Page 1

iConverter® Gx User Manual

Port 1 (P1)

Port 2 (P2)

iConverter Gx Dual Fiber Modules

Fiber Type Distance

MM 220m/550m - 8502-0 8504-0 8506-0

SM 12 km - 8503-1 8505-1 8507-1

SM 34 km - 8503-2 - 85 07-2

SM 80 km - 8503-3 - 85 07-3

SM 140 km - 8503-5 - -

Fiber /

Connector

SM / SC 20 km 8510-1 8511-1

SM / SC 40 km 8510-2 8511-2

For wide temperature (-40 to 60º C), add a "W" to the end of the

model number. Consult factory for extended temperature(-40 to

+75º C) models.

When using single-fiber (SF) media converter models, the Tx

wavelength on one end has to match the Rx wavelength on the

other.

*A minimum of 3dB of attenuation is required for these models.

For c o mp l e te fibe r s p ecif icat i o ns , r e fe r to thi s p r o d uc t' s d a ta sheet .

iConverter Gx Single-Fib e r Mo d ules

Distance

Type

Connector Type

ST SC MT-RJ LC

Tx: 1310 nm,

Rx: 1550 nm

Tx: 1550 nm,

Rx: 1310 nm

ABOUT THIS MANUAL:

This document supports revision “xx/07” of the iConverter

Gx. Please refer to the serial number label on the Gx for

the revision number of your product. This revision

incorporates the following improvements to the Gx:

1. Enhanced UTP Auto-Negotiation options.

2. Compatibility with NetOutlook and NMM version 3.2

or later.

OVERVIEW:

The iConverter Gx media converter supports the IEEE

802.3 Ethernet Standard and converts 1000BASE-X

fiber to 1000BASE-T unshielded twisted pair (UTP).

Models are available for multimode (MM) and singlemode (SM), dual fiber and single-mode single-fiber.

The Gx supports UTP Half-Duplex and Full-Duplex

auto-negotiation and features UTP automatic crossover

for easy attachment to hubs, switches and workstations.

The Gx can be used in an unmanaged or managed fashion.

When unmanaged, it can be installed in a chassis without

an iConverter Network Management Module (NMM). To

be managed, an NMM or a media converter with integrated

management, such as the GX/TM, must be installed in

the same chassis.

MOUNTING AND CABLE ATTACHMENT:

iConverter modules are hot-swappable and can be installed

into any iConverter chassis.

Installation Instructions

1. Carefully slide the

slot, aligning the module with installation guides. Ensure

that module is firmly seated against backplane.

iConverter module into installation

Page 2 Page 3

2. Secure the module by securing panel fastener screw

(attached to module) to the front of the chassis.

3. Attach the UTP port via a category 5 cable to a

1000BASE-TX Ethernet device.

4. Attach the fiber port via an appropriate fiber cable

(multimode or single-mode) to a 1000BASE-FX Fast

Ethernet device. The iConverter transmit (TX) must

attach to the receive side on other device; the receive

(RX) must attach to the transmit.

5. When using single-fiber (SF) media converter models,

the TX wavelength on one end has to match the RX

wavelength on the other. Based on this guideline, SF

media converter models must be used in pairs, such

as the 8510-1 matched with the 8511-1.

LINK MODES:

In order to accommodate different user needs, the Gx

supports three different linking modes.

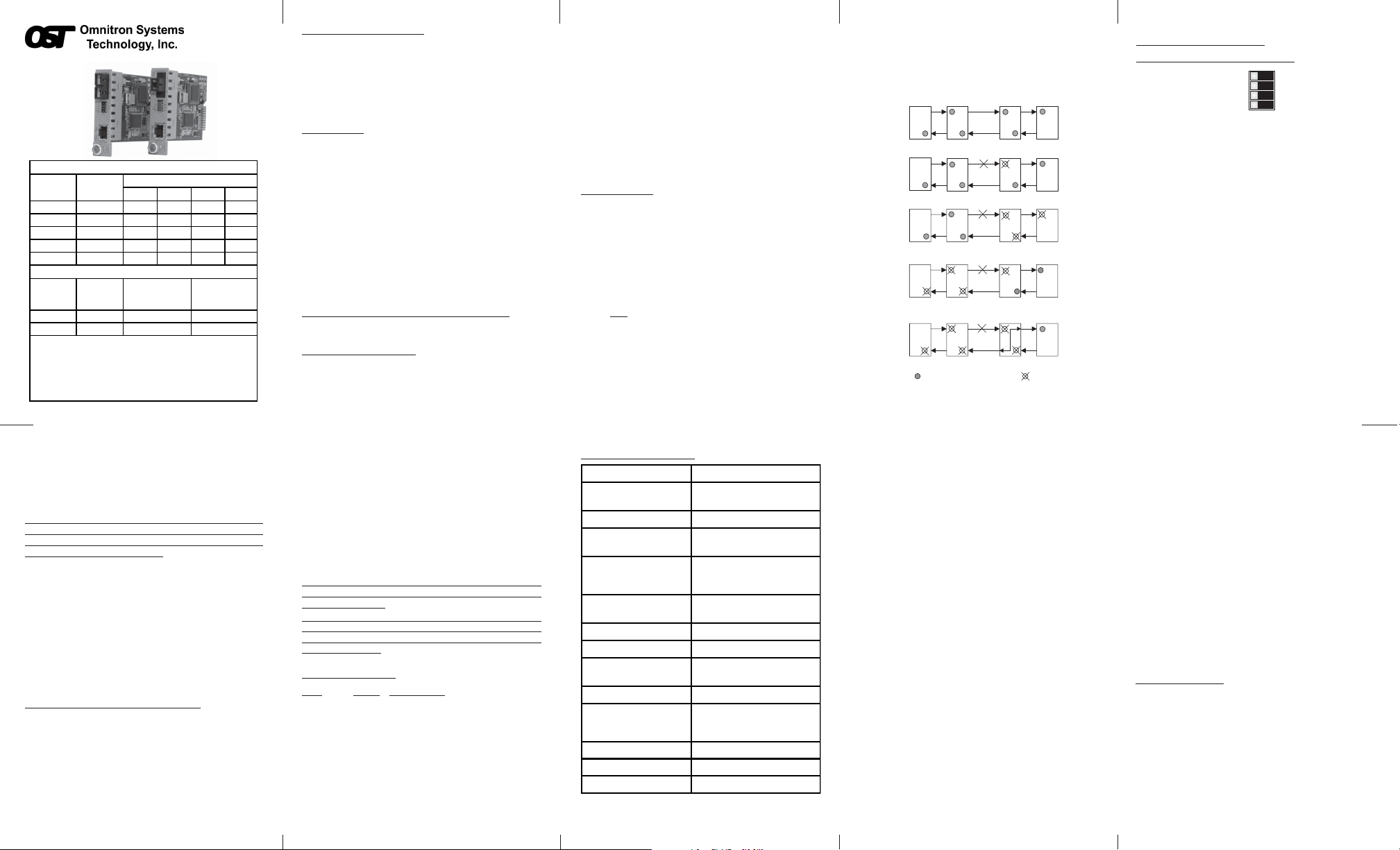

In Link Segment (LS), sometimes referred to as Normal

mode, a converter port transmits a Link signal

independently of any received Link at any other port.

For example, the UTP transmits a Link regardless of

the fiber receiving a Link [Fig 1(a) & (b)].

In Link Propagate (LP), sometimes referred to as Link

Loss Carry Forward, a converter port transmits a Link

only when receiving a Link at its other port. For

signal

example, the UTP transmits a Link only when receiving

a Link at the fiber port. [Fig 1(c)].

In Remote Fault Detection + Link Segment (RFD+LS),

the fiber port transmits a Link signal only when receiving

a Link at the fiber port. As a result, fiber faults (no

Link received at the fiber) are looped-back and can be

reported to the network core [Fig. 1(d)].

In Remote Fault Detection + Link Propagate (RFD+LP),

the UTP port transmits a Link signal only when receiving

a Link at the fiber port. The fiber port transmits a Link

signal only when receiving a Link signal at both the fiber

port and the UTP port. As a result, fiber faults are

looped-back and can be reported to the network core

[Fig. 1(e)].

(a)

Switch 1 Converter A Converter B Switch 2

(b)

Switch 1 Converter A Converter B Switch 2

(c)

Switch 1

(d)

Switch 1

(e)

Switch 1 Converter A Converter B Switch 2

UTP

LED Lit

LS

LS

LP

Converter

LP

ConverterAA

LP

Fiber

Fiber

LS

LS

LP

Converter B

RFD+LS

Converter B

RFD+LP

UTP

Switch 2

Switch 2

LED Off

Fig.1 Link Modes

Page 4

DIP-SWITCH SETTINGS:

Front Panel DIP-Switch Settings:

Link Segment

UTP Auto Negotiate

UTP Full-Duplex

Pause Enable

Pause En

=

LS

=

AN

=

FDX

=

UTP

Link Segment/Link Propagate “LS/LP” DIP-Switch:

This DIP-Switch controls Link Segment or Link Propagate

modes. When in the “LS” position, Link Segment mode

is enabled (factory setting). When in the “LP” position,

Link Propagate mode is enabled.

Auto/Manual Negotiate “AN/Man” DIP-Switch:

When the Auto/Manual Negotiate “AN/MAN” DIP-Switch

is in the Auto-Negotiate “AN” position (factory setting)

and the FDX/HDX DIP-Switch is in the “FDX” position,

the converter auto negotiates and matches the duplex

mode of a mating auto-negotiating device connected

to its UTP port. When the “AN/MAN” DIP-Switch is in

the “AN” position and the FDX/HDX DIP-Switch is in

the “HDX” position, the converter auto-negotiates and

operates in half-duplex mode only.

When in the Manual “Man” position, the converter autonegotiates and operates only in the mode selected by

the “FDX/HDX” DIP-Switch.

UTP Full/Half Duplex “FDX/HDX” DIP-Switch:

When the Auto/Manual Negotiate DIP-Switch is in the

Manual “Man” position, the Full/Half-Duplex “FDX/HDX”

DIP-Switch selects the duplex mode for the converter.

When the UTP Full/Half-Duplex DIP-Switch is in the

Page 5

Link Propagate

=

LP

Man

UTP Manual

=

UTP Half-Duplex

HDX

=

Dis

Pause Disable

=

Full-Duplex “FDX” position (factory setting), the

converter operates in Full-Duplex. This is the

recommended mode.

When in the “HDX” position, the converter

auto-negotiates and operates in Half-Duplex.

When the “AN/Man” DIP-Switch is in the “AN”

position, please consult the Auto/Manual

Negotiate DIP-Switch section (pg. 5) for

information on this setting.

It should be noted that Half-Duplex must be used when

connecting to a hub. Full-Duplex can be used when

connecting to a switch, or between a switch and a

Full-Duplex capable workstation.

UTP Pause Enable/Disable “Pause En/Dis” DIP-Switch:

Setting this DIP-Switch to Pause Enable “Pause En”

(factory default) allows the UTP port to auto-negotiate to

Symmetrical and Asymmetrical Pause. Setting the

DIP-Switch to Pause Disable “Dis” forces the UTP port

to auto-negotiate only to No Pause. Pause frames are

always passed through the converter.

Board Mounted DIP-Switch Settings:

Remote Fault Detection DIP-Switch (Not Shown):

The board mounted DIP-Switch controls the Remote

Fault Detection function. To enable Remote Fault

Detection, change the position of DIP 1 from disable

(down, factory default) to enable (up).

When this DIP-Switch is in the enable (up) position and

the “LS/LP” DIP-Switch is in the “LS” position, Remote

Fault Detection + Link Segment mode is enabled. In

Page 6 Page 7 Page 8

RFD+LS mode, the fiber port transmits a Link signal

only when receiving a Link at the fiber port. As a result,

fiber faults (no Link received at the fiber) are looped-back

and can be reported to the network core.

When this DIP-Switch is in the enable (up) position and

the “LS/LP” DIP-Switch is in the “LP” position, Remote

Fault Detection + Link Propagation mode is enabled. In

RFD+LP mode, the Gx propagates the presence or

absence of an incoming Link signal from a Fiber port

receive side to the transmit side of both the Fiber and

the UTP ports.

Note that connecting two converters when both are

set to RFD mode is illegal and will cause a “deadly

embrace” lockup.

The Gx fiber port is always in Manual Mode, and

sometimes a link-up will not occur with other

devices. A user must switch the connected device

to Manual Mode.

LED INDICATORS:

LED Color Description

Pwr: Yellow On--Power on

F/O Lk: Green On--Link; Blink--Activity

FDx: Green On--Full-Duplex mode

UTP/Link: Green On--UTP Link; Blink--Activity

Gx SPECIFICATIONS:

Model Type Gx

Protocols

UTP Connectors

Fiber Connectors

Controls

LED Displays

Dimensions

Weight

Compliance

Pow e r Requirement

Temperature

Humidity

Altitude

MTBF (h r s)

1000BASE-SX/LX,

1000BASE-T

SC, LC, MT-RJ,

Single-Fiber SC

LS/LP, RFD, UTP,

FDX/HDX, AN/Man,

Pause En

Power, FO link,

UTP link, FDX/HDX

W:0.85" x D:4.5" x H:2.8"

UL, CE , FCC Class A ,

NEBS Level 3

1.4A @ 3.3VDC (typical)

Standard: 0 to 50º C

Wide: -40 to 60º C

Storage: -40 to 80º C

5 to 95% (non-condensing)

-100m to 4000m

1,100,000

RJ-45

8 oz.

The operating description in this Instruction Manual is

for use by qualified personnel only. To avoid electrical

shock, do not perform any servicing of this unit other

than that contained in the operating instructions, unless

you are qualified and certified to do so by Omnitron

Systems Technology, Inc.

Warranty

Warning

This product is warranted to the original purchaser

against defects in material and workmanship for a

period of TWO YEARS from the date of shipment. A

LIFETIME warranty may be obtained by the original

purchaser by REGISTERING this product with Omnitron

within 90 days from the date of shipment. TO

REGISTER, COMPLETE AND MAIL OR FAX

ENCLOSED REGISTRATION FORM. Or you may

register your product on the Internet at www.omnitronsystems.com. During the warranty period, Omnitron

will, at its option, repair or replace a product which is

proven to be defective.

For warranty service, the product must be sent to an

Omnitron designated facility, at Buyer’s expense.

Omnitron will pay the shipping charge to return the

product to Buyer’s designated US address using

Omnitron’s standard shipping method.

Limitation of Warranty

The foregoing warranty shall not apply to defects

resulting from improper or inadequate use and/or

maintenance of the equipment by Buyer, Buyersupplied equipment, Buyer-supplied interfacing,

unauthorized modifications or tampering with equipment

(including removal of equipment cover by personnel

Page 9

not specifically authorized and certified by Omnitron),

or misuse, or operating outside the environmental

specification of the product (including but not limited

to voltage, ambient temperature, radiation, unusual

dust, etc.), or improper site preparation or maintenance.

No other warranty is expressed or implied. Omnitron

specifically disclaims the implied warranties of

merchantability and fitness for any particular purpose.

Exclusive Remedies

The remedies provided herein are the Buyer’s sole and

exclusive remedies. Omnitron shall not be liable for

any direct, indirect, special, incidental, or consequential

damages, whether based on contract, tort, or any legal

theory.

Technical Support:

For help with this product, contact our T echnical Support:

Phone: (949) 250-6510

Fax: (949) 250-6514

Address: Omnitron Systems Technology, Inc.

140 Technology Dr., #500

Irvine, CA 92618 USA

E-mail: support@omnitron-systems.com

URL: www.omnitron-systems.com

Form: 040-08500-001K 1/10

Page 10

Loading...

Loading...