Page 1

iConverter

®

1-Module Redundant Chassis

User Manual

140 Technology #500, Irvine, CA 92618

Phone: (949) 250-6510; Fax: (949) 250-6514

Page 2

Table of Contents

1.0 INTRODUCTION ............................................................................. 3

1.1 General Description....................................................................... 3

1.2 About This Manual ........................................................................ 3

1.3 Chassis Model Numbers ............................................................... 4

2.0 INSTALLATION ............................................................................... 4

2.1 Chassis Installation ....................................................................... 4

2.2 Module Installation ........................................................................ 5

2.3 Fiber Installation ............................................................................ 5

3.0 CONFIGURATION........................................................................... 6

3.1 Redundant Power Configurations................................................ 6

3.1.1 AC/DC Power Option (Low V olt age Barrel).................................. 6

3.1.2 24 VDC Option (Low Voltage T erminal)........................................ 7

3.1.3 48 VDC Option (High V oltage Terminal) ....................................... 8

3.1.4 Power over Ethernet (PoE) Option ............................................. 10

3.2 LED Indicators ............................................................................. 11

3.3 Contact Closure Sensors ............................................................ 12

3.4 Ethernet Backplane ..................................................................... 14

4.0 CHASSIS MANAGEMENT ............................................................ 15

4.1 Overview ...................................................................................... 15

4.1.1 Configuring and Monitoring the Chassis .................................. 15

5.0 APPLICATIONS ............................................................................ 21

5.1 Battery Backup with Alarms ....................................................... 21

5.2 Contact Closure Sensor Configuration...................................... 22

6.0 SPECIFICATIONS......................................................................... 23

7.0 TECHNICAL SUPPORT................................................................ 26

Page 2

Page 3

1.0 INTRODUCTION

1.1 General Description

The iConverter 1-Module chassis features a number of redundant power inputs,

UTP port and alarm options. It supports primary and secondary power input

options and variety of power connection types. By utilizing the optional UTP

ports, the unit can be powered from a connected Power Sourcing Equipment

(PSE). Optional contact closure sensors are provided for connection to external

alarm indicators. By installing a managed iConverter module into the chassis,

the chassis functions can be remotely managed by Telnet and SNMP software

such as Omnitron’s NetOutlook® Management software.*

1.2 About This Manual

This document supports release 1.1 of the iConverter 1-Module Redundant

chassis.

*iConverter management module and NetOutlook must be at version 3.3c or

higher.

Page 3

Page 4

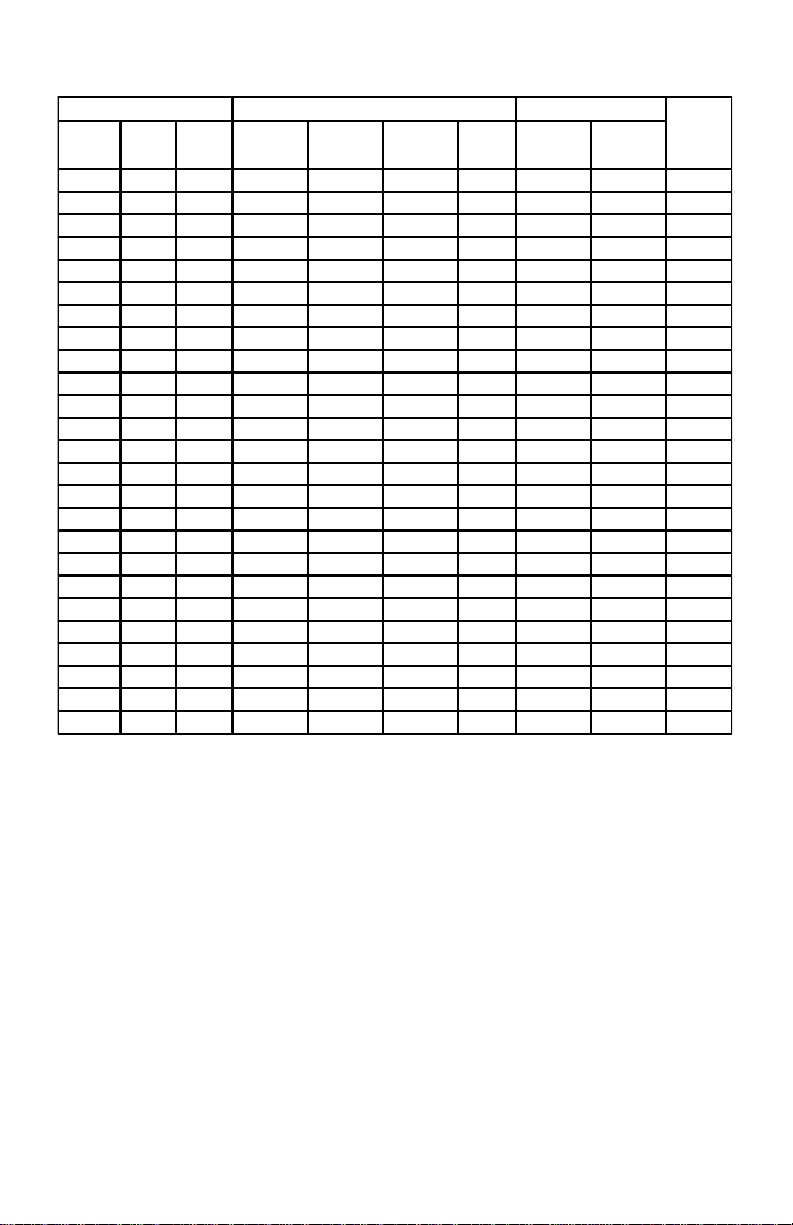

1.3 Chassis Model Numbers

Primary Power Backup Power

Two UTP

Contact

Closure

8245-111 x x Two US

8245-112 x x Two Univ.

8246-111 x x x Two US

8246-112 x x x Two Univ.

8246-511 x x x One US.

8246-512 x x x One Univ.

8247-111 x x x Two US

8247-112 x x x Two Univ.

8247-121 x x xOne US

8247-122 x x xOne Univ.

8247-220 x x x 8247-311 x x x One US.

8247-312 x x x One Univ.

8247-320 x x x 8248-111 x x x x Two US

8248-112 x x x x Two Univ.

8248-121 x x x xOne US.

8248-122 x x x xOne Univ.

8248-220 x x x x 8248-311 x x x x Two US.

8248-312 x x x x Two Univ.

8248-320 x x x x 8248-511 x x x x One US.

8248-512 x x x x One Univ.

8248-520 x x x x -

RJ-45

Ports

Low Voltage

DC-Barrel

(9-24V)

Low Voltage

DC-Terminal

(9-24V)

High Voltage

DC-Terminal

(24-60V)

RJ-45

POE

Low Voltage

DC-Barrel

(9-24V)

Low Voltage

DC-Terminal

(9-24V)

AC/DC

Power

SupplyModel

T able 1: Chassis Model Numbers

2.0 INST ALLATION

2.1 Chassis Installation

The iConverter 1-Module Redundant chassis is designed to accommodate

wall-mount or tabletop installations. For wall-mounting, the 8249-0 iConverter

Wall-Mount kit (sold separately) is designed to attach the chassis to a wall,

backboard or other flat surface.

For tabletop installations, place the unit on a flat level surface. Attach the rubber

feet to the bottom of the chassis to prevent the unit from sliding. Make sure the

unit is placed in a safe, dry and secure location.

For external power installation and configuration, see section 3.0.

Page 4

Page 5

2.2 Module Installation

The iConverter 1-Module Redundant chassis supports a variety of managed

and unmanaged iConverter modules. When installing a module into the chassis,

carefully slide the module into the open slot. Align the module with the inst allation

guides and ensure that the module is firmly seated against the backplane.

Secure the module by fastening the front panel thumbscrew (push in and turn

clockwise to tighten) to the chassis front.

Figure 1: Module Installation

Note: iConverter plug-in modules are hot-swappable and can be installed into

any chassis in the iConverter family. For additional information regarding

iConverter module installation, please consult the specific module’s user manual.

2.3 Fiber Installation

Connect an appropriate multimode or single-mode fiber cable to the fiber port

of the installed module. It is important to make sure that the transmit (TX) is

attach to the receive side of the device at the other end and the receive (RX) is

attach to the transmit side.

Single-fiber (SF) media converter models operate in pairs. The TX wavelength

must match the RX wavelength at the other end and the RX wavelength must

match the TX wavelength at the other end.

For additional information regarding iConverter module fiber installation, please

consult the specific module’s user manual.

Page 5

Page 6

3.0 CONFIGURATION

3.1 Redundant Power Configurations

The chassis support multiple redundant load sharing power configurations.

The power is connected to the back of the chassis with connectors labeled

“Pwr1” and “Pwr2”. “Pwr1” is the primary power connection and “Pwr2” is the

backup. There are four primary power options and two backup options. The

combinations of primary and backup power include low voltage barrel

connector, low voltage terminal, high voltage terminal and PoE from the UTP

ports. The manner in which the power is connected will depend on the model

selected. Refer to Table 1 for the specific power input options supported on

each chassis model.

3.1.1 AC/DC Power Option (Low V olt age Barrel)

T o power the chassis using AC/DC adapter , connect the AC/DC adapter to the

AC outlet. Then connect the barrel plug at the end of the wire on the AC/DC

adapter to the 2.5mm DC barrel connector on the chassis. A wire saddle is

located below each barrel connector to secure the power line and prevent

accidental removal. Repeat the process if the chassis was ordered with the

additional low voltage barrel option.

Figure 2: Redundant AC/DC Configuration

Note: The chassis must be used with an Omnitron supplied AC/DC

Power Adapter.

Confirm that the unit has powered up properly by checking the power status

LED located on the front of the chassis. See Section 3.2 for the details

concerning the operation and definition of the front panel LEDs.

Page 6

Page 7

3.1.2 24 VDC Option (Low Voltage Terminal)

The 8247-x2x, 8247-2xx, 8248-x2x and the 8248-2xx chassis require

9-24 VDC/1.5 Amps power input. The appropriate overload protection should

be provided at the power source. To power the chassis using 24 VDC power

source, locate the 24 VDC circuit breaker and switch the circuit breaker to the

off position. Prepare the power cable using a two-conductor insulated wire

with a 14 A WG gauge (not supplied). Cut the power cable to the length required.

Strip approximately 3/8 of an inch of insulation from the power cable wires.

Connect the power cable to the chassis by fastening the stripped ends to the 24

VDC power connector. Repeat the process if the chassis was ordered with the

additional low voltage terminal option.

Warning: Note the wire colors used in making the positive, negative and

ground connections. Use the same color assignment for the connection

at the circuit breaker.

Note: The 9-24VDC power input can accept an input voltage up to 28VDC.

Connect the power wires to the circuit breaker and switch the circuit breaker

ON. Confirm that the unit has powered up properly by checking the power

status LED located on the front of the installed chassis. See Section 3.2 for the

details concerning the operation and definition of the front panel LEDs.

+ -

Figure 3: Redundant 24 VDC Configuration

Page 7

Page 8

3.1.3 48 VDC Option (High V oltage Terminal)

The DC power source should be available within 5 ft. of the chassis. The over

current protection for the connection with centralized DC shall be provided in

the building installation and shall be a UL listed breaker rated at 20 Amps, and

installed per the National Electrical Code, ANSI/NFPA-70. The 8247-3xx and

the 8248-3xx require 24-60 VDC/0.6 Amps power . The appropriate overloading

protection should be provided on all DC power source outlets utilized.

WARNING: Only a DC power source that complies with safety extra low

voltage (SELV) requirements can be connected to the DC-input power.

WARNING REGARDING EARTHING GROUND

This equipment shall be connected to the DC supply system

earthing electrode conductor or to a bonding jumper from an

earthing terminal bar or bus to which the DC supply system

earthing electrode is connected.

This equipment shall be located in the same immediate area

(such as adjacent cabinets) as any other equipment that has

a connection between the earthed conductor of the same DC

supply circuit and the earthing conductor, and also the point of

earthing of the DC system. The DC system shall not be earthed

elsewhere.

The DC supply source is to be located within the same

premises as this equipment.

There shall be no switching or disconnecting devices in the

earthed circuit conductor between the DC source and the

earthing electrode conductor.

To power the chassis using a 48 VDC power source, locate the DC circuit

breaker and switch the circuit breaker to the OFF position. Prepare a power

cable using a three conductor insulated wire (not supplied) with a 14 AWG

gauge. Cut the power cable to the length required. Strip approximately 3/8 of

an inch of insulation from the power cable wires. Connect the power cables to

the chassis by fastening the stripped ends to the DC power connector.

Page 8

Page 9

Figure 4: 48 VDC and AC/DC Redundant Power Configuration

WARNING: Note the wire colors used in making the positive, negative

and ground connections. Use the same color assignment for the

connection at the circuit breaker.

Connect the power wires to the circuit breaker and switch the circuit breaker

ON. Confirm that the unit has powered up properly by checking the power

status LED located on the front of the installed chassis. See Section 3.2 for the

details concerning the operation and definition of the front panel LEDs.

Page 9

Page 10

3.1.4 Power over Ethernet (PoE) Option

On models with the PoE feature (see Table 1), UTP Port A (the left port on the

front of the chassis) can be configured as a PoE Powered Device (PD). It

accepts power from a UTP-based Power Sourcing Equipment (PSE) and

supports the following PoE standards:

1. IEEE 802.3af-2003 Alternative A – power over data wires

2. IEEE 802.3af-2003 Alternative B – power over sp are wires

3. Pre-Standard Cisco PoE – power over spare wires, with reversed polarity

(older Cisco switches)

The following table summarizes the UTP pinouts for each of the three

PoE Standards supported by this product.

dradnatS

EEEI

fa.208

atadgnisu

)A(sriap

EEEI

fa.208

erapsgnisu

)B(sriap

-dnatS-erP

ocsiCdra

ecruoS

egatloV

CDV84

CDV84

CDV84

1niP2niP3niP4niP5niP6niP7niP8niP

,XR

,XR

detcetorp

+CD

XRXRXT+CD+CDXT-CD-CD

detcetorp

XRXRXT-CD-CDXT+CD+CD

detcetorp

,XT

+CD

-CD

Table 2: UTP PoE Connections

UTP Port B does not support the PoE feature.

erapSerapS

,XT

-CD

erapSerapS

Page 10

Page 11

3.2 LED Indicators

The following table details the LED status indicators:

LED Function Color Legend Off State On / Blinking state

Solid: Power applied to power source 1

0.5 Hz Blinking: Power applied to source 1

and contact closure is in the alarm state

On: UTP A li nked at 10 Mbps or 100 Mbps

10 Hz Blinking: Rx and Tx 10 or 100 Mbps

data activity on Port A

On: UTP Port linked at 100 Mbps

Solid: Power applied to power source 2

0.5 Hz Blinking: Power applied to source 2

and contact closure is in the alarm state

1

2

3

4

Power

Supply 1

LED

Port A

Link/Activity

Port A

Speed

Power

Supply 2

LED

Green PWR1

Green Lnk/Act No link on Port A

Green 10/100

Green PWR2

No power applied to

power source 1

If Port A link is

active, the port is

linked at 10 Mbps

No power applied to

power source 2

5

6

Port B

Link/Activity

Port B

Speed

Green Lnk/Act No link on Port B

Green 10/100

If Port B link is

active, the port is

linked at 10 Mbps

T able 3: LED Definitions

On: UTP B linked at 10 Mbps or 100 Mbps

10 Hz Blinking: Rx and Tx 10 or 100 Mbps

data activity on Port B

On: UTP Port B linked at 100 Mbps

Page 1 1

Page 12

3.3 Contact Closure Sensors

+ Rt1+ Rt2+ Rt3+ Rt

On models with the contact closure sensor feature (see Table 1), the chassis

provides an optional 8-pin connector (4 contact sensors) on the back of the

chassis that can be used to sense the state of external alarm conditions. Each

of the four sensor pins can detect if the wired circuit is open or closed, or has

high or low voltage from the external equipment. A DIP-switch located on the

back of the chassis enables or disables alarm reporting. If no external equipment

is connected to the 8-pin connector, it is important to disable the alarm reporting

by configuring each DIP-switch to the DISABLE position. See Figure 5 for the

location of the switch and terminal connector.

Enable

Alarms

1 2 3 4

Disable

4

Figure 5: DIP-switch and Alarm Terminal Details

Page 12

Page 13

The table describes the function of each switch.

hctiwS-PID

noitisoP

11mralA

22mralA

33mralA

44mralA

noitcnuFetatSnoitacidnIgnitropeR

delbasiD=nwoDgnitropermralaoN

delbanE=pUnoitacidnimralalenaptnorF

delbasiD=nwoDgnitropermralaoN

delbanE=pUnoitacidnimralalenaptnorF

delbasiD=nwoDgnitropermralaoN

delbanE=pUnoitacidnimralalenaptnorF

delbasiD=nwoDgnitropermralaoN

delbanE=pUnoitacidnimralalenaptnorF

Table 4: Contact Sensors - DIP-switch Configuration

NOTE: Not all chassis are equipped with the contact sensors. Internally, all

signal return (“Rt”) pins are connected.

The 8-pin connector has the following pin configuration:

#niPnoitpircseD)egatlovwol(tiucriCdesolC)egatlovhgih(tiucriCnepO

1)"+"(1rosneSmralAoNmralA

2)"tR"(nruteRlangiS

3)"+"(2rosneSmralAoNmralA

4)"tR"(nruteRlangiS

5)"+"(3rosneSmralAoNmralA

6)"tR"(nruteRlangiS

7)"+"(4rosneSmralAoNmralA

8)"tR"(nruteRlangiS

T able 5: Contact Closure Sensors Pinout Configuration

Page 13

Page 14

3.4 Ethernet Backplane

The chassis contains two Ethernet backplane buses (A and B) that operate at

10/100Mbps. Both buses are enabled by default. When an iConverter module

that features Ethernet backplane connectivity is installed in the chassis, the A

bus connects directly to UTP Port A, and the B bus connects directly to UTP

Port B as shown in Figure 6.

Inserted Module

Port 1

Backplane B

Ethernet

Port 2

Switch

UTP

Port A

UTP

Port B

Backplane A

Figure 6: Backplane Connectivity

The data traversing across the Ethernet backplane can be controlled by

configuring the installed iConverter module. See the specific iConverter module’s

User Manual for additional details.

Page 14

Page 15

4.0 CHASSIS MANAGEMENT

4.1 Overview

The 1-Module Redundant chassis features configurable options and status

information depending on the model. Configurable parameters and status

information available through the serial console port on the installed iConverter

Management Module are:

• Contact Closure Alarm notification - Enable/disable (physical DIP-switches)

• Port A/B Control - UTP auto-negotiation, 10/100 and Full/Half-Duplex

• Pause Control - Enable/disable

• Port Access Control - Enable/disable

• Power Supply 1/2 - V olt age, current and temperature

4.1.1 Configuring and Monitoring the Chassis

Remote configuration of the chassis is provided by installing an iConverter

Management Module such as a 10/100M. T o configure, attach the Management

Module to a RS-232 equipped computer with terminal emulation software such

as HyperTerminal. The Management Module Serial Console Port (DCE) is a

mini DIN-6 female connector which can be changed to a DB-9 connector with

the adapter included with the module (Part #8082-0). Attach the ends of serial

cable to the serial port of the PC and the Serial Console Port of the Management

Module. This is a standard asynchronous serial interface

Start HyperTerminal and select the correct COM Port in the HyperTerminal

“Connect To:” window.

Set the PC’s serial port to the following:

Bits Per Second 57,600

Stop Bits 1

Data Bits 8

Parity NONE

Hardware Flow Control NONE

Page 15

Page 16

Power the chassis containing the Management Module and press <ENTER>

to bring up a command line prompt on the attached PC.

The Management Options screen will be displayed.

Management Options iConverter, Serial Agent

Network Management

1: Chassis and Module Management

2: Set Module Identifier

Management Module Preferences

3: IP and Control Preferences

4: SNMP Preferences

5: Abandon Preference Changes

6: Save Preference Changes

7: Restore to Factory Defaults

8: Restart Management Module

9: Other Networking Features

Management Module Maintenance

10: Firmware Update

11: Set Date/Time

IP Address = 192.168.1.220

Chassis Number = 1

Enter Choice, (H)elp, E(x)it >

Figure 7: Management Option Screen

A new Management Module does not have a password, and will skip the

Password Entry screen and go straight to the Management Options screen.

Page 16

Page 17

If a password has been set, the Password Entry screen will be displayed.

Type the password and press <ENTER>, the Management Options screen

will be displayed.

Omnitron Systems Technology, Inc. iConverter, Serial Agent

Copyright 2001-2007 OST, Inc.

Password Entry

----------------------------------------------------------Omnitron Systems Technology Technical Support:

(949) 250-6510

140 Technology #500 Sales/Products: (800) 675-8410

Irvine, CA 92618 On the web at:

www.omnitron-systems.com

-----------------------------------------------------------

IP Address 192.168.1.220

MAC 00:00:00:00:00:00

[xxxxxxxx]

Please enter the password >

Figure 8: Password Screen

To access the chassis configuration screens, select 1 at the Management

Options screen, press <ENTER>. The Chassis View screen will be displayed.

From the Chassis View screen, select the slot number corresponding to the

chassis.

NOTE: Chassis configuration is also available using NetOutlook.

Chassis View 1-Module Redundant

Chassis Number = 7

Slot Model Type Module Identifier

1 8959-0 2FXM

2 8248-512 1-Module Redundant

Module to View(1-2), Mgmt Opt(0),(R)eset, (H)elp, E(x)it >

2

Figure 9: Chassis View Screen

Page 17

Page 18

The Module Screen (DIP-switch control shown) provides general information

concerning the configuration and status of the module. The screen displays

the model and serial numbers, hardware and software revisions, as well as the

condition of the LEDs, Alarm Indicators and DIP-switches. The DIP-switches

1 - 4 correspond with the physical switches on the back of the chassis. These

switches can be changed from the Module Screen by selecting the appropriate

switch number. DIP-switches 9 - 15 can only by configured from the Module

Screen options. Select the appropriate option to change the DIP-switch setting.

Module Screen - iConverter 1-Module Redundant

Identifier -

Switch ON Condition OFF Condition H/W Actual

1: Alarm 1 Enable Alarm 1 Disable On On

2: Alarm 2 Enable Alarm 2 Disable Off Off

3: Alarm 3 Enable Alarm 3 Disable Off Off

4: Alarm 4 Enable Alarm 4 Disable Off Off

5: Not Available

6: Not Available

7: Not Available

8: Not Available

Soft Switch ON Condition Off Condition State

9: Port A Manual Port A AN Mode Off

10: Port A 10 Mbps Port A 100 Mbps Off

11: Port A HDX Port A FDX Off

12: Port B Manual Port B AN Mode Off

13: Port B 10 Mbps Port B 100 Mbps Off

14: Port B HDX Port B FDX Off

15: Pause Enabled Pause Disabled Off

16: Not Available

Toggle Switch(1-16), ....... (S)tatus, Port(C)tl >

Figure 10: Module Screen - Showing DIP-switches Only

Page 18

Page 19

The Module Screen also provides access to the status and control screen. T o

select the Status Screen, enter S.

Module Screen - iConverter 1-Module Redundant

Identifier -

Chassis Number = 7

Slot Number = 2

Model Number = 8248-512

Serial Number = xxxxxxxx

Manufacturing Date = xxxxxxxx

Product Revision = x

Software Revision = x.x

P1 Volts = 0.0 V P2 Volts = 3.6 V

P1 Current = 0.0 A P2 Current = 0.9 A

Temp = 113 F 45 C

PoE = Installed

Fan = Not Installed

Alarm 1 = On

Alarm 2 = On

Alarm 3 = On

Alarm 4 = On

Enter Choice, Previous Screen(0), (H)elp, E(x)it >

Figure 1 1: S tatus Screen

Page 19

Page 20

For models with UTP ports, the Control Screen is available to enable or disable

Port A and Port B. To select the Control Screen, enter C.

Module Screen - iConverter 1-Module Redundant

Identifier -

Chassis Number = 7

Slot Number = 2

Model Number = 8248-512

Port Access Control Setup

------------------------ 1: Port A Enable On

2: Port B Enable On

Port VLAN Path Setup

------------------- 3: Port A to Backplane A On

4: Port A to Backplane B Off

5: Port B to Backplane A Off

6: Port B to Backplane B On

7: Port A to Port B Off

Enter Choice, Previous Screen(0), (H)elp, E(x)it >

Figure 12: Control Screen

Page 20

Page 21

5.0 APPLICATIONS

5.1 Battery Backup with Alarms

When the chassis is used with a battery backup power system, the alarm contact

sensor can be used to report conditions associated with the backup power

system. In this configuration, the chassis can provide a managed power fault

detection system.

The figure below depicts an APC PowerShield battery backup unit connected

to the chassis using the 8-pin terminal connector on the back of the chassis,

In this configuration, the chassis is monitoring the power conditions of the AP C

units and will report any failures to the network management system.

DC Power

1-Module Redundant Chassis

APC PowerShield

Alarm indicators

Figure 13: Redundant Chassis Power Utilizing the Contact Closure Sensors

Page 21

Page 22

The four sensors are compatible with APC PowerShield product. The table

below defines the pinouts for both units.

CPA

#niP

32 nruteRlangiSA/NA/N

41 ecruoSrewoPrewoPytilitUrewoPyrettaB

53 evreseRyrettaBdegrahC-lluFyrettaBtseT-fleSsliaFyrettaB

65 noitidnoCyrettaBtneserPyrettaBgnissiMyrettaB

77 yrettaBwoLyticapaCraeNyrettaByticapaC%02<yrettaB

retrevnoCi

sissahC

#niP

noitpircseDtiucriCdesolCtiucriCnepO

T able 6: APC PowerShield Alarm Contact Configuration

5.2 Contact Closure Sensor Configuration

The contact closures can be used to alert the network management system of

problems associated with the remote location. The contact closure sensor can

also detect the opening and closing of a switch, such as a equipment door

being opened or closed. The figure below illustrates this application.

Open Door Alarm Condition

Figure 14: Chassis Configured for Open Door Alarm

Page 22

Page 23

6.0 SPECIFICATIONS

Description iConverter 1-Module Redundant-Power Chassis

Ports 2 x RJ-45

Protocols 10Base-T, 100Base-Tx with 1536 max. frame size

Cable Types

UTP EIA /TIA 568A/568B

Connector Types

UTP RJ-45

Contact Closure Sensors Field-wireable 16-24 AWG

Power Requirements

Low Voltag e D C P ower 9 - 24 VDC

Low Vo lt a g e DC P ower

Connector

High Voltage DC Power +24 to +60 VDC

High Voltage DC Power

Connector

PoE Power +44 to +57 VDC

PoE Connector RJ-45 IEEE 802.3af-2003 Alternative A & B,

AC Power Ada pter [US] 100-120 VAC, 60Hz

AC Power Adapter [Universal] 100-240 VAC, 50-60 Hz

Dimensions 5.4" (W) x 6.8" (L) x 1.0" (H)

Weight

without power adapter 1.5 lbs.

with power a dapte r 2.0 lbs.

Compliance UL, CE, FCC, AS/NZS 3548, & VCCI Class A

Temperature

Operational - Commercial 0 to +50

Operational - Wi de Range -40 to +60

Storage -40 to +80

Humidity (non-condensing) 5 to 95%

Altitude -100m to 4000m

MTBF [hrs]

without power adapter 540,000

with US power adapter 250,000

with Univ. power adapter 100,000

2.5mm Barrel Connec tor or Fi e ld-wireable 16-20 AWG Terminal Connector

Field-wireable 16-20 AWG Terminal Connector

1.5A @ 9.0VDC

or

-24 to -60 VDC

0.3A @ 48VDC

or

-44 to -57 VDC

0.27A @ 48VDC

Pre-standard Cisco PoE

0.2A @ 120VAC

0.2A @ 120VAC

o

C

o

C

o

C

T able 7: Model Specifications

Refer to Table 1 for applicable product features.

Page 23

Page 24

Warning

The operating description in this Instruction Manual is for use by qualified

personnel only . To avoid electrical shock, do not perform any servicing of this

unit other than that contained in the operating instructions, unless you are

qualified and certified to do so by Omnitron Systems Technology , Inc.

Caution

All user-required operations can be performed without opening the unit. Never

attempt to open or remove the cover or tamper with the unit. There are no user

replaceable or serviceable parts in this unit. Equipment is not intended to be

installed and used in a place (home, school, or public area) accessible to the

general population.

Page 24

Page 25

Warranty

This product is warranted to the original purchaser against defects in material

and workmanship for a period of TWO YEARS from the date of shipment. A

LIFETIME warranty may be obtained by the original purchaser by REGISTERING

this product with Omnitron within 90 days from the date of shipment. TO

REGISTER, COMPLETE AND MAIL OR FAX THE ENCLOSED

REGISTRATION FORM. Or you may register your product on the Internet at

http://www.omnitron-systems.com. During the warranty period, Omnitron will,

at its option, repair or replace a product which is proven to be defective.

For warranty service, the product must be sent to an Omnitron designated

facility , at Buyer’s expense. Omnitron will pay the shipping charge to return the

product to Buyer’s designated US address using Omnitron’s standard shipping

method.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from improper or

inadequate use and/or maintenance of the equipment by Buyer, Buyersupplied equipment, Buyer-supplied interfacing, unauthorized modifications or

tampering with equipment (including removal of equipment cover by personnel

not specifically authorized and certified by Omnitron), or misuse, or operating

outside the environmental specification of the product (including but not limited

to voltage, ambient temperature, radiation, unusual dust, etc.), or improper site

preparation or maintenance.

No other warranty is expressed or implied. Omnitron specifically disclaims the

implied warranties of merchantability and fitness for any particular purpose.

Exclusive Remedies

The remedies provided herein are the Buyer’s sole and exclusive remedies.

Omnitron shall not be liable for any direct, indirect, special, incidental, or

consequential damages, whether based on contract, tort, or any legal theory .

Page 25

Page 26

7.0 TECHNICAL SUPPORT

If you encounter problems with this product, contact Omnitron Technical

Support.

Phone: +1 800-675-8410 USA

+1 949-250-6510

Fax: 949-250-6514

Address: Omnitron Systems Technology, Inc.

140 Technology Dr., #500

Irvine, CA 92618

Email: support@omnitron-systems.com

URL: http://www.omnitron-systems.com

Page 26

Form 040-8245-001D 10/07

Loading...

Loading...