Page 1

________________________________________________________________________

OmniHawk™ 4/16 Token Ring

Fiber Converter

User’s Manual

___________________________________________________

27 Mauchly, Suite #201, Irvine, CA 92618 ( 714) 250-6510

Document # 040-00039-001

Page 2

SAFETY CONSIDERATIONS

WARNING

The instructions in this User Manual are for use by qualified personnel only. To avoid electrical shock, do not

perform any servicing of this unit or the power supply module, other than that contained in the operating

instructions, unless you are qualified and certified to do so by OST.

CAUTION

All user required operations may be performed without ever opening the unit. Never attempt to open or

remove the cover or tamper with the power supply module.

LINE VOLTAGE

Before connecting the power units to the line voltage, make sure that the voltage of the power source (wall

outlet) matches the voltage specified on the power units.

WARRANTY

This OST product is warranted to the original purchaser against defects in material and workmanship for a

period of TWO YEARS from the date of shipment. A LIFETME warranty may be obtained by the original

purchaser by REGISTERING this product with OST within 90 days from the date of shipment. TO REGISTER, PLEASE COMPLETE AND MAIL OR FAX THE REGISTRATION CARD. During the warranty period,

OST will, at its option, repair or replace products which prove to be defective.

For warranty service, the product must be sent to an OST designated repair facility, at Buyer’s expense.

OST will then pay the postage/shipping charges to return the product to Buyer (using OST’s standard shipping method).

LIMITATIONS OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or inadequate use and/or maintenance of the equipment by Buyer, Buyer-supplied equipment, Buyer-supplied interfacing, unauthorized

modifications or tampering with equipment (including removal of equipment cover by personnel not specifically authorized and certified by OST), or misuse, or operation outside the environmental specification of the

product (including but not limited to voltage, ambient temperature, radiation, unusual dust, etc.), or improper

site preparation or maintenance.

No other warranty is expressed or implied, OST specifically disclaims the implied warranties of merchantability and fitness for any particular purpose.

EXCLUSIVE REMEDIES

The remedies provided herein are the Buyer’s sole and exclusive remedies. OST shall not be liable for any

direct, indirect, special, incidental, or consequential damages, whether based on contract, tort, or any legal

theory.

FCC WARNING

This equipment has been tested and found to comply with the limits for a class A digital device, pursuant to

part 15 of the FCC rules. These limits are designed to provide a reasonable protection against harmful

interference when the equipment is operated in a commercial environment. The equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. Any changes or modifications not expressly approved by the manufacturer could

void the user authority to operate the equipment.

NOTES

____________________________________________________________________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

__________________________________________________________

Page 3

TECHNICAL SUPPORT

If you encounter any problems in installing or maintaining this equipment,

do not hesitate to call, fax or write Omnitron’s technical support:

Omnitron Systems Technology, Inc.

27 Mauchly, Suite 201

Irvine, CA 92618

Phone: 714-250-6510

Fax: 714-250-6514

OmniHawk™ 4/16 Token Ring

Fiber Converter

USER’S MANUAL

GENERAL DESCRIPTION

The OmniHawk™ 4/16 Token Ring fiber converter provides a solution to

heterogeneous Token Ring media environments. Conversions between

copper (CAT-5 or Type 1) and fiber optic interfaces are required in most

modern Token Ring installations.

Fiber optic cabling is the media of choice for connecting separate buildings

within a campus network. Even trunk connections between floors of a single

building benefit from the advantages of fiber optic media. In heavy industrial

settings, fiber optic media may provide the only reliable connectivity even

when the distances traveled are short. Moreover, a growing number of workstation interface cards now feature fiber optic connection.

12

The OmniHawk™ is packaged for a wide variety of media conversion applications. It can be wall mounted, rack mounted, or attached directly to the

DB9 connector of a workstation.

ALWAYS CONNECT

The OmniHawk™ is specifically designed with an intelligent connection algorithm which assures dependable communications. Whether it is attached

to passive or active devices, the OmniHawk™ will always make a good

connection. The fiber optic interface adheres to the IEEE 802.5j specification for fiber optic attachment.

1

Page 4

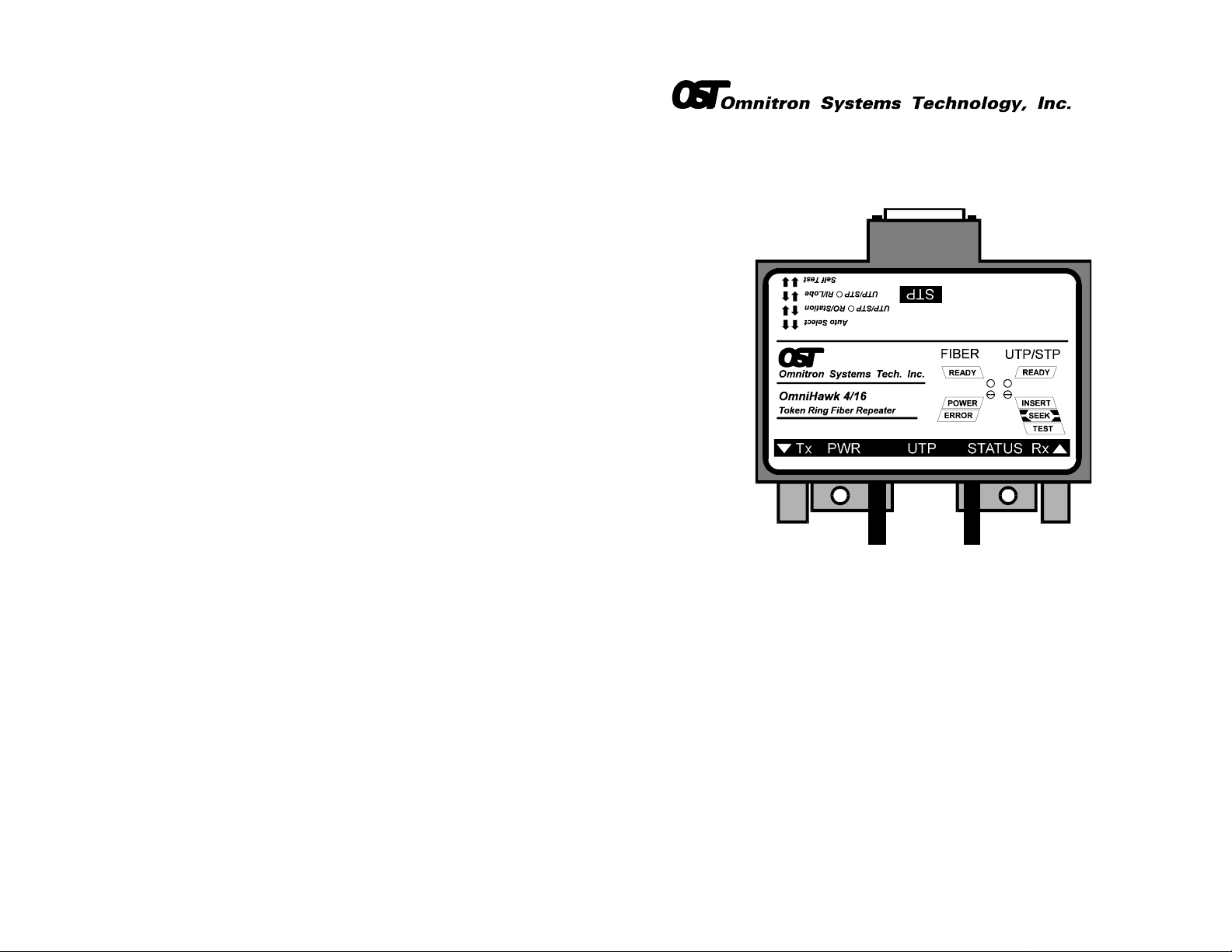

CONNECTORS, SWITCHES & INDICATORS

CONNECTORS

The OmniHawk™ has three interface connectors: a fiber optic transmitter

and receiver pair, an RJ45 jack, and a DB9 male connector.

The DB9 connector and the chassis are designed to attach directly to the

rear of a workstation network interface card. The jack screws ensure a solid

connection.

The RJ45 connector is designed to attach directly to a hub lobe or ring out

via a CAT-5 patch cable. The RJ45 connector may attach to a ring in with a

crossed patch cable (transmit and receive pairs crossed).

TECHNICAL SPECIFICATIONS

• Protocol: Token Ring (IEEE 802.5)

• Cables

Fiber Optic: Multi-mode glass fiber of sizes 50/125,

62.5/125, or 100/140 micron

STP: DB9 female

UTP: CAT-5 (EIA/TIA 568):

(lower grade wiring at shorter distances)

• Data Rate: 16 Mbps or 4 Mbps

Note that only one copper interface may be used at a time. Other connections are possible with special cables. Omnitron’s technical support department can assist you with your special needs.

SWITCHES

The OmniHawk™ has two switches which control the attachment mode.

The switches are located to the right of the DB9 connector.

Both switches are placed in the UP position at the factory. The following

table explains the switch settings.

ATTACHMENT MODE SWITCH 1 SWITCH 2

Automatic Sensing Up Up

UTP/STP --> RO or Station Up Down

UTP/STP --> RI or Lobe Down Up

• Supported Distances

Fiber Optic: 2.5 Km multi-mode

20 Km single-mode

UTP: 300 m

• Indicators

FO Ready Yellow - Green LED

Cu Ready Yellow - Green LED

Power/Error Yellow - Red LED

Insert Status Yellow - Green LED

• Dimensions: W: 3.46” x D: 2.83” x H: 0.78”

• Power: External Power Supply 9 VDC @ 1.2A

• Temperature

Operating: 0 to 45 degrees C

Storage: -40 to 75 degrees C

• Humidity: Up to 90% (non condensing)

Self Test / Media Test Down Down

CONNECTORS

In addition to the two switches there are four LED indicators in a 2 x 2

cluster. Refer to the drawing below.

2

11

Page 5

Yellow for 1/2 second then Green or Red

COPPER READY

fiber

copper

left)

INSERT STATUS

copper interfaces have

attempted

C. Hub Ring Out (RJ45) to distant hub Ring In (RJ45)

OST PART #

CONNECT FROM

CONNECT TO

Application C shows the Ring Out of one hub connected to the Ring In of

another hub via a pair of OmniHawk™ converters. Note that the cable from

the second OmniHawk™ to the Ring In is a crossed cable.

D. Distant Lobe Extension

Application D shows a distant hub in lobe extension via a pair of OmniHawk™

converters. In this configuration a standard CAT-5 cable connects the extended hub to the first OmniHawk™, fiber optic cables connect the two

converters, and another standard CAT-5 patch cable connects the second

OmniHawk™ to the target hub.

The bottom left LED is yellow / red, the remaining three LEDs are yellow /

green. The meaning of the LEDs are shown on the cover of the OmniHawk™

and in the tables below.

E. Other Applications

The above examples show the most common applications of the

OmniHawk™. Your network may require an application not listed here. The

configuration you need will be supported by the OmniHawk™ as long as

the correct cable is used. The fiber optic cables will always be the same.

The table below will guide you in selecting the proper copper cables, media

filters, and connector adapters.

9300-P45 OmniHawk™ RJ45 Lobe, RJ45

OmniHawk™ RJ45 Ring Out, RJ45

9301-P45X OmniHawk™ RJ45 Ring In, RJ45

OmniHawk™ RJ45 Workstation, RJ45

5700-CMF &

9301-P45X

5701-IP45 &

9300-P45

5701-IP45 &

9301-P45X

9310-IF9 OmniHawk™ DB9 Ring In, IBM Data Connector

9311-IF9X OmniHawk™ DB9 Ring Out, IBM Data Connector

9320-FM9 OmniHawk™ DB9 Workstation, DB9(if not directly

OmniHawk™ RJ45 Workstation, DB9(if not directly

attaching the OmniHawk™ to the

workstation)

OmniHawk™ RJ45 Lobe, IBM Data Connector

OmniHawk™ RJ45 Ring Out, IBM Data Connector

OmniHawk™ RJ45 Ring In, IBM Data Connector

OmniHawk™ DB9 Lobe, IBM Data Connector

attaching the OmniHawk™ to the

workstation)

POWER UP LED TEST

ALL LEDS MEANING

or 1/2 second

Any other behavior Failed Self Test, Call Technical Support

Self Test OK

The OmniHawk™ performs a self test every time power is newly applied.

OPERATIONAL MODES

FIBER READY

(top left)

GREEN

Off

POWER /

ERROR (bot.

YELLOW Power is on GREEN

RED

MEANING

Data received from

No data is being

received from Fiber

MEANING

An attachment error

occurred

(top right)

GREEN

OFF

(bot. right)

FLASHING

GREEN

OFF

MEANING

Data received from

No data is being

received from copper

MEANING

The fiber optic and

both actively inserted

Still attempting to

insert

Insertion is not being

10

3

Page 6

The operational modes are:

FIBER READY

r

1. AUTOMATIC SENSING

2. UTP/STP —> RO or STATION

3. UTP/STP —> RI or LOBE

The power / error LED turns red when an attachment error occurs. An error

can only occur when attaching to active devices (devices which signal for

insertion with phantom current or the fiber optic key). The error condition

occurs when copper device initiates the phantom current and the fiber optic

device initiates the fiber optic key. In Token Ring, the active insertion process may only be directed from one direction.

SELF TEST / MEDIA TEST MODE

COPPER

(top left)

GREEN

OFF

MEANING

Data received from

fiber

No data is being

received from fiber

READY (top

right)

GREEN

OFF

MEANING

Data received from

copper

No data is being

received from coppe

APPLICATIONS

The following drawing illustrates three different applications of the

OmniHawk™.

DIAGNOSTIC FEATURES

The OmniHawk™ diagnostic features make it easy to install and maintain.

There are four levels of diagnostics: Power-On LED Test, Self Test / Media

Test, Installation Test, and run-time ready and error monitoring.

POWER /

ERROR (bot.

left)

YELLOW Power is on YELLOW

MEANING

INSERT

STATUS (bot.

right)

4

MEANING

The OmniHawk™ is

in the self test /

media test mode.

A. STP Workstation (DB9) to distant hub (RJ45)

Application A shows an STP workstation connecting via its DB9 connector

directly to one OmniHawk™, which is connected to a second OmniHawk™

via fiber optic cables. The last connection to the hub is made via a standard

CAT-5 patch cable.

B. Fiber optic Workstation to hub (RJ45)

Application B shows a fiber optic workstation connecting to an OmniHawk™

vi its fiber optic cables. The OmniHawk™ connects to the hub via a standard CAT-5 patch cable.

9

Page 7

To test the integrity of copper patch cables and any intervening baluns connect the OmniHawk™ to an unused lobe of any powered hub. If the cable is

unbroken, the copper ready LED will light green. If the cable is broken, the

LED will be off.

Note that the power / error LED and the test mode LED will both be yellow.

NOTE: TURN OFF THE SELF TEST / MEDIA TEST MODE TO RETURN

TO NORMAL OPERATIONAL MODES.

POWER-ON LED TEST

Every time power is newly applied to the OmniHawk™ the LEDs will flash

through all possible colors to give the user the assurance that other diagnostic information may be correctly interpreted. The LEDs will flash all yellow, then either green or red. After that, the LED test is over and the LEDs

will illuminate according to the mode (as set by the switches) and the current media connections.

SELF TEST / MEDIA TEST

The self test / media test ensures that the OmniHawk™ is fully operational.

Testing occurs when the switches both set to the DOWN position. The bottom two LEDs will both illuminate yellow indicating that power is on and that

the unit is in the test mode. The testing checks both the data passing capability of the OmniHawk™ and the physical continuity of the media. For both

fiber optic and copper media test data is looped back to the OmniHawk™.

When a looped back fiber cable is connected from the transmit (TX) to the

receive (RX) fiber optic connectors, the fiber optic ready LED lights green.

When a CAT-5 patch cable is connected from the OmniHawk™ to an unused lobe of a hub, the copper ready LED lights green. If good connections

are made and the corresponding LED does not illuminate, then the media is

broken. This CAT-5 cable used in this test may be inserted into an operating hub since the OmniHawk™ will not assert phantom current during the

test mode (and consequently will not enter the network).

INSTALLATION TEST

The OmniHawk™ tests for proper installation and lights the power / error

LED red if a wrong connection is made. This check will only be made when

the connecting devices are stations and/or active hubs. Among active devices, there are initiators and echoers. An initiator is a device that either

sends phantom current or the fiber optic insertion key. An echoer is a device that receives phantom current or the fiber optic insertion key.

The OmniHawk™ installation test feature warns the installer that an initiator

has been connected to both the fiber optic interface and to the copper interface. Since it doesn’t make sense to connect two ring out (RO) trunk lines

together, the power / error LED warns of this condition by lighting red.

8

5

Page 8

RUN-TIME ACTIVITY & ERROR MONITORING

During normal operation the fiber optic and copper ready LEDs provide

continuous diagnostic information. These LEDs detect and display token

ring activity.

SITE REQUIREMENTS

A power outlet should be available within 5 ft. of the unit. The following

power supply modules are required for the following power outlets:

The insert status LED informs the user of the insert status of the fiber optic

and copper media. This LED lights green when both the active signaling

fiber optic and copper devices have successfully reached insertion.

The insert status LED flashes when the OmniHawk™ has received phantom current on its copper side but has not yet achieved insertion on its fiber

optic side, or conversely, when the unit has received the fiber optic key on

its fiber side but has not yet sensed a phantom current echoer on its copper

side.

When the OmniHawk™ connects to passive devices, the insert status LED

will always be off.

UNPACKING

a. Visual Inspection - before unpacking, a visual inspection should be con-

ducted in order to detect any physical damage to the equipment. Any

evidence of damage should be noted and reported immediately.

b. Unpacking - place shipping container on a flat surface, cut straps or

tape, open top. Take out each item carefully and place securely on a

clean flat surface. Return all packing material into container (foam, boxes

etc.), close and store away for future re-use.

c. Inspection - Inspect each item for any apparent damage, any evidence

of damage should be noted and reported immediately.

d. Content - Review the content; the following items should be included:

MODEL POWER OUTLET

3900 110 Volt - 60 Hz

3900-2 220 Volt - 50 Hz

3910 110 Volt - 60 Hz

3910-2 220 Volt - 50 Hz

NORMAL CONFIGURATION

a. Attach the workstation or hub with the appropriate cable to the

OmniHawk™.

b. Plug the external power supply into the appropriate AC wall outlet.

c. Plug the power jack into the OmniHawk™ power connector.

f. The LEDs will flash during their self test, then settle according to the

current connection status.

Refer to the APPLICATIONS section for useful application information.

ALTERNATE POWER SOURCE

Some Token Ring network interface cards supply power via the DB-9 connector. Compatible network interface cards supply +5V on pin 3 and ground

on pins 2, 4, 7, and 8. When power from the network interface card is available, the OmniHawk™ will use that power and the external power supply

may be disconnected.

• OmniHawk™ module (1)

• power supply module

• User’s Manual (the document you are now reading)

Please note any missing items or discrepancies and report them immediately.

6

INSTALLATION TEST CONFIGURATIONS

The OmniHawk™ supports the following media test configuration.

Loopback Media Test

To test the integrity of fiber optic media connect the fiber optic patch cable

in a loopback fashion (i.e., one end in the transmit port and the other in the

receive port). If the fiber is unbroken, the OmniHawk™ fiber ready LED will

illuminate green. If the fiber is partially or completely broken, the LED will be

off.

7

Loading...

Loading...