Page 1

OmniConverter

GHPoE/S

User Manual

Warranty

This product is warranted to the original purchaser against defects in material and

workmanship for a period of two (2) years from the date of shipment. A LIFETIME

warranty may be obtained by the original purchaser by registering this product within

ninety (90) days from the date of shipment at www.omnitron-systems.com/support.

During the warranty period, Omnitron will, at its option, repair or replace a product

which is proven to be defective with the same product or with a product with at least

the same functionality.

For warranty service, the product must be sent to an Omnitron designated facility, at

Buyer’s expense. Omnitron will pay the shipping charge to return the product to Buyer’s

designated US address using Omnitron’s standard shipping method.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from improper or inadequate

®

use and/or maintenance of the equipment by Buyer, Buyer-supplied equipment, Buyer-

supplied interfacing, unauthorized modications or tampering with equipment (including

removal of equipment cover by personnel not specically authorized and certied by

Omnitron), or misuse, or operating outside the environmental specication of the product

(including but not limited to voltage, ambient temperature, radiation, unusual dust, etc.),

or improper site preparation or maintenance.

No other warranty is expressed or implied. Omnitron specically disclaims the implied

warranties of merchantability and tness for any particular purpose.

The remedies provided herein are the Buyer’s sole and exclusive remedies. Omnitron

shall not be liable for any direct, indirect, special, incidental, or consequential damages,

whether based on contract, tort, or any legal theory.

Environmental Notices

The equipment covered by this manual must be disposed of or recycled in accordance

with the Waste Electrical and Electronic Equipment Directive (WEEE Directive) of

the European Community directive 2012/19/EU on waste electrical and electronic

equipment (WEEE) which, together with the RoHS Directive 2011/65/EU, for electrical

and electronic equipment sold in the EU after July 1, 2006. Such disposal must follow

national legislation for IT and Telecommunication equipment in accordance with the

WEEE directive: (a) Do not dispose waste equipment with unsorted municipal and

household waste. (b) Collect equipment waste separately. (c) Return equipment using

collection method agreed with Omnitron.

The equipment is marked with the WEEE symbol shown to indicate that it must be

collected separately from other types of waste. In case of small items the symbol may

be printed only on the packaging or in this manual. If you have questions regarding

the correct disposal of equipment go to www.omniton-systems.com/support or e-mail

to Omnitron at intlinfo@omnitron-systems.com.

38 Tesla, Irvine, CA 92618 USA

Phone: (949) 250-6510; Fax: (949) 250-6514

©2019 Omnitron Systems Technology, Inc.

Page 2

Page 2

OmniConverter® GHPoE/S

User Manual

PRODUCT OVERVIEW

The OmniConverter GHPoE/S is a multi-port media converter that converts

10/100/1000BASE-T copper to 1000BASE-X or 100BASE-X ber and supports Power

over Ethernet up to 60 watts. Classied as Power Sourcing Equipment (PSE), the

GHPoE/S can provide power to one or two Powered Devices (PDs) using standard

UTP cables that carry the Ethernet data.

The main function of the PSE is to automatically detect a PD, classify the PD and supply

power to the link (only if a PD is detected). The PSE detects a PD by applying a low

voltage on the cable and then looks for a signature from the attached PD. A compliant

PD is required to have the valid signature. Classication of the PD is done to determine

the maximum power levels required by the PD. After the PD is classied, the PSE will

allow the PD to draw power up to the maximum classication level.

The GHPoE/S automatically preforms the detection, classication and powering

functions. It supports IEEE 802.3af PoE (15W) and IEEE 802.3at PoE+ (30W) standard.

It can also provide up to 60W PoE per RJ-45 port for latest high-power outdoor PDs

such as cameras and Wi-Fi access points.

Installation Procedure

1) Congure DIP-switches

2) Apply AC Power

3) Apply DC Power

4) Connect Cables

5) Verify Operation

1) Congure DIP-switches

DIP-switches are located on the side of the OmniConverter module. The DIP-switches

are used to congure ports, link modes and PoE/PSE options.

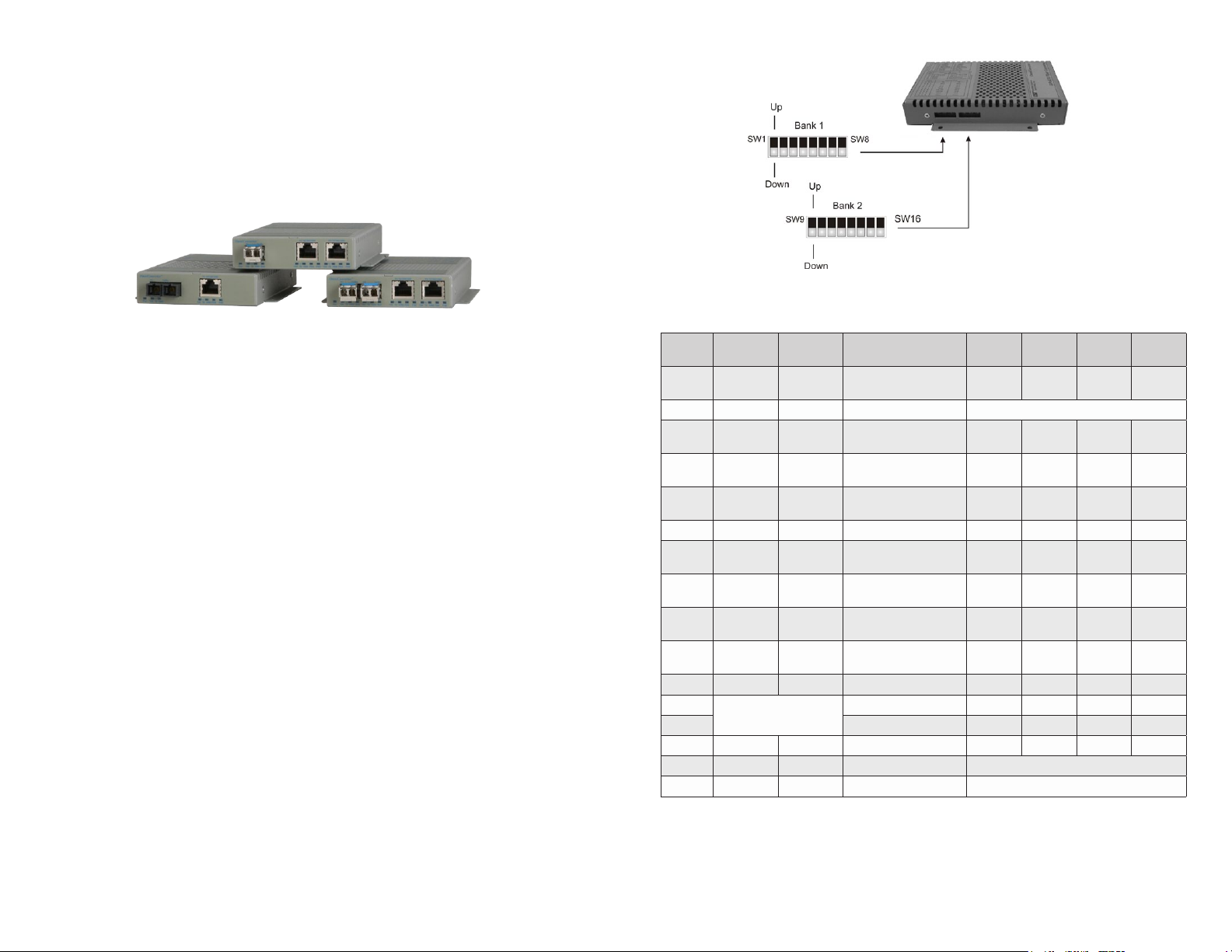

DIP-switch Bank Locations

The table below provides a description of each DIP-switch position and function.

Switch DOWN UP Function

1 Auto

2 N/A N/A N/A N/A

3 Auto Man

4 100 10

5 FDX HDX

6 Off On Pause Capability x x x x

7 Enabled Disabled

8 Enabled Disabled

9 Normal Forced On

10 Normal Forced On

11 On Off MAC Learning N/A x N/A x

12

13 Link Mode Selection x x x x

14 Off On PSE Reset x x x x

15 N/A N/A N/A N/A

16 N/A N/A N/A N/A

See DIP-switch

Forced

100M

Description

Port 1

Fiber Speed

Port 2

Auto/Manual

Port 2 Speed

(Only in MAN mode)

Port 2 Duplex

(Only in MAN mode)

Port 2

PSE Power

Port 3

PSE Power

Port 2

PSE Power Override

Port 3

PSE Power Override

Link Mode Selection x x x x

1 FF

1 RJ-45

N/A x N/A x

N/A x N/A x

1 FF

2 RJ-45

x x x x

x x x x

x x x x

x x x x

x x x x

x x x x

1 SFP

1 RJ-45

2 RJ-45

1 SFP

Page 3

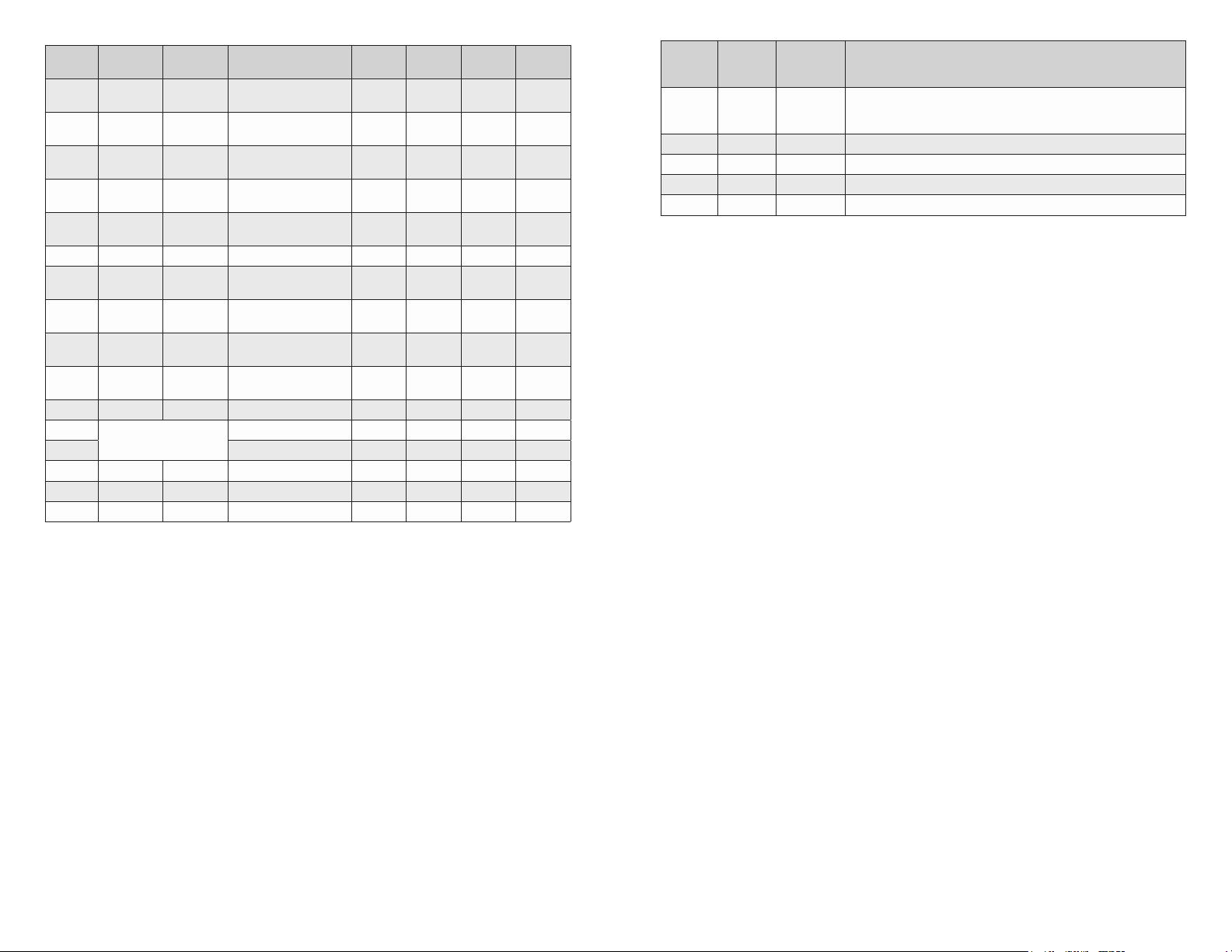

DIP-switch Denitions for Models with 1 Fiber Port

Page 4

Page 3

Switch DOWN UP Function

1 Auto

2 Auto

3 Auto Man

4 100 10

5 FDX HDX

6 Off On Pause Capability x x x x

7 Enabled Disabled

8 Enabled Disabled

9 Normal Forced On

10 Normal Forced On

11 On Off MAC Learning x x x x

12

13 Link Mode Selection x x x x

14 Off On PSE Reset x x x x

15 Off On Redundant Fiber Link x x x x

16 Off On Return to Port 1 x x x x

See DIP-switch

Forced

100M

Forced

100M

Description

Port 1

Fiber Speed

Port 2

Fiber Speed

Port 3

Auto/Manual

Port 3 Speed

(Only in MAN mode)

Port 3 Duplex

(Only in MAN mode)

Port 3

PSE Power

Port 4

PSE Power

Port 3

PSE Power Override

Port 4

PSE Power Override

Link Mode Selection x x x x

2 FF

1 RJ-45

N/A x N/A x

N/A x N/A x

2 FF

2 RJ-45

x x x x

x x x x

x x x x

x x x x

x x x x

x x x x

x x x x

2 SFP

1 RJ-45

2 SFP

2 RJ-45

DIP-switch Denitions for Models with 2 Fiber Port

SW1 and SW2: F/O Speed “100/1000”

These DIP-switches congure the speed of the transceivers installed in the SFP ports. If

these DIP-switches are in the Down (default) position, the ports will automatically detect

the data rate of the transceivers installed and operate at 100M or 1000M accordingly.

If these DIP-switches are in the UP position, a 100M capable transceivers must be

installed in the SFP ports.

When an RJ-45 transceiver is installed in a SFP receptacle or for xed ber models,

setting this DIP-switch to Up “100” position enables the port to operate at 100Mbps*.

*Special compatibility mode for the xed ber models only.

SW3, SW4 and SW5: RJ-45 Conguration

These DIP-switches congure the rst RJ-45 port on the module (Port 2 on a single ber

model and Port 3 on a dual ber model). The second RJ-45 port is always congured

for auto-negotiation.

When DIP-switch SW3 is in the Down “AN” position, SW4 and SW5 are ignored.

SW3

RJ-45

AN/Man

AN 10 or 100 FDX or HDX

MAN 100 FDX The RJ-45 port is set to manual negotiation and is forced to 100FDX.

MAN 100 HDX The RJ-45 port is set to manual negotiation and is forced to 100HDX.

MAN 10 FDX The RJ-45 port is set to manual negotiation and is forced to 10FDX.

MAN 10 HDX The RJ-45 port is set to manual negotiation and is forced to 10HDX.

SW4

RJ-45

100/10

SW5

RJ-45

FDX/HDX

Mode of Operation

The RJ-45 port is set to auto-negotiation with the following modes

advertised: 1000FDX, 1000HDX, 100FDX, 100HDX, 10FDX,

10HDX

RJ-45 Port Conguration Matrix

SW6: Pause “On/Off”

In auto-negotiation mode, setting this DIP-switch to the Up “On” position allows the

unit to advertise Symmetrical and Asymmetrical Pause capability. In auto-negotiation

mode, setting the DIP-switch to the Down “Off” position allows the unit to advertise no

Pause capability. In the manual mode, this DIP-switch determines the Symmetrical

Pause behavior of the ports.

SW7: Power Sourcing “Enable/Disable”, RJ-45 Port

The OmniConverter automatically detects the attached PD and provides the equipment

with the necessary power.

This DIP-switch controls the power sourcing for rst RJ-45 port on the module (Port 2

on the single ber models and Port 3 on dual ber models). When this DIP-switch in

the Down “On” position, the power sourcing is enabled. When the DIP-switch is in the

Up “Off” position, the power sourcing is disabled.

SW8: Power Sourcing “Enable/Disable”, RJ-45 Port

This DIP-switch controls the power sourcing for the second RJ-45 port on the module

(Port 3 on the single ber models and Port 4 on dual ber models). When this DIP-

switch in the Down “On” position, the power sourcing is enabled. When the DIP-switch

is in the Up “Off” position, the power sourcing is disabled.

SW9, SW10 “Normal/Forced” PoE Power Mode

This DIP-switch allows the PoE power to be forced ON when connected to a PD with

non-standard detection characteristics.

DIP-switch SW9 controls the forced capability for the rst RJ-45 port on the module

(Port 2 on the single ber models and Port 3 on dual ber models) and SW10 controls

the forced capability for the second RJ-45 port on the module (Port 3 on the single ber

models and Port 4 on dual ber models).

When these DIP-switches are in the Down “Normal” position, the port will automatically

preform the detection, classication and powering functions for the attached PD. When

these DIP-switches are in the Up “Forced” position, a maximum of 60 watts of power

will be available to the PD.

SW11: MAC Learning “On/Off”

When this DIP-switch is in the Down “On” position, all ports on the module will learn the

source MAC address of each received packet and store the address so packets destined

for the stored addresses can be forwarded to the appropriate interface on the module.

Page 5

Page 6

Page 4

When the DIP-switch is in the Up “Off” position, learning is turned off and all received

packets are forwarded to all ports.

Models with one ber port and one copper port have MAC learning disabled.

SW12 and SW13: Link Modes

The OmniConverter supports Link Segment and Asymmetrical Link Propagate.

Link Segment

In Link Segment mode, all ports operate independently. A loss of a receive link signal

will only affect the port detecting the loss of signal. All the other ports will continue to

generate a link signal. A loss of link on the RJ-45 port will only affect the RJ-45 port,

and the other ports will remain unaffected.

Asymmetrical Link Propagate

In Asymmetrical Link Propagate mode, faults are propagated based on the port notation.

Port 1 to Port 2 notation indicates the direction the loss of link signal will propagate.

A loss of receive link on the ber optic Port 1 causes the RJ-45 Port 2 to drop its link

due to the propagated state (Port 1 to Port 2). The loss of link on the RJ-45 Port 2

does not cause the loss of link to propagate. The loss only propagates in the Port 1 to

Port 2 direction.

Note: A loss of link or loss of signal is when the optical receiver on the media

converter can no longer detect the presence of an optic signal.

Note: On models with 2 ber ports or 2 RJ-45 ports, both ports of the same media

type must be in link fault condition before the fault will propagate.

SW12 SW13 Function

DOWN DOWN Link Segment (LS)

Asymmetrical Link Propagate Port 1 to Port 2 (1+1 - 2 Port models),

UP DOWN

DOWN UP

UP UP Invalid Conguration

Port 1 to Port 2 and Port 3 (1+2 - 3 Port models),

Port 1 and Port 2 to Port 3 (2+1 - 3 Port models) and

Port 1 and Port 2 to Port 3 and Port 4 (2+2 - 4 Port models).

Asymmetrical Link Propagate Port 2 to Port 1 (1+1 - 2 Port models),

Port 2 and Port 3 to Port 1 (1+2 - 3 Port models)

Port 3 to Port 1 and Port 2 (2+1 - 3 Port models)

and Port 3 and Port 4 to Port 1 and Port 2 (2+2 - 4 Port models)

SW15 controls the port redundancy mode of the module. When SW15 is in the Down

“Off” (default) position, the ber ports operate in a non-redundant (independent) mode.

When SW15 is in the Up “On” position, the ber ports operate as redundant links. A

fault on the primary ber port (Port 1), will cause a fail over to the secondary ber port

(Port 2) within 50msec.

SW16: Return to P1 “Off/On”

SW16 is only valid on models with 2 ber ports.

SW16 enables the module to return to the primary ber port (Port 1) after the ber link

has been restored and stable for 6 seconds. When SW16 is in the Down “Off” position,

return to primary is disabled (inactive). When the SW16 is in the Up “On” position,

return to primary is enabled.

When SW15 is in the Down “Off” position, SW16 is ignored.

Switch 15

P1+P2 Redun

DOWN (Off) DOWN (Off) Non-redundant mode - normal mode

DOWN (Off) UP (On) Non-redundant mode - normal mode

UP (On) DOWN (Off) Redundant mode - no return to primary

UP (On) UP (On) Redundant mode - return to primary

Switch 16

Rtn P1

Function

Port Redundancy Modes

2) APPLY AC POWER

To power the unit using the AC/DC adapter, connect the DC plug at the end of the

wire on the AC/DC adapter to the DC connector on the unit. Then connect the AC/DC

adapter to the AC outlet. Conrm that the unit has powered up properly by checking

the Power LED located on the front of the installed module.

Installation of the equipment should be such that the air ow in the front, back, side

and top vents of the chassis are not compromised or restricted.

If the installation requires grounding, secure the grounding wire to the ground screw.

See the gure below for the location of the grounding screw.

Link Modes

SW14: Power Sourcing Reset “Off/Reset”

The OmniConverter can be congured to reset the PoE output power for 2 seconds

after a loss of receive link on any ber port. This feature is typically used to allow a PD

to re-initialize after a failure on the incoming ber.

When this DIP-switch is in the Up “Reset” position, the module will disable PoE output

power for 2 seconds following a loss of receive link on any ber port. When this DIPswitch is in the Down “Off” position, PoE output power does not reset on ber link loss.

SW15: Link Redundant “Off/On”

SW15 is only valid on models with 2 ber ports. Port redundancy is available when

connected to Omnitron and third party devices with 2 ber ports.

Page 7

Rear View with AC Power Connector

Page 8

Page 5

WARNING!!!

WARNING REGARDING EARTHING GROUND:

o

o

o

o

This equipment shall be connected to the DC supply

system earthing electrode conductor or to a bonding

jumper from an earthing terminal bar or bus to which the

DC supply system earthing electrode is connected.

This equipment shall be located in the same immediate

area (such as adjacent cabinets) as any other equipment

that has a connection between the earthed conductor of

the same DC supply circuit and the earthing conductor,

and also the point of earthing of the DC system. The DC

system shall not be earthed elsewhere.

The DC supply source is to be located within the same

premises as this equipment.

There shall be no switching or disconnecting devices in

the earthed circuit conductor between the DC source and

the earthing electrode conductor.

NEVER ATTEMPT TO OPEN THE CHASSIS OR

SERVICE THE POWER SUPPLY. OPENING THE

CHASSIS MAY CAUSE SERIOUS INJURYOR DEATH.

THERE ARE NO USER REPLACEABLE OR

SERVICEABLE PARTS IN THIS UNIT.

3) APPLY DC POWER

A power source should be available within 5 ft. of the chassis. The over current protection

for connection with centralized DC shall be provided in the building installation, and shall

be a UL listed circuit breaker rated 20 Amps, and installed per the National Electrical

Code, ANSI/NFPA-70.

The GHPoE requires 48 to 57VDC @ 2.27 Amp max rated power when powering two

60W PoE PDs. Appropriate overloading protection should be provided on the DC

power source outlets utilized.

WARNING: OnlyaDC power source that complies with

safety extra low voltage (SELV) requirements can be

connected to the DC-input power supply.

WARNING: Note the wire colors used in making the positive, negative and ground

connections. Use the same color assignment for the connection at the circuit

breaker.

Connect the power wires to the circuit breaker and switch the circuit breaker ON. If any

modules are installed, the Power LED should indicate the presence of power.

Installation of the equipment should be such that the air ow in the front, back, side

and top vents of the chassis are not compromised or restricted.

If the installation requires grounding, secure the grounding wire to the ground screw.

See the gure below for the location of the grounding screw.

Rear View with DC Terminal Connector

WARNING!!!

NEVER ATTEMPT TO OPEN THE CHASSIS OR

SERVICE THE POWER SUPPLY. OPENING THE

CHASSIS MAY CAUSE SERIOUS INJURYOR DEATH.

THERE ARE NO USER REPLACEABLE OR

SERVICEABLE PARTS IN THIS UNIT.

Locate the DC circuit breaker of the external power source, and switch the circuit

breaker to the OFF position.

Prepare a power cable using a three conductor insulated wire (not supplied) with a 14

AWG gauge minimum. Cut the power cable to the length required.

Strip approximately 3/8 of an inch of insulation from the power cable wires.

Connect the power cables to the terminal by fastening the stripped ends to the DC

power connector.

Page 9

4) CONNECT CABLES

a. When using the SFP model, insert the SFP Fiber transceiver into the SFP receptacle

on the front of the module.

NOTE: The release latch of the SFP Fiber transceiver must be in the closed

(up) position before insertion.

b. Connect an appropriate multimode or single-mode ber cable to the ber port on

the front of the module. It is important to ensure that the transmit (TX) is attached

to the receive side of the module at the other end and the receive (RX) is attached

to the transmit side. When using single-ber (SF) models, the TX wavelength must

match the RX wavelength at the other end and the RX wavelength must match the

TX wavelength at the other end.

c. Connect the Ethernet 10/100/1000 RJ-45 port via a Category 5 or better cable to

an external 10BASE-T, 100BASE-TX or 1000BASE-T Ethernet device.

Page 10

Page 6

5) VERIFY OPERATION

Once the module has been installed and congured per steps 1 - 4, verify the module

is operational by viewing the LED indicators.

The Power LED indicates the module is receiving power.

The Fiber Optic LEDs indicates the ber optic connection has been established.

The RJ-45 10/100/1000 LEDs indicate the speed of the UTP connection.

The PSE LED indicates the module has established a successful detection of a PD

and is supplying Power over Ethernet.

Power LED Indicators

Legend Indicator Description

OFF Unit not powered

Pwr

Green - ON Unit powered

Amber - ON Over temperature condition

Power LED Indicators

Fiber Port LED Indicators

Legend Indicator Description

OFF No link

Green - ON Port linked at 100Mbps

100

1000

10

(100+1000)

Stat

Green - Blinking at 10Hz Port data activity at 100Mbps

Green - Blinking at 1Hz Port linked at 100Mbps and in redundant standby mode

Amber - Blinking at 1Hz

OFF No link

Green - ON Port linked at 1000Mbps

Green - Blinking at 10Hz Port data activity at 1000Mbps

Green - Blinking at 1Hz Port linked at 1000Mbps and in redundant standby mode

Amber - Blinking at 1Hz Port linked at 1000Mbps and receiving AN Remote Fault

OFF No link

Green - ON Port linked at 10Mbps

Green - Blinking at 10Hz Port data activity at 10Mbps

Green - Blinking at 1Hz Port linked at 10Mbps and in redundant standby mode

OFF

Green - ON

Amber - ON

Port linked at 100Mbps and receiving Far End Fault Indicator

(FEFI)

Transceiver does not support digital diagnostics or no

transceiver (SFP) is installed

Transceiver (SFP) supports digital diagnostics and no alarm is

detected

Transceiver (SFP) supports digital diagnostics and alarms are

present

UTP Port Indicators

Legend Indicator Description

OFF No link

100

1000

10

(100+1000)

FDX

PSE

Green - ON Port linked at 100Mbps

Green - Blinking at 10Hz Port data activity at 100Mbps

OFF No link

Green - ON Port linked at 1000Mbps

Green - Blinking at 10Hz Port data activity at 1000Mbps

OFF No link

Green - ON Port linked at 10Mbps

Green - Blinking at 10Hz Port data activity at 10Mbps

Amber - Blinking at 1Hz Port linked at 10Mbps and receiving AN Remote Fault

Green - ON

OFF

Green - ON Port PSE is active

Amber - ON Port PSE inactive

OFF Port PSE disabled

Port is congured for full-duplex via DIP-switch or has

negotiated to full-duplex in AN mode

Port is congured for half-duplex via DIP-switches or Port 2 has

negotiated to half-duplex in AN mode or Port 2 in AN mode has

not established the correct connection

UTP LED Indicators

SPECIFICATIONS

AC/DC Adapter Temperature Derating

Total Available Wattage to RJ-45 Ports

Model RJ-45 Ports

GHPoE/S

1 60 watts Full Power Full Power Full Power Full Power 50 watts

2 120 watts Full Power 100 watts 80 watts 60 watts 50 watts

Watts

Required

°C 50°C 60°C 70°C

40

75°C

The AC/DC Adapter Temperature derating table is not applicable to models with DC

Terminal (see Ordering table for Direct DC -9 option). The DC Terminal models will

provide full PoE power over the operating temperature range of the module as long as

the DC input power meets the requirements stated in the specication table.

Fiber LED Indicators

Page 11

Page 12

Page 7

OmniConverter GHPoE/S

Description

Standard Compliances

PoE Supported Modes IEEE Alternate A (Alt A) and 4 Pair

Regulatory Compliances UL, CE, FCC Class A, RoHS, WEEE, REACH

Frame Size Up to 10,240 bytes

Port Types

Cable Types

AC Power Requirements

(Models with AC/DC Adapters)

DC Power Requirements

(Models with DC Terminals)

Dimensions W: 4.5” x D: 6.0” x H 1.0” L: 114.3 mm x B: 152.4 mm x H: 25.4 mm

Weight

Operating Temperature

(See Temperature Derating Table)

Humidity 5 to 95% (non-condensing)

Altitude -100m to 4,000m

MTBF (hours)

Warranty Lifetime warranty with 24/7/365 free Technical Support

10/100/1000BASE-T to 1000BASE-X or 100BASE-X Fiber Media

Converter with 60W PoE

IEEE 802.3,

IEEE 802.3af (15.40 watts max),

IEEE 802.3at (30 watts max)

High Power 60W PoE

10/100/1000BASE-T (RJ-45)

Copper:

Fiber: 100BASE-X (SFP)

1000BASE-X (ST, SC, LC, SFP)

1000BASE-BX (SC, SFP)

EIA/TIA 568A/B, Cat 5 UTP and higher

Copper:

Fiber: Multimode: 50/125, 62.5/125µm

Single-mode: 9/125µm

1 RJ-45 Port

100 - 240VAC/47 to 63Hz

0.62A @ 120VAC (typical)

2 RJ-45 Ports

100 - 240VAC/50 - 60Hz

1.19A @ 120VAC (typical)

1 RJ-45 Port

+/-48 to +/-57VDC;

1.18A @ 56VDC

3 Pin Terminal (isolated)

2 RJ-45 Ports

+/-48 to +/-57VDC;

2.27A @ 56VDC

3 Pin Terminal (isolated)

A minimum DC input voltage of 50VDC is required to guarantee

25.5 watts (for 802.3at) or 51 watts (for HPoE) at the end of 100

meters on Cat 5 cable or better.

Module Only: 1.1 lbs.; 498.9 grams

Module w/ Adpater:

Commercial: 0 to 50°C

Wide: -40 to 60°C (-20°C AC cold start)

Extended: -40 to 75°C (-20°C AC cold start)

Storage: -40 to 80°C

Module Only: 474,000

AC/DC Adapter: 100,000

2.8 lbs.; 1256.4 grams

CUSTOMER SUPPORT INFORMATION

If you encounter problems while installing this product, contact Omnitron Technical

Support:

Phone: (949) 250-6510

Fax: (949) 250-6514

Address: Omnitron Systems Technology, Inc.

38 Tesla

Irvine, CA 92618, USA

Email: support@omnitron-systems.com

URL: www.omnitron-systems.com

General and Copyright Notice

This publication is protected by U.S. and international copyright laws. All rights reserved.

The whole or any part of this publication may not be reproduced, stored in a retrieval

system, translated, transcribed, or transmitted, in any form, or by any means, manual,

electric, electronic, electromagnetic, mechanical, chemical, optical or otherwise, without

prior explicit written permission of Omnitron Systems Technology, Inc.

The following trademarks are owned by Omnitron Systems Technology, Inc.: FlexPointTM,

FlexSwitchTM, HybridNID®, iConverter®, miConverterTM, NetOutlook®, OmniLightTM,

OmniConverterTM, Omnitron Systems Technology, Inc.TM, OSTTM and the Omnitron logo.

All other company or product names may be trademarks of their respective owners.

The information contained in this publication is subject to change without notice. Omnitron

Systems Technology, Inc. is not responsible for any inadvertent errors.

Page 13

040-09500-001D 6/19

Page 14

Loading...

Loading...