Page 1

XL 250

PR-2225/PR-2225M

This product manual contains important information about the safe installation and use of this

projector. Please read and follow these instructions carefully and keep this manual in a safe place

for future reference.

PR LIGHTING LTD.

http://www.pr-lighting.com

Page 2

INDEX

SAFE USAGE OF THE PROJECTOR 3

INSTALLING THE PROJECTOR 4

FITTING THE LAMP 4

POWER SUPPLY – MAINS 5

CONTROL CONNECTIONS 5

DMX TERMINATOR 6

SETUP OPTIONS-PROJECTOR CONFIGURATION 6

TO SET THE DMX START ADDRESS 6

MASTER/SLAVE MODE 7

STAND-ALONE MODE 7

OPERATION MENU 8

ERROR MESSAGES 12

REPLACING GOBOS 12

DMX PROTOCOL 13

LED INDICATION 16

MAINTENANCE 16

LUBRICATION 16

KEEPING THE PROJECTOR CLEAN 16

TROUBLESHOOTING 17

TECHNICAL DATA 18

ELECTRICAL DIAGRAM 21

COMPONENT ORDER CODES 23

Please note that as part of our ongoing commitment to continuous product development, specifications are subject to change without

notice. Whilst every care is taken in the preparation of this manual we reserve the right to change specifications in the course of

product improvement. The publishers cannot be held responsible for the accuracy of the information herein, or any consequence

arising from them.

Every unit is tested completely and packed properly by the manufacturer. Please make sure the packing and / or the unit are in good

condition before installation and use. Should there be any damage caused by transportation, consult your dealer and do not use the

unit. Any damage caused by improper use will not be assumed by the manufacturer and / or dealer.

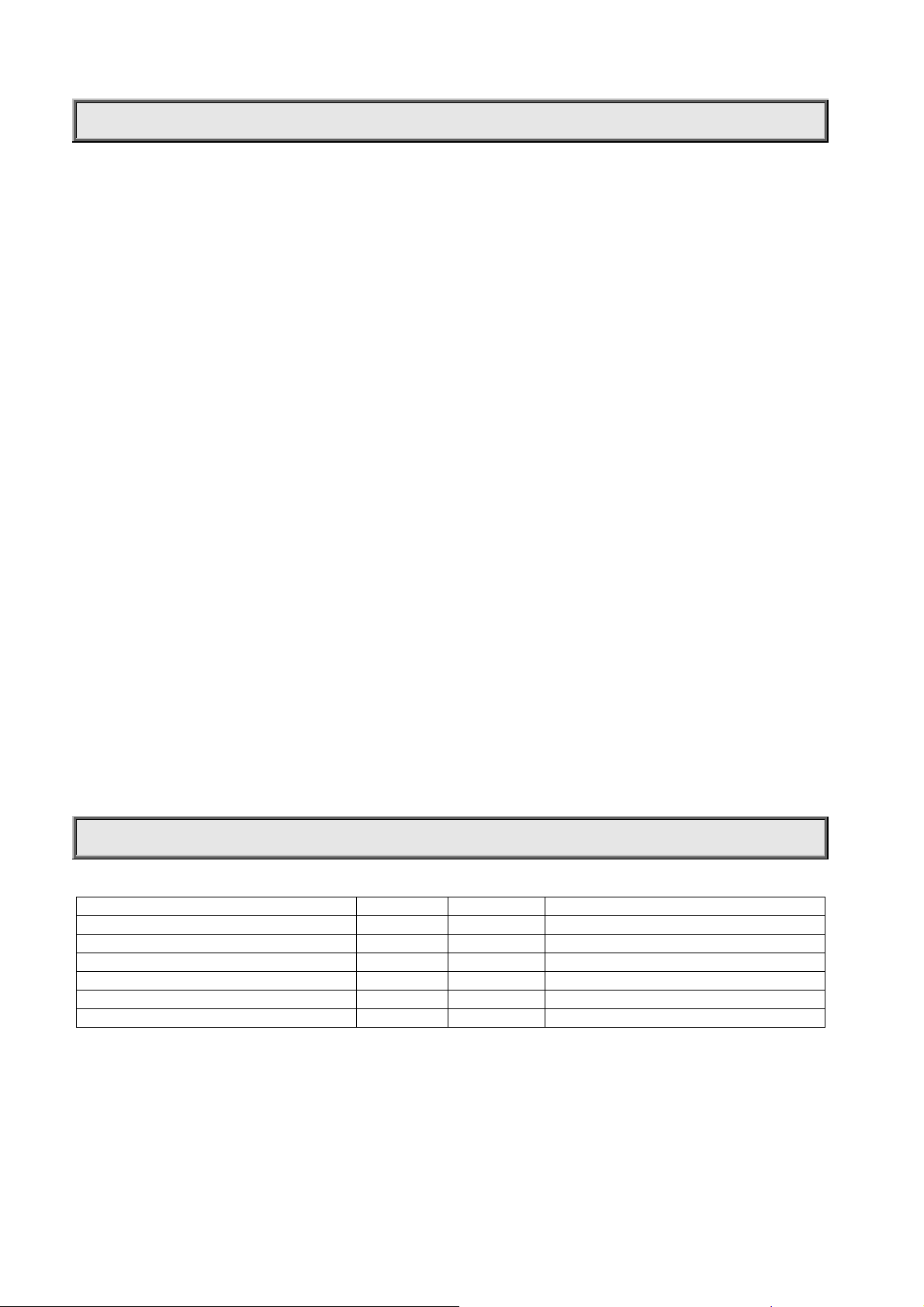

ACCESSORIES

These items are packed together with the projector:

Name Quantity Unit Remark

G clamps 2 Pcs

XLR cable 1 Pc 5-pin plug

Safety cord 1 Pc

Spare gobos 4 Pcs

This manual 1 Pc

Ω clamps 2 Pcs Options

2/24

Page 3

SAFE USAGE OF THE PROJECTOR

When unpacking and before disposing of the carton check there is no transportation damage before using the projector.

Should there be any damage caused by transportation, consult your dealer and do not use the apparatus.

The projector is for indoor use only, IP20. Use only in dry locations. Keep this device away from rain and moisture,

excessive heat, humidity and dust. Do not allow contact with water or any other liquids.

The projector is not designed or intended to be mounted directly on to inflammable surfaces.

The projector is only intended for installation, operation and maintenance by qualified personnel.

The projector must be installed in a location with adequate ventilation, at least 50cm from adjacent wall surfaces. Be sure

that no ventilation slots are blocked.

Do not project the beam onto inflammable surfaces, minimum distance is 5m. 5m

Avoid direct exposure to the light from the lamp. The light is harmful to the eye.

Do not attempt to dismantle and/or modify the projector in any way.

Electrical connection must only be carried out by qualified personnel.

Before installation, ensure that the voltage and frequency of power supply match the power requirements of the projector.

It is essential that each projector is correctly earthed and that electrical installation conforms to all relevant standards.

Do not connect this device to any other types of dimmer apparatus.

Make sure that the power-cord is never crimped or damaged by sharp edges. Never let the power-cord come into contact

with other cables. Only handle the power-cord by the plug. Never pull out the plug by tugging the power-cord.

Keep the lamp clean. Do not touch the lamp glass with bare hand.

The projector should always be installed with a secondary safety fixing. A safety cord is supplied for this; it should be

attached as shown in “installing the projector” section.

The lamp used in this projector is a discharge lamp. After switching off don’t attempt to restart the projector until lamp has

cooled, this will require approx 15 minutes. Switching the lamp on and off at short intervals will reduce the life of both the

lamp and the projector. But occasional breaks will prolong the life of the lamp and projector.

Never run the projector without a lamp.

The lamp shall be changed if it has become damaged or thermally deformed.

Shields and lens shall be changed if they have become visibly damaged to such an extent than their effectiveness is

impaired, for example by cracks or deep scratches.

Exterior surface temperatures of the luminaire after 5 minutes operation is 80℃, when steady state is achieved 120℃,

There is no user serviceable parts inside the projector, do not open the housing and never operate the projector with the

covers removed.

Always disconnect from the mains, w hen the device is not in use or before cleaning it or

before attempting any main tenance work !

If you have any questions, don’t hesitate to consult your dealer or manufacturer.

3/24

Page 4

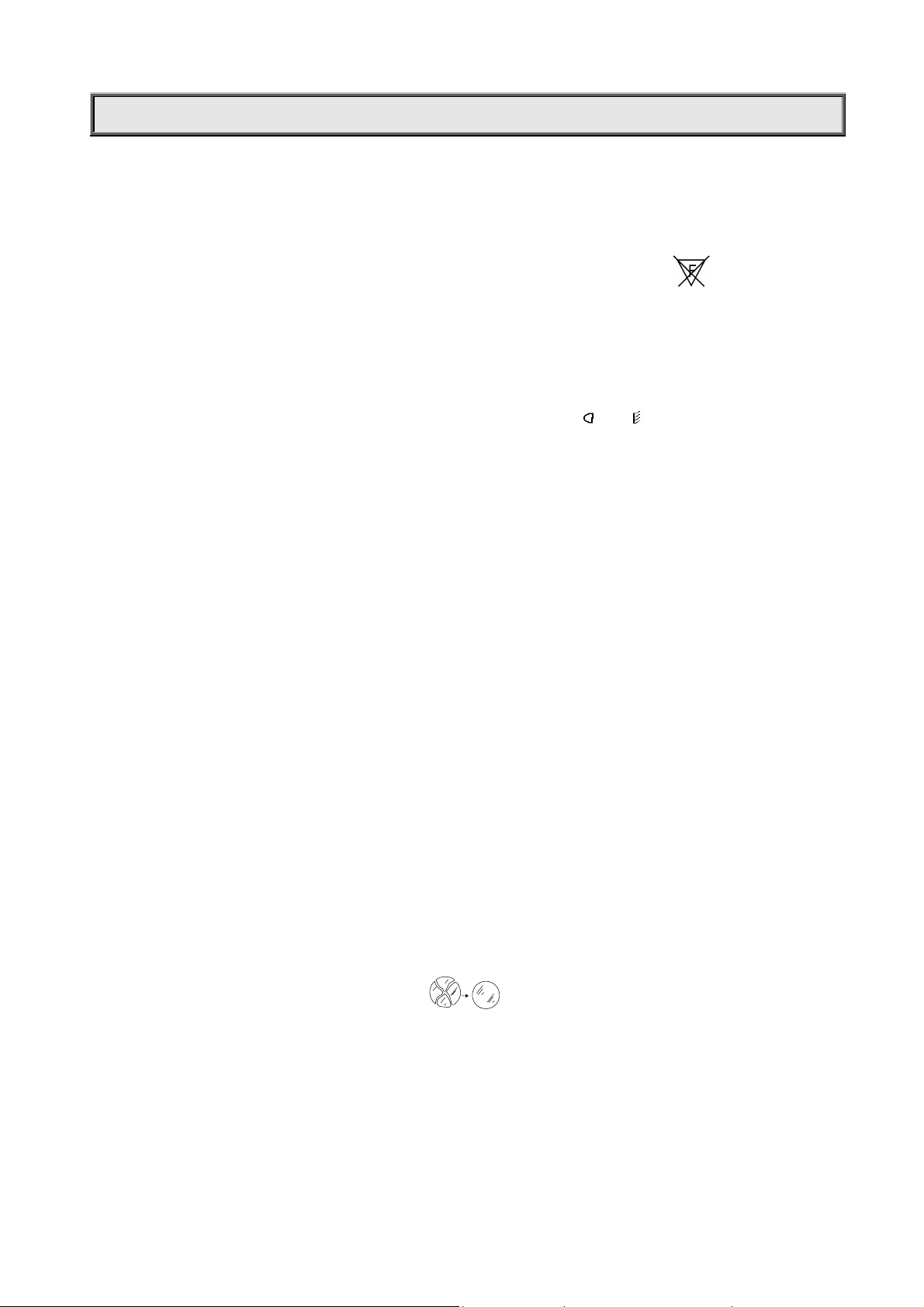

INST ALL THE PROJECTOR

Take 2 clamps and the safety cord out from the package and mount 2 clamps on the underside of fixture with 2 retainers

attached to each clamp. Hang the fixture on the structure and fasten the screws attached to each clamp. (See the

WARNING

Always ensure that the projector is firmly anchored to avoid vibration and slipping whilst functioning. Always ensure that

the structure that you are going to mount the projector is secure and is strong enough to support a weight of XL 250.

WARNING:

1. Unlock the P AN and TILT before the 1

2. The projector MUST be lifted or carried by the HANDLES instead of clamps.

3. For safety the safety cord should afford 10 times of the unit’s weight.

on the underside of the base as shown above) To pass SAFETY CORD through 2 HOLES for safety!

st

application of projector for safety .

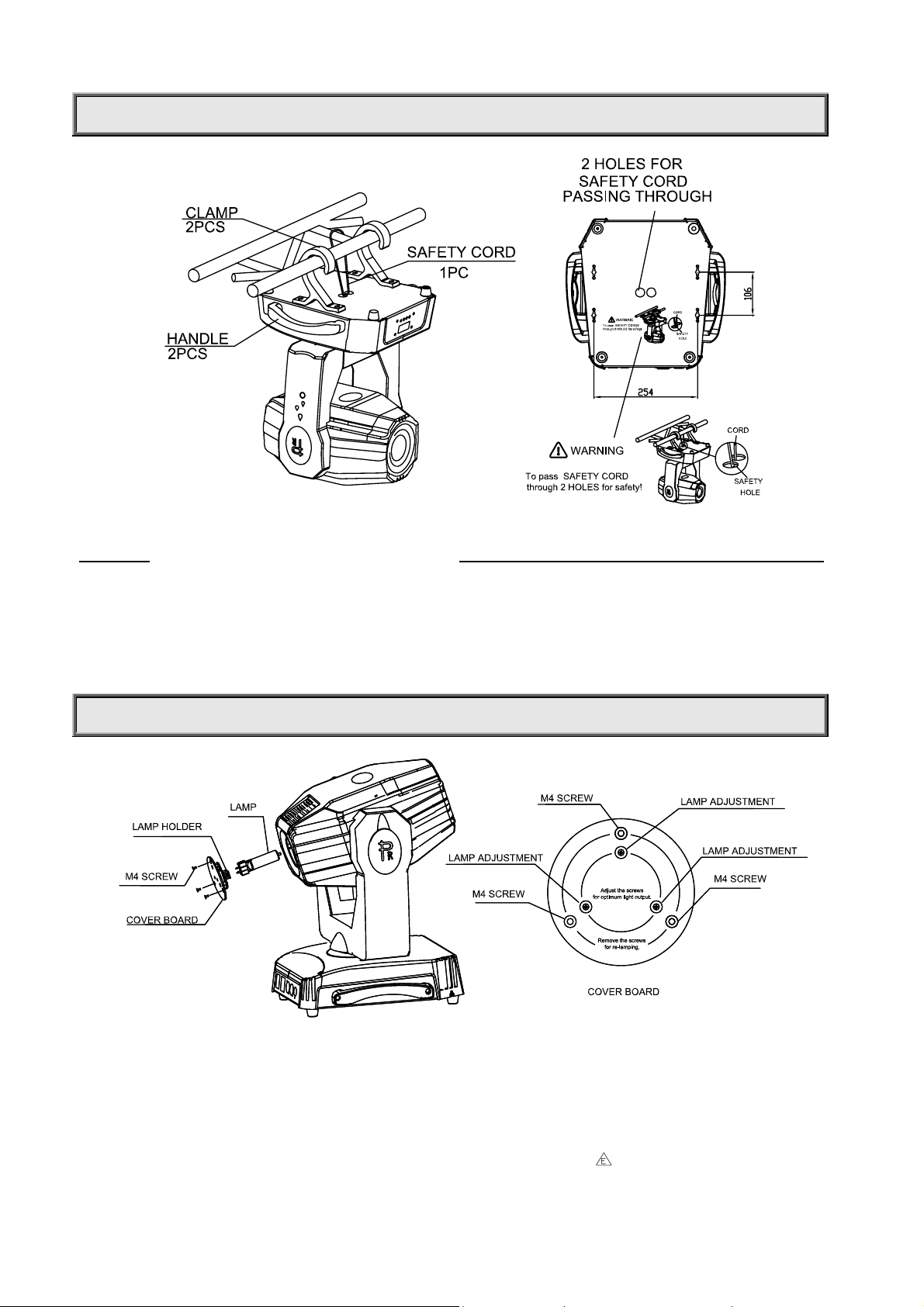

FITTING THE LAMP

Lock the yoke before fitting/replacing the lamp.

Open the cover board at the rear of the projector by loosening 3 screws, you can see the structure as shown in the figure

above.

Gently pull out lamp holder assembly.

Take out the worn-ou t lamp. Insert the new lamp to the socket. Note: don’t touch the bulb of the new lamp with bare

hand so as not to influence the beam output.

Close the rear cover and fasten 3 screws.

WARNING: The MSD series are high-pressure lamps w ith external igniters (

4/25

). Care should alwa ys be taken

Page 5

POWER SUPPLY-MAINS

Connect the power cord as follows:

L (live) =brown

E (earth) =yellow/green

N (neutral) =blue

Use the plug provided to connect the mains power to the projector paying attention to the voltage and frequency marked

on the panel of the projector. It is recommended that each projector be supplied separately so that they may be

individually switched on and off.

IMPORT ANT

It is essential that each projector is correctly earthed and the electrical installation conforms to a ll relevant

standards.

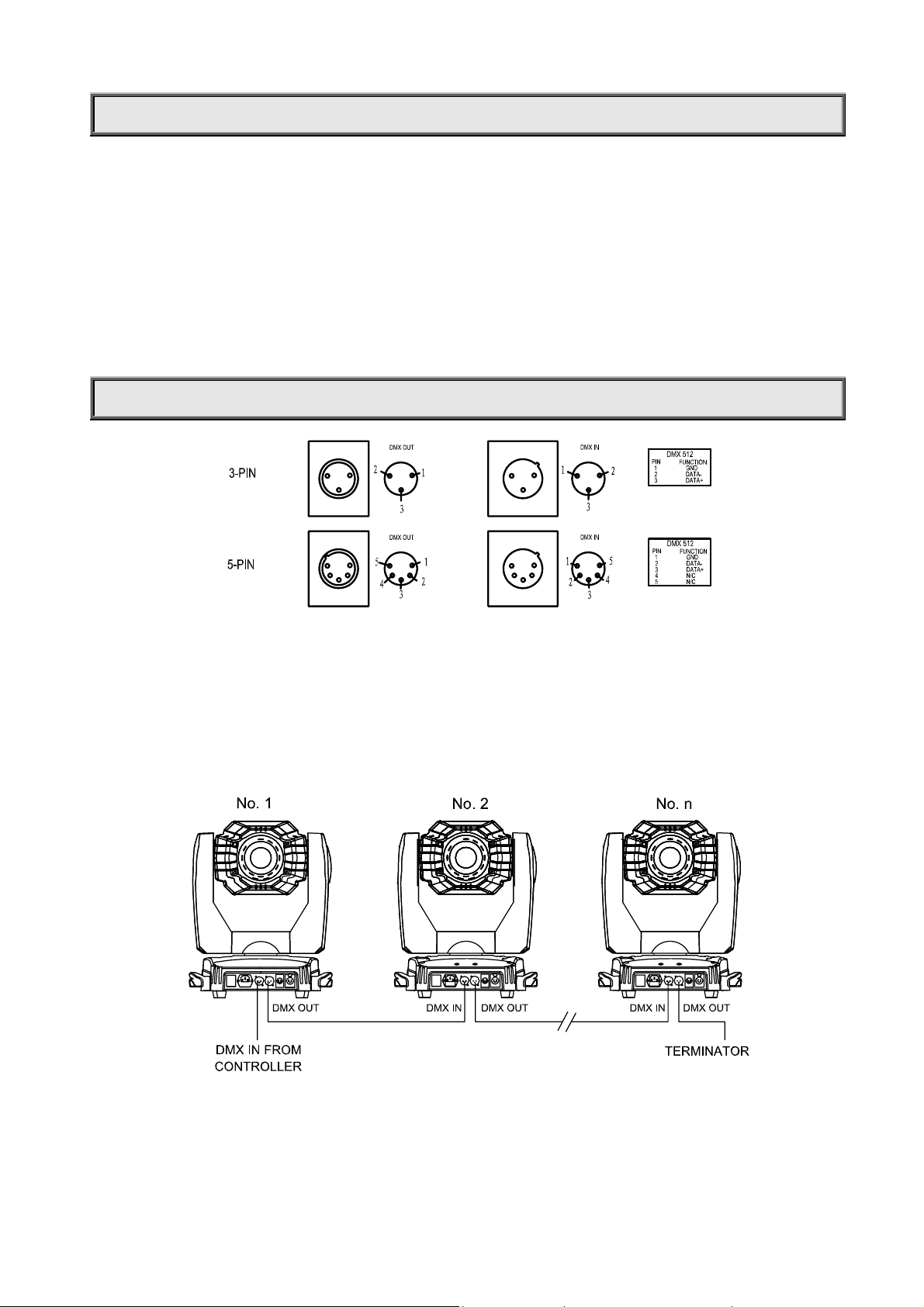

CONTROL CONNECTION

Connection between controller and projector and between one projector and another must be made with a 2

core-screened cable, with each core having at least a 0.5mm diameter. Connection to and from the projector is via

cannon 3 pin (which are included with the projector) or 5 pin XLR plugs and sockets. The XLR's are connected as shown

in the figure above.

Note: care should be taken to ensure that none of the pins touch the metallic body of the plug or each other. The body of

the plug is not connected in any way. The XL 250 accepts digital control signals in protocol DMX512 (1990).

Connect the controller’s output to the first fixture’s input, and connect the first fixture’s output to the second fixture’s input

and connect the rest fixtures in the same way. Eventually connect the last fixture’s output to a DMX terminator as shown

in the figure below.

5/24

Page 6

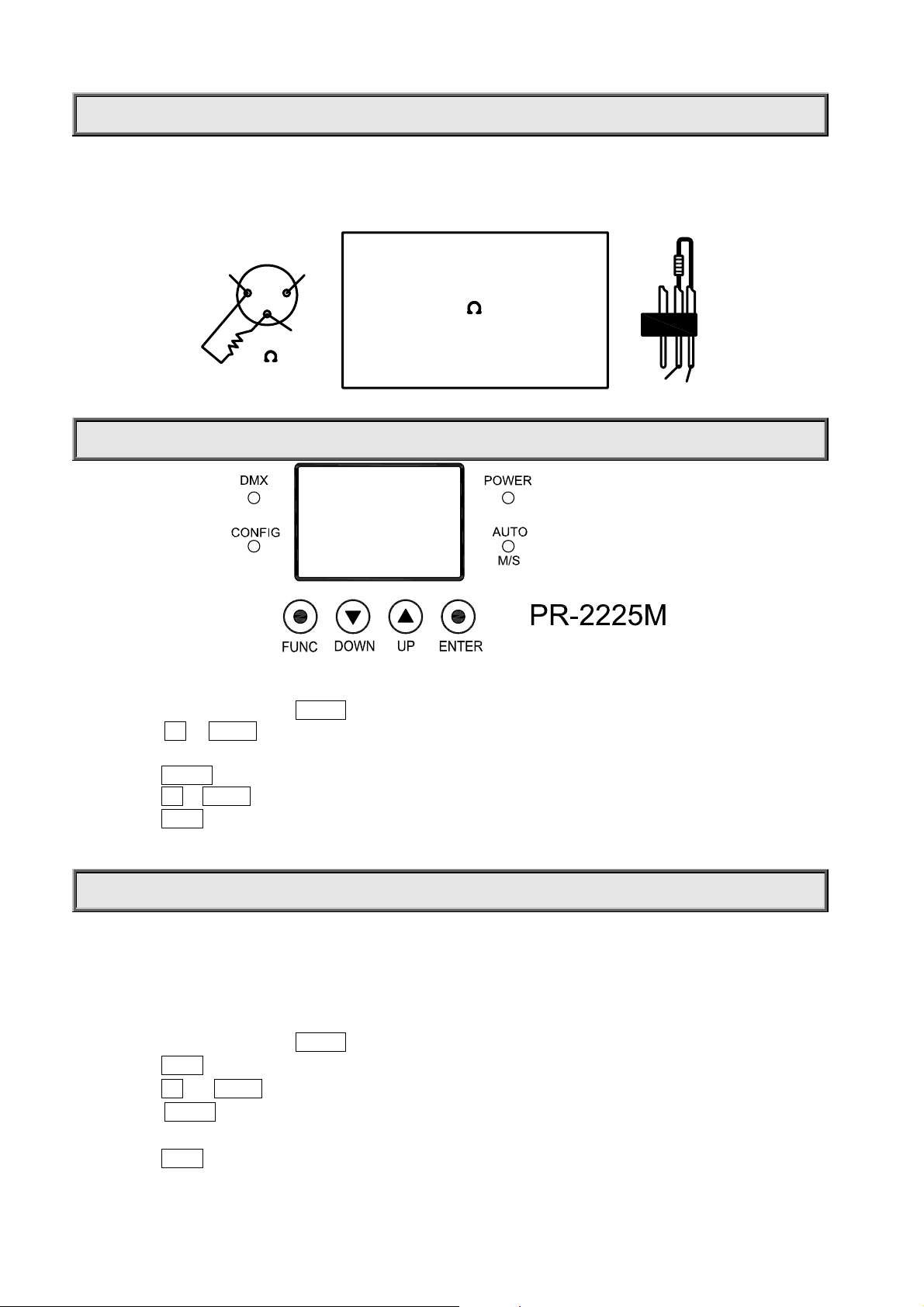

DMX TERMINATOR

In the Controller mode, at the last fixture in the chain, the DMX output has to be connected with a DMX terminator. This

prevents electrical noise from disturbing and corrupting the DMX control signals.

The DMX terminator is simply an XLR connector with a 120Ω (ohm) resistor connected across pins 2 and 3, which is

then plugged into the output socket on the last projector in the chain. The connections are illustrated below.

2

120

1

3

DMX TERMINATOR

CONNECTION

Connect a 120 (OHM) resistor

across pins 2 and 3 in an XLR plug

and insert into the DMX out socket

on the last unit in the chain.

PIN 2

PIN 3

SETUP OPTIONS-PROJECTOR CONFIGURATION

Projector configuration can be set conveniently via pressbutton switch and LCD display. Turn the projector on and the

LCD display will show DMX address you set and save last time and it can be reset and saved again as you please.

Launch the projector. Press button ENTER more than 5 seconds to unlock panel.

Press button UP or DOWN if you want to browse through the various Setup Options. There are 10 option codes

from DMX Address to User Mermories, and each code has a specific function.

Press button ENTER to save your settings or enter the next menu.

Press button UP or DOWN to shift.

Press button FUNC, it will return to the upper menu one by one. If you stay for minutes defaulted will show display status

automatically.

TO SET THE DMX START ADDRESS

Each XL 250 must be given a DMX start address so that the correct projector responds to the correct control signals.

This DMX start address is the channel number from which the projector starts to “listen” to the digital control information

being sent out from the controller. The XL 250 has 3 DMX modes. There are standard mode, extended mode and short

mode. For example standard mode has 18 channels, so set the No. 1 projector’s address 001, No. 2 projector’s address

019, No. 3 projector’s address 037, No. 4 projector’s address 055, and so on.

Launch the projector. Press button ENTER more than 5 seconds to unlock panel.

Press button FUNC to display DMX address;

Press button UP and DOWN, you can set the address;

Press button ENTER to confirm; In the same time. The GREEN LED will flash one time. It means the setting has

been enabled.

Press button FUNC, it will return to the upper menu one by one.

6/24

Page 7

STAND-ALONE MODE

Operate the projector without connecting a controller, enable the master mode in the operation panel, the

projector will run in Stand-Alone mode automatically.

MASTER/SLAVE MODE

Without using a controller, many projectors can run synchronously in the Master/Slave mode by linking them

with each other. Select one projector as the master with setting options master mode enabled but slaves.

Regard the other projectors as the slaves with setting options slave mode enabled and all DMX start

address “001”.

Connect the controller’s output to the first fixture’s input, and connect the first fixture’s output to the second fixture’s input

and connect the rest fixtures in the same way. Eventually connect the last fixture’s output to a DMX terminator as shown

in the figure below.

7/24

Page 8

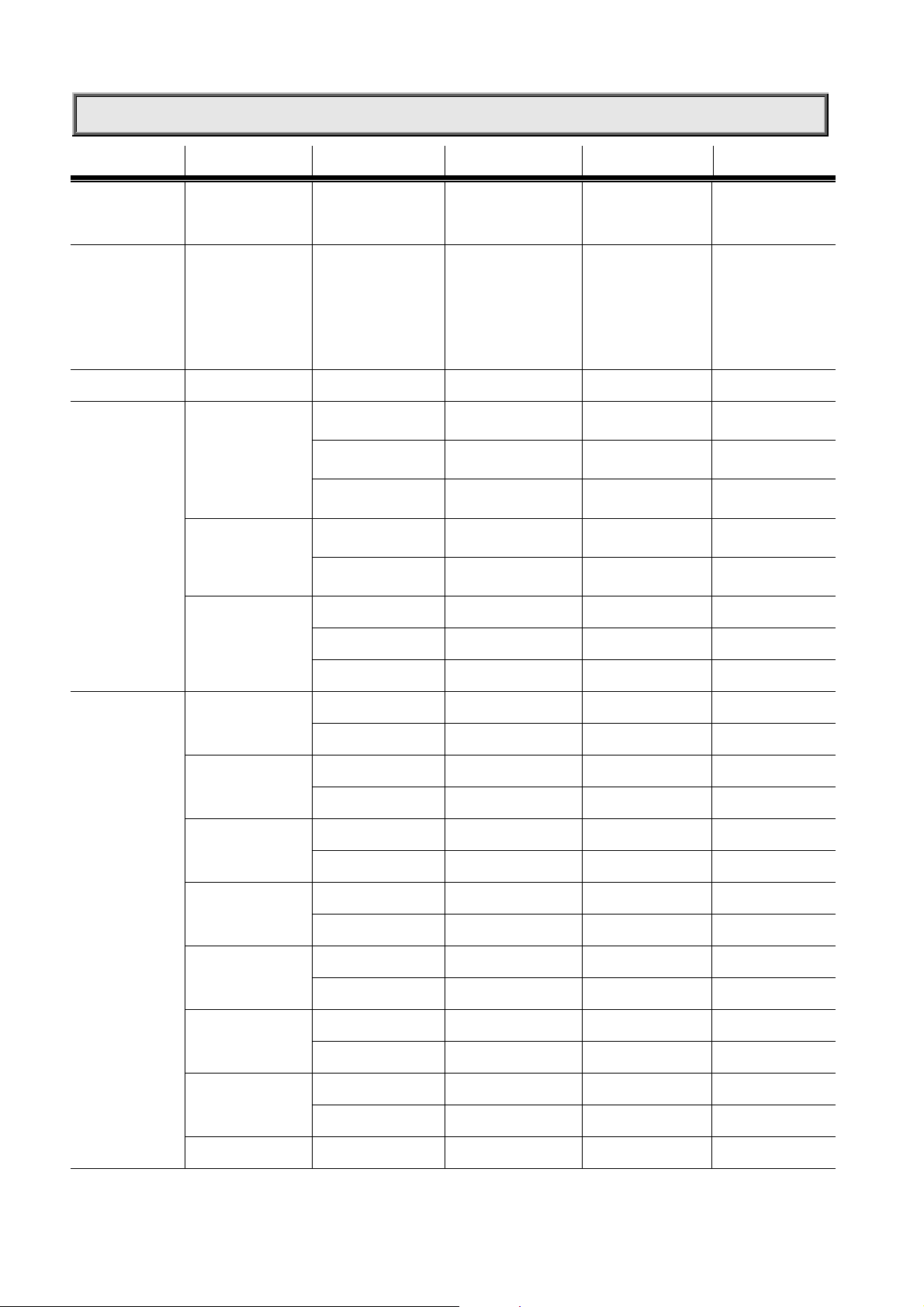

OPERATION MENU

1st LEVEL 2nd LEVEL 3rd LEVEL 4th LEVEL 5th LEVEL 6th LEVEL

PR LIGHTING

XL

SERIES

XL 250

DMX Address

Reset

Config Settings

Option Settings

001-499 in Short

001-495 Standard

F-Gobo Positions

DMX Address

Mode

Mode

001-491in

Extended Mode

Reset

Are you sure

DMX Mode

Loss of DMX

Lamp Control

Colour Positions

Pan DMX Invert

Tilt DMX Invert

Pan Tilt Swap

Dimmer Invert

Iris Invert

Zoom Invert

When DMX is Lost

Normal Time Out

When DMX is Lost

Lamp Control By

Lamp Control By

Lamp Control By

F-Gobo Positions

F-Gobo Positions

DMX Mode

Standard

DMX Mode

Extended

DMX Mode

Short

Hold Last Value

Control Channel

Power On

DMX Present

Colour Positions

STEPPED

Colour Positions

LINEAR

STEPPED

LINEAR

Pan DMX Invert

OFF

Pan DMX Invert

ON

Tilt DMX Invert

OFF

Tilt DMX Invert

ON

Pan Tilt Swap

OFF

Pan Tilt Swap

ON

Dimmer Invert

OFF

Dimmer Invert

ON

Iris Invert

OFF

Iris Invert

ON

Zoom Invert

OFF

8/24

Page 9

Display Options

Information

Zoom Invert

ON

Defaults

Defaults

Display Mode

Display Invert

Display Dimming

Display Contrast

Lamp Hours

Total Hours Total Hours=XX

Temperature

Software Version Display Board

OFF

Defaults

Restore Defaults

Display Mode

On Always

Display Mode

Off After Delay

Display Invert

OFF

Display Invert

ON

Disp Dim Level

XXX(Min,1~9,Full),

Default is 8)

Display Contrast

XX(0~20, Default is

10)

Lamp Hours=

XX

Temperature

Driver Board

Head Sensor

Reset Lamp Hours

Are You Sure?

Driver Board=

XX℃

Head Sensor=

XX ℃

Display Board=

X.X.X

Test Modes

Lamp Manual

Control

Operation Mode

View DMX values

Electronic SN

Factory Setup

Self Test

Lamp Status

Turn Lamp On

Turn Lamp Off

Operation Mode=

DMX Operation

DMX Channel

1=0

Electronic SN=

=************

Factory Setup

OFF

Factory Setup

ON

Self Test

OFF

Self Test

ON

Status = XX

Control = XX

Select Memory

User Memory 1

Select Memory

User Memory 2

Operation Mode=

Master Mode

Operation Mode=

Select Memory

Preset Memory 1

Select Memory

Preset Memory 2

Select Memory

Preset Memory 3

Select Memory

9/24

Page 10

User Memory 1

Slave Mode

Mode=

Static Scene

User Memories Edit User Memory

Select Memory

User Memory 2

Select Memory

Preset Memory 1

Select Memory

Preset Memory 2

Select Memory

Preset Memory 3

User Memory 1

User Memory 2

10/24

Scene XX

(1~28)

Scene

XXX(1~28)

Shutter

Dimmer

Colour

Iris

Fixed Gobo

R Gobo Wheel

R Gobo Rotate

R Prism Wheel

R Prism Rotate

Focus

Zoom

Pan Coarse

Pan Fine

Tilt Coarse

Tilt Fine

M-Speed

Delay

Link To Step

Shutter

Dimmer

Colour

Iris

Fixed Gobo

R Gobo Wheel

R Gobo Rotate

R Prism Wheel

R Prism Rotate

Focus

Shutter

XXX

Dimmer

XXX

Colour

XXX

Iris

XXX

Fixed Gobo

XXX

R Gobo Wheel

XXX

R Gobo Rotate

XXX

R Prism Wheel

XXX

R Prism Wheel

XXX

Focus

XXX

Zoom

XXX

Pan Coarse

XXX

Pan Fine

XXX

Tilt Coarse

XXX

Tilt Fine

XXX

M-Speed

XXX(000~255)

Delay

XX Seconds

(0.25s~100min)

Link To Step

XXX(1~28)

Shutter

XXX

Dimmer

XXX

Colour

XXX

Iris

XXX

Fixed Gobo

XXX

R Gobo Wheel

XXX

R Gobo Rotate

XXX

R Prism Wheel

XXX

R Prism Wheel

XXX

Focus

XXX

Page 11

Static Scene

Reset User

Memory 1

Shutter

Dimmer

Colour

Iris

Fixed Gobo

R Gobo Wheel

R Gobo Rotate

R Prism Wheel

R Prism Rotate

Focus

Zoom

Pan Coarse

Pan Fine

Tilt Coarse

Tilt Fine

M-Speed

Reset User 1 ?

<Unlock> 2 3 & 4?

Zoom

Pan Coarse

Pan Fine

Tilt Coarse

Tilt Fine

M-Speed

Delay

Link To Step

Shutter

XXX

Dimmer

XXX

Colour

XXX

Iris

XXX

Fixed Gobo

XXX

R Gobo Wheel

XXX

R Gobo Rotate

XXX

R Prism Wheel

XXX

R Prism Wheel

XXX

Focus

XXX

Zoom

XXX

Pan Coarse

XXX

Pan Fine

XXX

Tilt Coarse

XXX

Tilt Fine

XXX

M-Speed

XXX(000~255)

Memory 1 Has

Been Reset

Zoom

XXX

Pan Coarse

XXX

Pan Fine

XXX

Tilt Coarse

XXX

Tilt Fine

XXX

M-Speed

XXX(000~255)

Delay

XX Seconds

(0.25s~100min)

Link To Step

XXX(1~28)

Init User Memory

Reset User

Memory 2

Reset

Static Scene

Reset User 2 ?

<Unlock> 2 3 & 4

Reset Static Scn

<Unlock> 2 3 & 4

Memory 2 Has

Been Reset

Static Scene Has

Been Reset

11/24

Page 12

ERROR MESSAGES

In the course of launch, XL 250 examines automatically whether there are errors and if there are, it will display

information as follows:

Display

Sensor Err M8 Motor 8 (zoom) error

Sensor Err M9 Motor9(Fixed Gobo wheel ) error

Sensor Err M10 Motor 10 (colour wheel) error

Sensor Err M1 Motor 1 (focus) error

Sensor Err M5 Motor 5 (iris) error

Sensor Err M6 Motor 6 (rotating gobo wheel) error

Message

REPLACING GOBOS

Disconnect the fixture from power. Lock Tilt. Carefully lift off the cover by undoing the 6 screws.

For gobos replacement on the fixed gobo: Remove the gobo and insert the new one into the position by h ands.

For gobos replacement on the rotating gobo wheel: Remove the gobo h older with gobo from gobo wheel by

hands.

Pull out the spring and drop the old gobo out of the holder.

Insert the new gobo into the holder, and then insert the spring with the narrow end against the gobo.

Push the end of the spring in under lip of the holder.

Pick the spring clip up and put the gobo holder back into the position, if necessary, a small screwdriver will be

helped.

Note: If the gobo is a glass one, it should be touched with glabrous, clean and soft tissue or cloth matted between hand

and glass instead of with bare hand.

Close the rear cover and fasten 6 screws.

12/24

Page 13

DMX PROTOCOL

Short

mode

1 1 1 Strobe

2 2 2 Dimmer 000-255 Dimming from dark to light (0-100%)

3 3 4 Colour Wheel

4 4 5 Iris

5 5 7

Standard

mode

3 Dimmer Fine 000-255 Dimmer in 16 Bit precision

6 Iris Fine 000-255 Iris n 16 Bit precision

Extended

mode

FUNCTION DMX DESCRIPTION

000-009 Black

010-020 Open

021-244 Strobe speed from slow to fast

245-255 Open

White

Colour 1

Colour 2

Colour 3

Colour 4

Colour 5

Colour 6

colour 7

Colour 8

Colour 9

Colour 10

Colour 11

Colour 12

white

Rainbow rotation from slow to fast

Stop in current position

Rainbow reverse rotation from slow to

fast

Clear

Gobo1

Gobo 2

Gobo 3

Gobo 4

Gobo 5

Gobo 6

Gobo 7

Gobo 8

Gobo 9

Gobo 10

Rotation from slow to fast

Reverse rotation from slow to fast

Gobo shake 1 from slow to fast

Fixed Gobo

Wheel

000-020

021-028

029-037

038-045

046-054

055-062

063-071

072-080

081-088

089-097

098-105

106-114

115-123

124-127

128-187

188-195

196-255

000-135 Iris from large to small (0-100%)

136-167 Macro 1

168-199 Macro 2

200-231 Macro 3

232-255 Minimal

000-011

012-023

024-034

035-046

047-057

058-069

070-080

081-092

093-103

104-115

116-127

128-150

151-171

172-183

13/24

Page 14

184-191

192-199

200-207

208-215

216-223

224-231

232-239

240-247

248-255

000-016

017-032

033-048

049-064

065-080

081-096

097-112

6 6 8

Rotating Gobo

Wheel

113-127

128-150

151-171

172-183

184-195

196-207

208-219

220-231

232-243

244-255

000-159 0~540°index

7 7 9 Gobo rotation

8 10

8 9 11 Prism / Frost

9 10 12 Prism rotation

10 11 13 Focus 000-255 Linearly focusing

14 Focus Fine 000-255 Focus in 16 precision

11 12 15 Zoom 000-255 From large to small

16 Zoom Fine 000-255 Zoom in 16 precision

12 13 17 Pan 000-255 Pan rotation 540°

14 18 Pan Fine 000-255 Pan rotation in 16 precision

13 15 19 Tilt 000-255 Tilt rotation 270°

16 20 Tilt Fine 000-255 Tilt rotation in 16 precision

17 21

Gobo rotation

Fine

Pan & Tilt

speed

160-188 Gobo rotation from slow to fast

189-229 Stop rotating

230-255 Reverse rotation from slow to fast

000-255 Gobo rotation in 16 Bit precision

000-020 Open

021-255 Prism

000-009 Stop rotating

010-127 Prism rotation from slow to fast

128-136 Stop rotating

137-255 Reverse rotation from slow to fast

000-255 Pan &Tilt speed from fast to slow

000-048

049-080

081-112

14 18 22 Control

113-144

145-168

169-200

201-223

224-255

14/24

Gobo shake 2 from slow to fast

Gobo shake 3 from slow to fast

Gobo shake 4 from slow to fast

Gobo shake 5 from slow to fast

Gobo shake 6 from slow to fast

Gobo shake 7 from slow to fast

Gobo shake 8 from slow to fast

Gobo shake 9 from slow to fast

Gobo shake 10 from slow to fast

white

Gobo1

Gobo 2

Gobo 3

Gobo 4

Gobo 5

Gobo 6

Gobo 7

Rotation speed from slow to fast

Reverse rotation from slow to fast

Gobo shake 1 from slow to fast

Gobo shake 2 from slow to fast

Gobo shake 3 from slow to fast

Gobo shake 4 from slow to fast

Gobo shake 5 from slow to fast

Gobo shake 6 from slow to fast

Gobo shake 7 from slow to fast

Reserved

Reset

Reserved

Lamp off ( stop in DMX value for 10 s)

Reserved

Lamp power reduced to 50%

Reserved

Lamp on (See remark below)

Page 15

Remark:

If you intend to turn on/off the lamp via the last channel of the controller, don’t attempt to push the channel to value

224-255 immediately after turning it off, or push the slide bar to value 224-255 to wait it cooling. Under these 2

circumstances, the lamp can not be turned on. The right operation is: turn it off---cool down---push the slide bar to turn it

on.

15/24

Page 16

LED INDICATION

On

Green

Yellow On

Blue On Power

Red/Green

Off

Flash

Red

Green

DMX signal OK

No DMX signal

DMX signal error

Setting the panel

Running slave mode or self test mode

Running master mode

MAINTENANCE

If the projector’s lens becomes damaged or broken it should be replaced. If the lamp becomes damaged or deformed in

any way it must be replaced. If the light from the lamp appears dim this would normally indicate that it is reaching the end

of its life and it should be changed at once, aged lamps run to the extremity of their life might explode. If the projector

does not function, check the fuses on the power socket of the projector, they should only be replaced by fuses of the

same specification. Should these be damaged call a qualified technician before replacement. The projector has thermal

protection device that will switch off the projector in case of overheating, should either of these operate, check that the

fans are not blocked, and if they are dirty clean them before switching on the projector again. Check that the fans are

operational, if not call a qualified technician.

Any maintenance work s hould only be carried out by qualified tec hnicians.

LUBRICATION

To ensure the continuous rotation of the rotating gobos and linear motion of the lens for focusing, it is recommended that

the bearings for the rotating gobos and the 2 shafts for the focusing lens holder be lubricated periodically, preferably

every two months. Use only high quality, high-temperature resistant grease instead of any type of oil. When lubricating

the bearings, a syringe with a fine needle is the easiest way to introduce the grease to the bearings around each gobo.

KEEPING THE PROJECTOR CLEAN

To ensure the reliability of the projector it should be kept clean. It is recommended that the fans should be cleaned every

15 days. The lens and dichroic colour filters should also be regularly cleaned to maintain an optimum light output.

NOT use any type of solvent on dichroic colour filters.

Cleaning frequency depends on the environment in which the fixture operates: damp, smoke or particularly dirty

surroundings can cause greater accumulation of dirt on the unit’s optics. A soft cloth and typical glass cleaning products

should be used in cleaning. It is recommended to clean the external optics at least once every 20 days and clean the

internal optics at least once every 30 / 60 days.

Do not use any organic solvent, e.g. alcohol, to clean the ref lector mirror, dichroic colour filters or housing of

the apparatus.

Do

16/24

Page 17

TROUBLESHOOTING

PROBLEM ACTION

The projector doesn’t switch on

The lamp comes on but the projector

doesn’t respond to the controller

The projector only functions intermittently ¾ Make sure the fan is working and not dirty.

Defective projection

The project image appears to have a halo

The beam appears dim

¾ Check the fuse on the power socket.

¾ Replace the lamp.

¾ Make sure that the projector is correctly configurated.

¾ Replace or repair the DMX cable.

¾ Check the lenses are not broken.

¾ Remove dust or grease from the lenses.

¾ Make sure the lamp is installed correctly.

¾ Carefully clean the optical group lenses and the projector

components.

¾ Check the optics is clean.

¾ Replace with a new lamp of the specified type and rating.

17/24

Page 18

TECHNICAL DATA

VOLTAGES:

Electronical ballast(PR-2225): 100V/120V/200V/220V/230V/240V AC,50/60Hz

Magnetic ballast(PR-2225M): 100V/120V/200V/220V/30V/240V AC,50/60Hz

POWER CONSUMPTION:

Electronical ballast(PR-2225):

Magnetic ballast(PR-2225M):

LAMP:

PHILIPS MSD 250W/2

Colour Temperature 8500°K

Socket GY9.5, single ended

Manufacturers Rated Lamp Life 2000 Hours replacement

Or

OSRAM HSD 250/78

Colour Temperature 7800°K

Socket GY9.5, single ended

Manufacturers Rated Lamp Life 3000 Hours replacement

Or

GE CSD250/2/SE

Colour Temperature 8500°K

Socket GY9.5, single ended

Manufacturers Rated Lamp Life 3000 Hours replacement

COLOURS:

1 wheel with 12 dichroic colour filters plus white

With variable speed bi-directional rainbow effect

Step/linear colour changing is available

GOBOS:

1 Rotating gobo wheel:

7 interchangeable gobos+ white, glass or metal gobos can be fixed

Indexable, bi-directionally rotatable at variable speeds

1 Fixed gobo wheel :

10 interchangeable gobos+ white

bi-directional wheel scrolling at variable speeds

Gobo diameter: Φ22.5mm

Gobo image diameter: Φ17mm

PRISM/ FROST:

1x3 facet prism, bi-directionally rotatable at variable speeds

385W@220V

410W@220V

18/24

Page 19

Iris

0-100% linearly adjustable

Macros

FOCUS:

DMX controlled focus

DIMMER:

0-100% linearly adjustable

SHUTTER:

Double shutter blades, 0.3~12 F.P.S

HEAD MOVEMENT:

Pan 540º, Tilt 270º with auto position correction

BEAM ANGLE:

14°~22°

CONTROL:

DMX512, 3 pin, 5 pin interfaces

14 channels in short mode, 18 channels in standard mode, and 22 channels in extended mode.

Master/slave mode

Stand-alone mode

Self-test mode

OTHER FUNCTIONS:

Adjustable Pan & Tilt speed

Fixture and lamp usage time display

LCD display menu in English

Energy saving function of the ballast

Adjustable fan speed

Built-in analyzer for easy fault finding, error messages

Built-in demo sequences

Input signal isolating protection

HOUSING:

Composite plastic, IP20

WEIGHT:

Electronical ballast(PR-2225):

Magnetic ballast(PR-2225M):

SIZES:

18Kg

23Kg

19/24

Page 20

See at below

LIGHT OUTPUT :

20/24

Page 21

S11S12

+

+

-

SW1 SW2 SW3 SW4

LCD DISPLAY

DMX-IN DMX-OUT

3

V

S

G

12

S1 S6

-

-

12345

+

+

+

-

-

-

s

s

-

-

678910

+

+

+

TILT

-

+

A1 A2

CN6

-

DMX

CN3

PAN

CN9

M1 M2 M3 M4 M5 M6 M7 M8 M9 M10 M11 M12

mark side

mark side

mark side

-

-

VSG VSG VSG VSG VSG

S1 S2 S3 S4 S5

+

+

SENS

M21

M22

M23

M24

M25

M11

M12

M13

M14

M15

M1

ZOOM

M2

PRISM

M9

FIXED GOBOS

M10

COLOUR

M4-1

STROBE

M4-2

STROBE

DMX-IN DMX-OUT

1

2

4

51

3

3

12

3

4

5

2

+

-

CN7CN8

BOX FAN

+

HEAD FAN

-

+

-

-

mark side

ZOOMPRISM PRISM ROTATING STROBE IRIS ROTATING-GOBOGOBO ROTATINGFOCUS FIXED GOBOS COLOUR

VSG

S1 S2 S3 S4 S5

VSG VSG

mark side

mark side

VSG

VSG

PAN TILT

+

+

SENS

M21

M22

M23

M24

M25

M11

M12

M13

M14

M15

M8

FOCUS

M5

IRIS

GOBO ROTATING

M7

ROTATING-GOBO

M6

M3

PRISM ROTATING

M11 M12

PAN TILT

AC20V

-

+

TILT-EncoderPAN-Encoder

AC

IG

DL

N

LAMP

BCBLBH

Thermostat

Ignitor

CH

POWER-SW

E

Filter

AC Plug

N

L

Ph

Ballast

50Hz

60Hz

Ph

Ballast

Transformer

50Hz

60Hz

0V

100V

24VAC

Delay Fuse

120V

200V

220V

230V

230V

240V

CAP1

CAP2

Page 22

S11S12

+

+

-

SW1 SW2 SW3 SW4

LCD DISPLAY

S1 S6

-

-

12345

+

+

+

-

-

-

s

s

-

-

678910

+

+

+

TILT

-

+

A1 A2

CN6

PAN

CN9

M1 M2 M3 M4 M5 M6 M7 M8 M9 M10 M11 M12

mark side

mark side

mark side

-

-

VSG VSG VSG VSG VSG

S1 S2 S3 S4 S5

+

+

SENS

M11

M21

M12

M22

M13

M23

M14

M24

M1

ZOOM

M2

PRISM

M9

FIXED GOBOS

M10

COLOUR

DMX

CN7CN8

-

CN3

V

S

G

12

DMX-IN DMX-OUT

3

DMX-IN DMX-OUT

1

2

4

51

3

3

12

3

4

5

2

+

BOX FAN

+

HEAD FAN

ZOOMPRISM PRISM ROTATING STROBE IRIS ROTATING-GOBOGOBO ROTATINGFOCUS FIXED GOBOS COLOUR

mark side

mark side

M4

M15

M25

-

-

VSG

S1 S2 S3 S4 S5

VSG VSG

+

+

SENS

M11

M21

M12

M22

M13

M23

STROBE

FOCUS

IRIS

GOBO ROTATING

M8

M5

M7

M14

mark side

-

-

+

AC20V

+

TILT-EncoderPAN-Encoder

AC

IG

LAMP-ON/OFF

BCBLBH

CH

12 12 12

View of Control side

ELECTRONIC

BALLAST

LAMP-STATUS

LAMP-DIMMER

GND

IGNITORLAMP

12

PAN TILT

N

L

AC Plug

E

POWER-SW

24VAC

Transformer

Delay Fuse

0V

100V

120V

200V

220V

230V

230V

240V

Filter

VSG

VSG

M24

M15

M25

ROTATING-GOBO

M6

M3

PRISM ROTATING

M11 M12

PAN TILT

L

N

TO IGNITOR

GROUND

View of input side

BALLAST

ELECTRONIC

Page 23

COMPONENT ORDER CODES

NAME PART NO. QUANTITY REMARK

TRANSFORMER 040030309 1 20V 100W

TRANSFORMER**** 040030039 1 21V 100W/230V 320W

THERMOSTAT 190010065 1 75℃

BALLAST 040070085 1 250W 90-265V

BALLAST**** 040070022 2 230V 50/60Hz

IGNITOR 040090051 1 230W

IGNITOR**** 040090016 1 230V 50/60Hz

LAMP 100050057 1 MSD250/2

TILT B E LT 290151252 1 HTD-612-3M

PAN BELT 290151251 1 HTD-447-3M

FAN IN BOX 030060057 1 DC24V/2.88W

FAN NEAR THE LAMP 030060053 1 24V 1.4W

PAN MOTOR 030040053 1 57BYGH301-3A

TILT MOTOR 030040052 1 57BYGH101-2A

PRISM ROTATION MOTOR 1

SHUTTER BLADE MOTOR 1

IRIS MOTOR 1

SHUTTER BLADE MOTOR 2

GOBO ROTATION MOTOR 1

PRISM/FROST MOTOR

ROTATING GOBO WHEEL MOTOR 030040148 1 17HD0013-62

FOCUS MOTOR 1

ZOOM MOTOR 1

FIXED GOBO WHEEL MOTOR 1

COLOUR WHEEL MOTOR

MOTOR DRIVE PCB 230020250 1

DISPLAY PCB 230020255 1

NOTE:

**** Only apply to Magnetic ballast.

030040095

030040092

030040132

030040112

1

1

1

17HD0013-36L

17HD0013-32L 5*7

14HD0013-31L

17HD0013-38L 5*15

1

23/24

Page 24

PR LIGHTING L TD.

1582 Xingye Avenue, Nancun Panyu

Guangzhou, 51 1442 China

TEL: +86-20-3995 2888

FAX: +86-20- 3995 2330

P/N: 320020005

Last Revision: 20080811

24/24

Loading...

Loading...