Cat. No. I563-E1-01

USER’S MANUAL

3G3AX-RBU

Regenerative Braking Unit

Introduction

Thank you for choosing the Regenerative Braking Unit 3G3AX-RBU. This User's Manual

(hereinafter called “this manual”) describes the installation/wiring of the 3G3AX-RBU model, as well

as troubleshooting and inspection methods.

zThis manual should be delivered to the actual end user of the product.

zAfter reading this manual, keep it handy for future reference.

zThis manual describes the specifications and functions of the product as well as the relations

between them. You should assume that anything not described in this manual is not possible with

the product.

zIntended readers

This manual is intended for:

Those with knowledge of electrical systems (qualified electrical engineers or the equivalent), and

also in charge of:

• Introducing the control equipment

• Designing the control system

• Installing and/or connecting the control equipment

• Field management

Introduction

1

Read and Understand This Manual

Read and Understand This Manual

Please read and understand this manual before using the product. Please consult your OMRON representative

if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on

which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

2

Read and Understand This Manual

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

the combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions

or uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

3

Read and Understand This Manual

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be

changed without any notice. When in doubt, special model numbers may be assigned to fix or establish

key specifications for your application on your request. Please consult with your OMRON representative

at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and

does not constitute a warranty. It may represent the result of OMRON's test conditions, and the users

must correlate it to actual application requirements. Actual performance is subject to the OMRON

Warranty and Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

4

Safety Precautions

Safety Precautions

Indications and Meanings of Safety Information

In this user’s manual, the following precautions and signal words are used to provide information to ensure the

safe use of the Regenerative Braking Unit 3G3AX-RBU.

The information provided here is vital to safety. Strictly observe the precautions provided.

Meanings of Signal Words

Indicates an imminently hazardous situation which, if not

WARNING

CAUTION

avoided, is likely to result in serious injury or may result in death.

Additionally there may be severe property damage.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury, or in property damage.

Alert Symbols in This Document

Turn off the power supply and implement wiring correctly.

Not doing so may result in a serious injury due to an electric shock.

Wiring work must be carried out only by qualified personnel.

Not doing so may result in a serious injury due to an electric shock.

Be sure to ground the unit.

Not doing so may result in a serious injury due to an electric shock or fire.

Do not remove the front cover during the power supply and 10 minutes after the power shutoff.

Doing so may result in a serious injury due to an electric shock.

Do not operate the switches with wet hands.

Doing so may result in a serious injury due to an electric shock.

Do not touch the inside of the Regenerative Braking Unit or terminals, and do not check a signal,

wire, put on or take off the connectors while the power is being supplied. Doing so may result in a

serious injury due to an electric shock or fire.

WARNING

Do not remove the front cover during the power supply. Doing so may result in a serious injury due

to an electric shock. Be sure to put on the front cover before turning on the input power.

Turn off the input power of the Inverter and wait for more than 10 minutes before changing wiring or

operating the DIP switch. Not doing so may result in a serious injury due to an electric shock.

5

Safety Precautions

Place covers on the openings or take other precautions to make sure that no metal objects such as

cutting bits or lead wire scraps go inside when installing and wiring.

Install a stop motion device to ensure safety. Not doing so might result in a minor injury.

Be sure to use a specified type of Braking Resistor/Regenerative Braking Unit. In case of a Braking

Resistor, install a thermal relay that monitors the temperature of the Resistor.

Not doing so might result in a moderate burn due to the heat generated in the Braking Resistor/

Regenerative Braking Unit.

Configure a sequence that enables the Inverter power to turn off when unusual overheating is

detected in the Braking Resistor/Regenerative Braking Unit.

Do not connect Resistors to the DC terminals (P, N) directly. Doing so might result in a small-scale

fire, heat generation or damage to the unit.

CAUTION

Do not touch the fins, Braking Resistors, which become too hot during the power supply and for

some time after the power shutoff. Doing so may result in a burn.

The models of 3G3AX-RBU23/-RBU24/-RBU42/-RBU43 do not have terminals for the alarm input

(R1, R2). Configure a sequence that enables the Inverter power to turn off when unusual overheating

is detected.

The 3G3AX-RBC Braking Resistor does not have a built-in thermal fuse. Be sure to use the alarm

contact terminals (AL1, AL2) of the Resistor and configure a sequence that enables the Inverter

power to turn off when unusual overheating is detected. Not doing so might result in a small-scale

fire, heat generation or damage to the unit.

Do not dismantle, repair or modify the product. Doing so may result in an injury.

6

Installation and Wiring

Turn off the power supply and implement wiring correctly.

Not doing so may result in a serious injury due to an electric shock.

Wiring work must be carried out only by qualified personnel.

Not doing so may result in a serious injury due to an electric shock.

Be sure to ground the unit.

Not doing so may result in a serious injury due to an electric shock or fire.

Safety Precautions

WARNING

CAUTION

Place covers on the openings or take other precautions to make sure that no metal objects such as

cutting bits or lead wire scraps go inside when installing and wiring.

Install a stop motion device to ensure safety. Not doing so might result in a minor injury.

Be sure to use a specified type of Braking Resistor/Regenerative Braking Unit. In case of a Braking

Resistor, install a thermal relay that monitors the temperature of the Resistor.

Not doing so might result in a moderate burn due to the heat generated in the Braking Resistor/

Regenerative Braking Unit.

Configure a sequence that enables the Inverter power to turn off when unusual overheating is

detected in the Braking Resistor/Regenerative Braking Unit.

Do not connect Resistors to the DC terminals (P, N) directly. Doing so might result in a small-scale

fire, heat generation or damage to the unit.

7

Safety Precautions

Operation

Do not remove the front cover during the power supply and 10 minutes after the power shutoff.

Doing so may result in a serious injury due to an electric shock.

Do not operate the switches with wet hands.

Doing so may result in a serious injury due to an electric shock.

Do not touch the inside of the Regenerative Braking Unit or terminals, and do not check a signal,

wire, put on or take off the connectors while the power is being supplied. Doing so may result in a

serious injury due to an electric shock or fire.

WARNING

CAUTION

Do not touch the fins, Braking Resistors, which become too hot during the power supply and for

some time after the power shutoff. Doing so may result in a burn.

The models of 3G3AX-RBU23/-RBU24/-RBU42/-RBU43 do not have terminals for the alarm input

(R1, R2). Configure a sequence that enables the Inverter power to turn off when unusual overheating

is detected.

The 3G3AX-RBC Braking Resistor does not have a built-in thermal fuse. Be sure to use the alarm

contact terminals (AL1, AL2) of the Resistor and configure a sequence that enables the Inverter

power to turn off when unusual overheating is detected. Not doing so might result in a small-scale

fire, heat generation or damage to the unit.

8

Maintenance and Inspection

Do not remove the front cover during the power supply. Doing so may result in a serious injury due

to an electric shock. Be sure to put on the front cover before turning on the input power.

Turn off the input power of the Inverter and wait for more than 10 minutes before changing wiring or

operating the DIP switch. Not doing so may result in a serious injury due to an electric shock.

Do not touch the fins, Braking Resistors, which become too hot during the power supply and for

some time after the power shutoff. Doing so may result in a burn.

Safety Precautions

WARNING

CAUTION

Do not dismantle, repair or modify the product. Doing so may result in an injury.

9

Precautions for Safe Use

Precautions for Safe Use

Installation and Storage

Do not store or use the product in the following places.

• Locations subject to direct sunlight.

• Locations subject to ambient temperature exceeding the specifications.

• Locations subject to relative humidity exceeding the specifications.

• Locations subject to condensation due to severe temperature fluctuations.

• Locations subject to corrosive or flammable gases.

• Locations subject to exposure to combustibles.

• Locations subject to dust (especially iron dust) or salt.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

Transportation, Installation, and Wiring

Observe the following instructions during transportation, installation, and wiring.

• Do not drop or apply a strong impact on the product. Doing so may result in damaged parts or

malfunction.

• Do not hold by the front cover, but hold by the fins during transportation.

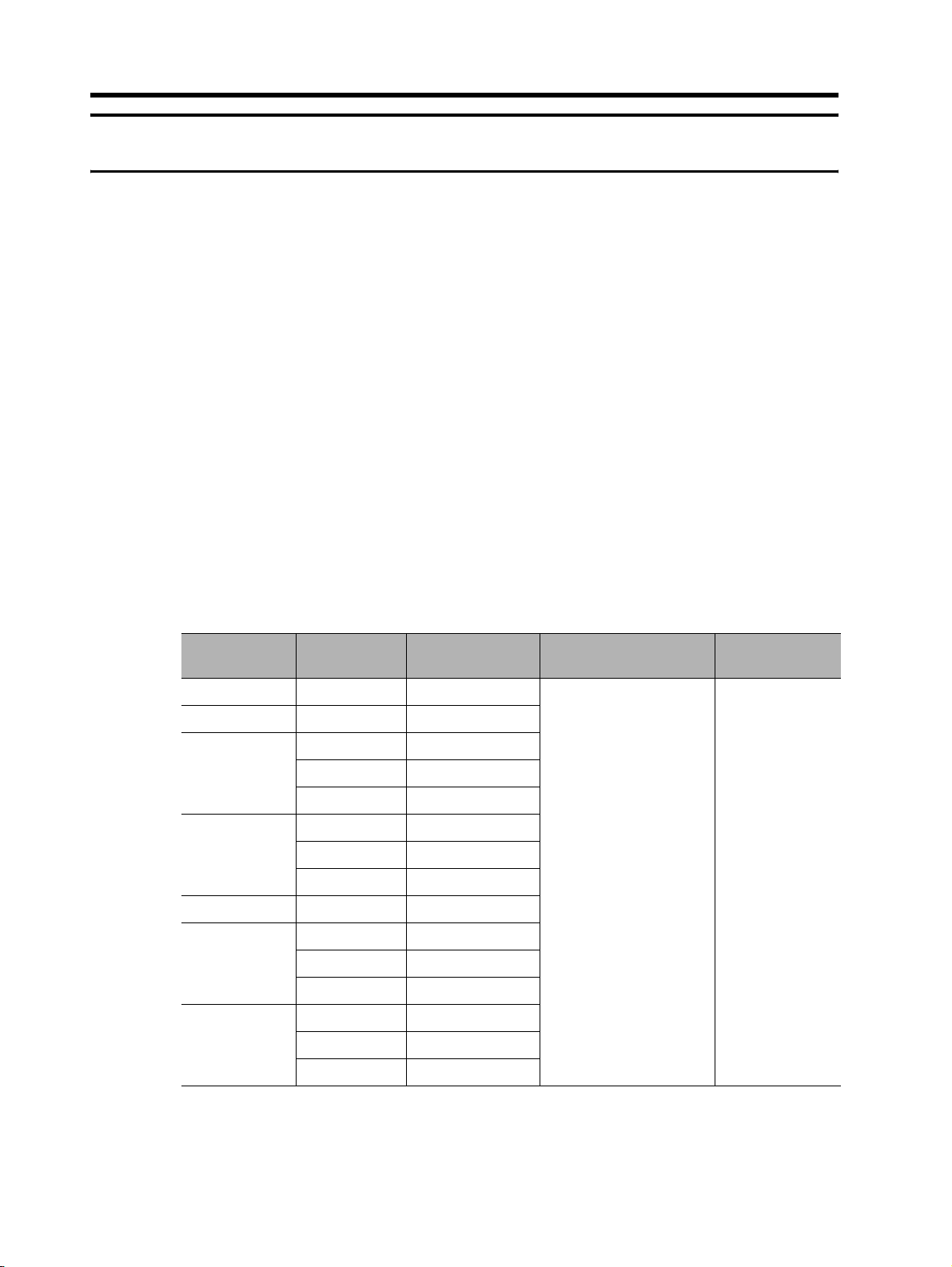

• The specified wire size or larger one must be used for the power lines.

Model

(3G3AX-)

RBU21 17 Ω min. 3.5 mm2 min.

RBU22 17 Ω min. 3.5mm

RBU23

RBU24

RBU41 34 Ω min. 3.5 mm

RBU42

RBU43

Connectable

resistance

8 Ω min. 5.5 mm

5 to 7.9 Ω 8 mm

4 to 4.9 Ω 14 mm

4 Ω min. 14 mm

3 to 3.9 Ω 22 mm

2 to 2.9 Ω 38 mm

17 Ω min. 3.5 mm

13 to 16.9 Ω 5.5 mm

10 to 12.9 Ω 8 mm

10 Ω min. 8 mm

7.5 to 9.9 Ω 14 mm

6 to 7.4 Ω 22 mm

P, RB, N

connection wires

2

min.

2

min.

2

min.

2

min.

2

min.

2

min.

2

min.

2

min.

2

min.

2

min.

2

min.

2

min.

2

min.

2

min.

SL1, SL2, MA1, MA2

connection wires

2

0.75 mm

min. 5.5 mm2 min.

Ground wire

10

Note 1. For wires connecting to the P, RB and N terminals use an MLFC wire (flame retardant

Polyflex wire, dielectric strength of 600 V).

Note 2. If the wiring length between the Regenerative Braking Unit and Braking Resistor exceeds

10 m, use the wire size larger than the specified one.

A wire of more than 10 m to 25 m : One rank higher wire size

A wire of more than 25 m to 50 m : Two ranks higher wire size

For the 3G3AX-RBU42 model, keep the wiring length between the Regenerative Braking

Unit and Braking Resistor within 5 m.

Maintenance and Inspection

Be sure to confirm safety before conducting maintenance, inspection or parts replacement.

Precautions for Safe Use

11

Precautions for Correct Use

Precautions for Correct Use

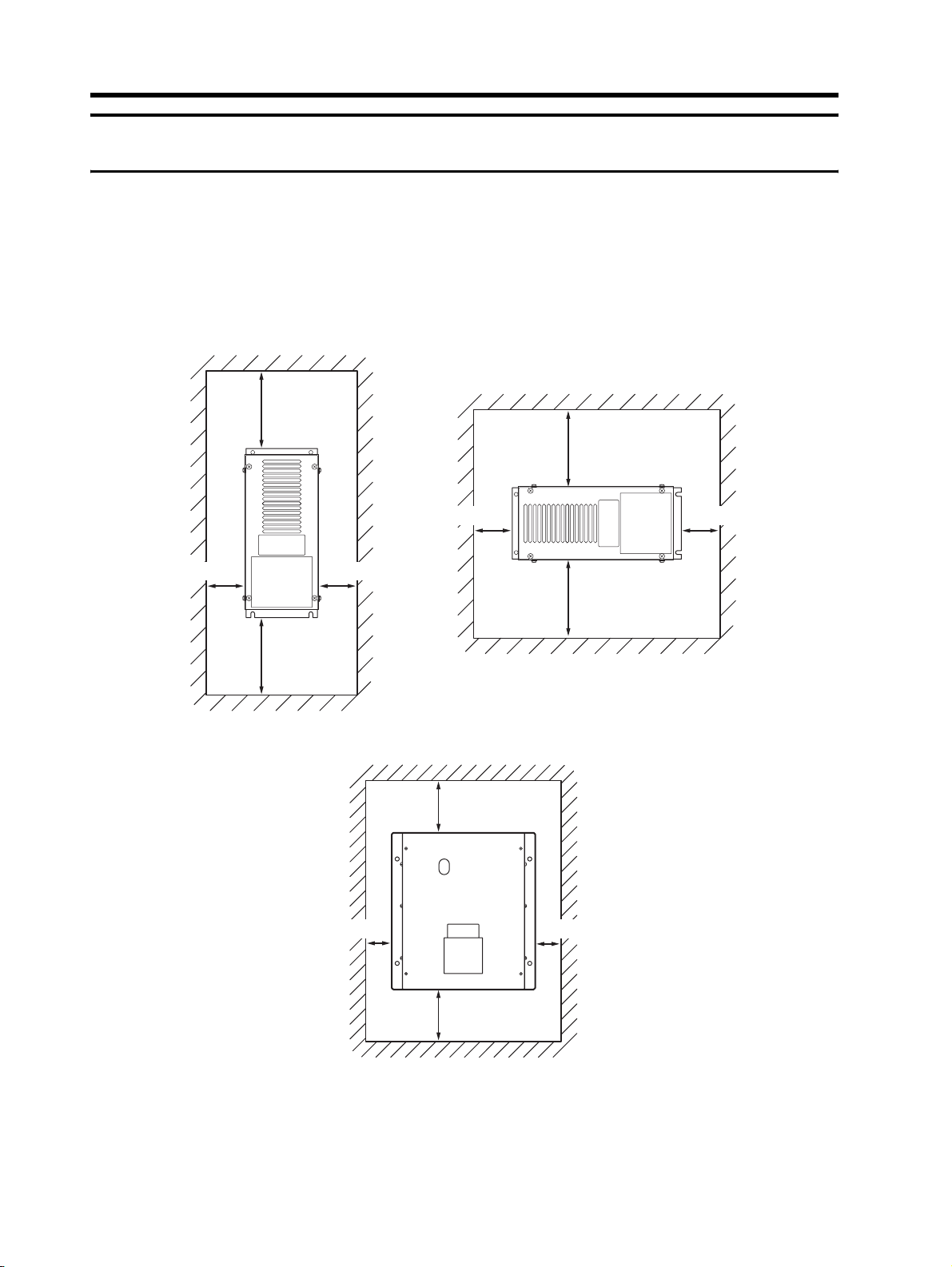

Installation

Mount the product on the vertical wall.

The material of the wall has to be nonflammable such as a metal plate, and do not place flammable

materials nearby.

3G3AX-RBU21/RBU22/RBU41/RBU42

10 cm min.

10 cm min.

5 cm min.5 cm min.

10 cm min.

3G3AX-RBU23/RBU24/RBU43

5 cm min.5 cm min.

10 cm min.

10 cm min.

5 cm min.5 cm min.

Note. The product cannot be mounted horizontally, but vertically only.

Rated Voltage

Confirm that the rated voltage of the product is the same as that of the Inverter to be used.

12

10 cm min.

Product Disposal

Comply with the local ordinance and regulations when disposing of the product.

Warning Labels

Warning labels are located on the product as shown in the following illustration.

Be sure to follow the instructions.

Precautions for Correct Use

Warning Description

13

Checking Before Unpacking

Checking Before Unpacking

Checking the Product

On delivery, be sure to check that the delivered product is the Regenerative Braking Unit

3G3AX-RBU model that you ordered.

Should you find any problems with the product, immediately contact your nearest local sales

representative or OMRON sales office.

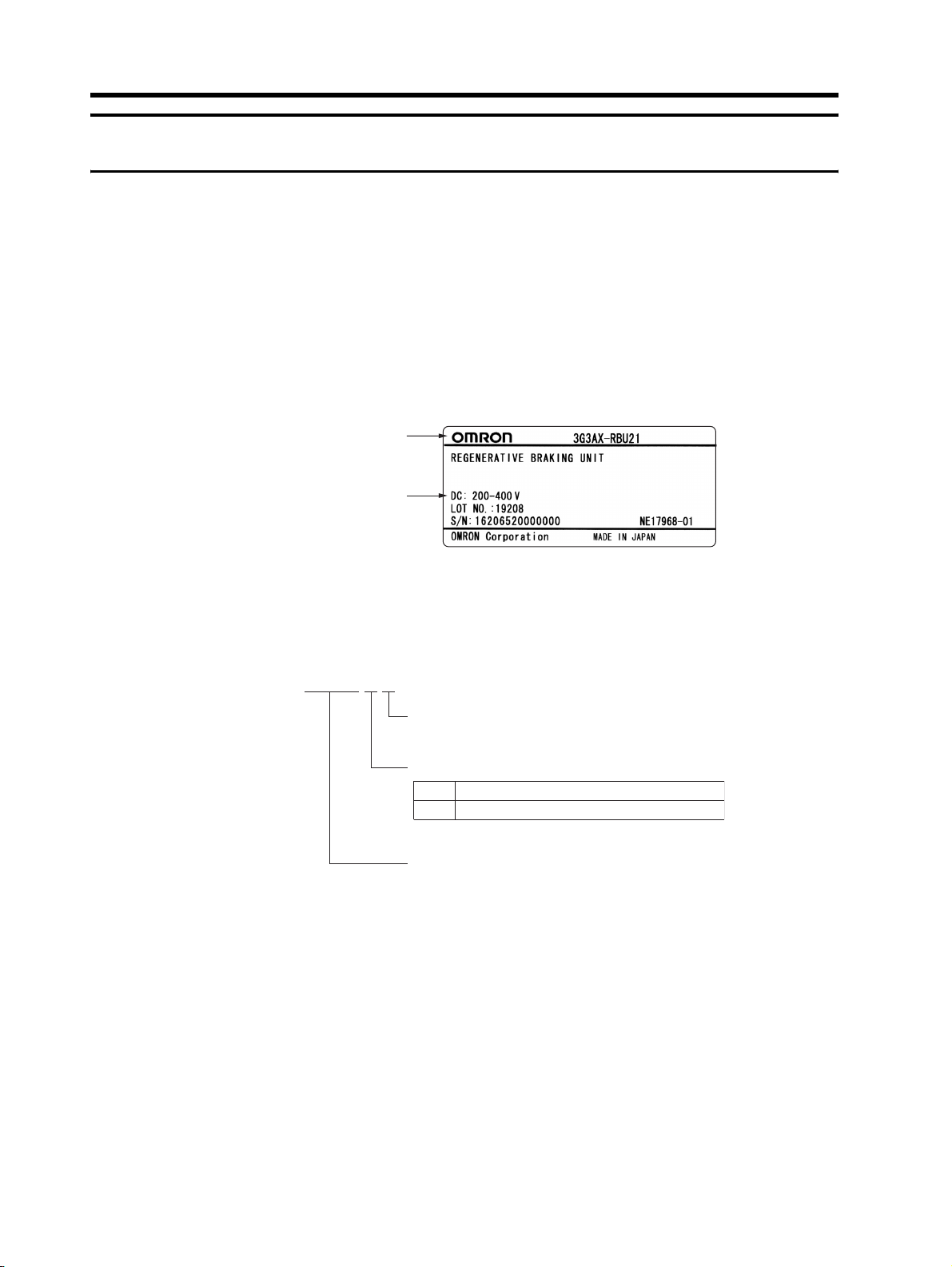

Checking the Nameplate

Regenerative Braking Unit

model name

Voltage specifications

Checking the Model

3G3AX− RBU21

Checking the Accessories

Note that this manual is the only accessory included with the Regenerative Braking Unit

3G3AX-RBU model.

Mounting screws and other necessary parts must be provided by the user.

Serial number

Maximum applicable motor capacity

24200-V class

400-V class

Regenerative Braking Unit

14

Revision History

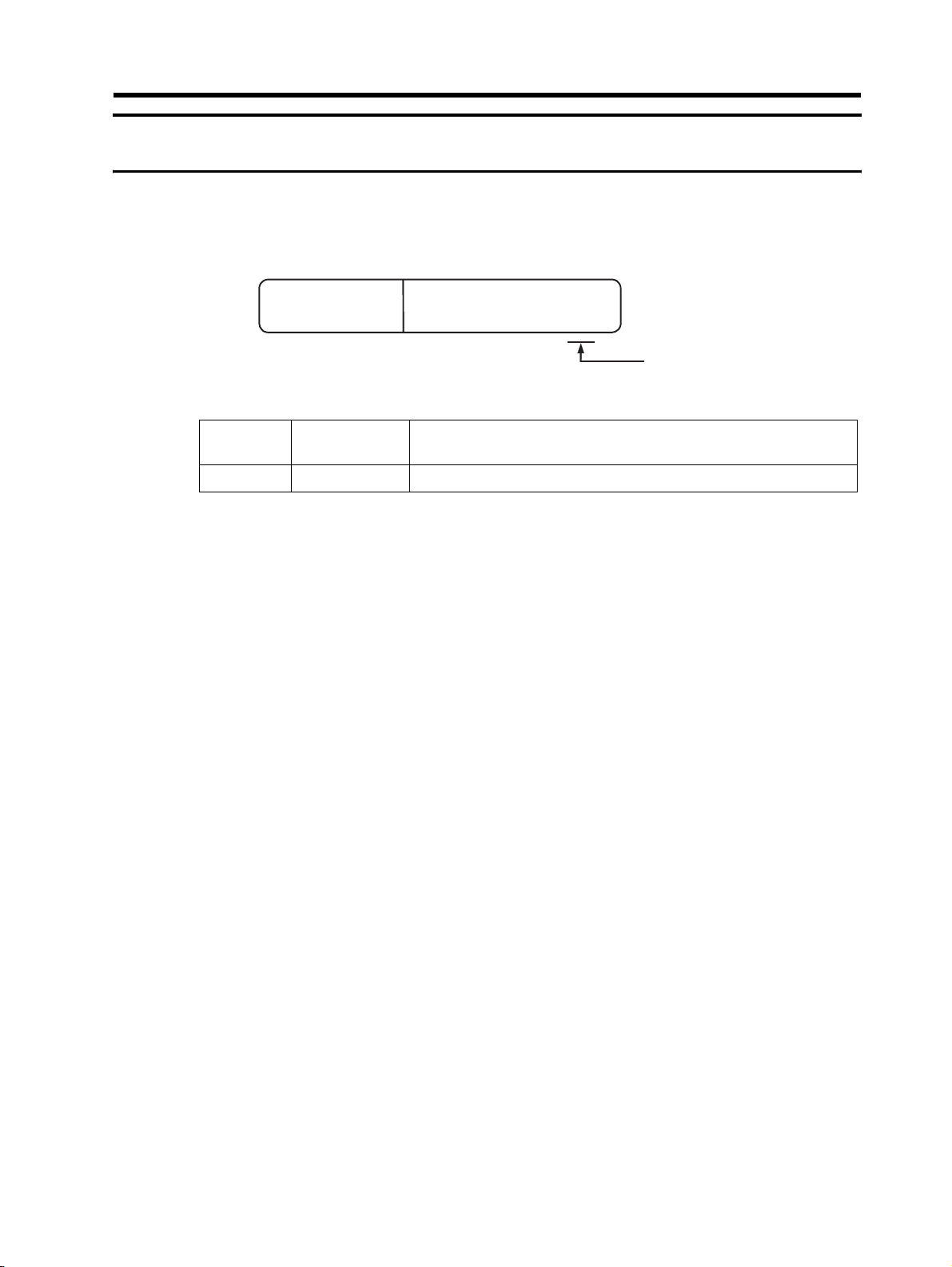

e

A manual revision code appears as a suffix to the catalog number located at the lower left of the

front and back covers.

Revision History

Cat.No.

Revision

code

01 April 2008 First printing

Revision date Changes and revision pages

I563-E1-01

Revision cod

15

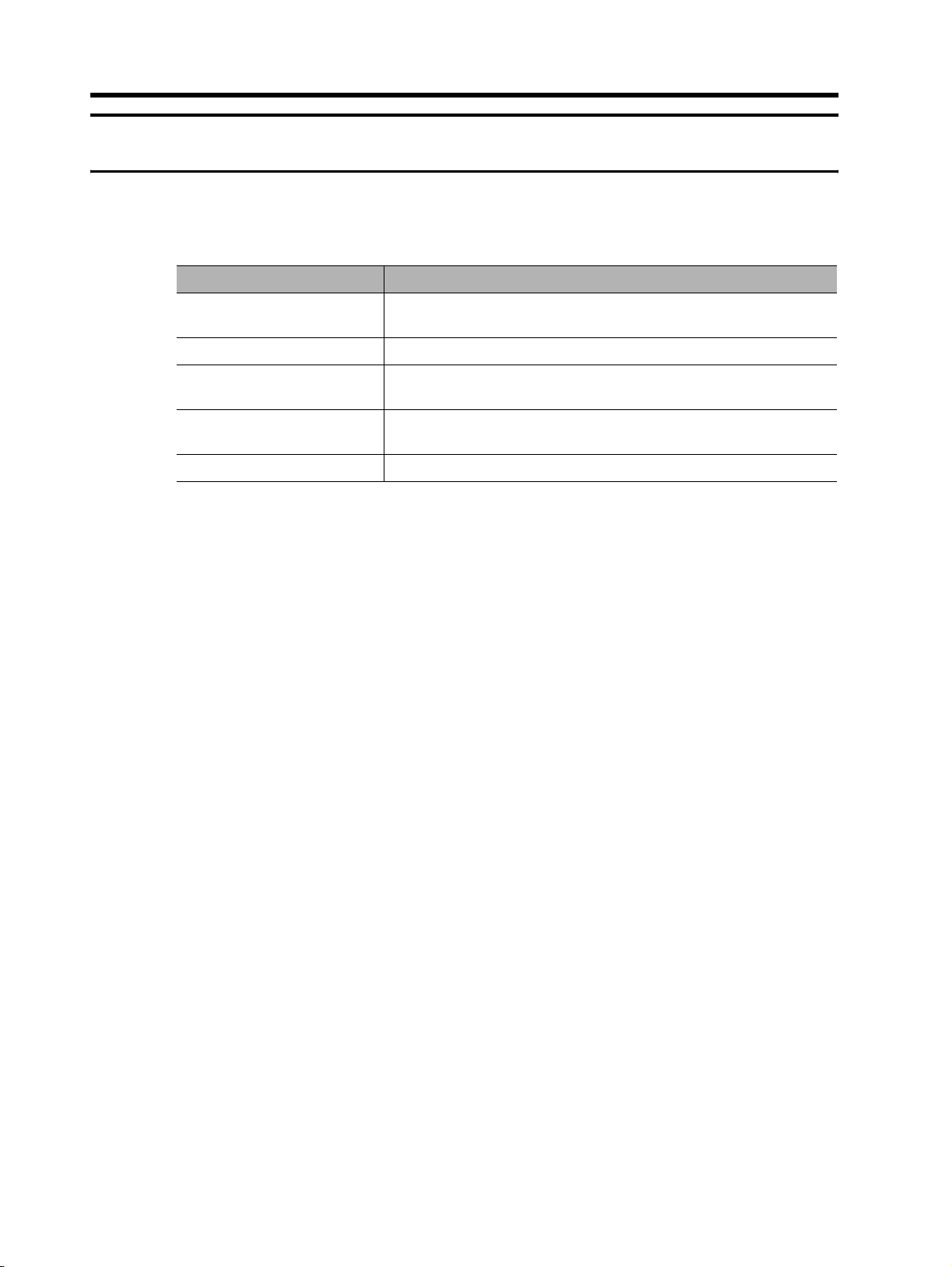

About This Manual

About This Manual

This User's Manual is compiled chapter by chapter for user's convenience as follows:

Understanding the following configuration ensures more effective use of the product.

Chapter Overview

Chapter 1 Design

Chapter 2 Functions Describes the DIP switch settings.

Chapter 3

Chapter 4

Chapter 5 Specifications Describes the product specifications and dimensions.

Maintenance

Operations

Inspection and

Maintenance

Describes installation and wiring procedures, terminal names and

other information required for design.

Describes the analysis of possible trouble causes as well as

troubleshooting methods.

Describes items for periodic inspection and/or maintenance for the

product.

16

Contents

Introduction.............................................................................................. 1

Read and Understand This Manual.........................................................2

Safety Precautions ..................................................................................5

Precautions for Safe Use......................................................................... 10

Precautions for Correct Use ....................................................................12

Checking Before Unpacking ....................................................................14

Revision History....................................................................................... 15

About This Manual...................................................................................16

Chapter 1 Design

1-1 Wiring....................................................................................................... 1-1

1-2 Terminals ................................................................................................. 1-3

1-3 Removing the Built-in Resistor ................................................................1-6

1-4 Connection............................................................................................... 1-7

Chapter 2 Functions

2-1 DIP Switch Setting ................................................................................... 2-1

Chapter 3 Maintenance Operations

3-1 Precautions before Operation.................................................................. 3-1

3-2 When the Alarm Contact is Activated ...................................................... 3-2

3-3 When an Inverter Overvoltage Trip Occurs ............................................. 3-3

Chapter 4 Inspection and Maintenance

4-1 Inspection and Maintenance.................................................................... 4-1

4-2 Daily Inspection and Periodic Inspection .................................................4-2

4-3 Megger Test.............................................................................................4-4

4-4 Checking the Main Element..................................................................... 4-5

4-5 Capacitor Life Curve ................................................................................ 4-6

Chapter 5 Specifications

5-1 Standard Specification List ...................................................................... 5-1

5-2 Dimensional Drawing...............................................................................5-5

17

Contents

18

Chapter 1

Design

1-1 Wiring................................................................ 1-1

1-2 Terminals .......................................................... 1-3

1-3 Removing the Built-in Resistor....................... 1-6

1-4 Connection ....................................................... 1-7

1-1 Wiring

1Design

1

Design

1-1 Wiring

For connections of the Regenerative Braking Unit, Inverter and Braking Resistor (P, RB, and N terminals), use cables with the following length:

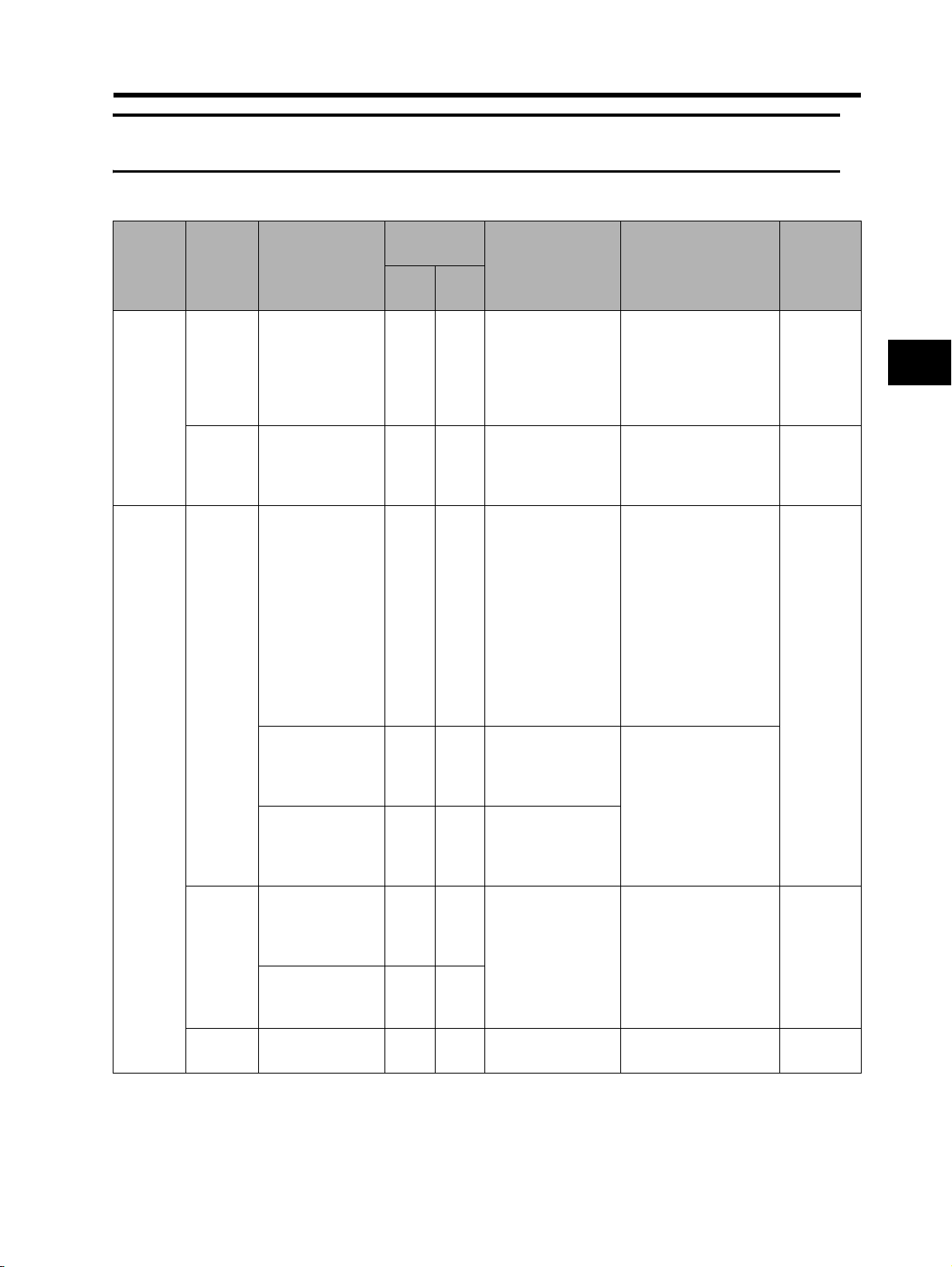

Model

(3G3AX-)

RBU21 5 m max. 5 m max.

RBU22 5 m max. 5 m max.

RBU23 4 m max. 50 m max.

RBU24

RBU41 5 m max. 5 m max.

RBU42 4 m max. 5 m max.

RBU43 4 m max. 50 m max.

The wiring must be routed at the shortest distance. Be sure not to coil up any surplus cables. Doing

so may cause a fault in the equipment.

The cable connected to the P and N terminals for wiring between the Regenerative Braking Unit

and the Inverter, as well as the cable connected to the P and RB terminals for wiring between the

Regenerative Braking Unit and the Braking Resistor must be bundled with a tie band, so that these

cables are not placed at a distance.

Between Regenerative Braking Unit and

Inverter

Braking resistance: 4 Ω min. 4 m max.

Less than 4 Ω 3 m max.

Between Regenerative Braking Unit and

Braking Resistor

50 m max.

Correct example :

Incorrect example :

In order to prevent the Braking Register in the Regenerative Braking Unit from burning due to overheating, be sure to connect the alarm contacts (AL1 and AL2) and provide a circuit to turn off the

primary power supply for the Inverter.

When several Regenerative Braking Units are connected in parallel, the length of the signal cables

(MA1, MA2, SL1, SL2) between individual Regenerative Braking Units must be 5 m or less, and the

cable size must be 0.75 mm

cable.

Inverter

Inverter

Main circuit

cable

Regenerative

Braking Unit

Regenerative

Braking Unit

2

or more. Be sure to separate the signal cables from the main circuit

Signal cable

10 cm min.

Braking

Resistor

Braking

Resistor

1-1

1-1 Wiring

When multiple resistors are used in combination, a voltage rise during switching is increased due

to the internal inductive components of the resistor. In this case, increase the cable size, or twist the

cable.

For the Braking Resistor, use a non-inductive resistor. Do not use six or more resistors in combination.

For connections on the PCB terminal block, be sure to use crimp terminals with insulation coating.

To use the optional Braking Resistor, select the model with combined resistance higher than the

specified connectable resistance. If a resistor whose resistance is less than the connectable resistance is used, it may result in a fault of the Regenerative Braking Unit. Use thorough caution in regards to the resistance.

When using these Braking Resistors, be sure to remove the built-in resistor. (3G3AX-RBU21/RBU22/-RBU41 only)

Model

(3G3AX-)

RBU21 17 Ω min.

RBU22 17 Ω min.

RBU23 4 Ω min.

RBU24 2 Ω min.

RBU41 34 Ω min.

RBU42 10 Ω min.

Connectable resistance

1

Design

RBU43 6 Ω min.

1-2

1-2 Terminals

1

Design

1-2 Terminals

Terminal Position and Arrangement

The terminal arrangement on the Regenerative Braking Unit is shown below.

3G3AX-RBU21/-RBU22/-RBU41

Main circuit terminals (screw size:M4)

Tightening torque: 1.2 to 1.3 N⋅m

NRB P P

Control circuit terminals (screw size:M3)

Tightening torque: 0.6 to 0.9 N⋅m

SL1 SL2

Alarm terminals (screw size:M3)

Tightening torque: 0.5 to 0.6 N⋅m

AL1 AL2 R1 R2

MA1 MA2

3G3AX-RBU42

1-3

Main circuit terminals (screw size:M5)

Tightening torque: 3.4 to 3.7 N⋅m

NRB

Control circuit terminals (screw size:M3)

Tightening torque: 0.6 to 0.9 N⋅m

SL1 SL2 MA1

PP

MA2 AL1 AL2

1-2 Terminals

3G3AX-RBU23/-RBU43

3G3AX-RBU24

Main circuit terminals (screw size:M8)

Tightening torque: 12 to 13.5 N⋅m

NRB

Control circuit terminals (screw size:M3)

Tightening torque: 0.6 to 0.9 N⋅m

SL1 SL2 MA1 MA2

Alarm terminals (screw size:M3)

Tightening torque: 0.6 to 0.9 N⋅m

AL2 AL1

Main circuit terminals (screw size:M10)

Tightening torque: 25 to 28 N⋅m

NRB

PP

PP

1

Design

Control circuit terminals (screw size:M3)

Tightening torque: 0.6 to 0.9 N⋅m

SL1 SL2 MA1 MA2

Alarm terminals (screw size:M3)

Tightening torque: 0.5 to 0.6 N⋅m

AL2 AL1

1-4

1-2 Terminals

1

Terminal Description

Design

Terminal name

Main circuit

terminal

Control circuit

terminal

Alarm terminal

Terminal

symbol

N Connect to the N/− terminal of the Inverter.

Connect to the Braking Resistor.

RB

P Connect to the P/+2 terminal of the Inverter.

P

SL1

SL2

MA1

MA2

AL1

AL2

R1

R2

With the default connection, this terminal is connected to the builtin resistor.

(Only for the models 3G3AX-RBU21/-RBU22/-RBU41)

Connect to the Braking Resistor.

With the default connection, this terminal is connected to the builtin resistor.

(Only for the models 3G3AX-RBU21/-RBU22/-RBU41)

Connect to the MA1 and MA2 terminals of a master unit when

used as slave unit terminals in parallel operation.

Connect to the SL1 and SL2 terminals of a slave unit when used

as master unit terminals in parallel operation.

The alarm output terminals for the Regenerative Braking Unit.

Provide a circuit to turn off the primary power supply for the Inverter when the temperature relay of the built-in resistor or optional

Braking Resistor is activated.

Connect to the AL1, AL2 (1, 2) terminals of the Braking Resistor

when the optional Braking Resistor is used.

Short-circuit between the AL1 and AL2 terminals when the optional Braking Resistor is not used.

(Only for the models 3G3AX-RBU21/-RBU22/-RBU41)

Description

1-5

1-3 Removing the Built-in Resistor

1-3 Removing the Built-in Resistor

To remove the built-in resistor, follow the procedure described below (3G3AX-RB21/-RBU22/RBU41 only).

1. Disconnect the lead wires connected from the built-in resistor to the P and RB terminals on the PCB, and to the R1 and R2 terminals on the fin.

RB

P

PCB

AL1

AL2

R1

R2

Fin

1

Design

Disconnect all four cables.

Built-in resistor

2. Remove the built-in resistor from the bottom of the unit.

3. Reconnect the wiring between the AL1 and R1 terminals and between the AL2 and

R2 terminals on the fin.

1-6

1-4 Connection

1

Design

1-4 Connection

3G3AX-RBU21/-RBU22 Connection Example

When the built-in resistor is used

The following is an example of connections using the built-in resistor.

Up to five units can be connected in parallel.

For DIP switch settings, refer to "2-1 DIP Switch Setting"(page 2-1).

MC1

MC2

BSS

BS

EF

Inverter

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

P/+2

N/-

Motor

SL1SL2 AL1AL2

P

P

N

MA1MA2

3-phase

200 V

MC2

MCB

R

S

T

MC1

RY

3G3AX-RBU21

/-RBU22

Master

RB

R1

R2

RY

MC1

MC2

(*1)

1-7

Alarm terminal internal connections

SL1SL2 AL1 AL2

AL1 AL2

Built-in resistance

temperature relay

R1

R2

P

P

3G3AX-RBU21

N

/-RBU22

Slave

MA1MA2

SL1 SL2 AL1 AL2

P

P

3G3AX-RBU21

N

/-RBU22

Slave

MA1MA2

*1. To select RY, check the MC coil and RY contact specifications.

RB

R1

R2

RB

R1

R2

1-4 Connection

When the optional Braking Resistor 3G3AX-RBA/-RBB/-RBC is used

The following is an example of connections using the Braking Resistor 3G3AX-RBA/-RBB/-RBC.

Up to five units can be connected in parallel.

For parallel connection, use Braking Resistors with the same resistance. Be sure to remove the

built-in resistor from the bottom of the Regenerative Braking Unit.

For DIP switch settings, refer to "2-1 DIP Switch Setting"(page 2-1).

MC1

3-phase

200 V

MC2

BSS

BS

EF

MC2

MCB

R

S

T

MC1

R/L1

S/L2

T/L3

Inverter

U/T1

V/T2

W/T3

P/+2

N/-

Motor

SL1 SL2 AL1 AL2

P

P

3G3AX-RBU21

N

MA1MA2

RY

/-RBU22

Master

RB

R1

R2

RY

MC1

MC2

3G3AX-RBA

/-RBB/-RBC

1(AL1)

2(AL2)

1

Design

(*1)

RB

P

Alarm terminal internal connections

AL1 AL2

Built-in resistance

temperature relay

R1

R2

Temperature relay

*1. To select RY, check the MC coil and RY contact specifications.

•To use the Braking Resistor (3G3AX-RBA/-RBB/-RBC), be sure to remove the

built-in resistor. If the Braking Resistor (3G3AX-RBA/-RBB/-RBC) is used with the

built-in resistor connected, it may cause the built-in resistor to burn due to

overheating, or result in an overheating detection failure when the Braking Resistor

temperature relay is activated.

•To prevent overheating, be sure to connect the alarm contacts 1 (AL1) and 2 (AL2)

of the Braking Resistor.

3G3AX-RBA

/-RBB/-RBC

1 (AL1)

2 (AL2)

SL1 SL2 AL1 AL2

P

P

3G3AX-RBU21

N

/-RBU22

Slave

MA1MA2

SL1 SL2 AL1 AL2

P

P

3G3AX-RBU21

N

/-RBU22

Slave

MA1MA2

RB

R1

R2

RB

R1

R2

3G3AX-RBA

/-RBB/-RBC

1(AL1)

RB

2(AL2)

P

3G3AX-RBA

/-RBB/-RBC

1(AL1)

RB

2(AL2)

P

1-8

1-4 Connection

1

Design

3G3AX-RBU41 Connection example

When the built-in resistor is used

The following is an example of connections using the built-in resistor.

Up to five units can be connected in parallel.

For DIP switch settings, refer to "2-1 DIP Switch Setting"(page 2-1).

MC1

MC2

200 V 50/60 Hz

220 V 60 Hz

Operation power

supply

MCB

400 V

R

S

T

3-phase

MC1

MC2

BS

R/L1

S/L2

T/L3

Inverter

U/T1

V/T2

W/T3

P/+2

N/-

BSS

Motor

SL1 SL2 AL1 AL2

P

P

3G3AX-RBU41

N

MA1MA2

RY

Master

RB

R1

R2

RY

MC1

MC2

(*1)

Alarm terminal internal connections

AL1 AL2

Built-in resistance

temperature relay

R1

R2

SL1 SL2 AL1 AL2

P

P

3G3AX-RBU41

N

P

P

N

Slave

MA1MA2

SL1 SL2 AL1 AL2

3G3AX-RBU41

Slave

MA1MA2

*1. To select RY, check the MC coil and RY contact specifications.

RB

R1

R2

RB

R1

R2

1-9

1-4 Connection

When the optional Braking Resistor 3G3AX-RBA/-RBB/-RBC is used

The following is an example of connections using the Braking Resistor 3G3AX-RBA/-RBB/-RBC.

Up to five units can be connected in parallel.

For parallel connection, use Braking Resistors with the same resistance. Be sure to remove the

built-in resistor from the bottom of the Regenerative Braking Unit.

For DIP switch settings, refer to "2-1 DIP Switch Setting"(page 2-1).

RY

MC1

MC2

(*1)

1(AL1)

2(AL2)

1(AL1)

2(AL2)

200 V 50/60 Hz

220 V 60 Hz

Operation

power supply

MCB

R

3-phase

S

400 V

T

MC1

MC2

MC1

BS

R/L1

S/L2

T/L3

MC2

Inverter

U/T1

W/T3

P/+2

V/T2

N/-

BSS

Motor

SL1 SL2 AL1 AL2

P

P

3G3AX-RBU41

N

MA1MA2

RY

Master

RB

R1

R2

1

Design

RB

P

RB

P

Alarm terminal internal connections

AL1 AL2

Built-in resistance

temperature relay

R1

R2

Temperature relay

*1. To select RY, check the MC coil and RY contact specifications.

3G3AX-RBA

/-RBB/-RBC

1(AL1)

2(AL2)

SL1 SL2 AL1 AL2

P

P

3G3AX-RBU41

N

P

P

N

Slave

MA1MA2

SL1 SL2 AL1 AL2

3G3AX-RBU41

Slave

MA1MA2

3G3AX-RBA/-RBB/-RBC

Two resistors connected in series

1(AL1)

2(AL2)

1(AL1)

2(AL2)

1(AL1)

2(AL2)

1(AL1)

2(AL2)

RB

P

RB

P

RB

P

RB

P

RB

R1

R2

3G3AX-RBA/-RBB/-RBC

Two resistors connected in series

RB

R1

R2

3G3AX-RBA/-RBB/-RBC

Two resistors connected in series

1-10

1

Design

1-4 Connection

•To use the Braking Resistor (3G3AX-RBA/-RBB/-RBC), be sure to remove the

built-in resistor. If the Braking Resistor (3G3AX-RBA/-RBB/-RBC) is used with the

built-in resistor connected, it may cause the built-in resistor to burn due to

overheating, or result in an overheating detection failure when the Braking Resistor

temperature relay is activated.

•To use the Braking Resistor (3G3AX-RBA/-RBB/-RBC) for 3G3AX-RBU41, be sure

to connect two resistors of the same model in series. If the 3G3AX-RBU41 is

operated with a single resistor, the Braking Resistor may have a fault.

•To prevent overheating, be sure to connect the alarm contacts 1 (AL1) and 2 (AL2)

of the Braking Resistor.

1-11

1-4 Connection

3G3AX-RBU23/-RBU24 Connection Example

When the optional Braking Resistor 3G3AX-RBA/-RBB/-RBC is used

The following is an example of connections using the Braking Resistor 3G3AX-RBA/-RBB/-RBC.

Up to two units can be connected in parallel.

For parallel connection, use Braking Resistors with the same resistance.

For DIP switch settings, refer to "2-1 DIP Switch Setting"(page 2-1).

MC1

MC2

RY

/-RBU24

Master

RB

MC1

MC2

3G3AX-RBA

/-RBB/-RBC

1(AL1)

2(AL2)

3-phase

200 V

BSS

BS

EF

MC2

MCB

R

S

T

MC1

Inverter

R/L1

S/L2

T/L3

U/T1

V/T2

W/T3

P/+2

N/-

Motor

SL1 SL2 AL1 AL2

P

P

3G3AX-RBU23

N

MA1MA2

RY

1

Design

(*1)

RB

P

SL1 SL2 AL1 AL2

P

P

3G3AX-RBU23

N

/-RBU24

Slave

MA1MA2

*1. To select RY, check the MC coil and RY contact specifications.

•To prevent overheating, be sure to connect the alarm contacts 1 (AL1) and 2 (AL2)

of the Braking Resistor.

•The models of 3G3AX-RBU23/-RBU24 do not have terminals for the alarm input

(R1, R2). Configure a sequence that enables the Inverter power to turn off when

unusual overheating is detected.

RB

3G3AX-RBA

/-RBB/-RBC

1(AL1)

RB

2(AL2)

P

1-12

1-4 Connection

1

Design

3G3AX-RBU42/-RBU43 Connection Example

When the optional Braking Resistor 3G3AX-RBA/-RBB/-RBC is used

The following is an example of connections using the Braking Resistor 3G3AX-RBA/-RBB/-RBC.

Up to two units can be connected in parallel.

For parallel connection, use Braking Resistors with the same resistance.

For DIP switch settings, refer to "2-1 DIP Switch Setting"(page 2-1).

MC1

200 V 50/60 Hz

220 V 60 Hz

Operation

power supply

MCB

R

3-phase

S

400 V

T

MC1

MC2

BS

R/L1

S/L2

T/L3

MC2

Inverter

U/T1

V/T2

W/T3

P/+2

N/-

BSS

Motor

SL1 SL2 AL1 AL2

P

P

3G3AX-RBU42

N

MA1MA2

RY

RB

/-RBU43

Master

RY

MC1

MC2

3G3AX-RBA

/-RBB/-RBC

1(AL1)

2(AL2)

(*1)

RB

P

SL1 SL2 AL1 AL2

P

P

3G3AX-RBU42

N

/-RBU43

Slave

MA1MA2

RB

•A voltage of 800 V DC (max.) is applied to the Braking Resistor. Check the rated

dielectric strength of the resistor to be connected.

•To use the optional Braking Resistor (3G3AX-RBA/-RBB/-RBC), be sure to connect

two resistors of the same model in series. If the 3G3AX-RBU42 or -RBU43 is

operated with a single resistor, the Braking Resistor may have a fault.

•To prevent overheating, be sure to connect the alarm contacts 1 (AL1) and 2 (AL2)

of the Braking Resistor.

•The models of 3G3AX-RBU42/-RBU43 do not have terminals for the alarm input

(R1, R2). Configure a sequence that enables the Inverter power to turn off when

unusual overheating is detected.

*1. To select RY, check the MC coil and RY contact specifications.

3G3AX-RBA

/-RBB/-RBC

1(AL1)

RB

2(AL2)

P

1-13

Chapter 2

Functions

2-1 DIP Switch Setting ........................................... 2-1

2-1 DIP Switch Setting

2Functions

2-1 DIP Switch Setting

2

Operating voltage level setting (SW1, SW2)

Functions

Parallel operation settings (SW3, SW4)

Set up operating voltage level and parallel operation with the DIP switches.

Note: Be sure to turn off the power supply before setting the DIP switches.

The operating voltage of the Regenerative Braking Unit can be set at 3 levels: “Standard” (default

setting), “−5 %” and “−10 %”, by the DIP switch settings.

This function is useful in preventing an overvoltage trip by lowering the operating voltage of the Regenerative Braking Unit when an overvoltage trip occurs due to the receiving voltage, deceleration

time or other factor.

Depending on the receiving voltage, however, the Regenerative Braking Unit will operate continuously even by just turning on the Inverter power supply. When you change the DIP switch settings,

use thorough caution in regards to the receiving voltage.

Receiving voltage × √2 + 20 V < Operating voltage

Interlocking operation can be performed by two units (master and slave units) in parallel connection

via the signal lines (MA1, MA2, SL1, SL2) connection between the units and the DIP switch setting.

When a unit is set as the slave using the DIP switches, the operating voltage of the slave unit depends on the master unit settings.

The DIP switch settings are as follows:

Note: The DIP switches are located at the upper left of the PCB in the Regenerative Braking Unit.

The switch numbers are indicated on the switch body.

Setting functions

Master unit

Operating voltage level:

Standard

Master unit

Operating voltage level:

−5 %

Master unit

Operating voltage level:

−10 %

Slave unit

(X: Either ON or OFF is acceptable.)

DIP switch setting

OFF

OFF2ON3ON

1

ON

OFF2ON3ON

1

ON

1ON2ON3ON4

X

1X2

OFF3ON

Note

ON

OFF

4

ON

OFF

4

ON

OFF

ON

OFF

4

Default setting

Operating voltage of the

slave unit depends on the

master unit settings.

2-1

Chapter 3

Maintenance

Operations

3-1 Precautions before Operation......................... 3-1

3-2 When the Alarm Contact is Activated ............ 3-2

3-3 When an Inverter Overvoltage Trip Occurs... 3-3

3-1 Precautions before Operation

3Maintenance Operations

3-1 Precautions before Operation

Before operation, check the following items:

• There is no incorrect wiring.

Incorrect wiring may result in damage or malfunction of the Regenerative Braking Unit.

3

• Check for grounding of any terminal other than the ground terminal.

Improper grounding may result in damage or malfunction of the Regenerative Braking Unit.

• Check for any short-circuits caused by a wire scrap or crimp terminal left in the unit after wiring

work.

A short circuit may result in damage or malfunction of the Regenerative Braking Unit.

• There is no short circuit or ground fault.

A short circuit or ground fault may result in damage or malfunction of the Regenerative Braking

Unit.

Maintenance Operations

3-1

3-2 When the Alarm Contact is Activated

3-2 When the Alarm Contact is Activated

In principle, the alarm contacts of the Regenerative Braking Unit are activated when the Braking Resistor is overheated by excessive regenerative energy or frequent braking.

As a countermeasure, review the capacity of the Braking Resistor, model and number of Regenerative Braking Units, as well as Inverter deceleration time. Incorrect wiring and improper receiving

voltage can be also considered as a cause of an alarm. Use the flowchart to diagnose the problem:

Alarm contact is activated.

Is the main element (IGBT)

defective? (*1)

NO

Is the resistance higher than

"connectable resistance" selected?

YES

Regenerative Braking Unit is defective.

Replace or repair the unit.

NO

3

Maintenance Operations

YES

Are the units in parallel

operation?

NO

Is the operation LED indicator lit in

any other status than Inverter

deceleration (during Inverter

acceleration, or in standby status)?

NO

Is the main circuit terminals

correctly wired?

Review the resistor selection.

YES

During operation, are the

operation LED indicators of all

units lit?

YES

Does either the master or slave

unit have a wire breakage?

NO

YES

Is the Inverter's receiving voltage

outside ±10 % of the rated

voltage?

Is the control circuit terminals

correctly wired?

(For single operation, this terminal

need not be connected.)

YES

NO

YES

NO

Check the wiring and DIP switch

settings are correct.

YES

Replace the resistor.

Review resistor selection.

YES

Correct the voltage.

NO

Be sure to wire correctly and securely.

NO

Be sure to wire correctly and securely.

*1. For the IGBT check procedure, refer to "4-4 Checking the Main Element"(Page 4-5).

The Regenerative Braking Unit

is defective. Replace or repair

the unit.

3-2

3-3 When an Inverter Overvoltage Trip Occurs

3-3 When an Inverter Overvoltage Trip Occurs

In principle, an Inverter overvoltage trip occurs when the Inverter cannot completely absorb a voltage rise due to excessive regenerative energy.

As a countermeasure, review the resistance of the Braking Resistor, model and number of Regenerative Braking Units, as well as Inverter deceleration time. Wire breakage in the Breaking Resistor,

incorrect wiring, and/or improper DIP switch settings can be also considered as a cause of an In-

3

verter overvoltage trip. Use the flowchart to diagnose the problem:

Overvoltage trip occurs.

During Inverter deceleration,

is the operation LED indicator

lit?

NO

Maintenance Operations

Are the DIP switches set to

slave?

Set the DIP

switches to slave.

YES

The Braking Resistor model selection is improper. Review

resistor selection, or extend the inverter deceleration time.

(There may be a wire breakage in the Braking Resistor.)

NO

Is the operation LED indicator on

the master unit (or the unit in

single operation) unlit?

YES

Is wiring between the P and N

terminals, as well as the control

circuit terminals connection correct?

YES

The Regenerative Braking Unit

is defective. Replace or repair

the unit.

YES

Are the DIP switches set to

master?

YES

NO

Be sure to wire correctly and

securely.

Set the DIP

switches to master.

NONO

3-3

Chapter 4

Inspection and

Maintenance

4-1 Inspection and Maintenance........................... 4-1

4-2 Daily Inspection and Periodic Inspection...... 4-2

4-3 Megger Test ...................................................... 4-4

4-4 Checking the Main Element ............................ 4-5

4-5 Capacitor Life Curve ........................................ 4-6

4-1 Inspection and Maintenance

4Inspection and Maintenanc e

4-1 Inspection and Maintenance

Daily Inspection

Basically, check the following during operation.

1) There are no errors in the installation environment.

2) There are no errors in the cooling system.

3) There are no abnormal vibrations or sounds.

4

Cleaning

4) There are no abnormal overheat or discoloration.

5) There are no abnormal odors.

Always keep the Regenerative Braking Unit clean for operation.

Lightly remove any dirt with a soft cloth moistened with a neutral detergent.

Note: Do not use such solutions as acetone, benzene, toluene, or alcohol for cleaning. Doing so

may cause the Regenerative Braking Unit surface to dissolve or its coating to come off.

Periodic Inspection

Check the parts that cannot be checked without stopping operation, as well as those that require

periodic inspection.

1) Check that there are no errors in the cooling system (Clean the air filter).

2) Check that all parts that need tightening are secure (Screws and bolts may become loose because

of vibration or temperature change).

Inspection and Maintenance

3) Check that there is no corrosion or damage to the conductors and/or insulators.

4) Measurement of insulation resistance

5) Check and replace the capacitor.

4-1

4-2 Daily Inspection and Periodic Inspection

4-2 Daily Inspection and Periodic Inspection

Inspection

Daily

period

Inspection method Criteria Meter

1

year

Inspec-

tion part

Inspec-

tion item

Inspection point

General

Main

circuit

Ambient

environment

Entire

device

General

Check ambient

temperature, as

well as humidity

and dust levels.

Check that there

are no abnormal

vibrations or

sounds.

Megger test

(between main

circuit terminal

and ground

terminal)

Check that any

parts which may

need tightening

are secure.

Check that no

part has indications of overheating.

{

{

{

{

Refer to "Installation"(Page 12).

Visual or acoustic

inspection

Disconnect the wirings of the main

and the control circuit terminals, use

a megger to measure the resistance

{

between the

ground terminal

and the short-circuited parts of main

circuit terminals P,

RB, and N.

Tighten securely.

Visual inspection

Ambient temperature

−10 °C to 50 °C,

no freezing

Ambient humidity 90 %

max., no condensation.

No faults

5 M Ω min.

Refer to "4-3 Megger

Test".

No faults

Thermometer,

Hygrometer,

Recorder

500 V DC

megger

4

Inspection and Maintenance

Connection conductor and

wire

Terminal

block

Check that there

is no distortion

with the conductor.

Check that there

is no tearing in the

wire coverings.

Check that there

is no damage.

{

Visual inspection No faults

{

Visual inspection No faults

{

4-2

4-2 Daily Inspection and Periodic Inspection

Inspection

Daily

{

period

Inspection method Criteria Meter

1

year

Visual inspection.

Cement resistor,

wire-wound resistor, etc.

Disconnect one

end of the cable,

and measure the

{

resistance using a

tester.

Simulate the

protection circuit

{

output

No faults

Error must be within

±10% of the nominal

resistance.

Error is found in the sequence.

Tester,

Digital

multimeter

Inspec-

tion part

Main

circuit

4

Control

circuit

Protection

circuit

Inspec-

tion item

Resistor

Operation

check

Inspection point

There are no

crack or discoloration.

Check for any

wire breakage

Check that there

are no errors in

protection and

display circuits

through sequence

protection

operation.

Check that there

are no abnormal

General

Components

Inspection and Maintenance

Smoothing capacitor

on the

PCB

*1.

odors, discoloration, or significant

rusting.

Check that there

is no liquid leakage.

Check that the

safety valve has

not come out and

that there are no

bulges.

The life of the capacitor depends on ambient temperatures. Refer to "4-5 Capacitor Life Curve"(Page

4-6) for the replacement reference.

•Do not conduct a withstand voltage test on any part of the Regenerative Braking

Unit.

The Regenerative Braking Unit uses semiconductors in the main circuit. If the unit

undergoes a withstand voltage test, it may cause semiconductor deterioration.

{

{

Visual inspection No faults

{

Visual inspection

No faults

Standard replacement

period: 5 years (*1)

4-3

4-3 Megger Test

For a megger test of the external circuit, be sure to disconnect all the terminals of the Regenerative

Braking Unit, so as not to apply the test voltage to the Regenerative Braking Unit.

Use a high resistance tester for a power distribution test of the control circuit. Do not use a megger

or buzzer.

Conduct a Regenerative Braking Unit megger test only to the main circuit, not to the control circuit.

Use a 500 V DC megger for a megger test.

Gradually increase the applied voltage, and reduce it to 0 V.

To conduct a megger test for the main circuit, short-circuit the P, RB and N terminals with a wire.

Regenerative Braking Unit

4-3 Megger Test

4

P

RB

N

500 V DC megger

Ground terminal

Applied voltage Applied voltage

Time Time

0.1 s min. 0.1 s min.

Note: Do not connect the power cable.

Inspection and Maintenance

4-4

4-4 Checking the Main Element

4-4 Checking the Main Element

The quality of the main element can be checked using a tester.

Preparation

Make preparations for the check by following the procedure below.

1. Disconnect the cables (N, RB, P and P terminals), and the built-in resistor cable (RB

and P terminals).

4

Checking method

2. Prepare a tester. (Usable range is 1 Ω measurement resistance.)

The quality can be judged by measuring the conduction state of the N, RB and P terminals on the

Regenerative Braking Unit terminal block (main circuit terminals) while alternating the tester polarity.

Inspection and Maintenance

• First, measure the voltage between the P and N terminals in the DC voltage range. Then, make

sure that there is no residual voltage before performing the check.

• A nearly infinite value is shown in a no-conduction state. The value shown ranges from a few to a

few dozen Ω in a conduction state. If the measurement result for each item is as listed below, the

quality is judged as being acceptable.

IGBT

P

FD

(flywheel diode)

IGBT

(main element)

Tester polarity

+ (red) − (black)

RB N Conduction

N RB No conduction

RB

N

Measurement results

4-5

FD

P RB Conduction

RB P No conduction

4-5 Capacitor Life Curve

A

mbient

temperature

(°C)

50

12-hour operation/day

40

30

4-5 Capacitor Life Curve

4

20

10

0

-10

1

Note 1: Ambient temperature refers to the surrounding (atmospheric) temperature of the

Regenerative Braking Unit, or the temperature inside if it’s encased or installed in an

enclosure.

Note 2: The smoothing capacitor, which will waste because of the internal chemical reaction,

should normally be replaced once every 5 years.

If the ambient temperature is high, however, frequent operation of the Regenerative

Braking Unit will cause its service life to be significantly shortened due to capacitor

deterioration.

3

245678910

24-hour operation/day

Capacitor life (year)

Inspection and Maintenance

4-6

4-5 Capacitor Life Curve

4

Inspection and Maintenance

4-7

Chapter 5

Specifications

5-1 Standard Specification List............................. 5-1

5-2 Dimensional Drawing....................................... 5-5

5-1 Standard Specification List

5Specifications

5-1 Standard Specification List

Models with a Built-in Resistor (3G3AX-RBU21/-RBU22/-RBU41)

Voltage class 3-phase 200 V class 3-phase 400 V class

Model (3G3AX-) RBU21 RBU22 RBU41

Connectable resistance 17 Ω min. 17 Ω min. 34 Ω min.

Operating voltage

ON/OFF

(−5 % or −10 % setting available)

5

Operation indication LED ON (Lit)

Maximum number of

units in parallel

operation

*2

ON: 362.5 ± 5 V,

OFF: 355 ± 5 V

5 units

ON: 725 ± 5 V,

OFF: 710 ± 5 V

(−5 % or −10 %

setting available)

*1

Built-in resistance

Allowable consecutive ON time

Allowable operation cycle

Specifications

Built-in resistor

Power

consumption

Built-in resistance

overheat protection

Protective functions

Ambient

temperature

Ambient storage

temperature

Humidity 20 % to 90 % (with no condensation)

Vibration 5.9 m/s

Operating environment

Location At a maximum altitude of 1000m; indoors (without corrosive gases or dust)

120 W 180 Ω 120 W 20 Ω

10s max. 0.5s max. 10s max.

Cycle 1/10

(10s ON/90s OFF)

Instantaneous: 0.73 kW

Short-time rating: 120 W

Built-in relay specifications

• The temperature relay operates if the built-in resistor reaches approx. 200 °C or

more, and recovers at approx. 170 °C or less.

• Built-in thermal fuse (recovery impossible)

• Rating of contact 250 V AC 200 mA (R load)

12 V DC 500 mA(R load)

42 V DC 200 mA(R load)

• Minimum load 1 mA

−20 °C to 65 °C (short-time temperature during transport)

Cycle 1/80

(0.5s ON/40s OFF)

Instantaneous: 6.6 kW

Short-time rating: 120 W

*3

−10 °C to 50 °C

2

(0.6G) 10 to 55 Hz

120 W 180 Ω

x 2 in series

Cycle 1/10

(10s ON/90s OFF)

Instantaneous: 1.46 kW

Short-time rating: 240 W

Paint color Munsell 5Y7/1 (cooling fan: aluminum ground color)

*1. To use the Braking Resistor (3G3AX-RAB/-RBB/-RBC) for the 400-V class Regenerative

Braking Unit, be sure to remove the built-in resistor, and connect two resistors of the same

model in series.

If the 400-V class Regenerative Braking Unit is operated with a single Braking Resistor, the

Braking Resistor may be damaged.

*2. Set the DIP switches.

5-1

5-1 Standard Specification List

*3. The built-in resistor has a thermal fuse.

If the alarm terminal is not connected, the fuse may blow out in order to prevent the resistor

from burning due to overheating.

If the fuse blows out, the built-in resistor must be replaced.

5

Specifications

5-2

5-1 Standard Specification List

Models without a Built-in Resistor (3G3AX-RBU23/-RBU24/-RBU42/RBU43)

Voltage class 3-phase 200-V class 3-phase 400-V class

Model (3G3AX-) RBU23 RBU24 RBU42

Continuous

operation

6 Ω min. 4 Ω min. 24 Ω min. 12 Ω min.

*1

RBU43

*1

Short-time

operation/

Allowable operation

cycle / Allowable

continuous ON time

5

Specifications

Connectable resistance

Operating voltage

ON/OFF

Operation indication LED ON (Lit)

Maximum number of

units in parallel

operation

Built-in power

module overheat

protection

Protective functions

Ambient

temperature

Ambient storage

temperature

4 Ω min.

Cycle 1/5

(2 min ON/

8 min OFF)

2 min

ON: 362.5 ± 5 V, OFF: 355 ± 5 V

(−5 % or −10 % setting available)

*2

Built-in relay specifications

• The temperature relay operates if the cooling fin reaches approx. 100°C or more.

• Rating of contact 240 V AC 3 A (R load)

• Minimum load 5 V DC 50 mA (R load)

−20 °C to 65 °C (short-time temperature during transport)

2 Ω min.

Cycle 1/5

(2 min ON/

8 min OFF)

2 min

2 units

36 V DC 2 A(R load)

−10 °C to 50 °C

10 Ω min.

Cycle 1/10

(10 s ON/

90 s OFF)

10 s

ON: 725 ± 5 V, OFF: 710 ± 5 V

(−5 % or −10 % setting available)

6 Ω min.

Cycle 1/5

(2 min ON/

8 min OFF)

2 min

Humidity 20 % to 90 % (with no condensation)

2

Vibration 4.9 m/s

Location At a maximum altitude of 1000m; indoors (without corrosive gases or dust)

Operating environment

Paint color Munsell 5Y7/1 (cooling fan: aluminum ground color)

(0.5G) 10 to 55 Hz

*1. To use the Braking Resistor (3G3AX-RAB/-RBB/-RBC) for the 400-V class Regenerative

Braking Unit, be sure to connect two resistors of the same model in series.

If the 400-V class Regenerative Braking Unit is operated with a single Braking Resistor, the

Braking Resistor may be damaged.

*2. Set the DIP switches.

5-3

5-1 Standard Specification List

Specifications of Braking Resistors (3G3AX-RBA/-RBB/-RBC)

Model

Resistance (Ω) 180 100 50 35 180 100 50 35 50 35 17

Capacity (W) 120 200 300 400 400 600 1200

Allowable braking frequency

(%ED)

Allowable continuous braking

time(s)

1201 1202 1203 1204 2001 2002 3001 4001 4001 6001

5 2.5 1.5 1.0 10 7.5 7.5 7 10

20 12 5 3 30 20 10

3G3AX-RBA 3G3AX-RBB 3G3AX-RBC

12001

5

Specifications

5-4

5-2 Dimensional Drawing

5-2 Dimensional Drawing

3G3AX-RBU21/-RBU22/-RBU41

5

Specifications

3G3AX-RBU23

95

75

2-φ5

5

208

218

5

Ground terminal

Screw size : M5

145

35

100

217

237

258

258

4-φ8

16045

250

Ground terminal

Screw size : M5

151

86

51

109

5-5

3G3AX-RBU24

5-2 Dimensional Drawing

234

254

275

275

4-φ8

20050

300

Ground terminal

Screw size : M5

171

101

67

127

5

Specifications

3G3AX-RBU42

95

75

2-φ5

5208

218

5

Ground terminal

Screw size : M5

145

35

100

5-6

5-2 Dimensional Drawing

3G3AX-RBU43

217

237

258

5

258

4-φ8

250

16045

Ground terminal

Screw size : M5

151

86

51

109

Specifications

5-7

Terms and Conditions of Sale

1. Offer; Acceptance. These terms and conditions (these "Terms") are deemed

part of all quotes, agreements, purchase orders, acknowledgments, price lists,

catalogs, manuals, brochures and other documents, whether electronic or in

writing, relating to the sale of products or services (collectively, the "Products

by Omron Electronics LLC and its subsidiary companies (“Omron”). Omron

objects to any terms or conditions proposed in Buyer’s purchase order or other

documents which are inconsistent with, or in addition to, these Terms.

2. Prices; Payment Terms.

out notice by Omron. Omron reserves the right to increase or decrease prices

on any unshipped portions of outstanding orders. Payments for Products are

due net 30 days unless otherwise stated in the invoice.

3. Discounts.

sent to Buyer after deducting transportation charges, taxes and duties, and will

be allowed only if (i) the invoice is paid according to Omron’s payment terms

and (ii) Buyer has no past due amounts.

4. Interest.

the maximum legal rate, whichever is less, on any balance not paid within the

stated terms.

5. Orders

6. Governmental Approvals.

costs involved in, obtaining any government approvals required for the importation or sale of the Products.

7. Taxes

real property and income taxes), including any interest or penalties thereon,

imposed directly or indirectly on Omron or required to be collected directly or

indirectly by Omron for the manufacture, production, sale, delivery, importation, consumption or use of the Products sold hereunder (including customs

duties and sales, excise, use, turnover and license taxes) shall be charged to

and remitted by Buyer to Omron.

8. Financial.

to Omron, Omron reserves the right to stop shipments or require satisfactory

security or payment in advance. If Buyer fails to make payment or otherwise

comply with these Terms or any related agreement, Omron may (without liability and in addition to other remedies) cancel any unshipped portion of Products sold hereunder and stop any Products in transit until Buyer pays all

amounts, including amounts payable hereunder, whether or not then due,

which are owing to it by Buyer. Buyer shall in any event remain liable for all

unpaid accounts.

9. Cancellation; Etc.

unless Buyer indemnifies Omron against all related costs or expenses.

10. Force Majeure

resulting from causes beyond its control, including earthquakes, fires, floods,

strikes or other labor disputes, shortage of labor or materials, accidents to

machinery, acts of sabotage, riots, delay in or lack of transportation or the

requirements of any government authority.

11. Shipping; Delivery.

a. Shipments shall be by a carrier selected by Omron; Omron will not drop ship

b. Such carrier shall act as the agent of Buyer and delivery to such carrier shall

c. All sales and shipments of Products shall be FOB shipping point (unless oth-

d. Delivery and shipping dates are estimates only; and

e. Omron will package Products as it deems proper for protection against nor-

12. Claims.

Products occurring before delivery to the carrier must be presented in writing

to Omron within 30 days of receipt of shipment and include the original transportation bill signed by the carrier noting that the carrier received the Products

from Omron in the condition claimed.

13. Warranties

Products will be free from defects in materials and workmanship for a period of

twelve months from the date of sale by Omron (or such other period expressed

in writing by Omron). Omron disclaims all other warranties, express or implied.

(b) Limitations

EXPRESS OR IMPLIED, ABOUT NON-INFRINGEMENT, MERCHANTABIL-

Cash discounts, if any, will apply only on the net amount of invoices

Omron, at its option, may charge Buyer 1-1/2% interest per month or

. Omron will accept no order less than $200 net billing.

. All taxes, duties and other governmental charges (other than general

If the financial position of Buyer at any time becomes unsatisfactory

except in “break down” situations.

constitute delivery to Buyer;

erwise stated in writing by Omron), at which point title and risk of loss shall

pass from Omron to Buyer; provided that Omron shall retain a security interest in the Products until the full purchase price is paid;

mal handling and extra charges apply to special conditions.

Any claim by Buyer against Omron for shortage or damage to the

. (a) Exclusive Warranty. Omron’s exclusive warranty is that the

All prices stated are current, subject to change with-

Buyer shall be responsible for, and shall bear all

Orders are not subject to rescheduling or cancellation

. Omron shall not be liable for any delay or failure in delivery

Unless otherwise expressly agreed in writing by Omron:

. OMRON MAKES NO WARRANTY OR REPRESENTATION,

ITY OR FITNESS FOR A PARTICULAR PURPOSE OF THE PRODUCTS.

BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

")

INTENDED USE. Omron further disclaims all warranties and responsibility of

any type for claims or expenses based on infringement by the Products or otherwise of any intellectual property right. (c) Buyer Remedy

gation hereunder shall be, at Omron’s election, to (i) replace (in the form

originally shipped with Buyer responsible for labor charges for removal or

replacement thereof) the non-complying Product, (ii) repair the non-complying

Product, or (iii) repay or credit Buyer an amount equal to the purchase price of

the non-complying Product; provided that in no event shall Omron be responsible for warranty, repair, indemnity or any other claims or expenses regarding

the Products unless Omron’s analysis confirms that the Products were properly handled, stored, installed and maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of any Products by

Buyer must be approved in writing by Omron before shipment. Omron Companies shall not be liable for the suitability or unsuitability or the results from the

use of Products in combination with any electrical or electronic components,

circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in writing,

are not to be construed as an amendment or addition to the above warranty.

See http://www.omron247.com

l

ished information.

14. Limitation on Liability; Etc

FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS

BASED IN CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual

price of the Product on which liability is asserted.

15. Indemnities

their employees from and against all liabilities, losses, claims, costs and

expenses (including attorney's fees and expenses) related to any claim, investigation, litigation or proceeding (whether or not Omron is a party) which arises

or is alleged to arise from Buyer's acts or omissions under these Terms or in

any way with respect to the Products. Without limiting the foregoing, Buyer (at

its own expense) shall indemnify and hold harmless Omron and defend or settle any action brought against such Companies to the extent based on a claim

that any Product made to Buyer specifications infringed intellectual property

rights of another party.

16. Property; Confidentiality.

sive property of Omron Companies and Buyer shall not attempt to duplicate it

in any way without the written permission of Omron. Notwithstanding any

charges to Buyer for engineering or tooling, all engineering and tooling shall

remain the exclusive property of Omron. All information and materials supplied

by Omron to Buyer relating to the Products are confidential and proprietary,

and Buyer shall limit distribution thereof to its trusted employees and strictly

prevent disclosure to any third party.

17. Export Controls.

licenses regarding (i) export of products or information; (iii) sale of products to

“forbidden” or other proscribed persons; and (ii) disclosure to non-citizens of

regulated technology or information.

18. Miscellaneous

and no course of dealing between Buyer and Omron shall operate as a waiver

of rights by Omron. (b) Assignment

without Omron's written consent. (c) Law.

law of the jurisdiction of the home office of the Omron company from which

Buyer is purchasing the Products (without regard to conflict of law principles). (d) Amendment

Buyer and Omron relating to the Products, and no provision may be changed

or waived unless in writing signed by the parties. (e) Severability

sion hereof is rendered ineffective or invalid, such provision shall not invalidate

any other provision. (f) Setoff

against the amount owing in respect of this invoice. (g) Definitions

herein, “including

nies” (or similar words) mean Omron Corporation and any direct or indirect

subsidiary or affiliate thereof.

. Buyer shall indemnify and hold harmless Omron Companies and

Buyer shall comply with all applicable laws, regulations and

. (a) Waiver. No failure or delay by Omron in exercising any right

” means “including without limitation”; and “Omron Compa-

or contact your Omron representative for pub-

. OMRON COMPANIES SHALL NOT BE LIABLE

Any intellectual property in the Products is the exclu-

. Buyer may not assign its rights hereunder

These Terms are governed by the

. These Terms constitute the entire agreement between

. Buyer shall have no right to set off any amounts

. Omron’s sole obli-

. If any provi-

. As used

Certain Precautions on Specifications and Use

1. Suitability of Use. Omron Companies shall not be responsible for conformity

with any standards, codes or regulations which apply to the combination of the

Product in the Buyer’s application or use of the Product. At Buyer’s request,

Omron will provide applicable third party certification documents identifying

ratings and limitations of use which apply to the Product. This information by

itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application

or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system.

Buyer shall take application responsibility in all cases but the following is a

non-exhaustive list of applications for which particular attention must be given:

(i) Outdoor use, uses involving potential chemical contamination or electrical

interference, or conditions or uses not described in this document.

(ii) Use in consumer products or any use in significant quantities.

(iii) Energy control systems, combustion systems, railroad systems, aviation

systems, medical equipment, amusement machines, vehicles, safety equipment, and installations subject to separate industry or government regulations.

(iv) Systems, machines and equipment that could present a risk to life or property. Please know and observe all prohibitions of use applicable to this Product.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS

RISK TO LIFE OR PROPERTY OR IN LARGE QUANTITIES WITHOUT

ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON’S PRODUCT IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE

OVERALL EQUIPMENT OR SYSTEM.

2. Programmable Products.

user’s programming of a programmable Product, or any consequence thereof.

3. Performance Data

and other materials is provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent the result of Omron’s

test conditions, and the user must correlate it to actual application requirements. Actual perfor mance is subject to the Omron’s Warranty and Limitations

of Liability.

4. Change in Specifications

changed at any time based on improvements and other reasons. It is our practice to change part numbers when published ratings or features are changed,

or when significant construction changes are made. However, some specifications of the Product may be changed without any notice. When in doubt, special part numbers may be assigned to fix or establish key specifications for

your application. Please consult with your Omron’s representative at any time

to confirm actual specifications of purchased Product.

5. Errors and Omissions.

checked and is believed to be accurate; however, no responsibility is assumed

for clerical, typographical or proofreading errors or omissions.

Omron Companies shall not be responsible for the

. Data presented in Omron Company websites, catalogs

. Product specifications and accessories may be

Information presented by Omron Companies has been

Note: Specifications are subject to change. © 2008 Omron Electronics LLC Printed in U.S.A.

OMRON ELECTRONICS LLC • THE AMERICAS HEADQUARTERS

Schaumburg, IL USA • 847.843.7900 • 800.556.6766 • www.omron247.com

OMRON CANADA, INC. • HEAD OFFICE

Toronto, ON, Canada • 416.286.6465 • 866.986.6766 • www.omron.ca

OMRON ELETRÔNICA DO BRASIL LTDA • HEAD OFFICE

São Paulo, SP, Brasil • 55.11.2101.6300 • www.omron.com.br

OMRON ELECTRONICS MEXICO SA DE CV • HEAD OFFICE

Apodaca, N.L. • 52.811.156.99.10 • mela@omron.com

OMRON ARGENTINA • SALES OFFICE

Cono Sur • 54.11.4787.1129

OMRON CHILE • SALES OFFICE

Santiago 56.2206.4592

OTHER OMRON LATIN AMERICA SALES

56.2206.4592

I563-E1-01

Loading...

Loading...