OmniTurn GT-75 Service Manual

Safety Warnings

Read and heed all “DANGER “ and “CAUTION” labels on the machine.

MOVING PARTS CAN CAUSE INJURIES! Keep hands and clothing

clear of spindle and tooling plate at all times.

DO NOT OPERATE WITH DOOR or SPLASH SHIELD OPEN!

DO NOT OPEN DOOR DURING OPERATION!

DO NOT operate machine without guards, doors and covers in place.

DO NOT operated while under the influence of alcohol or drugs,

including prescription drugs.

DO NOT wear loose clothing while operating machine.

DO NOT wear jewelry (necklaces, bracelets, watches, rings) while

operating machine.

!

Keep long hair tied up and out of the way.

Wear eye and face protection.

Report any malfunction to your supervisor.

1.1

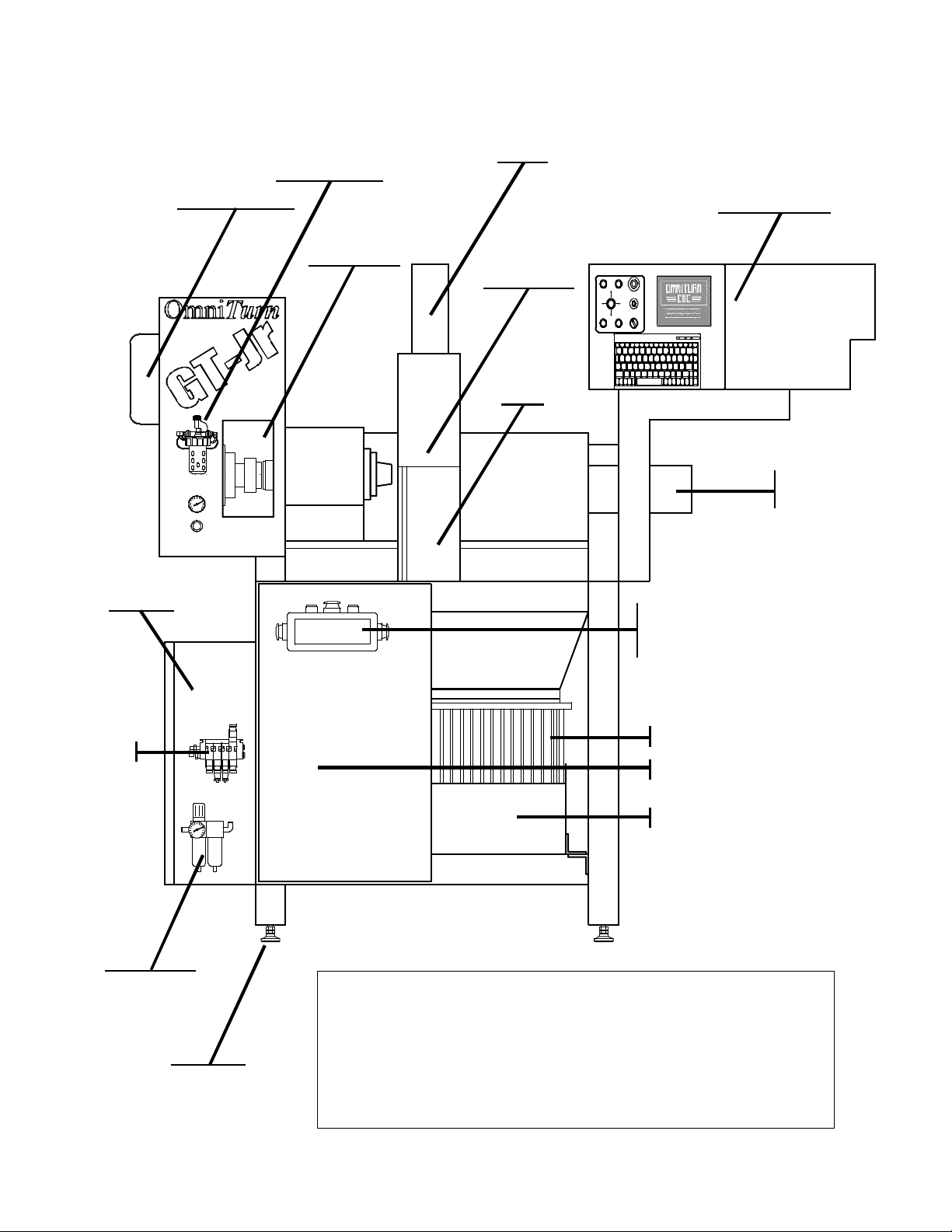

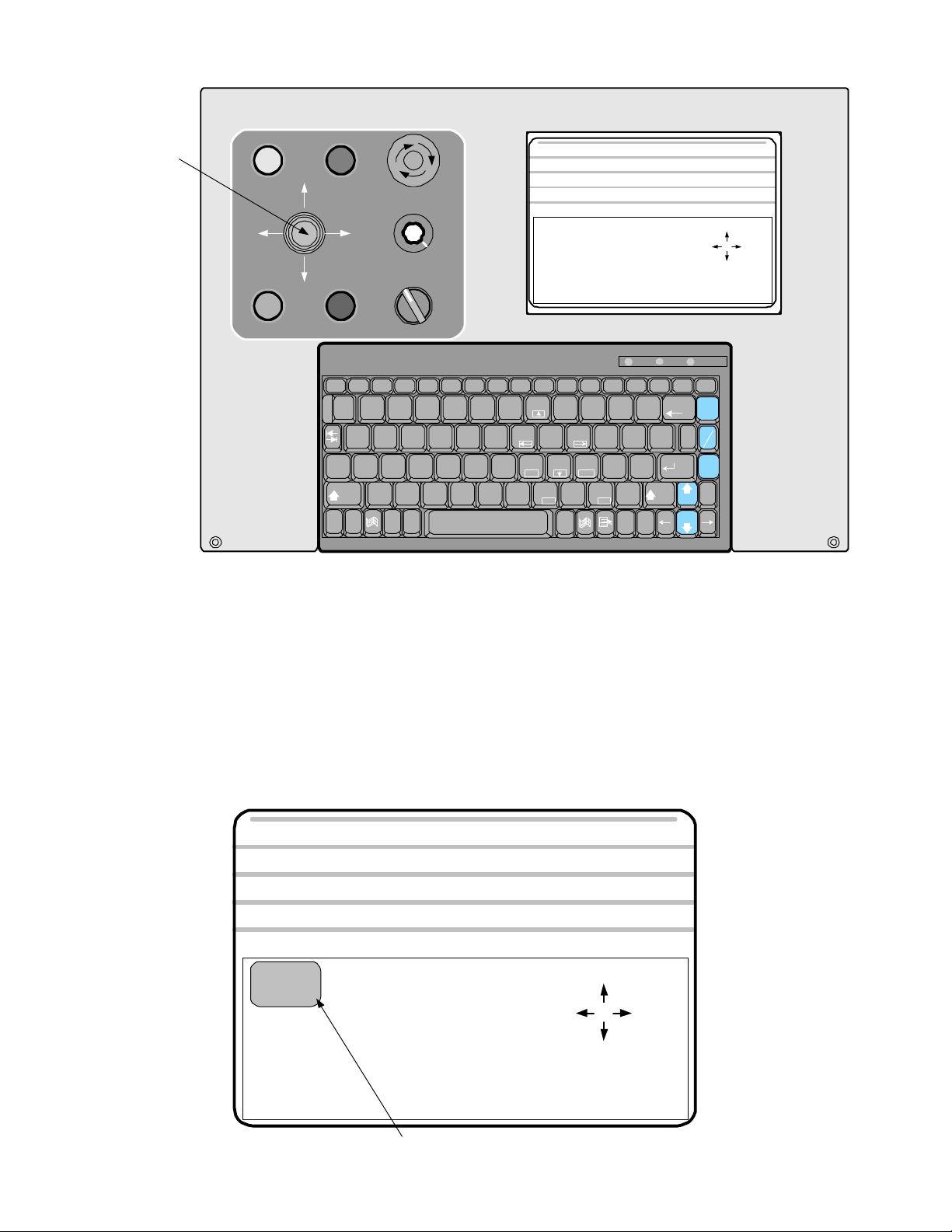

OmniTurn GT-75 Major Components

CNC Control

Spindle Motor

Collet Actuator

Air Lube for Actuator

(hidden)

Palm Box

(Two-hand Cycle-Start &

Manual Collet open/close)

Tooling

Plate

X-Axis

Motor

Sliding Door

(Interlocked)

Collet Closer Air

Pressure

Air Pack

Main Air

Regulator/

Filter

Spindle Drive

Cabinet

Leveling

Mounts

Chip Pan

Coolant Pump

Coolant Tank

(Door removed for clarity)

Door Interlocks

Opening the sliding door will put machine into E-Stop, same as Palm Box E-Stop.

If this door is opened before pressing Cycle Start, program will not start: Main

OmniTurn Menu will appear. Secure door, select Automatic Mode then press

Cycle Start.

If door is opened while program is running, all motion will stop and Main

OmniTurn Menu will appear. Secure door, select Jog Mode then send slide Home

(H,Z,X) before re-starting program.

If door is opened during threading cycle, all motion will stop as above, but

CNC Control must be shut off, then on to re-boot.

1.2

OmniTurn GT-Jr Major Components

Collet Closer

Air Pressure

& Air Lube

for Actuator

X-Axis

Motor

Spindle Motor

Spindle Drive

Cabinet

Hatch

(Interlocked)

CNC Control

Splash

Guard

(Interlocked)

Tooling

Plate

Z-Axis

Motor

Palm Box

(Two-hand Cycle-Start &

Manual Collet open/close)

Air Pack

Main Air

Regulator/

Filter

Leveling

Mounts

Chip Pan

Coolant Pump (hidden)

Coolant Tank

(Door removed for clarity)

Door Interlocks

Lifting the splash guard or opening the hatch will put GT-Jr into E-Stop, same as

Palm Box E-Stop. If these are opened before pressing Cycle Start, program will

not start: Main OmniTurn Menu will appear. Secure hatch or splash guard, select

Automatic Mode then press Cycle Start.

If guard or hatch is opened while program is running, all motion will stop and

Main OmniTurn Menu will appear. Secure guard or hatch, select Jog Mode then

send slide Home (H,Z,X) before re-starting program.

If guard or hatch is opened during threading cycle, all motion will stop as

above, but CNC Control must be shut off, then on to re-boot.

1.3

OmniTurn

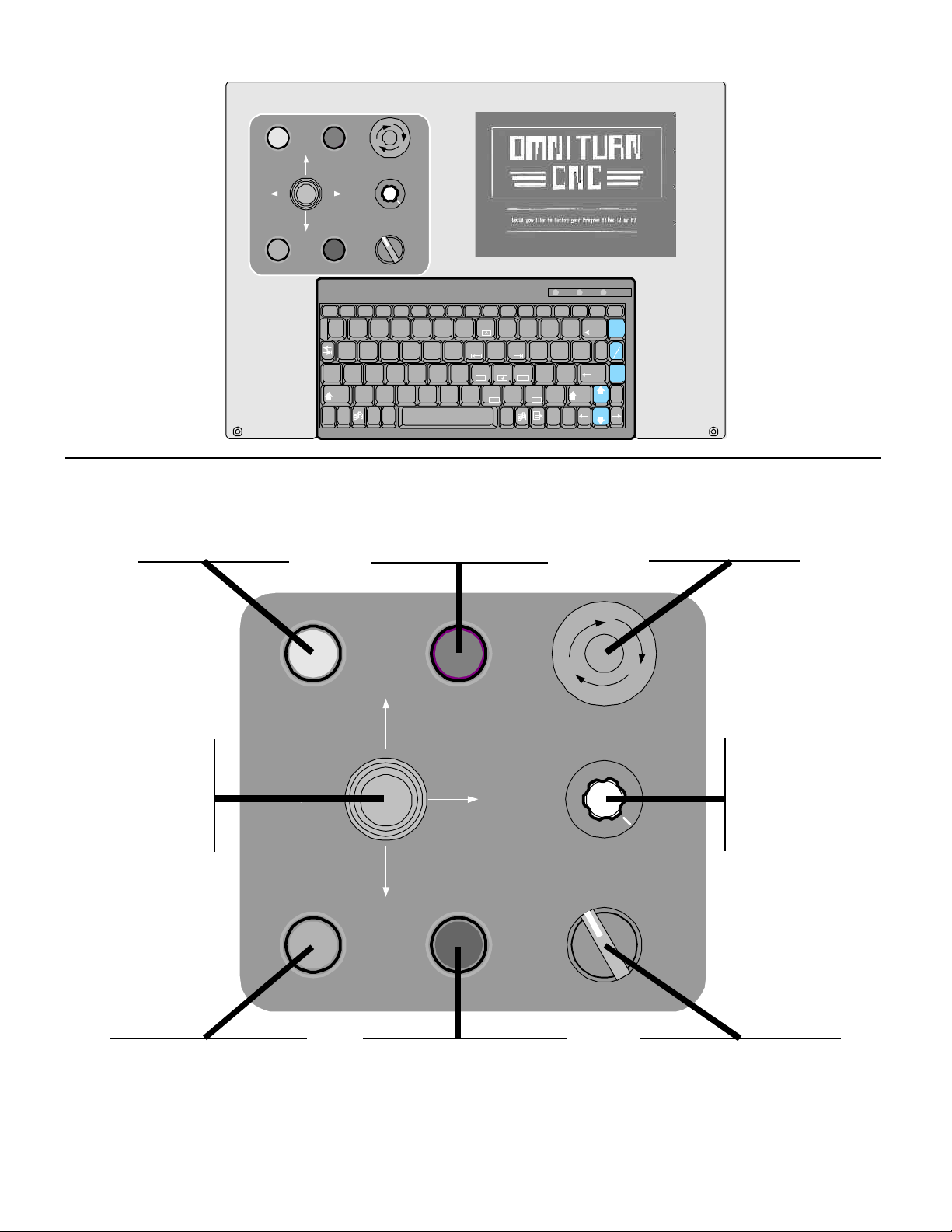

OmniTurn Front Panel: Knobs & Switches

CONTROL

ON

JOG JOG

CYCLE

START

Sets Control ON or OFF.

Illuminates with power ON.

Press ON/Press OFF

SERVOS

ON

Z +Z -

!1@2#

Q W

A

Z

Shift

EMERGENCY

SPINDLE

OVERRIDE

SPINDLE

3

Alt

STOP

1000

OFFAUTO

*8&7^6%5$

(9)

GFDS

Home PgUp

H

MNBVCX

KJ

Ins

4

~

`

X -

X +

MOTION

STOP

Esc F1 F10F9F8F7F6F5F4F3F2 F11 F12

Caps

Lock

Ctrl Fn

Sets Servos ON when

Control is ready. Illuminates when Servos are

ON. Momentary action

Caps

Num

Lock

Num

Lock

0

{

P

OIUYTRE

[

PgUpEnd

?/>

<

.

,

Del

Alt

Ins

Scroll

Lock

Lock

PrtSc

Scroll

Pause

SysRq

Lock

Break

Spindle

+=_

Backspace

100%

|

}

\

]

Coolant

"':;L

Parts

Enter

Catcher

End

Shift

Spindle

Spindle

Del

Halts all machine

movement and resets

all M-Functions.

Press ON/Twist OFF

Manually move the

slide when in Jog

Mode. Continuous

or incremental

according to key-

board selection.

Starts program in Auto

Mode. Executes command

in MDI Mode. Illuminates

while program is running.

CONTROL

ON

JOG JOG

CYCLE

START

SERVOS

ON

X -

Z +Z -

X +

MOTION

STOP

Stops slide movement during

program. Illuminates when

active. Press Cycle Start to

continue or Esc Key to stop

program.

EMERGENCY

STOP

SPINDLE

OVERRIDE

SPINDLE

Adjusts speed of

spindle. (Not

effective for C-Axis

machines). Spindle

1000

OFFAUTO

will not run when

this is full CCW.

Manually set spindle OFF

and ON as required during

setup. Lever action.

1.4

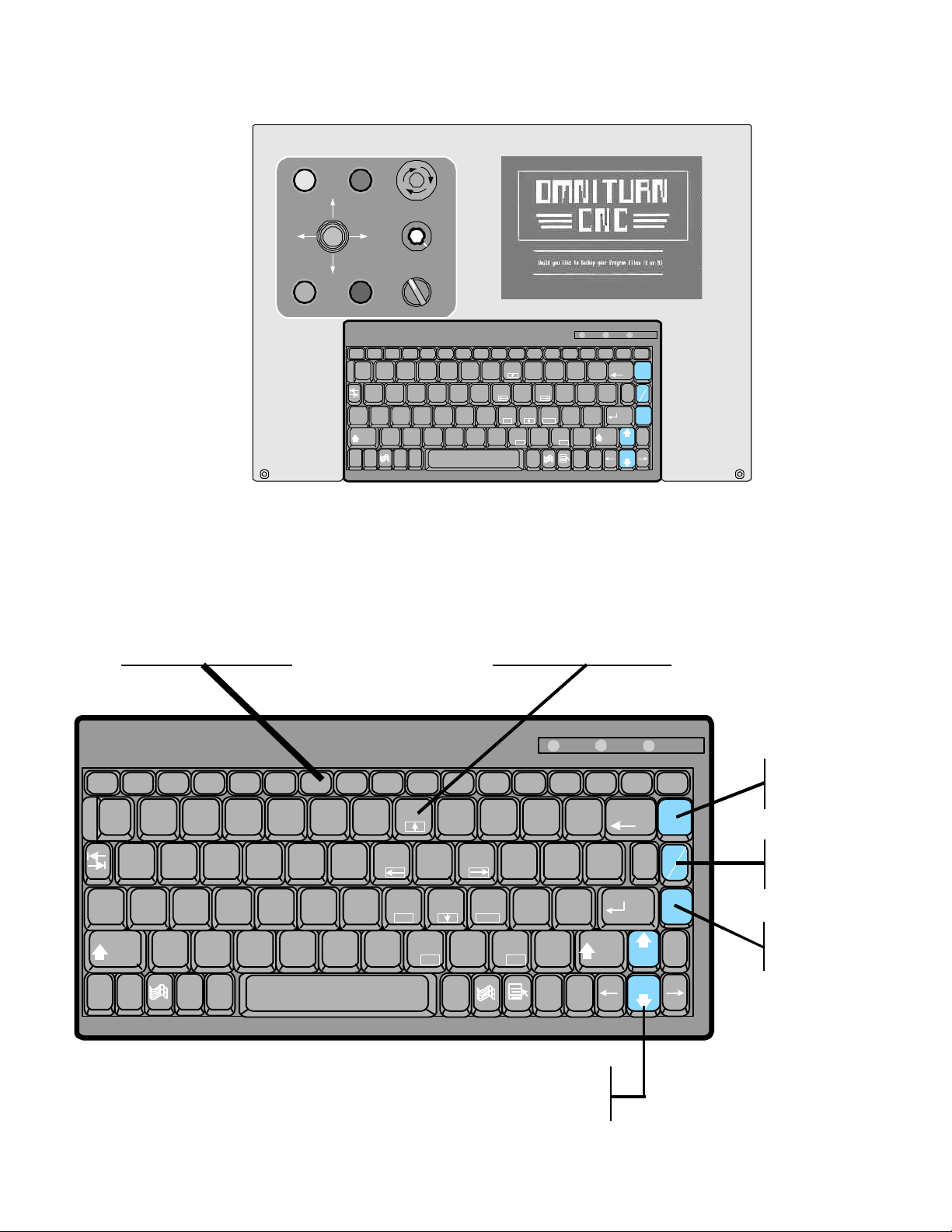

OmniTurn

OmniTurn Front Panel: Keyboard

Function Keys set Feed

Rate Override while

running program.

Special functions are

described on page 5.3.

CONTROL

ON

JOG JOG

CYCLE

START

SERVOS

ON

Z +Z -

STOP

!1@2#

Q W

A

Shift

Z

EMERGENCY

STOP

SPINDLE

OVERRIDE

SPINDLE

3

Alt

1000

OFFAUTO

*8&7^6%5$

GFDS

Home PgUp

H

MNBVCX

KJ

Ins

4

~

`

X -

X +

MOTION

Esc F1 F10F9F8F7F6F5F4F3F2 F11 F12

Caps

Lock

Ctrl Fn

Number Keys set Jog

speed and Jog increment in Jog Mode.

Functions are described

starting on page 1.9.

(9)

OIUYTRE

<

,

Alt

Caps

Num

Lock

Num

Lock

0

{

P

[

PgUpEnd

?/>

.

Del

Ins

Scroll

Lock

Lock

PrtSc

Scroll

Pause

SysRq

Lock

Break

Spindle

+=_

Backspace

100%

|

}

\

]

Coolant

"':;L

Parts

Enter

Catcher

End

Shift

Spindle

Spindle

Del

Esc F1 F10F9F8F7F6F5F4F3F2 F11 F12

Caps

Lock

Ctrl

!

1@2

Q W

A

Shift

Fn

#

$

3

4

^

%

6

5

GFDS

Z

~

Alt

`

*

&

Home PgUp

8

7

H

KJ

End

MNBVCX

Ins

(

9

)

0

P

OIUYTRE

:

L

PgUp

<

,

;

>

.

Del

Alt

Increase or Decrease spindle

speed. Effective for C-Axis

and standard spindles.

1.5

Num

Lock

Num

Lock

_

{

[

?

/

Ins

Caps

Scroll

Lock

PrtSc

SysRq

+

Backspace

=

}

]

"

'

Scroll

Lock

Enter

|

\

Lock

Pause

Break

Spindle

100%

Coolant

Parts

Catcher

Set spindle

speed to 100%.

(PgUp)

Set coolant

ON/OFF

(PgDn)

Set M25/M26

Del

Shift

Spindle

Spindle

End

or Parts

Catcher out/in

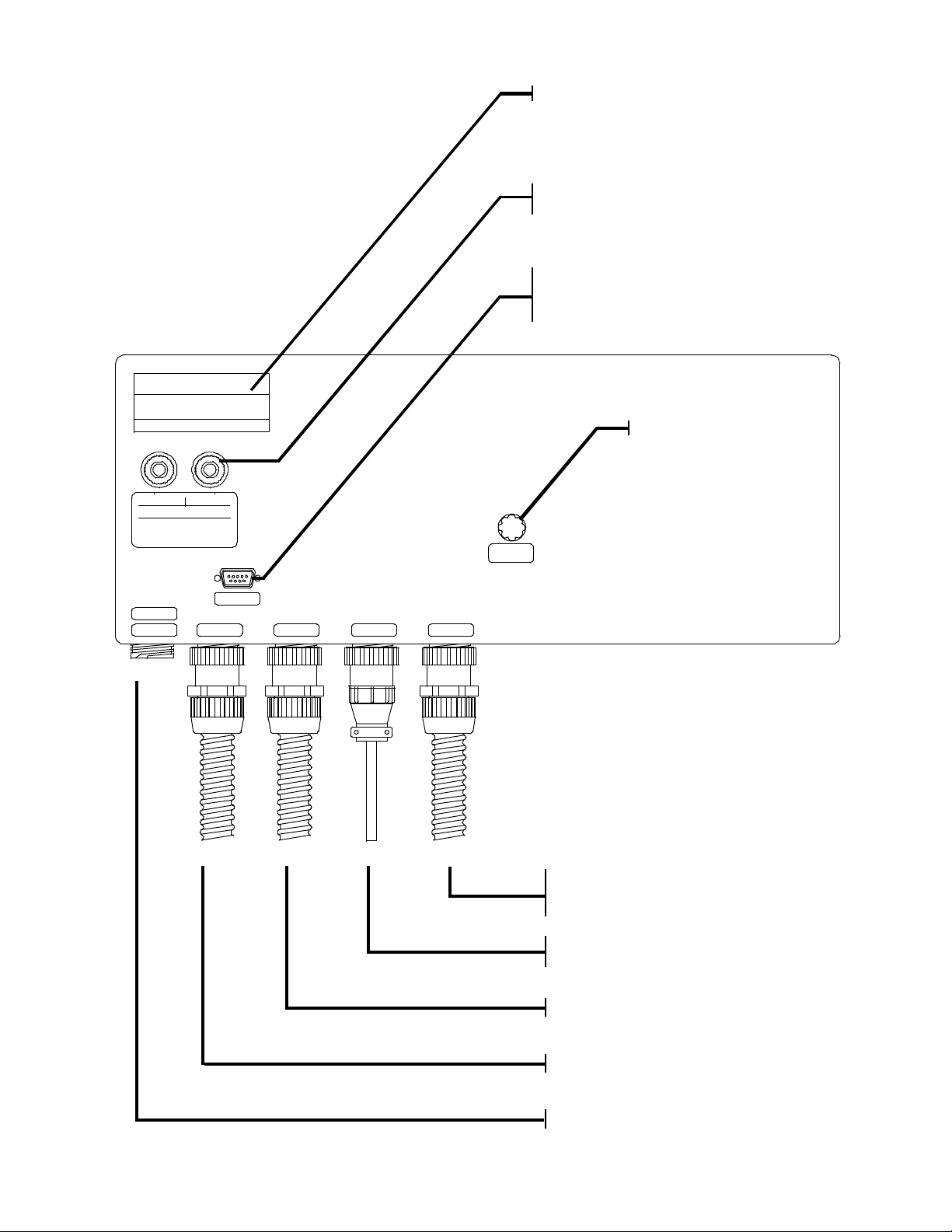

OmniTurn Rear Panel

Serial Number Label

Servo overloads.

Press to reset.

RS-232 Port

For transfering files. Also

used with C-Axis option.

OMNITURN

X Axis Z Axis

Servo Error due to Overload

If the breaker has not tripped,

the servo-amp may have.

To reset amp,wait one minute

with servos off, then set servos on.

PLC

C AXIS

CNC Attachments

X AXIS

RS 232

CNC Control Main Fuse

(10A)

F1

SPINDLEZ AXIS

Z AXISX AXIS

SPINDLE

MISC

MISC

Miscellaneous Cable:

Carries signals to and from Spindle

Cabinet.

Spindle Encoder:

Enables threading and IPR feeds.

Z-Axis Motor-Tach-Encoder

X-Axis Motor-Tach-Encoder

Optional C-Axis or PLC Connector

1.6

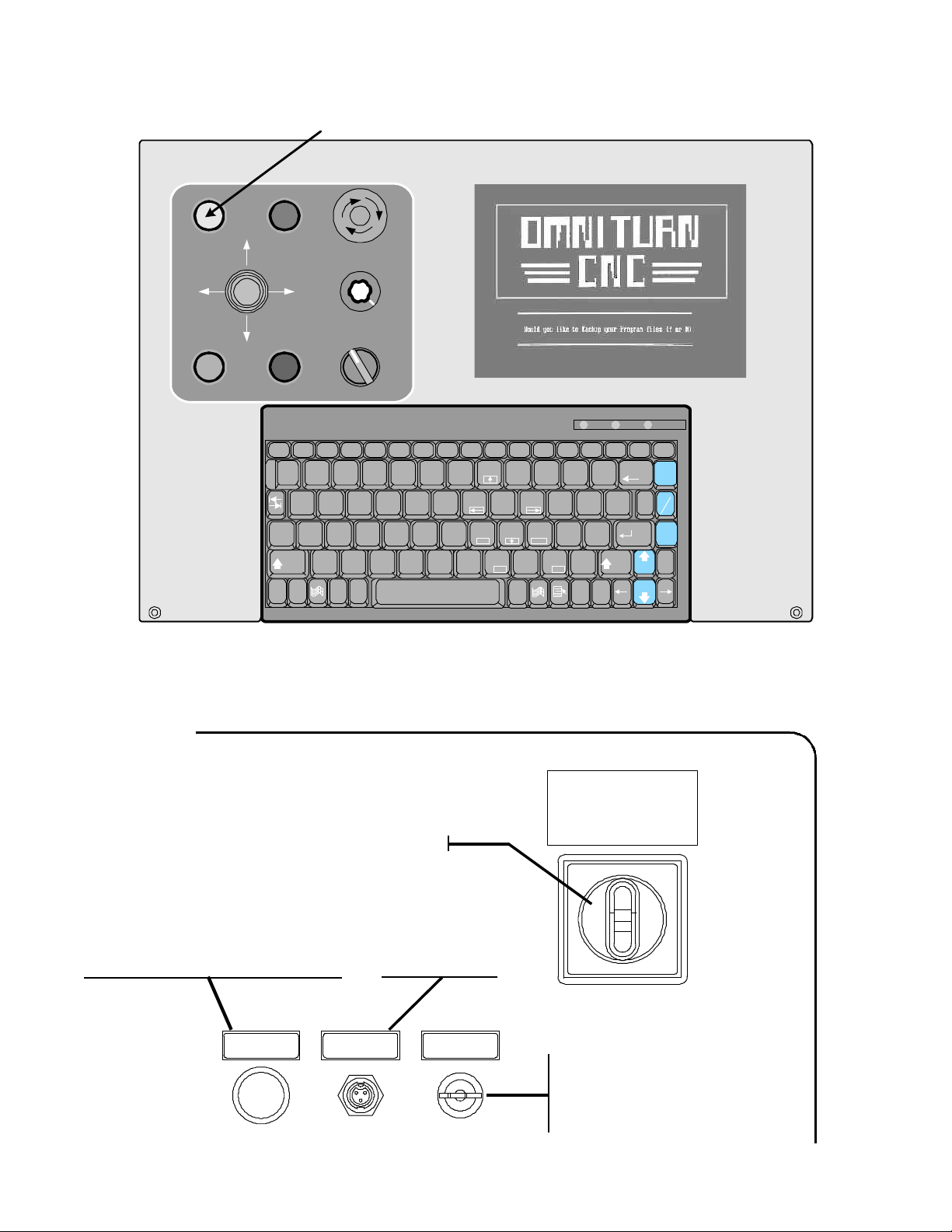

Start - Up: Apply Power

After the OmniTum has been installed and all of the cables are connected set 220vac disconnect ON.

The 220vac disconnect is located on the Spindle Drive Cabinet at left-hand side of the GT-75 or GT-Jr, as

illustrated below.

Turn CNC ON here AFTER setting 220vac disconnect ON

CONTROL

ON

JOG JOG

CYCLE

START

SERVOS

ON

X -

X +

MOTION

STOP

Esc F1 F10F9F8F7F6F5F4F3F2 F11 F12

!1@2#

Caps

Lock

Shift

Ctrl

Z +Z -

Q W

A

Fn

Z

EMERGENCY

STOP

SPINDLE

OVERRIDE

SPINDLE

3

Alt

1000

OFFAUTO

%

$

4

~

`

6

5

GFDS

*8&7^

Home PgUp

H

End

MNBVCX

Ins

(9)

KJ

Alt

Omni

0

P

OIUYTRE

L

PgUp

<

>

.

,

Del

Turn

Num

Caps

Scroll

Lock

Lock

Num

Lock

SysRq

+

_

=

{

[

"':

;

?

/

Del

Ins

PrtSc

}

]

Backspace

Shift

Scroll

Lock

Enter

Spindle

Spindle

Lock

Pause

Break

Spindle

100%

|

\

Coolant

Parts

Catcher

End

OmniTurn front panel Keyboard

After boot-up, the first screen you see will ask you to back-up your program files. Always select “Y” to

backup. Only those programs which have been edited will be copied to the floppy disk at rear of machine

Spindle Drive Cabinet

220 VOLTS

Main Power Disconnect

ON

I

Spindle Fault Switch

This Push-Button will light with spindle

drive fault, if interlock is opened, or if

machine is in Palm-Box E-Stop. Reset

is effective only with fault.

SPINDLE FAULT

Press to Reset

TripleAir Barfeed

EoB Connector

Barfeed EoB

Connect TripleAir

barfeed EofB here

Puts OmniTurn in

Palm-Box E-Stop.

Interlock

Override Switch

OFF

O

Interlock Bypass Key-Switch

To Jog, or operate the machine with

splash-guard or hatch open, this

switch must have key turned CW. Key

should be under supervisor’s control

1.7

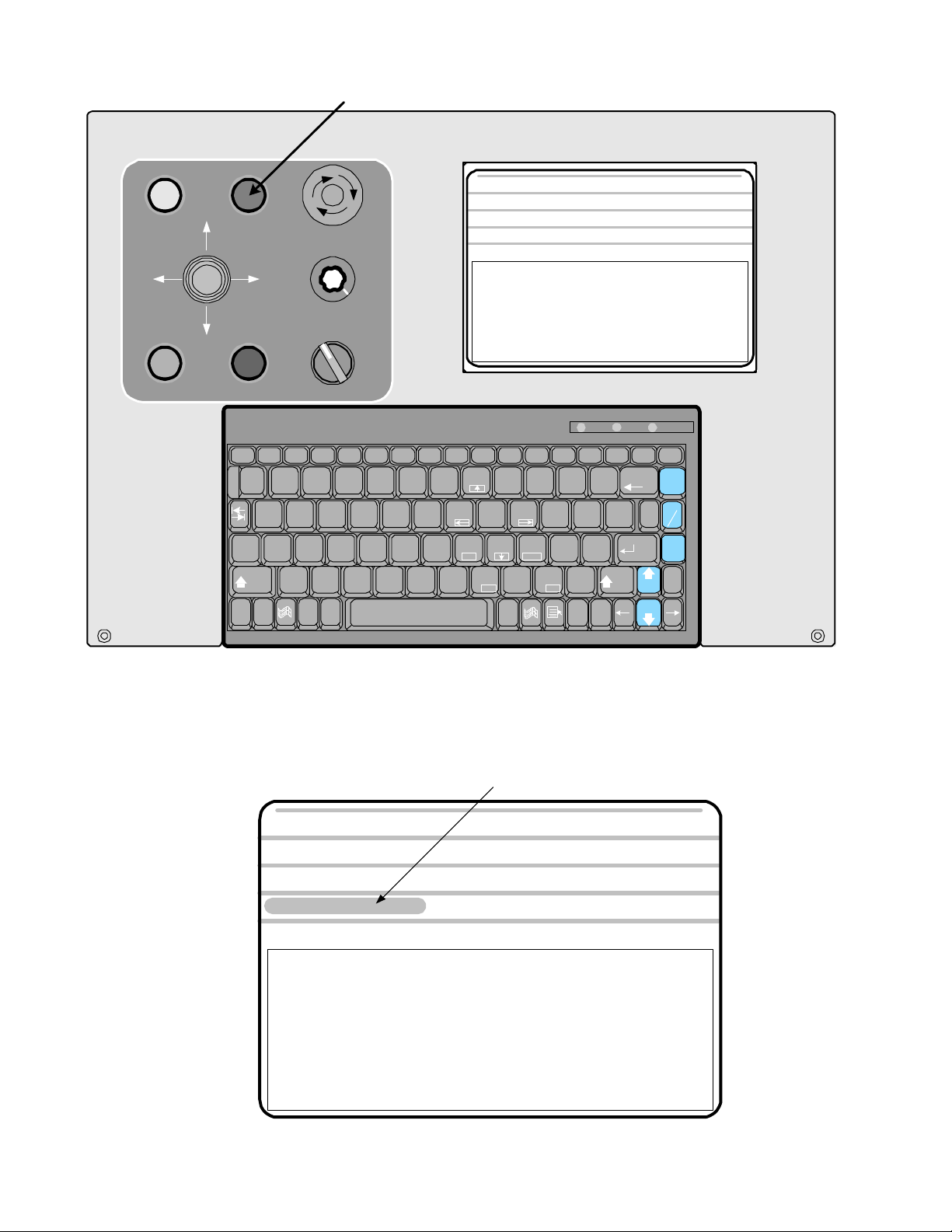

Start - Up: Turn on Servos

After the programs have been backed up you will be prompted to turn the servos on.

Turn servos ON with Blue button

CONTROL

ON

JOG JOG

CYCLE

START

POSITION

COMMAND

SERVOS

ON

X -

Z +Z -

X +

MOTION

STOP

Esc F1 F10F9F8F7F6F5F4F3F2 F11 F12

!1@2#

Q W

Caps

Lock

Shift

Ctrl

Fn

EMERGENCY

STOP

1000

SPINDLE

OVERRIDE

OFFAUTO

SPINDLE

^

%

$

3

4

A

Z

~

Alt

`

6

5

GFDS

PLEASE TURN SERVOS ON

Jog Automatic Single Block

Jog mode allows manual motion, tool offsets, and zero

Single Block and Automatic allow execution of stored programs,

and also give access to tool offsets and the Editor

Manual Data Input allows immediate execution of program

statements, as well as tool offset and editing functions

*

&

Home PgUp

7

H

(

8

9)0

KJ

End

MNBVCX

Alt

Omni

: X +0.00000 Z +0.00000 FEED 10.0 IPM

P

OIUYTRE

L

PgUp

<

>

,

.

DelIns

_

{

[

:

;

?

/

Ins

Turn

Caps

Num

Lock

Lock

Num

PrtSc

Lock

SysRq

+

Backspace

=

}

]

"

'

Shift

Del

Scroll

Lock

Enter

Spindle

Spindle

Scroll

Lock

|

\

PERCENT FEED: 100

Manual Data Input

Pause

Break

Spindle

100%

Coolant

Parts

Catcher

End

OmniTurn front panel Keyboard

Press the blue “Servos On” pushbutton. It should illuminate and you should hear a slight hum as the axes

motors engage. This part of the screen is the prompt area, and different information will be presented here

according to the current mode or page.

The prompt area requests "Servos on."

POSITION

COMMAND

PLEASE TURN SERVOS ON

Jog Automatic Single Block

Jog mode allows manual motion, tool offsets, and zero

Single Block and Automatic allow execution of stored programs,

and also give access to tool offsets and the Editor

Manual Data Input allows immediate execution of program

statements, as well as tool offset and editing functions

: X +0.00000 Z +0.00000 FEED 10.0 IPM

PERCENT FEED: 100

Manual Data Input

1.8

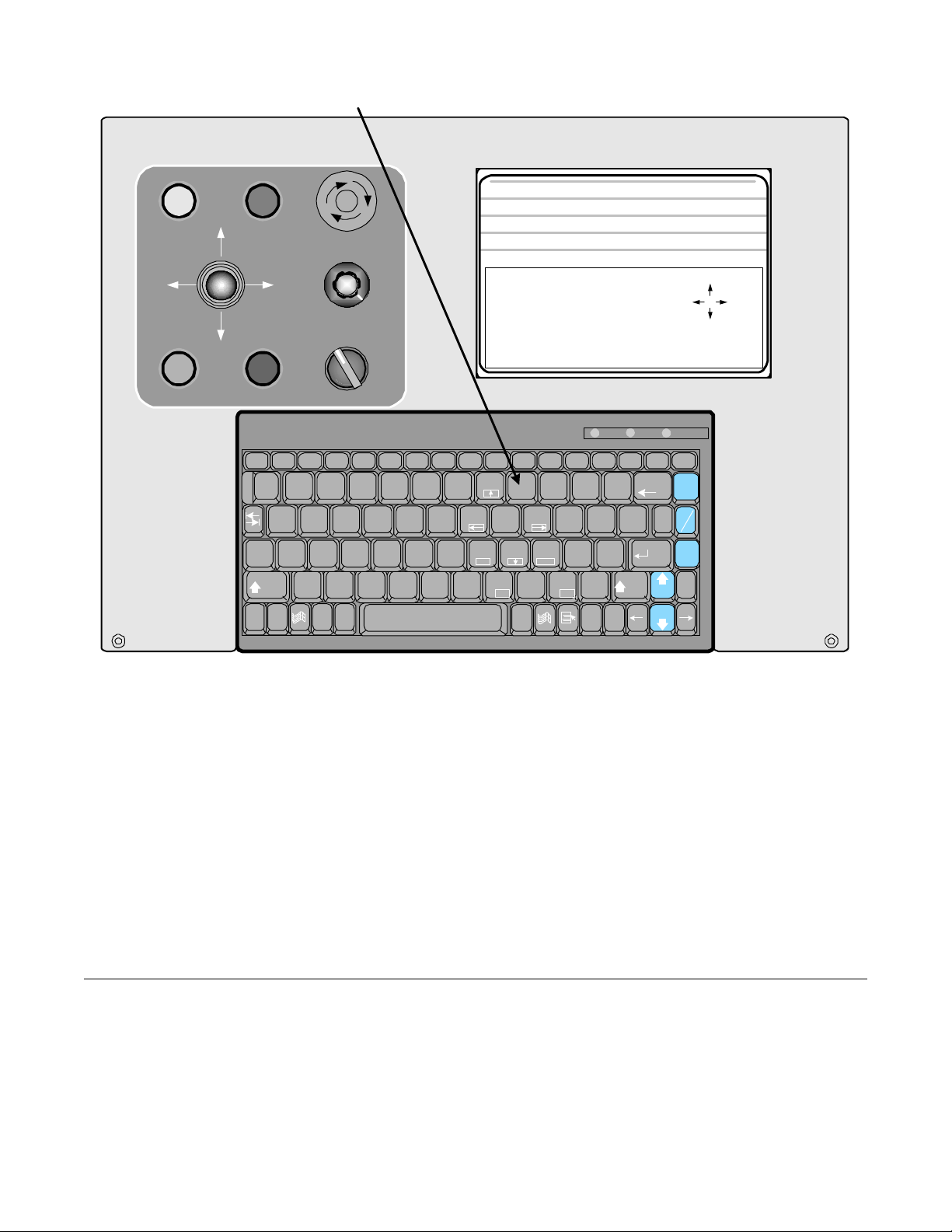

Start - Up: Establish Home

Press "9" key to establish Home

CONTROL

ON

JOG JOG

CYCLE

START

POSITION

COMMAND

SERVOS

ON

X -

Z +Z -

X +

MOTION

STOP

Esc F1 F10F9F8F7F6F5F4F3F2 F11 F12

!1@2#

Q W

Caps

Lock

Shift

Ctrl

Fn

EMERGENCY

STOP

1000

SPINDLE

OVERRIDE

OFFAUTO

SPINDLE

^

%

$

3

4

A

Z

~

Alt

`

6

5

GFDS

HOME MUST BE ESTABLISHED

Jog Automatic Single Block

1. Slow

2. Medium

3. Fast

4. .00005

5. .0010

6. .0100

PRESS 'ESC TO RETURN TO MENU

*

&

Home PgUp

8

7

End

KJ

MNBVCX

H

(

9

Alt

Omni

: X +0.12635 Z -0.10475

:

7. .1000

8. 1.0000

9. Est Home

S. Set Zero

H. Go Home

T. Set Tool

)

_

0

-

P

OIUYTRE

L

PgUp

<

,

{[

:

;

?

>

/

.

DelIns

Ins

Turn

Caps

Num

Lock

Lock

Num

PrtSc

Lock

SysRq

+

Backspace

=

}]

"

'

Shift

Del

Scroll

Lock

Ente

r

Spindle

Spindle

Scroll

Lock

|

\

FEED 10.0 IPM

PERCENT FEED: 100

Manual Data Input

- X

- Z

+X

Pause

Break

Spindle

100%

Coolant

Parts

Catcher

End

+Z

OmniTurn front panel Keyboard

Establish “Home”

After the servos are turned on, the control automatically goes to the JOG mode. This is done so that

machine “HOME” can be established. The control will not allow you to leave the JOG mode until the

homing procedure has been completed.

Press “2” (Medium Jog) or “3” (Fast Jog) on the Keyboard, and use the Jog Stick to move slide to within

0.200” from Zero in X and Z as illustrated on the next page. Press “9” on the Keyboard, then press Cycle

Start to start the homing procedure. The slide will move slowly in +Z, then in -X, seeking the home marks

on the motor encoders. When homing is complete, X & Z position indicators will read 0.00000.

The following three pages describe the homing procedure in detail.

Power Down Procedure

It is a good practice, but not necessary, to press the E-Stop before turning the control off. To turn the

control off, press the amber Control ON button. Then set the spindle drive disconnect to OFF.

1.9

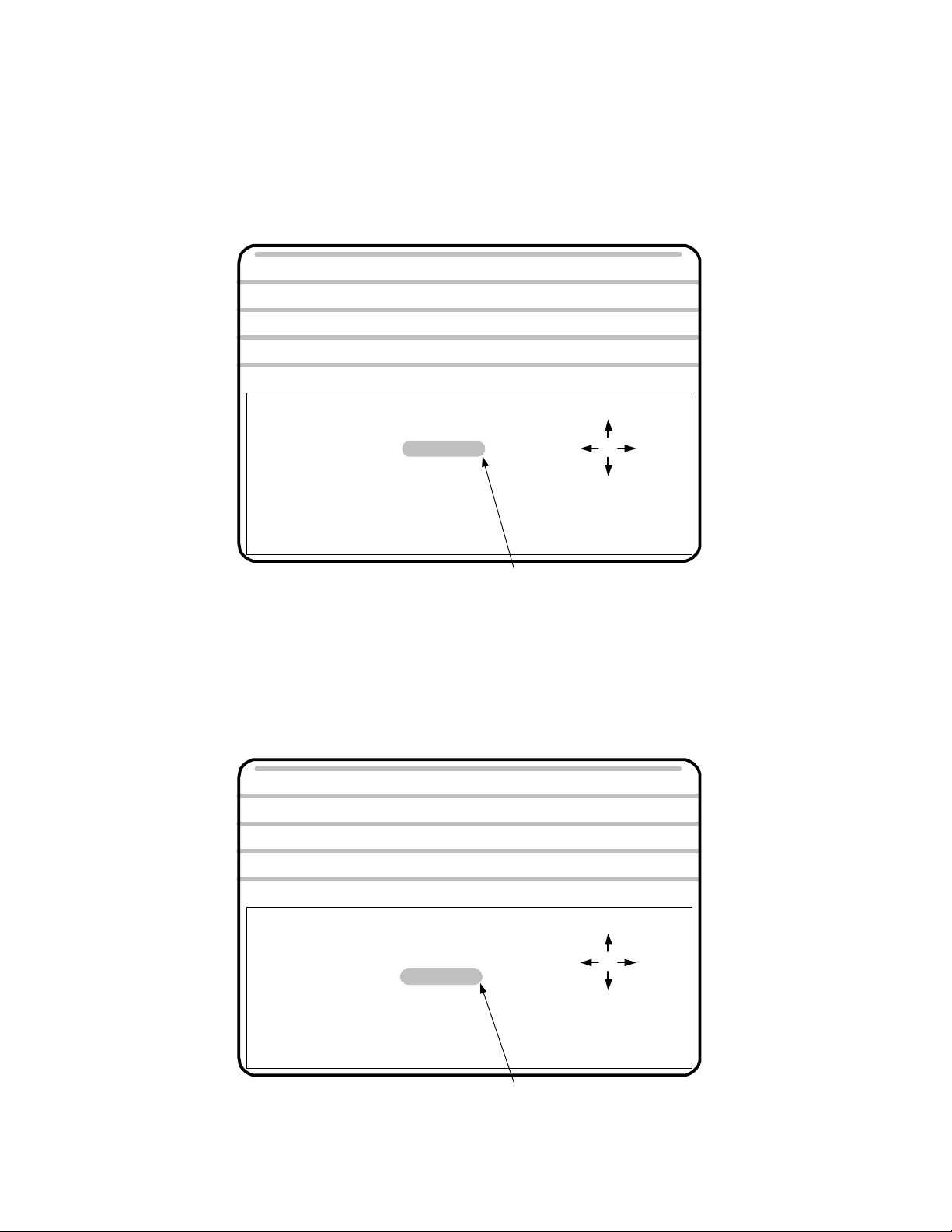

Establish Home: Detail

Press “2” (Medium Jog) or “3” (Fast Jog) on the Keyboard, and use the Jog Stick to move

slide to within 0.200” from Zero in X and Z as illustrated below. The X axis should be on

the plus side of zero, and the Z axis should be on the minus side.

If you are too far away from zero you will be off by .200” when the Ref Zero is found

because the axis has a “home” every revolution.

Too far away to start Ref Zero

0

0

1 2 3 4 5 6 7 8 9

Within .2" of 0; this is close

enough to begin Ref Zero

0

10

When the slide has been jogged to within 0.200” of zero for both axes, press the ”9” key

on the keyboard, then press Cycle Start pushbutton to complete the homing sequence.

The control will first move the Z and then X axis.

After the procedure, check that the location for zero is where you want it. If you have

missed the zero, press the “2” key (Med Jog) then jog the slide to the correct location, then

press “9” then Cycle Start again.

Verify that the position display at the top of the screen now reads zero for both axes.

1 0

See following page for the screens which display the process.

1.10

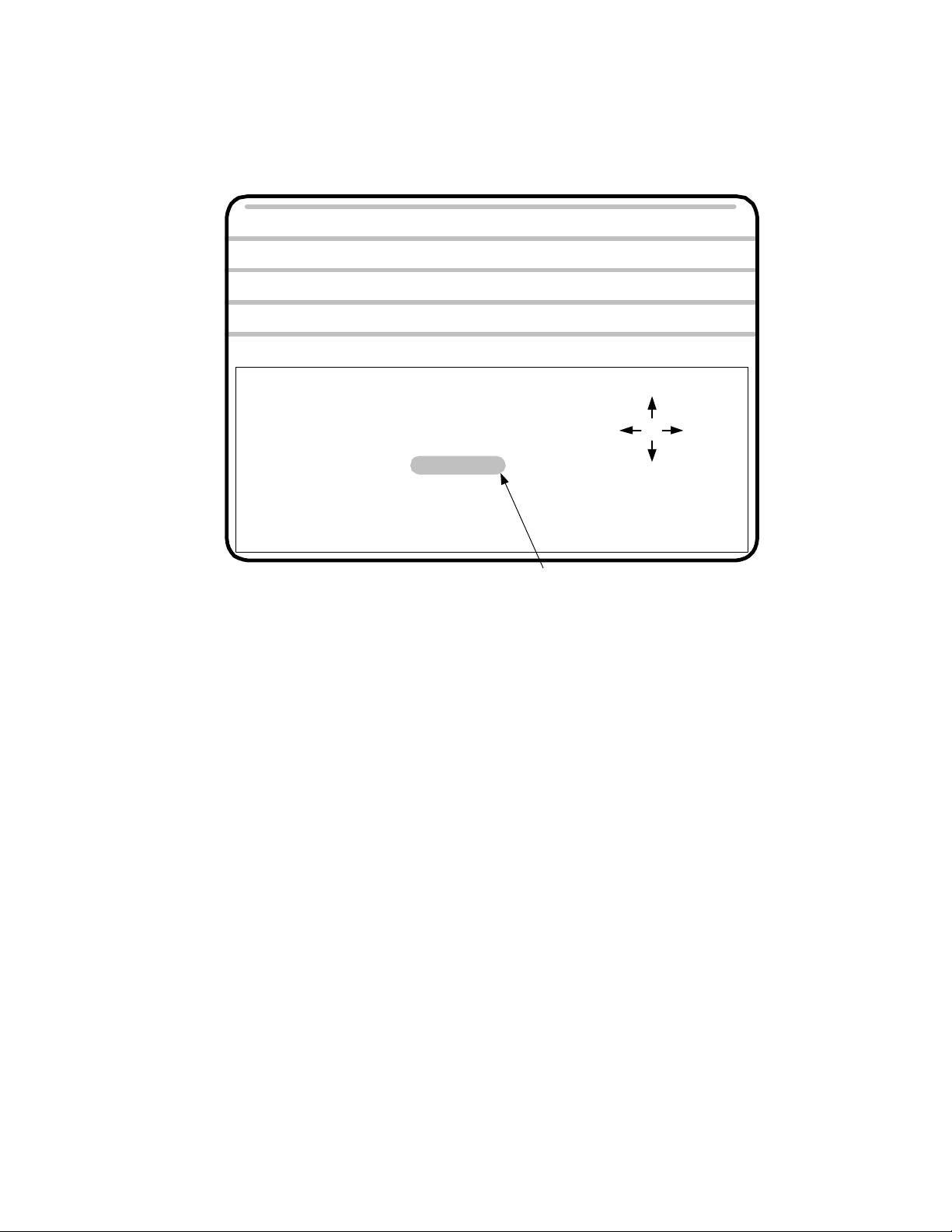

Establish Home: Screens

POSITION

COMMAND : X-40

MAKE JOG SELECTION

Jog Automatic Single Block

1. Slow

2. Medium

3. Fast

4. .00005

5. .0010

6. .0100

PRESS 'ESC TO RETURN TO MENU

: X +0.15095 Z -0.15860 FEED 10.0 IPM

7. .1000

8. 1.0000

9. Est Home

S. Set Zero

H. Go Home

T. Set Tool

PERCENT FEED: 100

Manual Data Input

- X

- Z

Press 9 when BOTH axes are

within 0.200" of Home.

+Z

+X

POSITION

COMMAND : X-40

PRESS CYCLE START TO ESTABLISH HOME

Jog Automatic Single Block

1. Slow

2. Medium

3. Fast

4. .00005

5. .0010

6. .0100

PRESS 'ESC TO RETURN TO MENU

: X +0.00000 Z +0.00000 FEED 10.0 IPM

PERCENT FEED: 100

Manual Data Input

7. .1000

8. 1.0000

9. Est Home

S. Set Zero

H. Go Home

T. Set Tool

After selecting "Jog 9" (Est Home),

press Cycle Start to complete the

homing sequence.

- Z

- X

+Z

+X

After Home has been established, you can leave the Jog Mode by pressing ”Esc”key

on the keyboard to go to the Main Menu, or you can stay in the Jog Mode and establish the tool offsets. On the following pages the Jog Mode is discussed in detail.

1.11

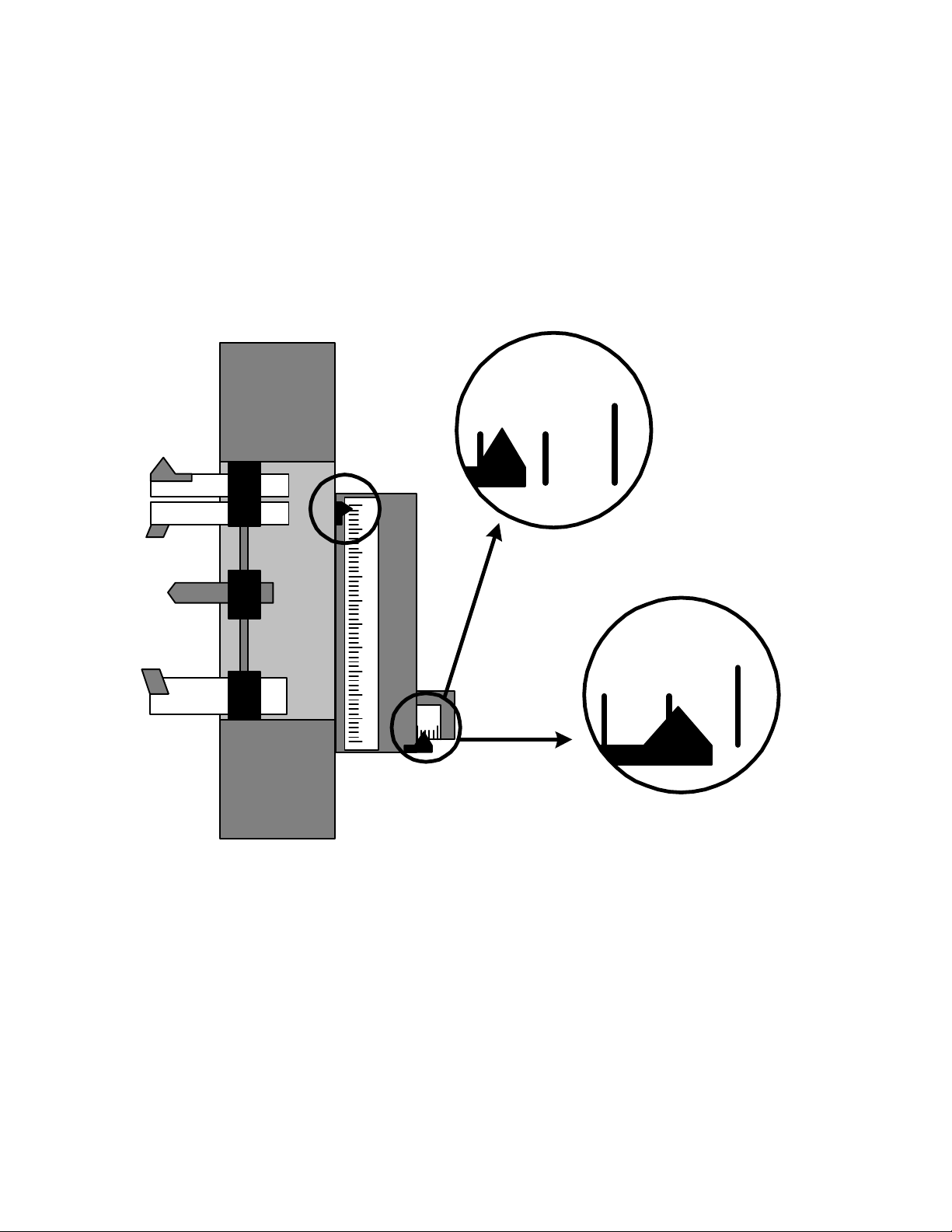

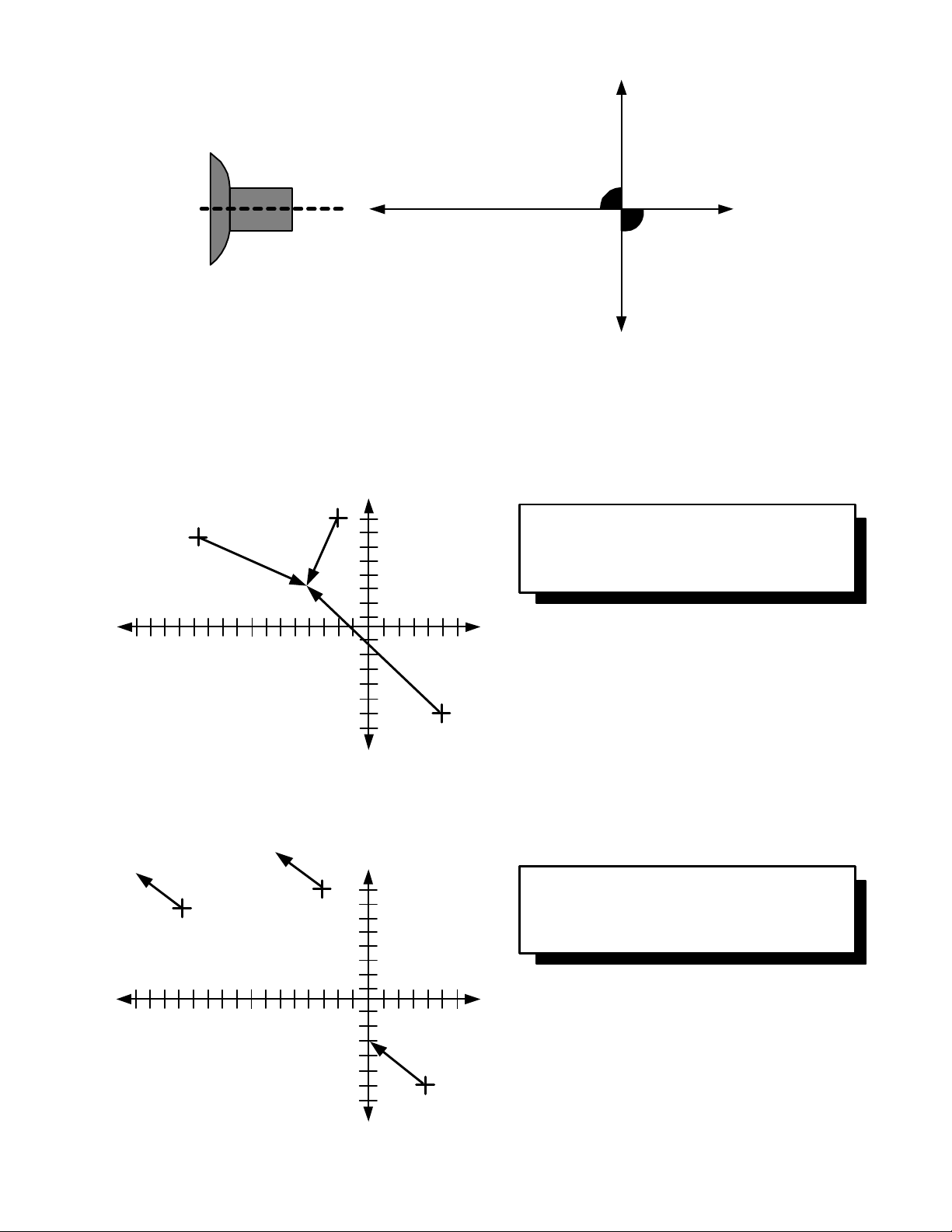

Establish Home: Explanation

On each axis is a scale that is marked with .2” graduations. These scales are used to establish HOME.

Home is a reference point that can be easily found and repeated. The .2” scales are just an aid to find

this home point.

0

1 2 3 4 5 6 7 8 9

X axis Ref Zero Marker

123 0

10

Z axis Ref Zero Marker

1 marker pulse

1,000 encoder lines

How HOME is established

The HOME location will repeat itself from start-up to start-up within .00005”. So when you start up the

machine from one day to the next it will repeat itself very closely. The point is established by the following:

On the end of the servo motor that drives the axis is an encoder that tells the control how far the slide

has traveled. This encoder follows the slide travel incrementally. The encoder does not know exactly

where the slide is, only how far it has traveled. The encoder works by counting fine lines printed on a disk.

The drawing above is a sketch of this type of rotary encoder. The inside ring of lines is counted to maintain

location. The outside line is used to find a definite location. The encoder will ”see” this line once every

revolution of the ball screw used to position the slide. The ball screw used on the OmniTurn moves the slide

.2” / revolution. So if we position the slide within .2” of what we want to call HOME and then tell the

control to slowly rotate the screw while looking for the single pulse we can establish this as an easily repeatable location. This is how HOME is established.

1.12

Jog

The purpose of the jog mode is to:

• Establish your ”HOME” position. This is always done after starting up the control.

• Set tool offsets

• Move the slide manually

• Bore soft jaws or collets

To enter the jog mode:

If you are just powering up the control it will automatically take you to the jog screen after the servos are

turned on.

If you are at the main menu as shown below, type ”J” .

POSITION

COMMAND

SELECT OPERATION MODE

Jog Automatic Single Block

Jog mode allows manual motion, tool offsets, and zero

Single Block and Automatic allow execution of stored programs,

and also give access to tool offsets and the Editor

Manual Data Input allows immediate execution of program

statements, as well as tool offset and editing functions

: X +0.00000 Z +0.00000 FEED 10.0 IPM

PERCENT FEED: 100

Jog

Ref Zero

Tool Offsets established

Program run

Program Edit

Program Enter

Tool offsets adjustment

Secondary tool offsets

Disk operations

Calcaid programming system

Manual Data Input

Jogging with the Joy Stick

The method for moving the slide is to use the ”Joy stick” actuator on the operators panel. Deflecting this

actuator in the four directions available produces the following motions:

Up X axis minus (away from you on attachment; up on GT-75 & Jr)

Down X axis plus (toward you on attachment; down on GT-75 & Jr)

Left Z axis minus (toward spindle)

Right Z axis plus (away from spindle)

1.13

Jog

Joy stick for

jog operations

CONTROL

ON

JOG JOG

OmniTurn

POSITION

: X +0.00000 Z +0.00000 FEED 10.0 IPM

COMMAND

SERVOS

ON

X -

X +

EMERGENCY

STOP

Z +Z -

1000

SPINDLE

OVERRIDE

OFFAUTO

MAKE JOG SELECTION

Jog Automatic Single Block

1. Slow

2. Medium

3. Fast

4. .00005

5. .0010

6. .0100

PRESS 'ESC TO RETURN TO MENU

7. .1000

8. 1.0000

9. Est Home

S. Set Zero

H. Go Home

T. Set Tool

PERCENT FEED: 100

Manual Data Input

- X

- Z

+Z

+X

CYCLE

START

MOTION

STOP

Esc F1 F10F9F8F7F6F5F4F3F2 F11 F12

!1@2#

Q W

Caps

Lock

Shift

Ctrl

Fn

SPINDLE

*

6

GFDS

&7^

8

Home PgUp

H

End

MNBVCX

(9)

KJ

<

,

Alt

0

P

OIUYTRE

L

PgUp

DelIns

3

A

Z

Alt

5

4

~

`

%

$

Num

Caps

PrtSc

SysRq

}

]

Lock

Backspace

Shift

Scroll

Lock

Enter

Spindle

Spindle

Scroll

Lock

Pause

Break

Spindle

100%

|

\

Coolant

Parts

Catcher

End

Lock

Num

Lock

+=_

{

[

"':

;

?

/>.

Del

Ins

OmniTurn front panel Keyboard

The speed or increment of the jog mode can be selected. This is done by pressing a number between 1 -8

on the keyboard. The jog speed or increment selected zzzwill change shade. To select a new speed just

select a new number.

Continuous Jog Mode

Deflecting the joystick after selecting 1 -3 will move the slide at a continuous rate:

1. SLOW 1 inch per minute

2. MEDIUM 10 inches per minute

3. FAST 100 inches per minute

POSITION

COMMAND

: X +0.00000 Z +0.00000 FEED 10.0 IPM

PERCENT FEED: 100

MAKE JOG SELECTION

Jog Automatic Single Block Manual Data Input

1. Slow

2. Medium

3. Fast

4. .00005

5. .0010

6. .0100

7. .1000

8. 1.0000

9. Est Home

S. Set Zero

H. Go Home

T. Set Tool

- Z

- X

+Z

+X

PRESS 'ESC TO RETURN TO MENU

Continuous jog selections

1.14

Jog

Incremental Jog Mode

Deflecting the joystick after selecting 4 -8 will move the slide the indicated increment in the direction deflected. Each deflection produces one increment. Holding the joystick in the deflected position will not move

the slide more than one increment. The cycle start light flashes to indicate recognition and then execution of

the increment.

POSITION

COMMAND

MAKE JOG SELECTION

Jog Automatic Single Block

1. Slow

2. Medium

3. Fast

4. .00005

5. .0010

6. .0100

PRESS 'ESC TO RETURN TO MENU

: X +0.00000 Z +0.00000 FEED 10.0 IPM

7. .1000

8. 1.0000

9. Est Home

S. Set Zero

H. Go Home

T. Set Tool

Incremental jog selections

The #9 selection is covered in the Establish Home section

PERCENT FEED: 100

Manual Data Input

- X

- Z

+Z

+X

POSITION

COMMAND

MAKE JOG SELECTION

Jog Automatic Single Block

1. Slow

2. Medium

3. Fast

4. .00005

5. .0010

6. .0100

PRESS 'ESC TO RETURN TO MENU

: X +0.00000 Z +0.00000 FEED 10.0 IPM

7. .1000

8. 1.0000

9. Est Home

S. Set Zero

H. Go Home

T. Set Tool

1.15

PERCENT FEED: 100

Manual Data Input

- X

- Z

Begin finding "HOME"of slide

+Z

+X

Jog

To set a floating zero

Depressing ”S” will cause the present position of the axis to become the zero point. This setting of zero

does not effect the location of the Home. This is a local zero that is used in the manual mode if the

operator cares to use it. When this option is used, the control will prompt you to ”PRESS X TO ZERO

X, Z TO ZERO Z”. You can terminate this procedure at any time by pressing the ”ESC” key.

POSITION

COMMAND

PRESS X TO ZERO X, Z TO ZERO Z

Jog Automatic Single Block Manual Data Input

1. Slow

2. Medium

3. Fast

4. .00005

5. .0010

6. .0100

PRESS 'ESC TO RETURN TO MENU

: X +0.00000 Z +0.00000 FEED 10.0 IPM

PERCENT FEED: 100

7. .1000

8. 1.0000

9. Est Home

S. Set Zero

H. Go Home

T. Set Tool

Set current jposition to Zero

- Z

- X

+Z

+X

To send the slide HOME

Depressing ”H” will bring up the message ”PRESS X TO HOME X, Z TO HOME Z”. It is suggested to

depress Z first, as this will home Z axis and get the tools back out of the way. Then depress X and the slide

will home in the X axis. This function is used to check that the Home you have set is still where you think it

should be. Never use this function until you have first gone through the ”REFERENCE ZERO” procedure

after start-up.

POSITION

COMMAND

PRESS X TO HOME X, Z TO HOME Z

Jog Automatic Single Block Manual Data Input

1. Slow

2. Medium

3. Fast

4. .00005

5. .0010

6. .0100

PRESS 'ESC TO RETURN TO MENU

: X +0.00000 Z +0.00000 FEED 10.0 IPM

PERCENT FEED: 100

7. .1000

8. 1.0000

9. Est Home

S. Set Zero

H. Go Home

T. Set Tool

Send the slide HOME

- X

- Z

+X

1.16

+Z

Jog

To set Tool Offsets

The ”T” selection is used to begin the Tool Offset procedure.

This is covered in Section 3, ”TOOL OFFSETS”.

POSITION

COMMAND

OFFSET NUMBER:

Jog Automatic Single Block

1. Slow

2. Medium

3. Fast

4. .00005

5. .0010

6. .0100

0 IS NOT A VALID OFFSET NUMBER

PRESS 'ESC TO RETURN TO MENU

: X +0.00000 Z +0.00000 FEED 10.0 IPM

7. .1000

8. 1.0000

9. Est Home

S. Set Zero

H. Go Home

T. Set Tool

PERCENT FEED: 100

Manual Data Input

- X

- Z

+X

Begin the Tool Offset

entering procedure

+Z

1.17

Hard Disk Features

Backing Up Programs

OmniTurn CNC Controls are shipped with a solid-state hard drive (C:) for system and programs, and one

3.5 floppy drive, (A:) for part program backup.

The user is given an opportunity to backup his program files when machine is booted up. There is no

convenient, automatic way to backup before shutting down, so we back-up at turn-on instead.

The solid-state hard-drives are very reliable, and unlikely to ‘crash’ but like any piece of machinery, they

will crash someday. Back up your programs when you boot up.

The message "Do you want to back up your program files?" will be displayed.

Answering yes by pressing ‘Y’will backup the files to drive A:.

Only new programs or those which have changed since last backup are copied.

Copying Programs

User can copy programs between hard drive and floppy using the file handler from Auto Mode by selecting

F8 (DiskOps), then choosing 1 (Copy Files to/from Hard Drive).

See next page for full description of file handling.

Programs are listed in alphabetical order, and can be searched by the first letter of the name. The first ten

lines of each program are displayed, but the entire program can be reviewed if desired: tab to the preview

window below the programs window, then use arrow keys or page up/page down keys to look at every

block. Editing in these windows will not change program.

Individual programs can be deleted from the hard drive by hi-lighting them in the hard drive window, then

pressing Ctrl-D. To copy an entire diskette of programs to hard drive, hi-light any file in

floppy window, then press Ctrl-C.

To Restore Hard Drive

The hard-drive is high-reliability ‘solid-state, with no moving parts. A hard drive restore disk is shipped in

a pouch inside the rear panel of the control for use in the rare event that thehard drive fails for any reason.

After the new hard drive is installed, follow the instructionson the restore disk label.

1.18

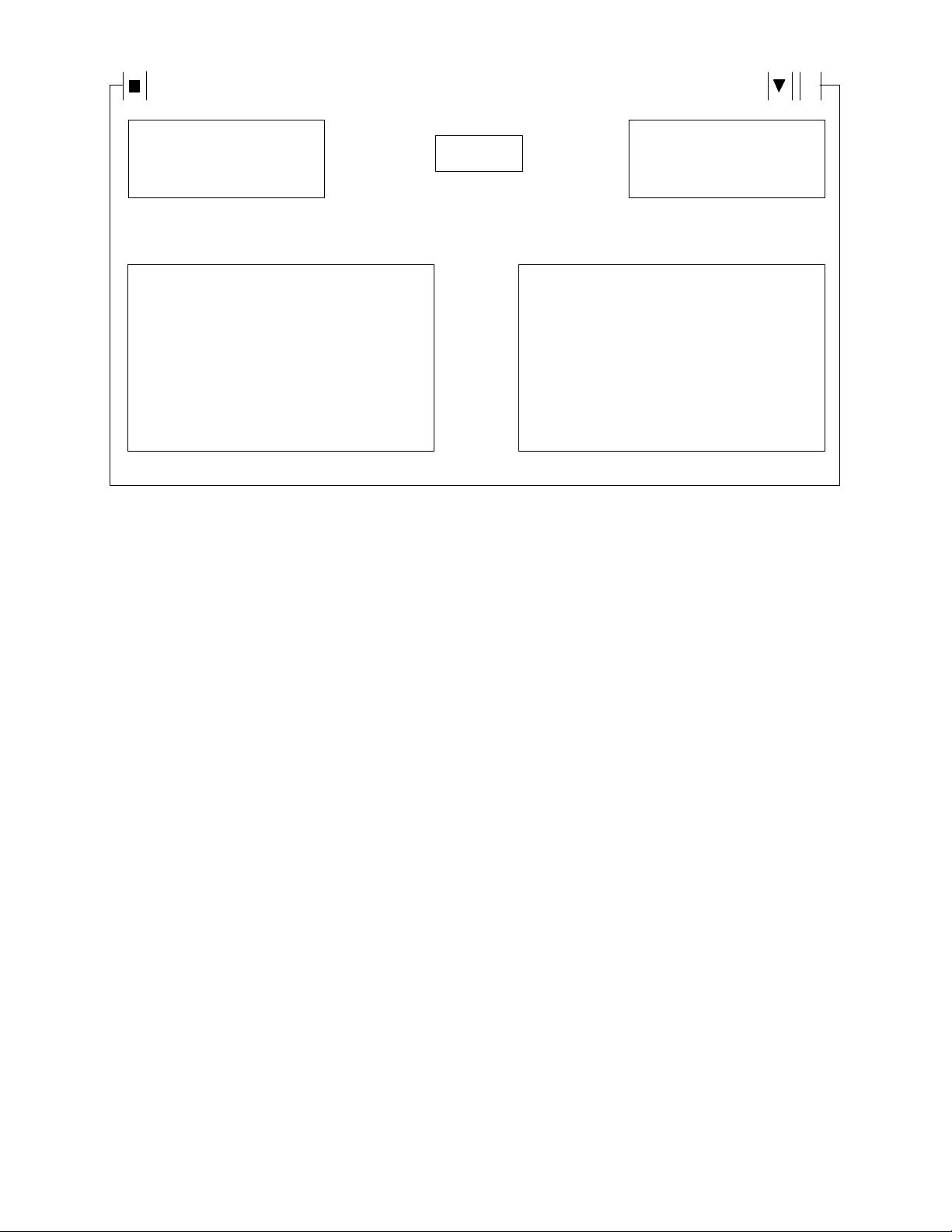

Copying Programs to and from the Hard Drive

The OmniTurn allows true “background editing” because programs copied to the Users Disk may be edited

at a desk-top computer while the program is running on the OmniTurn. The newly edited program can be

copied back to the hard drive from the Auto Mode screen with almost no interruption in the machining

process.

In Auto Mode select F8.

Disk Options Menu will appear.

Press 1 to copy programs TO or FROM the hard drive.

OmniTurn File Copy Screen will appear.

There are four windows, a help line and an exit button.

1. Upper left window lists the programs on the User Disk

2. Lower left window displays the program lines of the program high-lighted in the upper left window.

3. Upper right window lists the programs on the Hard Drive

4. Lower right windows displays the program lines of the program high-lighted in the upper right window.

5. The text below the top two windows displays the action as the highlight is moved from window to

window.

Use the arrow keys, or the initial letter of the program name to highlight a program to view or copy.

Use the Tab key to move from window to window, including the Exit box. Holding the Shift key, then

pressing Tab will move the cursor to the previous window.

To copy a high-lighted program to or from the hard drive, press the Rtrn key.

To delete a high-lighted program from the hard drive press and hold Ctrl key, then press d key (Ctrl-D).

There is no prompt: the program is deleted. You cannot delete programs from the floppy.

To copy all programs from floppy to hard drive, high-light any program in floppy window, then press Ctrl-

C.

Changes made in the preview window WILL NOT change the program.

To exit the file handler press and hold the Alt key, then press X, or use the Tab key to move the cursor to

highlight the Exit button, then press Rtrn.

1.19

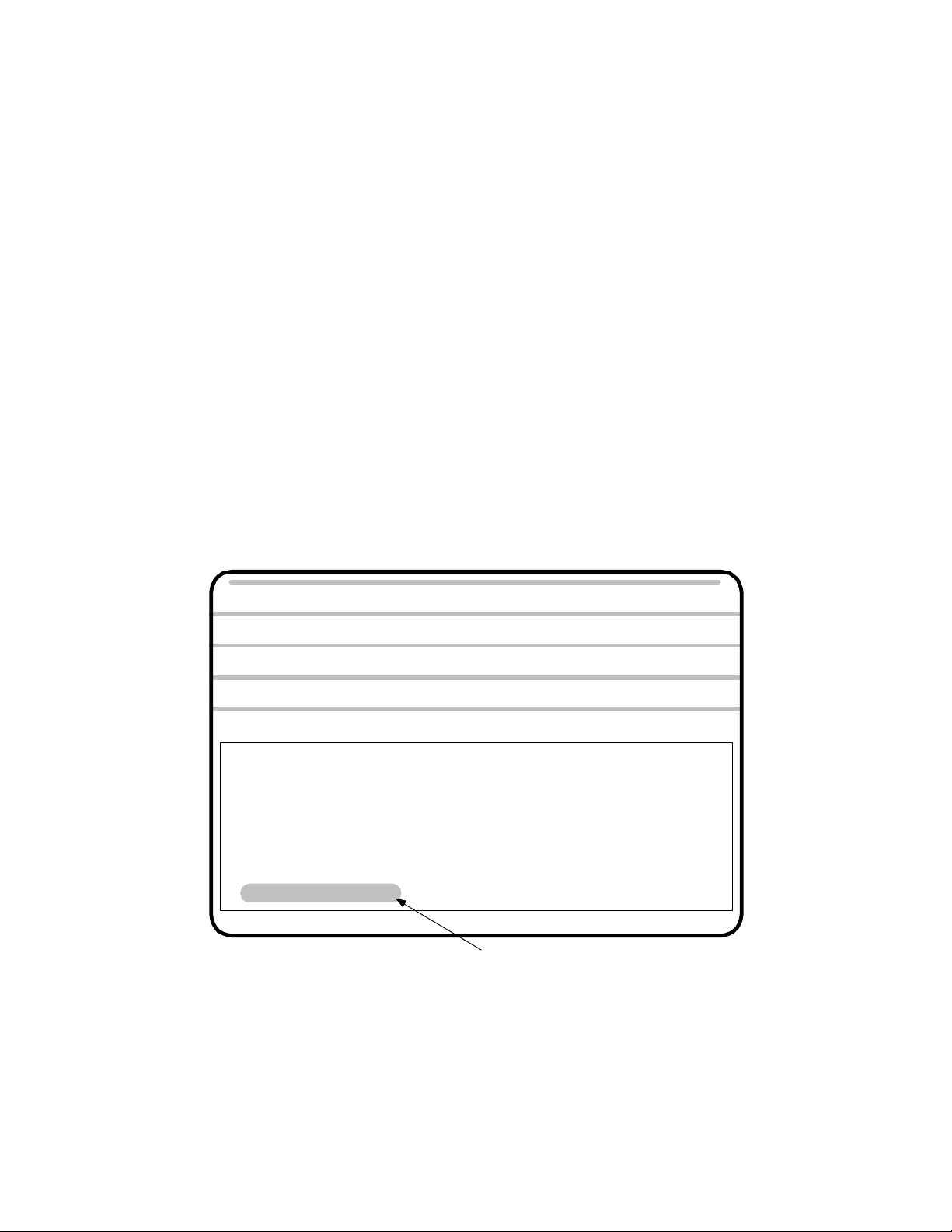

OmniTurn FILE COPY MENU

Programs on Floppy

DEMO

PROG1

PROG2

PROG3

Top prompt line area (see Notes on Use, below)

/- - - - - - - - - - - - - - - - - - - - - - - - - -

Program on Floppy Program on Hard Drive

Use Tab or Shft-Tab Between Boxes, arrows Within Boxes, Rtrn to Select

Exit

PREVIEW PROGRAMS

- - - - - - - - - - - - - - - - - - - - - - - - - -\

Using the File Handler: Notes and

Programs on Hard disk

DEMO

PROG1

PROG2

PROG3

Prompts

NOTE: You must have floppy in drive a:

Bottom Prompt Line: (moving around)

Use Tab or Shft-Tab Between Boxes, Arrows Within Boxes, Rtrn to Select

Use tab key to move counter-clockwise between windows; shift key with tab key to move clockwise.

When in any window, use up and down arrow keys to move from line to line.

Top Prompt Line, Initial condition:

Press Arrow or Initial Letter to Select Progarm. Press Tab Key for Next Window

The cursor is in the Programs on Floppy window. If user presses the initial letter of any program on disk,

the cursor will jump to first program which starts with that letter, the program will be selected, and the

program lines will be displayed in the Floppy Preview Programs window. If the user presses the down

arrow, the first program will be selected, and the program lines displayed.

When program is selected, Top Prompt Line changes:

Copy filename to Hard Drive? (Rtrn = Copy this File; Ctrl-C = Copy ALL Files)

If the user presses Enter, the program is copied and the Top Prompt changes as follows:

Copying filename to Hard Drive

appears while program is being copied, then filename Copied to Hard

Drive appears after program has been copied. If the user presses and holds Ctrl key, then presses ‘C’ key

(Ctrl-C), all programs will be copied to the hard drive.

Tab to program view window with program selected:

User may view entire program by using arrow keys. Changes made in preview window will not

affect program.

Tab to Hard Drive window to copy programs to floppy, or to delete programs:

Copy FILENAME to Floppy? (Rtrn = Copy: Ctrl-D to Delete !NO PROMPT!)

To Exit, Tab to exit window:

Press Rtrn (or Space) to Exit, else Tab to Next Window

1.20

Codes Honored by the OmniTurn control

(Sort by Code)

Code Usage Description Pages

G00 G00 Rapid move ......................................................................11,12

G01 G01Fn Feed move ........................................................................12,13

G02 G02XnZnInKnFn Arc -Clockwise .......................................................... 6,15,17-24

G02 G02XnZnRn Arc -Clockwise ...............................................................6,17-24

G03 G03XnZnInKnFn Arc -Counter Clockwise ...................................................6,17-24

G03 G03XnZnRn Arc -Counter Clockwise ...................................................6,17-24

G04 G04Fn Dwell.............................................................................6,25,62

G10 G10XnZn Work Shift................................................................. 6,26-28,73

G33 G33XnZnInKnCnPO Threading cycle ..............................................................6,29-36

G35 G35n Extra Course feeds in IPR............................................ 6,29,36,74

G36 G36 Cancels G35 .................................................................. 6,36,74

G40 G40 Cancels Tool Nose Radius Compensation.........................16,37-43

G41 G41 Left hand Tool Nose Radius Compensation ......................16,37-43

G42 G42 Right hand Tool Nose Radius Compensation ........................ 37-43

G70 G70 Inch mode.......................................................................... 6,44

G71 G71 Metric mode ....................................................................... 6,44

G72 G72 Diameter programming mode ...6,10,14,16,21,22,29,38,44,46,49,59

G73 G73 Radius programming mode .6,10,14,16,21,20,22,29,38,44,46,49,59

G74 G74XnZnInUnFn Box Roughing cycle ........................................................... 45-47

G75 G75InUnFnPn Box Contour Roughing cycle ..........................................48-52,54

G76 G76Sn Minimum spindle speed for constant surface feet..................... 6,60

G77 G77Sn Maximum spindle speed for constant surface feet .................... 6,60

G78 G78UnFnPn Rough Contour Cycle ........................................................ 51-55

G81 G81ZnFn Drill cycle ........................................................................... 6,56

G83 G83ZnKnFn RnLnCn Peck drill cycle ................................................................6,57,58

G89 G89 Stop spindle and lock (C-Axis only)

G90 G90 Absolute mode selection.................5,6,10,12,17,19,21,20,56,57,59

G91 G91 Incremental mode selection ..............................5,6,10,17,56,57,59

G92 G92XnZn Preset axis position ....................................................... 36,59,74

G94 G94Fn Inches per minute mode ..........................6,7,11,12,20,45,49,56,59

G95 G95Fn Inches per revolution mode.......................... 6,7,11,12,45,49,56,59

G96 G96Sn Spindle speed set as surface feet................................... 6,60,62,65

G97 G97 Spindle speed set as RPM .................................................... 6,60

M00 M00 Program stop - does not cancel active ”M” functions.................. 61

M0l M0l Optional stop ........................................................................61

M02 M02 End program - does not cancel active”M” functions...........26,62,65

M03 M03Sn Spindle on, CW ........................................................16,62,65,74

M04 M04Sn Spindle on, CCW .......................................................... 62,65,74

2.1

Codes Honored by the OmniTurn control

(Sort by Code)

Code Usage Description Pages

M05 M05 Spindle off, stop.....................................................................62,65,74

M08 M08 Coolant on.............................................................................. 16,62,65

M09 M09 Coolant off....................................................................................... 62

M12 M12 Collet clamp.....................................................................................62

M13 M13 Collet unclamp ................................................................................. 62

M19 M19 Spindle Positioning (optional C-Axis only) .......................................62,74

M25 M25 User assigned on .............................................................................. 62

M26 M26 User assigned off .............................................................................. 62

M30 M30 End of program - cancels all active ”M” functions ........................ 26,62,65

M31 M31 Cancels Cycle Repeat mode ............................................................... 62

M89 M89 Stop the spindle and lock it (optional: C-Axis only)................................63

M91 M91 Wait for TB2-5 to be open circuit (optional: C-Axis only) ....................... 63

M92 M92 Wait for TB2-5 to be short to 0VDC (optional: C-Axis only).................... 63

M93 M93 Wait for TB2-7 to be open circuit (optional: C-Axis only) ....................... 63

M94 M94 Wait for TB2-7+ to be short to 0VDC (optional: C-Axis only) ................. 63

M95 M95 Jump to subroutine 1 if TB2-9 is short to 0VDC (opt: C-Axis only) .......... 63

M97 M97InCnPn Jump to subroutine, conditional (optional: PLC option only) ..................63

M98 M98Pn Jump to subroutine ........................................................................... 63

M99 M99 End subroutine.................................................................................63

CI CInnn.nn Incremental spindle angle (optional: C-Axis only) .................................. 74

CA CAnnn.nn Absolute spindle angle (optional: C--Axis only) .....................................74

C XnZnCn Automatic chamfer at intersection..............................................15,16,67

D Dn Secondary offsets, axis correction or TNR comp value ..................... 68-71

F Fn Feedrates, dwell............................................................................48,56

LS LSn Loop start........................................................................................72

LF LF Loop finish ...................................................................................... 73

R XnZnRn Automatic radius at intersection .....................................................15,16

S Sn Spindle speed selection, SFM or RPM ....................................60,65,66,74

T Tn Tool offset call command .....................................................................9

/ / Block delete .........................................................................Section 5.3

} }n Begin subroutine ..............................................................................63

2.2

Codes Honored by the OmniTurn control

(Sort by Description)

Code Usage Description Pages

G90 G90 Absolute mode selection ...............................5,6,10,12,17,19-21,56,59

CA CAnnn.nn Absolute spindle angle (optional: C—Axis only) ............................... 74

G02 G02XnZnInKnFn Arc -Clockwise.................................................................6,1517-24

G02 G02XnZnRn Arc -Clockwise.....................................................................6,17-24

G03 G03XnZnInKnFn Arc -Counter Clockwise.........................................................6,17-24

G03 G03XnZnRn Arc -Counter Clockwise.........................................................6,17-24

C XnZnCn Automatic chamfer at intersection ........................................ 15,16,67

R XnZnRn Automatic radius at intersection ............................................... 15,16

} }n Begin subroutine ......................................................................... 63

/ / Block delete ....................................................................Section 5.3

G75 G75InUnFnPn Box Contour Roughing cycle................................................48-52,54

G74 G74XnZnInUnFn Box Roughing cycle ................................................................ 45-47

M31 M31 Cancels Cycle Repeat mode .......................................................... 62

G36 G36 Cancels G35........................................................................6,36,74

G40 G40 Cancels Tool Nose Radius Compensation..............................16,37-43

M12 M12 Collet clamp................................................................................ 62

M13 M13 Collet unclamp ............................................................................ 62

M09 M09 Coolant off ................................................................................. 62

M08 M08 Coolant on ........................................................................ 16,62,65

G72 G72 Diameter programming mode ........6,10,14,16,21,22,29,38,44,46,49,59

G81 G81ZnFn Drill cycle ................................................................................ 6,56

G04 G04Fn Dwell..................................................................................6,25,62

M30 M30 End of program - cancels all active M functions ..................... 26,62,65

M02 M02 End program - does not cancel active M functions .................26,62,65

M99 M99 End subroutine............................................................................ 62

G35 G35n Extra Course feeds in IPR................................................. 6,29,36,74

G01 G01Fn Feed move............................................................................. 12,13

F Fn Feedrates, dwell...................................................................... 48,56

G70 G70 Inch mode ............................................................................... 6,44

G94 G94Fn Inches per minute mode .......................... 6,7,11,12,20,45,49,56,57,59

G95 G95Fn Inches per revolution mode ...........................6,7,11,12,45,49,56,57,59

G91 G91 Incremental mode selection............................... 5,6,10,17,56,57,59,70

CI CInnn.nn Incremental spindle angle (optional: C-Axis only) ............................. 74

M98 M98Pn Jump to subroutine......................................................................63

M95 M95 Jump to subroutine 1 if TB2-9 is short to 0VDC (opt: C-Axis only).....63

M97 M97InCnPn Jump to subroutine, conditional (optional: PLC option only) ............. 63

2.3

Codes Honored by the OmniTurn control

(Sort by Description)

Code Usage Description Pages

G41 G41 Left hand Tool Nose Radius Compensation............................16,37-43

LF LF Loop finish .................................................................................73

LS LSn Loop start...................................................................................72

G77 G77Sn Maximum spindle speed for constant surface feet.......................... 6,60

G71 G71 Metric mode ............................................................................ 6,44

G76 G76Sn Minimum spindle speed for constant surface feet ..........................6,60

M0l M0l Optional stop......................................................................... 61,62

G83 G83ZnKnFn RnLnCn Peck drill cycle......................................................................6,57,58

G92 G92XnZn Preset axis position.............................................................36,59,74

M00 M00 Program stop - does not cancel active M functions ...................... 61,62

G73 G73 Radius programming mode.......6,10,17,18,20,29,31,32,38,44,46,49,59

G00 G00 Rapid move........................................................................... 11,12

G42 G42 Right hand Tool Nose Radius Compensation.............................. 37-43

G78 G78UnFnPn Rough Contour Cycle .............................................................. 51-55

D Dn Secondary offsets, axis correction or TNR comp value ................ 68-71

M05 M05 Spindle off, stop ................................................................. 62,65,74

M04 M04Sn Spindle on, CCW................................................................62,65,74

M03 M03Sn Spindle on, CW............................................................. 16,62,65,74

M19 M19 Spindle Positioning (optional C-Axis only) ................................. 62,74

S Sn Spindle speed selection, SFM or RPM .............................. 60,65,66,74

G97 G97 Spindle speed set as RPM..........................................................6,60

G96 G96Sn Spindle speed set as surface feet ........................................ 6,60,62,65

G89 G89 Stop spindle and lock (C-Axis only)

M89 M89 Stop the spindle and lock it (optional: C-Axis only)...........................63

G33 G33XnZnInKnCnPO Threading cycle ................................................................... 6,29-36

T Tn Tool offset call command ................................................................9

M26 M26 User assigned off .........................................................................62

M25 M25 User assigned on .........................................................................62

M91 M91 Wait for TB2-5 to be open circuit (optional: C-Axis only) ..................63

M92 M92 Wait for TB2-5 to be short to 0VDC (optional: C-Axis only)...............63

M93 M93 Wait for TB2-7 to be open circuit (optional: C-Axis only) ..................63

M94 M94 Wait for TB2-7+ to be short to 0VDC (optional: C-Axis only)............63

G10 G10XnZn Work Shift ......................................................................6,26-28,73

2.4

Nomenclature

AXIS: X AND Z

ABSOLUTE - G90

IN INCREMENETAL (G91) THE FOLLOWING

X -

Z -

Z+

X +

The slide has two axis’s of travel.

X: Towards and away from you. Travel away from you is (-) minus. Towards you is plus (+).

Z: The slide that travels along the axis of the spindle. Going towards the spindle is (-) minus. Away from the

spindle is (+) plus.

Z -

X -

Z+

IN ABSOLUTE (G90) THE FOLLOWING

MOVE BRINGS YOU TO THE SAME POINT

NO MATTER WHERE YOU START

X-3 Z-4

INCREMENTAL - G91

Z -

X +

X -

MOVES YOU THE SAME AMOUNT FROM

EVERY START.

X-3 Z-4

Z+

X +

2.5

• The default mode for X moves is G73 - radius moves, to program in diameters you must

Programming Format

use G72 in the beginning of the program.

• The first command of a program must be G90 or G91 to define if the program is in

absolute or incremental.

• No blank lines are allowed in a program, blank spaces are OK.

• Comments are any text or data enclosed in parentheses“( )”.

Their purpose is to convey to the operator any information that the programmer might think is

useful. Comments are displayed in the lower left corner of the screen. They stay on the screen till the

comment is changed. As an example, you may want to use the comment to tell the operator what

action to take when the spindle stops. For an example, the slide is told to go ”HOME” and then the

comment is displayed on the screen. Then the slide stops with the message on the screen.

- Do not put text on lines by itself. Comments must be on a line with a command!

- Keep the amount of text to a minimum, to much text can cause problems.

- A good place to put comments is on a line with a tool call ie: T1(LH turn tool)

-Use only text, do not use periods or commas or any other symbol such as i.e.:

! @ # $ % ^ & * “ ‘ ? > < / \| = -.

• Do not put any text in a loop.

• Commas are not allowed anywhere in the program

• Dimensional data is interpreted with a resolution of .00005”. The fifth digit to the right

of a decimal point must be a 0 or a 5. NOTE: when programming in diameter mode the

X axis resolution is .0001 ”, not .00005”.

• Decimal point programming is used. Leading and trailing zeros need not be entered.

For example ”X1” is interpreted as 1 inch. X1 = X1.00000

• G and M codes must be programmed as two digit codes. ”G2” is not a legal code and it

will be ignored. Also be sure to use the zero and not the letter O as part of the G and M codes.

• Model commands: These are commands that remain active until canceled:

G90, G91 -G94, G95 -G70,G71 -G76, G77, G96,G97 -G72, G73

All ”M” codes, G35, G36 (GT-75 only)-G10

• One shot commands: These act only on the statement they are programmed in:

G02, G03 -G04 -G33, G34 -G81, G83 -G92

• Conflicting commands:

There can be only one ”M” command per line of code

There can be only one “one shot” G code per line of code

There can be more than one nonconflicting modal G code per line

The S and F commands can be with any other command

• N sequence are not allowed. They can cause intermittent problems.

2.6

Programming Format

• Feedrate:

This command specifies the speed at which the tool will travel. Once a Feedrate has been

established, it remains until it is changed. Feedrates are specified as either Inches per minute (IPM)

or Inches per revolution (IPR).

X.1Z-.4F7 This line of code has a feedrate of 7 IPM when in G94 (F300 max)

X1Z-.4F.005 This line of code has a Feedrate of .005 IPR when in G95

• Tool Selection:

This command is used to make a new tool offset active. The letter ”T” identifies a tool

command.

T2 Makes the tool offset for T2 active. After this command is executed

the absolute position display will show the distance from the tip of

tool two to the absolute zero of the work piece.

T1

X0Z2

M00 (PUT PART IN COLLET)

POSITION

COMMAND : X +0.00000 Z +0.00000

PRESS CYCLE START

Jog Automatic Single Block

F1-F10 FEED 10-100%

FILE IN MEMORY: TEST

'0' FOR OPTIONAL STOP

'/ ' FOR BLOCK DELETE

'C' FOR CYCLE REPEAT

PRESS 'S' FOR SINGLE BLOCK

PUT PART IN COLLET

1QUIT 2OFFSET 3EDIT 4DIR 5NEWPROG 6SEARCHTO 7PROG 8DISKOP 9SECCMP 0

• Secondary offsets:

These are activated by the letter D. See the section of secondary offsets.

: X +0.00000 Z +0.00000 FEED 10.0 IPM

PERCENT FEED: 100

Manual Data Input

Comments appear here

X.2Z-.35D2 Calls secondary tool offset number two

2.7

There are a number of ways to create a new program. Here are a few:

Creating a new program

-Use the text editor in OmniTurn. This is found in the Automatic

section, use F3. (for additional information on the editor and this function

please refer to section 5).

-Go to the Automatic mode menu. First a new program name has to

be created. This is done by going into the Automatic mode and typing in the

new name when the control asks “FILE TO BE PROCESSED”. After the

RETURN key is hit the control will answer “FILE NOT FOUND, PRESS

ANY KEY TO CONTINUE”. By doing this you have accomplished two

things.

1. If there was already a program with the name you just entered, the control

would now be ready to run it. If this is the case, then you would have to

select a new name or change the program of the existing one already there.

2. If there was no other program that had the new name then there was one

created and loaded into the text editor. Once the new name is entered into

the text editor, press F3 to enter the editor. The text editor will ask ”PRESS

F1 TO CREATE A NEW FILE, ESC TO ABORT”. After pushing F1 the

editor will provide a new blank screen to enter your program.

-CAM system off line. Transfer a file via floppy or RS-232. Once they are

on the OmniTurn program disk they can be run like any other existing

program. Please refer to the section in DOS notes on the format.

-RS-232 or Disk transfer. Manually enter a program in a text editor on

another computer, transfer as above. Once they are on the OmniTurn

program disk, they can be run like any other existing program. Please refer

to the section in DOS notes on the format.

-Use Calcaid in OmniTurn. See the section on using Calcaid.

2.8

The “tool call statement” is done in two lines:

Tool call statements

Tn

XnZn

The T command must have a tool number in the range of I through 32. When this command is executed the

slide will not move. The display showing the absolute location will change to show the distance the tool

being used is from the absolute zero of the part. In order to use this command the tool must have its tool

offset established first.

The following line must be a X and Z move. You must have both values given! This is the location that the

tool will move to. In the beginning you should have the tool come to a location that is clear of the part in Z,

and then move the tool into the work. This will help eliminate some the tool interference problems new users

encounter.

T1...................................................Tool call for #1

X.25Z1 ...........................................move the tool to a location of X=.25 and Z= I

Z.1 .................................................move the tool closer to the work, still in rapid mode

2.9

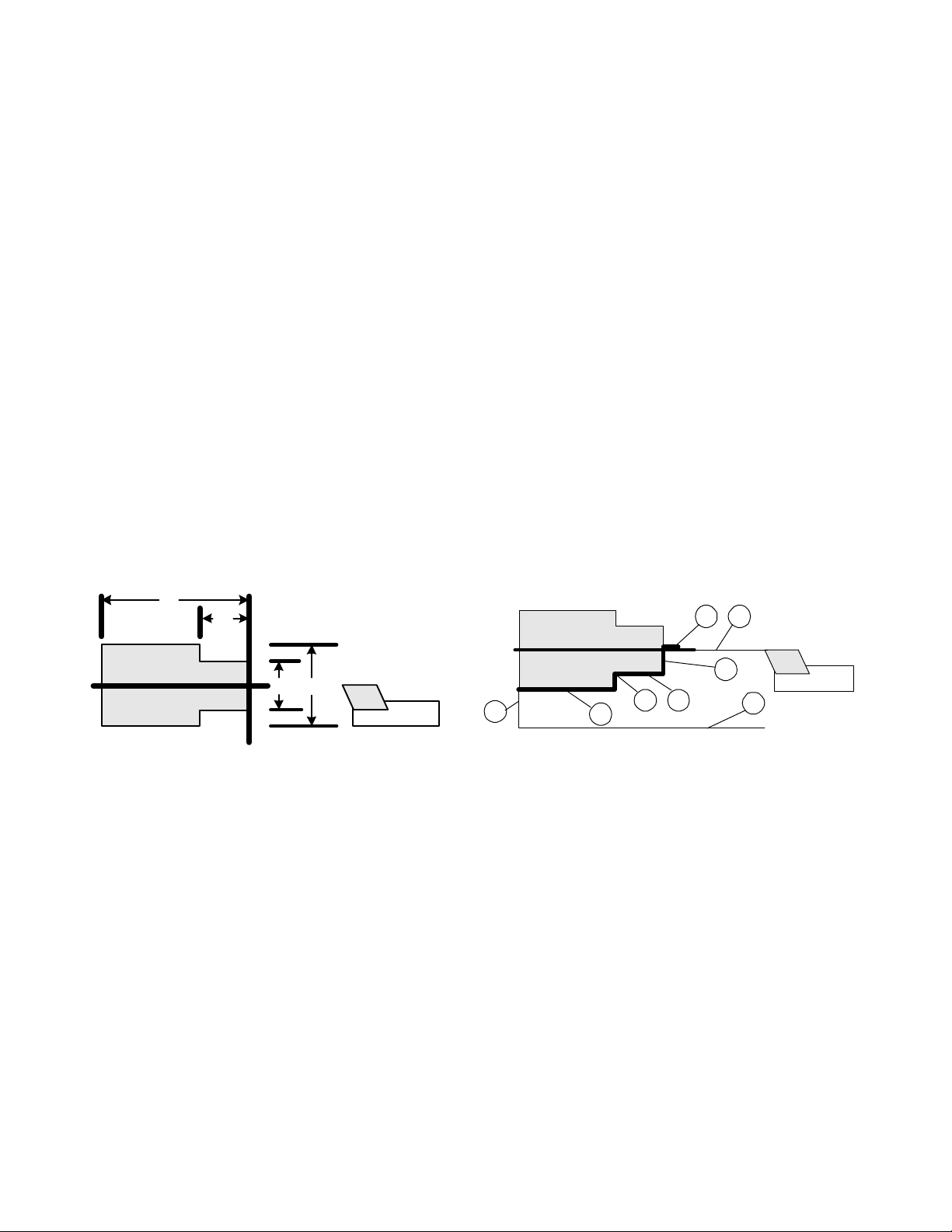

Linear one and two axis moves are accomplished by giving the axis and the value to move. The result

Linear moves X n Z n XnZn

of a command will depend on which mode is active: G90 or G91, and G73 (radius) or G72 (diameter).

X moves default to RADIUS mode (G73), not diameters. If you want your moves to be in diameter you

must put a G72 in the beginning of your program. See the example at the end of-this chapter

Feed and Rapid moves are accomplished as follows:

Movement in X:

Xn Single axis (X) move

example: X.25 This will move to a diameter of .5

The programming in X can be done as radius movements (G73) or diameter (G72).

Movement in Z:

Zn Single axis (Z) move

example: Z-.1 This will move the tool -.1 into the material

Z moves can be programmed directly off the print.

Movement in X and Z simultaneously

XnZn Two axis linear move (X & Z)

Example for linear moves

1.1

.5

12

3

.5

.7

7

6

45

8

The moves to generate this tool path could be as shown below. The tool path given does not show any of

the codes needed to determine the feedrates or spindle speeds etc. The code is shown in the;

diameter mode: radius mode:

G90G94F300G72 G90G94F300G73

M03S2000 M03S2000

M08 M08

T1 Tl

X0 Z1 X0 Z1

(1) Z.1 Z.1

(2) Z0 G95f.003 Z0G95f.003

(3) X.5 X.25

(4) Z-.5 Z-.5

(5) X.7 X.35

(6) Z-1.1 Z-1.1

(7) X 1 X . 5

(8) Z1 G00 Z1G00

M30 M30

2.10

Loading...

Loading...