Omitec OM503 Owners Manual

User’s Manual

OmiDetect 100

TPM Sensor Tester

CH041006 Rev A.1

OM503/2

The information, specifications and illustrations in this manual are based on

the latest information available at the time of publication. The manufacturer

reserves the right to make equipment changes at any time without notice.

© Copyright 2007 Omitec, Inc.

All rights reserved. OmiDetect is a

registered trademark of Omitec, Inc.

Printed in the U.K.

.

OmiDetect 100

Table of Contents

1. INTRODUCTION............................................................................2

Direct Versus Indirect Systems...................................................3

About Sensors ............................................................................4

Activating Sensors......................................................................5

Reprogramming..........................................................................5

2. SAFETY INFORMATION ..............................................................7

3. KIT CONTENTS.............................................................................9

4. CONTROLS AND INDICATORS.................................................10

5. OPERATING INSTRUCTIONS....................................................11

6. WHAT TO DO IF OMIDETECT CANNOT

ACTIVATE THE TPM SENSOR..................................................15

Technique A..............................................................................15

Technique B..............................................................................15

7. REPROGRAMMING THE TPM CONTROL MODULE ...............16

8. TPM SENSOR TYPE SELECTION CHART ...............................17

9. SPECIFICATIONS.......................................................................21

10. TROUBLESHOOTING ...............................................................22

11. CARE AND MAINTENANCE .....................................................23

12. WARRANTY...............................................................................23

13. TECHNICAL SUPPORT.............................................................24

Introduction

1. Introduction

Congratulations on your purchase of the OmiDetect 100 Tire

Pressure Monitoring (TPM) sensor tester. To enjoy safe and the best

performance from your OmiDetect 100, please read and follow all

instructions, recommendations and warnings.

Understanding the basics of tire pressure monitoring systems is

essential to using the OmiDetect effectively, so be sure to review the

following sections thoroughly.

OmiDetect is a state-of-the-art tester designed especially for automated

and manual testing of TPM valve sensors for proper operation. Used

correctly, it will allow you to quickly:

Confirm that the vehicle’s TPM sensors are working properly

before you start tire/wheel service work (including rotating,

changing or balancing tires/wheels). This will reduce the risk of

your having to replace a sensor that was defective prior to your

starting the work.

Confirm that the vehicles TPM sensors are working properly

after you complete tire/wheel service work.

After rotating the vehicle’s wheels, activate their TPM sensors

to allow the vehicle control unit monitoring the TPM sensors to

identify their new location.

Diagnose problems with TPM sensors and other TPM system

components.

Confirm that a TPM sensor you replaced is working properly.

Confirm that you installed the correct type of sensor.

History of TPM Systems

In the wake of tire safety issues involving SUVs in the late ‘90s,

Congress passed the Transportation Recall Enhancement, Accountability,

and Documentation (TREAD) Act in 2000. The TREAD Act mandated that

automotive manufacturers start phasing TPM systems into all their new

light vehicles with a GVWR of 10,000 pounds or less beginning in

November 2003. By 2006, 90% of all light vehicles are to comply, and by

Sept. 1, 2007, all new light vehicles must comply. The total population of

vehicles with TPM systems will grow from approximately 4 million units in

2003 to close to 50 million units by the end of the decade.

2

Introduction

The NHTSA, which is responsible for establishing and enforcing vehicle

safety standards, published a mandate requiring that the TPM system

must be capable of monitoring all four tires and alerting the driver if a tire

is under inflated by 25% or more of the OEM’s recommended tire

pressure. Testing showed that proper tire inflation significantly improves

vehicle handling safety, decreases tread wear, improves fuel economy,

and decreases stopping distances. Underinflated tires are dangerous

because they build up internal heat that can damage the tire structure,

potentially resulting in fatal blowouts.

Direct Versus Indirect Systems

The NHTSA’s mandate on TPM systems allows two system architectures.

The first, called the “direct” system, uses a direct RF link from each wheel

to a central receiving control unit, and the second, called the "indirect"

system, works in conjunction with the vehicle's antilock-braking (ABS)

system.

Direct Systems. Wireless sensor in or on each wheel that

measures internal tire air pressure and temperature separately

and communicates the readings by RF signals to a

receiver/controller control unit at regular intervals. The sensors

have an integral low frequency transmitter and are typically built

into or mounted on the valve stem. The end of the valve stem

serves as the sensor’s antenna. Most direct systems share the

receiver control unit with the vehicle’s keyless entry system.

Indirect Systems. Monitors rotation of tires via the vehicle’s

antilock braking system (ABS) to calculate whether they are

properly inflated. Does not measure tire pressure or

temperature. The system measures the wheel speed of all four

tires and calculates a “rolling circumference” for each one. In

the event of a tire pressure loss, the rolling circumference of

that tire is reduced, producing a change in the tire’s rotational

speed.

The NHTSA found that direct TPM systems are preferred

because they are better able to detect under- or over-inflation

and are quicker to provide alerts. Virtually all vehicle

manufacturers today have moved to direct systems.

3

Introduction

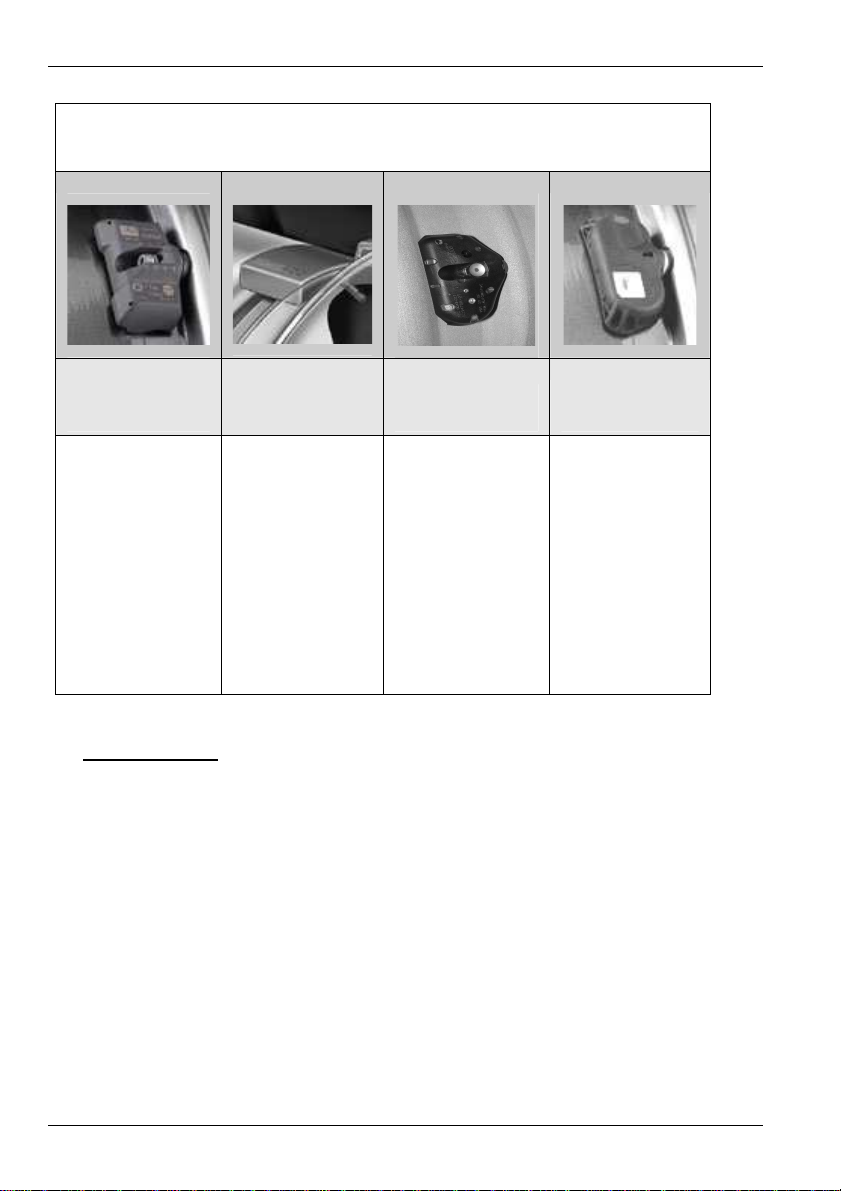

Examples of TPM sensors used in today’s direct TPM systems.

Beru

Audi

Volkswagen

Bentley

Bugatti

BMW

Ferrari

Kia

Land Rover

Maserati

Mercedes-Benz

Porsche

Chrysler

Dodge

Jeep

Mazda

Suzuki

Siemens

TRW Pacifica

GM

Honda

Acura

Hyundai

Kia

Lexus

Toyota

About Sensors

TPM sensors are micromechanical devices (a silicon-based vacuum cell)

powered by a lithium battery with a minimum life expectancy of up to 10

years. Using their piezoresistive technology, they monitor tire pressure via

measuring the deformation of an internal diaphragm.

They typically transmit measurement values and sensor ID data at 433

MHz (for European systems) or 315 MHz (for U.S. systems) to the

receiver control unit once per hour when the vehicle is parked (and only if

the pressure changes), to preserve battery life, and every few seconds

when the vehicle is traveling above a certain speed (typically about 20

mph). If the tire pressure rises or falls outside calibration limits, a warning

light or message is displayed in real time on the vehicle’s instrument

panel, along with an audible warning, to alert the driver.

4

Introduction

Activating Sensors

To activate, or “wake up,” a TPM sensor to test its ability to sense and

transmit tire pressure and sensor ID information to the TPM control

module, you must use one of three different methods, depending on the

type/brand of sensor:

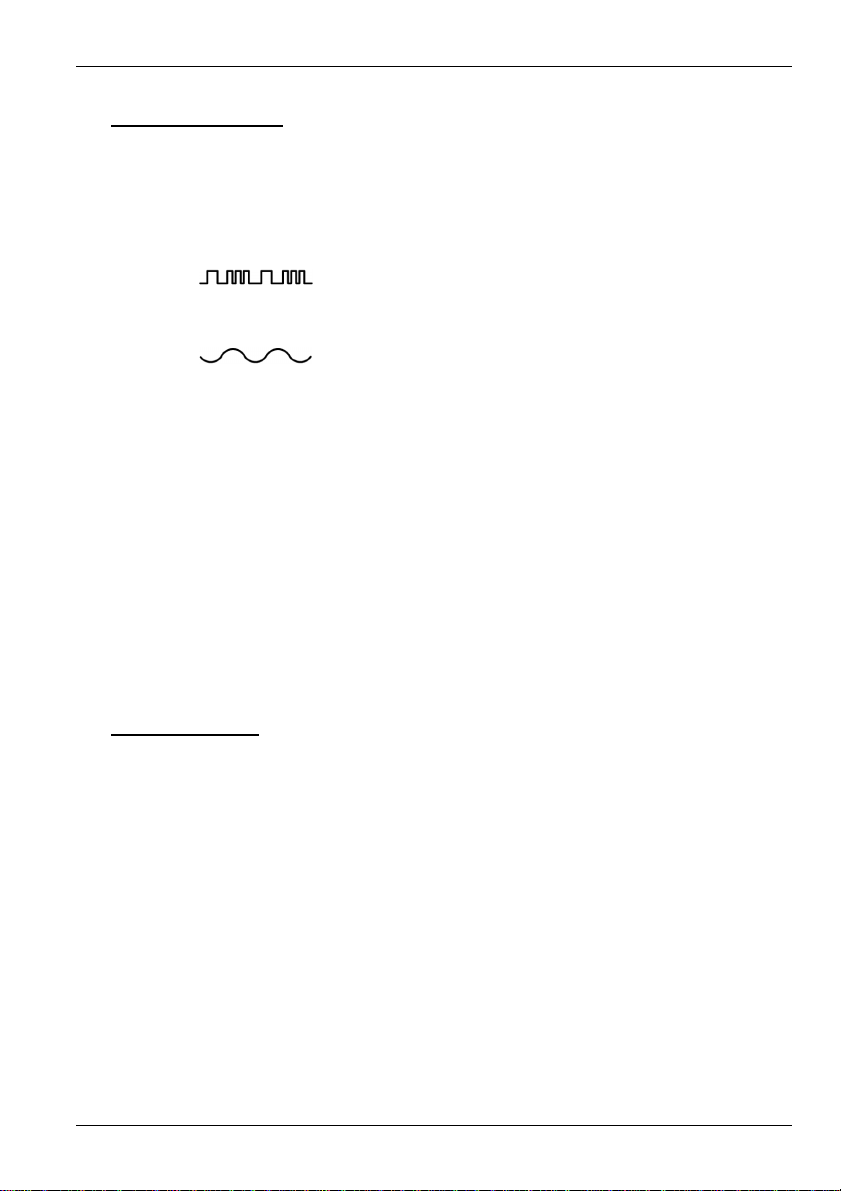

Send the sensor a 125 KHz “modulated” wave command signal

( ). (OmiDetect is capable of generating a variety

of modulated waveforms.)

Send the sensor a 125 KHz “continuous” wave command signal

( ).

Position the magnetic tool specified by the OEM in close

proximity to the sensor. The tool is provided with the vehicle or

is available from the OEM.

Most of the current-generation sensors can be activated using either the

first or the second method. The OmiDetect 100 uses only ‘modulated’

wave command signals to test valves.

Once a sensor is activated, OmiDetect 100 will listen for the appropriate

response signal. If it detects a valid signal, it will provide both visual and

audible confirmation and indicate its frequency (either 315 MHz or 434

MHz).

Note: Older generation sensors may not have the electronics required to

activate them using these methods.

Reprogramming

Each TPM sensor has a unique internal identification code. With most

current generation TPM systems, anytime you rotate a vehicle’s tires or

replace one or more TPM sensors, you must “reset” (reprogram) the TPM

system’s control module by placing it in the “learn” mode and activating

each sensor so the control module can identify the new sensor locations.

Refer to the Omitec TPM System Quick Reference Guide provided with

your OmiDetect system for instructions on how to reset the TPM system

of a specific vehicle make and model.

IMPORTANT: If you do not reprogram the control module, it will

continue to report the correct tire pressures, but will assign them to

the wrong wheel locations.

5

Introduction

Other Cases Where You Will Need to Reprogram the TPM Control

Module

If the vehicle’s battery or the TPM control module is disconnected or the

voltage to the TPM system drops below a certain value, the control

module will loose all its sensor ID information and will set a DTC for a

TPM fault. In this case, you will need to reprogram the control module and

clear the DTC.

Figure 1. OmiDetect shown in use in testing a TPM sensor.

6

Safety Information

2. Safety Information

IMPORTANT SAFETY NOTICE

For your safety, read this manual thoroughly before operating your

OmiDetect system. It is intended for use by properly trained professional

automotive technicians. The safety messages presented below and

throughout this user’s manual are reminders to the operator to exercise

care when using it. Before using your OmiDetect system, always refer to

and follow the safety messages and applicable service procedures

provided by the manufacturer of the vehicle being serviced.

WARNING – Risk of injury

●

This device emits an electromagnetic field which may interfere with the

safe operation of medial equipment such as a heart pacemaker.

Individuals fitted with a pacemaker should never use this device.

WARNING – Risk of injury

●

Never contact the OmiDetect tester to moving components, drive belts

and other moving components.

WARNING – Risk of electrical shock

●

To avoid possible serious injury from electrical shock, never contact

OmiDetect to electrical components.

CAUTION – General Safety Precautions

●

1. Do not attempt to use the Tire Pressure Monitor System while

adjusting tire pressures, since they do not function as a real-time

tire pressure gauge.

2. Tire pressure monitor equipment was calibrated for the original

vehicle tire size. Use only original tire sizes to maintain system

accuracy.

3. Tire sealants should not be used on vehicles equipped with a Tire

Pressure Monitor System. Those sealants can clog the sensors,

rendering them ineffective.

4. Do not attempt to install a tire pressure sensor in a steel or

aftermarket wheel. Tire pressure monitor equipment is only to be

used on original style factory wheels.

5. Always replace a damaged or inoperative TPM sensor/transmitter.

7

Loading...

Loading...