Page 1

FlexSwitchTM 1Fx+4U

Model 6750-FK

Replacement Kit

User Manual

140 Technology #500, Irvine, CA 92618

Phone: (949) 250-6510; Fax: (949) 250-6514

Page 2

Table of Contents

1.0 INTRODUCTION.................................................................... 3

1.1 General Description ............................................................. 3

1.2 Chassis Models .................................................................... 3

2.0 INSTALLATION...................................................................... 4

2.1 Chassis Installation .............................................................. 4

2.2 Module Installation............................................................... 4

2.3 Fiber Installation ................................................................... 4

2.4 UTP Installation .................................................................... 4

3.0 CONFIGURATION ................................................................. 5

3.1 DC Powered Chassis Site Preparation............................... 5

3.2 DC Powered Chassis Mounting .......................................... 5

3.3 Configuring the DIP-switches ............................................. 7

3.3.1 4Tx Switch Module ............................................................... 7

3.3.2 Media Converter Module - Front Panel............................... 8

3.3.3 Media Converter Module - On-Board.................................. 9

4.0 LED INDICA TORS ............................................................... 11

4.1 4Tx Switch Module............................................................. 11

4.2 Media Converter Module ................................................... 12

5.0 SPECIFICATIONS................................................................ 13

6.0 LINK MODE DESCRIPTION................................................ 14

Page 2

Page 3

1.0 INTRODUCTION

1.1 General Description

The 6750-FK is the replacement for the discontinued FlexSwitch Model

600XC 1Fx + 4U. The 6750-FK replacement kit consists of one

iConverter 10/100BASE-TX to 100BASE-FX Media Converter Module

and one iConverter 4Tx Switch Module installed in a iConverter 2-Module

Chassis.

The 6750-FK provides five auto-negotiating 10/100 UTP ports with auto-crossover

that enables easy attachment to hubs, switches and workstations. The

100BASE-FX fiber port supports half or full duplex operation.

The 6750-FK features on-board and front panel accessible DIP-switches for

manual configuration of the ports.

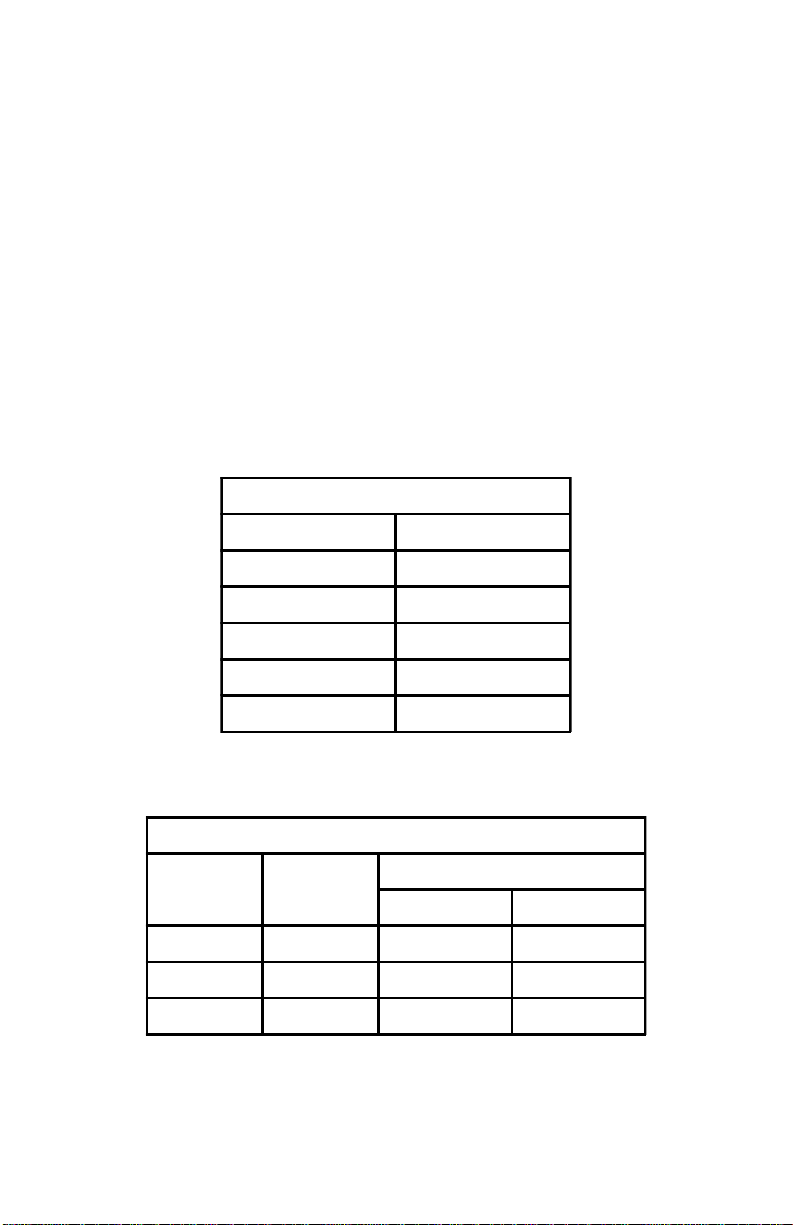

1.2 Chassis Models

FlexSwitch Replacement Matrix

Discontinued Part Replacement Part

6750-0 6750-0-FK

6750-2 6750-2-FK

6750-3 6750-3-FK

6751-0 6751-0-FK

6751-2 6751-2-FK

Replacement Matrix

FlexSwitch Model 6750

Fiber Type Distance

MM 5km 6750-0-FK 6751-0-FK

SM 30km 6750-2-FK 6751-2-FK

SM 60km 6750-3-FK -

Model Numbers

Connector Type

SC ST

Page 3

Page 4

2.0 INST ALLATION

2.1 Chassis Installation

The 6750-FK is designed to accommodate wall-mounting and tabletop

installations. For wall-mounting, the 8249-0 W all-Mount kit (sold separately)

is designed to attach the chassis to a wall, backboard or other flat surfaces.

For tabletop installations, place the unit on a flat level surface. Attach the

rubber feet to the bottom of the chassis to prevent the unit from sliding. Make

sure the unit is placed in a safe, dry and secure location.

For external power installation and configuration, see section 3.0.

2.2 Module Installation

The modules are pre-installed in the iConverter 2-Module chassis with the

backplanes enabled on both modules and Link Segment selected (see Section

6.0). If the modules are removed, carefully slide the module into the open

slot. Align the module with the installation guides and ensure that the module

is firmly seated against the backplane. Secure the module by fastening the

front panel thumbscrew (push in and turn clockwise to tighten) to the chassis

front.

2.3 Fiber Installation

Connect an appropriate multimode or single-mode fiber cable to the fiber port

of the installed module. It is important to make sure that the transmit (TX) is

attach to the receive side of the device at the other end and the receive (RX) is

attach to the transmit side.

2.4 UTP Installation

Connect the UTP ports via a Category 5 cable to 10BASE-T or 100BASE-TX

Ethernet devices.

Page 4

Page 5

3.0 CONFIGURATION

3.1 DC Powered Chassis Site Preparation

• Power source should be available within 5 ft. of the chassis. The over

current protection for connection with centralized DC shall be provided in

the building installation, and shall be a UL listed circuit breaker rated

20Amps, and installed per the National Electrical Code, ANSI/NFPA-70.

• This equipment requires 18-60VDC/1.0Amp rated power. Appropriate

overloading protection should be provided on the DC power source outlets

utilized.

WARNING: Only a DC power source that complies with

safety extra low voltage (SELV) requirements can be

connected to theDC-input power supply.

WARNING REGARDING EARTHING GROUND:

o

This equipment shall be connected to the DC supply

system earthing electrode conductor or to a bonding

jumper from an earthing terminal bar or bus to which the

DC supply system earthing electrode is connected.

o

This equipment shall be located in the same immediate

area (such as adjacent cabinets) as any other equipment

that has a connection between the earthed conductor of

the same DC supply circuit and the earthing conductor,

and also the point of earthing of the DC system. The DC

system shall not be earthed elsewhere.

o

The DC supply source is to be located within the same

premises as this equipment.

o

There shall be no switching or disconnecting devices in

the earthed circuit conductor between the DC source and

the earthing electrode conductor.

• The operating temperature of this equipment is 0 to 50 degrees C. If installed

in a closed or multi-module rack assembly, the operating ambient

temperature of the rack must not exceed the maximum rated 50 degrees C.

• Installation of the equipment should be such that the air flow in the front

and back of the chassis is not compromised or restricted.

• Never use this equipment to carry any weight except its own. Never use it

as a shelf to support weight of other equipment.

3.2 DC Powered Chassis Mounting

• Locate the DC circuit breaker, and switch the circuit breaker to the OFF

position.

Page 5

Page 6

• Prepare a power cable using a three conductor insulated wire (not supplied)

with a 14 AWG gauge minimum. Cut the power cable to the length required.

• Strip approximately 3/8 of an inch of insulation from the power cable

wires.

• Connect the power cables to the iConverter Chassis by fastening the

stripped ends to the DC power connector.

WARNING: Note the wire colors used in making the positive, negative

and ground connections. Use the same color assignment for the connection

at the circuit breaker.

• Connect the power wires to the circuit breaker and switch the circuit breaker

ON. If any modules are installed, their Power LED should indicate the

presence of power.

Rear of 2-Module Chassis with DC Power Connector

WARNING!!!

NEVER ATTEMPT TO OPEN THE CHASSIS OR SERVICE THE

POWER SUPPLY OR FAN MODULE. OPENING THE CHASSIS

MAY CAUSE SERIOUS INJURY OR DEATH.

THERE ARE NO USER REPLACEABLE OR SERVICEABLE

PARTS IN THIS UNIT.

Page 6

Page 7

3.3 Configuring the DIP-switches

The 6750-FK has been pre-configured with auto-negotiation enabled on all

UTP ports for plug and play easy of use. However, the iConverter Modules

offer additional configuration flexibility.

3.3.1 4Tx Switch Module

The 4Tx Switch Module has been pre-configured for auto-negotiation.

Board-mounted DIP-switches are available to manually configure Port 1 and

2. The figure below indicates the factory default settings.

BP A EN

BP B EN

MAN

10

HD

MAN

10

HD

(Left Position) (Right Position)

__

__

AN

100

FD

AN

100

FD

P1

P2

(Port 1)

(Port 2)

4 Port Switch Module DIP-Switches

Backplane Port A Enable/Disable “BP A EN” DIP-switch

This DIP-switch must be in the LEFT position (factory default) for the module

to operate correctly. The switch provides backplane connectivity with the

Media Converter Module.

Backplane Port B Enable/Disable “BP B EN” DIP-switch

This DIP-switch must be in the LEFT position (factory default) for the module

to operate correctly. The switch provides backplane connectivity with the

Media Converter Module.

UTP Auto-Negotiate/Manual “AN / MAN” DIP-switch (Port 1 or Port 2)

When this DIP-switch is in the UTP auto-negotiate “AN” position (factory

default), the UTP port automatically determines the speed and duplex mode of

the connecting UTP device. If the connecting UTP device cannot provide the

proper signal to indicate its own mode of operation, this DIP-switch should be

set to the UTP Manual mode “MAN” position. Manual mode requires manually

configuring the UTP port to match the speed and the duplex mode of the

connecting UTP device using the “10/100” and UTP “FDX/HDX” DIP-switches.

When a UTP port is configured for auto-negotiation, the automatic crossover

detection is enabled for that particular UTP port. Automatic crossover detection

is disabled when the UTP port is configured for manual negotiation.

Page 7

Page 8

UTP 10/100Mbps “10/100” DIP-switch (Port 1 or Port 2)

When the UTP “AN/MAN” DIP-switch (described above) is in the manual

“MAN” position, the “10/100” DIP-switch determines the speed of operation

for the designated UTP port. Setting the “10/100” DIP-switch to “100”

position (factory default) forces the UTP port to operate at 100Mbps.

Setting this DIP-switch to “10” position forces the UTP port to operate at

10Mbps. Adjust the “10/100” DIP-switch to match the speed of the

connecting UTP device.

UTP Full/Half-Duplex “HD/FD” DIP-switch (Port 1 or Port 2)

When the UTP “AN/MAN” DIP-switch (described above) is in the manual

“MAN” position, the “HD/FD” DIP-switch determines the duplex operation

mode for the UTP port. Setting the “HD/FD” DIP-switch to UTP Full-Duplex

“FD” (factory default) position forces the UTP port to operate in Full-Duplex.

Setting this DIP-switch to “HD” forces the UTP port to operate in

Half-Duplex. Adjust the UTP Half/Full-Duplex DIP-switch to match

duplex mode the connecting UTP device.

When the UTP “AN/MAN” DIP-switch is in the auto-negotiate “AN” position

and the UTP Full/Half Duplex DIP-switch is in the Full-Duplex “FD” position,

the UTP port auto-negotiates to Full or Half-Duplex. When in the Half-Duplex

“HDX” position, the UTP port functions only in Half-Duplex.

3.3.2 Media Converter Module - Front Panel

The Media Converter Modules have been pre-configured as illustrated below .

Using the front panel DIP-switches, the module can be configured for customerspecific applications.

Media Converter Module Front Panel DIP-Switches

Fiber Full/Half-Duplex “FDX / HDX” DIP-switch

When in the Fiber Full/Half-Duplex DIP-switch is in the “FDX” position

(factory default), the fiber port operates in Full-Duplex mode. When in the

“HDX” position, the fiber port operates in Half-Duplex mode and its distance

is limited by the IEEE 802.3 standard to 412 meters.

UTP Auto/Manual Negotiate “AN / MAN” DIP-switch

When the UTP “AN/Man” DIP-switch is in the auto-negotiate “AN”

position (factory default), the converter auto-negotiates and matches the

Page 8

Page 9

10/100 speed and duplex mode of a mating auto-negotiating device

connected to its UTP port.

When the UTP “AN/Man” DIP-switch is in the “Man” position, the converter

does not auto-negotiate and operates in the mode selected by the Full/HalfDuplex “FDX/HDX” and “10/100” DIP-switches.

UTP 10/100 “10 / 100” DIP-switch

When the UTP “AN/Man” DIP-switch is in the “Man” position, the UTP

“10/100” DIP-switch selects the speed of the UTP port. When in the “100”

position (factory default), the UTP port operates at 100 Mbps. When in

the “10” position the UTP port operates at 10 Mbps.

UTP Full/Half-Duplex “FDX / HDX” DIP-switch

When the UTP “AN/Man” DIP-switch is in the “Man” position, the “FDX/HDX”

DIP-switch selects the duplex mode of the UTP port. When in the “FDX” position

(factory default), the UTP port operates in Full-Duplex mode. When in the

“HDX” position, the UTP port operates in Half-Duplex. Set the duplex mode

to match the connecting device and check for link status.

Note: Attaching an auto-negotiating UTP port of the 6750-FK to a device with

a manual/forced/hard-coded UTP port may result in an unpredictable port

setting with excessive collisions and poor link performance. When operating

in Manual mode, both mating ports MUST be set manually to the same speed

and duplex mode.

3.3.3 Media Converter Module - On-Board

The Media Converter Module has an on-board DIP-switch for the configuration

of the Link Mode and Backplane connectivity. See Section 6.0 for more

information on the Link Modes. The module is preconfigured as illustrated

below.

=

4

3

2

1

Media Converter Module On-Board DIP-switches

Remote Fault Detection “RFD” DIP-switch

RFD

BPOEN

LP

Down

Remote Fault Detect Enable

=

Backplane Enable

=

Link Propagate/Link Segment

=

Not Used (Factory Set)

When the Remote Fault Detect “RFD” DIP-switch is in the UP position, the

RFD mode is selected. When in the DOWN position (factory default), the

RFD mode is disabled.

Note: Connecting two converters with both set to RFD mode is an illegal

setting and will cause a “deadly embrace” lockup.

Page 9

Page 10

A and B Backplane Enable “BPOEN” DIP-switch

This DIP-switch must be in the UP position (factory default) for the module to

operate correctly. The backplane must be enabled for the Media Converter

Module to communicate.

Link Propagate/Link Segment “LP” DIP-switch

When both the Link Propagate/Link Segment “LP” and the Remote Fault Detect

“RFD” DIP-switches are in the DOWN position (factory default), Link Segment

mode is enabled. When the Link Propagate/Link Segment “LP” DIP-switch is

in the UP position, and the Remote Fault Detect “RFD” DIP-switch is in the

DOWN position, Link Propagate mode is enabled.

Note: Setting both the “LP” and the “ RFD” to the UP positions on the same

module is an illegal mode that will result in unpredictable behavior.

Page 10

Page 11

4.0 LED INDICA TORS

4.1 4Tx Switch Module

The 4Tx Switch Module has LED indicators to provide connection information.

4Tx Switch Module

LED Functi on Color Off State ON State

Po wer "P w r" Yellow No Power On: Module has P ower

Port 1 "100 Link" Green Not Li nked at 100Mbps On: Port Linked at 100Mbps

Blinking: Data Acti vi ty

Port 1 "10 Link" Green Not Linked at 10Mbps On: Port Linked at 10Mbps

Blinking: Data A c t i vi t y

Port 2 "100 Link" Green Not Li nked at 100Mbps On: Port Linked at 100Mbps

Blinking: Data A c t i vi t y

Port 2 "10 Link" Green Not Linked at 10Mbps On: Port Linked at 10Mbps

Blinking: Data A c t i vi t y

Port 3 "100 Link" Green Not Li nked at 100Mbps On: Port Linked at 100Mbps

Blinking: Data A c t i vi t y

Port 3 "10 Link" Green Not Linked at 10Mbps On: Port Linked at 10Mbps

Blinking: Data A c t i vi t y

Port 4 "100 Link" Green Not Li nked at 100Mbps On: Port Linked at 100Mbps

Blinking: Data A c t i vi t y

Port 4 "10 Link" Green Not Linked at 10Mbps On: Port Linked at 10Mbps

Blinking: Data A c t i vi t y

4 Port Switch Module LED Indicators

Page 11

Page 12

4.2 Media Converter Module

The Media Converter Module has LED indicators to provide information on

how the module is communicating to its link partner. The LED indicators can

also be used to troubleshoot problems with the connections.

Media Converter Module

LED Function Color OFF State ON State

Po wer "P wr" Yello w No P ower On: Mod ule has powe r

Fiber "FD X" Green Fiber in Half Duplex On: F iber in Full Duplex

Fiber "Lk Act" Green No Fiber Link On: Fiber Li nk is Active

Blinking: Data Acti vity

UTP "AN" Green UTP is in Manual

Negotiation

UTP "100" Green UTP no t Linked at

100Mbps

UTP "1 0" Green UTP no t Linked at

10Mbps

UTP " FDX" Green UTP in Half Duplex On: UTP in Full Duplex

UTP "Lk Act" Green No UTP Link On: UTP Link i s Active

Media Converter Module LED Indicators

On: UTP is in Auto-Negotiation

Enabled.

On: UTP Linked at 100 Mbps

On: UTP Linked at 10Mbps

Blinking: Data Acti vity

Page 12

Page 13

5.0 SPECIFICATIONS

Description Fast Ethernet Swi tch with

5 10/100 UTP Ports and 1 100BASE-FX Fib er Port

Protocols 10BASE-T, 100BASE-TX, 100BASE-FX

with 1535 bytes max. frame size

UTP C able Type EIA/TIA 568A /B

Category 5 and higher

Fiber Cable Type Multimode: 50/125, 6 2.5/125, 100/140um

Singlemo de: 9/125um

UTP C onnector Type RJ45

Fiber Connector Type D ual Fiber: ST, SC

DIP-S witches F i ber: FDX/HDX

UTP : AN/MAN, 10/100, FDX/HDX

Link Modes: LS, LP, RFD

Power Requirements +/- 18 to 60VD C

-48VDC @ 1.0A

Dimensions W: 6.7" x D: 5.51" x H: 1.87"

Weight 3.5 lbs

Compliance s UL, C E , FCC CLass A, NEB S Level 3

Temperature Operati ng: 0 to +50 C

Storage: -50 to +80 C

Humidity

(non-condensing)

Altitude (operational) -100m to 4000m

5 to 95%

Page 13

Page 14

6.0 LINK MODE DESCRIPTION

In order to accommodate different user requirements, the 6750-FK Media

Converter Module supports three different link modes.

Link Segment (LS)

LS mode transmits a link signal independently of any received Link at any

port. Utilizing this configuration, a loss of a receive link signal will only affect

the port detecting the loss of signal. All the other ports will continue to generate

a link signal. A loss of link on the UTP port, only affects the UTP port; the

other ports remain unaffected.

Link Propagate (LP)

LP mode transmits a link signal only when a link signal is detected. Utilizing

this configuration, a loss of a receive link signal will continue to propagate

through to the next port in the network. A loss of link on the UTP port will

cause the fault to propagated forward causing the fiber and UTP ports at the

remote end to drop its link. This setting allows the loss of a link to be detected

by SNMP or other managed network devices.

Remote Fault Detect + Link Propagate (RFD+LP)

RFD+LP mode transmits a link signal only when a link signal is detected.

When a loss of link is detected, this mode will perform both a loop back and

propagate forward. A loss of RX fiber causes the fault to loop back causing

the port on the other media converter to lose link. It also propagates the fault

forward toward the UTP port causing the UTP port to lose link.

Note: Connecting two converters together both set to RFD+LP mode will

cause a lockup condition. This is an illegal setting.

Page 14

Page 15

Warning

The operating description in this Instruction Manual is for use by qualified

personnel only. To avoid electrical shock, do not perform any servicing of this

unit other than that contained in the operating instructions, unless you are qualified

and certified to do so by Omnitron Systems Technology, Inc.

Caution

All user-required operations can be performed without opening the unit. Never

attempt to open or remove the cover or tamper with the unit. There are no user

replaceable or serviceable parts in this unit. Equipment is not intended to be

installed and used in a place (home, school, or public area) accessible to the general

population.

Warranty

This product is warranted to the original purchaser against defects in material and

workmanship for a period of TWO YEARS from the date of shipment. A LIFETIME

warranty may be obtained by the original purchaser by REGISTERING this product

with Omnitron within 90 days from the date of shipment. TO REGISTER, COMPLETE

AND MAIL OR F AX THE ENCLOSED REGISTRATION FORM. Or you may register

your product on the Internet at http://www .omnitron-systems.com. During the warranty

period, Omnitron will, at its option, repair or replace a product which is proven to be

defective.

For warranty service, the product must be sent to an Omnitron designated facility, at

Buyer’s expense. Omnitron will pay the shipping charge to return the product to Buyer’s

designated US address using Omnitron’s standard shipping method.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from improper or

inadequate use and/or maintenance of the equipment by Buyer, Buyer-supplied

equipment, Buyer-supplied interfacing, unauthorized modifications or tampering

with equipment (including removal of equipment cover by personnel not

specifically authorized and certified by Omnitron), or misuse, or operating outside

the environmental specification of the product (including but not limited to voltage,

ambient temperature, radiation, unusual dust, etc.), or improper site preparation

or maintenance.

No other warranty is expressed or implied. Omnitron specifically disclaims the

implied warranties of merchantability and fitness for any particular purpose.

Exclusive Remedies

The remedies provided herein are the Buyer’s sole and exclusive remedies.

Omnitron shall not be liable for any direct, indirect, special, incidental, or

consequential damages, whether based on contract, tort, or any legal theory

.

Page 16

TECHNICAL SUPPORT

If you encounter problems with this product, contact Omnitron Technical

Support.

Phone: 800-675-8410

949-250-6510

Fax: 949-250-6514

Address: Omnitron Systems Technology , Inc.

140 Technology Dr., #500

Irvine, CA 92618

Email: support@omnitron-systems.com

URL: http://www.omnitron-systems.com

Form: 040-06750-FK1 B 7/08

Loading...

Loading...