Page 1

Cat. No. O008-E1-04

USER’S MANUAL

3F88L-160/162 Cam Positioner

Page 2

Thank you for choosing this 3F88L-160/162 Cam Positioner. Proper use and handling of

the product will ensure proper product performance, will lengthen product life, and may

prevent possible accidents.

Please read this manual thoroughly and handle and operate the product with care.

1. To ensure safe and proper use of the OMRON Cam Positioners, please read this USER’S

MANUAL (Cat. No. O008-E1) to gain sufficient knowledge of the devices, safety information,

and precautions before actual use.

2. The products are illustrated without covers and shieldings for closer look in this USER’S

MANUAL. For actual use of the products, make sure to use the covers and shieldings as specified.

3. This USER’S MANUAL and other related user’s manuals are to be delivered to the actual end

users of the products.

4. Please keep this manual close at hand for future reference.

5. If the product has been left unused for a long time, please inquire at our sales representative.

NOTICE

1. This manual describes the functions of the product and relations with other products. You

should assume that anything not described in this manual is not possible.

2. Although care has been given in documenting the product, please contact your OMRON

representative if you have any suggestions on improving this manual.

3. The product contains potentially dangerous parts under the cover. Do not attempt to open

the cover under any circumstances. Doing so may result in injury or death and may damage

the product. Never attempt to repair or disassemble the product.

4. We recommend that you add the following precautions to any instruction manuals you prepare for the system into which the product is being installed.

S Precautions on the dangers of high-voltage equipment.

S Precautions on touching the terminals of the product even after power has been turned off. (These

terminals are live even with the power turned off.)

5. Specifications and functions may be changed without notice in order to improve product

performance.

Items to Check Before Unpacking

1. Check the following items before removing the 3F88L-160/162 Cam Positioner from the

package:

S Has the correct product been delivered (i.e., the correct model number and specifications)?

S Has the product been damaged in shipping?

S Are any screws or bolts loose?

S Have all accessories been correctly delivered together with or attached to the product? The acces-

sory for the 3F88L-160/162 Cam Positioner is the Safety Precautions only.

Mounting screws and other necessary parts must be provided by the customer. Should there

be any problems with this product, contact your nearest OMRON sales representative.

2. Check the following items before removing the 3F88L-RS17/17T/15/15W Resolver from

the package:

S Has the correct product been delivered (i.e., the correct model number and specifications)?

S Has the product been damaged in shipping?

S Are any screws or bolts loose?

S Have all accessories been correctly delivered together with or attached to the product? The acces-

sories for the 3F88L-RS17/17T are one 3F88L-RL10 Coupling and one copy of the user’s manual.

The accessories for the 3F88L-RS15/15W are one 3F88L-RL6 Coupling and three mounting claws.

Should there be any problems with this product, contact your nearest OMRON sales representative.

Page 3

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified

operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death

or serious injury. Additionally, there may be severe property damage.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death

!

or serious injury. Additionally, there may be severe property damage.

Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor

!

or moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when

it refers to an OMRON product, regardless of whether or not it appears in the proper name

of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means “word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation

for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different

types of information.

Note Indicates information of particular interest for efficient and convenient operation of the product.

OMRON, 1999

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted,

in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual

is subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Page 4

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

S Personnel in charge of installing FA systems.

S Personnel in charge of designing FA systems.

S Personnel in charge of managing FA systems and facilities.

General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the manual or applying the

product to nuclear control systems, railroad systems, aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines,

and equipment that may have a serious influence on lives and property if used improperly, consult

your OMRON representative.

Make sure that the ratings and performance characteristics of the product are sufficient for the systems, machines, and equipment, and be sure to provide the systems, machines, and equipment with

double safety mechanisms.

This manual provides information for programming and operating the Unit. Be sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

WARNING It is extremely important that a PC and all PC Units be used for the specified purpose

!

and under the specified conditions, especially in applications that can directly or

indirectly affect human life. You must consult with your OMRON representative

before applying a PC System to the above-mentioned applications.

Safety Precautions

General Warnings

WARNING Do not attempt to disassemble the Unit while power is being supplied. Doing so may

!

result in electrical shock.

WARNING Do not touch any of the terminals while power is being supplied. Doing so may result

!

in electrical shock.

WARNING Take safety measures outside the Cam Positioner to ensure safety for the entire

!

system in the event of Cam Positioner failure or error caused by external factors of

the Cam Positioner.

Faulty operations may result in serious accidents.

S Emergency stop circuits, interlock circuits, limit circuits, and similar safety mea-

sures must be included in control circuits outside the Cam Positioner.

S The Cam Positioner turns OFF all outputs when its self-diagnostic function detects

an error (ERROR is OFF), when TRIG input turns ON, or when RESET input turns

ON. Take safety measures outside the Cam Positioner to ensure safety for the entire system in such an event.

S The Cam Positioner output may remain ON or OFF due to damage to an output

transistor or for some other reason. Take safety measures outside the Cam Positioner to ensure safety for the entire system in such an event.

Page 5

General Precautions

Caution Fail-safe measures must be taken by the customer to ensure safety in the event of

!

incorrect, missing, or abnormal signals caused by broken signal lines, momentary

power interruptions, or other causes.

Caution Always use the power supply voltages specified in the operation manuals.

!

Caution Take appropriate measures to ensure that the specified power with the rated voltage

!

and frequency is supplied. Be particularly careful in locations where the power supply is unstable.

Caution Install external breakers and take other safety measures against short-circuiting in

!

external wiring.

Caution Disconnect the functional ground terminal from the protective ground terminal when

!

performing insulation resistance or withstand voltage tests

Caution Always connect to a ground of 100 Ω or less when installing the Unit.

!

Caution Do not attempt to disassemble, repair, or modify the Unit.

!

Caution Leave the label attached to the Unit when wiring.

!

Caution Remove the label after the completion of wiring to ensure proper heat dissipation.

!

Caution Use crimp terminals for wiring. Do not connect bare stranded wires directly to termi-

!

nals.

Caution Thoroughly check all wiring before turning ON the power supply.

!

Caution Wire all connections correctly.

!

Caution Do not place objects on top of the cables or other wiring lines.

!

Caution Do not pull on the cables or bend the cables beyond their natural limit.

!

Caution Before touching a Unit, be sure to first touch a grounded metallic object in order to

!

discharge any static built-up.

Caution Be sure that all the mounting screws, terminal screws, and cable connector screws

!

are tightened to the torque specified in the operation manual. For DIN track mounting, push the Cam Positioner forward until the lock snaps into place.

Page 6

Caution Be sure that cables and other items with locking devices are properly locked into

!

place.

Caution Always turn OFF the power supply to the Unit before attempting any of the following.

!

S Assembling the Unit.

S Setting switches.

S Connecting cables or wiring the system.

S Connecting or disconnecting the connectors.

Caution Thoroughly check the newly created cam programs, parameter settings, and switch

!

settings for proper execution before actually running them.

Caution Confirm that no adverse effect will occur in the system before attempting any of the

!

following.

S Switching the operating mode of the Unit

S Origin compensation

S Switching the execution bank

Caution When installing the Unit, adjust the origin before starting operation.

!

Caution Be sure that the number of resolver rotations is always within the allowable range.

!

Caution When replacing the Unit, transfer all the parameters and cam programs from the old

!

Unit to the new Unit before restarting operation.

Caution Do not apply voltages to the input terminal in excess of the rated input voltage.

!

Caution Do not apply voltages or connect loads to the output terminal or cam output connec-

!

tor in excess of the maximum switching capacity.

Caution Do not touch the terminals for one minute after the power is turned OFF.

!

Page 7

Installation Precautions

Caution Install the Unit properly as specified in the operation manual.

!

Caution Do not install the Unit in the following locations.

!

S Locations subject to direct sunlight.

S Locations subject to temperatures or humidity outside the range specified in the

specifications.

S Locations subject to condensation as the result of severe changes in temperature.

S Locations subject to corrosive or flammable gases.

S Locations subject to dust (especially iron dust) or salts.

S Locations subject to exposure to water, oil, or chemicals.

S Locations subject to shock or vibration.

Caution Take appropriate and sufficient countermeasures when installing the Unit in the fol-

!

lowing locations.

S Locations subject to static electricity or other forms of noise.

S Locations subject to strong electromagnetic fields and magnetic fields.

S Locations subject to possible exposure to radioactivity.

S Locations close to power supplies.

Conformance to EC Directives

H Applicable Directives

S EMC Directives

S Low Voltage Directive

Concepts

EMC Directives

EMC Directives stipulate that the system must comply with both EMS and EMI standards

(see the following note). Because OMRON devices are designed for installation in various

equipment or machines, they comply with the relevant EMC standards so that the equipment or machines can easily comply with the EMC standards. However, the systems used

by customers are diverse, and EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions

of the equipment or control panel in which the OMRON devices are installed. The customer

must, therefore, perform final checks to confirm that devices and the overall machine conform to EMC standards.

Note Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN61131-2

EMI (Electromagnetic Interference): EN61000-6-4

(Radiated emission: 10-m regulations)

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 V AC or 75 to 1,500 V DC

meet the required safety standards (EN61131-2).

Page 8

Conformance to EC Directives

The 3F88L-160/162 Cam Positioner complies with EC Directives. To ensure that the system in which

the 3F88L-160/162 is installed complies with EC Directives, the following precautions must be observed.

1. The 3F88L-160/162 is defined as an in-panel device according to the Low-voltage Directive.

The 3F88L-160/162 must, therefore, be installed within a control panel.

2. Reinforced insulation or double insulation must be used for the DC power supplies used as

I/O power supplies.

3. The 3F88L-160/162 conforms to the Common Emission Standard (EN61000-6-4) in relation to EMI. However, the radiated emission (10-m regulations) may vary depending on the

configuration of the control panel, connected devices, wiring, and other conditions. The user

must, therefore, confirm that devices and the overall machinery conform to EC Directives.

Page 9

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive

Warranty

Limitations OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR

Buyer Remedy Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the

Omron’s exclusive warranty is that the Products will be free from defects in materials

and workmanship for a period of twelve months from the date of sale by Omron (or

such other period expressed in writing by Omron). Omron disclaims all other warranties, express or implied.

IMPLIED, ABOUT NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE OF THE PRODUCTS. BUYER ACKNOWLEDGES

THAT IT ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY

MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or

expenses based on infringement by the Products or otherwise of any intellectual

property right.

form originally shipped with Buyer responsible for labor charges for removal or

replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal to the purchase price of the noncomplying Product; provided that in no event shall Omron be responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored,

installed and maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of any Products by Buyer must be approved in writing

by Omron before shipment. Omron Companies shall not be liable for the suitability

or unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials

or substances or environments. Any advice, recommendations or information given

orally or in writing, are not to be construed as an amendment or addition to the

above warranty.

Limitation on

Liability; Etc

See http://www.omron.com/global/ or contact your Omron representative for published information.

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT, WARRANTY,

NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of

the Product on which liability is asserted.

Page 10

Application Considerations

Suitability of

Use

Programmable

Products

Disclaimers

Performance

Data

Omron Companies shall not be responsible for conformity with any standards,

codes or regulations which apply to the combination of the Product in the Buyer’s

application or use of the Product. At Buyer’s request, Omron will provide applicable

third party certification documents identifying ratings and limitations of use which

apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product,

machine, system, or other application or use. Buyer shall be solely responsible for

determining appropriateness of the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK

TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A

WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE

OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED FOR THE

INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or any consequence thereof.

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for the user in determining suitability and does not constitute a warranty. It may represent the result of Omron’s test conditions, and the user must

correlate it to actual application requirements. Actual performance is subject to the

Omron’s Warranty and Limitations of Liability.

Change in

Specifications

Errors and

Omissions

Product specifications and accessories may be changed at any time based on

improvements and other reasons. It is our practice to change part numbers when

published ratings or features are changed, or when significant construction changes

are made. However, some specifications of the Product may be changed without

any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to confirm actual specifications of purchased Product.

Information presented by Omron Companies has been checked and is believed to

be accurate; however, no responsibility is assumed for clerical, typographical or

proofreading errors or omissions.

Page 11

USER’S MANUAL

3F88L-160/162 Cam Positioner

Page 12

Table of Contents

Chapter 1. Outline 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 Functions 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-1 Basic Operation 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-2 Resolution 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-3 Modes 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-4 Selecting the Function Level 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-5 Basic Functions 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-6 Initial Settings Functions 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1-7 Applied Functions 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 System Configuration 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Name and Function of Each Part 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-1 Display Section 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-2 Switches 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-3 Operation Keys 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3-4 Terminal Block and Connectors 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Glossary 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Operation Procedure 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5-1 Before Operation 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2. Design 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 System Design 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 Selecting the Resolver 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-2 Selecting the Output Device 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Installation 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-1 External Dimensions 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-2 Installation Environment 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-3 Mounting the Resolver 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Wiring 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-1 System Connection Diagram 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-2 Standard Wiring Method 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-3 Terminal Block Wiring 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-4 Resolver Wiring 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-5 Cam Output Wiring 2-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3-6 Connecting a Display Unit 2-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3. Operation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Nomenclature of Display and Operation Sections 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Modes, Functions, and Display 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Operation Procedure 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3-1 Before Operation 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Selecting Function Levels 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 Basic Operation 3-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-1 Function Level Selection Setting (SET Mode) 3-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-2 Initial Settings 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-3 Cam Program Creating and Checking (PRGM Mode/SET Mode) 3-24. . . . . . . . . . . . . . .

3-5-4 Resolver and Machinery Connection 3-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-5 Origin Compensation 3-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-6 Start Operation (RUN Mode) 3-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-7 I/O Monitor Function (RUN Mode) 3-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5-8 Control I/O Signals 3-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 13

Table of Contents

3-6 Applied Functions 3-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-1 Function Level Selection Setting (SET Mode) 3-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-2 Parameter List (SET Mode) 3-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-3 Parameter Explanation and Operation 3-49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-4 Origin Compensation and Origin Shift 3-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-5 Backlash Compensation 3-60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-6 Advance Angle Compensation 3-62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-7 Cam Protect 3-69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-8 One-direction Function 3-75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-9 Output Hold Function 3-77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-10 Present Value Output Function 3-78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-11 Pulse Output Function 3-80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-12 Teaching 3-83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-13 Copy Function (Data Transfer) 3-88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6-14 Trial/Adjustment Operation 3-93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4. Communications 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 Overview of CompoWay/F Communications 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Command and Response Frames 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-1 Command Frame 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-2 Response Frame 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Command Types 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-1 Memory Area Read (RUN) 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-2 Parameter Area Read/Write (SET) 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-3 Controller Data Read (RUN, PRGM, SET) 4-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-4 Unit Attribute Read (RUN, PRGM, SET) 4-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-5 Controller Status Read (RUN, PRGM, SET) 4-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-6 Operation Command (RUN) 4-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-7 Internode Echo Test (RUN, PRGM, SET) 4-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4 Executing CompoWay/F Commands with Protocol Macros 4-23. . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5. Operation 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Diagnosis using Error Codes 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 CompoWay/F Communications Errors 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Troubleshooting 5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4 Inspection and Maintenance 5-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5 Cam Positioner Replacement 5-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6. Specifications 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1 Cam Positioner Specifications 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Resolver Specifications 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 I/O Block Specifications 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4 Display Specifications 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7. Appendix 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1 Application Examples 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2 Performance 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3 Resolver Life Expectancy 7-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-4 Standard Models 7-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 14

Table of Contents

7-5 Displays by Mode 7-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-6 Error Codes 7-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-7 Cam Programming Sheet 7-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-8 Parameter Settings Log Chart 7-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index I-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History R-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 15

1

Chapter 1

Outline

1-1 Functions

1-2 System Configuration

1-3 Name and Function of Each Part

1-4 Glossary

1-5 Operation Procedure

Page 16

Outline Chapter 1

1-1 Functions

The 3F88-L160 and 3F88L-162 Cam Positioners are Units that detect angles through a

Resolver (a sensor that detects absolute angles) and turn output signals ON and OFF at

a preset angle through a cam program.

The 3F88L-160 Cam Positioner has 16 cam output points and the 3F88L-162 Cam Positioner has 32 cam output points.

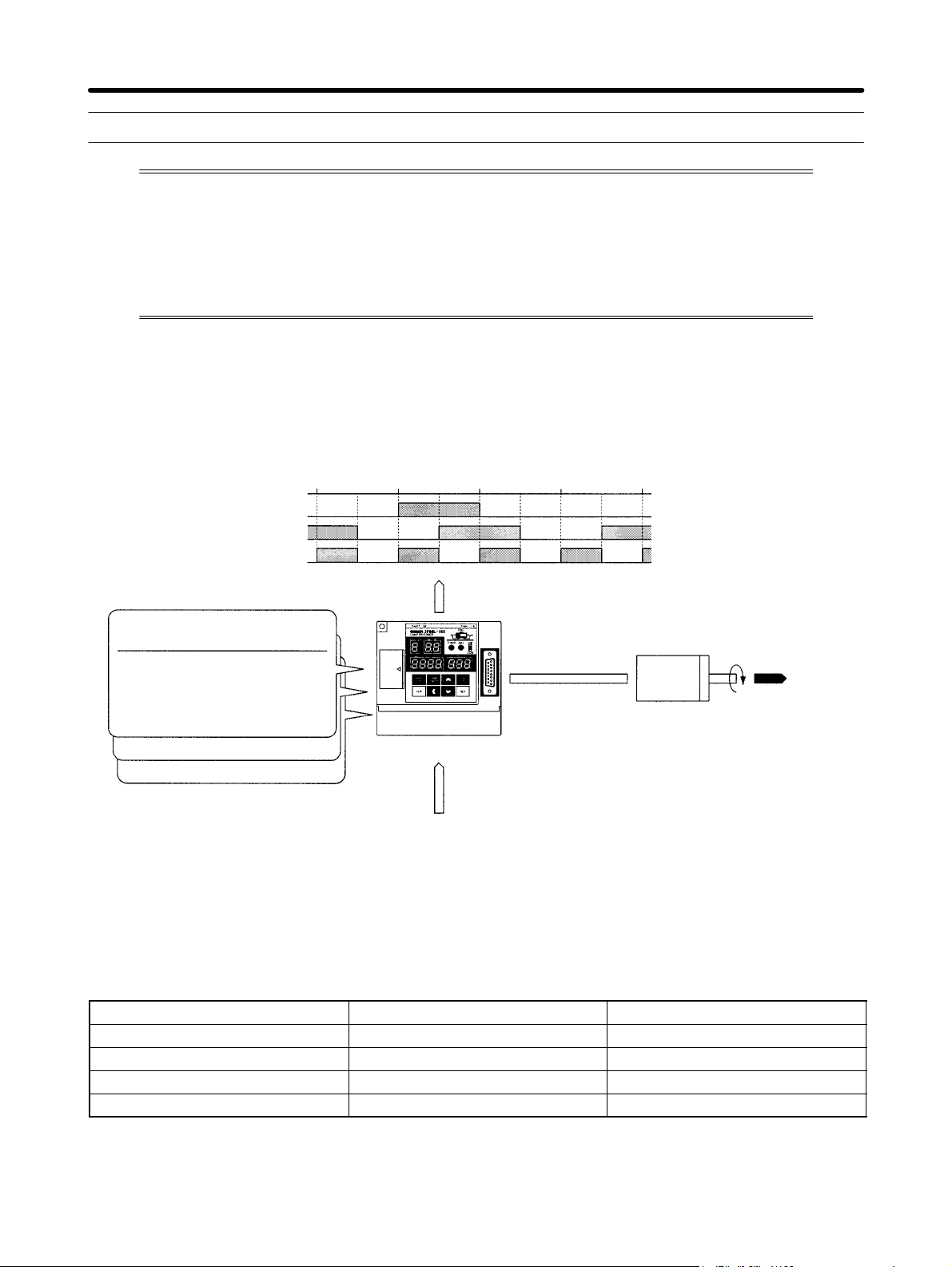

1-1-1 Basic Operation

• Input a cam program (the ON/OFF pattern for cam outputs) into the Cam Positioner, use the bank

switching signal to select the bank number, and turn ON the operation signal to start operation.

Resolver angle

Cam output 1

Cam output 2

Cam output 3

(Programming example for 360 resolution)

Cam Program (Bank No. 1)

Cam No.

Step ON angle OFF angle

1

1

1

2

1

---

90

315

135

0

---

---

---

2

2

3

---

Cam Program (Bank No. 2)

Cam Program (Bank No. 3)

0° 90° 180° 270° 0°

180

45

225

45

---

1-1-2 Resolution

Cam output

Cam Positioner

Control input

Bank switching signal (Bank numbers 1 to 3)

Operation signal (START)

Resolver

User machine or

device

• The angle resolution can be set to 360 (divisions/revolution) or 720 (divisions/revolution).

• The following table shows how functions and performances are affected by resolution settings.

Function or Characteristic 360 resolution 720 resolution

Angle setting and display units 1° is set and displayed as “1.” 0.5° is set and displayed as “1.”

Permissible Resolver speed 1,600 r/min 800 r/min

No. of cam program steps 180 max. 360 max.

Number of banks 8 4

Note For example, to set the ON angle at 90°, the setting is “90” for a 360 resolution and “180” for a 720

resolution.

1-2

Page 17

Outline Chapter 1

1-1-3 Modes

• The 3F88-L160 and 3F88L-162 Cam Positioners have three modes: RUN, PRGM, and SET. These

are set using the mode selection switch on the front of the Unit. The functions of each mode are outlined below. (Refer to 3-2 Mode, Functions, and Display.)

RUN mode: Operation and compensation.

PRGM mode: Creation, editing, deletion, and trial operation of cam programs.

SET mode: Unit parameters and various compensation value settings, teaching, and communications settings.

1-1-4 Selecting the Function Level

• Three function levels are available to limit Cam Positioner functions. (Refer to 3-4 Selecting Function

Levels.)

Function Level 0 (Monitor Only)

Cam output and monitoring are enabled. Cam programs are write protected and parameter settings

cannot be made. This function level is designed to prevent inadvertent changes to the cam program

or parameters.

Function Level 1 (Basic Operation/Monitor Only)

In addition to the functions available at function level 0, cam programs may be edited. This function

level is used for basic operation.

Function Level 2 (All Functions)

All Cam Positioner functions are enabled. This function level is for using applied functions.

1-1-5 Basic Functions

H Cam Program Write Function

• Cam programs set the angle at which the cam output is turned ON and OFF. Up to 180 steps can be set

and up to 8 banks registered for 360 resolution and up to 360 steps and 4 banks for 720 resolution can

be set for each cam output point. (Refer to 3-5-3 Cam Program Creating and Checking.)

• Cam programs are normally input by using the operation keys on the front of the Unit but settings can

be made from a personal computer by using a special communications protocol (CompoWay/F). (Refer to Chapter 4 Communications.)

Note 1. A step is one ON/OFF combination for one cam.

Note 2. A bank is a program unit made up of cam outputs 1 to 32 for the 3F88L-162 and cam outputs 1

to 16 for the 3F88L-160. By changing the bank, the program that will be operated will change.

H Cam Output

• While START input is ON, this function turns cam outputs ON and OFF in the bank specified at BANK

input according to the ON/OFF angles set for each cam.

H Monitor

• Monitors cam output and control I/O status. (Refer to 3-5-7 I/O Monitor Function.)

1-3

Page 18

Outline Chapter 1

H Data Save

• Saves parameters and cam programs in non-volatile memory (EEPROM). As the data is stored in

non-volatile memory, battery replacement, and other maintenance is not required.

H Program Number Check

• The number of programs and origin compensation angle can be checked. (Refer to 3-5-3 Cam Program Creating and Checking.)

1-1-6 Initial Settings Functions

H Switching Resolution

• Switches between 360 and 720 divisions per Resolver revolution. (Refer to 3-5-2 Initial Settings.)

H Changing Rotation Direction

• Sets the direction of increasing angle to suit the mechanical configuration. (Refer to 3-5-2 Initial Set-

tings.)

1-1-7 Applied Functions

H Origin Compensation

• Sets any angle to 0° according to the mechanical origin. (Refer to 3-6-4 Origin Compensation and

Origin Shift.)

H Origin Shift

• Sets any angle to 0° according to the mechanical origin when the trigger turns ON in RUN mode. (Re-

fer to 3-6-4 Origin Compensation and Origin Shift.)

H Backlash Compensation

• Sets a difference between the detection angles in CW and CCW directions to absorb mechanical

vibration. (Refer to 3-6-5 Backlash Compensation..)

H Advance Angle Compensation

• Advances the cam output angle in proportion to the number of Resolver revolutions. (Refer to 3-6-6

Advance Angle Compensation.)

H Cam Protect

• Protects each bank and cam to prevent the cam ON/OFF data being inadvertently changed or deleted.

H One-direction Function Setting

• Enables cam output in one rotational direction only. (Refer to 3-6-8 One-direction Function.)

1-4

Page 19

Outline Chapter 1

H Output Hold Function

• Holds the immediately preceding cam output status when the user switches to PRGM mode or when

there is an error. (Refer to 3-6-9 Output Hold Function.)

H Present Value Output Function

• Uses the cam output signal and outputs the signal to the Display Unit (M7E, M7F, or other Display

Units.) The present angle or number of revolutions can be displayed on the Display Unit. (Refer to

3-6-10 Present Value Output Function.)

H Pulse Output Function

• Automatically sets data that turns ON and OFF at regular intervals in a desired bank or cam in order to

edit memory contents. (Refer to 3-6-11 Pulse Output Function.)

H Teaching

• The Resolver angle data may be input as cam program settings during manual operation of the

machinery. (Refer to 3-6-12 Teaching.)

H Copy Function

• By making the settings for one Cam Positioner, the cam program, the various compensation values,

and settings in one operation may be copied to another Cam Positioner.

H Trial Operation

• When adjusting the ON/OFF angles to suit the machinery, performs cam output and changes the ON/

OFF angle in real time regardless of the control input signal status. (Refer to 3-6-14 Trial/Adjustment

Operation.)

H Compensation Operation

• When adjusting the ON/OFF angles to suit the machinery, changes the ON/OFF angles in real time

while in operation status (cam output status). (Refer to 3-6-14 Trial/Adjustment Operation.)

H Communications Function

• Has a communications port that conforms to shape B in CompoWay/F. Communications can be used

to read and write cam programs and monitor present angles and number of revolutions. (Refer to

Chapter 4 Communications.)

Note CompoWay/F is a uniform procedure in OMRON serial communications. CompoWay/F has uni-

form frame formats and commands that conform to FINS (Factory Interface Network Service) that

is used in OMRON PCs. It facilitates easier communications between multiple components and

between personal computers and components.

1-5

Page 20

Outline Chapter 1

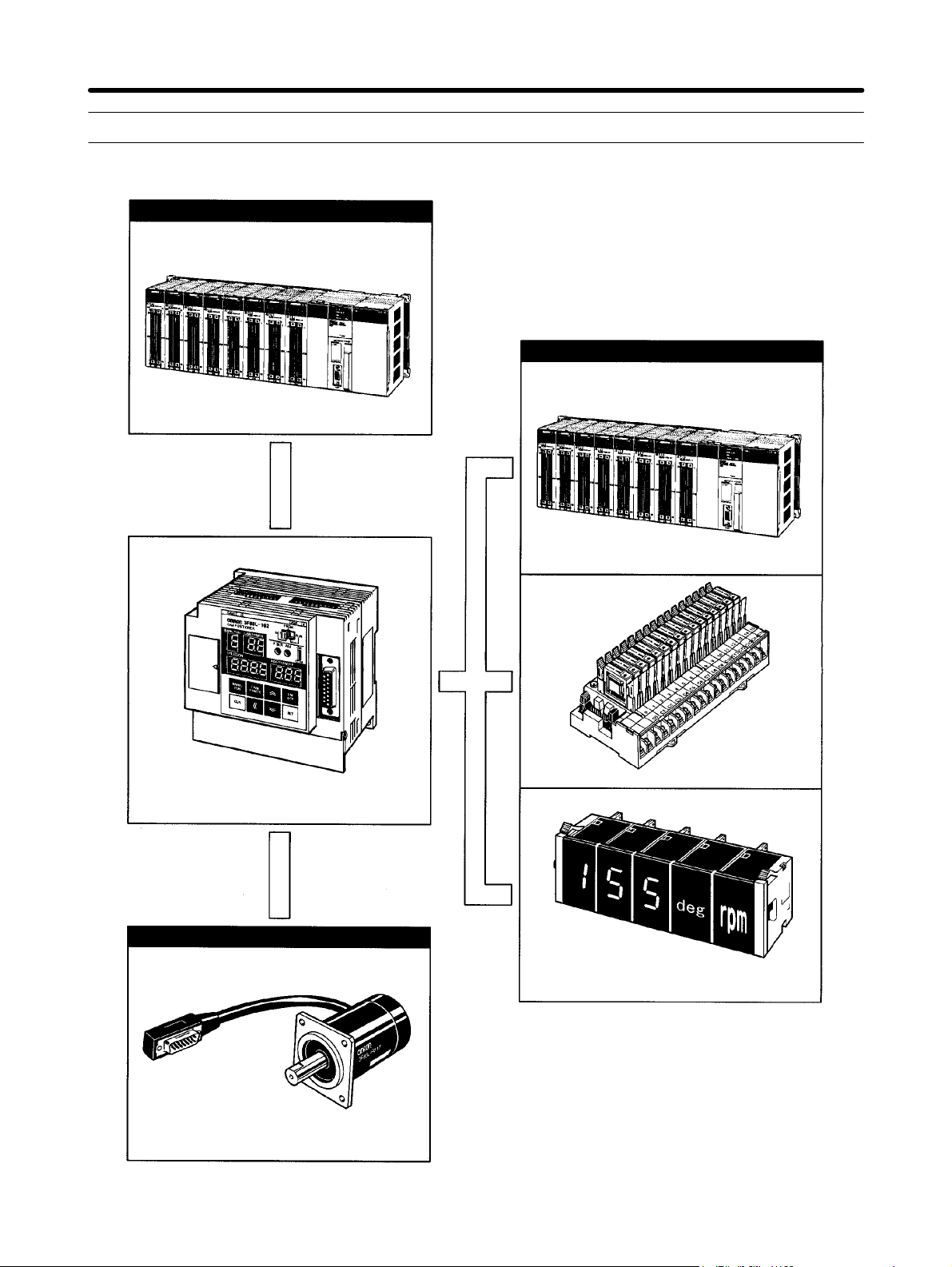

1-2 System Configuration

Control Section

Output Section

SYSMAC CS1-series PC or other PC

Control I/O signal

3F88L-160 or 3F88L-162 Cam Positioner

Cam

output

signal

SYSMAC CS1-series PC or other PC

G7TC-OC16 I/O Block

1-6

Detection Section

3F88L-RS17, 3F88L-RS17T, 3F88L-RS15,

or 3F88L-RS15W Resolver

M7E or M7F Display Unit

Note Refer to 2-3 Wiring or 7-4 Standard

Models for information on various

connection cables.

Page 21

Outline Chapter 1

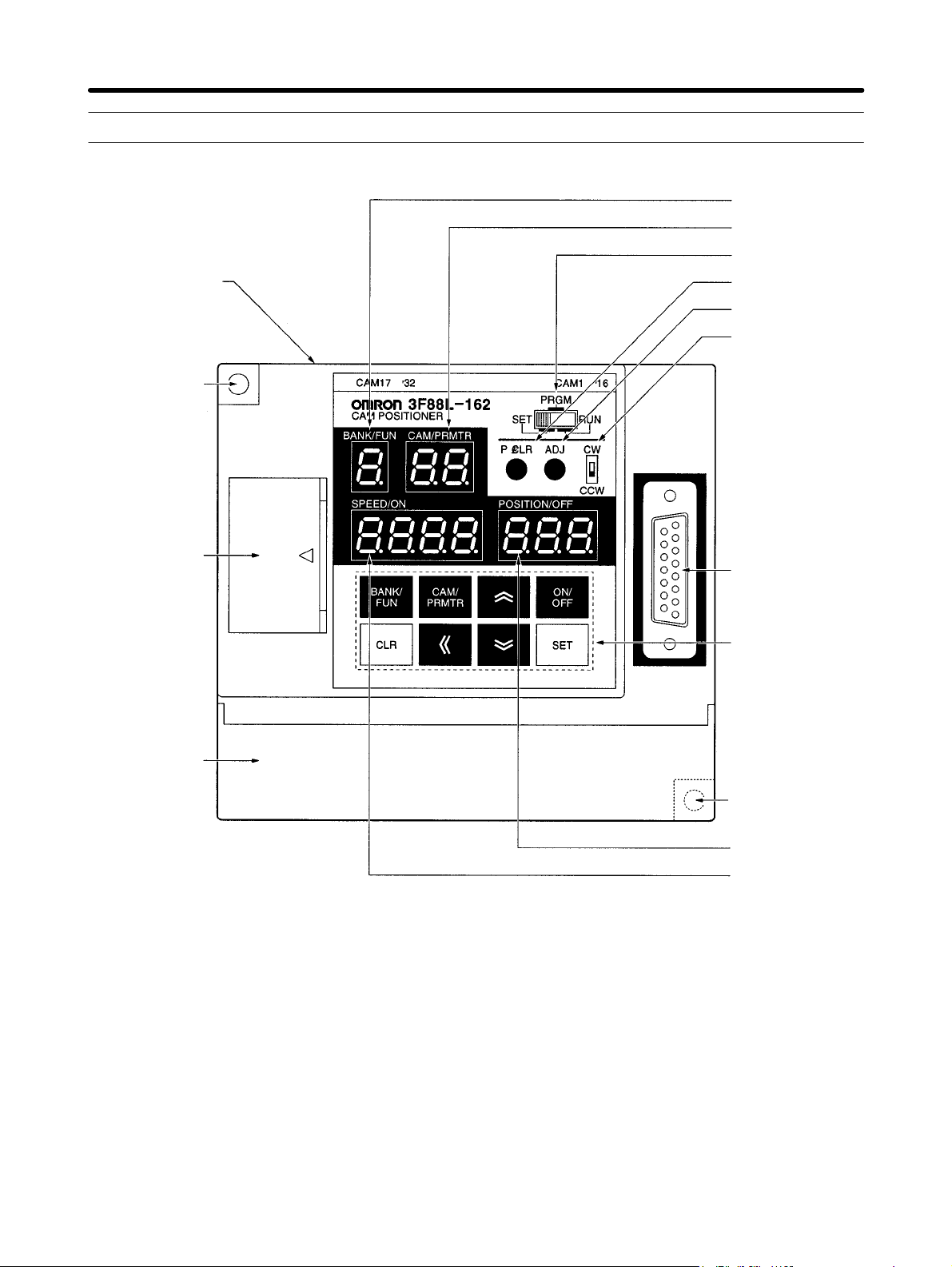

1-3 Name and Function of Each Part

1. Bank/Function

display

2. Cam/Parameter

No. display

5. Mode selection

switch

11. Cam output

connector (top)

Mounting hole

6. P⋅ CLR switch

7. ADJ switch

8. CW/CCW setting

switch

12. Communications port

13. Terminal block

(under the cover)

10. Resolver

connector

9. Operation keys

Mounting hole

4. POSITION/OFF

(Present angle/

OFF angle) display

5. SPEED/ON

(Number of revolutions/ON angle)

display

1-7

Page 22

py

u be d sp ay

g

Outline Chapter 1

1-3-1 Display Section

• Displays the operation status, error status, and settings data.

• The data displayed will differ depending on the mode.

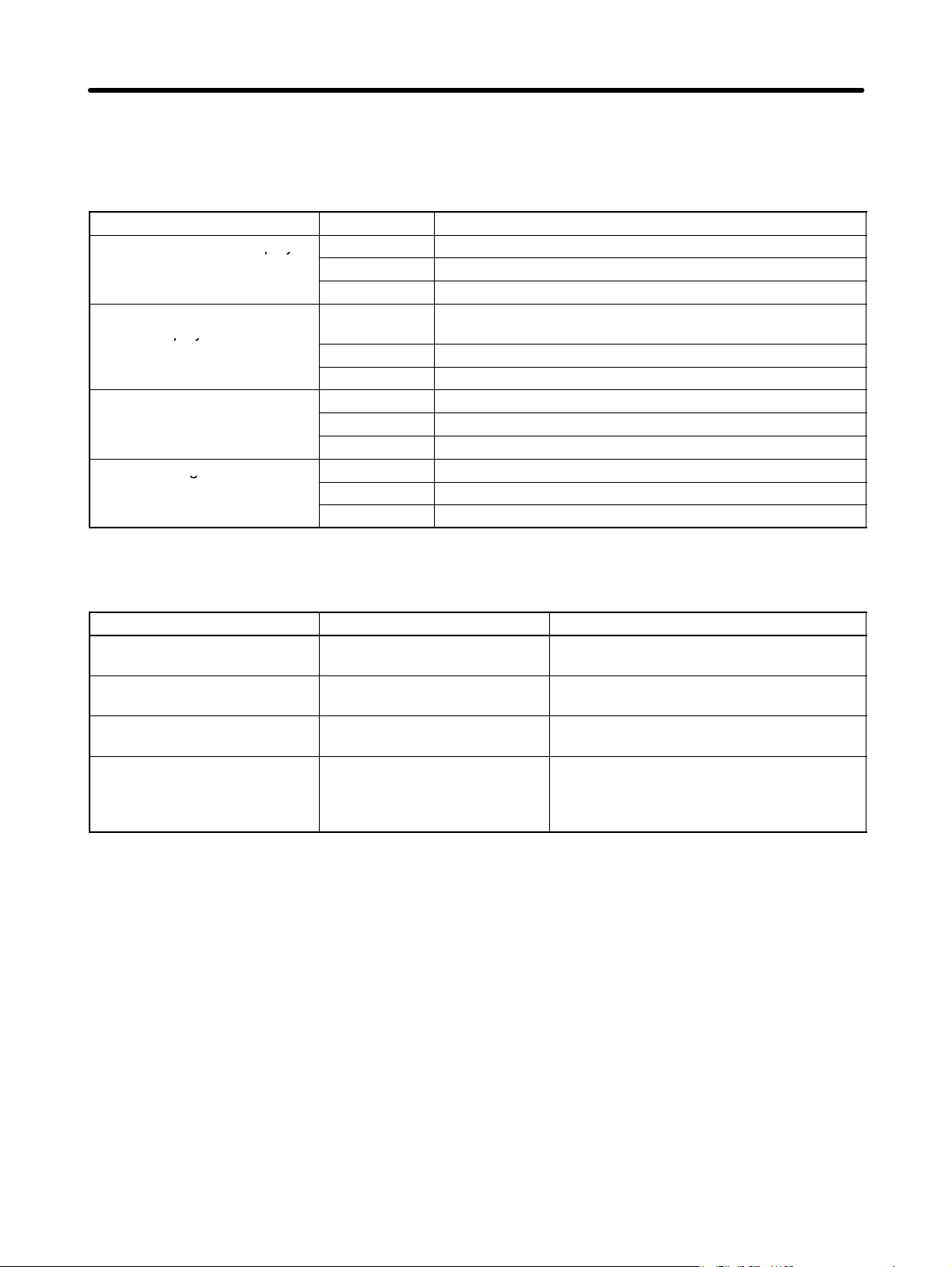

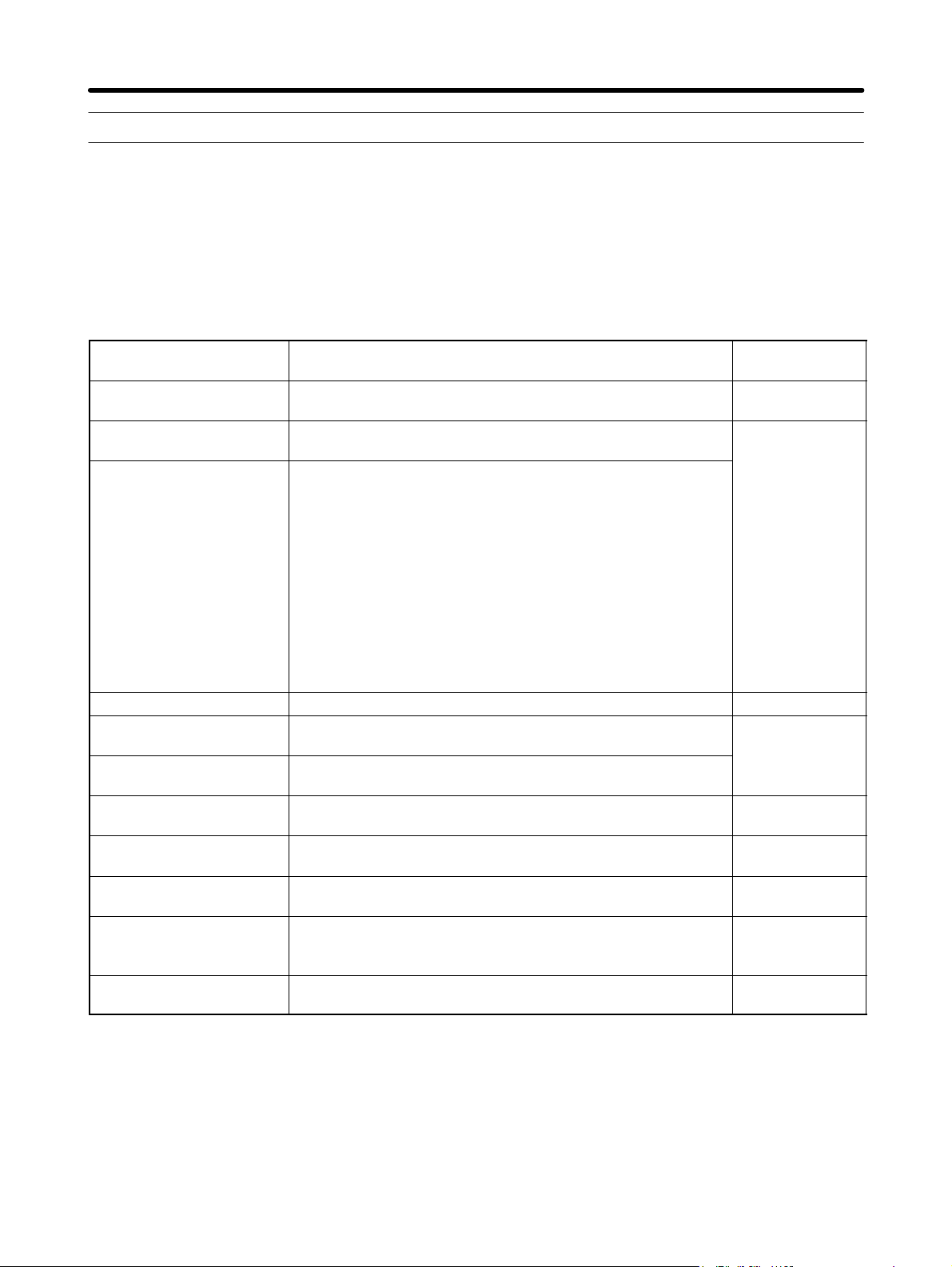

Name Mode Display

1. Bank and function display

2. Cam and parameter

number display

3. Number of revolutions and

ON angle display

4. Present angle and OFF

angle display

RUN Display the number of the operating bank.

PRGM Display the number of the bank being programmed.

SET Display the number of the function being set.

RUN Displays “ru” when the START signal is ON and is blank

when the START signal is OFF.

PRGM Displays the number of the cam being programmed.

SET (Different for different settings functions.)

RUN Displays the number of revolutions or an error message.

PRGM Displays the ON angle or an error message.

SET (Differs for different settings functions.)

RUN Displays the present angle.

PRGM Displays the OFF angle.

SET (Different for different settings functions.)

1-3-2 Switches

Name Mode Function

5. Mode selection switch --- Switches between the three operation

modes: RUN, PRGM, and SET.

6. P ⋅ CLR switch PRGM Deletes all cam programs in the Cam

Positioner.

7. ADJ switch SET Adjusts the compensation by executing

origin compensation.

8. CW/CCW setting switch When power is turned ON Changes the rotation direction. The direction of increasing angle is set to either CW

(clockwise) or CCW (counterclockwise)

when viewed from the Resolver axle side.

1-8

Page 23

Outline Chapter 1

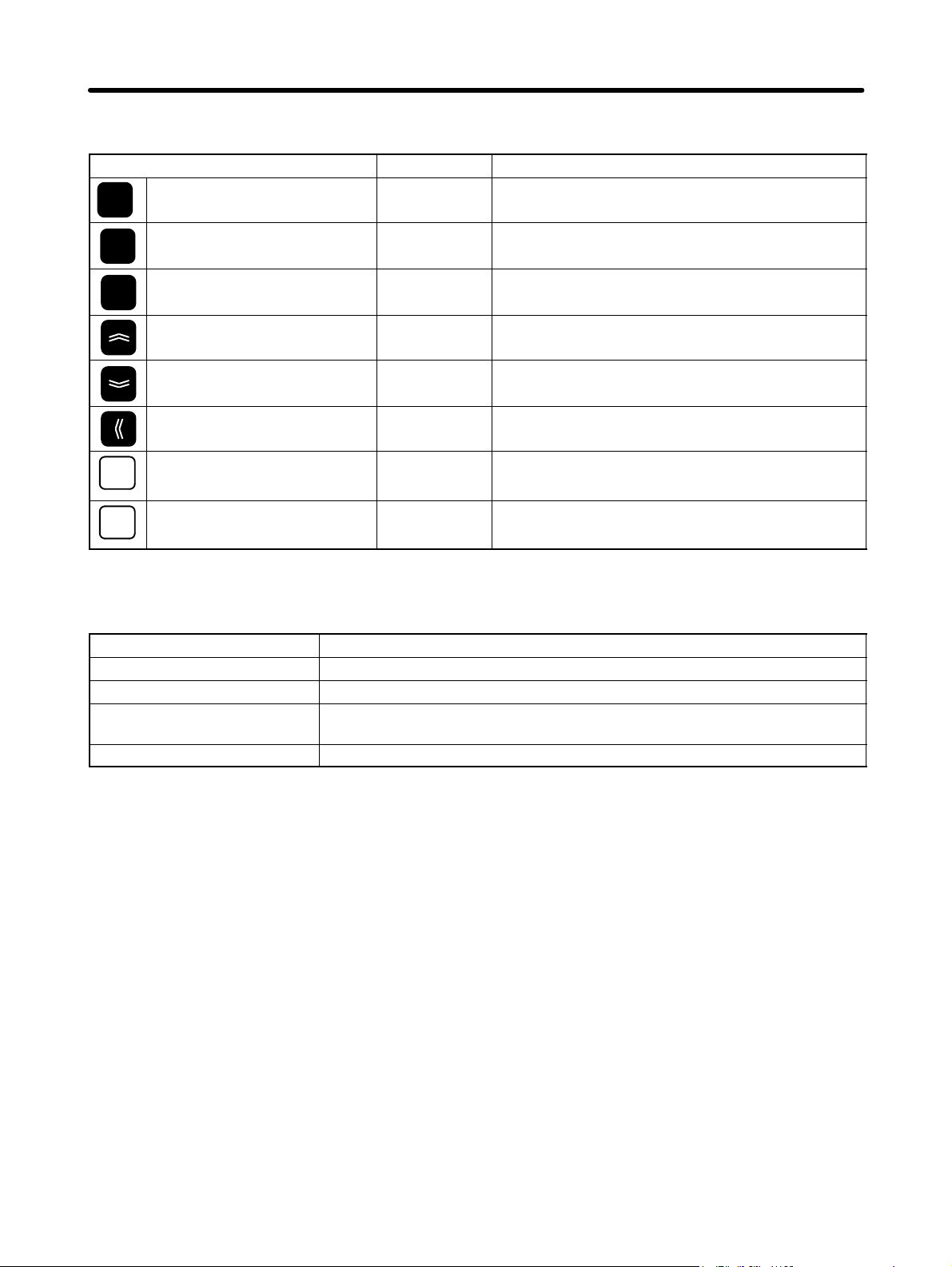

1-3-3 Operation Keys

Name Mode Function

BANK/

FUN

Bank/Function Key PRGM/SET Increases bank and function numbers.

CAM/

PRMTR

Cam/Parameter Key --- Increases cam and parameter numbers.

ON/OFF Switching Key --- Switches between ON and OFF angles.

ON/

OFF

Up Key --- Increases the numeral that is flashing.

Down Key --- Decreases the numeral that is flashing.

Forward Key --- Changes the digit of the numeral to be set.

Clear Key --- Clears data.

CLR

Set Key --- Saves input data.

SET

1-3-4 Terminal Block and Connectors

Name Function

10. Resolver connector Connects to the Resolver cable connector.

11. Cam output connector Used for cam output.

12. Communications port CompoWay/F communications connector (connects to a personal computer

and other Cam Positioners) (9-pin D-sub connector)

13. Terminal block Power input, control input, and control output terminals.

1-9

Page 24

Outline Chapter 1

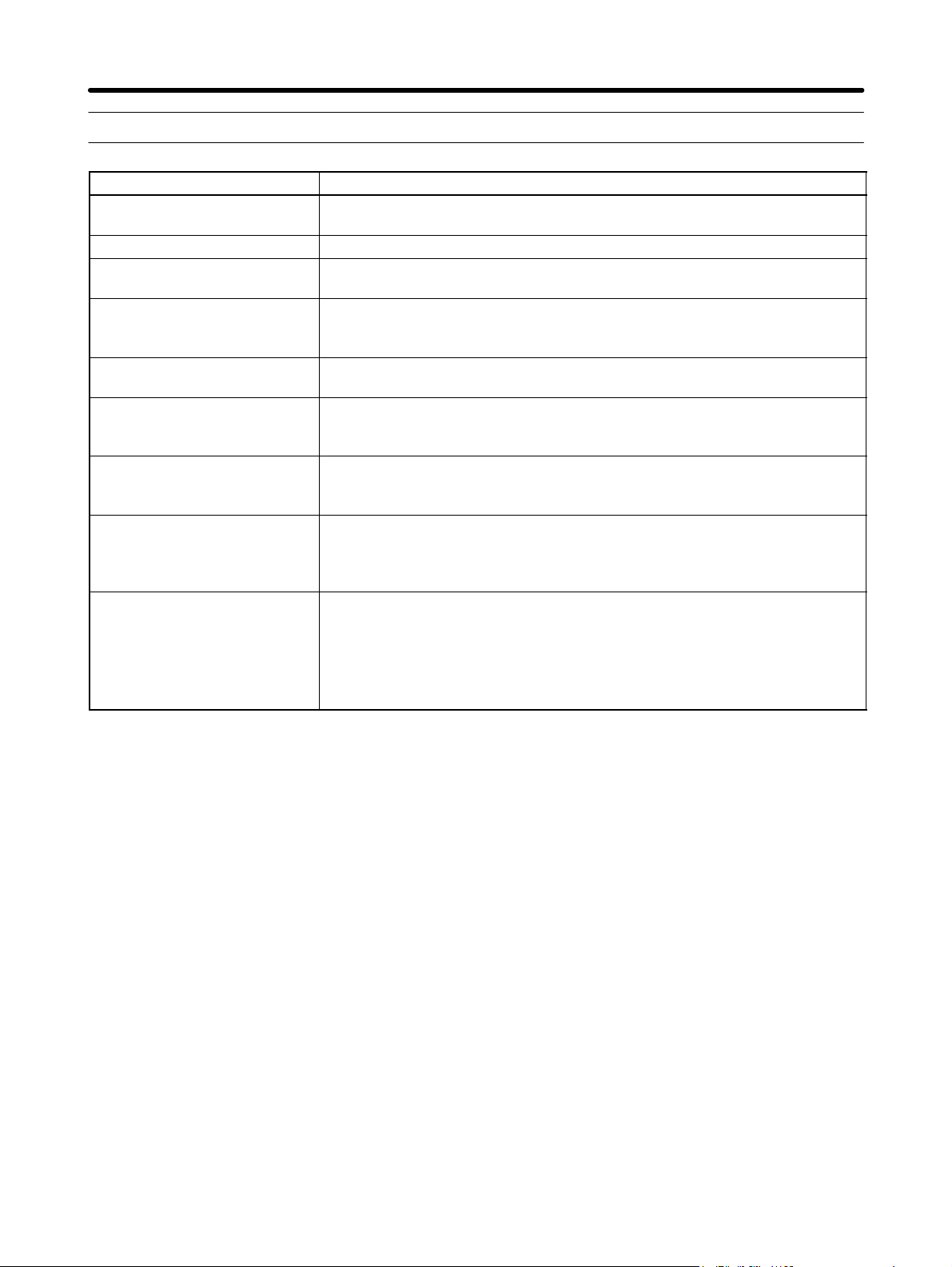

1-4 Glossary

Term Meaning

Cam output Cam output consists ON/OFF outputs for the Resolver angle according to

the ON/OFF angles set by the user (the cam program).

Cam program A cam program consists ON/OFF angle data set by the user.

Cam protect The cam data protect function protects the cam ON/OFF data from being

inadvertently changed or deleted.

Compensation operation When in RUN mode, this function can be used to adjust the cam output ON

and OFF angles by using the operation keys in order to check mechanical

operation.

Origin compensation When in SET mode, the mechanical origin and the Resolver origin can be

aligned by pressing the ADJ switch on the front of the Cam Positioner.

Origin shift When in RUN mode, this function can be used to temporarily shift the

displayed angle to the origin by shorting the TRIG terminal with the 0-V

terminal.

Origin value The origin value is a value set as the origin of the Resolver. This value can

be set to any angle when origin compensation or origin shift has been

performed. The default setting is 0.

Resolver The Resolver is a sensor that detects the absolute angle. One of four

Resolver models (3F88L-RS17, 3F88L-RS17T, 3F88L-RS15, and

3F88L-RS15W) can be selected for 3F88L-160 and 3F88L-162 Cam

Positioners.

Trial operation When in PRGM mode, this function can be used to adjust the cam output

ON and OFF angles by using the operation keys in order to check

mechanical operation.

The greatest difference from compensation operation is the ability to adjust

the ON and OFF angles of any bank or cam number without any external

control signal input during trial operation.

1-10

Page 25

Outline Chapter 1

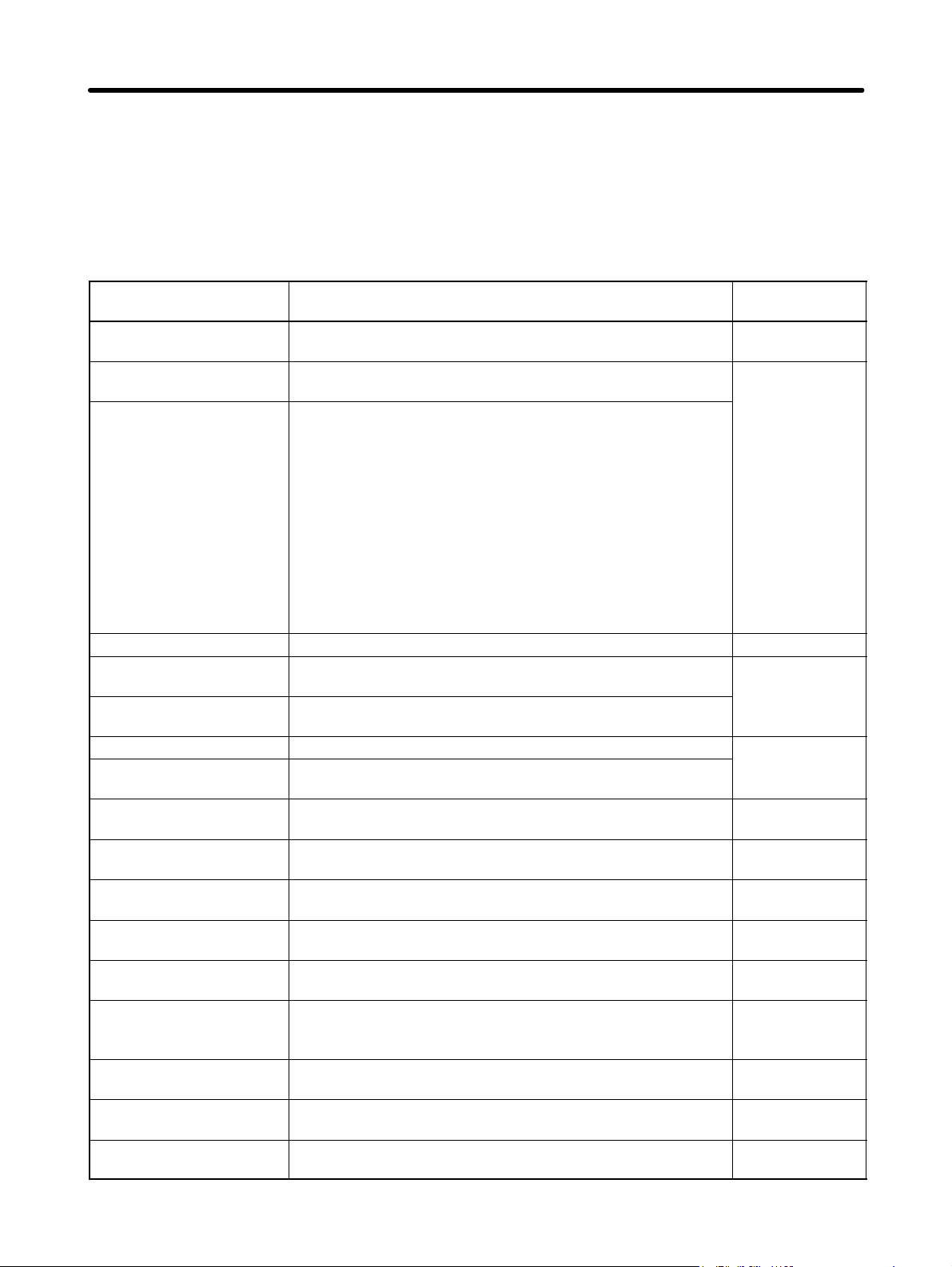

1-5 Operation Procedure

1-5-1 Before Operation

H Basic Use

• The procedure for using the Cam Positioner at function level 1 (basic operation/monitor only) is outlined below.

Procedure Contents Reference

section

Installation Install the Cam Positioner according to the installation

environment conditions.

Wiring Connect the wiring for the power supply, Resolver, and

peripheral devices.

Power ON Before the power is turned ON:

• Check that the wires and connectors for the Resolver and

peripheral devices have been connected properly.

• Check that the Resolver and the machinery are not connected.

After the power is turned ON:

• Check that there are no error codes displayed (E–**).

• Set the mode selection switch to RUN and check that the

number of revolutions and the present angle display changes

when the Resolver axis is rotated by hand.

Function level selection Select function level 1 (basic operation/monitor only). 3-5-1

Initial settings Set the resolution (SET mode) and rotation direction

(CW/CCW) to suit the application.

Power resetting (OFF to

ON)

Creation and confirmation

of cam programs

Connection between

Resolver and machinery

Execution of origin

compensation

Operation/monitoring Change to RUN mode and check the operation of the

Function level selection If required, set to function level 0 (monitor only) to prevent

Turn ON the power to enable the set parameters.

Create and check cam programs (PRGM mode).

Check the number of programs (SET mode).

Turn OFF the power and connect the Resolver and the

machinery.

Turn ON the power and execute origin compensation (use

the ADJ switch in SET mode).

machinery and monitor the I/O status. Correct the cam

program if required (PRGM mode).

faulty operation.

2-2

2-3

3-5-2

3-5-3

3-5-4

3-5-5

3-5-6

3-4

Note This procedure is applicable when only the basic functions (function level 1) are used. In the

cases outlined below, the applied functions (function level 2) must be used. (Refer to 3-6 Applied

Functions.)

S When setting origin compensation values, using backlash compensation, advance angle com-

pensation, and other compensation functions.

S When executing a trial or compensation operation.

1-11

Page 26

Outline Chapter 1

S When using the teaching function.

S When making pulse output, cam data protect, output hold, one-direction function, and present

value output settings.

H Applied Functions

• The procedure for using the Cam Positioner at function level 2 (all functions) is outlined below.

Procedure Contents Reference

section

Installation Install the Cam Positioner according to the installation

environment conditions.

Wiring Connect the wiring for the power supply, Resolver, and

peripheral devices.

Power ON Before the power is turned ON:

• Check that the wires and connectors for the Resolver and

peripheral devices have been connected properly.

• Check that the Resolver and the machinery are not connected.

After the power is turned ON:

• Check that there are no error codes displayed (E–**).

• Set the mode selection switch to RUN and check that the

number of revolutions and the present angle display changes

when the Resolver axis is rotated by hand.

Function level selection Select function level 2 (all functions). 3-6-1

Initial settings Set the resolution (SET mode) and rotation direction

(CW/CCW) to suit the application.

Power resetting (OFF to

ON)

Parameter settings Make the parameter settings.

Power resetting (OFF to

ON)

Creation and confirmation

of cam programs

Connection between

Resolver and machinery

Execution of origin

compensation

Teaching If required, use the teaching function (SET mode) and create

Trial operation Change to PRGM mode, and, if required, adjust the cam

Operation/monitoring Change to RUN mode and check the operation of the

Origin shift execution If required, turn ON TRIG input and execute origin shift

Compensation operation If required, adjust the cam program while checking the timing

Function level selection If required, set to function level 0 (monitor only) to prevent

Turn ON the power to enable the set parameters.

Turn ON the power to enable the set parameters.

Create and check cam programs (PRGM mode).

Check the number of programs (SET mode).

Turn OFF the power and connect the Resolver and the

machinery.

Turn ON the power and execute origin compensation (use

the ADJ switch in SET mode).

a cam program while operating the machinery manually.

program while checking the timing of the cam output.

machinery and monitor the I/O status. Correct the cam

program if required (PRGM mode).

(RUN mode).

of the cam output.

faulty operation.

2-2

2-3

3-5-2

3-6-2 and 3-6-3

3-5-3

3-5-4

3-5-5

3-6-12

3-6-14

3-5-6

3-6-4

3-6-14

3-4

1-12

Page 27

Design

2-1 System Design

2-2 Installation

2-3 Wiring

2

Chapter 2

Page 28

Design Chapter 2

2-1 System Design

WARNING Take safety measures outside the Cam Positioner to ensure safety for the entire

!

system in the event of Cam Positioner failure or error caused by factors external to

the Cam Positioner.

Faulty operation may result in a serious accident.

S Emergency stop circuits, interlock circuits, limit circuits, and similar safety mea-

sures must be included in control circuits outside the Cam Positioner.

S The Cam Positioner turns OFF all outputs when its self-diagnostic function detects

an error (ERROR is OFF), when TRIG input turns ON, or when RESET input turns

ON. Take safety measures outside the Cam Positioner to ensure safety for the entire system in such an event.

S The Cam Positioner output may remain ON or OFF due to damage to an output

transistor or for some other reason. Take safety measures outside the Cam Positioner to ensure safety for the entire system in such an event.

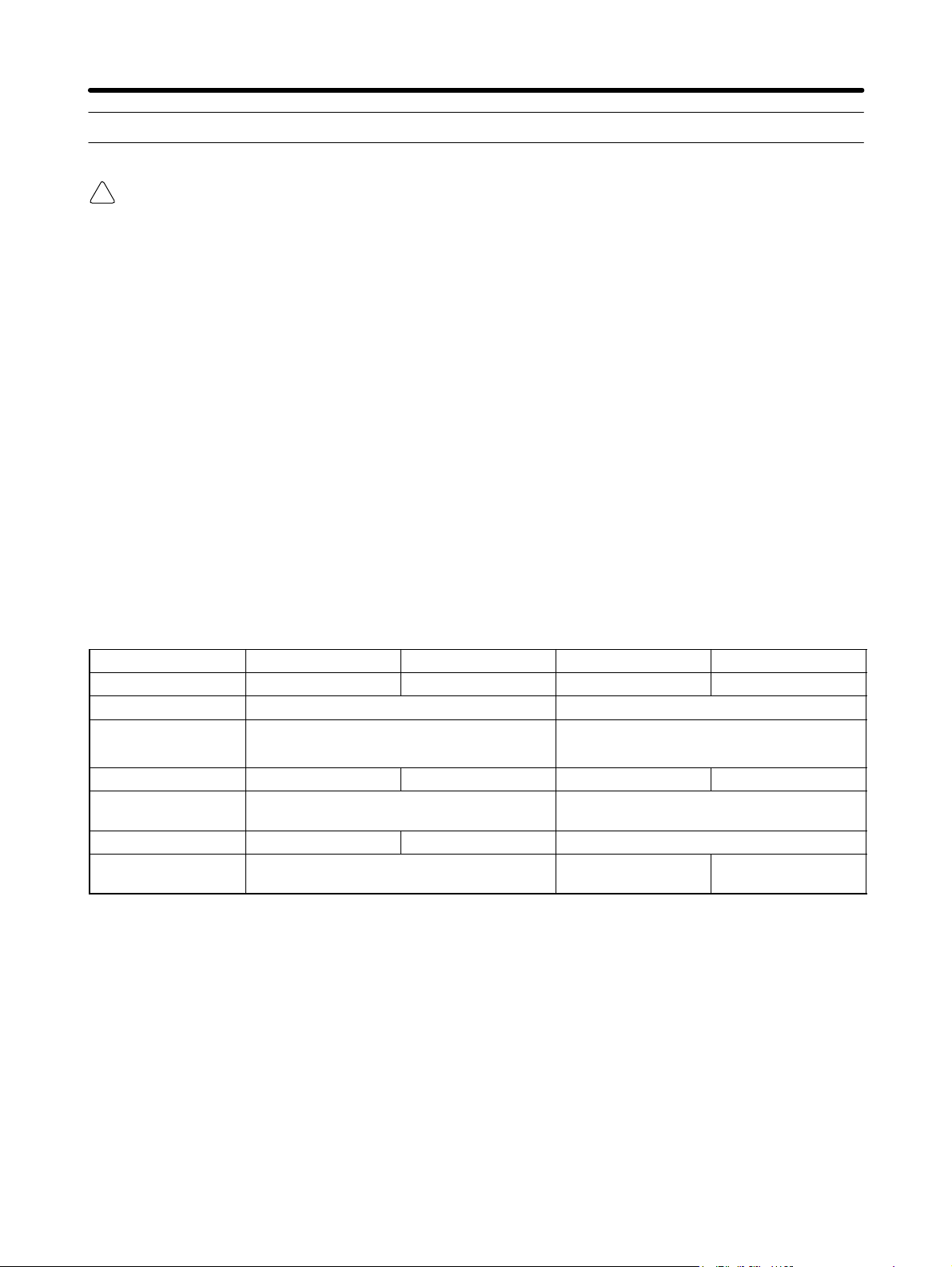

2-1-1 Selecting the Resolver

There are four Resolver models available. Select the Resolver suitable for the application.

H Resolvers

Type Large-diameter High-torque Connector Lead-wire

Model 3F88L-RS17 3F88L-RS17T 3F88L-RS15 3F88L-RS15W

Axle diameter 10 mm 6 mm

Rated axle load Thrust load: 196 N max.

Radial load: 196 N max.

Total length 101 mm 110 mm 154 mm 97 mm

Attachment

method

Friction torque

Connection to

Cam Positioner

Note High-torque Resolvers have oil seals.

Flange Connected to the servo.

12 mN S m max. 49 to 147 mN S m 2.9 mN S m max.

Shown in diagram A. Shown in diagramB.Shown in diagram

Thrust load: 98N max.

Radial load: 98 N max.

C.

2-2

Page 29

Design Chapter 2

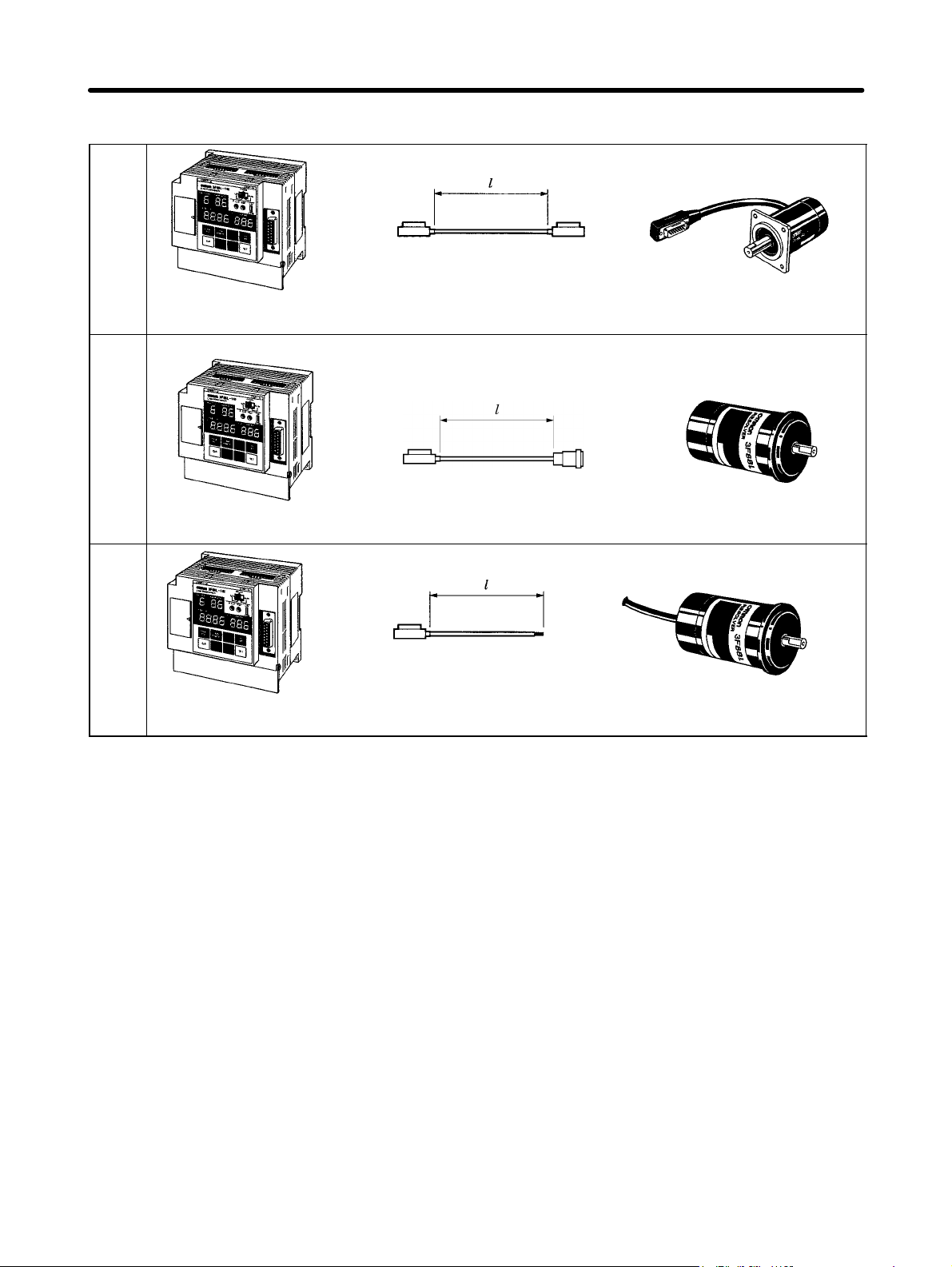

H Cam Positioner and Resolver Configuration

A

3-m Plug-in cable

3F88L-160 or 3F88L-162

Cam Positioner

3F88L-CRjjjC

Resolver Extension Cable

B

3F88L-160 or 3F88L-162

Cam Positioner

3F88L-CRjjjNA

Resolver Cable

C

3F88L-RS17/-RS17T

Resolver

Connector type

3F88L-RS15 Resolver

35-cm Separate wire

plug-in cable

3F88L-160 or 3F88L-162

Cam Positioner

3F88L-CRjjjSA

Resolver Cable

3F88L-RS15S Resolver

Note 1. 3F88-RS17 and 3F88-RS17T Resolvers have 3-m cables. Use the 3F88L-CRjjjC Re-

solver Extension Cable if more cable is required.

Note 2. The jjj in the Extension Cable model number indicates the length of the Extension Cable.

For example, the 3F88L-CR010C Extension Cable is 10 m in length.

Note 3. The distance between the Cam Positioner and the Resolver can be up to 100 m.

2-3

Page 30

Design Chapter 2

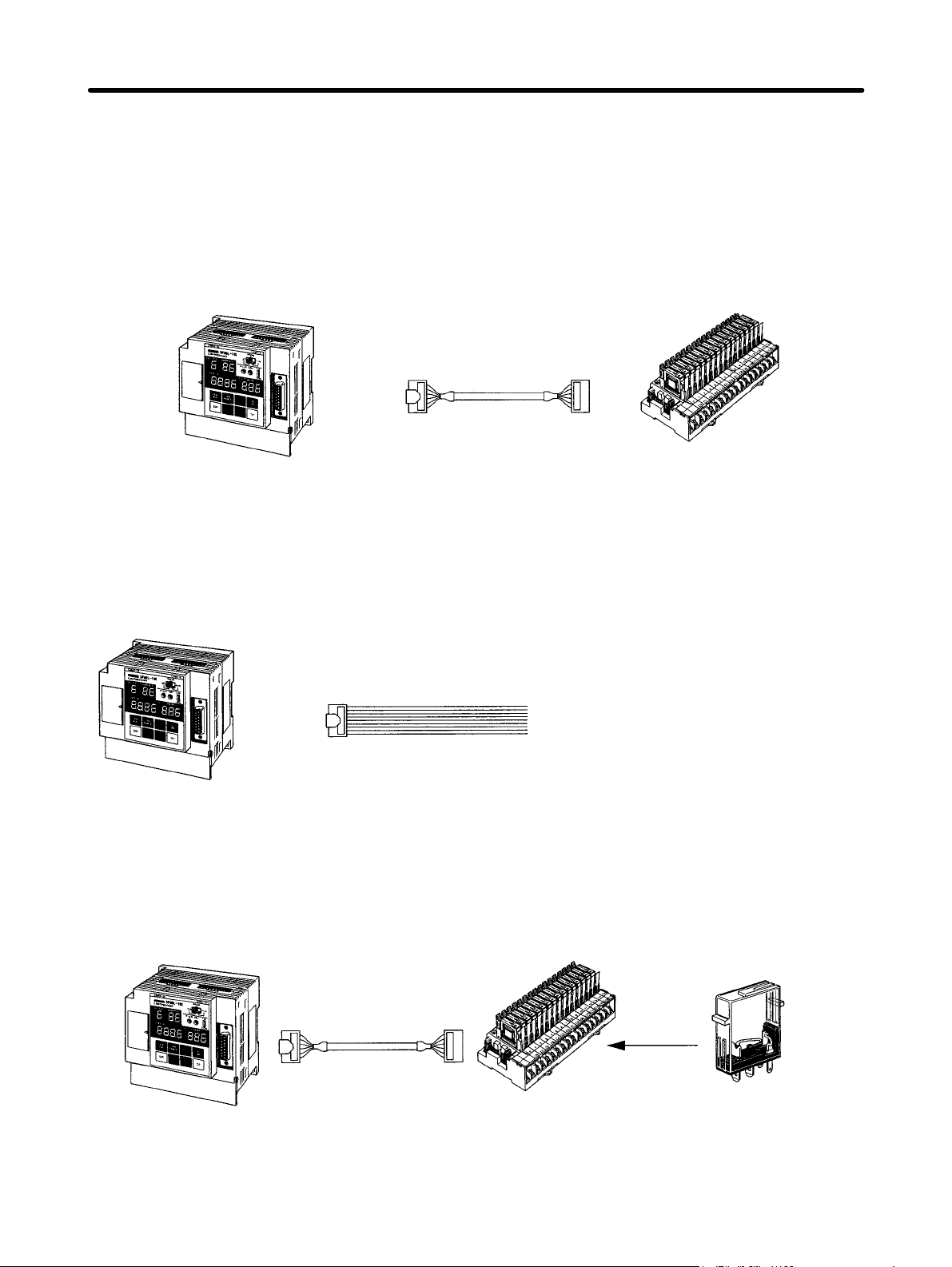

2-1-2 Selecting the Output Device

Select the device and connection method for ON/OFF outputs from the Cam Positioner. (Refer to 2-3

Wiring for information on connecting output devices.)

H For Relay Output

Use an I/O Block for relay output.

3F88L-160 or 3F88L-162

Cam Positioner

3F88L-CGjjjN

Cam Output Cable

G7TC-OC16

I/O Block

H For Transistor (Open Collector) Output

Use the outputs straight from the Cam Output Cable.

Open collector output

3F88L-160 or 3F88L-162

Cam Positioner

3F88L-CGjjjS

Cam Output Cable

H For Mostly Relay Output with Some Open Collector Output

Use an I/O Block and use an Output Short-circuit Module to give some open collector output.

3F88L-160 or 3F88L-162

Cam Positioner

2-4

3F88L-CGjjjN

Cam Output Cable

G7TC-OC16

I/O Block

Output

Short-circuit

Module

Page 31

Design Chapter 2

H To Display Present Angles and Other Data on a Display Unit

Connect a M7E or M7F Display Unit to the Cam Output Cable.

3F88L-160 or 3F88L-162

Cam Positioner

3F88L-CGjjjS

Cam Output Cable

M7E or M7F Display Unit

Note Parameters must be set to output present values. The present value output and cam output termi-

nals will be shared which means that some cam output signals can no longer be used.

2-5

Page 32

Design Chapter 2

2-2 Installation

2-2-1 External Dimensions

Note All units are in millimeters unless otherwise indicated.

H 3F88L-160 and 3F88L-162 Cam Positioners

w When the Resolver

Cable is connected

Two, 4.5 dia.

101±0.2

91± 0.2

2-6

Page 33

Design Chapter 2

Resolvers

3F88L-RS17 and 3F88L-RS17T

280.5 72 (81) (see note)

Four, 4.5 dia.

10–0.005/–0.017 dia.

40 dia.

50 0.3 dia.

35+0/–0.05 dia.

XM3A-1521 (OMRON) or the equivalent

15-pin D-sub Plug

Approx. 3 m

8.6 dia.

XM3D-1521 (OMRON) or the equivalent

15-pin D-sub Socket

Note The dimensions in parentheses are for the 3F88L-RS17T Resolver.

3F88L-RS15

16.5±0.5

3

9

5.5

6–0.004/–0.016 dia.

72

2.5

44 max.

8.6 dia.

43 dia.

33.32+0/–0.05

39 dia.

Hirose RM15WTP-10S-(8)

Connector

Hirose RM15WTR-10P

Connector

2-7

Page 34

Design Chapter 2

D 3F88L-RS15W

16

max.

16.5±0.5

6–0.004/–0.016 dia.

350 max.

43 dia.

33.32+0/–0.05

39 dia.

2-2-2 Installation Environment

Take precautions with the installation environment to improve the reliability and to fully

utilize the functions of the Cam Positioner system.

H Do not install the Unit in the following locations.

• Locations subject to direct sunlight.

• Locations subject to ambient temperatures or relative humidities outside the following ranges.

Ambient temperature: 0° to 55°C (Cam Positioner Unit) and –10° to 80°C (Resolver)

Ambient humidity: 10 to 90 % (with no condensation).

• Locations subject to condensation as the result of severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

H Take appropriate and sufficient countermeasures when installing the

Unit in the following locations.

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields and magnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies.

2-8

Page 35

Design Chapter 2

H Conformance to EC Directives

The 3F88L-160/162 Cam Positioner complies with EC Directives. To ensure that the system in which

the 3F88L-160/162 is installed complies with EC Directives, the following precautions must be observed.

• The 3F88L-160/162 is defined as an in-panel device according to the Low-voltage Directive. The

3F88L-160/162 must, therefore, be installed within a control panel.

• Reinforced insulation or double insulation must be used for the DC power supplies used as I/O power

supplies.

• The 3F88L-160/162 conforms to the Common Emission Standard (EN50081-2) in relation to EMI.

However, the radiated emission (10-m regulations) may vary depending on the configuration of the

control panel, connected devices, wiring, and other conditions. The customer must, therefore, confirm

that devices and the overall machine conform to EC Directives.

2-2-3 Mounting the Resolver

Use the Resolver Coupling to connect the Resolver to the machinery. This Coupling protects the Resolver from vibrations and shocks from the machinery.

H Mounting Method

D 3F88L-RS17/17T (Flange-mounted)

w Recommended

mounting holes

Four, M4-screws

+0.025

35

dia.

/

+0.009

50 ± 0.3 dia.

w Mounting example

Four, M4

screws

50 dia.

3-mm sheet min.

2-9

Page 36

Design Chapter 2

D 3F88L-RS15/15W (Servo-mounted)

w Recommended

w Mounting example

mounting hole

Three, M4 screws

(Evenly spaced around

circumference)

33.332

dia.

52 dia.

+0.025

/

+0.009

52 dia.

67 dia.

3-mm sheet min.

w Mounting hook (Resolver attachment)

4.4 dia.

H Connecting with the Coupling

As a rule, the Resolver Coupling should be used when connecting the Resolver to the machinery. The

Coupling will break near the center if 1.7 to 2 times the rated tightening torque is applied and, therefore,

protects the Resolver from excessive torque.

Keep the axle center displacement and bend angle of the Coupling within the specifications when

mounting.

D Coupling Specifications

3F88L-

Cou-

plings

RL10 RS17/RS17J 10 22 26.2 19 3.6 7.1 12 10°

RL6 RS15/RS15W 6 15 22 16.4 2.8 5.5 11 10°

3F88L-

Resolvers

D dia. E dia. L P A B C

Dimensions (mm)

Max.

bend

angle

θ1 (see

note 2)

max.

max.

Axle cen-

note 3)

1.0 mm

max.

1.2 mm

max.

Note 1. The Coupling is made from 25% Duracon glass fiber.

Hexagonal set screw

D dia.

E dia.

ter dis-

place-

ment

t1 (see

Rated tightening

torque

+20°C +80°C Size Tighten-

2.94

N S m

0.98

N S m

1.76

N S m

0.58

N S m

Screw sets

ing

torque

M4 × 6 0.44

N S m

M3 × 4 0.24

N S m

2-10

Page 37

Design Chapter 2

Note 2. Maximum bend angle

Θ1

Note 3. Axle center displacement

t1

D Precautions when Connecting with the Coupling

Take the following precautions when connecting the Resolver to the machinery via the Coupling.

• Make sure the axle center does not protrude into the area marked C in the diagram. If the axle center is

protruding when the Resolver rotates, the Coupling will no longer function and the machinery may be

damaged.

• If the bend angle or displacement of the axle center is large, the life of the Coupling will be shortened

and the accuracy of the Resolver rotation angle will be adversely affected.

Resolver axle centerMechanical axle center

H Connecting without the Coupling

Give sufficient consideration to the load that will be applied to the Resolver axle if it is connected to the

machinery without the Coupling. Make sure the applied load will be below the rated load.

D Rated Resolver Axle Load

Model 3F88L-RS17 3F88L-RS17T 3F88L-RS15 3F88L-RS15W

Rated axle load Thrust load: 196 N max.

Radial load: 196 N max.

Thrust load (load

parallel to the axle)

Thrust load: 98 N max.

Radial load: 98 N max.

Radial load (load

perpendicular to

the axle)

2-11

Page 38

Design Chapter 2

D Connection Examples

Using a Timing Belt

A pulley is attached directly onto the Resolver axle and connected to a rotating machinery by a timing

belt.

In this case, the load on the axle is the tension on the timing belt and the weight of the pulley.

Timing belt

Resolver

Using Gears

Pitch errors, total alignment errors, and other gear errors apply a repeated load in the radial direction.

Gear

Resolver

Using Chains

A sprocket can be attached directly to the Resolver axle and the axle then connected to a rotating

machinery with a chain.

The weight of both the sprocket and the chain will be a load on the axle. Rattles in the sprocket and chain

will become shock loads applied to the axle when machine movement stops and starts.

Chain

2-12

Resolver

Page 39

Design Chapter 2

2-3 Wiring

2-3-1 System Connection Diagram

G7TC-OC16 I/O Block SYSMAC CS1 or other

3F88L-CGjjjN

Cam Output Cable

Programmable Controller

3F88L-CGjjjS

Cam Output Cable

Cam Output Connector

Display Units

M7E

M7F

3F88L-CGjjjS

Cam Output Cable

3F88L-160/162

Cam Positioner

Resolver Connection Cables

3F88L-CRjjjC

Resolver Extension Cable

3F88L-RS17/-RS17T Resolver 3F88L-RS15 Resolver 3F88L-RS15W Resolver

3F88L-CRjjjNA

Resolver Cable

3F88L-CRjjjSA

Resolver Cable

2-13

Page 40

Design Chapter 2

2-3-2 Standard Wiring Method

The number of man hours required for wiring will be reduced and the reliability of the Unit

will be improved if OMRON Cables are used.

Give sufficient consideration to noise countermeasures when wiring

H Using Connection Cables

Use the following Cables to connect the Unit to peripheral devices. Always use OMRON Cables when

connecting the Resolver, in particular, to ensure reliability of the Unit.

Peripheral device

Cable name Model Remarks

to be connected

Resolver Resolver Cable

I/O Block Cam Output Cable

PC or similar device

Cam Output Cable

3F88L-CRjjjC

3F88L-CRjjjNA

3F88L-CRjjjSA

3F88L-CGjjjN

3F88L-CGjjjS

Extension Cable for 3F88L-RS17/-RS17T

Cable for 3F88L-RS15

Cable for 3F88L-RS15W

Connectors at both ends.

Connector on one end.

(for cam output)

Display Unit Cam Output Cable

3F88L-CGjjjS

Connector on one end.

Note The jjj in the cable model numbers indicates the length of the cable. Refer to 7-4 Standard

Models for details.

H Wiring for Improved Noise Resistance

The noise resistance of the system can be improved by the wiring method. The following points must be

given attention when wiring.

D Connection Method

Control panel

AC power

supply

Power

device

2-14

Surge

absorber

Insulation

transformer

Noise filter

Control

power

supply

Ground board

Control

device

Cam

Positioner

Ground to 100 Ω or less.

Resolver

If metal ducted

2

2.0 mm

ground min.

Page 41

Design Chapter 2

• Use a ground board as shown in the diagram and ground (FG) each Unit to one point on the ground

board.

• Do not bundle the ground together with the power supply, motor drive, or Resolver signal wires or run

the ground through the same duct as these wires.

• If using metal conduit or running wires through metal duct, ground the metal to one point.

Note To make the 3F88L-160/162 Cam Positioner conform to EC Directives, be sure to install the Unit

within a control panel.

D External Wiring

• Use a different cable for the Cam Positioner I/O and the control wire. Do not run these wires through

the same cable.

• It is recommended that the Cam Positioner cables and other control and power cables are wired as

shown below.

• Parallel cable racks must be a minimum of 300 mm apart.

• If multiple terminals are to be housed in one duct, shield the terminals with a grounded conductive

plate.

Low-current

cable

1

2

Control cable

3

Power cable

4

Conductive

plate (steel)

300 mm min.

300 mm min.

1. Resolver cable

2. Cam Positioner input cable

3. Cam Positioner power supply cable

General control cable

4. Power cable

Ground to 100 Ω or less

Conductive

plate (steel)

12 3 4

Ground to 100 Ω or less

200 mm min.

Note The 3F88L-160/162 conforms to the Common Emission Standard (EN50081-2) in relation to

EMI. However, the radiated emission (10-m regulations) may vary depending on the configuration of the control panel, connected devices, wiring, and other conditions. The customer must,

therefore, confirm that devices and the overall machine conform to EC Directives.

H Points to Consider when Wiring to Peripheral Devices

• Install a surge absorber and noise filter on the AC power supply input wiring.

• Pay attention to the following points when using relays, electromagnetic valves, and other noise-gen-

erating devices.

S Separate noise-generating devices, parts and the wiring as much as possible.

S Use a separate power supply system.

2-15

Page 42

Design Chapter 2

S Use a separate grounding system.

S Attach a surge absorber or diode to the device or parts generating the noise, as shown in the fol-

lowing diagram.

AC relays or AC valves DC relays

AC

power

supply

~

Surge absorber

DC

power

supply

Note Select withstand pressure and current suitable for the load.

2-3-3 Terminal Block Wiring

Use crimp terminals and firmly tighten to the appropriate torque.

H Terminal Block Layout

Power supply input

Function

Earth

Protect

Earth

Control input

Diode

Control output

H Power Supply Input Wiring

D Wiring Method

Func-

Protect

tion

Earth

Earth

100 to 240 V AC

50/60 Hz

2-16

~

Ground to 100 Ω

or less

Terminal screw size: M3.5

Tightening torque: 0.8 N S m

Page 43

input terminal

Positioner. Provide a 100 to 240 V AC

Design Chapter 2

D Terminal Functions

Terminal name Symbol Function Recommended

connection wire

diameter

Main circuit power supply

input terminal

Function earth terminal This is the primary ground terminal

Protect earth terminal This is the frame ground terminal. 2.0 mm

AC1/L

AC2/N

Inputs the AC power supply for the Cam

Positioner. Provide a 100 to 240 V AC

50/60 Hz power supply. (Rated power

supply voltage 85 to 264 V AC)

connected for the power supply.

1.25 mm

2.0 mm

Note 1. Use M3.5 round crimp terminals for AC 1/L and AC 2/N terminals.

Note 2. Use M3.5 round or forked crimp terminals for function earth and protect earth terminals.

w Round crimp terminal w Forked crimp terminal

2

2

2

7 mm max.

7 mm max.

Note If the power supply voltage of the Cam Positioner slowly increases or decreases at less than 85%

of the rated voltage (i.e., less than 85 V), operation may stop intermittently. If this affects the operation of equipment, provide protective circuits that interrupt output enough to cause the voltage

to increase to more than 85% of the rated value.

H Control Input Wiring

D Wiring Method

24 V DC

Terminal screw size: M3

Tightening torque: 0.5 N S m

2-17

Page 44

p

pp y

Design Chapter 2

D Terminal Functions

Terminal

name

Control I/O

power

supply

Operation

start input

Bank

switching

input

Symbol Function Recommended

connection

wire diameter

24 V

The control I/O power supply terminal is used for the power

1.25 mm

2

supply for control I/O.

0 V

Provide a 24-V DC power supply. (Rated power supply voltage

20.4 to 26.4 V DC)

START Cam output will start if the START signal is shorted with 0V. 0.5 mm

BANK1 The BANK signals are used to select the execution bank for the

0.5 mm

2

2

Cam Positioner.

The BANK signals turn ON when shorted with 0V.

BANK2

Bank No. 1 2 3 4 5 6 7 8

BANK1 OFF ON OFF ON OFF ON OFF ON

BANK3

BANK2 OFF OFF ON ON OFF OFF ON ON

BANK3 OFF OFF OFF OFF ON ON ON ON

Origin shift

input

TRIG

Origin shift is performed when this signal is shorted with 0V.

Note 1. The TRIG signal is disabled when the Resolver rotates at

0.5 mm

2

4 r/min or greater.

Note 2. The TRIG signal is enabled when it is ON for 10 ms or

more.

Inside

Origin shift execution

Reset input RESET If this signal is shorted with 0V, a hardware reset will be

New origin value

Y

0.5 mm

2

performed and the Unit will return to the state it was in upon

power ON. Regardless of output-hold settings, all outputs will be

turned OFF. Also, the origin value for the origin shift will be lost.

Note 1. Use M3.5 round or forked crimp terminals for functional ground and protective ground termi-

nals.

w Round crimp terminal w Forked crimp terminal

6.2 mm

max.

6.2 mm

max.

Note 2. Reinforced insulation or double insulation must be used for the DC power supplies used as

I/O power supplies in order to comply EC Directives.

2-18

Page 45

Design Chapter 2

D Control Input Specifications

Item Specification

Rated input voltage 24 V DC –15%/10%

Input impedance 4.7 kΩ

Input current 4.7 mA TYP. (for 24 V DC input)

ON voltage 17 V min. between 24-V terminal and control input terminals.

OFF voltage 5 V max. between 24-V terminal and control input terminals.

ON/OFF response time 1.0 ms

Internal circuit

START

BANK1 to 3

TRIG

RESET

H Control Output Wiring

4.7 kΩ

D Wiring Method

LL

Terminal screw size: M3

MSDET

L

COM

/0 V

24 V DC

for load

Tightening torque: 0.5 N S m

D Terminal Functions

Terminal name Symbol Function Recommended

connection wire

Control output common

terminal

RUN output RUN The RUN terminal indicates the operation

Resolver movement

detection output

Error output ERROR The ERROR terminal turns OFF when an

COM/0 V The COM/0 V terminal is the common

terminal for control output.

It is connected to the 0V terminal on the

control I/O output power supply.

status of the Unit.

It turns ON when cam output is enabled.

MSDET

The M⋅DET terminal turns ON when the

Resolver is rotating at 4 r/min or faster.

error is generated.

0.5 mm

0.5 mm

0.5 mm

0.5 mm

diameter

2

2

2

2

2-19

Page 46

Design Chapter 2

Note 1. Use M3.5 round or forked crimp terminals for functional ground and protective ground termi-

nals.

w Round crimp terminal w Forked crimp terminal

6.2 mm

max.

6.2 mm

max.

Note 2. Reinforced insulation or double insulation must be used for the DC power supplies used as

I/O power supplies in order to comply EC Directives.

Note 3. The control I/O power supply must be turned ON to operate the control output circuit.

D Control Output Specifications

Item Specification

Maximum switching capacity 24 V DC –15%/10%, 0.3 A/point

Leakage current 0.1 mA max.

Residual voltage 1.5 V max.

ON response time 0.5 ms max.

OFF response time 1.0 ms max.

Internal circuit

RUN

M-DET

ERROR

2-20

Page 47

Design Chapter 2

2-3-4 Resolver Wiring

Use OMRON Resolver Cables which are designed to reduce noise.

Resolver Cables transfer signals that require a high degree of accuracy. Separate the

Resolver Cables from other cables as much as possible to prevent the accuracy being

affected by induction noise resulting from low signal voltage.

S Separate Resolver Cables as much as possible from control and drive wiring inside

the control panel.