Page 1

iConverter

Model Type Connectors Distance

8340-0

For wide temperature (-40 to 60º C) modules, add a "W" to the end

of the model number. Consult factory for other configurations and

extended temperature (-40 to +75º C) modules.

®

10T/2 User Manual

UTP 100m

Coax 185m

Page 1 Page 2 Page 3 Page 4 Page 5

OVERVIEW:

The iConverter 10T/2 converter supports the IEEE

802.3 standard and converts 10BASE-T cabling (UTP)

to 10BASE-2 coax cabling. The iConverter supports

Half-Duplex 10Mbps Ethernet and provides a crossover

UTP switch for easy attachment to hubs, switches and

workstations. It also features a termination switch for

easy coax termination.

The 10T/2 can be used as a standard two-port UTP to

fiber converter. It can also use its two additional

10/100 backplane Ethernet ports to connect to adjacent

modules and accommodate flexible network

configurations like In-Band management and multimodule configurations. The

5-Module or 2-Module Chassis have backplanes that

facilitate connectivity between adjacent modules.

The 10T/2 can be used in an unmanaged or managed

fashion. When unmanaged, it can be installed in a

chassis without a Network Management Module (NMM).

T o be managed, a NMM module must be installed in the

same chassis.

Due to the Ethernet 5-4-3 rule, no more than

4 iConverter 10T/2 modules can be

linked together via the backplane buses.

iConverter 19-Module,

PORT STRUCTURE:

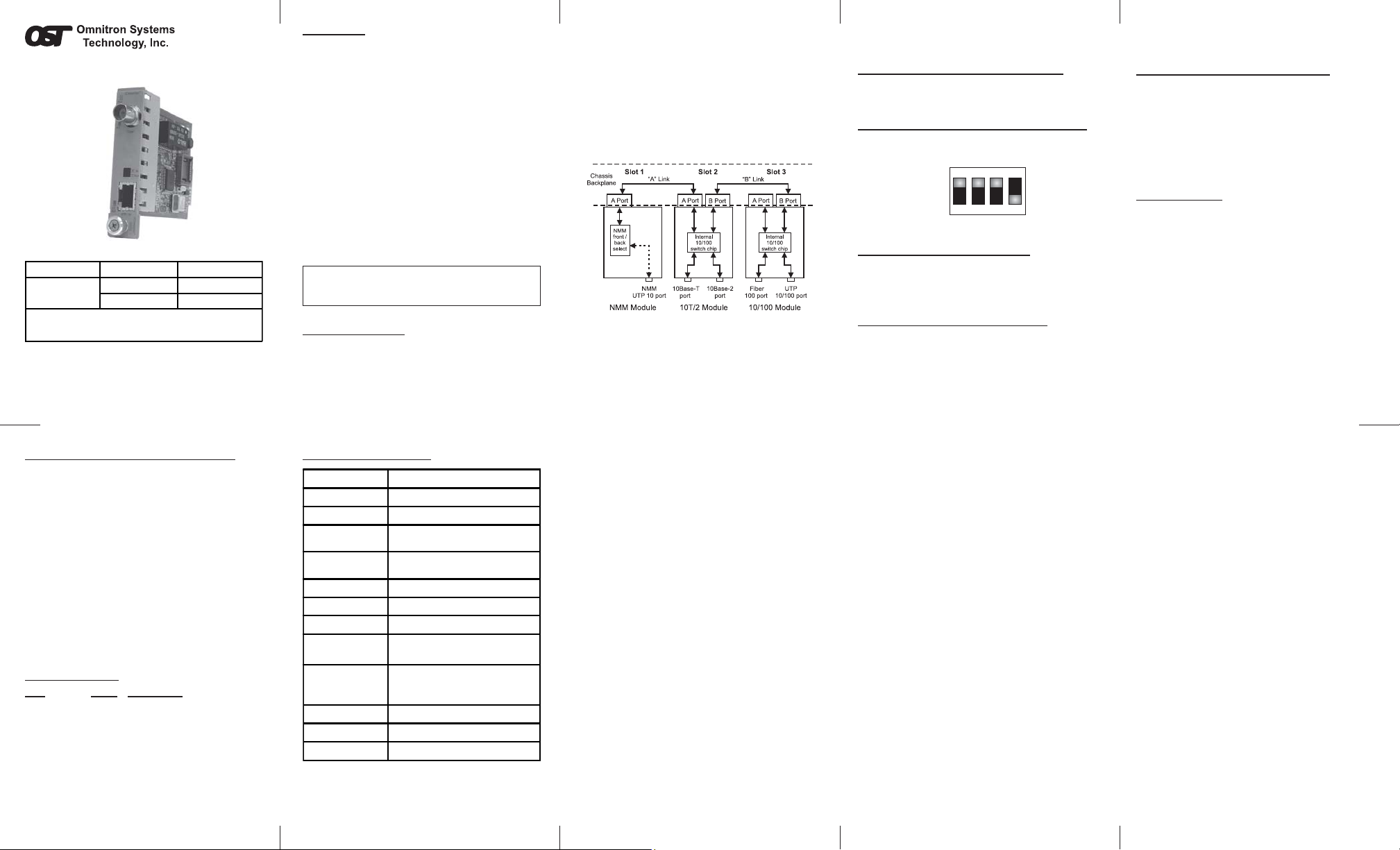

Fig. 1 depicts a chassis with three modules plugged

into three of its adjacent backplane slots. The adjacent

slots are connected to the “A” and “B” backplane links

via the module’s “A” and “B” backplane Ethernet ports.

In this example, the 10T/2 in the center slot connects

to the slot on its left using the “A” link and to the slot on

its right using the “B” link.

In this example, the module on the left is an NMM and

it connects via its “A” link to the 10T/2 facilitating

In-Band management. The module on the right is an

iConverter 10/100 module and it connects via its “B”

link to the 10T/2 facilitating a 2-port 10/100 Ethernet

hub/switch with a 10BASE-2 port and a fiber uplink. This

3-module configuration provides an effective

10BASE-2 to 10/100 managed switch with a fiber uplink.

Fig. 1 10T/2 Application Example

This example shows how the 10T/2 can be used either

as a traditional managed or unmanaged media converter

or to create flexible and effective network hub/switch

configurations.

To find out about individual chassis A and B

backplane links, refer to the specific chassis’ user

manual.

Front Plane RJ45 Crossover “= / X” Switch:

When connecting to a workstation, set this DIP-Switch

to Straight-Through “=” (factory setting). When

connecting to a hub or switch, set to Crossover “X”.

BOARD MOUNTED DIP-SWITCH SETTINGS:

A-EN

B-EN

T-IN

ON

OFF

1234

Fig. 2 Board Mounted DIP-Switches

Coax Termination “T-IN” DIP-Switch:

When the Coax Termination “T-IN” DIP-Switch is in the

“ON” position, the coax port is terminated. Use this

DIP-Switch setting when this coax port is at the end of

the network.

Backplane A Enable “A-EN” DIP-Switch:

When the Backplane A Enable “A-EN” DIP-Switch is in

the “ON” position, the iConverter 10T/2 module’s “A”

backplane Ethernet port is enabled. This port allows

connectivity to adjacent modules and facilitates

In-Band management of the Network Management

Module (NMM). When the Backplane A Enable “A-EN”

TST

DIP-Switch is in the “OFF” position, the

10T/2 module’s A backplane Ethernet port will be isolated

from the backplane.

Backplane B Enable “B-EN” DIP-Switch:

When the Backplane B Enable “B-EN” DIP-Switch is in

the “ON” position, the

backplane Ethernet port is enabled. This port allows

connectivity to adjacent modules and facilitates

In-Band management of the Network Management

Module (NMM). When the Backplane B Enable “B-EN”

DIP-Switch is in the “OFF” position, the iConverter

10T/2 module’s B backplane Ethernet port will be isolated

from the backplane.

“TST” DIP-Switch:

This switch is reserved for factory use, and should be

left in the “OFF” position.

iConverter 10T/2 module’s B

iConverter

MOUNTING AND CABLE ATTACHMENT:

iConverter modules are hot-swappable and can be

installed into any chassis in the

1. Carefully slide the

installation slot, aligning the module with installation

guides, and secure using the front panel fastener

screw. NOTE: Ensure that module is firmly seated

against the backplane.

2. Secure module by securing panel fastener screw

(attached to module) to chassis front.

3. Attach the

category 5 cable to a 10Base-T Ethernet device.

4. Attach the iConverter 10T/2, via a coax cable to a

10BASE-2 Ethernet device.

5. If using the

network, set Coax Termination “T-IN” DIP-Switch to

the “ON” position.

iConverter 10T/2 RJ45 connector via a

iConverter 10T/2 at the end of a coaxial

iConverter module into the

iConverter family.

LED INDICATORS:

LED Color Description

Pwr: Yellow On - Power on

Col: Yellow On - Coax collision

Act: Green On - Coax activity

Lk/Act: Green On - UTP link

Blink - UTP activity

10T/2 SPECIFICATIONS:

Model Type 10T/2

Protocols

Connectors

Controls

LED Displays

Dimensions

Weight

Compliance

Power

Requirement

10BASE-T and 10BASE-2

RJ-45 and B NC

Coax Termina tion,

Backplane Enables

Power, Coax Collision,

Coa x Ac ti vi ty, UTP Li nk/A ctivity

W:0.85" x D:4.5" x H:2.8"

8 oz.

UL, CE , F CC C la s s A

1.0A @ 3.3VDC (typi cal)

Standard: 0 to 50º C

Temperature

Wide: -40 to 60º C

Storage: -40 to 80º C

Humidity

Altitude

MTBF (h rs )

5 to 95% (non-condensing)

-100m to 4000m

722,000

Page 7 Page 8 Page 9Page 6 Page 10

Warning

The operating description in this Instruction Manual is

for use by qualified personnel only. To avoid electrical

shock, do not perform any servicing of this unit other

than that contained in the operating instructions, unless

you are qualified and certified to do so by Omnitron

Systems Technology, Inc.

Warranty

This product is warranted to the original purchaser

against defects in material and workmanship for a

period of 2 YEARS from the date of shipment. A

LIFETIME limited warranty may be obtained by the

original purchaser by REGISTERING this product with

Omnitron within 90 days from the date of shipment. To

register, complete and mail or fax the enclosed

Registration Card to the indicated address. You may

also register your product on the internet at

www.omnitron-systems.com/Register. During the

warranty period, Omnitron will, at its option, repair or

replace a product which is proven to be defective.

For warranty service, the product must be sent to an

Omnitron designated facility, at Buyer’s expense.

Omnitron will pay the shipping charge to return the

product to Buyer’s designated US address (within the

48 contiguous states and the District of Columbia)

using Omnitron’s standard shipping method.

Limitation of Warranty

The foregoing warranty shall not apply to defects

resulting from improper or inadequate use and/or

maintenance of the equipment by Buyer, Buyersupplied equipment, Buyer-supplied interfacing,

unauthorized modifications or tampering with equipment

(including repairs of equipment by personnel not

specifically authorized and certified by Omnitron), or

misuse, or operating outside the environmental

specification of the product (including but not limited

to voltage, ambient temperature, radiation, unusual

dust, etc.), or improper site preparation or maintenance.

No other warranty is expressed or implied. Omnitron

specifically disclaims the implied warranties of

merchantability and fitness for any particular purpose.

Exclusive Remedies

The remedies provided herein are the Buyer’s sole and

exclusive remedies. Omnitron shall not be liable for

any direct, indirect, special, incidental, or consequential

damages, whether based on contract, tort, or any legal

theory.

Technical Support:

For help with this product, contact our T echnical Support:

Phone: (949) 250-6510

Fax: (949) 250-6514

Address: Omnitron Systems Technology, Inc.

140 Technology Dr., #500

Irvine, CA 92618 USA

Email: support@omnitron-systems.com

URL: www.omnitron-systems.com

Form: 040-08340-001D 9/07

Loading...

Loading...