Page 1

2.1 - 5

2.1

4 11 R1

Supersedes 3 08 R0

Closed Loop Speed Controller For

3 Phase Brushless DC Motor

DC BRUSHLESS MOTOR CONTROLLER

FEATURES

DESCRIPTION

The OMC506 is an integrated, high density, three phase Brushless DC (BLDC)

motor, speed controller housed in a MP-3T package. The OMC506 contains the

power, driver and control electronics to adjust timing functions and speed control loop

parameters to optimize the controller for each application. The electronics contained

in the OMC506 are assembled using mixed process technologies: surface mount

components on a printed circuit board and chip & wire on an Insulated Metal

Substrate. This combination offers small size, excellent thermal characteristics and

electrically isolated heat sink.

ABSOLUTE MAXIMUM RATINGS

Motor Supply Voltage, VM………………………………………………………………32 Vdc

Peak Motor Supply Voltage, VMpk ……………………………………….….…......……48 V

Average Phase Output Current, IO ………………………………………………..…..……10 A

Pulsed Output Current (<1% Duty Cycle), I

OP

…………………………….…..…………30 A

Oscillator Input Current (Source or Sink), I

OSC

………………………………………30 mA

Reference Output Voltage V

REF(IREF

= 1.0 mA) ……………………………………..6.5 V

Digital Inputs (Fwd/Enable/Brake/SA/SB/SC) …………………………………….……..6.5 V

Reference Ouput Current, I REF (V REF=6.2 V) ………………………………………10 mA

Speed Control Input Voltage, V

SPEED

………………………………..……..…-0.3 to V REF V

Tachometer Input Voltage, V

TACH

……………………………………………..-0.3 to V REF V

Temperature Control Input Voltage, V

CNTL

… ……………………………………………..6.2 V

Regulator Output Current, (V

REG

+15V)………………………………………………100 mA

Current Sense Input Voltage, V

CS

………………………………………………...…-0.3 to 5 V

Operating Temperature Range, T

OP

…………………….…………………...…-25 to +85oC

OMC506

• 10A Average Phase Output Current

• Over Temperature Protection

• Compensation Circuitry Adjustable To Motor Parameters

• Speed Controlled by 0 To 5V Linear Input Signal

• Forward Or Reverse Direction

• Isolated, Low Profile Package

Page 2

2.1 - 6

OMC506

2.1

MP3 PACKAGE APPLICATION

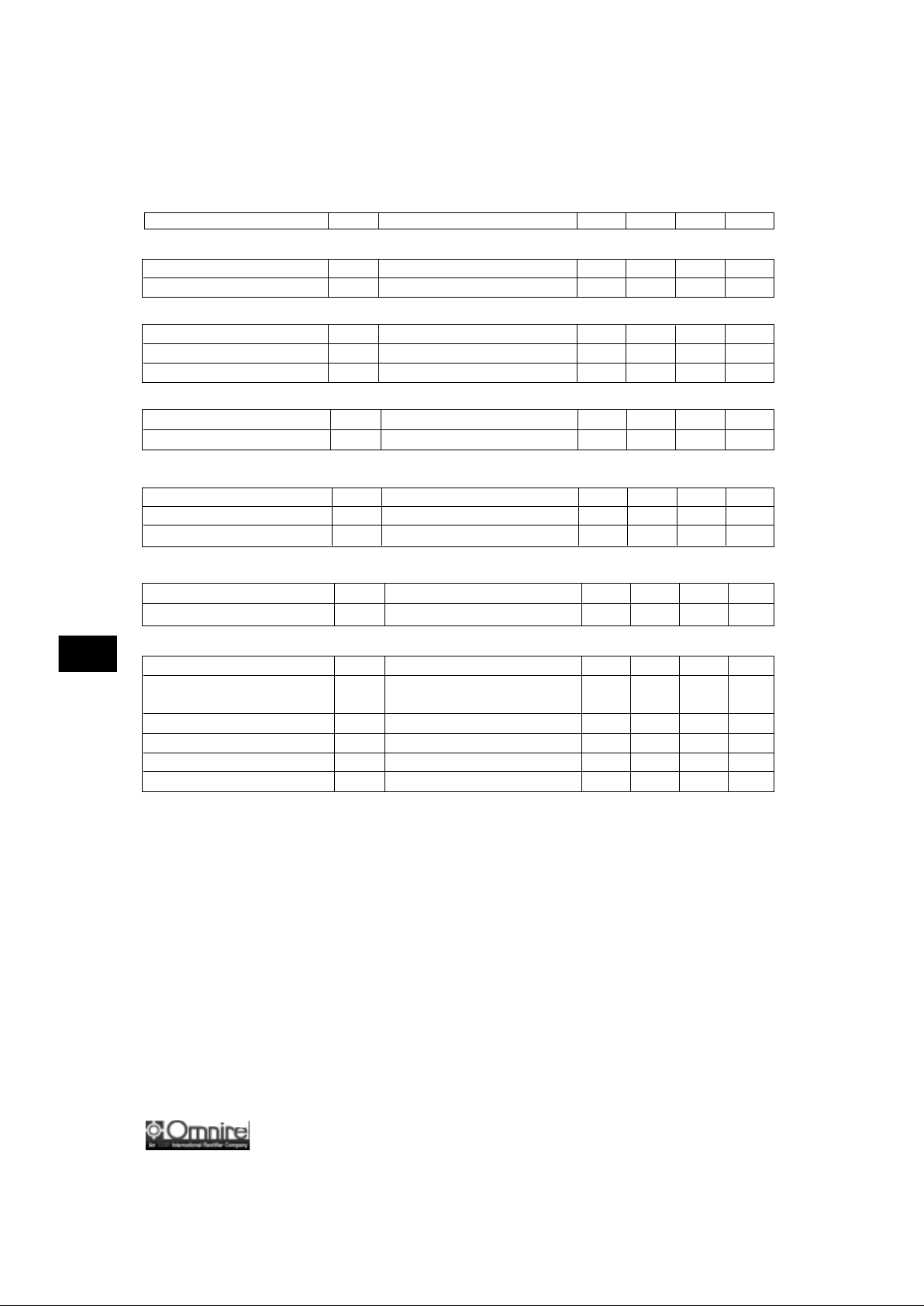

ELECTRICAL CHARACTERISTICS(T

C

= 25°C unless otherwise specified)

Characteristic Symbol Test Conditions Min. Typ. Max. Unit

REFERENCE

Reference Ouput Voltage V REF I REF = 1mA 5.9 6.24 6.5 V

Reference Load Current I REF - 5 8 mA

OSCILLATOR

Oscillator Frequency F OSC 22 25 28 kHz

Sawtooth Peak Voltage V OSCpk ROSC = 4.7k, COSC = 0.01 mF - 4.1 4.5 V

Sawtooth Valley Voltage V oscva 1.2 1.5 - V

DIGITAL INPUTS

High Input Threshold Voltage V ih 3 2.2 - V

Low Input threshold Voltage V il - 1.7 0.8 V

CURRENT SENSE

Threshold Voltage V th 85 101 115 mV

Input Common ModeVolt Range V icr - 3 - V

Input Bias Current I ib - -0.9 -5 mA

VOLTAGE REGULATOR

Ouput Voltage V reg 14.0 14.5 15.0 V

Load Regulation I reg 10 mA < Io<100mA 0.1 0.3 %

THERMAL

Output Trip Voltage V OUT T > T trip’ RL =100K 13 13.31 14.79 V

Output Normal Voltage V ON T > T trip’ RL =100K - 0.13 0.4 V

Trip Temperature T trip T trip 137 145 150 C

Reset Temperature T reset 129 137 142 C

Internal Current Sense Resistor R S 9.5 10 10.5 m*

Jun to Case MOSFET Resistance R thjc - - 1.6 oC/W oC/W

A new mixed signal module fully integrates power, control functions, and drive circuitry into a

single 2" x 4" x 0.48" package. The module provides closed loop speed control of three

phase, brushless DC (BLDC) motors used in a variety of system applications . The OMC506

has been designed with flexibility in mind. Timing functions and loop parameters can be

adjusted to optimize the OMC506 to each customer’s application. In addition, the OMC506

has been designed into a MP-3T package. This package uses an insulated metal substrate,

thereby, isolating the module's electronics from chassis while providing the necessary

thermal interface for proper performance. The OMC506 offers a high efficiency, flexible,

compact, motion control system in an industry standard footprint.

Page 3

2.1 - 7

OMC506

2.1

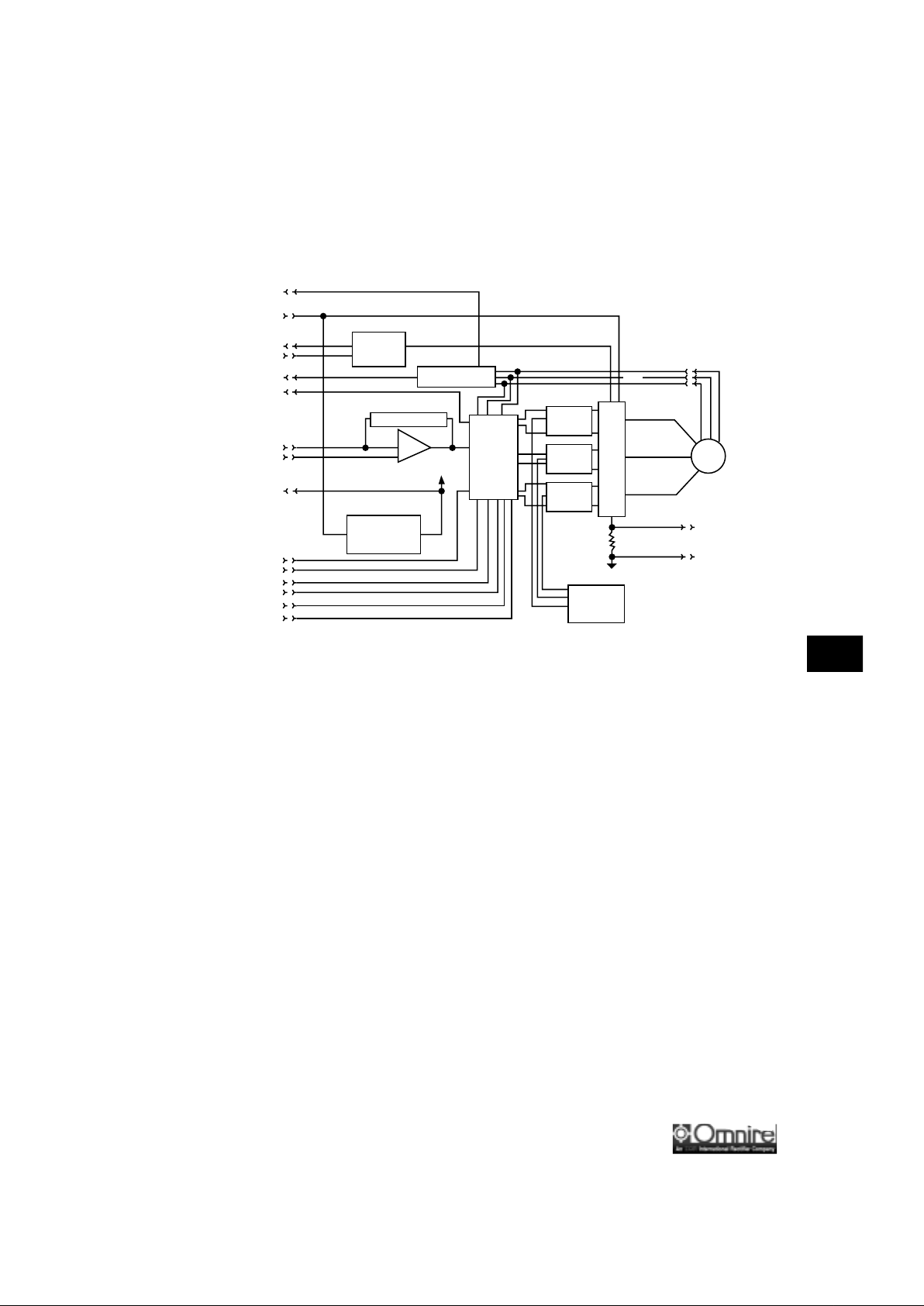

BLOCK DIAGRAM

RT/CT

V

MOTOR

CONTROL

F

OUT

6.2 V

REF

TACH IN

V

SPEED

+15 V

FWD/REV

OSC

C.S.+

C.S.-

BRAKE

ENABLE

REGULATOR

THREE

PHASE

REFRESH

R

SENSE

R

SENSE

RTN

R

SENSE

C OUT

B OUT

A OUT

MOT

POWER STAGE

SA

SC

SB

DRIVER

A

DRIVER

B

DRIVER

C

TACHOMETER

COMPENSATION

LOOP

SHAPING

+15 V

COMMUTATION

AND

CONTROL

V

OUT

OVER

TEMP

CKTRY

Controller

The OMC506 is based on the Motorola MC33035 Brushless Motor Control I.C. This controller is used in

concert with the Motorola MC33039 Closed Loop Brushless Motor Adapter I.C. to provide direct duty

cycle control of the motor speed. The OMC506 provides two quadrant speed control via an analog 0 to

5V signal applied to the V

speed

(pin 22) input. The OMC506 is selectable for 60/120 degree hall sensor

spacing. The commutation truth table for the OMC506 is shown below.

Page 4

2.1 - 8

OMC506

2.1

Table 1 - Commutation Truth Table

Closed Loop Circuits

Additional amplifiers are used in the OMC506 to provide the necessary control loop compensation for

extended bandwidth. By extending the bandwidth of the direct duty cycle control system, torque

perturbations can be accounted for while regulating the speed of the motor. This allows the module to be

used in relatively dynamic systems as well as constant torque applications. Internally, the compensation

circuitry used for control loop shaping can be tuned to optimize the OMC506 for various applications.

The OMC506 provides directional, braking, and enable interfaces from the controller I.C. (pins 32, 24,

and 25, respectively). The module also allows the user to externally set the pulse width modulation

(PWM) frequency (pin 21) as well as the pulse width from the Closed Loop Brushless Motor Adapter (pin

34). This allows a common module to be used in many applications.

Motor commutation and speed control are derived from the Hall effect sensor signals provided from the

motor. The signals are provided as inputs to the OMC506 (pins 29, 30 and 31). The amplitude of the

sensor signals must be limited, by the user, to + 6.2V to insure proper operation of the module.

Finally, the output from the Closed Loop Brushless Motor Adapter is also provided as an output of the

OMC506. This signal has a fixed amplitude and pre-set pulse width. The frequency is six times that of

the motor. This signal is integrated to produce a voltage proportional to motor speed.

Inputs Outputs

120

o

SA SB SC F/R Enable Brake AOUT BOUT COUT Fault Notes

1 0 0 1 1 0 1 - 0 1

11 0 1 1 0 - 1 0 1

01 0 1 1 0 0 1 - 1

01 1 1 1 0 0 - 1 1

00 1 1 1 0 0 - 0 1

10 1 1 1 0 1 0 - 1

10 0 0 1 0 0 - 1 1

11 0 0 1 0 - 0 1 1

01 0 0 1 0 1 0 - 1

01 1 0 1 0 1 - 0 1

00 1 0 1 0 - 1 0 1

10 1 0 1 0 0 1 - 1

1 1 1 X X 0 - - - 0 1

0 0 0 X X 0 - - - 0

1 11 X X 10 0001

0 0 X X 1 1 0 0 0 0

VVV X 1 10 0012

VV V X 0 1 0 0 0 0

VV V X 0 0 - - - 0

Notes:

1.) Invalid Sensor Inputs; X = Don’t Care

2.) V = Valid Sensor Input

Page 5

2.1 - 9

OMC506

2.1

Current Limit

The OMC506 provides outputs from the internal current sense resistor (pin 7 & 8). These outputs can be

directly wired to the C.S.+, and C.S.- (pin 28 & 27) inputs. The outputs can also be used in external

current limit circuitry. Figure 2 shows a typical connection of the OMC506’s current limit circuitry

Figure 2 - Current Limit Circuitry

Over Temperature Protection

The OMC506 has been designed with an internal over temperature protection circuit. The circuit provides

a diagnostic in the event an over temperature condition occurs in the power stage. The circuit normally

outputs a voltage level < 0.5Vdc. When the power stage reaches 140°C the V

OUT

(pin 19) will rise to

+15Vdc. The OMC506 also outputs a control function for this circuitry. A logic “0” at pin 18 will disable the

over temperature circuit and a logic “1” will force V

OUT

to go high. The over temperature circuitry has been

designed to interface with a system controller. The system controller can act on the pretense of an over

temperature and shut the OMC506 down. The system controller may opt to over ride the over temperature

flag and disable the circuit over temperature circuitry. In addition, the system controller can force the V

OUT

high as part of a built in test (BIT) feature at the system level. The over temperature circuitry will reset

when the power stage has cooled to 130°C. Finally, an internal diode can be jumpered causing the

temperature circuitry to latch on trip, requiring a power off reset.

Typical Motor Connections

Figure 3 shows a typical application of the OMC506. The user must externally connect an electrolytic

capacitor (value is dependent on the application) bypassed with a ceramic decoupling capacitor. These

capacitors should be as close to the module as feasible. In addition, it is recommended that a transient

suppressor also be added in parallel with the external capacitors to prevent high voltage transients on the

motor bus.

+

-

100

100

0.1uf 0.01uf

C.S. Amplifier

P/O MC33035

Rs

0.01

Im

P/O OMC506

28

27

8

7

To control

logic

Page 6

2.1 - 10

OMC506

2.1

Figure 3 - Typical Motor Connections

Conclusion

Omnirel’s OMC506 offers a complete motor control system, that is flexible in design, in a high density,

high power industrial module. The assembly technology makes the OMC506 an ideal candidate in

systems where package size is critical. This power module integrates all the functions necessary to

control a DC brushless motor. The design of the OMC506 is flexible enough to be customized for various

applications while still maintaining a turn-key solution to the end user. Finally, the MP310, as other

industrial packages from Omnirel, makes the user’s mechanical interface simple while optimizing the

thermal transfer from the module to the heatsink.

5 V

MOT

480µF

+

145 C TRIP

DISABLE

FORCE TRIP

DIAGNOSTIC

100K

0.01µF

0.01µF

0.1µF

80.6K634 6.65K

Power GND

Power GND

NC

Phase C

Phase C

NC

R

R

+15 V

Signal GND

Phase A

Phase A

NC

Phase B

Phase B

V

m

V

m

RT/CT

F (Tach)

Fwd/Rev

SA

SB

SC

CS+

CS-

Fault

Enable

Brake

Tach Input

V

O

sc

6.2 V

V

OUT

Control

OUT

speed

ref

sense return

V

Hall

V

MOT

sense

5 V

Page 7

OMC506

2.1

205 Crawford Street, Leominster, MA 01453 USA (508) 534-5776 FAX (508) 537-4246

Contact factory for lead bending options.

2.000

1.350

.150

(4) PLCS.

4.0003.000

.150

.500

.500

.250

.250

.600

.325

.050

(34) PLCS.

.300

.480 MAX.

.180

.020

2.450

.135

MP-3T MECHANICAL OUTLINE WITH PIN CONNECTIONS

Pin 1: Power GND

Pin 2: Power GND

Pin 3: NC

Pin 4: Phase C

Pin 5: Phase C

Pin 6: NC

Pin 7: R

sense return

Pin 8: R

sense

Pin 9: +15 V

Pin 10: Signal GND

Pin 11: Phase A

Pin 12: Phase A

Pin 13: NC

Pin 14: Phase B

Pin 15: Phase B

Pin 16: V

m

Pin 17: V

m

Pin 34: RT/CT

Pin 33: F

OUT

(Tach)

Pin 32: Fwd/Rev

Pin 31: SA

Pin 30: SB

Pin 29: SC

Pin 28: CS+

Pin 27: CSPin 26: Fault

Pin 25: Enable

Pin 24: Brake

Pin 23: Tach Input

Pin 22: V

speed

Pin 21: Osc

Pin 20: 6.2 V

REF

Pin 19: V

OUT

Pin 18: Control

Loading...

Loading...