Page 1

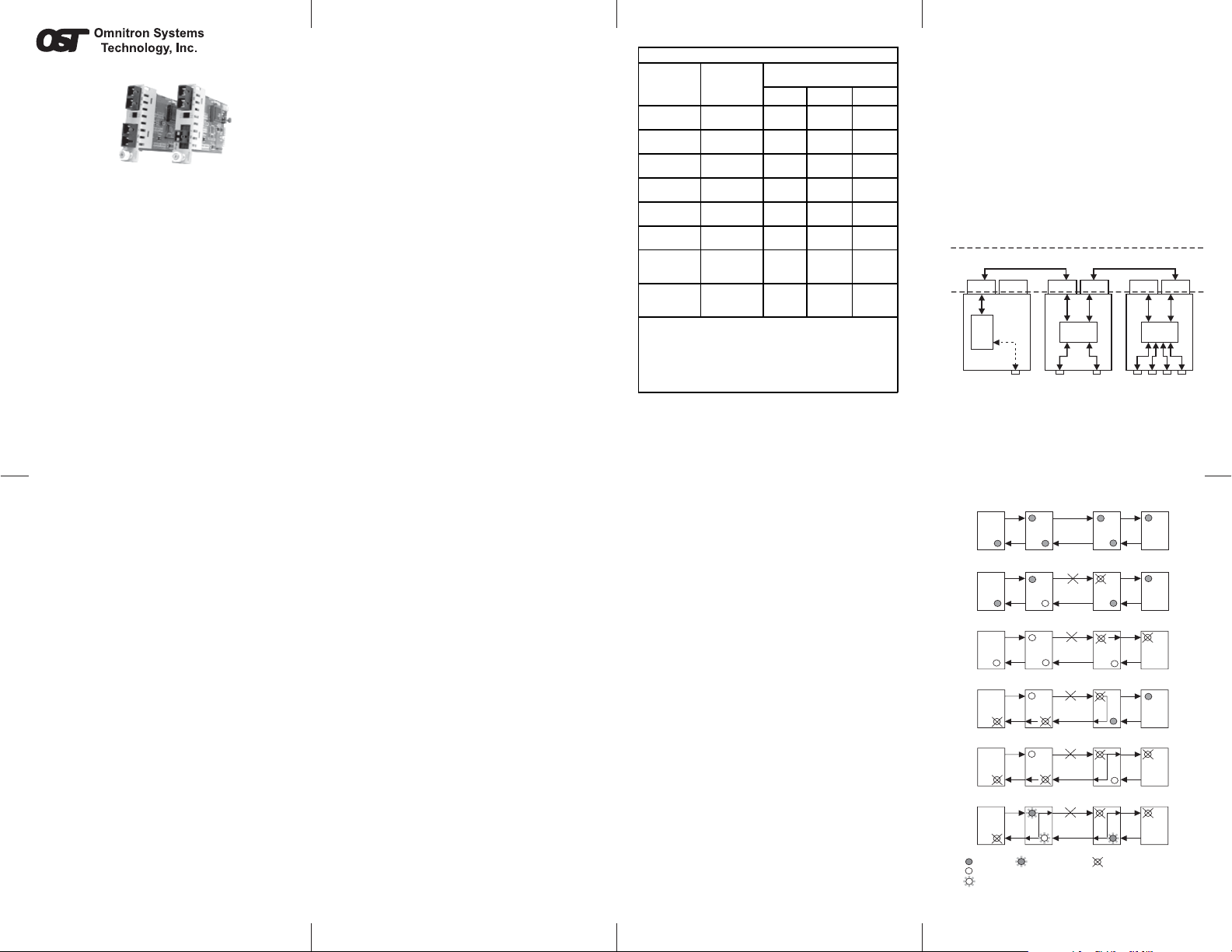

iConverter

Chassis

Backplane

GX/X Module

Internal

10/100/1000

switch chip

Fiber

1000 port

Fiber

1000 port

NMM Module

NMM

front /

back

select

NMM UTP

10 port

4Tx Module

Internal

10/100

switch chip

4-port 10/100 UTP

Switch

“A” Link

“B” Link

A Port

B Port

A Port

B Port

A Port

B Port

Slot 1 (odd) Slot 2 (even) Slot 3 (odd)

®

GX/X User Manual

Port 1

Port 2

ABOUT THIS MANUAL

This document supports revision “xx/10” of the GX/X.

Please refer to the serial number label on the GX/X for

the revision number of your product. This revision

incorporates the following improvements to the GX/X:

1. Product enhancements now prevent unpredictable

behavior under undefined or incompatible DIP-Switch

selections.

2. LINK MODES have been increased to include RFD+LS

and RFD+LP modes. Improvements to LED behavior

have been made to accommodate these new link modes.

OVERVIEW

The iConverter GX/X manageable two-port Gigabit

Ethernet switch and media converter is a member of

the modular iConverter product family. It provides

fiber-to-fiber conversion for extending network distances

and connecting dissimilar fiber network connections.

iConverter GX/X regenerates, reshapes and re-times

The

the fiber optic signal, and multiple GX/X converters can

be cascaded to extend total network distances.

Page 1 Page 2 Page 3

The GX/X can be used as a standard two-port fiber

converter. It can also use its two additional 10/100 backplane

ports to connect to adjacent modules and accommodate

flexible network configurations like In-Band management

and multi-module configurations. The iConverter 19-Module,

5-Module or 2-Module Chassis have backplanes that

facilitate connectivity between adjacent modules.

The GX/X can be used in an unmanaged or managed

fashion. When unmanaged, it can be installed in a chassis

without a management module and can be configured by

using two onboard DIP-Switches. To be managed, a

Network Management Module (NMM) or an iConverter

module with built-in management (such as a GX/TM or

10/100M) must be installed in the same chassis.

Advanced Features

The GX/X features Port VLAN and T ag VLAN, which allow

control of traffic flow among the fiber ports and chassis

backplane ports. It also features Port Access Control,

which facilitates enabling and disabling of individual ports.

The GX/X supports reporting of MIB statistics. Statistics

are available for 32 variables per port, reporting a wide

range of real-time packet statistics to provide

performance and operational monitoring.

NOTE: Using the advanced features listed above

requires the use of an NMM or an iConverter module

with built-in management (such as a GX/TM or 10/100M)

and NetOutlook

™

Management Software, or third-party

SNMP management software or Telnet.

For information on using and configuring these advanced

features, please refer to the NetOutlook Management

Software user manual.

GX/X MODEL NUMBER REFERENCE CHART

iConverter

Port 1

(Fiber Type /

Distance /

Wavelength)

MM / 220m /

1

/ 850nm

550m

MM / 220m /

1

/ 850nm

550m

SM / 12km /

1310nm

SM / 34km /

1310nm

SM / 34km /

1310nm

SM / 80km /

1550nm

MM / 220m /

1

/ 850nm

550m

MM / 220m /

1

550m

/ 850nm

Consult the factory for wide temperature (-40 to 60º C) and extended

temperature (-40 to +75º C) models.

When using single-fiber (SF) media converter models, the Tx

wavelength on one end has to match the Rx wavelength on the other

1

62.5/125µm, 100/140µm multimode fiber up to 220m. 50/125µm

multimode fiber up to 550m. Refer to the fiber cable manufacturer for

multimode distance specifications.

Port 2

(Fiber Type /

Distance /

Wavelength)

MM / 220m /

550m1 / 850nm

SM / 12km /

1310nm

SM / 12km /

1310nm

SM / 34km /

1310nm

SM / 80km /

1550nm

SM / 80km /

1550nm

SM / SF / 20km

/ Tx 1310nm,

1550nm

SM / SF / 20km

/ Tx 1550nm, Rx

1310nm

GX/X

Connector Types

SC MT-RJ LC

8542-00 8544-00 -

8543-10 - -

8543-11 8545-11 8547-11

8543-22 - 8547-22

8543-23 - -

8543-33 - 8547-33

8550-01 - -

Rx

8551-01 - -

PORT STRUCTURE

Using a 4-port switch design, the GX/X features two

front-plane 1000Mbps fiber ports (Port 1 is the top port,

and Port 2 is the lower port nearest the thumb screw).

It also features two 10/100 Ethernet backplane ports

(“A” and “B”) that can connect to adjacent modules

within the same chassis.

When the GX/X “A” and “B” Ethernet backplane ports are

enabled (using the “BPAEN” and “BPBEN” DIP-Switches),

they connect via the backplane of the chassis to the

slots on the left and right sides of the GX/X module.

When another switch-based module with backplane port

connections such as a second GX/X or an NMM is installed

in an adjacent slot, it can be connected via the backplane

to the GX/X to facilitate a multi-module configuration.

GX/X APPLICATION EXAMPLE

Fig. 1 In-Band Managed GX/X Application

Page 4

Fig. 1 depicts a chassis with three modules plugged into

three of its adjacent backplane slots (beginning with an

odd-numbered slot). The adjacent slots are connected

via the backplane using the “A” and “B” 10/100 links. In

this example, the module on the left is a Network

Management Module (NMM) connecting via its A

backplane port to the GX/X, facilitating “In-Band”

management (via the fiber uplink). The module on the

right is a 4-port 10/100 switch module (4Tx) connecting

via its B link port to the GX/X, facilitating a 4-port 10/100

Ethernet switch with a fiber uplink configuration. This

3-module configuration provides an effective 4-port

10/100 managed switch with a gigabit fiber uplink and a

fiber link to another iConverter chassis configuration in a

daisy chain.

This example shows how the GX/X can be used either as a

traditional managed or unmanaged media converter or as

a building block to create flexible and effective network

switch configurations.

For more information on individual chassis A and B

backplane links, refer to the specific chassis’ user manual.

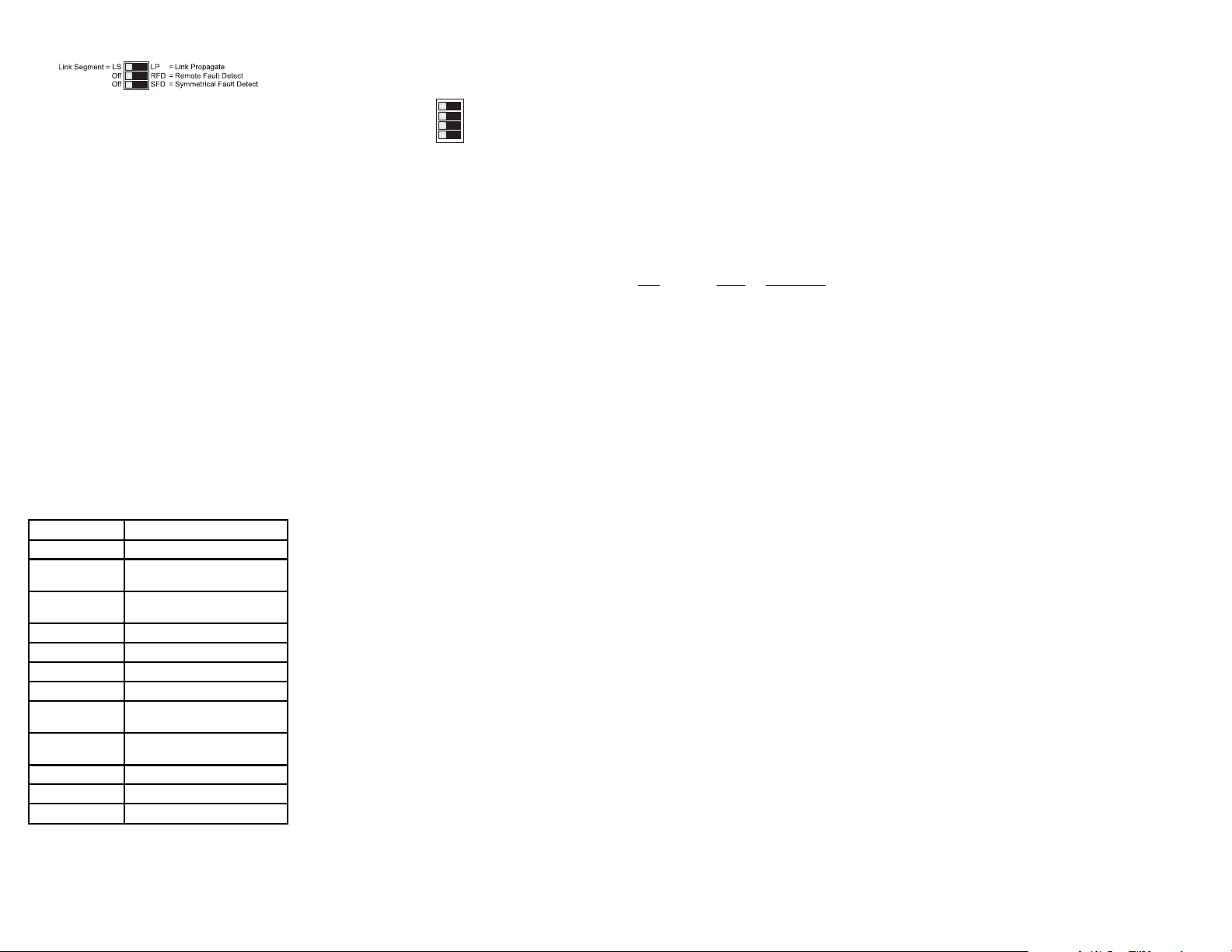

LINK MODES

In order to accommodate different user needs, the GX/X

supports five different linking modes (see Fig. 2).

In Link Segment (LS), a port transmits a Link signal

independently of any received Link at any other port.

For example, the UTP transmits a Link regardless of

the fiber receiving a Link [Fig. 2(a) & (b)].

In Link Propagate (LP), a port transmits a Link signal

only when receiving a Link at its other port. For example,

Page 5

the UTP transmits a Link only when receiving a Link at

the fiber port [Fig. 2(c)].

In Remote Fault Detection + Link Segment (RFD+LS),

the fiber port transmits a Link signal only when receiving

a Link at the fiber port. As a result, fiber faults (no Link

received at the fiber) are looped-back and can be

reported to the network core [Fig. 2(d)].

In “Remote Fault Detection + Link Propagate” (RFD+LP)

mode, a port transmits a Link signal only when both

itself and the other port are receiving Link signals. A

loss of a received Link signal at a port is “Looped-back”

and the port stops transmitting a Link signal. The same

loss of Link is propagated to the other port which also

stops transmitting the Link signal. For example, the

loss of Link into P2 causes both P1 and P2 ports to stop

transmission of the Link signal [Fig. 2(e)].

NOTE: Connecting two converters with both acting in RF D

mode is not supported and will cause a “deadly embrace”

lockup.

When the fiber is set to Auto-Negotiation Mode, the

device receiving the fault acts as if it is in RFD mode

[Fig. 2(d), (e) and (f)].

NOTE: In older versions of firmware, RFD was not

defined on ports set to Auto-Negotiation.

“Symmetrical Fault Detection” (SFD) mode operates

similarly to the Remote Fault Detection (RFD) mode.

In SFD mode, the loss of a received Link at P1 is

Looped-Back to P1 and propagated to P2, causing both

to stop transmitting the Link signal [Fig. 2(f)] and also

causing blinking in a connected GX/X P1 “Link” LED

indicator.

Page 6

Connecting two converters which are both set to SFD is

permitted and facilitates a dual-loop-back feature where

P1 fiber faults can be reported to both ends of the network.

NOTE: Converters in SFD mode must be deployed in pairs,

and the “LS” DIP-Switch position must also be selected.

Page 7 Page 8

LS

Fiber

(a)

Switch 1 Converter A Converter B Switch 2

LS

Fiber

Fiber

LS

Fiber

LS

(b)

Switch 1 Converter A Converter B Switch 2

LP

LP

(c)

Switch 1 Converter A Converter B Switch 2

LP

RFD+LS

(d)

Switch 1 Converter A Converter B Switch 2

LP

RFD+LP

(e)

Switch 1 Converter A Converter B Switch 2

SFD

SFD

(f)

Switch 1 Converter A Converter B Switch 2

LED Lit LED Blinking LED Off

LED Status depends on connected device

LED Status (Blinking/off) depends on connected device

Fig. 2 GX/X Link Modes

Page 2

DIP-SWITCH SETTINGS

Front Panel DIP-Switch Settings

Fig. 3 Front Panel DIP-Switches

Link Segment/Link Propagate “LS/LP” DIP-Switch

This DIP-Switch controls the Link Propagate or Link

Segment modes. When the DIP-Switch is in the “LS”

position (factory setting), Link Segment mode is enabled.

In the “LP” position, Link Propagate mode is enabled.

Remote Fault Detection “RFD” DIP-Switch

To enable Remote Fault Detection mode, set the “RFD”

DIP-Switch to the “RFD” position.

To enable RFD + LS mode, also set the LS/LP DIPSwitch to the “LS” position. To enable RFD + LP mode,

set the LS/LP DIP-Switch to the “LP” position.

The RFD DIP-Switch selection is ignored on ports set to

Auto-Negotiation mode.

NOTE: Connecting two converters with both set to RFD

mode is not supported and will cause a “deadly embrace”

lockup.

Symmetrical Fault Detection “SFD” DIP-Switch

To enable Symmetrical Fault Detection mode, set the

“SFD” DIP-Switch to the “SFD” position, the “LS/LP”

DIP-Switch to the “LS” position and the “RFD”

DIP-Switch to the “Off” position.

Any other DIP-Switch configuration will disable

Symmetrical Fault Detection mode.

NOTE: Converters in SFD mode must be deployed in pairs.

Board Mounted DIP-Switch Settings

ON

=

Off

Off

P1 Auto Negotiate

P2 Auto Negotiate

=

AN

=

AN

Fig. 4 Board Mounted DIP-Switches

Backplane “A” Enabled

BPAEN

=

Backplane “B” Enabled

BPBEN

=

P1 Manual

MAN

=

P2 Manual

MAN

Backplane A Enable “BPAEN” DIP-Switch

When the “BPAEN” DIP-Switch is in the right position,

the A 10/100 Ethernet backplane port is enabled. This

port allows connection to an adjacent module (in the

same chassis) via the backplane A link of the chassis.

When the “BPAEN” DIP-Switch is in the left “off”

position (factory setting), the A port is isolated from

the backplane.

Backplane B Enable “BPBEN” DIP-Switch

When the “BPBEN” DIP-Switch is in the right position,

the B 10/100 Ethernet backplane port is enabled. This

port allows connection to an adjacent module (in the

same chassis) via the chassis’ backplane B link. When

the “BPBEN” DIP-Switch is in the left “off” position

(factory setting), the B port is isolated from the

backplane.

Fiber Port 1 Auto/Manual “ P1 AN/MAN” DIP-Switch

When the P1 AN/MAN switch is in the “AN” (left) position

(factory setting) it enables Port 1 to determine duplex

mode automatically. If the device connected to Port 1

cannot provide the proper signal to indicate its own

mode of operation, then the DIP-Switch should be set

to the “MAN” (right) position, forcing Port 1 to

Full-Duplex mode.

Fiber Port 2 Auto/Manual DIP-Switch (P2 AN/MAN)

When the P2 AN/MAN switch is in the “AN” (left)

position (factory setting) it enables Port 2 to

determine duplex mode automatically. If the device

connected to Port 2 cannot provide the proper signal

to indicate its own mode of operation, then the

DIP-Switch should be set to the “MAN” (right) position,

forcing Port 2 to Full-Duplex mode.

NOTE: When a fiber port is in manual mode, sometimes

a link-up will not occur with other devices. Both devices

must be set to the same mode (either Manual or

Auto-Negotiate) for the link-up to occur.

LED INDICA TORS

LED Color Description

Pwr: Y ellow On--Power

F/O P1 FDX: Green On--Full-Duplex detected

F/O P1 Lk/Act: Green On--Link / Blink--activity

F/O P2 Lk/Act: Green On--Link / Blink--activity

F/O P2 FDX: Green On--Full-Duplex detected

MOUNTING AND CABLE ATT ACHMENT

The iConverter modules are hot-swappable and can

be installed into any chassis in the

T o install the module in a chassis, perform the following

steps:

iConverter family.

1. Carefully slide the iConverter module into the

installation slot, aligning the module with the

installation guides. Ensure that the module is firmly

seated against the backplane.

2. Secure the module in the chassis by using the

panel fastener screw (attached to the module).

3. Connect the appropriate multimode or single-mode

fiber cable to a 1000BASE-X Ethernet device.

NOTE: The iConverter transmit (Tx) must attach to the

receive side on other device; the receive (Rx) must

attach to the transmit.

4. When using single-fiber (SF) media converter

models, the Tx wavelength on one end has to match

the Rx wavelength on the other.

NOTE: Based on this guideline, the SF media converter

models must be used in pairs, such as the 8550-01

matched with the 8551-01.

Page 9

GX/X SPECIFICATIONS

Model Type GX/X

Protocols

Fiber

Connectors

Controls

LED Displays

Dimensions

Weight

Compliance

Power

Requirement

Temperature

Humidity

Altitude

MTBF (hrs)

It is recommended when connecting two GX/X modules

together to use port 1 as the common port between

modules (or port 1 to port 2).

The GX/X should not be installed in the 1-slot chassis

because of power and heat constraints.

1000BASE-SX/LX

SC, MT-RJ, LC ,

Single-Fiber SC

BP Enable, LS/LP, RFD,

SFD, F/O Auto/Man

Power, FO link, FDX/HDX

W:0.85" x D:4.5" x H:2.8"

8 oz.

UL, CE, FCC Class A

2.2A @ 3.3VDC (typical)

Standard: 0 to 50º C

Storage: -40 to 80º C

5 to 95% (non-condensing)

-100m to 4000m

640,000

Page 13

Page 10 Page 11

Warning

The operating description in this Instruction Manual is for use by qualified

personnel only. T o avoid electrical shock, do not perform any servicing of

this unit other than that contained in the operating instructions, unless you

are qualified and certified to do so by Omnitron Systems T echnology, Inc.

Warranty

This product is warranted to the original purchaser against defects

in material and workmanship for a period of TWO YEARS from the

date of shipment. A LIFETIME warranty may be obtained by the

original purchaser by REGISTERING this product with Omnitron

within 90 days from the date of shipment. TO REGISTER,

COMPLETE AND MAIL OR FAX THE ENCLOSED

REGISTRATION FORM. Or you may register your product on the

Internet at www.omnitron-systems.com. During the warranty period,

Omnitron will, at its option, repair or replace a product which is

proven to be defective.

For warranty service, the product must be sent to an Omnitron designated

facility, at Buyer’s expense. Omnitron will pay the shipping charge to

return the product to Buyer’s designated US address using Omnitron’s

standard shipping method.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from improper

or inadequate use and/or maintenance of the equipment by Buyer, Buyersupplied equipment, Buyer-supplied interfacing, unauthorized

modifications or tampering with equipment (including removal of

equipment cover by personnel not specifically authorized and certified by

Omnitron), or misuse, or operating outside the environmental

specification of the product (including but not limited to voltage, ambient

temperature, radiation, unusual dust, etc.), or improper site preparation

or maintenance.

No other warranty is expressed or implied. Omnitron specifically

disclaims the implied warranties of merchantability and fitness for any

particular purpose.

Page 14 Page 16

Exclusive Remedies

The remedies provided herein are the Buyer’s sole and exclusive

remedies. Omnitron shall not be liable for any direct, indirect, special,

incidental, or consequential damages, whether based on contract,

tort, or any legal theory.

TECHNICAL SUPPORT

For help with this product, contact our Technical Support:

Phone: (949) 250-6510

Fax: (949) 250-6514

Address: Omnitron Systems Technology, Inc.

140 Technology Dr., #500

Irvine, CA 92618 USA

E-mail: support@omnitron-systems.com

URL: www.omnitron-systems.com

Page 15

Page 12

Form: 040-08540-001D 9/07

Loading...

Loading...