Page 1

iConverter® T3/E3 User Manual

OVERVIEW:

iConverter T3/E3 managed media converter is a member of the

The

iConverter product family. The T3/E3 provides standard T3

modular

(B3ZS line protocol, 44.763Mbps) or E3 (HDB3 line protocol, 34.368Mbps)

coax to fiber conversion and can be used by telco service providers

and enterprise users to connect devices such as PBXs, multiplexers,

routers and video servers via multimode (MM), single-mode (SM) or

single-mode single-fiber (SF) fiber.

Designed to extend the standard T3/E3 Coax network distances over

fiber, this converter provides protection from environmental noise and

effectively increases high-speed network reliability.

The T3/E3 module can be used in any of the

as the 1-Module, 2-Module, 5-Module and 19-Module chassis.

The T3/E3 can be used in a managed or unmanaged fashion. When

unmanaged, it can be installed in an

Network Management Module (NMM). T o be managed, a NMM module

must be installed in the same chassis as the T3/E3 module. To read

about specific management functionality, refer to the

user manual T3/E3 section.

This User Manual covers the models listed in the following table.

Page 1

iConverter chassis such

iConverter chassis without a

NetOutlook

T3/E3 MODEL NUMBER REFERENCE CHART:

iConverter

T3/E3 Coax Dual Fiber Modules

Fiber Type Distance

- - ---MM 5 km

SM 30 km

SM 60 km

SM 120 km -

iConverter

Fiber /

Connector

Type

SM / SC 20 km 8750-1 8751-1

SM / SC 40 km 8750-2 8751-2

For wide temperature (-40 to 60º C), add a "W" to the end of the model number.

Consult factory for extended temperature (-40 to 75º C) models.

When using single-fiber (SF) media converter models, the TX wavelength on one end

has to match the RX wavelength on the other.

*See SFP data sheet under Fast Ethernet for supported transceiver models.

™

Distance

ST SC MT-RJ LC SFP

8740-0 8742-0 8744-0

8741-1 8743-1 8745-1 8747-1

8741-2 8743-2

T3/E3 Coax Single-Fiber Modules

Tx: 1310 nm,

Rx: 1550 nm

Connector Type

8743-3

-

-

Page 2

8759-0*

--

8747-2

8747-3

Tx: 1550 nm,

Rx: 1310 nm

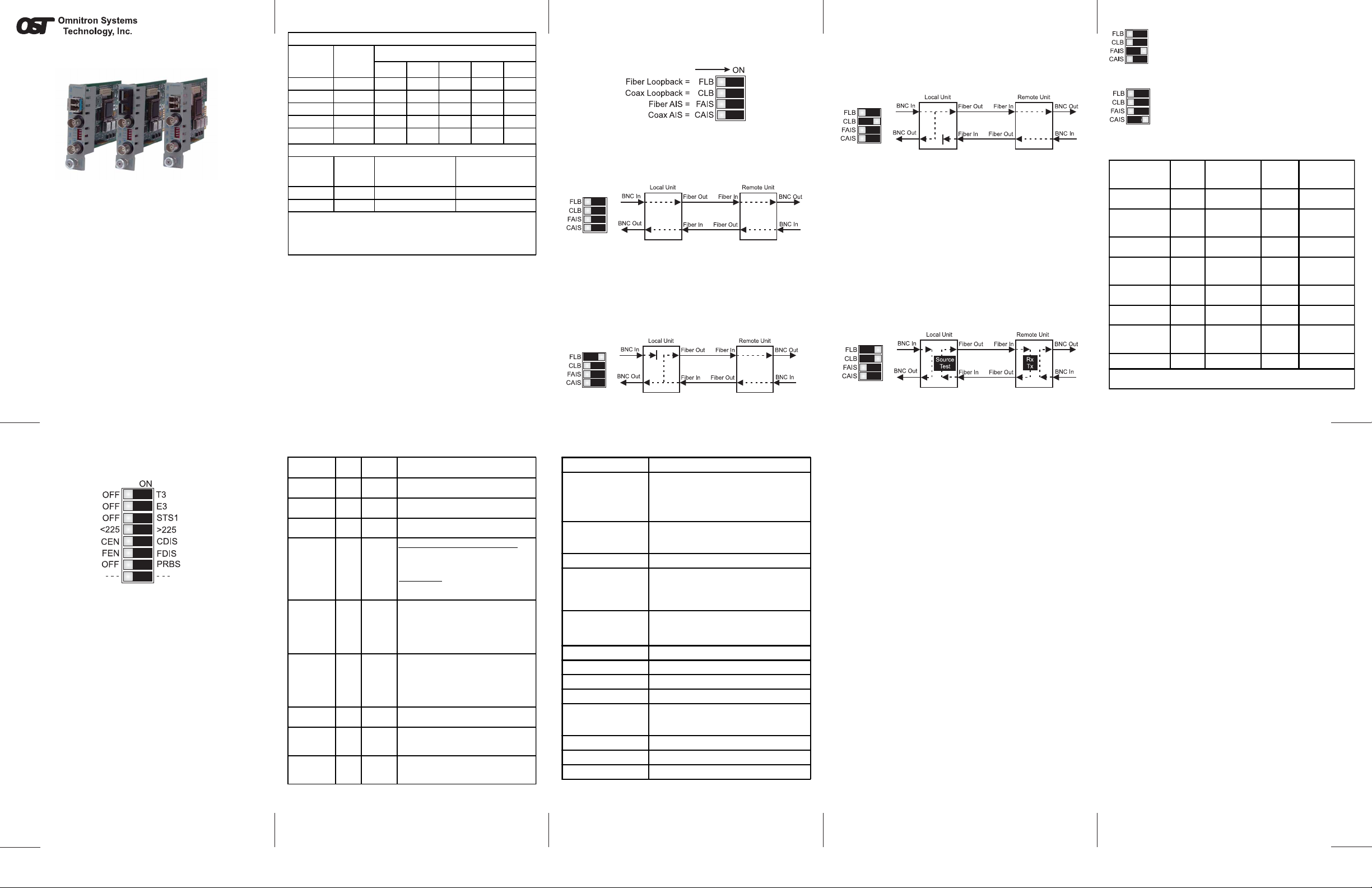

FRONT PANE L DIP-SWITCH SETTINGS:

The following DIP-switches are located on the front of the T3/E3 converter.

These switches provide data path control (normal operation and loopbacks) and test patterns (all 1’s) that assist in installation and fault isolation.

“CLB” DIP-Switch - Local Coax Mode Operation (Coax Loopback):

This DIP-switch facilitates the testing of the coax cables. When the “CLB”

dip-switch is in the right position, it sets the coax port to a Local Coax

Loopback Mode (Figure 4) and the “CLB” LED is turned ON. When in this

mode, data received at the BNC-In is forwarded to the BNC-Out and the

Fiber-Out. If no data is received at BNC-In, an AIS pattern is transmitted

out both BNC-Out and Fiber-Out. By returning the DIP-switch to the left

position, the unit resumes normal operation.

“FAIS” Force AIS to Fiber (Force 1’s to Fiber):

When the “FAIS” dip-switch is in the right position, an “all

ones” pattern is forced out the Fiber-Out port. The Coax-In

data is discarded and Fiber-In data is passed through to

BNC-Out. By returning the dip-switch to the left position,

the unit resumes normal operation.

“CAIS” Force AIS to Coax (Force 1’s to Coax):

When the “CAIS” dip-switch is in the right position, an “all

ones” pattern is forced out the BNC-Out port. The Fiber-In

-

-

-

Normal Mode Operation (Straight Through):

The default DIP-switch setting (all dip-switches to the left) sets the converter

to its Normal Mode and allows data to flow straight through between the

Fig. 1 Front Panel DIP-Switches

BNC and Fiber ports (Figure 2).

Fig. 4 Coax Loopback and DIP-Switch Settings

Remote Loopback Mode:

ON BOARD DIP-SWITCH SETTINGS:

When both the “FLB” and “CLB” DIP-switches are in the right position, they

force a remote unit to loop back its fiber and coax ports (Figure 5). This

facilitates test of the fiber cables and the remote unit without having to

physically set DIP-switches on the remote unit. While in this mode, the

local unit’s BNC is set to a local loopback, and its “FLB” and “CLB” LEDs

are turned ON.

Fig. 2 Normal Mode and DIP-Switch Settings

“FLB” Dip-Switch - Local Fiber Mode Operation (Fiber Loopback):

This DIP-switch facilitates the testing of the fiber cables. When the “FLB”

dip-switch is in the right position, it sets the fiber port to a Local Fiber

Loopback Mode (Figure 3) and the “FLB” LED is turned ON. When in this

mode, data received at the Fiber-In is forwarded to the BNC-out and the

Fiber-Out. If no data is received at Fiber-In, an AIS pattern is transmitted

out both BNC-Out and Fiber-Out. By returning the DIP-switch to the left

position, the unit resumes normal operation.

Fig. 3 Fiber Loopback and DIP-Switch Settings

Page 3

While in the Remote Loopback Mode, the local unit sends a test pattern to

the remote unit. This pattern forces the remote unit into the loopback mode

and is also returned back to the local unit. When forced into the Remote

Loopback Mode, the remote unit’s “FLB” and “CLB” blink slowly (1Hz).

When the test pattern is received successfully at the local unit’s Fiber-In,

the “TST” LED blinks rapidly (10Hz). Any other data causes slow “TST”

blinking (1Hz). If no data is returned to Fiber-In, the LED is turned OFF.

Returning both dip-switches to the left position, causes the local and

remote units to resume normal operation.

Fig. 5 Remote Loopback and DIP-Switch Settings

Page 4

STS-1 Select

Coax build-out

distance selection

Coax port control

Fib er por t c o ntro l

Force PRBS to

8 = Reserved - - - -

Note: [1 ] Pse udo Rando m Bit Seq ue nce [PRBS] is a da ta p a ttern

defined by ITU O.151 spec: E3: 2^23-1, T3: 2^15-1

data is discarded and BNC-In data is passed through to

Fiber-Out. By returning the dip-switch to the left position,

the unit resumes normal operation.

[Switch

Position]

Function

[1]

T3 Sel ec t

[2]

E3 Select

[3]

[4]

[5]

[6]

[7]

BNC-Out

Left

Position

OFF

(default)

OFF

(default)

OFF

(default)

<225

(default)

CEN

(default)

FEN

(default)

OFF

(default)

Left Function

-T3T3 Selected

E3 is selected

when T3 and

STS-1 are OFF

- STS-1 STS-1 Selected

Short distance,

less than 225ft.

Coax port

enabled

Fiber port

enabled

Normal data PRBS

Right

Position

E3 E3 Selected

>225

CDIS

FDIS

Page 5

Right Function

Long distance,

equal-to or

more than 225ft

Coax port

disabled [OFF]

Fiber port

disabled [OFF]

Force PRBS[1]

to BNC-Out

The On Board DIP-switches facilitate the selection between T3, E3,

STS-1 protocols, the coax distance, fiber and coax port control and the

injection of pseudo random data patterns into the coax.

Fig. 6 Board Mounted DIP-Switches

“T3” “E3” and “STS-1” DIP-Switches - Select Protocol:

When the “T3” DIP-switch is in the right position, the T3 protocol is

selected. When the “E3” DIP-switch is in the right position, the E3 protocol

is selected. When the “STS-1” DIP-switch is in the right position, the STS-1

protocol is selected. Only one of the three DIP-switches may be in the

right position at any one time. The default setting of the module has no

mode selected (the module will default to E3 mode with no switches set).

“<225/>225” Coax Build-Out Distance selection:

When this DIP-switch is in the left position, a distance of less than 225 ft.

is selected. When in the right position, a distance of 225 ft. or higher is

selected. Select the appropriate distance for your application.

“CEN/CDIS” and “FEN/FDIS” Port Control DIP-Switches:

When both DIP-switches are in the left position, the ports are enabled.

When the “CEN/CDIS” is in the right position, the coax port is disabled.

When the “FEN/FDIS” is in the right position, the fiber port is disabled.

“PRBS” Pseudo Random Pattern Generator Control DIP-Switch:

When in the right position, the converter forces Pseudo Random pattern

out of the Coax-Out port. The data received at Fiber-In is discarded and

the data at Coax-In is passed through to Fiber-Out.

Note: Some combinations of DIP-switch settings are illegal, and

will be indicated by the Fiber Test “TST” LED blinking quickly three

times followed by a pause.

Page 6

T3/E3 LED REFERENCE CHART:

Function

"Legend"

Power

"Pwr"

Fib er Activity

"Act"

Fiber AIS

"AIS"

Fiber Test

detected

"TST"

Fiber

Loopback

"FLB"

Coax

Loopback

"CLB"

Coa x Ac tivity

"ACT"

Coax AIS

detected

"AIS"

Coax PRBS

detected

"PRBS"

Amber No Power On: Power available

Green

Amber -- Fast blink (10Hz): AIS Received.

Amber

Amber Normal

Amber Normal

Green

Amber -- Fast blink (10Hz): AIS Received.

Amber --

Color

OFF

State

No valid

data

No Test

Data

Received

No valid

data

ON / Blinking state

Fast b link (10Hz): Da ta Re c eived

Local unit asserting Remote Loopback:

Fast blink (10Hz): Test pattern received.

Slow blink (1 Hz): Unexpected pattern

received.

Special Case:

Three quick blinks (2Hz) and pause (1sec.):

Illegal dip-switch selection.

ON: Local Fiber Loopback.

If "CLB " also "ON" indicates that the unit is

the Local Unit in Remote Loopback Mode.

Slow blink (1Hz) and also "CLB" in slow

blink: indic ates that the unit is the Remote

Unit in Remote Loopback Mode.

ON: Local Coax Loopback.

If "FLB" also "ON" indicates that the unit is

the Local Unit in Remote Loopback Mode.

Slow blink (1Hz) and also "FLB" in slow

blink: indic ates that the unit is the Remote

Unit in Remote Loopback Mode.

Fast b link (10Hz): Da ta Re c eived

Blink 10 Hz: PRBS Received.

Blink 1 Hz: Forcing PRBS onto BNC-Out.

T3/E3 SPECIFICATION CHART :

Model Type

Protocols

ETSI: EN 300 689, 300 686, 300 687

Copper Connectors

Fiber Connectors

T3/E3 S e l , C o a x Bui ld - Out, Co ax En/Dis,

Controls

Fiber En/Dis, AIS to Fiber, AIS to Coax,

Power, Fiber Act, Coax Act, Fiber AIS Det,

LED Displays

Fiber Test, Fiber Loop-Bk, Coax Loop-Bk

Dimensions

Weight

Compliance

Power Requ irement

Standard: 0 to 50º C

Temperature

Wide: -40 to 60º C

Storage: -40 to 80º C

Humidity

Altitude

MTB F (hr s )

T3/E3

ANSI: T1.102, T1.107,

T1.404, T1-404a (T3),

ITU: G.703, (E3), G.751, O.151

RG-59 Coax, 75 ohm, BNC

DS3: 380m, E3: 440m

SC, ST, LC, MT-RJ, SFP

PRBS to Coax, Loop-Bk Coax,

Loop-Bk Fiber, Loop-Bk Remote

Coax AIS Det, Coax PRBS Det,

W:0.85" x D:4.5" x H:2.8"

8 oz.

UL, C E, FCC Cl a ss A

0.7A @ 3.3VDC (typical)

5 to 95% (non-condensing)

-100m to 4000m

510,000

MOUNTING INSTRUCTIONS and CABLE A TTACHMENTS:

iConverter modules are hot-swappable and can be installed into any

chassis in the

1. Carefully slide the

the module with the installation guides. Ensure that module is firmly

iConverter family.

iConverter module into the installation slot, aligning

seated against the backplane.

2. Secure the module by securing the panel fastener screw (attached to

module) to chassis front.

3. When using an SFP model (8759-0), insert the SFP Fiber transceiver

into the SFP receptacle on the module.

Note: The release latch of the SFP Fiber transceiver must be in

the closed position before insertion.

4. Connect the fiber cables between the T3/E3 converters. The Transmit

(TX) must attach to the Receive (RX) and the Receive must attach

to the Transmit.

5. When using a single-fiber models, you must use mating converters.

For example, if one converter is the model 8750-1 (TX=1310nm,

RX= 1550nm), the other converter must be model 8751-1 (TX=1550nm,

RX=1310nm).

6. Attach the BNC cables to the T3/E3 converter and attach the other

end of the cables to appropriate network equipment. The Transmit must

attach to the Receive and the Receive must attach to the Transmit.

Warning

The operating description in this Instruction Manual is for use by qualified

personnel only. To avoid electrical shock, do not perform any servicing of

this unit other than that contained in the operating instructions, unless you

are qualified and certified to do so by Omnitron Systems Technology, Inc.

Warranty

This product is warranted to the original purchaser against defects in

material and workmanship for a period of TWO YEARS from the date of

shipment. A LIFETIME warranty may be obtained by the original purchaser by

REGISTERING this product with Omnitron within 90 days from the date of

shipment. TO REGISTER, COMPLETE AND MAIL OR FAX THE ENCLOSED

REGISTRATION FORM. Or you may register your product on the Internet

at www.omnitron-systems.com. During the warranty period, Omnitron will,

at its option, repair or replace a product which is proven to be defective.

Page 7 Page 9

Page 8

For warranty service, the product must be sent to an Omnitron designated facility, at Buyer’s expense. Omnitron will pay the shipping charge

to return the product to Buyer’s designated US address using Omnitron’s

standard shipping method.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from improper

or inadequate use and/or maintenance of the equipment by Buyer, Buyersupplied equipment, Buyer-supplied interfacing, unauthorized modifications or tampering with equipment (including removal of equipment cover

by personnel not specifically authorized and certified by Omnitron), or misuse, or operating outside the environmental specification of the product

(including but not limited to voltage, ambient temperature, radiation, unusual dust, etc.), or improper site preparation or maintenance. No other

warranty is expressed or implied. Omnitron specifically disclaims the implied warranties of merchantability and fitness for any particular purpose.

Exclusive Remedies

The remedies provided herein are the Buyer’s sole and exclusive

remedies. Omnitron shall not be liable for any direct, indirect, special,

incidental, or consequential damages, whether based on contract, tort, or

any legal theory.

TECHNICAL SUPPORT :

For help with this product, contact our Technical Support:

Phone: (949) 250-6510

Fax: (949) 250-6514

Address: Omnitron Systems Technology, Inc.

140 Technology Dr., #500

Irvine, CA 92618 USA

E-mail: support@omnitron-systems.com

URL: www.omnitron-systems.com

Form: 040-08740-001D 2/08

Page 10

Loading...

Loading...