Page 1

12 Omnitron Systems Technology , Inc.

SPECIFICATIONS

Protocol: IEEE 802.3, 10Base-T, 100Base-Tx, 100Base-Fx

Interface Connectors:

UTP: (12/24) RJ45 pins 1-2, 3-6 active

Fiber Optic: (1) SC or ST

Cable T ypes:

UTP , 10Base-T: EIA/TIA 568, Category 3, 4, or 5

UTP , 100Base-Tx: EIA/TIA 568, Category 5

Fiber , Multimode (MM): 50/125, 62.5/125, 100/140 um

Fiber , Single-Mode (SM): 9/125 um

Supported Distances:

UTP: 100 m / 328 ft.

MM, Extended: 2 km / 1.2 mi.

SM, Extended: 25 km / 15 mi.

SM, Long Haul (LH): 58 km / 35 mi.

Indicators:

Hub:

Power: LED (1), Yellow (10/100) or Green (100), power applied

Activity 10: LED(1), Green, activity detected

Collision 10: LED (1), Y ellow , collision detected

Activity 100: LED(1), Green, activity detected

Collision 100: LED (1), Y ellow , collision detected

Link / Partition: LED (12/24), Green, per port: device detected / port partitioned

Port Speed: LED (12/24), Green, per port: 10 / 100 / Searching

100Fx and 10/100Tx Modules:

Data Received: LED (1), Green, data received

Link / Speed: LED (1), Green / Y ellow , device detected and 10/100 speed

Duplex Mode: LED (1), Green / Y ellow, Full-Duplex / Half-Duplex

Collision: LED (1), Y ellow, collision detected

Switches:

Hub:

UTP Crossover: Straight / Crossed

Stack Control: Base / Stack

Port Access Control: 6/12 Switches, 2 per 4 ports: Auto-Sensing / 100Base-Tx / 10Base-T

100Fx Module:

Duplex Mode: Full / Half-Duplex

10/100Tx Module:

UTP Crossover: Straight / Crossed

Auto-Sensing Mode: Auto-Sensing / Manual

Duplex Mode: Full-Duplex / Half-Duplex

Speed Control: 100Base-Tx / 10Base-T

Dimensions / W eight: W:19.0"xD:8.0"xH:1.75" / 7 lb.

Power: 110 / 230 VAC, 50 / 60 Hz

Temperature: 0 to 40 degrees C

Humidity: 0-90% (non-condensing)

Omnitron Systems Technology, Inc. 1

FlexCenter™ 200

Auto-Sensing

Dual Speed 10/100 and 100 Stackable

Ethernet Hubs

User Manual

TECHNICAL SUPPORT

For assitance in installing this product, contact Omnitron’s Technical Support Department:

Phone: (949) 250-6510, Fax: (949) 250-6514

Address: Omnitron Systems Technology, Inc.

27 Mauchly, #201

Irvine, CA 92618, USA

Email: support@omnitron-systems.com

URL: www.omnitron-systems.com

27 Mauchly #201, Irvine, CA 92618 (949) 250-6510 Fax: (949) 250-6514

Page 2

2 Omnitron Systems Technology , Inc.

Omnitron Systems Technology, Inc. 11

Safety Considerations

Warning

The operating description in this Instruction Manual is for use by qualified personnel only. T o avoid

electrical shock, do not perform any servicing of this unit other than that contained in the operating

instructions, unless you are qualified and certified to do so by Omnitron Systems T echnology , Inc.

Caution

All user-required operations can be performed without opening the unit. Never attempt to open

or remove the cover or tamper with the unit or tamper with the power supply module.

Warranty

This product is warranted to the original purchaser against defects in material and workmanship

for a period of TWO YEARS from the date of shipment. A LIFETIME warranty may be obtained by

the original purchaser by REGISTERING this product with Omnitron within 90 days from the date

of shipment. TO REGISTER, COMPLETE AND MAIL OR FAX THE REGISTRATION CARD INCLUDED

IN THIS INSTRUCTION MANUAL TO THE INDICATED ADDRESS. During the warranty period,

Omnitron will, at its option, repair or replace a product which is proven to be defective.

For warranty service, the product must be sent to an Omnitron designated facility, at Buyer’s

expense. Omnitron will pay the shipping charge to return the product to Buyer’s designated US

address using Omnitron’s standard shipping method.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from improper or inadequate use and/or

maintenance of the equipment by Buyer, Buyer-supplied equipment, Buyer-supplied interfacing, unauthorized modifications or tampering with equipment (including removal of equipment cover by personnel not specifically authorized and certified by Omnitron), misuse, operating outside the environmental specification of the product (including but not limited to voltage, ambient temperature, radiation, unusual dust, etc.), or improper site preparation or maintenance.

No other warranty is expressed or implied. Omnitron specifically disclaims the implied warranties of

merchantability and fitness for any particular purpose.

Exclusive Remedies

The remedies provided herein are the Buyer’s sole and exclusive remedies. Omnitron shall not be

liable for any direct, indirect, special, incidental, or consequential damages, whether based on contract, tort, or any legal theory.

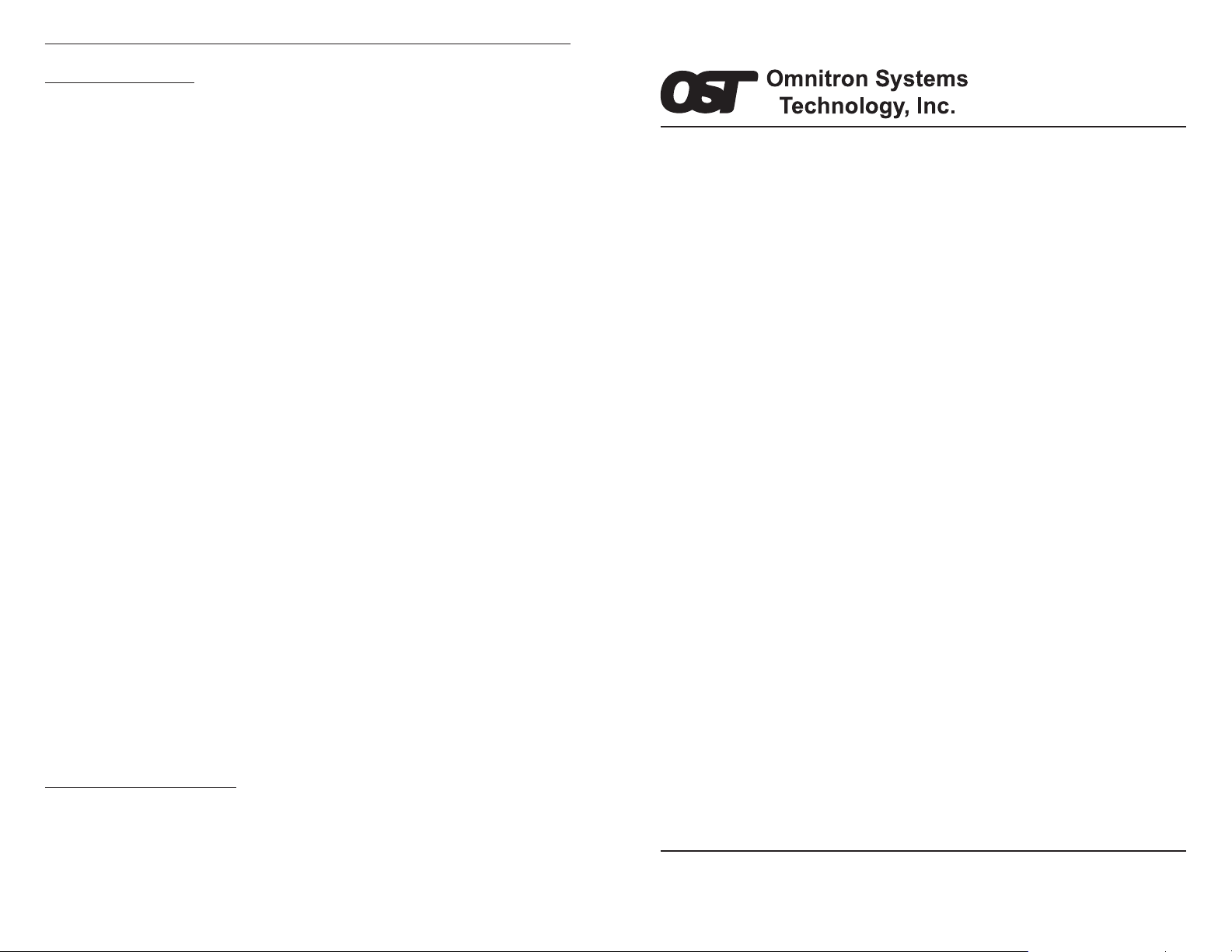

Application 7. Flat Fiber Backbone

This application depicts a flat fiber backbone where hubs are stacked, and connected via extended

fiber uplinks. As shown in this example, the module slots are used both for stacking as

well as for fiber modules. Using the extended distance modules isolates the collision

domains between each stack and facilitates a network that can span up to 58 km (35 mi.)

per uplink.

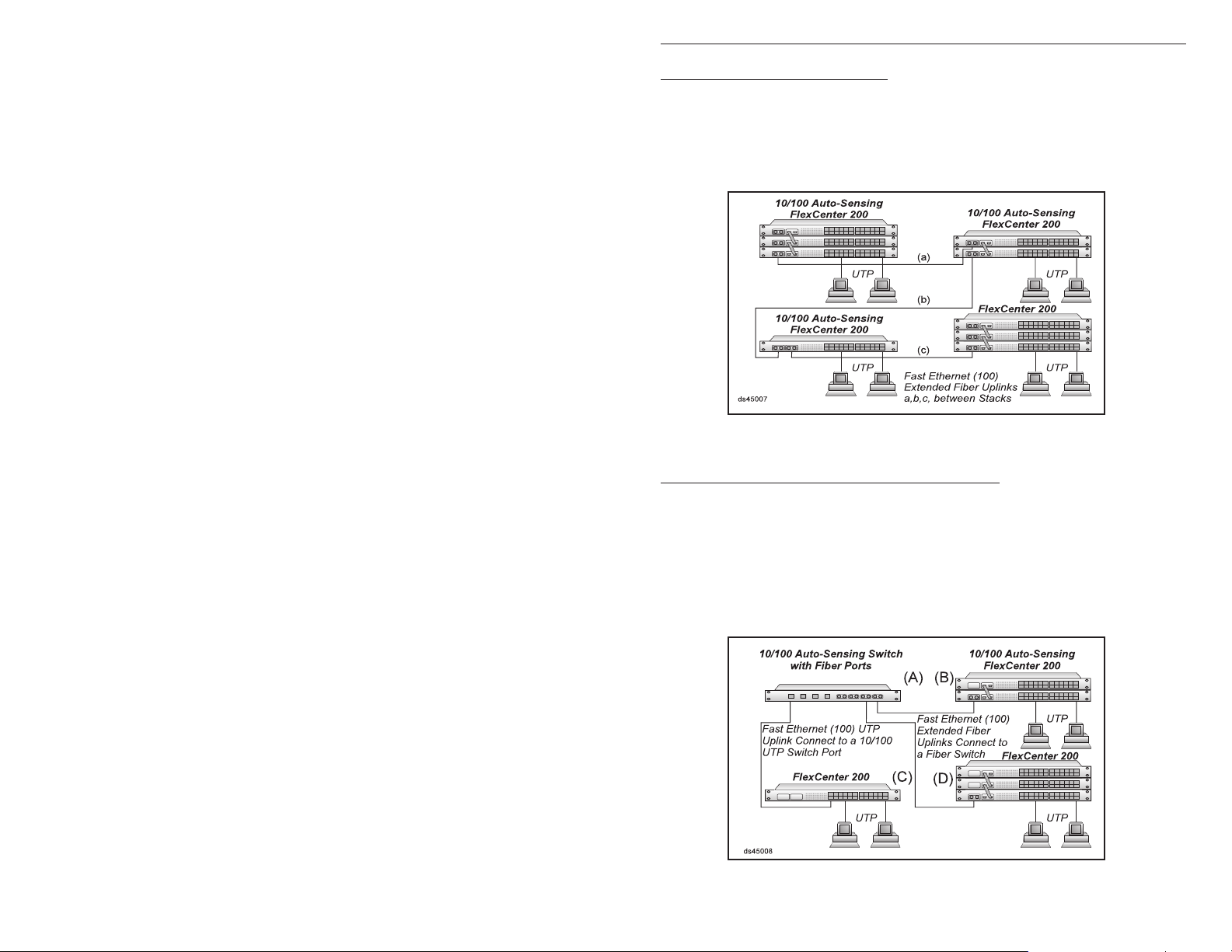

Application 8. Collapsed / Switched Fiber Backbone

This application depicts a collapsed fiber backbone where hubs are stacked, and

connected via fiber and UTP uplinks to a single location, 10/100 auto-sensing switch with

fiber ports, in a star fashion. This application is similar to the flat backbone with the

difference of being a single point of management and control for the different subnetworks.

In this case two stacks of hubs, B and D, are connected via extended distance fiber

modules to the fiber ports of the switch. The hub in location C is connected via UTP to a

10/100 UTP port on the switch and is able to reach a distance of 100 m (328 ft.).

FCC Warning

This equipment has been tested and found to comply with the limits for a class A digital device,

pursuant to part 15 of the FCC rules. These limits are designed to provide a reasonable protection

against harmful interference when the equipment is operated in a commercial environment. The

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operating this equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense. Any changes or modifications not

expressly approved by the manufacturer could void the user authority to operate the equipment.

Form:040-04500-003 9/03

Page 3

10 Omnitron Systems Technology , Inc.

Application 5. Single Wiring Closet / Multiple Hubs

This application depicts a single-wiring-closet-based network. It is a typical stacking

application of the FlexCenter 200. In this case six hubs are stacked, accommodating up

to 150 stations (144 ports plus six modules).

Application 6. Multiple Wiring Closets / Multiple Hubs

This case depicts two stacks of hubs connected via a fiber uplink. Since an extendeddistance-bridge-based module is used, full-duplex operation is possible for distances of 2

km (1.2 mi.) using multimode fiber, and 58 km (35 mi.) using single-mode fiber .

Omnitron Systems Technology, Inc. 3

FlexCenter 200

Auto-Sensing Dual Speed 10/100 and 100

Stackable Ethernet Hubs

User Manual

GENERAL DESCRIPTION

The FlexCenter 200 is a family of 12/24 port dual speed 10/100 and 100 stackable

workgroup Ethernet hub repeaters. They feature two optional interface modules used

for stacking and uplink interfaces to multimode and single-mode fiber hubs, switches

or workstations. This User’s Manual describes the following base models:

Model Description

4500 FlexCenter 200, 10/100, 12 Ports

4501 FlexCenter 200, 10/100, 24 Ports

4550 FlexCenter 200, 100, 12 Ports

4551 FlexCenter 200, 100, 24 Ports

The following modules are supported by the FlexCenter 200:

4570 10/100Tx, UTP , XD

4571 100Fx, Fiber, XD, SC/MM, 2 km / 1.2 mi.

4572 100Fx, Fiber, XD, SC/SM, 25 km / 15 mi.

4573 100Fx, Fiber, XD, ST/MM, 2 km / 1.2 mi.

4574 100Fx, Fiber, XD, ST/SM, 25 km / 15 mi.

4575 100Fx, Fiber, LH/XD, SC/SM, 58 km / 35 mi.

4576 100Fx, Fiber, LH/XD, ST/SM, 58 km / 35 mi.

4580 100Tx, UTP, SD, 100 m / 328 ft.

4581 100Fx, Fiber, SC/MM, SD, 100-200 m / 328-656 ft.

4582 100Fx, Fiber, SC/SM, SD, 100-200 m / 328-656 ft.

4583 100Fx, Fiber, ST/MM, SD, 100-200 m / 328-656 ft.

4584 100Fx, Fiber, ST/SM, SD, 100-200 m / 328-656 ft.

4590 STK, Stack Module

The FlexCenter’s 12/24 RJ45 ports provide 10Base-T or 100Base-Tx unshielded

twisted pair (UTP) wiring. Its fiber interface modules provide 100Base-Fx multimode

or single-mode SC or ST connectivity options for a variety of applications. The stacking module provides cable connection between stacked hubs.

The FlexCenter monitors and reports port activity. It detects operational devices

connected and displays their connection via a per-port green Link / Partition (L/P)

LED. If a port violates transmission rules, it is disconnected automatically (partitioned) and the L/P LED starts flashing indicating the “Partition” error status. The port

is reconnected only after normal behavior is restored. The per-port speed is indicated by a second per-port LED that flashes while not connected to a device, turns on

“solid” when detecting a 100 station and turns “off” when detecting a 10 station.

Page 4

4 Omnitron Systems Technology , Inc.

Omnitron Systems Technology, Inc. 9

The hub detects and displays per-segment activity (green LED) and collisions (yellow LED) for Ethernet and Fast Ethernet segments.

The FlexCenter features a special uplink Port 1 RJ45 connector. This uplink connector is equipped with a crossover switch that can switch between the receiving and

transmitting wire pairs. This feature eliminates the need for a “crossed cable” which

is otherwise required for connection between hubs.

The fiber and UTP uplink modules provide displays to show data speed, link and

activity, half/full duplex status and collisions. Controls include half/full duplex, autosensing and speed. The UTP module also features a crossover switch.

CONTROLS AND INDICATORS

FlexCenter 200 Mainframe:

Port 1 Control Switch

This switch provides the crossover feature for port 1 of the hub. It should be set to the

straight position for connection to a station or crossover position for connection to a

hub or a switch.

Position Description

Out Straight, use when connecting port 1 to a PC or workstation.

In Crossed-Over, use when connecting port 1 to another hub or switch.

Stack Control Switch

This switch controls the stacking features of the FlexCenter 200. When the FlexCenter 200 is used stand-alone, it must be set to the “Base’ position. When in a

stack, the first hub in a stack (with the “Out” cable only in the STK module) must be set

to the “Base”, and all other hubs must be set to the “Stack” position.

Application 2. 10Base-T and 100Base-Tx Integration via Fiber

In this case an Ethernet 10Base-T hub is connected to the FlexCenter 200 via a fiber

uplink. Since the Ethernet 10Base-FL fiber is specified (by 802.3) as 850 nm and the

Fast Ethernet 100Base-Fx fiber is specified as 1300 nm, they can never be connected.

The 10Base-FL link must be converted to 10Base-T before being connected to the

FlexCenter 200’s 10/100 UTP port. The 100Base-Fx uplink from the Fast Ethernet hub is

connected to the FlexCenter 200’s extended fiber uplink module facilitating 100 to 200 m

of fiber (depending on the Fast Ethernet hub’s network layout).

Application 3. 10Base-2 Coax to 100Base-Tx Integration

This application depicts the integration of legacy coax 10Base-2 network segments to a

modern 10/100 FlexCenter 200 hub. The first case (top) depicts connection via a 10Base2 Coax to 10Base-T UTP converter to a 10/100 FlexCenter 200 port. In the second case

(bottom), the distance between the coax segment and the FlexCenter 200 is more than

100 meters and it requires fiber conversion. A 10Base-2 coax to fiber converter is used to

convert coax to fiber, and a 10Base-FL fiber to 10Base-T UTP converter is used to convert

fiber to UTP which is connected to a 10/100 FlexCenter 200 port.

Position Description

Up Base, use when operating alone or as a base of a stack (the first hub).

Down Stack, use when in a stack. All hubs should be set to this state except

the first one in a chain.

Port Access Control Switches (6/12)

This set of switches is located in the back of the hub and control the operation of the

10/100 ports in groups of four ports; two switches per group. Normally , these switches

should be left in their factory default setting, which sets them to automatic sensing of

port speed and allows each port to auto-sense the highest level of service availble.

They should be used when the user desires to force a particular speed.

Application 4. Single Wiring Closet / T wo Hubs Application

This application depicts the basic connection between two 10/100 auto-sensing FlexCenter

200 hubs. A straight-through patch cord connects between Port 1 of both hubs. (The

crossover switch on one of them is set to the crossed mode.) This application is costeffective and simple, and it limits the distance between the hubs to 5 m / 15 ft. Only two

hubs can be connected this way thus limiting the station count to 46.

Page 5

8 Omnitron Systems Technology , Inc.

Omnitron Systems Technology, Inc. 5

b. When using in a stack, connect the stack cables “out” to “in” and set the first unit’s

Stack Control Switch to the “Base” position. All other stack units should be set to

the “Stack” position.

c. Plug the power cord into the FlexCenter 200 and the other side to the appropriate

AC outlet.

d. Plug any Ethernet 10Base-T or 100Base-Tx workstations into the RJ45 connec-

tors. The corresponding Link LED should turn ON.

e. Connect port 1 to a workstation or another hub. When connecting to a workstation

set the Crossover switch to its “Out” (Straight) position (factory setting). When

connecting to another hub set the switch to the “In” (Crossed) position. When the

device at the far end has become active, the port 1 Link LED should become ON.

f. Connect any fiber uplink cables to a fiber workstation, converter or another fiber

hub. Connect the Transmit (Tx) fiber of the FlexCenter to a Receive (Rx) fiber on

the connected device. Connect the Receive (Rx) fiber of the FlexCenter to a transmit (Tx) fiber on the connected device.

SAMPLE APPLICATIONS

Position Description

Up, Up Forced 100Base-Tx mode.

Up, Down Reserved for test, do not use.

Down, Up Forced 10Base-T mode.

Down, Down Auto-Sensing (Auto-Negotiating) mode (factory setting).

Common LEDs Display

Function Color/State Description

Power Yellow / ON Power applied.

Activity 10 Green / ON Ethernet (10) link / activity detected.

Collision 10 Yellow / ON Collision condition detected on the Ethernet (10)

segment.

Activity 100 Green / ON Fast Ethernet (100) link / activity detected.

Collision 100 Yellow / ON Collision condition detected on the Fast Ethernet

(100) segment.

Per Port LEDs Display

Function Color/State Description

Link / Partition

(L/P) Green / ON Device detected on UTP.

Green / Flash Port is partitioned.

Link (Lnk) Green / ON Fast Ethernet (100) device.

Green / OFF Ethernet (10) device.

Green / Flash No link detected.

Application 1. 10Base-T and 100Base-Tx UTP Integration

This application depicts a 10Base-T, a 100Base-Tx and a 10/100 FlexCenter 200 hub

configuration. Both the 10Base-T and the 100Base-Tx hubs are connected to the

FlexCenter 200’s 10/100 UTP ports via uplink wires. The 10Base-T uplink can be category

3,4 or 5 grade and can be 100 m (328 ft.) maximum length. The 100Base-Tx uplink must

be category 5 grade, and because it connects to a shared 10/100 port, it is limited to five

meters (15 ft.).

FlexCenter 200 10/100Tx UTP Module:

Crossover Control Switch

This switch provides the crossover feature for the UTP port module. It should be set

to the straight position for connection to a station or crossover position for connection

to a hub or a switch.

Position Description

Out Straight, use when connecting port to a PC or workstation.

In Crossed-Over, use when connecting port to another hub.

Mode Control Switches

These three switches control the operation of the UTP port. When set to “AutoSensing”, the hardware auto-senses the connected devices’ supported features

and automatically configures itself to the highest level of service possible (100BaseTx and Full-duplex). When specific operation is desired, the auto-sensing feature

can be disabled and specific speed (100 or 10) and full- or half-duplex modes can

be forced.

Page 6

6 Omnitron Systems Technology , Inc.

Omnitron Systems Technology, Inc. 7

Function Position Description

Auto-Sensing / Manual mode:

AN/MN Up Auto-sensing mode enabled.

Down Manual mode enabled.

Forced Full-Duplex / Half-Duplex (effective when in Manual mode):

FD/HD Up Forced Full-Duplex (when connecting to a switch or a sta-

tion with full-duplex capability).

Down Forced Half-Duplex (when connecting to a hub or a station

with half-duplex capability).

Forced Fast Ethernet / Ethernet (effective when in Manual mode):

100/10 Up Forced Fast Ethernet.

Down Forced Ethernet.

LEDs Display

Function Color/State Description

Rx Green / ON Received data on UTP line.

Lnk Green / ON Fast Ethernet Link detected.

Yellow / ON Ethernet Link detected.

Dpx Green / ON Full-Duplex operation.

Yellow / ON Half-Duplex operation.

Col Yellow / ON Collision detected.

FlexCenter 200 100Fx Fiber Module:

Since the IEEE 802.3 standard defines the Ethernet 10Base-FL fiber (850 nm) differently than the Fast Ethernet 100Base-Tx (1300 nm), it should be noted that they are

incompatible. The 100Fx module supports 100Base-Fx and can be operated in halfor full-duplex modes of operation.

Mode Control Switches

This switch controls the half / full-duplex operation of the fiber port. Half-duplex

should be used when connecting to another hub (with a shared / non-switched fiber

port) or a workstations fiber NIC that supports only half-duplex. Full-duplex can be

used when connecting to a switch or a NIC card that supports full-duplex operation.

Function Position Description

Full-Duplex / Half-Duplex Mode:

FD/HD Up Forced Full-Duplex.

Down Forced Half-Duplex.

FlexCenter STK Module:

Does not require any switches or displays.

SITE PREPARATION

The following are the minimal physical location preparations needed:

a. Power - A power outlet should be available within 5 feet of the unit.

b. Cabling - The following cabling should be used:

1. 10Base-T / UTP - Ideally the site should be cabled with category 5 wiring to

maximize performance but a category 3 or better is acceptable (100 ohms, 24

AWG solid copper).

2. 100Base-Tx / UTP - The site should be cabled with category 5 wiring to

maximize performance (100 ohms, 24 AWG solid copper).

3. 100Base-Fx / Fiber - Use 50/125, 62.5/125 or 100/140 micron multimode fiber

or 9/125 micron single-mode fiber.

UNPACKING

a. Visual Inspection - Before unpacking, a visual inspection should be conducted in

order to detect any physical damage to the equipment. Any evidence of damage

should be noted and reported immediately.

b. Unpacking - Place shipping container on a flat surface, cut straps or tape, open

top. Take out each item carefully and place securely on a clean flat surface.

Return all packing material into container (foam, boxes etc.), close and store away

for future reuse.

c. Inspection - Inspect each item for any apparent damage. Any evidence of damage

should be noted and reported immediately.

INVENTORY

Review content; the following items should be included:

(1) FlexCenter 200 unit.

(1) Power cord.

(1) User Manual (this document).

Please note any missing items or discrepancies and report them immediately.

INSTALLATION

LEDs Display

Function Color/State Description

Rx Green / ON Received data on UTP line.

Link Green / ON Fast Ethernet Link detected.

Dpx Green / ON Full-Duplex operation.

Yellow / ON Half-Duplex operation.

Col Yellow / ON Collision detected.

Cabling and Power-Up

a. When using the hub “stand alone”, set the Stack Control Switch to the up “Base”

position (factory setting).

Loading...

Loading...