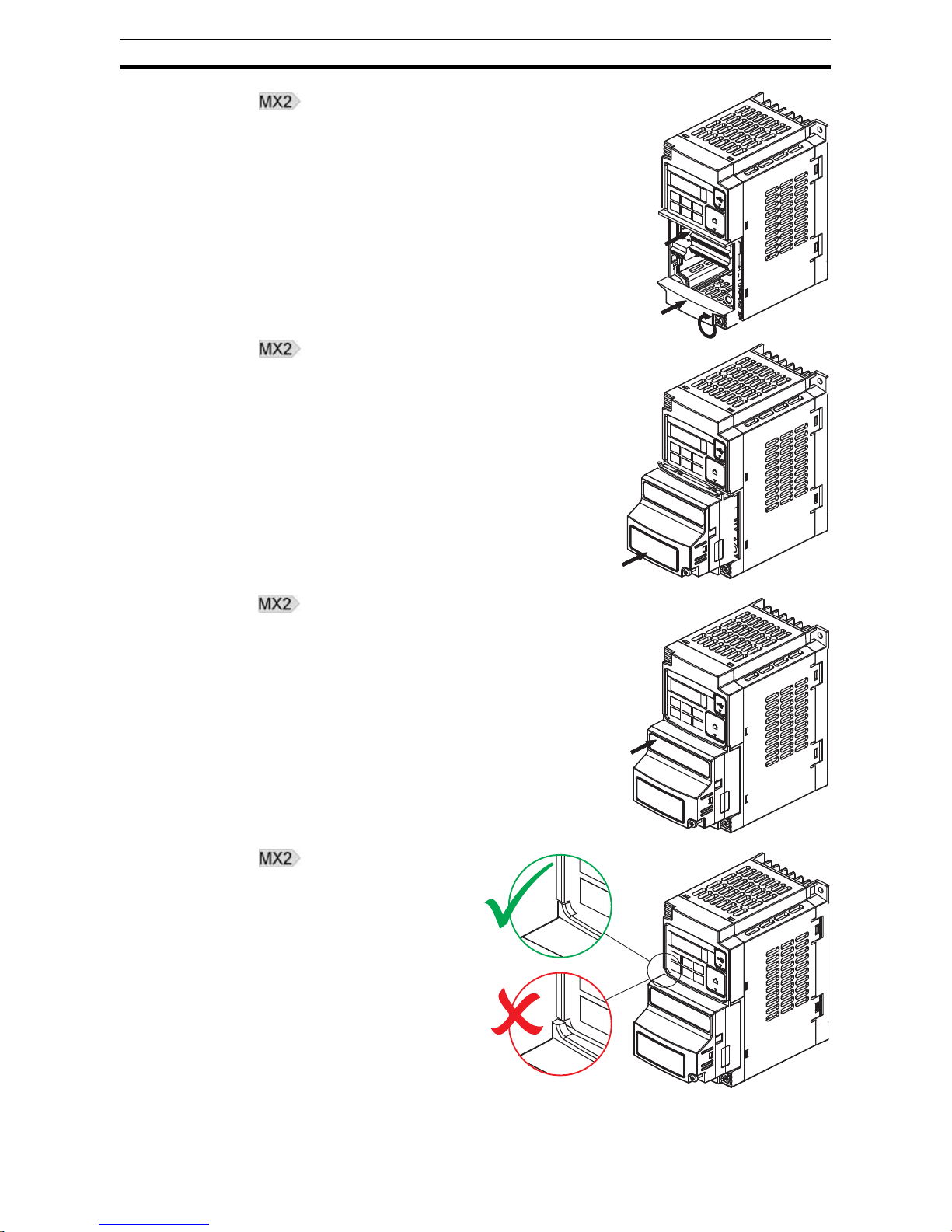

How to mount the Option Board on the Inverter Section 2-3

Step 4 If removed in Step 2, mount the termi-

nal cover again and tighten the

screw(s).

Step 5 Push the Option Board into the previ-

ous location of the option board cover

until it clicks into place

Step 6 Press down on the indicated corner

of the Option Board housing to

ensure proper connection of the

Option Board connector

Step 7 Check that there is

no gap between the

top edges of the

Option Board and the

Inverter casing.

Page 27

13

How to mount the Option Board on the Inverter Section 2-3

Step 8 Secure the Option Board in place

with the mounting screw (do not overtighten).

Step 9 Select the right warning language from the warning label sheet and replace

the English warning if appropriate.

Note Refer to section 2-1-3 in the MX2 user’s manual (Cat.-No. I570) for operations

related to assembly and disassembly of the Inverter

Note Some Inverter models do not include a screw for the grounding cable. Please

supply the recommended screw, lock-washer and washer to attach the

grounding cable

Table 3 Ground cable screw selection

Inverter models Grounding Cable Attachment Screw

3-phase 200 V 5.5 – 7.5 kW M4 x 6

3-phase 400 V 5.5 – 7.5 kW

3-phase 200 V 11 – 15 kW M5 x 6

3-phase 400 V 11 – 15 kW

Page 28

14

How to mount the Option Board on the Inverter Section 2-3

2-3-2 How to install the Option Board on the RX Inverter

2-3-2-1 Preparation

When the Option Board is mounted on the RX Inverter, the Digital Operator

Display can not be directly connected back on the RX Inverter.

There are two solutions:

Commissioning with

Digital Operator Display

This option is recommended, however it does require a straight Ethernet

cable.

Step 1 Mount the Option Board according paragraph 2-3-2-2 Mounting sequence of

the Option Board on the RX Inverter on page 14.

Step 2 Connect the Digital Operator Display using the 3G3AX CAJOP300-EE cable

or straight Ethernet cable.

Step 3 Set the desired parameters of the RX Inverter with the Digital Operator Dis-

play.

Commissioning via Profibus

Step 1 Configure the essential Profibus communication parameters before mounting

the Option Board. See also paragraph 3-2 Configuring the Network on page

26:

• Step 1 on page 23: Set the Device Profile using parameter P182.

• Step 3 on page 23: Set the Inverter parameter P180 PROFIBUS

Node Address.

Step 2 Mount the Option Board according paragraph 2-3-2-2 Mounting sequence of

the Option Board on the RX Inverter on page 14. Set the desired parameters

of the Inverter (Also referenced in this paragraph).

Step 3 Configure the Inverter without Digital Operator:

•Use the OMRON CX-Drive tool, or

•Use PROFIdrive DP-V1 Parameter Channel to access the parameters

directly (refer to APPENDIX E PROFIdrive DP-V1 Parameter Chan-

nel).

2-3-2-2 Mounting sequence of the Option Board on the RX Inverter

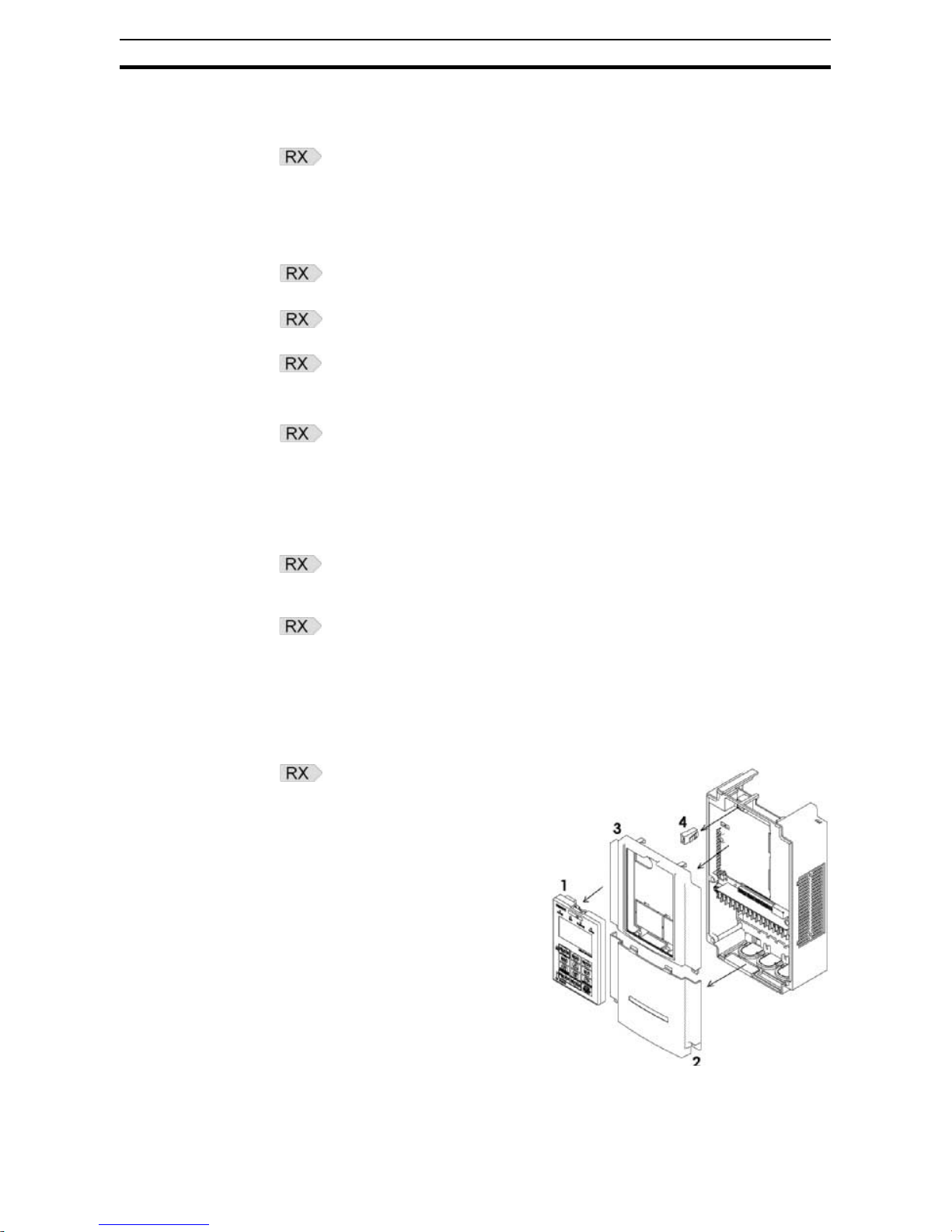

Step 1 Remove from the RX Inverter:

1. Digital Operator Display

2. Terminal cover

3. Front Cover

4. Operator connector.

Page 29

15

How to mount the Option Board on the Inverter Section 2-3

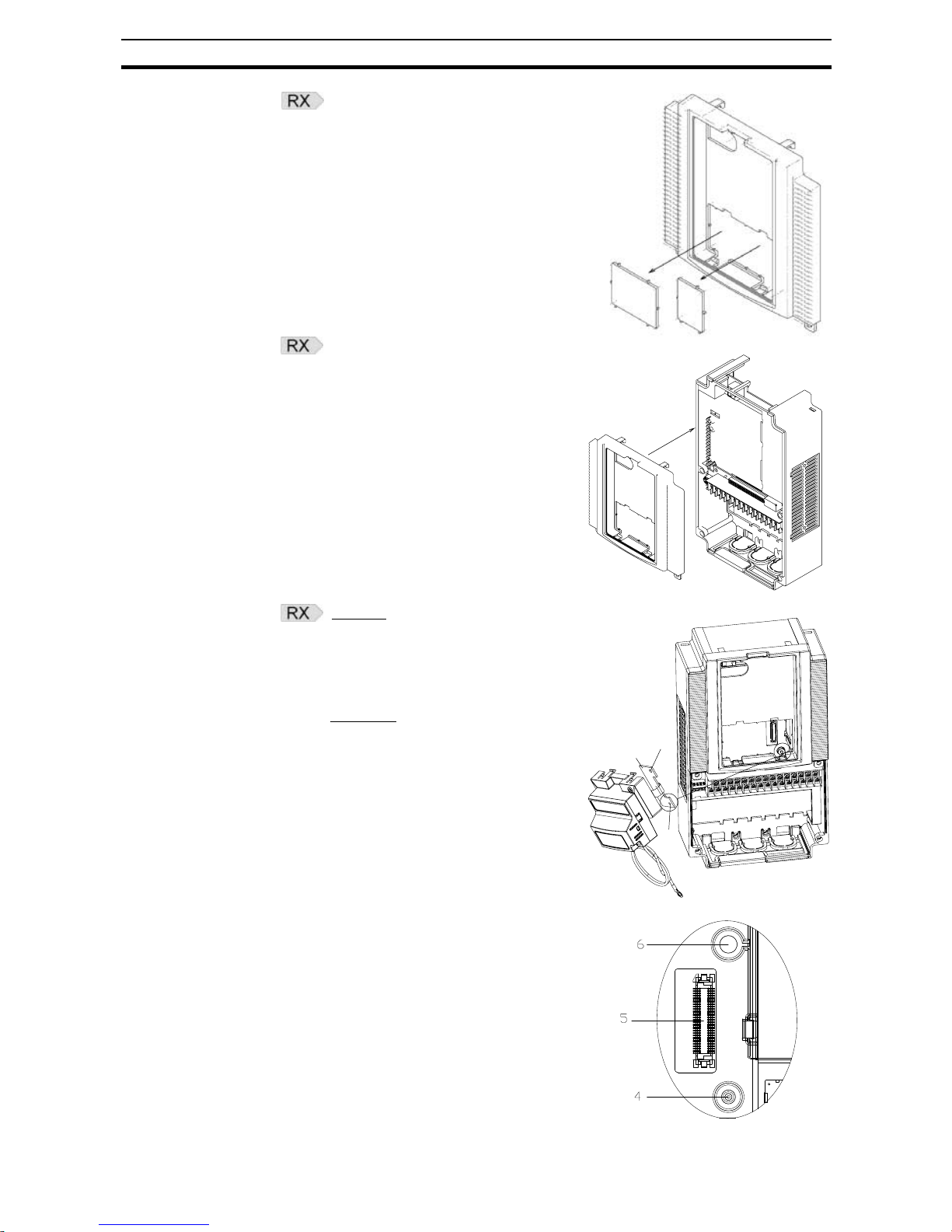

Step 2 Cut out the 2 plastic break-outs

from the Front Cover.

Make sure no sharp edges

remain.

Step 3 Remount the Front Cover and

tighten the screws

Step 4 Purpose

: mount the Inverter

Connector (no.1) of the Option Board

onto the interface connector (no.5) of

the RX Inverter.

How to do

:

First align the small hole of the

Inverter connector (no.2) with the

guide-post (no.4) in the Inverter.

Then align the larger hole on the

Inverter connector (no.3) with the

threaded hole (no.6) in the Inverter.

Push the Inverter connector into

place.

Page 30

16

How to mount the Option Board on the Inverter Section 2-3

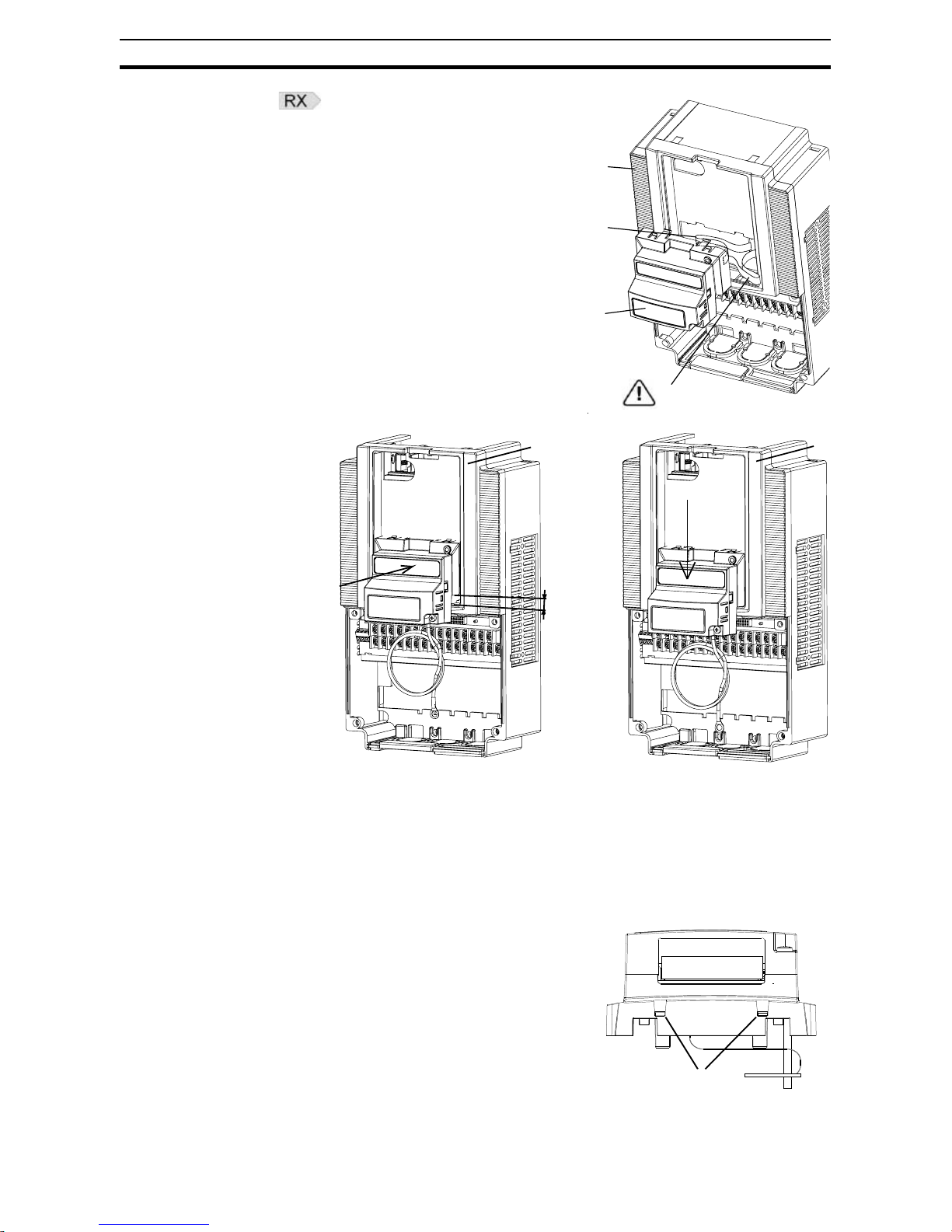

Step 5 Move the Option Board Cable (no.2)

to the left with your finger, so the

Option Board Cable is not pinched

between the Option Board and the

Inverter Front Cover.

Note Prevent a pinched Option Board

Cable, as shown in position A.

Note Do not pull on the Option Board

Cable.

Note Do not let the Option Board hang on

the Option Board Cable.

Insert the Option Board approximately 1 cm above the down-position into the

Front cover of the Inverter. See figure 1above.

Slide the Option Board down. See figure 2 above.

The snap-fits of the Option Board

(no.5) will be locked by the snap-fits

in the Front cover (no.4).

A

1

2

3

2

4

1

4

mc1±

3

Connector

Option Board bottom side

5

Page 31

17

How to mount the Option Board on the Inverter Section 2-3

Step 6 Press down carefully the two locking

pins (no. 1) of the Option Board.

Press carefully the top of the Option

Board in the Inverter.

Check the Option Board is being

locked by the locking pins (no.1).

Step 7 Insert the screw (no. 1) into the upper

right hole in the Option Board (no.2).

Tighten the screw into place (do not

over tighten).

Fix the Option Board grounding cable

to the chassis ground of the RXInverter under an already fixed chassis grounding bold.

See the bold with the grounding figure.

The position of the chassis ground

vary from inverter type. Illustrations

are only provided for one Inverter

size. The instructions however are

generic and may be followed for all

Inverter sizes.

1

2

G

Page 32

18

How to mount the Option Board on the Inverter Section 2-3

Step 8 Unscrew the mounting screws of the

Terminal cover nearly completely

from the plastic rings (no.1).

Remount the Terminal cover under

the Option Board onto the Inverter

(no.2).

Tighten the two screws (no.1).

Step 9 Connect the Digital Operator Display

via a 3G3AX CAJOP300-EE cable or

via a straight EtherNet cable with the

RJ45 connector in the Inverter.

Step 10 Define needed and desired parameters of the Inverter and set them according

SECTION 3 Configuring Drive Parameters and Option Board on page 23 and

also according SECTION 4 Operations and Monitoring on page 29.

Page 33

19

How to mount the Option Board on the Inverter Section 2-3

Step 11 If the desired parameters of the Inver-

ter have been set succesfully, disconnect the 3G3AX CAJOP300-EE cable

or straight EtherNet cable from the

Inverter.

Push the blind cover (no.1) into place.

Note Refer to section 2 in the RX User's Manual (Cat. No. I560) for operations

related to assembly and disassembly of the RX Inverter.

2-3-3 Installation Environment Clearance

Please adhere to the requirements of the Inverter for Installation Environment

clearance.

Please refer to the MX2 Inverter manual (Cat. No. I570) section 2-3-2.

Please refer to the RX Inverter manual (Cat. No. I560) section 2-1 Installation

Environment.

In addition to this, provide sufficient clearance to allow connection and

removal of the PROFIBUS Connector. No unnecessary strain should be

placed on the PROFIBUS cable or connector that could be transferred to the

Option Board.

2-3-4 PROFIBUS network connector

The PROFIBUS connector on the bottom of the Unit is a 9-pin female sub-D

connector, as recommended by IEC 61158. Fixtures have #4/40 UNC thread

for compatibility with PROFIBUS-DP connectors. No termination is provided

inside the Option Board.

The signals DGND and VP are used to power the bus terminator located in

the cable connector.

Note 1 The Option Board allows the use of PROFIBUS connectors with a straight

cable outlet.

1

Table 4 PROFIBUS connector pinout

Pin No. Signal Description

1 Shield Functional ground (do not connect)

2NC-

3 B-line Data signal

4 RTS Control signal for repeaters

(direction control)

5 DGND Signal ground

6 VP Termination power

7NC-

8 A-line Data signal

9NC-

9

5

1

6

Page 34

20

How to mount the Option Board on the Inverter Section 2-3

Note 2 The 9-pin sub-D connector uses #4/40 UNC thread for mechanical fixation of

the cable connector. Always use PROFIBUS connectors.

!Caution Do not use PROFIBUS connectors with a 90° cable outlet (Such connectors

place unnecessary strain on the Option Board connector).

2-3-5 Option Board Dimensions

c

d2

w

h1

h

d4

d3

d

d1

Table 5 Option Board Dimensions

Item Dimension Item Dimension Item Dimension

h 63.6 mm c 16.3 mm d2 31.3 mm

h1 57.9 mm d 52.6 mm d3 44.8 mm

w 67.6 mm

d1

1

1. Dimension d1 gives the increase in MX2@ Inverter dimension D when the Option Board is

fitted (Refer to section 2-3 of the Inverter user's manual).

26.4 mm d4 28.4 mm

3G3AX-PRT-MX2

RUN ERR BF COMM

Page 35

21

How to mount the Option Board on the Inverter Section 2-3

Table 6 Option Board Dimensions on the RX Inverter

Item Dimension Item Dimension Item Dimension

p 35.1 mm r 43.9 mm u 31.7 mm

q 79.8 mm s 66.5 mm v 32.7 mm

t 66.1 mm w 48.1 mm

Page 36

22

How to mount the Option Board on the Inverter Section 2-3

Page 37

23

Configuring the Option Board Section 3-1

SECTION 3

Configuring Drive Parameters and Option Board

3-1 Configuring the Option Board

All Option Board parameters are stored in the Inverter. This allows for easy

replacement of the Option Board without the need to re-configure. After connecting the Option Board to an Inverter for the first time however, proceed with

the following steps:

Step 1 The Option Board supports 3 device profiles. Each device profile supports a

subset of the modules listed in the GSD file. The device profile is selected

using Inverter parameter P182. Use the Inverter keypad to adjust P182 to

select the device profile and supported modules.

Step 2 It is recommended to set C102 = 3 to prevent the Inverter reset input and

Stop/reset button from interfering with Option Board during operation (Setting

C102 to another value causes the Option Board to reset when a trip condition

is cleared). Use the Inverter keypad to set C102 to 3.

Step 3 Inverter registers P180, P044, P045 and P181 configure the PROFIBUS net-

work-related parameters. Adjust these to configure the node address, CLEAR

mode behavior and required action when a Fieldbus failure occurs.

Table 7 Configuration of device profile

P182 Device Profile Supported Modules

0

(default)

PROFIdrive

[Appendix B]

PPO Type 1 (4 words PKW + 2 words PZD)

PPO Type 2 (4 words PKW + 6 words PZD)

PPO Type 3 (2 words PZD)

PPO Type 4 (6 words PZD)

PPO Type 5 (4 words PKW + 10 words PZD)

1 Conventional

[Appendix C]

Basic Data

Extended Data 1

Extended Data 2

2 Flexible

[Appendix D]

Flexible (10 words output and input)

Table 8 Configuration of Inverter Reset Mode Selection

Param Description Setting

C102 Reset mode selection Recommended to set to 3 (Reset mode selection

resets trip only, not Option Board)

Table 9 Configuration of PROFIBUS parameters

Param Description Setting

P180 PROFIBUS Node

Address

0 to 125, 0 (default) means node address 126

P044 Network Error Timer Time to wait after a network error occurs before

executing action in P045:

0 to 9999 in 0.1 s units

Page 38

24

Configuring the Option Board Section 3-1

Step 4 Registers A001 and A002 are used by the Inverter to adjust the frequency

source and control source. If the second motor parameter set is used, registers A201 and A202 also have to be set. Adjust these in accordance with the

following table:

Step 5 Registers P033, P036, C021, C022 and C028 are used by the Inverter to

adjust some Inverter function sources. If required (refer to usage examples),

adjust these in accordance with the following table:

Apply the source selection parameters according the following table for the

MX2 Option Board.

P045 Action on Network

Error

Set to 0 for inverter trip

Set to 1 for deceleration and trip

Set to 2 for no action

Set to 3 for stop due to free-run

Set to 4 for deceleration and stop

P181 Output Data Keep

Mode

Define behavior if PROFIBUS master indicates

CLEAR mode or if a network error occurs:

Set to 0 for clearing all output data (stop inverter)

Set to 1 for keeping output data (inverter continues

operating)

Table 9 Configuration of PROFIBUS parameters (continued)

Param Description Setting

Table 10 Configuration of Inverter source selection parameters

Param Description Setting

A001 Motor 1

Frequency Source

For option board as source:

Set to 3 if P182 equals 2

Set to 4 if P182 equals 0 or 1

Set to 5 if P182 equals 0 or 1

A201 Motor 2

Frequency Source

A002 Motor 1 Run

Command Source

A202 Motor 2 Run

Command Source

Table 11 Configuration of Source selection MX2 parameters

Param Description Setting

P033 Torque Command

Source

For Option Board as source:

Set to 6 (Use Option Board register) if P182

equals 1

Set to 3 (Use P034) if P182 equals 0 or 2

P036 Torque Bias Mode For Option Board as source:

Set to 5 (Bias set by Option Board) if P182

equals 1

Set to 0 (Bias according to sign) or 1 (Bias according to rotation direction) if P182 equals 0 or 2

C021 Output Terminal 11

Source

Set to 63 for Option Board as source

C022 Output Terminal 12

Source

Set to 63 for Option Board as source

C026 Alarm Relay Output

Terminal Source

Set to 63 for Option Board as source (Optional)

C028 Analog Output AM

Source

Set to 16 for Option Board as source

Page 39

25

Configuring the Option Board Section 3-1

Apply the source selection parameters according the following table for the

RX Option Board.

Step 6 The PPO modules and Flexible module give you the freedom to select/cus-

tomise the Inverter Modbus registers for Cyclic Data Exchange. Inverter registers P160 - P179 are used to configure and map the exchanged Modbus

registers. If required, adjust these registers to change the default content of

the exchanged data. Please refer to Appendices B-1 I/O Mapping on page 76

and Flexible I/O Mapping on page 83 for more details.

Param Description Setting

P033 Torque Command

Source

For Option Board as source:

Set to 7 (Use Option Board register) if P182

equals 1

Set to 3 (Use P034) if P182 equals 0 or 2

P036 Torque Bias Mode For Option Board as source:

Set to 6 (Bias set by Option Board) if P182

equals 1

Set to 0 (Bias according to sign) or 1 (Bias according to rotation direction) if P182 equals 0 or 2

C021 Output Terminal 11

Source

Set to 63 for Option Board as source

C022 Output Terminal 12

Source

Set to 63 for Option Board as source

C026 Alarm Relay Output

Terminal Source

Set to 63 for Option Board as source (Optional)

C028 Analog Output AM

Source

Set to 20 for Option Board as source

Table 12 Configuration of input and output content

Param Description Setting

P160 Output Register 1

contents

Modbus register mapped into PZD1 or flexible output word 1

P161 Output Register 2

contents

Modbus register mapped into PZD2 or flexible output word 2

P162 Output Register 3

contents

Modbus register mapped into PZD3 or flexible output word 3

P163 Output Register 4

contents

Modbus register mapped into PZD4 or flexible output word 4

P164 Output Register 5

contents

Modbus register mapped into PZD5 or flexible output word 5

P165 Output Register 6

contents

Modbus register mapped into PZD6 or flexible output word 6

P166 Output Register 7

contents

Modbus register mapped into PZD7 or flexible output word 7

P167 Output Register 8

contents

Modbus register mapped into PZD8 or flexible output word 8

P168 Output Register 9

contents

Modbus register mapped into PZD9 or flexible output word 9

P169 Output Register 10

contents

Modbus register mapped into PZD10 or flexible

output word 10

P170 Input Register 1 con-

tents

Modbus register mapped into PZD1 or flexible

input word 1

P171 Input Register 2 con-

tents

Modbus register mapped into PZD2 or flexible

input word 2

P172 Input Register 3 con-

tents

Modbus register mapped into PZD3 or flexible

input word 3

P173 Input Register 4 con-

tents

Modbus register mapped into PZD4 or flexible

input word 4

Page 40

26

Configuring the Network Section 3-2

Step 7 Restart the Inverter for the changes to take effect.

Note When restarting the Inverter, wait for the Inverter power indicator to go out

before switching on again.

!Caution Action on Network Error (P045) is disabled when P181 is set to 1 (Keep the

output data upon a network failure) I.e. when a network error occurs, the

Inverter will continue normal operation with the last received output data.

!Caution Check the network related Inverter settings regarding PROFIBUS node

address and PROFIBUS map selection. Not doing so may result in unexpected operation.

Tip Alternatively, P180 in Step 3 may be performed using the set-slave address

functionality of your PROFIBUS master or diagnostic tool.

Tip Alternatively, Step 2 up to Step 6 may be performed using OMRON CX-Drive.

Tip Alternatively, Step 7 may be performed by resetting the Option Board using

PNU972 (Refer to APPENDIX F Option Board Parameters).

3-2 Configuring the Network

Step 1 Download the GSD file named OC_0C6A for the Option Board via the Omron

website http://industrial.omron.eu.

Download the GSD file named OC_0D2B for the Option Board via the Omron

website http://industrial.omron.eu.

Step 2 Install / add this GSD file to the PROFIBUS master configuration program

used to configure your PROFIBUS master.

(It may be necessary to update the device catalogue before proceeding)

Step 3 Add your PROFIBUS master to the network in the configuration program.

Step 4 Add an Option Board to the network in the configuration program and open

the Option Board's settings.

Step 5 Set the Option Board's node address (also referred to as station address) to

match P180 in the Inverter.

Step 6 Choose a module that is supported by the selected device profile (Inverter

parameter P182).

P174 Input Register 5 con-

tents

Modbus register mapped into PZD5 or flexible

input word 5

P175 Input Register 6 con-

tents

Modbus register mapped into PZD6 or flexible

input word 6

P176 Input Register 7 con-

tents

Modbus register mapped into PZD7 or flexible

input word 7

P177 Input Register 8 con-

tents

Modbus register mapped into PZD8 or flexible

input word 8

P178 Input Register 9 con-

tents

Modbus register mapped into PZD9 or flexible

input word 9

P179 Input Register 10

contents

Modbus register mapped into PZD10 or flexible

input word 10

Table 12 Configuration of input and output content (continued)

Param Description Setting

Page 41

27

Configuring the Network Section 3-2

Step 7 Uncheck the Enable DPV1 option on the DPV1 tab before proceeding to Step

7 if you are using OMRON CX-Configurator.

Step 8 Save and download the configuration to your PROFIBUS master.

Step 9 Once the network is re-started with the new settings, check that the Option

Board LED indicators indicate proper operation: If everything is correctly configured, only the RUN and COMM indicators will be ON (green). Please refer

to section 5-1 Troubleshooting using the LED indicators on page 57 to trouble-

shooting any configuration errors if the LED indicators are displaying a different pattern.

Note Nothing prevents you from selecting an unsupported module in Step 6. If you

are uncertain, check the value of P182 before selecting the module.

Tip Refer to SECTION 5 Troubleshooting and Maintenance on page 57 in case of

errors.

Table 13 Configuration of module support

P182 Device Profile Supported Modules

0

(default)

PROFIdrive

[Appendix B]

PPO Type 1 (4 words PKW + 2 words PZD)

PPO Type 2 (4 words PKW + 6 words PZD)

PPO Type 3 (2 words PZD)

PPO Type 4 (6 words PZD)

PPO Type 5 (4 words PKW + 10 words PZD)

1 Conventional

[Appendix C]

Basic Data

Extended Data 1

Extended Data 2

2 Flexible

[Appendix D]

Flexible (10 words output and input)

Page 42

28

Configuring the Network Section 3-2

Page 43

29

Section

SECTION 4

Operations and Monitoring

This section provides some common usage examples to help you get started.

Unless otherwise specified, all usage examples make use of the PROFIdrive

device profile and associated modules (Refer to section 3-1 Configuring the

Option Board, Step 1). Prepare the Inverter and Option Board before starting

with the usage examples:

Step 1 Initialize the Inverter mode to Induction Motor, Constant Torque:

Set b171 = 1 and then b180 = 1, set b049 = 0.

Refer to MX2 User’s manual (Cat. No. I570) section 3-6-24.

Set b084 = 2 and then b180 = 1, set b049 = 0.

Refer to RX User’s manual (Cat. No. I560) section 4-2 Parameter Initialization).

Step 2 Configure the Option Board and Network as explained in sections 3-1 Config-

uring the Option Board and 3-2 Configuring the Network, but limit the follow-

ing choices:

• When selecting the device profile when configuring the Option Board

(Step 1 of section 3-1 Configuring the Option Board), select the PROFId-

rive device profile by setting P182 to 0.

• When configuring the process area content (of section 3-1 Configuring

the Option Board), set all parameters (P160 - P179 to 0).

• When choosing the module while configuring the network (Step 6 of section 3-2 Configuring the Network), select either the PPO Type 2 or PPO

Type 5 module.

If you configured everything correctly, your output and input process areas

should contain the following data:

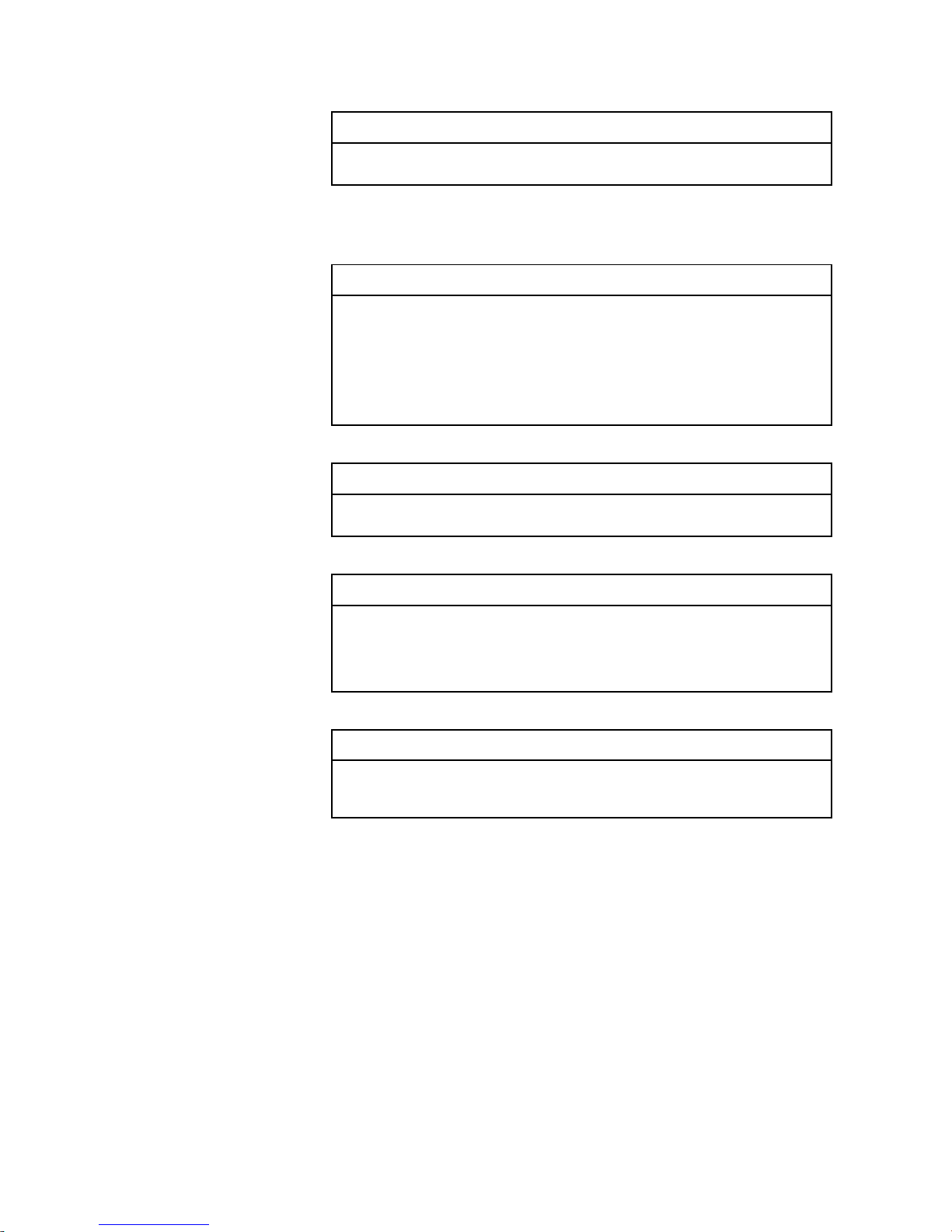

Table 14 Output Process Area

!WARNING A revision AAAA Inverter allows the motor to run immediately if a trip condition

is reset, and at the same time, Run (STW) is set. For safe operation clear Run

(STW) when you detect a rising-edge on Flt (ZSW). Refer to section 1-1-2

Inverter Support to determine the Inverter revision.

dec

hex

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

-----Ov

r

JR JF Rst - - Run En---

0000000000000000

En

Run Run operation

Run enable

JF Jog run forward

Rst Fault reset

PKE

IND

Task ID and parameter number

Parameter index

Ovr Control override

JR Jog run reverse

HSW

PWE

STW

Parameter value

Control word

Frequency reference

Value

-

+4

---

+9

STW HSW

+8

INDRegister

Word offset +1+0

PKE

000

PWE

0

+6 +7+2 +3 +5

0

0000000000000000000000000000

0

Value

0

00000000

Name

0

Bit

0

0000

Page 44

30

Source Selection Section 4-1

Table 15 Input Process Area

Note 1 Depending on your source selection, CS may already be 1 on your setup.

Note 2 For compatibility, some unsupported bits in ZSW are always 1.

!Caution Check the Inverter settings for proper Inverter behavior before actually oper-

ating the Inverter remotely via the PROFIBUS network.

!Caution The product will be used to control an adjustable speed drive connected to

high voltage sources and rotating machinery that is inherently dangerous if

not operated safely. Interlock all energy sources, hazardous locations, and

guards in order to restrict the exposure of personnel to hazards. The adjustable speed drive may start the motor without warning.

Signs on the equipment installation must be posted to this effect. A familiarity

with auto-restart settings is a requirement when controlling adjustable speed

drives. Failure of external or ancillary components may cause intermittent

system operation, i.e., the system may start the motor without warning or may

not stop on command. Improperly designed or improperly installed system

interlocks and permissives may render a motor unable to start or stop on command.

4-1 Source Selection

First select the appropriate control and frequency sources, before operating

the Inverter. We will be using the 1

st

motor:

Step 1 Set A001=4 and A002=4 so that the Inverter is controlled by the default PRO-

FIdrive control and frequency references registers.

Set A001=5 and A002=5 so that the Inverter is controlled by the default PROFIdrive control and frequency references registers.

Note The control override bit in the PROFIdrive control word (Section B-2 Control

and Status Words - STW/ZSW) can be used to override A001, A201, A002

and A202. When this bit is set, it has the same effect as temporarily setting

A001, A201, A002 and A202=4. Clearing this bit removes the override, and

the Inverter sources are once again determined by these registers.

If you are using a version AAAA Inverter, the control override bit is always disabled if A002 = 2.

Page 45

31

Operating the Motor Section 4-2

4-2 Operating the Motor

4-2-1 Starting the Motor

Step 1 Set the En bit to enable controlled acceleration and deceleration of the motor.

Step 2 Set the Run bit to put the Inverter in run mode. The RUN indicator on the

Inverter should light up at this point. If this is not the case, check your source

selection (Section 4-1 Source Selection).

Step 3 Set HIW=1000 (10.00 Hz forward).

Table 16 Output Process Area with Motor Started

The motor accelerates until it reaches the desired frequency. Notice that the

FA bit is set once the inverter has reached the desired reference frequency.

Table 17 Input Process Area with Reference Frequency Reached

4-2-2 Changing Direction

Step 4 Set HIW=-1000 (10.00 Hz reverse).

Table 18 Output Process Area with Motor Set to Run Reverse

The motor decelerates, stops and then accelerates in the opposite direction.

The FA bit clears as soon as the reference frequency is changed. Once the

new reference frequency is reached, the FA bit is once again set.

Table 19 Input Process Area with Reverse Frequency Reached

Page 46

32

Operating the Motor Section 4-2

4-2-3 Stopping the Motor - Controlled

Step 5 Clear the Run bit to bring the motor to a controlled stop.

Table 20 Output Process Area for Controlled Stop

The motor decelerates, and comes to a stop. The FA bit clears as soon as the

Run bit is cleared.

Table 21 Input Process Area after Controlled Stop

Before continuing set HSW to 0.

Note The motor can also be brought to a stop by setting HSW to 0 and leaving the

Run bit set. The Inverter will however stay in run mode once the motor has

stopped.

4-2-4 Stopping the Motor - Free-running

An alternative to Step 5 is to clear the En bit to request a free-run stop: The

Inverter stops controlling the motor, and the motor coasts to a stop. During a

free-run stop, you will notice that HIW immediately drops to 0 and the FA bit is

cleared.

4-2-5 Jog Operation

Step 6 Set the JF bit to start the jog operation.

Table 22 Output Process Area with Motor Jogging Forward

The motor immediately starts rotating forward at the pre-set jog frequency.

The Inverter jog frequency can be set by adjusting Inverter parameter A038.

When jogging, the Inverter immediately jumps to the jog frequency. No controlled acceleration is performed and the FA bit is immediately set.

Page 47

33

Customising the Process Area Section 4-3

Table 23 Input Process Area with Motor Jogging Forward

Note 1 To jog the motor in reverse, set the JR bit.

4-2-6 Frequency Reference and Output Frequency Scaling

HSW and HIW are signed word registers. Using normal scaling, you will

therefore not be able to set HSW higher than 327.67 Hz (327.68 Hz in

reverse).

The MX2 Inverter can however be set to operate in HF mode. Refer to the

MX2 User Manual section 3-6-24 for instructions on how to achieve this.

Doing this changes the scaling of HSW and HIW to 0.1 Hz. At 0.1 Hz scaling

you will be able to reach the full frequency range of the inverter by adjusting

HSW.

4-3 Customising the Process Area

The PROFIdrive device profile also gives you the capability to customise the

process area by mapping your choice of Modbus registers. Normally, P160,

P161, P170 and P171 are set to 0 so that STW, HSW, ZSW and HIW are

exchanged. The remaining parameters (P162 - P169 and P172 - P179) are

normally used to map additional Modbus registers into the cyclically

exchanged process areas. User parameters P160 - P169 configure the output

process area mappings where parameters P170 - P179 configure the input

process area mappings.

4-3-1 Double-word Frequency Reference and Output Frequency