Omnitec Design Omniaire 18000 Maintenance Manual

HEPA Air Filtration Machine

18000

Operation and Maintenance Manual

WARNING

Do not use with combustible or explosive material. Do not expose to water or rain. Connect

only to grounded outlet with GFCI device. Disconnect power for cleaning and servicing.

This equipment to be operated only by trained personnel.

CONFORMS TO UL STD 507

CERTIFIED TO CAN/CSA STD

C22.2 NO. 113-M1984

Safety Warning Instructions:

READ AND SAVE THESE INSTRUCTIONS

This equipment to be operated only by trained personnel.

Do not use with combustible or explosive material.

Do not expose to water or rain.

Connect only to grounded outlet with GFCI device.

Disconnect power for cleaning and servicing.

Do not operate if cord or plug is damaged. Contact a authorized service facility for examination and/or repair.

Do not run cord under carpeting. Do not cover cord with throw rugs, runners, or similar coverings. Arrange cord away

from traffic areas and where it is not a tripping hazard.

Avertissement de sécurité Instructions:

LIRE ET CONSERVER CES INSTRUCTIONS

Cet équipement doit être utilisé que par un personnel formé.

Ne pas utiliser avec des matières combustibles ou explosives.

Ne pas exposer à l’eau ou à la pluie.

Connectez uniquement à une prise mise à la terre avec un dispositif GFCI.

Coupez l’alimentation électrique pour le nettoyage et l’entretien.

Ne pas utiliser si le cordon ou la fiche est endommagé. Contactez un centre de service autorisé pour examen et / ou

réparation.

Ne pas passer le cordon sous un tapis. Ne pas couvrir le cordon avec des carpettes, les coureurs, ou revêtements similaires. Éloigner le cordon des endroits passants et où il n’est pas un risque de déclenchement.

contaminated

containment area

positive pressure

clean contained area

clean

ltered

air

sealed contaminated

containment area

sealed

clean room

clean

ltered

air

contaminated

air

contaminated

air

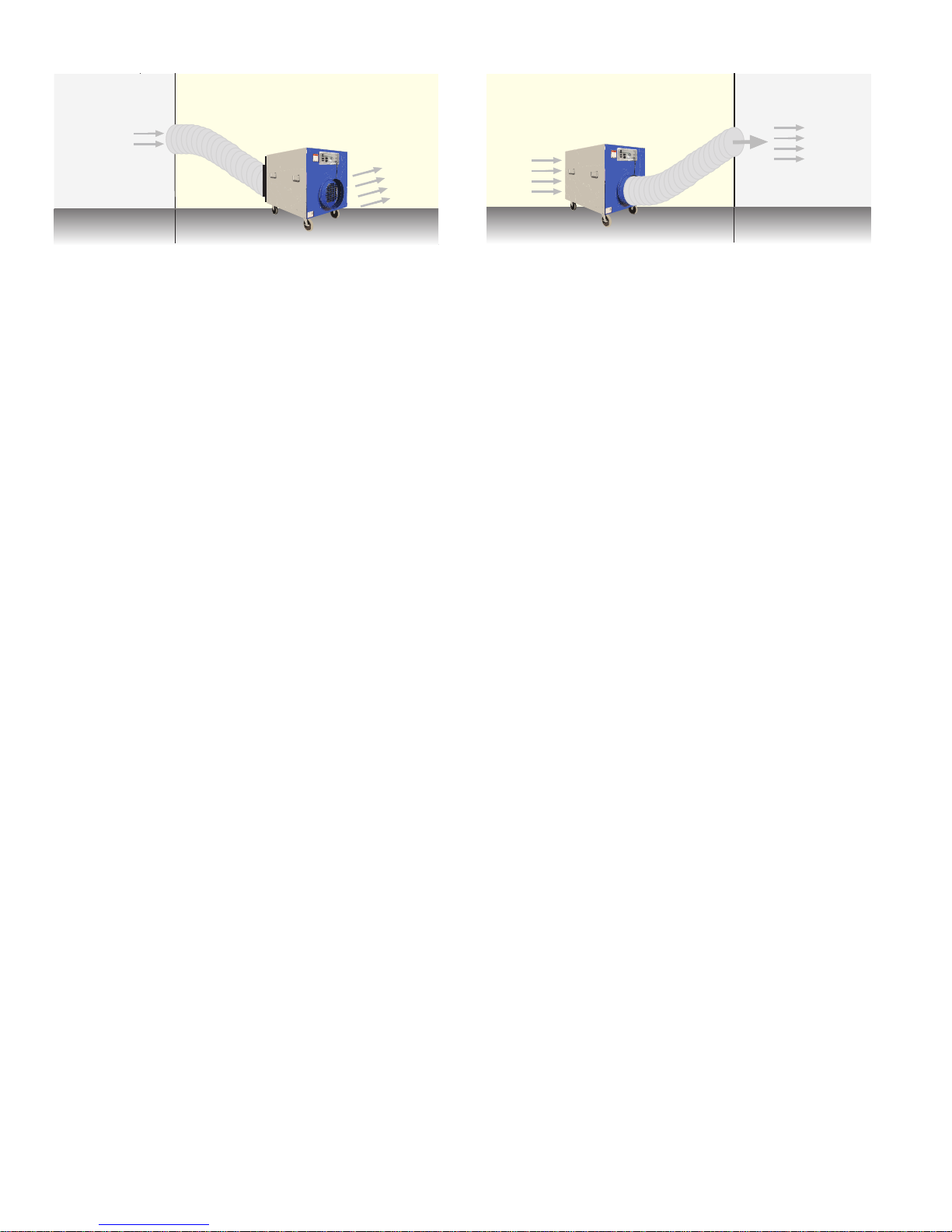

Application Examples

negative pressure

sealed contaminated

To create NEGATIVE PRESSURE inside the containment,

more air has to be exhausted out than leaks into the

containment. Place the machine inside the containment

and hook a flexible duct to the outlet ring of the

machine exhausting to outside the containment.

sealed

clean room

clean

ltered

air

contaminated

air

contaminated

containment area

positive pressure

clean contained area

clean

ltered

air

To create POSITIVE PRESSURE inside the containment,

more air has to be pumped in than leaks out of the

containment. Place the machine outside the containment

and hook a flexible duct to the outlet ring of the machine

ducting the exhaust into the containment. (See Above)

(See Above) All of the air being exhausted has been

treated by the HEPA filter so no contaminants are being

exhausted from the containment.

The OmniAire 18000 is our largest portable HEPA air system with a 18,000 CFM air flow capacity. The

OA18000 is a modular air filtration machine with a unique versatility in setup and number of optional filters to assist

you on your projects. The OmniAire 18000 can be used to purify and re-circulate air or create positive or negative air

pressure containment areas. It is used for mold, asbestos & lead abatement projects, construction sites, restoration

projects, water or fire damage clean-up and many other applications.

Blower Cabinet Features

The OmniAire 18000 modular system consists of Blower cabinet and three Filter cabinets, all connected by flex hoses.

The cabinets are easy to transport and setup at any type of projects, including high-rise buildings and HAZMAT

removal jobs. The Blower cabinet contains twin 22 vane-axial blowers with 7.5 HP motors and controls and operates

on a 3-phase 480 VAC/60HZ/30 AMP power source. The portable blower cabinet is mounted on (4) 4” heavy duty

casters with brakes. The reinforced steel internal frame enables the blower unit to be moved by forklift or crane.

HEPA Cabinet Features

Each Filter cabinet contains 3 filters, which could be 99.99% HEPA or bag filters. The individual filter cabinets each have

a differential pressure gauge to measure loading of the filters with particulates. Filter cabinets are mounted on casters

with brakes, weigh 200 lbs. when fully loaded with HEPA filters. Options such as HEPA, Carbon, and Bag filters allow

flexibility from project to project. Three (3) flex hoses connect the modular filter cabinets to the blower cabinet. Hoses

are 18” dia, 25’ long.

OmniAire 18000 Specifications

For Blower Unit: Quantity (1)

Airflow - 18000 cfm*

Power Requirement - 480V/60 Hz/3 phase/30 amp.

Controls - Dual motor starter boxes with 16A disconnects w/lockout feature, overload protection, contactor and ON/

OFF switch. Power ON Indicator and hour meter.

Blowers - (2) 22” Vaneaxial fans with 7.5 hp motors.

Blower Cabinets - Aircraft grade aluminum, closed end rivet construction. All seams are silicone sealed before riveting.

(4) - 4” locking casters for ease of movement, 900Lbs., 30” wide, 48” long, 72” high

Exhaust – (2) 24” diameter rings. Inlet (3) – 18” dia

Loading...

Loading...