Page 1

Inverter

RX Series

LX Series

MX2 Series

LCD Digital Operator

User’s Manual

I579-E2-01

3G3AX-OP05

Page 2

OMRON, 2013

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written

permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless,

OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting

from the use of the information contained in this publication.

Page 3

1

Introduction

LCD Digital Operator User’s Manual (I579)

Introduction

Thank you for purchasing the LCD Digital Operator (Model: 3G3AX-OP05).

This manual explains how to set parameters required to use the LCD Digital Operator (Model:

3G3AX-OP05), operation procedures and the remedies needed if problems occur.

For the use of the LCD Digital Operator 3G3AX-OP05, please refer also to RX (I560-E2), LX

(I120E-EN) or MX2 (I570-E2) User’s Manuals.

This manual is intended for the following individuals.

Those who have electrical knowledge (certified electricians or individuals who have equivalent

knowledge) and also are qualified for one of the following:

• Introducing control equipment

• Designing control systems

• Installing and connecting control systems

• Managing control systems and facilities

This manual contains information you need to know in order to correctly use the LCD Digital Operator

3G3AX-OP05.

Before using the LCD Digital Operator (Model: 3G3AX-OP05), read this manual and gain a full

understanding of the information provided herein.

After you finished reading this manual, keep it in a convenient place so that it can be referenced at any

time.

Make sure this manual is delivered to the end user.

Intended Readers

Notice

Page 4

Manual Configuration

2

LCD Digital Operator User’s Manual (I579)

Manual Configuration

This manual is compiled section by section for user’s convenience as follows.

Overview

Section 1 Overview This section provides features and specifications of the LCD Digital

Operator.

Section 2 Part Names and Functions This section describes the part names and functions of the LCD Digital

Operator.

Section 3 Installation and Wiring This section provides information on the installation and wiring of the

LCD Digital Operator.

Section 4 Operation Procedures This section provides an overview of the display modes supported by

LCD Digital Operator and how to operate the LCD Digital Operator in

each display mode.

Section 5 LCD Digital Operator Related

Parameters

This section describes the Inverter parameters related to the LCD Digital

Operator.

Section 6

Read/Write Functio ns This section describes how to read and write Inverter parameter settings

using the LCD Digital Operator.

Section 7 Error Messages and

Troubleshooting

This section describes the error messages and troubleshooting of the

LCD Digital Operator.

Section 8 Maintenance This section provides information on the maintenance of the LCD Digital

Operator.

Page 5

3

Manual Structure

LCD Digital Operator User’s Manual (I579)

Manual Structure

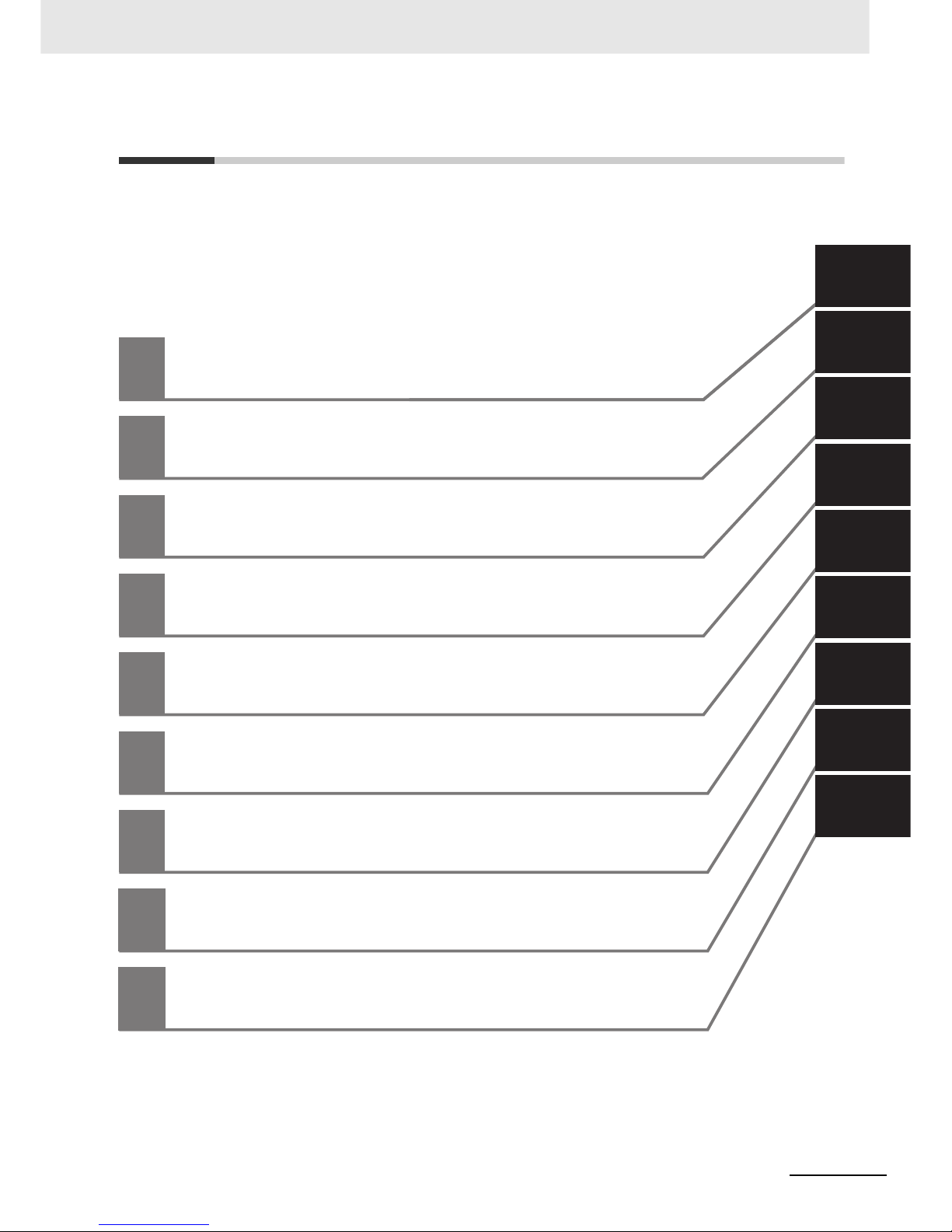

The following page structure and symbol icons are used in this manual.

Note The above page is only a sample for illustrative purposes. It is not the actual content of the manual.

Page Structure and Symbol Icons

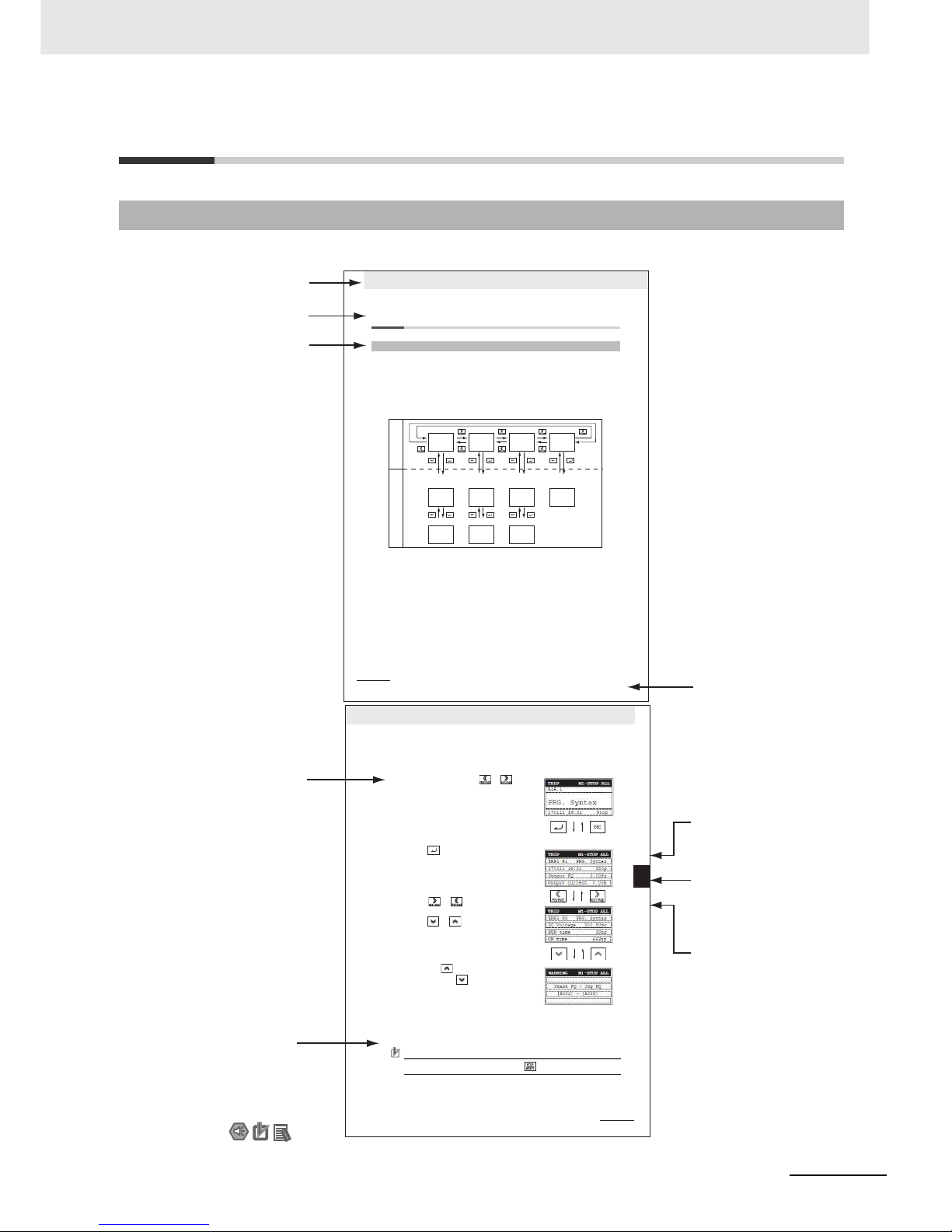

4 Operation Procedures

4 - 2

LCD Digital Operator User’s Manual

4-1 Overview of Display Modes

The LCD Digital Operator basically displays its screens in four modes as shown below.

Each mode has two levels: the higher Navigation level and the lower Edit level. The user can move

between each mode in the Navigation level only.

•

Monitor Mode A: The mode to display and set a single monitor function and a single parameter function.

• Monitor Mode B: The mode to display up to four monitor functions on a single screen.

• Function

Mode

: The

mode

to set parameter settings. The screen also displays the parameter name

and setting range.

• Trip Mode: The mode to display the trip and warning information.

In addition to the above, the LCD Digital Operator has the following three called modes. At any of the

above levels and in any operating state, you can call these modes by pressing the key(s) shown to the

right of the down arrow above each screen, as shown below. After calling these screens, you can press

the ESC key to restore the operating state before the call.

• All Read: The mode to read all Inverter parameter settings and Drive Programming data from the

Inverter.

• All Write: The mode to write all the stored Inverter parameter setting and Drive Programming program

data to the Inverter.

• Option Mode: The mode to set the LCD Digital Operator.

4-1-1 Transition of Screens

Monitor

Mode A

Monitor

Mode B

Function

Mode

Trip

Mode

Select the monitor item.

Select the setting item.

Select the setting

line.

Select the setting

item.

Monitor the overall

trip history.

Monitor

Mode A

Monitor

Mode B

Function

Mode

Tri p

Mode

Monitor

Mode A

Monitor

Mode B

Function

Mode

Change the set value. Change the set value. Change the set value.

Navigation levelEdit level

Level 2 heading

Level 3 heading

Level 1 heading

Manual Name

Level 2 heading

Section Number of

Level 1 heading

Level 3 heading

Shows which section

the content of the current

page belongs to.

Shows which sub-section

the content of the current

page belongs to.

Shows which paragraph

the content of the current

page belongs to.

Note, Supplementary

Information, Reference Target

A note, supplementary

information, reference target,

etc. are provided with

difference icons.

Operation Steps

Describes

the operation steps.

4 Operation Procedures

4 - 8

LCD Digital Operator User’s Manual

1

At the Navigation level, press the or

key to select the Trip Mode screen.

2

Press the key. Now, the screen shows

information on the past trips (six trip errors)

recorded in the Inverter and the warning

information (for a single occurrence).

The trip information for a single occurrence comprises

two pages.

To switch from page 1 (P1) to page 2 (P2),

press the or key.

To display the information on the past six trip errors,

press the or key.

3

If you press the key when ERR1 is being

displayed or press the key when ERR6 is

being displayed, the screen changes to the

Warning Mode.

Precautions for Correct UsePrecautions for Correct Use

If a trip occurs, the ALARM LED lights up. Then, press the key to reset the Inverter.

4-5 Operation in the Trip Mode

4

4-1-2 Basic Operation

Page 6

Manual Structure

4

LCD Digital Operator User’s Manual (I579)

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct UsePrecautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Special Informati on

Page 7

5

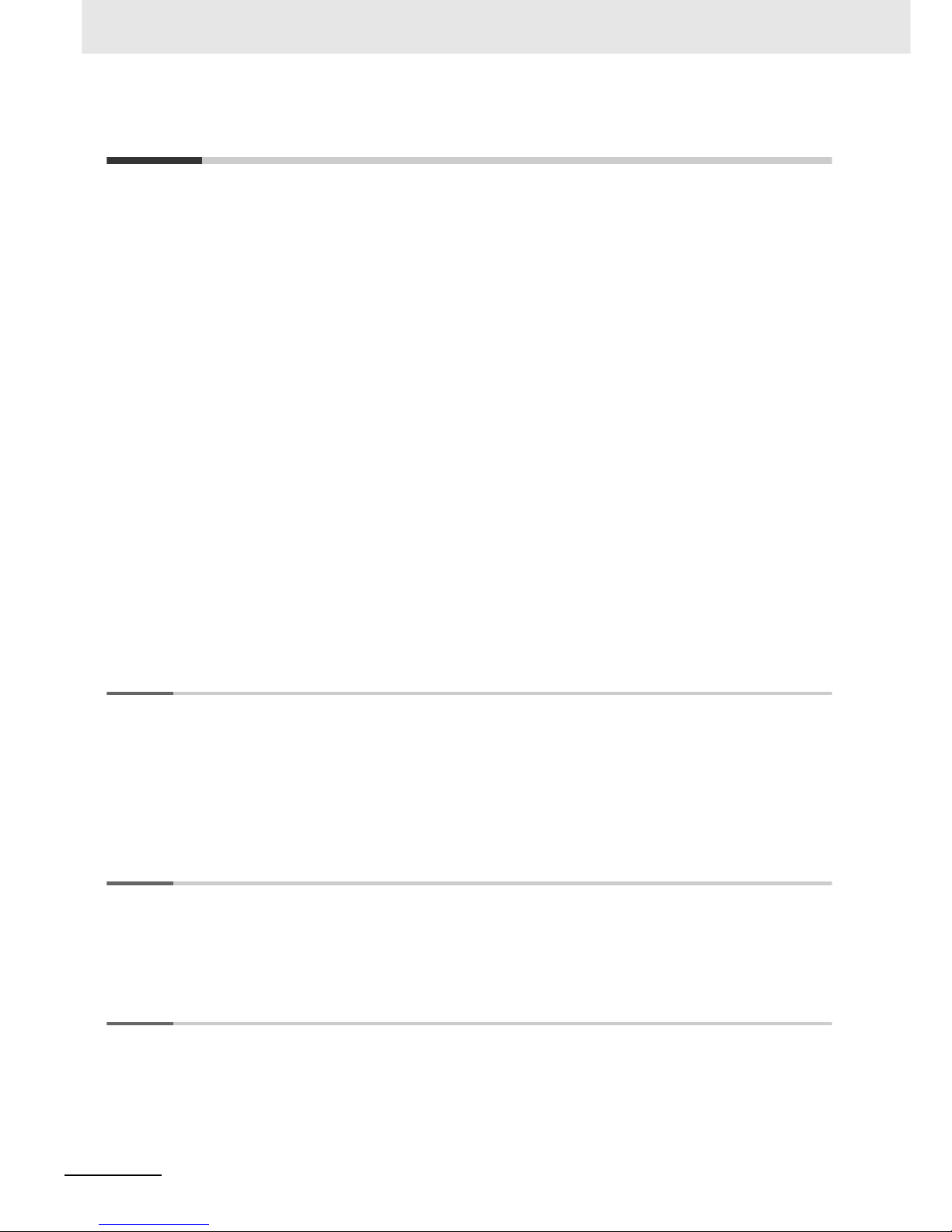

Sections in this Manual

LCD Digital Operator User’s Manual (I579)

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

Overview

Part Names and Functions

Installation and Wiring

Operation Procedures

LCD Digital Operator Related Parameters

Read/Write Functions

Error Messages and Troubleshooting

Maintenance

I

I

Index

Sections in this Manual

Page 8

6

LCD Digital Operator User’s Manual (I579)

CONTENTS

CONTENTS

Introduction ...............................................................................................................1

Manual Configuration ...............................................................................................2

Manual Structure.......................................................................................................3

Sections in this Manual............................................................................................5

CONTENTS.................................................................................................................6

Read and Understand this Manual ..........................................................................8

Safety Precautions............................................ ..... ................................. ................11

Precautions for Safe Use........................................................................................13

Precautions for Correct Use...................................................................................15

Regulations and Standards...................................................... .... ..........................16

Items to Check after Unpacking.............................................................................17

Related Manuals............................................................................ ..........................18

Revision History......................................................................................................19

Section 1 Overview

1-1 Features.................................................................................................................................... 1-2

1-2 Supported Models ...................................................................................................................1-4

1-3 Specifications .......................................................................................................................... 1-5

1-4 External Dimensions ............................................................................................................... 1-6

1-5 Recommended Cables ............................................................................................................ 1-7

Section 2 Part Names and Function s

2-1 Part Names............................................................................................................................... 2-2

2-2 Operation Keys ........................................................................................................................2-4

2-3 LCD Display ...... ...... ....... ...... ....... ...... ....... ............................................. ...... ....... ...... .... ............ 2-6

Section 3 Installation and Wiring

3-1 Installation on the Inverter......................................................................................................3-2

3-1-1 Direct Installation on the Inverter................................................................................................3-3

3-1-2 Installation on the Inverter via Cable...........................................................................................3-4

3-1-3 Checking the Operation After Installation....................................................................................3-5

3-1-4 Date and Time Setting ................................................................................................................3-6

3-1-5 Other Settings.............................................................................................................................3-6

Page 9

7

LCD Digital Operator User’s Manual (I579)

CONTENTS

Section 4 Operation Procedures

4-1 Overview of Display Modes....................................................................................................4-2

4-1-1 Transition of Screens..................................................................................................................4-2

4-1-2 Overview of Each Mode..............................................................................................................4-3

4-1-3 Changing the Display in Each Mode........................................................................................... 4-5

4-2 Operation in the Monitor Mode A........................................................................................... 4-6

4-3 Operation in the Monitor Mode B........................................................................................... 4-7

4-4 Operation in the Function Mode ............................................................................................ 4-8

4-5 Operation in the Trip Mode..................................................................................................... 4-9

Section 5 LCD Digital Operator Related Parameter s

5-1 Parameter Setting.................................................................................................................... 5-2

5-1-1 Operation in the Option Mode..................................................................................................... 5-2

5-1-2 Details of Each Option Mode Parameter .................................................................................... 5-4

5-2 Related Inverter Parameters................................................................................................... 5-6

Section 6 Read/Write Functions

6-1 Single READ Function ............................................................................................................ 6-2

6-2 Single WRITE Function........................................................................................................... 6-3

6-3 Quad READ Function .............................................................................................................. 6-4

6-4 Quad VERIFY Function ........................................................................................................... 6-6

6-5 Quad WRITE Function............................................................................................................. 6-8

6-6 Conditions for the Read/Write Operations.......................................................................... 6-10

Section 7 Error Messages and Troubleshooting

7-1 Error Messages and Remedies .............................................................................................. 7-2

7-1-1 Inverter Error Messages.............................................................................................................7-2

7-1-2 LCD Digital Operator Error Messages........................................................................................7-2

7-2 Troubleshooting ...................................................................................................................... 7-5

Section 8 Maintenance

8-1 Battery Replacement............................................................................................................... 8-2

Index

Page 10

Read and Understand this Manual

8

LCD Digital Operator User’s Manual (I579)

Read and Understand this Manual

Warranty and Limitations of Liability

WARRANTY

OMRON’s exclus ive w arran ty is th at the prod uc t s a re free from defe cts in materials and workmanship for a period of

one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS.

ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUIT ABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS

OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH

CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which liability

is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING

THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY

HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE,

MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

Page 11

9

Read and Understand this Manual

LCD Digital Operator User’s Manual (I579)

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer’s application or use of the products.

At the customer’s request, OMRON will provide applicable third party certification documents identifying ratings and

limitations of use th at ap ply to the products. This information by itself is no t sufficient for a complete determination of

the suitability of the products in combination with the end product, machine, system, or other application or use.

The following are some e xam pl es of app lications for which particular attentio n mu st b e giv en . This is not in tended to

be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses listed may be

suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not

described i n this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment,

amusement machines, vehicles, safety equipment, and installations subject to separate industry or government

regulations.

• Systems, machines, and equipment that could present a risk to life or property. Please know and observe all

prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY

WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS,

AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED FOR THE INTENDED USE

WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any consequence

thereof.

Page 12

Read and Understand this Manual

10

LCD Digital Operator User’s Manual (I579)

Disclaimers

CHANGE IN SPECIFICATIONS

Product specification s and ac cess ories may be chang ed a t any tim e bas ed on im prove ment s and othe r reason s. I t is

our practice to change mo del numbers when published ratings or features are changed, or when significant

construction changes are made. However, some specifications of the products may be changed without any notice.

When in doubt, special model num bers may be as sig ne d to fix or est ab li sh k ey sp ec ifi ca tions for your application on

your request. Please consult with your OMRON representative at any time to confirm actual specifications of

purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and ar e not to be used for manufact uring purpos es, even when tolerances ar e

shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does not

constitute a warranty. It may represent the result of OMRON’s test conditions, and the users must correlate it to

actual application requirements. Actual performance is subject to the OMRON Warranty and Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manua l has been careful ly chec ked and is believ ed to be accura te; howe ver, no responsibility

is assumed for clerical, typographical, or proofreading errors, or omissions.

Page 13

11

Safety Precautions

LCD Digital Operator User’s Manual (I579)

Safety Precautions

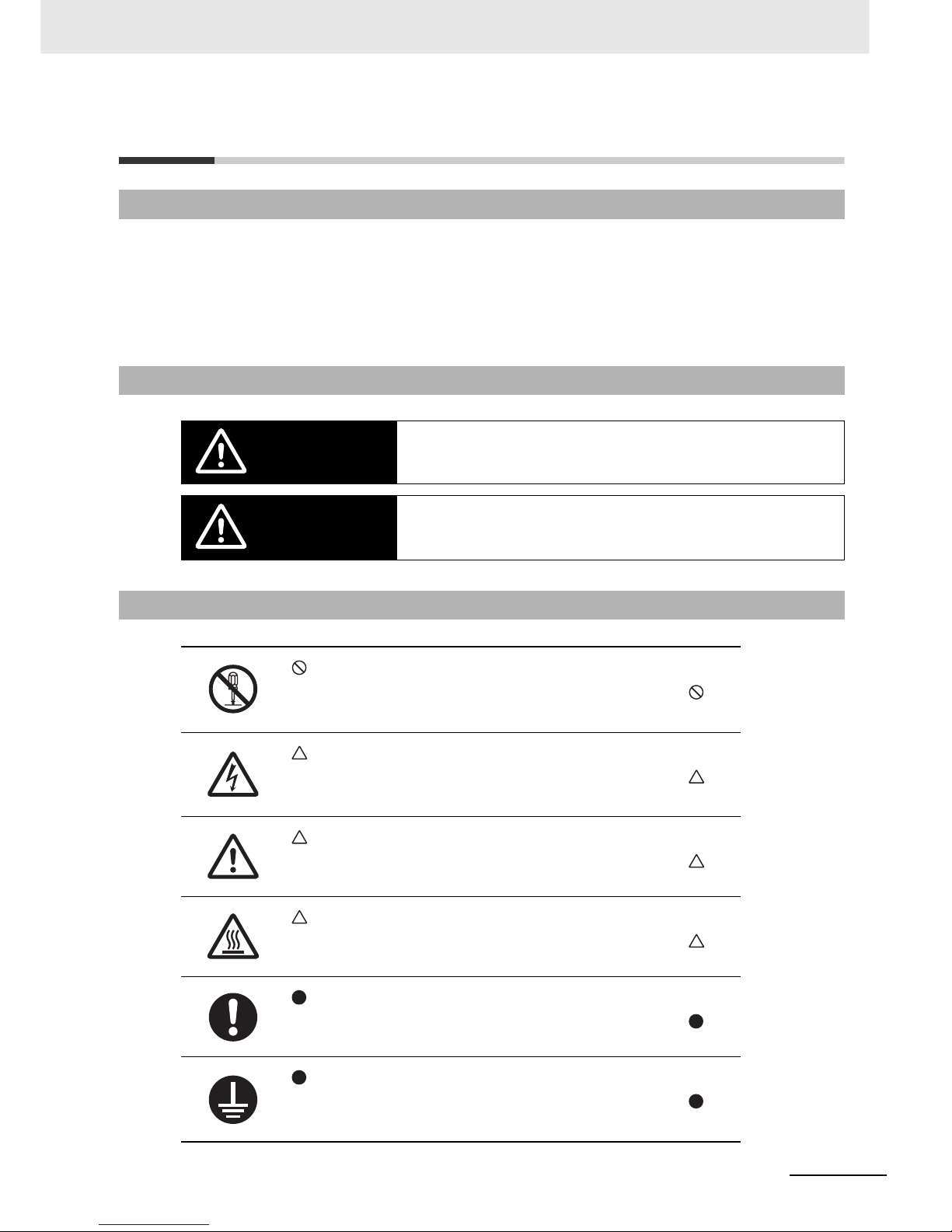

This manual uses the following precautionary symbols and signal words to ensure the safe use of the

LCD Digital Operator. The precautions explained in this section describe important information

regarding safety and must be followed without fail.

The precautionary symbols and signal words used in this manual and their meanings are explained

below.

Indications and Meanings of Safety Information

Meanings of Signal Words

Indicates an imminently hazardous situation which, if not avoided, is likely to result in

serious injury or may result in death. Additionally there may be severe property

damage.

Indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury or in property damage.

Explanation of Symbols

This symbol indicates a prohibited item (an item you must not do).

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “disassembly prohibited”.

This symbol indicates danger and caution.

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “beware of electric shock”.

This symbol indicates danger and caution.

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates a “non-specific general danger”.

This symbol indicates caution (including warning).

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “risk of hot surface”.

This symbol indicates a compulsory item (an item that must be done).

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates a “general compulsory item”.

This symbol indicates a compulsory item (an item that must be done).

The specific instruction is indicated using an illustration or text inside or near .

The symbol shown to the left indicates “grounding required”.

WARNING

CAUTION

Page 14

Safety Precautions

12

LCD Digital Operator User’s Manual (I579)

Turn off the power supply and implement wiring correctly.

Not doing so may result in a serious injury due to an electric shock.

Wiring work must be carried out only by qualified personnel.

Not doing so may result in a serious injury due to an electric shock.

Do not change wiring and slide switches (SW1), put on or take off Operator and optional devices, replace

cooling fans while the input power is being supplied. Doing so may result in a serious injury due to an

electric shock.

Be sure to ground the unit. Not doing so may result in a serious injury due to an electric shock or fire.

(200V class: type-D grounding, 400V class: type-C grounding)

Do not remove the terminal cover during the power supply and 10 minutes after the power shut off.

Doing so may result in a serious injury due to an electric shock.

Do not operate the Operator or switches with wet hands.

Doing so may result in a serious injury due to an electric shock.

Inspection of the Inverter must be conducted after the power supply has been turned off. Not doing so may

result in a serious injury due to an electric shock.

The main power supply is not necessarily shut off even if the emergency shut off function is activated.

Do not touch the Inverter fins, braking resistors and the motor, which become too hot during the power

supply and for some time after the power shut off. Doing so may result in a burn.

Do not connect resistors to the terminals (+1, P/+2, N/-) directly. Doing so might result in a small-scale fire,

heat generation or damage to the unit.

Install a stop motion device to ensure safety. Not doing so might result in a minor injury. (A holding brake is

not a stop motion device designed to ensure safety.)

Be sure to use a specified type of braking resistor/regenerative braking unit. In case of a braking resistor,

install a thermal relay that monitors the temperature of the resistor. Not doing so might result in a moderate

burn due to the heat generated in the braking resistor/regenerative braking unit. Configure a sequence that

enables the Inverter power to turn off when unusual over heating is detected in the braking resistor/

regenerative braking unit.

The Inverter has high voltage parts inside which, if short-circuited, might cause damage to itself or other

property. Place covers on the openings or take other precautions to make sure that no metal objects such

as cutting bits or lead wire scraps go inside when installing and wiring.

Take safety precautions such as setting up a molded-case circuit breaker (MCCB) that matches the

Inverter capacity on the power supply side.

Not doing so might result in damage to property due to the short circuit of the load.

Do not dismantle, repair or modify the product.

Doing so may result in an injury.

WARNING

CAUTION

Page 15

13

Precaution s for Safe Use

LCD Digital Operator User’s Manual (I579)

Precautions for Safe Use

Do not store or use the product in the following places.

• Locations subject to direct sunlight.

• Locations subject to ambient temperature exceeding the specifications.

• Locations subject to relative humidity exceeding the specifications.

• Locations subject to condensation due to severe temperature fluctuations.

• Locations subject to corrosive or flammable gases.

• Locations subject to exposure to combustibles.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

• Take sufficient shielding measures when using the product in the following locations. Not doing so

may result in damage to the product.

Locations subject to static electricity or other forms of noise.

Locations subject to strong magnetic fields.

Locations close to power lines.

• If a parameter is set incorrectly when starting up, adjusting, maintaining, or replacing, an unexpected

operation may occur.

Perform the operation after enough confirmation.

• If the clock command is used in Drive Programming, an unexpected operation may occur due to

weak battery. Take measures such as detecting a weak battery by a check that the clock data returns

to the initial setting and stopping the Inverter or programs. When the LCD Digital Operator is

removed or disconnected, Drive Programming is in a waiting status by the clock command.

Installation and Storage

T ransporting, Installation, and Wiring

Operation and Adjustment

Page 16

Precautions for Safe Use

14

LCD Digital Operator User’s Manual (I579)

• When disposing of LCD digital operators and wasted batteries, follow the applicable ordinances of

your local government.

When disposing of the battery, insulate it using tape.

• Do not short + and -, charge, disassemble, heat, put into the fire, or apply strong impact on the

battery. The battery may leak, explode, produce heat or fire. Never use the battery which was applied

strong impact due to such as fall on the floor, it may leak.

• UL standards establish that the battery shall be replaced by an expert engineer.

The expert engineer must be in charge of the replacement and also replace the battery according to

the method described in this manual.

• When the display of LCD Digital Operator can not be recognized due to the service life, replace the

LCD Digital Operator.

Maintenance and Inspection

The following display must be indicated when products using lithium primary batteries (with

more than 6 ppb of perchlorate) are transport to or through the State of California, USA.

The 3G3AX-OP05 has the lithium primary battery (with more than 6 ppb of perchlorate). Label

or mark the above display on the ext erio r of all out er shi ppi ng pa ck ag es of yo ur prod uc ts when

exporting your products which the 3G3AX-OP05 are installed to the State of California, USA.

Perchlorate Material - special handling may apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate

Page 17

15

Precautions for Correct Use

LCD Digital Operator User’s Manual (I579)

Precautions for Correct Use

• Be sure to confirm the RUN signal is turned off before resetting the alarm because the machine may

abruptly start.

• Provide a separate emergency stop switch because the STOP Key on the Operator is valid only

when function settings are performed.

Retry Selection Function

Operation Stop Command

Page 18

Regulations and Standards

16

LCD Digital Operator User’s Manual (I579)

Regulations and Standards

To export (or provide to nonresident aliens) any part of this product that falls under the category of

goods (or technologies) for which an export certificate or license is mandatory according to the Foreign

Exchange and Foreign Trade Control Law of Japan, an export certificate or license (or service

transaction approval) according to this law is required.

Overseas Use

Page 19

17

Items to Check after Unpacking

LCD Digital Operator User’s Manual (I579)

Items to Check after Unpacking

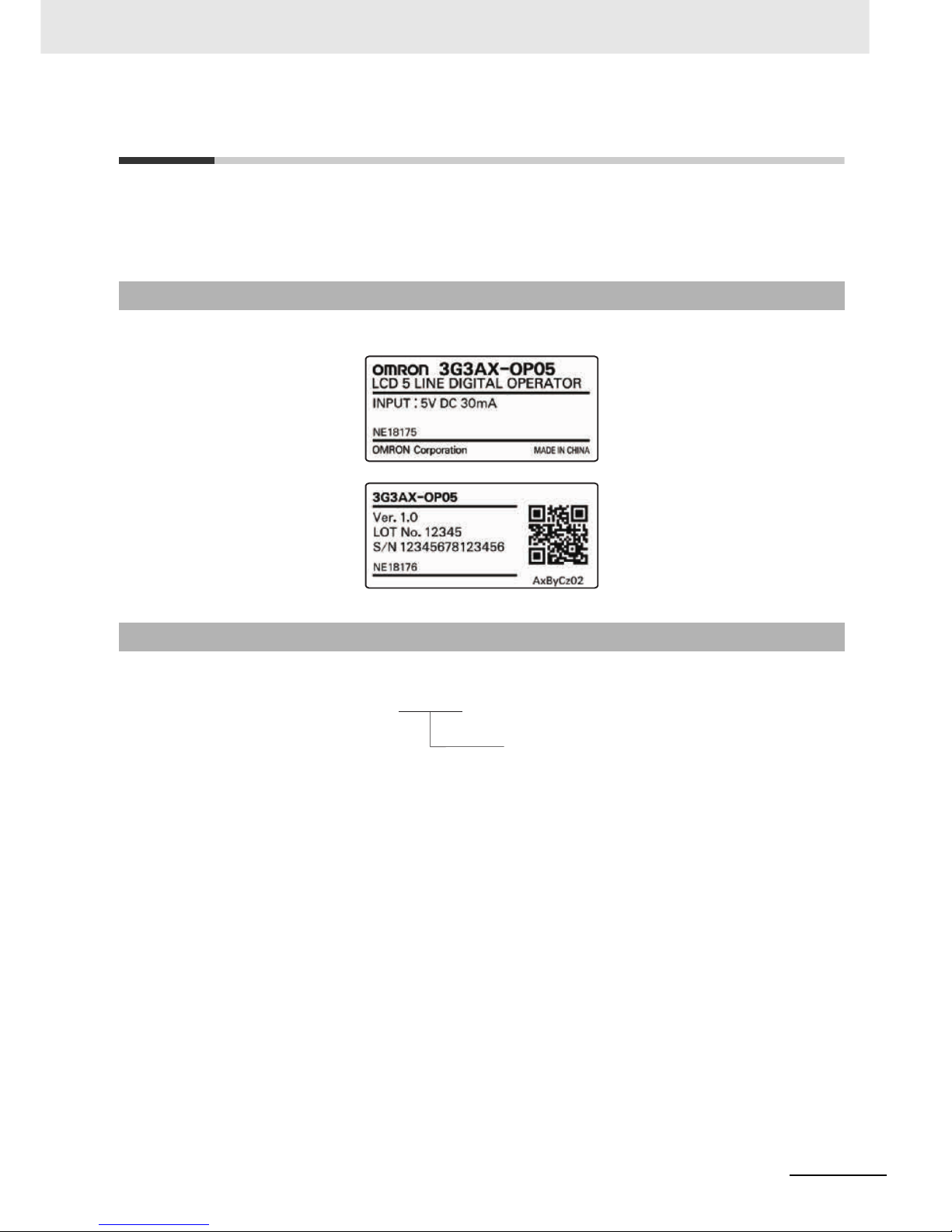

After unpacking the product, check the following items:

• Is this the model you ordered?

• Was there any damage sustained during shipment?

The product has

the following nameplate labels on its rear face

.

Checking the Nameplate

Checking the Model

3G3AX-OP 05

LCD Digital Operator

Page 20

Related Manuals

18

LCD Digital Operator User’s Manual (I579)

Related Manuals

To operate this product, you must be familiar with the equipment connected to it.

Please refer to the following manual for information on the related product.

Additional Information

For Inverter operation, please refer to the manual for the Inverter.

Name Catalog No.

RX User’s Manual I560-E2

LX User’s Manual I120E-EN

MX2 User’s Manual I570-E2

Page 21

19

Revision History

LCD Digital Operator User’s Manual (I579)

Revision History

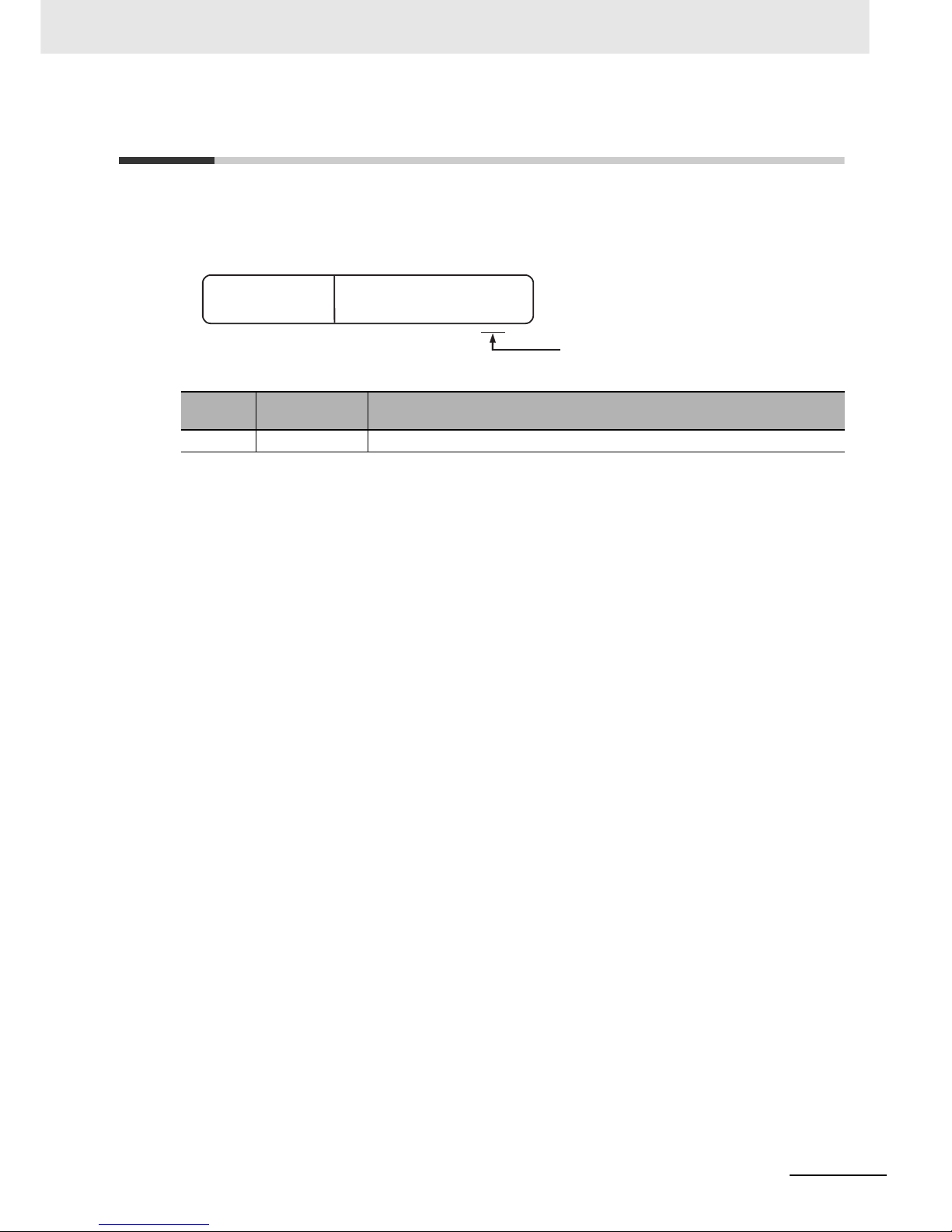

The manual revision code is a number appended to the end of the catalog number found in the bottom

right-hand corner of the front and back covers.

Example

Revision

Code

Revision Date Revised Content

01 January 2013 This manual replaces the LCD 5 Line Digital Operator Manual (I171E-EN-01)

Cat. No.

I579-E2-01

Revision code

Page 22

Revision History

20

LCD Digital Operator User’s Manual (I579)

Page 23

1 - 1

1

1

LCD Digital Operator User’s Manual (I579)

This section provides features and specifications of the LCD Digital Operator.

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Supported Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-4 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-5 Recommended Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Overview

Page 24

1 Overview

1 - 2

LCD Digital Operator User’s Manual (I579)

1-1 Features

This LCD Digital Operator is intended for use with the RX, LX or MX2 inverter series.

It can be connected with the RX and LX inverters directly or with the RX, LX and MX2 inverters via

cable (optional).

The LCD Digital Operator provides the following features:

A large 5-line LCD displays the name and setting range of parameters as well as the parameter

number, which improves the user’s recognition performance during parameter setting and

adjustment.

In addition, the display of up to four monitor functions enables you to check the status, adjust the

Inverter, and etc.

In case of a trip w ar ni n g, bo t h th e co d e a nd na m e of warning are displayed so tha t yo u c an pe r fo r m

early troubleshooting.

The all READ function enables to read all the parameter setting data stored in the Inverter. Up to

four sets of Inverter parameter setting data can be read and stored in the internal memory of the

LCD Digital Operator.

The parameter setting data in the memory can be all written, only if the Inverters are of the same

model and version.

Using this feature, the time for setting parameters can be reduced when the same devices are

started up or specifications are changed.

Or it is possible to store, upload and download up to a single set of Inverter parameter setting data

and a Drive Programming program.

This function enables to compare and verify parameters of the connected Inverter, Drive

Programming, and data stored in the internal memory of the LCD Digital Operator. It is useful when

checking conditions before shipment or in case of a trouble.

Using the optional cable (Model: 3G3AX-OPCN1/OPCN3) enables you to mount the LCD Digital

Operator on the surface of system panel. You can check and adjust the system status from outside

the control panel.

The LCD Digital Operator has the built-in clock function and a backup battery.

This enables the display of time information on the Current Time Monitor (d031).

This clock function is also available in the Drive Programming program.

5-Line English LCD

All Read/Write Functions for Inverter Parameters and Drive

Programming

VERIFY Function for Inverter Parameters and Drive Programming

Installation on the System Panel

Built-in Clock Function

Page 25

1 - 3

1 Overview

LCD Digital Operator User’s Manual (I579)

1-1 Features

1

Precautions for Safe Use

• If the clock command is used in Drive Programming, an unexpected operation may occur due

to weak battery. Take measures such as detecting a weak battery by a check that the clock

data returns to the initial setting and stopping the Inverter or programs. When the LCD Digital

Operator is removed or disconnected, Drive Programming is in a waiting status by the clock

command.

Precautions for Correct UsePrecautions for Correct Use

• The all WRITE function is available to write inverter parameters and Drive Programming only

with Inverters of the same model and version.

If the all WRITE function does not work, check the Inverter models and versions and, if they

are different, consider using the Inverter/Servo Parameter Support Tool CX-Drive.

Page 26

1 Overview

1 - 4

LCD Digital Operator User’s Manual (I579)

1-2 Supported Models

RX series inverter (Model: 3G3RX-).

LX series inverter (Model: 3G3LX-).

MX2 series inverter (Model: 3G3MX2-).

Page 27

1 - 5

1 Overview

LCD Digital Operator User’s Manual (I579)

1-3 Specifications

1

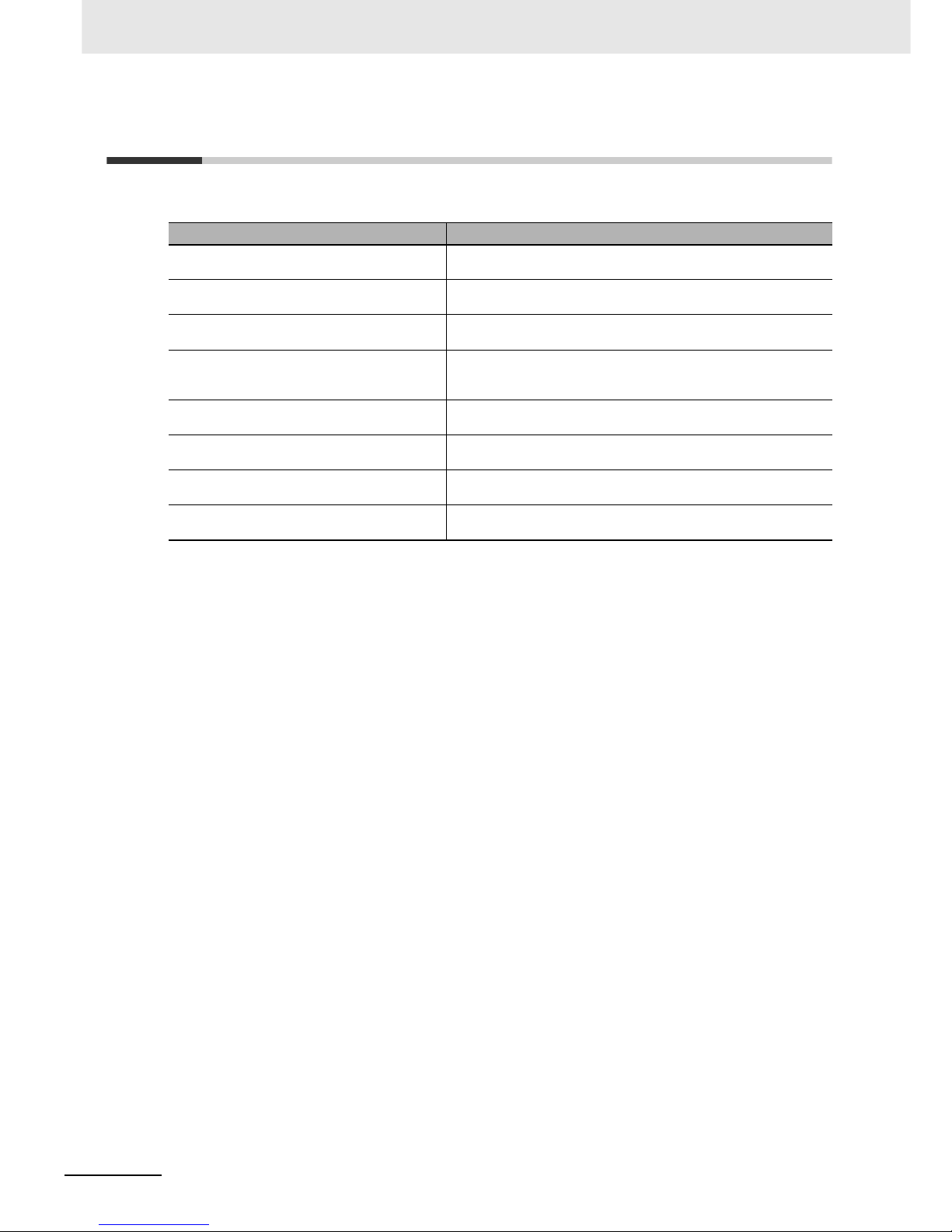

1-3 Specifications

Item Specification

Electrical

specifications

Input power supply

voltage

4.9 to 5.2 VDC

Transmission method RS-422 (R45)

Transmissi on rate 19.2 Kbps/4,800 bps (switching)

Environment Ambient operating

temperature

–10 to 50°C

Ambient operating

humidity

20% to 90% (with no condensation)

Ambient storage

temperature

–20 to 65°C

Location of use 1,000 m or less in height (at a place with no corrosive gas and dust)

Installation External dimensions 123 (H) x 80 (W) x 21 (D) mm

Connection type Direct or via cable (3G3AX-OPCN1/OPCN3)

Weight 0.1 kg

Display

specifications

Display Digital display on LCD (132 x 64 dots)

Display language English

Others Number of writes to

built-in EEPROM

during service life

100,000 times

Battery specifications Coin type lithium battery CR1220 (Recommended manufacturer:

Hitachi Maxell)

* Built-in real time clock backup duration: About 4 years (at 25°C)

(Including power OFF time)

Clock accuracy Error per month: –1.5 to 1.5 min

Page 28

1 Overview

1 - 6

LCD Digital Operator User’s Manual (I579)

1-4 External Dimensions

The following figures show the dimensions of LCD Digital Operator and panel cut dimensions to install.

When installing the LCD Digital Operator to the control panel, secure it from the back side using M3

screws (5 m m).

The recommended torque is 0.9 to 1.0 N·m.

80

18

2-ø4

26.5

18

2

103

6.5

External Appearance of the LCD Digital Operator Panel Cutout Diagram

Page 29

1 - 7

1 Overview

LCD Digital Operator User’s Manual (I579)

1-5 Recommended Cables

1

1-5 Recommended Cables

Use any of the following cables when installing the LCD Digital Operator separately from the RX, LX or

MX2 inverter series.

Digital Operator cables

• 3G3AX-CAJOP300-EE (Cable length: 3 m)

Page 30

1 Overview

1 - 8

LCD Digital Operator User’s Manual (I579)

Page 31

2 - 1

2

2

LCD Digital Operator User’s Manual (I579)

This section describes the part names and functions of the LCD Digital Operator.

2-1 Part Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-2 Operation Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-3 LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Part Names and Functions

Page 32

2 Part Names and Functions

2 - 2

LCD Digital Operator User’s Manual (I579)

2-1 Part Names

4. ALARM LED

1. POWER LED

2. RUN (Operation) LED

3. WARNING LED

7. LCD display

8. Operation keys

5. Remote LED

6. RUN command LED

indicator

10. Mounting holes

(M3: 2 positions)

9. RJ45 connector

Page 33

2 - 3

2 Part Names and Functions

LCD Digital Operator User’s Manual (I579)

2-1 Part Names

2

Precautions for Correct UsePrecautions for Correct Use

• Determine whether the operation keys (FWD RUN, REV RUN, and STOP/RESET keys) are

enabled based on the ON/OFF status of the RUN command LED indicator. Remember that

the operation keys may be enabled even when the remote LED is not lit.

• The remote LED lights only when the forced operator function is enabled by pressing the

LOCAL REMOTE key for 2 seconds or more.

Note that the remote LED does not light if the forced operator function is enabled by the

multi-function input which is set the forced operator function (OPE).

In this case, determine whether the forced operator function (OPE) is enabled based on the

status of the multi-function input terminal.

No. Name Color Description

1 POWER LED Green Lights when power is supplied to the LCD Digital Operator.

2 RUN (Operation)

LED

Green Lights during Inverter operation.

3 WARNING LED Red

Lights when the Inverter parameter settings are incorrect.

4 ALARM LED Red Lights when the Inverter trips.

5 Remote (OPE)

LED

Green Lights when the forced operator function is enabled by the

LOCAL REMOTE key. (Press the LOCAL REMOTE key for

2 seconds or more.).

6 RUN command

LED indicator

Green Lights when the RUN command is enabled on the LCD Digital

Operator. At this time, the FWD RUN, REV RUN, and

STOP/RESET keys can be used to operate the Inverter.

7 LCD display Displays various parameter settings, frequency, or other information. For

details, refer to

Section 4 Operation Procedures, Section 5 LCD Digital

Operator Related Parameters

, and

Section 6 Read/Write Functions

.

8 Operation keys These keys are u sed for display a nd setti ng. For d etails , refer to

Section 4

Operation Procedures

,

Section 5 LCD Digital Operator Related

Parameters

, and

Section 6 Read/Write Functions

.

9 RJ45 connector Connects the LCD Digital Operator with the Inverter directly or via cable

(sold separately).

10 Mounting holes Use these holes to install the LCD Digital Operator on the control panel.

Secure it from the back side using M3 screws.

Page 34

2 Part Names and Functions

2 - 4

LCD Digital Operator User’s Manual (I579)

2-2 Operation Keys

No. Key image Name Function

1

LOCAL REMOTE

key

Switches between the Local and Remote modes. If the key is

pressed for 2 seconds or more, the mode is switched; from

Local to Remote or from Remote to Local. When the LCD

Digital Operator is in the Local mode, the Remote (OPE) LED

is lit. Use the Local mode to operate the Inverter using the

LCD Digital Operator’s operation keys (FWD RUN, REV RUN,

and STOP/RESET).

2 READ key

Reads all the parameter setting data into the LCD Digital

Operator’s memory. For details, refer to Section 5 LCD Digital

Operator Related Parameters.

3WRITE key

Copies a single set of Inverter parameter setting data, or a

single set of Inverter parameter setting data and a Drive

Programming program, stored on the LCD Digital Operator

into the Inverter. For details, refer to Section 5 LCD Digital

Operator Related Parameters.

4 ESC key

Returns to a screen in the one level higher layer.

If pressed during a parameter change, the LCD Digital

Operator displays the previous screen with the change

cancelled.

5Enter key

Brings you forward to the screen that is one level lower in the

hierarchy.

If pressed during a parameter change, the LCD Digital

Operator displays the previous screen with the change fixed

and stored.

6Increment key

Moves the cursor up.

It is also used to increase the param eter numbe r or param eter

value.

Operation keys

Page 35

2 - 5

2 Part Names and Functions

LCD Digital Operator User’s Manual (I579)

2-2 Operation Keys

2

*1 Check the KEY ENABLED indicator (RUN command LED indicator).

Precautions for Safe Use

• Provide a separate emergency stop switch because the STOP key on the operator is valid

only when function settings are performed.

• The FWD RUN, REV RUN, and STOP/RESET keys are disabled while the Inverter parameter

settings are all read or written. Perform the all read/write functions during Inverter stop.

7 Decrement key

Moves the cursor do wn.

It is also used to decre ase the para meter number or p arameter

value.

8 PREV PAGE key

Moves the cursor to the left.

In Navigation lev el dis play mo de, mo ves to the pre vious mode .

9 NEXT PAGE key

Moves the cursor to the right.

In Navigation level display mode, moves to the next mode.

10

FWR RUN key

*1

Runs the motor in the forward direction.

This key is enabled in the following cases.

• The remote mode is enabled by pressing the LOCAL

REMOTE key for 2 seconds (the remote LED is lit).

•

RUN Command Selection (A002) is set to “02: Digital

operator”.

•

The forced operator function is enabled by the multi-func tion

input which is set the forced operator function (OPE).

11

REV RUN key

*1

Runs the motor in the reverse direction.

This key is enabled in the following cases.

•

The remote mode is enabled by pressing the LOCAL

REMOTE key for 2 seconds (the remote LED is lit).

•

RUN Command Selection (A002) is set to “02: Digital

operator”.

•

The forced operator function is enabled by the multi-func tion

input which is set the forced operator function (OPE).

12 STOP/RESET key

Stops the motor, or resets the alarm.

When the parameter b087 (Stop key selection) is set to “01:

Disable,” this key is enabled in the following cases only.

•

The remote mode is enabled by pressing the LOCAL

REMOTE key for 2 seconds (the remote LED is lit).

•

RUN Command Selection (A002) is set to “02: Digital

operator”.

•

The forced operator function is enabled by the multi-func tion

input which is set the forced operator function (OPE).

No. Key image Name Function

Page 36

2 Part Names and Functions

2 - 6

LCD Digital Operator User’s Manual (I579)

2-3

LCD Display

The LCD display has two backlight colors; white and orange.

The color of the backlight indicates the state of the Inverter, as shown in the following table.

The first line of LCD display always shows the display mode, the selected motor, the Inverter RUN

status, and the display selection.

Backlight

Backlight color State

White Normal (No relation to the RUN/Stop state of the Inverter)

Orange Warning (Parameter mismatch)

White/Orange

(Flashing alternately at intervals of 1 second)

Trip (Same as the ALARM LED)

LCD Display

Item Display item Description

Display mode

MONITOR-A Monitor Mode A

MONITOR-B Monitor Mode B

FUNCTION Function Mode

TRIP Trip Mode (Error)

WARNING Warning Mode (Warning)

READ Read Mode

WRITE Write Mode

OPTION Option Mode

Control target No.

M1 1st control (Normal)

M2 2nd control (allocate Multi-function Input S1 to S8

Selection (C001 to C008) to

“08: SET” and turn ON to

switch)

M3 3rd control (allocate Multi-function Input S1 to S8

Selection (C001 to C008) to “17: SET3” and turn ON to

switch)

Control target No.

Display mode

Inverter RUN status

Display selection

Page 37

2 - 7

2 Part Names and Functions

LCD Digital Operator User’s Manual (I579)

2-3 LCD Display

2

Inverter RUN status

STOP Stop

FWD Forward

REV Reverse

Setting in b037

(Display Selection)

ALL Complete display

UTL Individual display of functions

USR User setting display

CMP Data comparison display

BAS Basic display

Item Display item Description

Page 38

2 Part Names and Functions

2 - 8

LCD Digital Operator User’s Manual (I579)

Page 39

3 - 1

3

3

LCD Digital Operator User’s Manual (I579)

This section provides information on the installation and wiring of the LCD Digital

Operator.

3-1 Installation on the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-1-1 Direct Installation on the Inverter (RX, LX models) . . . . . . . . . . . . . . . . . . . . . 3-3

3-1-2 Installation on the Inverter via Cable (RX, LX, MX2 models) . . . . . . . . . . . . . . 3-4

3-1-3 Checking the Operation After Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-1-4 Date and Time Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-1-5 Other Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Installation and Wiring

Page 40

3 Installation and Wiring

3 - 2

LCD Digital Operator User’s Manual (I579)

3-1 Installation on the Inverter

This section shows how to install the LCD Digital Operator on the RX, LX and MX2 inverter series.

The installation procedure differs with installation methods. This section describes the following

2 methods.

• Direct installation on the Inverter

• Installation on the Inverter via cable

Precautions for Correct UsePrecautions for Correct Use

• Shut off the power supply to the Inverter before installing or removing the LCD Digital

Operator. Not doing so may result in failure.

• The LCD Digital Operator cannot be installed directly on an Inverter that is already mounted

with a Communications Unit.

Section Title Description

3-1-1 Direct installation on the Inverter Describes the procedure for installing the LCD Digital Operator

directly on the Inverter.

3-1-2 Installation on the Inverter via

Cable

Describes the pro cedure for i nst alling the LCD D igit al Operat or on

the Inverter via cable in situations where:

• The LCD Digital Operator is installed on the control panel.

• The use of a Communications Unit prev en t s dire ct ins tallation

on the Inverter.

Page 41

3 - 3

3 Installation and Wiring

LCD Digital Operator User’s Manual (I579)

3-1 Installation on the Inverter

3

3-1-1 Direct Installation on the Inverter (RX, LX models)

This section describes the procedure for installing the LCD Digital Operator directly on the Inverter.

Precautions for Correct UsePrecautions for Correct Use

The LCD Digital Operator cannot be installed directly on an Inverter that is already mounted with

a Communications Unit.

1

Remove the Digital Operator and the spacer cover

from the Inverter.

2

Install the LCD Digital Operator on the Inverter.

Additional Information

To facilitate installation, raise the connector of the Inverter and push the LCD Digital Operator

into the Inverter.

3-1-1 Direct Installatio n on the Inv e rt e r (RX, LX models)

Page 42

3 Installation and Wiring

3 - 4

LCD Digital Operator User’s Manual (I579)

1

If necessary, mount theLCD Digital

Operator to the pane l. Cut out the p anel

according to the panel cutout diagram

and, using M3 screws, secure the LCD

Digital Operator to the panel from the

back side.

The recommended torque is 0.9 to 1.0

N·m.

For panel cutout dimensions, refer to

1-4 External Dimensions on page 1-6.

2

Connect the LCD Digital Operator with the

Inverter via cable.

• Recommended cable model:

3G3AX-CAJOP300-EE (Cable length: 3 m)

3-1-2 Installation on the Inverter via Cable (RX, LX, MX2 models)

Page 43

3 - 5

3 Installation and Wiring

LCD Digital Operator User’s Manual (I579)

3-1 Installation on the Inverter

3

3-1-3 Checking the Operation After Installation

After checking that the system and surrounding areas are safe, turn ON the power supply to the

Inverter.

Check the LCD Digital Operator display.

The installation is completed successfully if the following Monitor screen is displayed.

However, when the power is supplied to the LCD Digital Operator for the first time after purchase, when

the built-in battery is consumed, or when the power supply is turned on for the first time after battery

replacement, the following screen appears, which prompts you to set the clock. If this screen is

displayed, press the ESC key to move to the normal screen and perform the Date and Time setting

from the OPTION MODE menu. For the Date and Time setting, refer to 3-1-4 Date and Time Setting on

page 3-6.

The LCD Digital Operator may display the COM ERROR screen, or the Read & Copy only screen when

the power is supplied. In this case, choose INV Type Select from the OPTION MODE menu and set the

type of the Inverter to be used.

For details, refer to 5-1-2 Details of Each Option Mode Parameter on page 5-4.

Precautions for Correct UsePrecautions for Correct Use

• The LCD Digital Operator can be used without configuring the Date and Time setting.

However, if the clock command is used in Drive Programming, configure the Date and Time

setting. Not doing so may result in an unexpected operation due to the lack of the correct date

and time information.

• The available display language is only English on this LCD Digital Operator. Be sure to set

the Language option to “01: English”.

If the language display is abnormal, check from the OPTION MODE menu to be sure that the

Language is set to “01: English”.

For details, refer to 5-1-1 Operation in the Option Mode on page 5-2.

3-1-3 Checking the Operation After Installation

Page 44

3 Installation and Wiring

3 - 6

LCD Digital Operator User’s Manual (I579)

If the screen, which prompts you to set the clock, appears as shown below, press the ESC key to return

to the normal screen

and simultaneously press the , , and keys to enter the Option Mode.

Select Date and Time by pressing the key to set the current date and time.

Additional Information

The screen, which prompts you to set the clock, disappears automatically in 3 minutes after the

power supply is turned on.

Change the LCD Digital Operator settings (in the Option Mode) and Inverter parameter settings as

required.

For details about changing the parameter settings, refer to Section 5 LCD Digital Operator Related

Parameters.

3-1-4 Date and Time Setting

3-1-5 Other Settings

Page 45

4 - 1

4

4

LCD Digital Operator User’s Manual (I579)

This section provides an overview of the display modes supported by LCD Digital

Operator and how to operate the LCD Digital Operator in each display mode.

For the Option Mode, refer to Section 5 LCD Digital Operator Related Parameters. For

the Read/Write Mode, refer to Section 6 Read/Write Functions.

4-1 Overview of Display Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-1-1 Transition of Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-1-2 Overview of Each Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4-1-3 Changing the Display in Each Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4-2 Operation in the Monitor Mode A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4-3 Operation in the Monitor Mode B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4-4 Operation in the Function Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4-5 Operation in the Trip Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Operation Procedures

Page 46

4 Operation Procedures

4 - 2

LCD Digital Operator User’s Manual (I579)

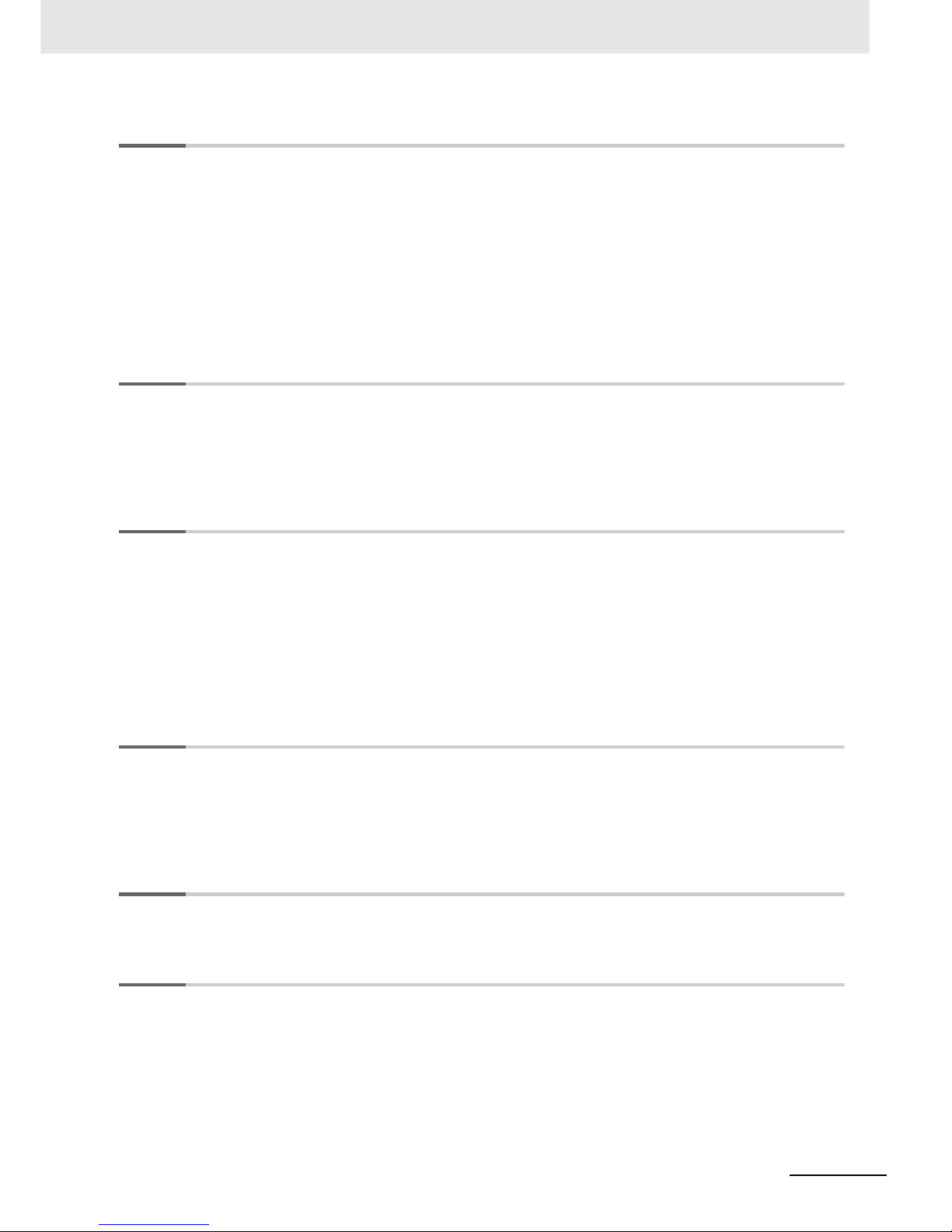

4-1 Overview of Display Modes

The basic display screens of LCD Digital Operator are displayed in four modes as shown below.

Each mode has two levels: the higher Navigation level and the lower Edit level. The user can move

between each mode in the Navigation level only.

• Monitor Mode A: The mode to display and set a single monitor function and a single parameter

function.

• Monitor Mode B: The mode to display up to four monitor functions on a single screen.

• Function

Mode

: The

mode

to set parameter settings. The screen also displays the

parameter

name

and setting range.

• Trip Mode: The mode to display the trip and warning information.

In addition to the above, the LCD Digital Operator has the following three called modes. At any of the

above levels and in any operating state, you can call these modes by pressing the key(s) shown to the

right of the down arrow above each screen, as shown on the next page. After calling these screens, you

can press the ESC key to restore the operating state before the call.

• All Read: The mode to read all Inverter parameter settings and Drive Programming data from the

Inverter.

• All Write: The mode to write all Inverter parameter setting and Drive Programming data to the

Inverter.

• Option Mode: The mode to set the LCD Digital Operator.

4-1-1 Transition of Screens

Navigation levelEdit level

Monitor

Mode A

Monitor

Mode B

Function

Mode

Trip

Mode

Select the monitor item.

Select the setting item.

Select the setting

line.

Select the setting

item.

Monitor the overall

trip history.

Monitor

Mode A

Monitor

Mode B

Function

Mode

Trip

Mode

Monitor

Mode A

Monitor

Mode B

Function

Mode

Change the set value. Change the set value. Change the set value.

Page 47

4 - 3

4 Operation Procedures

LCD Digital Operator User’s Manual (I579)

4-1 Overview of Display Modes

4

4-1-2 Overview of Each Mode

In this mode, one “d” group Inverter monitor function and one

“F to U” group Inverter parameter are displayed on the same

screen.

The content of “d” group Inverter monitor function is displayed

in a large font size. The parameter number such as “F001” and

the content of “F to U” parameter are displayed without the

function name.

In this mode, four “d” group Inverter

monitor functions can be displayed on the same screen.

At this time, the parameter numbers are not displayed.

These modes can be called at any level and in any operating state.

Press the ESC key to restore the operating state before the call.

4-1-2 Overview of Each Mode

Monitor Mode A

Monitor Mode B

Read

Mode

Write

Mode

Option

Mode

Option

Mode

Option

Mode

Change the set values of

the LCD Digital Operator.

Select the setting item.

Press three keys

simultaneously.

Page 48

4 Operation Procedures

4 - 4

LCD Digital Operator User’s Manual (I579)

In this mode, “F to U” group Inverter parameters can be

displayed and set.

The screen shows the parameter number, function name,

parameter data and setting range of the parameter.

Precautions for Correct UsePrecautions for Correct Use

In the Function Mode, “d” group Inverter monitor functions cannot be displayed and set.

Trip information and warning information are displayed in this

mode.

If a trip or a warning occurs in the Inverter, the trip screen is

displayed from any display mode.

In the Option Mode, Read Mode, and Write Mode, the trip

screen is not displayed even if an Inverter trip or warning

occurs.

The ALARM or WARNING LED lights up.

In this mode, a single set of Inverter parameter settings, or a

single set of parameter settings and a Drive Programming

program, can be all read and stored in the LCD Digital

Operator.

Select a single set or four sets of storage data by 5. R/W

Storage Mode in the OPTION MODE menu.

For details about the Read Mode, refer to Section 6

Read/Write Functions.

Function Mode

Trip Mode

Read Mode

Case: 5. R/W Storage Mode = “01 :Single”

Case: 5. R/W Storage Mode = “02: Quad”

Page 49

4 - 5

4 Operation Procedures

LCD Digital Operator User’s Manual (I579)

4-1 Overview of Display Modes

4

4-1-3 Changing the Display in Each Mode

In this mode, the Inverter parameter settings and

Drive Programming program data stored in the LCD

Digital Operator can be all written to the Inverter.

Change the number of storage data by selecting 5. R/W

Storage Mode in the OPTION MODE menu.

For details about the Write Mode, refer to Section 6

Read/Write Functions.

In this mode, the parameter settings of the LCD Digital Operator can be set and changed.

This mode supports the following settings of the LCD Digital

Operator.

1. Language

2. Date and Time

3. Read Lock

4. INV Type Select

5. R/W Storage Mode

6. Backlight Auto-off

7. Backlight Flicker

8. Operator Reset

9. Check Mode

For details about the Option Mode, refer to Section 5 LCD Digital Operator Related Parame ters.

Each display mode can be switched by pressing the or key in the Navigation level.

In each mode, press the key to move to the Edit level and press the key to move to the

Navigation level. To move to the Read or Write Mode, press the or key.

To move to the Option Mode, press the , , and keys simultaneously.

For the transition between display modes, refer to the figure in 4-1-1 T ransition of Screens on page 4-2.

Write Mode

Option Mode

4-1-3 Changing the Display in Each Mode

Case: 5. R/W Storage Mode = “01 :Single”

Case: 5. R/W Storage Mode = “02: Quad”

Page 50

4 Operation Procedures

4 - 6

LCD Digital Operator User’s Manual (I579)

4-2 Operation in the Monitor Mode A

1

At the Navigation level, press the or

key to select the Monitor Mode A (MONITOR-A)

screen.

Press the key to show the cursor on the “d”

group monitor function.

2

Press the or key to select th e mo n it o r

function to display on the MONITOR-A screen.

Select the parameter number c orre sponding to th e

monitor function to display.

• Press the key to return to the Navigation

level.

3

To move the cursor position displayed on the

screen, press the or key.

When the cursor moves to the Inverter parameter

number displayed on the last line (in this case,

F001), you can change the parameter number by

the or key.

• Press the key to return to the Navigation

level.

4

After changing the Inverter parameter number,

press the key to move the cursor to the

parameter data position.

Change the parameter data using the or

key.

• To save the change, press the key. The cursor returns to the parameter number.

• To cancel the change, press the key.

The cursor returns to the parameter number.

Press the key to return to the Navigation level.

,

Page 51

4 - 7

4 Operation Procedures

LCD Digital Operator User’s Manual (I579)

4-3 Operation in the Monitor Mode B

4

4-3 Operation in the Monitor Mode B

1

At the Navigation level, press the or

key to select the Monitor Mode B (MONITOR-B)

screen.

2

Press the key to show the cursor in the first

parameter line of the “d” group monitor function.

Press the or key to move between the

four inverter parameters.

• Press the key to return to the Navigation

level.

3

Select the parameter to change and press the

key.

The cursor moves to the parameter number of the

selected “d” group monitor function.

Press the or key to select the

parameter number to monitor.

• To register the parameter number, press the key.

The screen returns to the parameter display screen.

• To cancel the change, press the key. The screen returns to the parameter display

screen.

• Press the key again to return to the Navigation level.

or

Page 52

4 Operation Procedures

4 - 8

LCD Digital Operator User’s Manual (I579)

4-4 Operation in the Function Mode

1

At the Navigation level, press the or

key to select the Function Mode screen.

2

Press the key. The cursor moves to the

parameter number. Then, press the , ,

, or key to select the parameter No. to

change.

• Press the key to return to the Navigation

level.

3

Press the key . The cursor is now placed over

the parameter data. Press the or key

to select the value to set.

• To save the parameter val ue, press the key.

When saved, the cursor moves to the parameter

number.

• To cancel the change, press the key. The cursor moves to the parameter number.

or

Page 53

4 - 9

4 Operation Procedures

LCD Digital Operator User’s Manual (I579)

4-5 Operation in the Trip Mode

4

4-5 Operation in the Trip Mode

1

At the Navigation level, press the or

key to select the Trip Mode screen.

2

Press the key to show the information on the

past trips (six trip errors) recorded in the Inverter

and the information on the warning (one warning).

The information on one trip error comprises two pages.

To switch from page 1 (P1) to page 2 (P2),

press the or key.

To display the information on the past six trip errors,

press the or key.

3

If you press the key when ERR1 is displayed

or press the key when ERR6 is displayed,

the screen switches to the Warning Mode.

Precautions for Correct UsePrecautions for Correct Use

If a trip occurs, the ALARM LED lights up. Then, press the key to reset the Inverter.

Page 54

4 Operation Procedures

4 - 10

LCD Digital Operator User’s Manual (I579)

Page 55

5 - 1

5

5

LCD Digital Operator User’s Manual (I579)

This section describes the Inverter parameters related to the LCD Digital Operator.

5-1 Parameter Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-1-1 Operation in the Option Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-1-2 Details of Each Option Mode Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-2 Related Inverter Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

LCD Digital Operator Related

Parameters

Page 56

5 LCD Digital Operator Related Parameters

5 - 2

LCD Digital Operator User’s Manual (I579)

5-1 Parameter Setting

The LCD Digital Operator parameters can be set and changed in the Option Mode.

The Option Mode provides the following nine settings:

1. Language

2. Date and Time

3. Read Lock

4. INV Type Select

5. R/W Storage Mode

6. Backlight Auto-off

7. Backlight Flicker

8. Operator Reset

9. Check Mode

The next section describes how to operate in the Option Mode.

1

Press the , , and keys

simultaneously to enter the Option Mode.

The cursor appears in the first line of the OPTION

MODE menu. Press the or key to move

between the OPTION MODE menu.

To return to the Navigation level, press the key.

2

Select Language and press the key. The

cursor moves to the Language setting.

Press the or key to change the set

value.

• To save the change, press the key. The

screen returns to the OPTION MODE menu.

• To cancel the change, press the key.

The screen returns to the OPTION MODE menu.

Precautions for Correct UsePrecautions for Correct Use

The available display language is only English on this LCD Digital Operator. Even if other

language is set, the screen is displayed in English.

In the Language setting, always select “01: English”.

5-1-1 Operation in the Option Mode

or

Page 57

5 - 3

5 LCD Digital Operator Rela ted Parameters

LCD Digital Operator User’s Manual (I579)

5-1 Parameter Setting

5

5-1-1 Operation in the Option Mode

3

Press the to move the cursor over 2. Date

and Time in the second line.

4

In 2. Date and Time, press the key. The

cursor moves over the date and time data.

Press the or key to move among the day,

month, year, and time data. When the cursor is placed

over any of these data, you can change the value by

the or key.

• To save the change, press the key. The screen returns to the OPTION MODE menu.

• To cancel the change, press the key. The screen returns to the OPTION MODE menu.

or

Page 58

5 LCD Digital Operator Related Parameters

5 - 4

LCD Digital Operator User’s Manual (I579)

The table below shows the setting of each Option Mode item.

5-1-2 Details of Each Option Mode Parameter

Item Description Setting range Default

1. Language Select the display language. 01: English 01

2. Date and

Time

Set the date and time for the LCD Digital

Operator.

* On the screen, move the cursor over the

Format number and select the desired

format (1 to 3).

Format 1: (YYYY/MM/DD)

Date: 2000/01/01 to

2099/12/31

Time: 00:00 to 23:59

Format 2: (MM/DD/YYYY)

Date: 01/01/2000 to

12/31/2099

Time: 00:00 to 23:59

Format 3: (DD/MM/YYYY)

Date: 01/01/2000 to

31/12/2099

Time: 00:00 to 23:59

2009/01/01

THU 00:00

Format 1

3. Read Lock Select this to protect the parameter settings

stored in the LCD Digital Operator from

overwriting.

01: Enable

02: Disable

02

4. INV Type

Select

Select the type of the Inve rter used with this

LCD Digital Operator. If the set Inverter type

does not match the Inverter actually

connected, the LCD Digital Operator will

display “COM ERROR” automatically.

01: Type 1

(All models)

02: Type 2

(Do not set)

01

5. R/W Storage

Mode

Select a single set or four sets of Inverter

parameters to store in the LCD Digit a l

Operator’s internal memory. Setting this to

“01: Single” facilitates the operability and is

effective for writing to more than one

Inverter. For details, refer to Section 6

Read/Write Functions.

01: Single

(Single set of parameter

settings and one Drive

Programming program)

02: Quad

(Four sets of parameter

settings)

02

6. Backlight

Auto-off

Set the Backlight Auto-off function. The

backlight of LCD Digital Operator

automatically turns off if any key is not

pressed for 1 minute.

The backlight will light up again if you press

any key.

The Backlight Auto-off function will not work

if a trip occur.

01: Off (Disable)

02: 1 minute

01

Page 59

5 - 5

5 LCD Digital Operator Rela ted Parameters

LCD Digital Operator User’s Manual (I579)

5-1 Parameter Setting

5

5-1-2 Details of Each Option Mode Parameter

Precautions for Correct UsePrecautions for Correct Use

• The applicable Language option is “01: English” only.

The LCD Digital Operator may not provide the expected operation with other settings.

• Do not enable the EEPROM check. If you perform the EEPROM check, the data (parameter

setting and Drive Programming program data) stored in the LCD Digital Operator will be lost.

7. Backlight

Flicker

Set this to enable or disable the orange

backlight illumination.

01: Enable

02: Disable

01

8. Operator

Reset

Use this function to reset the LCD Digital

Operator to its default settings .

The following items will be reset:

1) Language: English

2) Date and Time:

2009/01/01 THU 00:00

3) Time Format: 01: YY/MM/DD

4) Read Lock: Disable

5) R/W Stora ge Mo de: Quad

6) Backlight Auto-off: Off

7) Backlight Flicker: Enable

After resetting the LCD Digital Operator, you

need to perf orm the Date and Time setting

again.

01: YES

02: NO

02

9. Check Mode Select this to check whether the LED s, ke ys

etc. work normally.

1: Key&Led Check

2: Lcd Check

3: RTC Check

4: EEPROM Check

5: Serial Loopback

6: Debug Mode

7: Firmware Version

–

Item Description Setting range Default

Page 60

5 LCD Digital Operator Related Parameters

5 - 6

LCD Digital Operator User’s Manual (I579)

5-2 Related Inverter Parameters

The table below shows the RX and MX2 Inverter parameters related to the LCD Digital Operator.

For details, please refer to RX (I560-E2) or MX2 (I570-E2) User’s Manuals.

*1 Setting b166 (Data Read/Write Selection) to “01: R/W protected” disables the all read/write functions and thus data

cannot be read/written from the LCD Digital Operator.

Parameter No. Function name Data

Default

value

Unit

b031 Soft Lock Selection

00: Data other than b031 cannot be changed when

terminal SFT is ON.

01: Data other than b031 and set freque nc y c an not be

changed when terminal SFT is ON.

02: Data other than b031 cannot be changed.

03: Data other than b031 and set freque nc y c an not be

changed.

10: Data can be changed during RUN.

01 –

b037 Display Selection 00: Complete display

01: Individual display of functions

02: User setting + b037

03: Data comparison display

04: Basic display

00 –

b038 Initial Screen Selection

000: Screen on w hich the Enter key was last pressed

001 to 060: d001 to d060

201: F001

202: Do not set

001 –

b087 STOP Key Selection 00: Enable

01: Disable

02: Only resetting enabled

00 –

b166 Data Read/Write

Selection

*1

00: R/W OK

01: R/W protected

00 –

Page 61

5 - 7

5 LCD Digital Operator Rela ted Parameters

LCD Digital Operator User’s Manual (I579)

5-2 Related Inverter Parameters

5

The table below shows the LX Inverter parameters related to the LCD Digital Operator.

For details, please refer to LX (I120E-EN) User’s Manual.

Parameter No. Function name Data

Default

value

Unit

F010 STOP Key Enable 00: Enable

01: Disable

02: Reset (disabling only the function to stop)

00 –

F011 Function Code Display

Restriction

00: ALL (full display)

01: FUNCTION (function-specific display)

02: USER (user setting)

03: COMPARE (data comparison display)

05: MONITOR (monitor only displ ay )

00 –

F013 Soft Lock Selection 00: MD0 (disabling change of data other than “F013”

when SFT is ON)

01: MD1 (disabling change of data other than “F013”

and frequency settings when SFT is ON)

02: MD2 (disabling change of data other than “F013”)

03: MD3 (disabling change of data other “F013” and

frequency settings)

00 –

F014 Copy Function Enable 00: Disable

01: Enable

00 –

Page 62

5 LCD Digital Operator Related Parameters

5 - 8

LCD Digital Operator User’s Manual (I579)

Page 63

6 - 1

6

6

LCD Digital Operator User’s Manual (I579)

This section describes how to read and write Inverter parameter settings using the LCD

Digital Operator.

6-1 Single READ Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-2 Single WRITE Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6-3 Quad READ Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6-4 Quad VERIFY Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6-5 Quad WRITE Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8