OmniWare 330 User Manual

By

WASTE OIL FIRED BOILER

OWB Series

Installation, Operation, And Service Instructions

Manual

Thank you and congratulations on your purchase of an Omni Waste Oil Fired Boiler. You have selected a

high quality, precision-engineered piece of equipment, designed to give you many benefits as well as years

of outstanding performance.

Econo Heat♦5714 1st Avenue♦Spokane Washington 99212.♦(509)534-1022♦www.econoheat.com

100270 Rev A3

TABLE OF CONTENTS

WASTE OIL BURNER........................................................................5

OIL BURNER TECHNOLOGY ..........................................................8

OIL BURNER/PUMP TECHNICAL DATA.......................................10

BOILER SPECIFICATIONS ...............................................................11

STANDARD EQUIPMENT.................................................................12

COMBUSTION AIR SUPPLY ............................................................14

CHIMNEY OR VENT REQUIREMENTS..........................................16

LOCATING THE BOILER..................................................................18

INSTALLING THE BOILER...............................................................19

BREECHING INSTALLATION..........................................................19

INSTALLING BOILER CONTROLS AND ACCESSORIES............20

WATER PIPING CONNECTIONS .....................................................22

SYSTEM PIPING.................................................................................24

BOILER ASSEMBLY AND WIRING ................................................33

BOILER STARTUP AND ADJUSTMENTS ......................................42

WASTE OIL BURNER STARTUP.....................................................43

WATER TREATMENT.......................................................................43

FREEZE PROTECTION......................................................................43

MAINTENANCE.................................................................................44

TROUBLE SHOOTING GUIDE .........................................................46

WARRANTY .......................................................................................47

2

Installation, Operation, And Service Instructions

PRECAUTIONS

Waste oil may contain many foreign materials. Waste oil may also contain

gasoline. Therefore, specific precautions on the handling and storage of waste

oils are to be observed when using, cleaning and maintaining this heater. Use a

screen in a funnel when pouring oil into storage tank to catch foreign

material, i.e., gasket material and sealant fibers, etc. WARNING: This

appliance is not designated for use in hazardous atmospheres containing

flammable vapors or combustible dust, or atmospheres containing

chlorinated or halogenated hydrocarbons. Do not expose this unit to rain

or moisture. If installed in high moisture atmosphere, a special cover for

the integrated air compressor must be obtained from factory to avoid

rusting of internal raw metals. If this occurs, see trouble-shooting guide for

remedy. Uses only crank case oil, gear oil, hydraulic oils, auto trans. Fluid or #1

and #2 furnace oil. Do not use old, contaminated oils that have been stored in

underground tanks or outside barrels for long periods. Excessive water and

sludge may be present, causing quick filter plugging.

NOTES: The instructions contained in this manual apply to the installation,

operation, and service of Omni Waste oil fired boiler. The following instructions

should be carefully followed for obtaining the best possible installation, operation

and service conditions. Specifications are subject to change without notice. This

product was designed to provide an economical disposal of waste oil. Proper

operation depends on the consistency of the oil. Any water or foreign material in

the oil may cause the unit to shut down.

This appliance is designed for commercial or industrial use only.

UNCRATING: Immediately upon uncrating units, check rating plate for certainty

of electrical and mechanical characteristics. Also check the unit for any damage

that may have been incurred in shipment, if any damage is found, file a claim

with the transporting agency. The unit has been tested and inspected at the

factory prior to crating and was in perfect condition at that time. If anything is

missing check packing slip for indications of possible backorder of those parts or

components. Otherwise a claim must be for those missing parts.

Installation, Operation, And Service Instructions 3

IMPORTANT

NOTICE TO OWNER

AND INSTALLER

To enjoy the long term benefits of burning your used oil in an Omni Waste Oil Boiler, it is

necessary to become familiar with the correct installation operation and maintenance of your new

boiler. Before installing or operating this appliance, make sure you read and understand this

manual.

IMPROPER INSTALLATION OR LACK OF

MAINTENANCE

WILL VOID THE WARRANTY

------------WARNING------------

Improper Installation, adjustment, alteration service or

maintenance can cause property damage, injury, or loss

of life. For assistance or additional information consult

a qualified installer or service agency. Read these

instructions carefully before installing

Identical to any oil burning appliance, without adequate draft over the fire, the combustion

gases cannot escape the appliance. The flame will lengthen resulting in an overheated

combustion chamber. Even if the heater is installed correctly and adequate draft achieved, a

flue passage blockage will affect the draft. Burning used oil is similar to burning wood. A fine gray

ash accumulates in the chamber and flue passage. This accumulation of ash will eventually affect

the draft. It is important to remove this ash before the draft is affected.

Note:

All illustrations and specifications contained herein are based on

the latest information available at time of publication approval.

Econo Heat reserves the right to make changes at any time

without notice, in material and specifications.

4

Installation, Operation, And Service Instructions

ONLY Authorized Technicians strictly complying with the manufacturer’s instructions

and the local standards should perform installation, maintenance and service on the

unit’s internal components. Installation and use of this used oil burning appliance shall

be in accordance with the standard for the Installation of Oil Burning Equipment –

ANSI/NFPA 31 – 1987, and National Electric Code – ANSI/NFPA 70 – 1990 and the

requirements of the inspection authorities having jurisdiction.

WASTE OIL BURNER

WARNING

Igniter

Transformer

Oil Primary

Control

Air Band

(Combustion Air

Supply Adjustment)

Power Switch

Figure 1 – Oil Burner (Back View Closed)

Run

Indicator

Power

Indicator

Oil Pressure

Gauge

Air Pressure

Air

Compressor

Air Pressure

Gauge

Adjuster

Installation, Operation, And Service Instructions 5

Oil Pre-Heater

Block

Photo Eye

Flame Sensor

Transformer

Igniter Springs

Pre-Heater Control

Circuit Board

Air

Muffler/Filter

Electrical

Terminal

Block

Heater

Electrical

Schematic

Figure 2 – Oil Burner (Back View Opened)

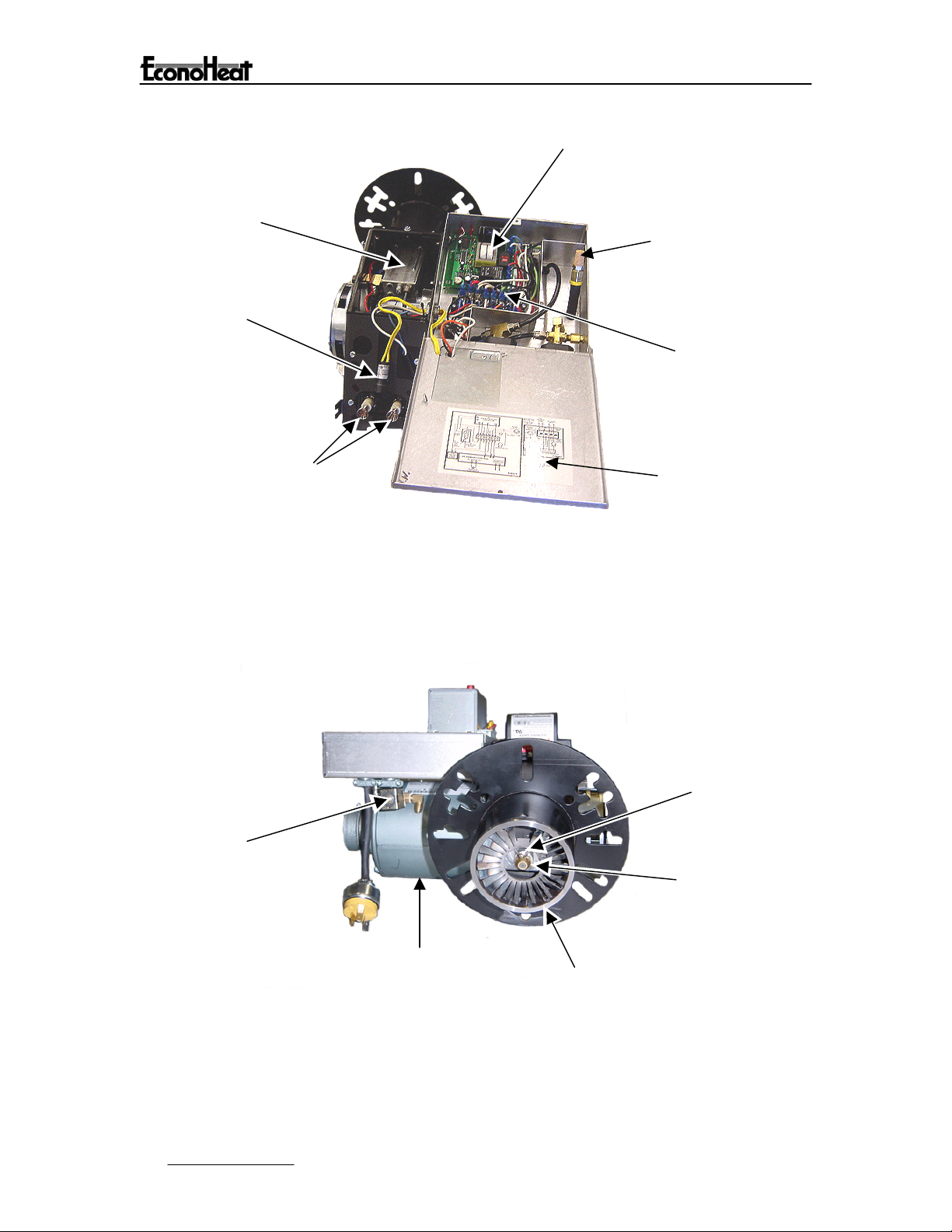

Oil Valve

Burner

Motor

Flame Cone

Electrodes

Nozzle

Figure 3 – Oil Burner (Front View)

6

Installation, Operation, And Service Instructions

t

Oil Outle

Oil Inlet

Figure 4 –Oil Pump Diagram

Figure 5 –Oil Pump Assembly

Installation, Operation, And Service Instructions 7

Omni’s patented burner technology improves the efficiency of the oil burn process by continuous

stabilization of the oil viscosity. Optimum atomization (spray) is accomplished by precisely preheating the oil and air prior to introduction to the combustion chamber. The waste oil enters into

the Oil Pre-Heater Block (figure2) and is pre-heated to operating thermo setpoint, then

compressed air from the air compressor (figure1) is mixed with the oil prior to spraying out the

nozzle similar to fuel injection, by breaking up the oil droplets into a finer mist or spray

(atomization). Electrodes mounted just above the nozzle (figure3) provides continuous electrical

arc across electrode to electrode igniting the fine oil mist as it sprays out of the nozzle. Once

ignited the flame is forced into a swirl caused by the burners blower and specially designed flame

cone (figure3) providing a very efficient and thorough burn of the waste oil.

Burner Components

• Igniter Transformer: (figure1) Supplies high voltage to the electrodes generating

electrical arc igniting the oil.

• Oil Valve: (figure3) energizes when burner is running and de-energizes when burner is

not running eliminating bleed back of oil out of the Pre-heater block.

• Air Band: (figure1) Adjusts amount of air introduced into the combustion chamber.

• Oil Primary Control: (figure1) Controls the oil burner ignition. Checks for flame in the

combustion chamber, if no flame is detected within 45 seconds, the oil primary will

shutdown the oil burner. To restart the unit, reset the red button on the oil primary.

OIL BURNER TECHNOLOGY

• Oil Pre-Heater Block: (figure2) Pre-heats the oil and air before entering combustion

chamber.

• Photo Eye: (figure2) Senses flame in combustion chamber and signals oil primary when

no flame is present.

• Igniter Springs: (figure2) Transfers the high voltage from the igniter transformer to the

electrodes (when door is closed)

• Air Pressure Gauge: (figure1) Displays air pressure supplied by onboard air

compressor.

• Air Compressor: (figure1) Supplies air used within pre-heater block to aid in atomization

of the oil.

• Air Muffler/Filter: (figure2) Filters air and muffles the sound generated by the

compressor.

• Pre-Heater Control Circuit Board: (figure2) Precisely controls temperature of the Oil

Pre-Heater Block and controls safety feature of not allowing burner to energize until oil

has established operating thermo setpoint or shutdown burner if Pre-Heater Block

temperature falls below shutdown thermo setpoint.

• Electrodes: (figure3) Provides continuous high voltage electrical arc from electrode to

electrode igniting the waste oil as it is being sprayed out of the nozzle.

• Nozzle: (figure3) Low pressure nozzle for oil spray pattern.

• Flame Cone: (figure3) Specially engineered flame cone forces the flame into a swirl

pattern improving the burn thoroughness.

• Burner Motor: (figure3) Multitask motor turns the burner blower and integrated air

compressor.

8

Installation, Operation, And Service Instructions

• Air Pressure Adjuster: (figure1) Adjusts the air pressure going to the pre-heater block.

Should be adjusted between 12 PSI and 13PSI as indicated on the Air Pressure Gauge

on the burner for thorough burn of the waste oil.

Note: In order to insure proper air adjustment, air gauge must read 0 when burner

is cycled off or powered down.

• Oil Pressure Gauge: (figure1) Displays oil pressure at the burner. Adjustment at the Oil

Pump must be made to achieve oil pressure readings at the burner as indicated below.

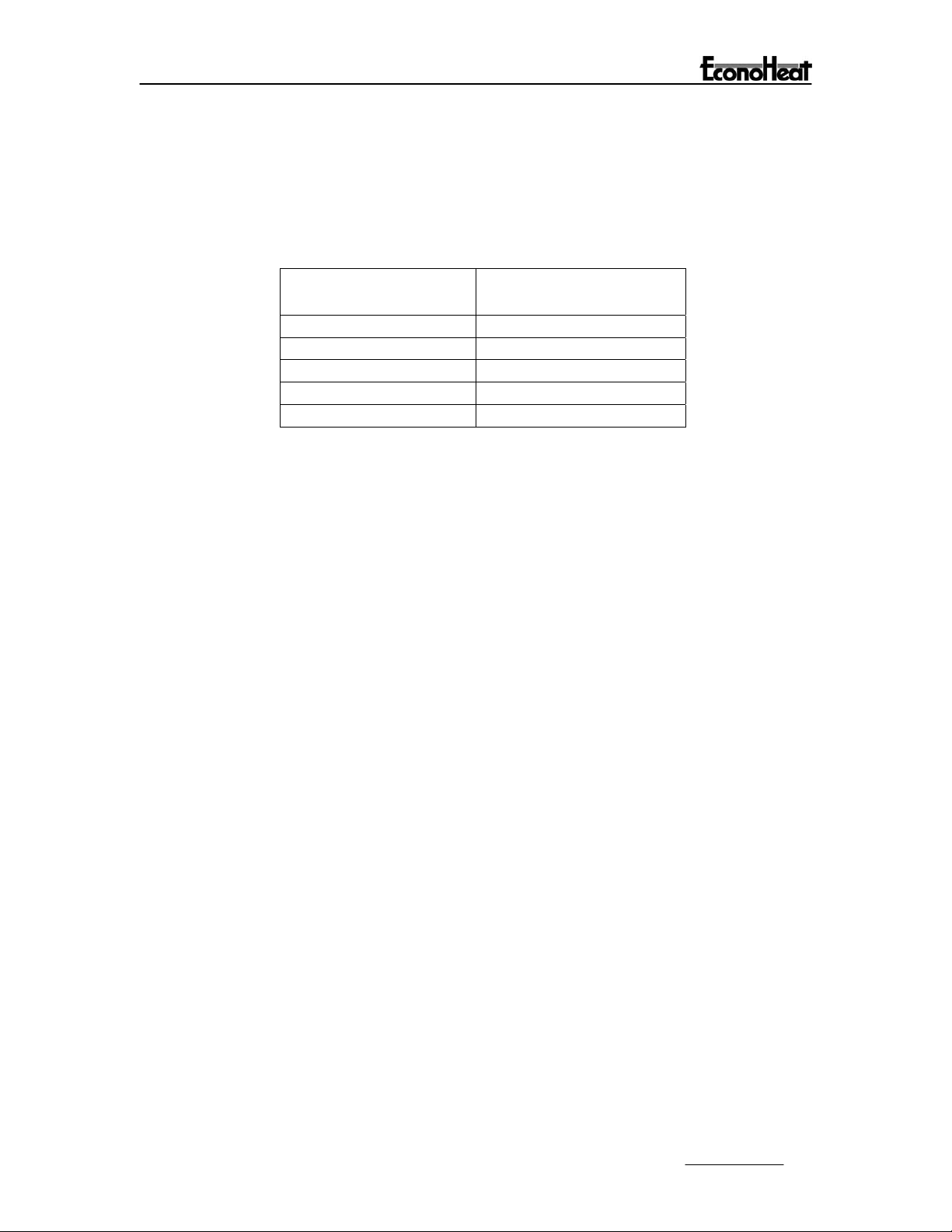

Boiler Model

OWB-9 1 PSI

OWB-15 2 PSI

OWB-25 4 PSI

OWB-35 6 PSI

OWB-50 11 PSI

Oil Pressure Reading At

Burner

• Power Indicator: (figure1) Indicates when power is present at the burner.

• Run Indicator: (figure1) Indicates that the burner is ready for operation after the initial

pre-heat time of approx. 5 minutes from initial power up.

• Power Switch: (figure1) Switches power off and on to the burner.

Installation, Operation, And Service Instructions 9

OIL BURNER/PUMP TECHNICAL DATA

BURNER ASSEMBLY

Performance Ratings

Voltage - 115 VAC

Cycles - 60Hz

Total Operating Amperage (Burner Only) Amp 8.4

Total Operating Amperage (Burner and Oil Pump) Amp 10.5

Electrical Operating Consumption (Burner Only) Watts 970

Electrical Operating Consumption (Burner and Oil Pump) Watts 1,212

Weight Lbs 36.5

Oil Primary Amp 0.2

Oil Valve Amp 0.075

Pre-Heater Block Amp 4.2

Pre-Heater Controller Board Amp 0.011

Igniter Transformer Amp 0.3

Burner Motor Amp 3.6

PUMP ASSEMBLY

Performance Ratings

Voltage - 115Vac

Cycles - 60Hz

Total Operating Amperage (Pump Assy Only) Amps 2.1

Electrical Operating Consumption (Pump Assy Only) Watts 241.5

Weight Lbs 16

Oil Valve Amps 0.075

Pump Motor Amps 2.0

10

Installation, Operation, And Service Instructions

BOILER SPECIFICATIONS

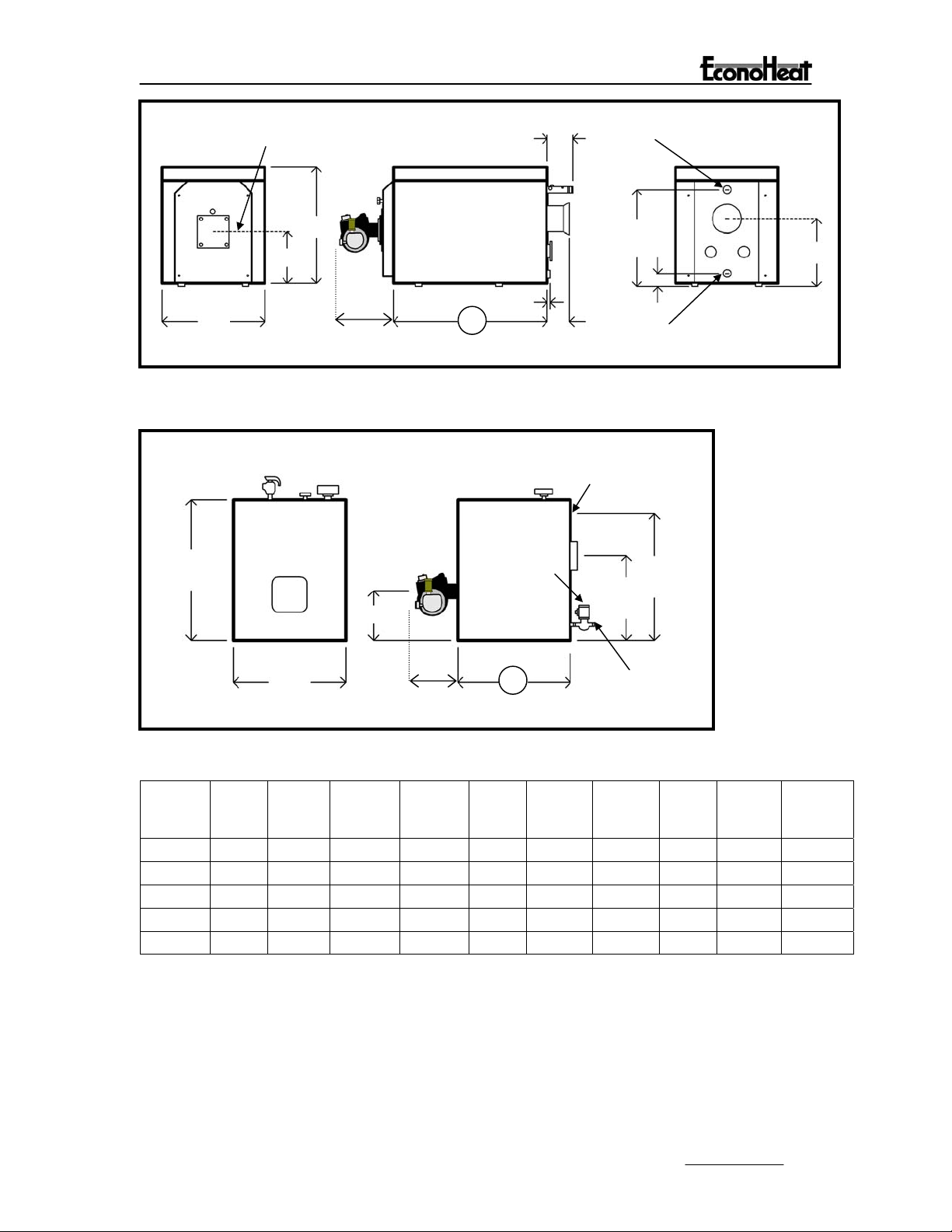

Figure 6 –Boiler (OWB-35 & OWB-50)

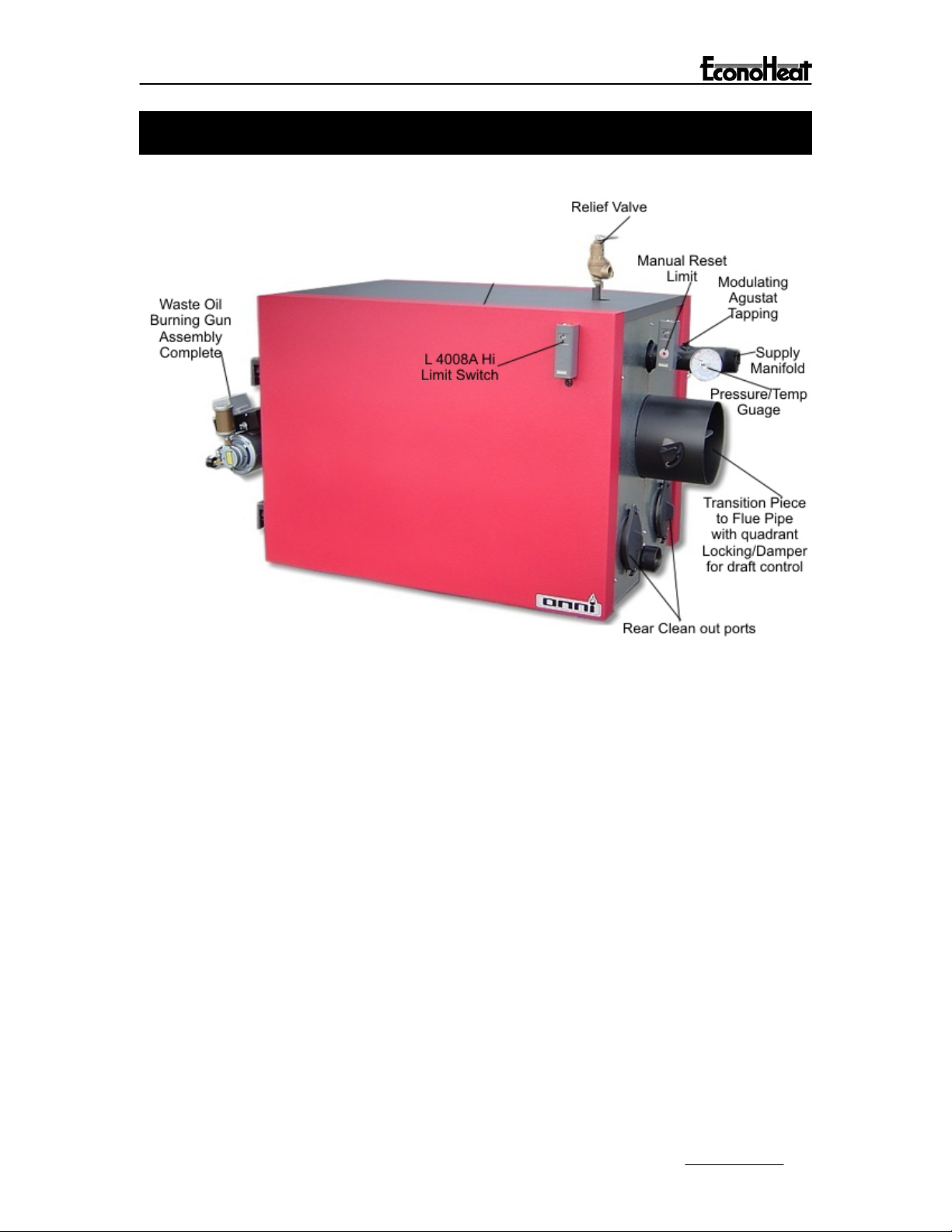

OWB series boilers are three pass Scotch Marine design with fully water backed transfer

surfaces. Boilers are designed for use in forced hot water heating systems. Heating is supplied

by a Waste Oil Burner that burns all petroleum products any weight combination up to SAE 90W

as well as fuel oils. Boiler–Burner units operate with no less than 0 to –0.01WC over fire and may

be vented using a conventional chimney.

Installation, Operation, And Service Instructions 11

CODE REQUIREMENTS

Installations must comply with all state, local, and utility codes, laws, regulations, and

ordinances, and CSA standard B139. Where required by the authority having

jurisdiction, the installation must conform to American society of Mechanical Engineers

Safety Code for Controls and Safety Devices for Automatically Fired Boilers, No. CSD-

1.

All electrical wiring must be done in accordance with the National Electrical codes latest

edition and all state and local codes.

* Factory Assembled Cast Iron Sections * Refractory Insulated Hinged front

* Flow Control Oil Supply Pump Door With Sight Glass

* Insulated Jacket * ASME Relief Valve 30 PSI

* Theraltimeter Gauge * Draft Inducer (optional)

* Boiler Drain * High Limit Aquastat Relay Combination

* Circulator – Except Models 35 and 50 (L-8148°) Except Models 35 and 50

* Relay – Models 35 and 50 Only * Serviceable Oil Filter

* Pre-built Control Manifold * Low Water Cut-off Control

Models 35 and 50 Only * Manual Reset High Limit Aquastat Control

STANDARD EQUIPMENT

12

Installation, Operation, And Service Instructions

A

r

A

Centerline Of Burner Plate

36”

17”

33”

pprox. 14”

OWB-35 and OWB-50 Specifications

26”

12-1/4”

L

3/4”

Circulato

9-3/8”

8”

1-1/2” Supply Connection

2-1/2 M.P.T. Supply Connection

29-1/2”

21-1/2”

15-1/2”

4”

2-1/2 F.P.T. Return Connection

20”

25”

OWB-9, OWB-15, and OWB-25 Specifications

pprox. 14”

L

1-1/2”

Return

Connection

Boiler

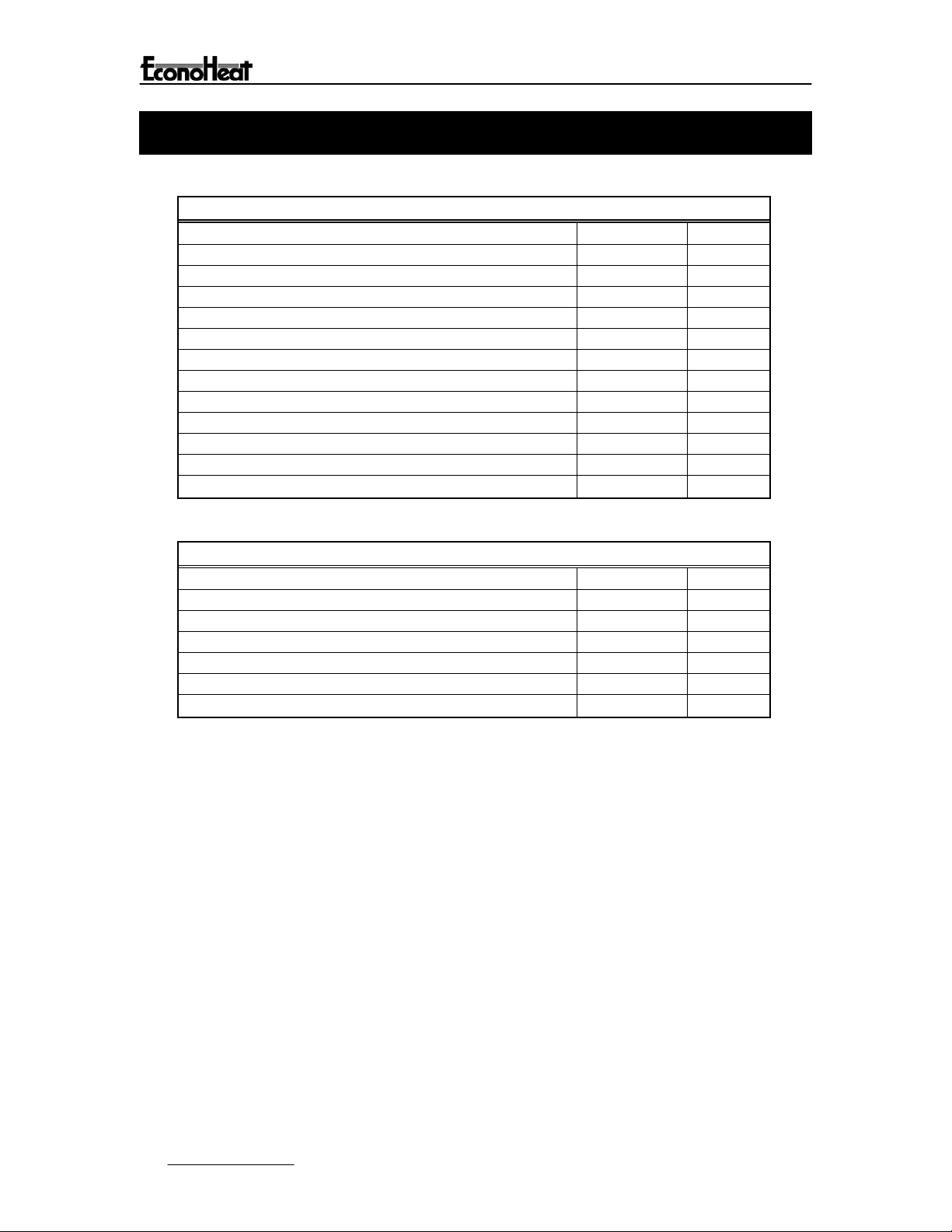

Model

OWB-9 .60 90,000 76,500 66,500 522 527 7 24-1/4 5.5 60PSI

OWB-15 1.0 150,000 127,500 110,800 875 716 7 34-1/4 8.2 60PSI

OWB-25 1.7 250,000 212,500 184,700 1,450 902 7 44-1/4 10.8 60PSI

OWB-35 2.4 350,000 297,500 258,600 2,030 1654 10 52 28.5 75PSI

OWB-50 3.3 500,000 425,000 369,500 2,900 1831 10 57 31.7 75PSI

Burner

GPH

Input

BTU’s

Output

Capacity

BTU’s

NET

Rating

Water

BTU/HR.

Table 1.

NOTES:

1. Net ratings shown are based on a piping and pick-up allowance of 1.15.

2. Net ratings in sq. ft. are based on 170 deg F average water temperature in radiators. For

higher water temperatures, select boiler on basis of net ratings in BTU/HR.

3. Firing rate in G.P.H. is based on oil having heat value of 150,000 BTU/GAL.

4. 4% reduction of output for every 1,000 ft. of elevation.

NET

Rating

Water

SQ.FT.

Approx.

Dry

Weight

Lbs.

Vent

Connect

Dia.

Inches

Dim

“L”

Inches

Water

Content

Gal.

Max.

Water

Working

Pressure

Installation, Operation, And Service Instructions 13

COMBUSTION AIR SUPPLY

WARNING

Failure to provide an adequate supply of fresh air for combustion will result in hazardous

operating conditions.

Note

If you use a fireplace or a kitchen or bathroom exhaust fan, you should install an outside

air intake. These devices will rob the boiler and water heater of combustion air.

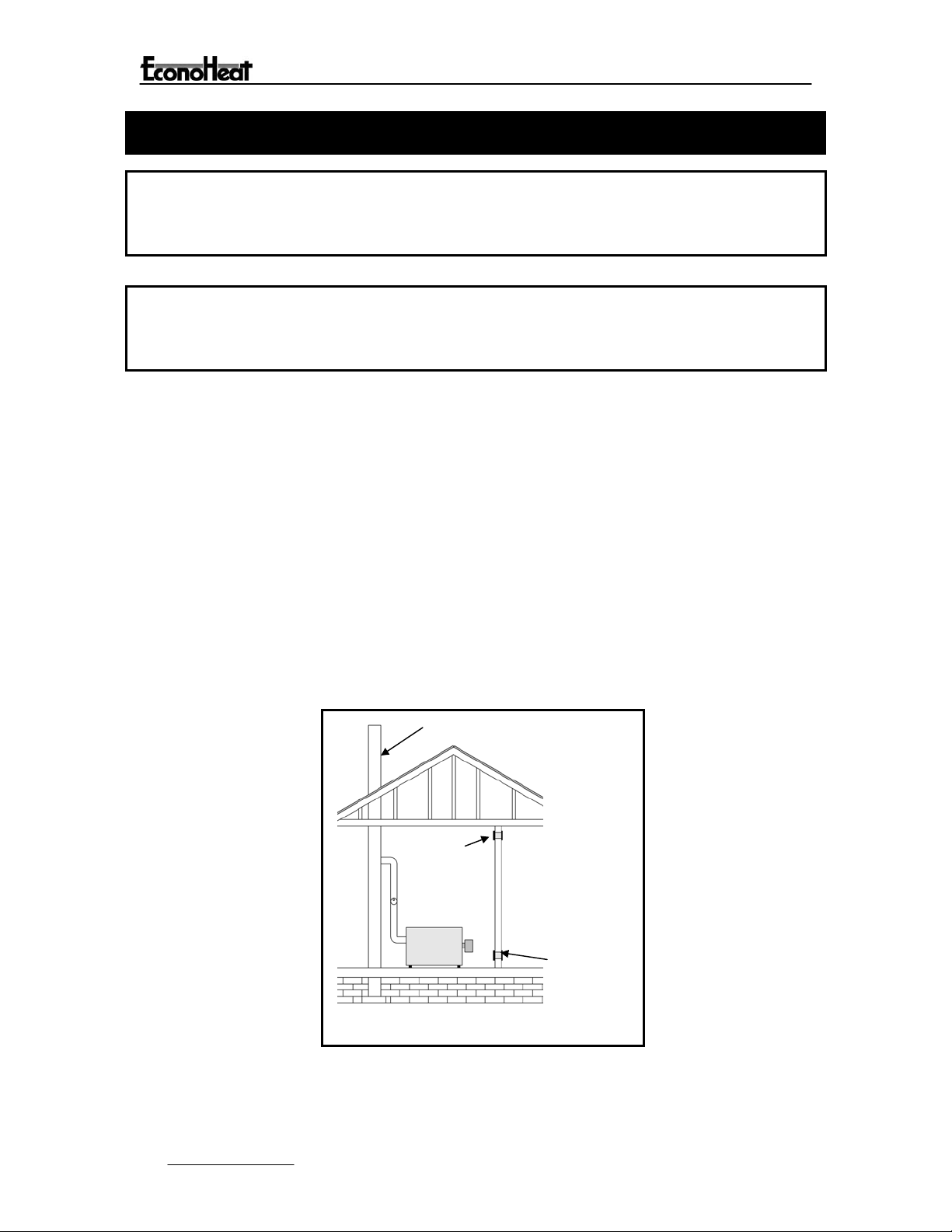

1. In unconfined spaces in buildings infiltration may be adequate to provide air for

combustion and ventilation. However, in buildings of unusually tight

construction, additional air must be provided as described in Item2. (b) below.

2. Boiler located in confined space:

[Note: Confined space may be defined as a space whose volume is less than 50

cubic feet per 1000 Btuh of total input of all appliances installed in that space.]

(a) All air from inside of building:

Providing infiltration in the rest of the building is adequate, the

confined space may be provided with two permanent openings

communicating directly with another room or rooms of sufficient

volume that the total volume of all spaces meets the criteria for

unconfined space. One opening must be within 12 inches of the

bottom of the enclosure. See Figure 7.

Chimney

Opening

Note: Each opening

shall have a free

area of not less than

one square inch per

1,000 Btu per hour of

the total input rating

of all equipment in

the enclosure, but

not less than 100

square inches.

Figure 7.

14

Opening

Installation, Operation, And Service Instructions

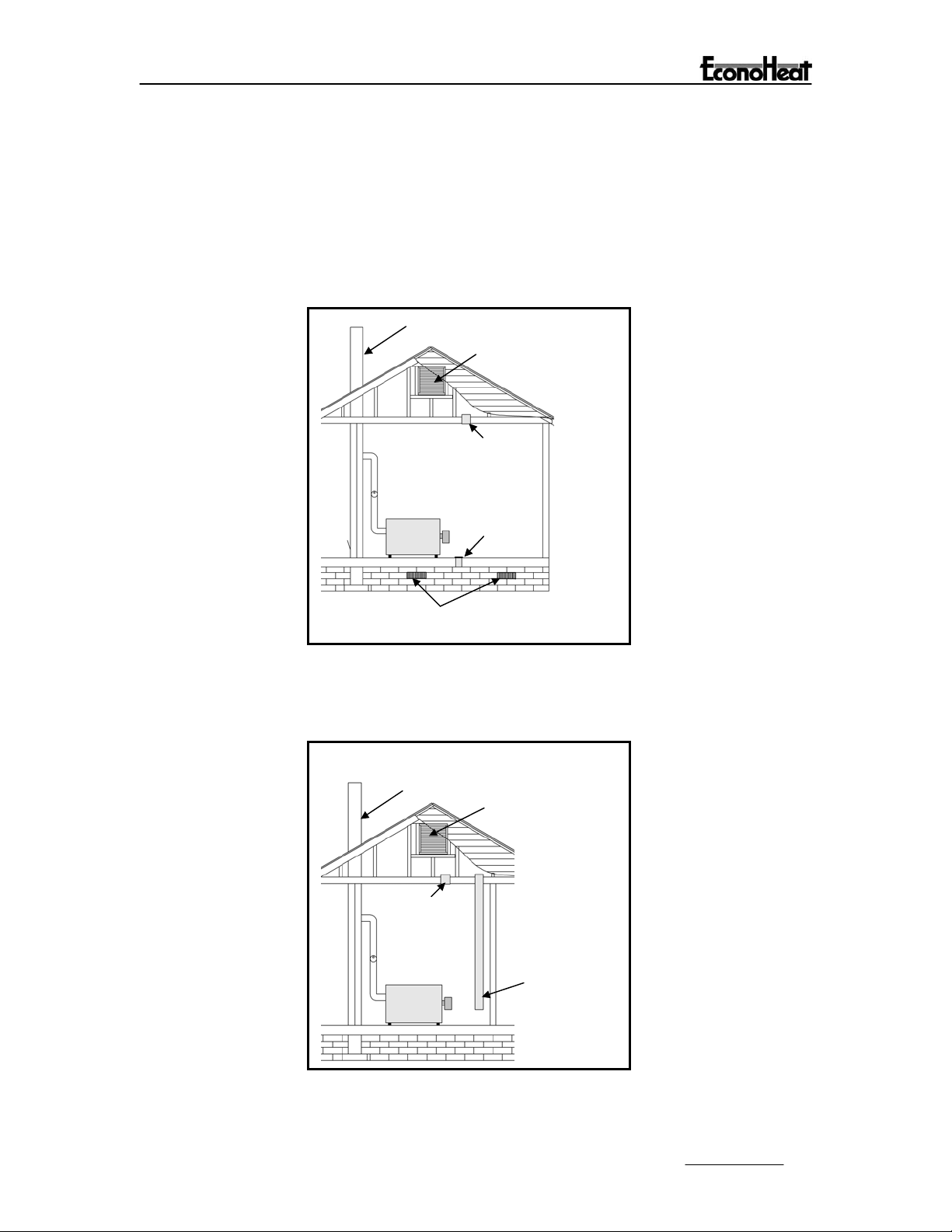

(b) All Air From Outdoors:

A

The confined space shall be provided with two permanent openings,

one within 12 inches of the top and another within 12 inches of the

bottom of the enclosure. The openings shall communicate directly, or

by ducts, with the outdoors or crawl or attic spaces which

communicate freely with the outdoors.

Direct To Outdoors, See Figure 8.

Chimney

Ventallation Louvers

(each end of attic)

lternative

Ventallation Louvers for Unheated Crawl Space

Figure 8.

With Vertical Ducts See Figure 9.

Chimney

Outlet Air

Outlet Air

Inlet Air

Ventallation Louvers

(each end of attic)

Note: The inlet

and outlet shall

each have a free

area of not less

than one square

inch per 4,000

Btu per hour of

the total input

rating of all

equipment in the

enclosure.

Note: The inlet

and outlet air

openings shall

each have a

free area of

not less than

one square

inch per 4,000

Btu per hour of

total input

rating of all

equipment in

the enclosure.

Inlet Air Duct

(ends 1 ft. above floor)

Figure 9.

Installation, Operation, And Service Instructions 15

Loading...

Loading...