CT Analyzer & CT SB2

User Manual

CT Analyzer & CT SB2 User Manual

Manual Version: CTAnalyzer+CTSB2UM.AE.3

© OMICRON electronics GmbH 2012. All rights reserved.

This manual is a publication of OMICRON electronics GmbH.

All rights including translation reserved. Reproduction of any kind, for example, photocopying,

microfilming, optical character recognition and/or storage in electronic data processing systems,

requires the explicit consent of OMICRON electronics GmbH. Reprinting, wholly or in part, is not

permitted.

The product information, specifications, and technical data embodied in this manual represent the

technical status at the time of writing and are subject to change without prior notice.

We have done our best to ensure that the information given in this manual is useful, accurate and

entirely reliable. However, OMICRON electronics GmbH does not assume responsibility for any

inaccuracies which may be present.

The user is responsible for every application that makes use of an OMICRON product.

OMICRON electronics GmbH translates this manual from the source language English into a number

of other languages. Any translation of this manual is done for local requirements, and in the event of a

dispute between the English and a non-English version, the English version of this manual shall govern.

CT Analyzer

User Manual

CT Analyzer User Manual

Manual Version: CTAnalyzerUM.AE.3

2

Contents

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operator Qualifications and Safety Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Conventions and Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

General Rules for Safe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Orderly Measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1.1 Designated Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.2 Functional Components of the CT Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2.2 Mains Connection Unit and Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2.3 Compact Flash Card Slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2.4 Remote Control Interface (PC Connection) . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.2.5 Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.2.6 I/0 Key with Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.2.7 Display with Soft Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.2.8 Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.3 License-Depending Functional Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.4 Scope of Delivery, Accessories, Available Licenses . . . . . . . . . . . . . . . . . . . . . 20

2 Setup and Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

2.1 General Safety Rules for Connecting and Operating the CT Analyzer . . . . . . . 21

2.2 Setting Up the CT Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.3 Connecting the CT Analyzer to a PC (optional). . . . . . . . . . . . . . . . . . . . . . . . . 23

2.4 Connection for Usual Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.4.1 Wiring for a CT Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.4.2 Wiring for a Burden Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.4.3 Wiring for Primary Resistance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.5 Connection for Special Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.5.1 Measurement on a Gapped Core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.5.2 Excitation Curve Measurement for an Unwound Iron Core . . . . . . . . . . . . . . . 29

2.5.3 Measurement on a GIS (SF6) Switch Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.5.4 Measurement on Bushing-Type CTs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.5.5 VT Ratio Measurement Using QuickTest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3

CT Analyzer User Manual

2.5.6 VT Winding Resistance Measurement Using QuickTest . . . . . . . . . . . . . . . . . 39

2.5.7 Polarity Check Using QuickTest and the CPOL Polarity Checker . . . . . . . . . . 39

2.6 Disconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.7 Improving the Quality of Measurement Results. . . . . . . . . . . . . . . . . . . . . . . . . 42

2.7.1 4-Wire Measurement vs. 2-Wire Measurement . . . . . . . . . . . . . . . . . . . . . . . . 42

2.7.2 Noise Reduction Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3 Short Guide for Running a CT Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4 Running a CT Test (Detailed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.1 Setting Up the CT Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.2 Preparing and Configuring the Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.3 Running the Automatic Test and Connecting the CT Analyzer . . . . . . . . . . . . . 52

4.4 After the Test is Finished. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.5 Disconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5 Operating and Configuring the CT Analyzer. . . . . . . . . . . . . . . . . . . . . . . . 59

5.1 Working in the User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.1.1 Displaying a Specific Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.1.2 Using the Soft Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.1.3 Editing a Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.2 The Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.3 New CT-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.4 New MR-Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.5 New Quick-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.6 File Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.6.1 Available Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.6.2 Working in the File System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.7 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.7.1 Available Options in the Settings Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.7.2 Default Test Card Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.7.3 Miscellaneous Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.8 Tools (Update Functions) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.8.1 Available Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.8.2 Update Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.8.3 Update Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.9 CT Analyzer Help System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.10 Operating the CT Analyzer from a Computer . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6 The CT Analyzer Test Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.1 Overview of Test Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.2 CT-Object Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4

Contents

6.2.1 Available Soft Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6.2.2 Information Fields to be Filled by the User . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.2.3 Parameters and Settings Used or Determined by the Test Process . . . . . . . . 82

6.3 Burden Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6.3.1 Test Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6.3.2 Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6.3.3 Connecting the Burden and Running the Burden Test . . . . . . . . . . . . . . . . . . 101

6.4 Residual Magnetism Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.4.1 Test Settings and Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6.4.2 Running a Residual Magnetism Measurement. . . . . . . . . . . . . . . . . . . . . . . . 103

6.5 Resistance Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6.5.1 Primary Winding Resistance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . 106

6.5.2 Secondary Winding Resistance Measurement . . . . . . . . . . . . . . . . . . . . . . . . 106

6.5.3 Test Settings and Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6.6 Excitation Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6.6.1 Available Soft Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

6.6.2 Test Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

6.6.3 Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

6.6.4 Excitation Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

6.6.5 Accuracy Limiting Error Graph* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

6.7 Ratio Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

6.7.1 Available Soft Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

6.7.2 Test Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

6.7.3 Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

6.7.4 Ratio Table and Phase Table for IEC 60044-1, IEC 60044-6 and

IEC 61869-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

6.7.5 Ratio Table and Phase Table for IEEE C57.13 . . . . . . . . . . . . . . . . . . . . . . . 123

6.8 Assessment Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

6.8.1 Assessed Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

6.9 Comment Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

7 CT Testing Using the Guesser Function . . . . . . . . . . . . . . . . . . . . . . . . . .131

7.1 About the Guesser Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

7.2 Setting Up and Connecting the CT Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . 132

7.3 Preparing and Configuring the Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

7.4 Running the Automatic Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

7.5 After the Test is Finished . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

7.6 Disconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

8 Using the Quick Test Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

8.1 Safety Notes and Notes for Using Quick Test . . . . . . . . . . . . . . . . . . . . . . . . . 136

5

CT Analyzer User Manual

8.2 Introduction to Quick Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

8.3 Performing Measurements with Quick Test. . . . . . . . . . . . . . . . . . . . . . . . . . . 139

8.4 Advanced Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

8.5 Polarity Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

8.6 CT Ratio Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

8.7 VT Ratio Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

8.8 Resistance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

8.9 Impedance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

8.10 Reactance Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

9 CT Analyzer PC Toolset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

9.1 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

9.2 Installing the CT Analyzer PC Toolset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

9.3 The CTA Start Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

10 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163

10.1 Mains Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

10.2 Generator Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

10.3 Measurement Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

10.4 Winding Resistance Measurement Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . 164

10.5 Ratio and Phase Measurement Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

10.6 Compact Flash Card Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

10.7 Remote Control Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

10.7.1 RS232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

10.7.2 USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

10.8 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

10.8.1 Climate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

10.8.2 Shock and Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

10.8.3 Mechanical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

10.8.4 Safety Standards, Electromagnetic Compatibility (EMC) . . . . . . . . . . . . . . . . 168

11 User Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

11.1 Care and Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

11.2 Replacing Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

11.3 Calibrating the CT Analyzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

12 Error and Warning Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

OMICRON Service Centers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

6

Preface

Using This Manual

This User Manual provides information on how to use the CT Analyzer. The

CT Analyzer User Manual contains important safety instructions for working with

the CT Analyzer and gets you familiar with operating the CT Analyzer. Read and

observe the safety rules described in "Safety Rules" on page 9 and all relevant

installation and operation instructions. Following the instructions in this User

Manual will help you to prevent danger, repair costs, and avoid possible down

time due to incorrect operation.

The CT Analyzer User Manual always has to be available at the site where the

CT Analyzer is used. It must be read and observed by all users of the

CT Analyzer. Reading the CT Analyzer User Manual alone does not release you

from the duty to comply with all relevant national and international safety

regulations.

Operator Qualifications and Safety Standards

Preface

Working on high-voltage power equipment can be extremely dangerous.

Testing with the CT Analyzer should only be carried out by authorized and

qualified personnel. Before starting to work, clearly establish the responsibilities.

Personnel receiving training, instruction, direction, or education on the

CT Analyzer should remain under the constant supervision of an experienced

operator while working with the equipment.

Testing with the CT Analyzer must comply with the internal safety instructions

as well as additional relevant documents.

In addition, observe the following safety standards, if applicable:

• EN 50191 (VDE 0104) "Erection and Operation of Electrical Equipment"

• EN 50110-1 (VDE 0105 Part 100) "Operation of Electrical Installations"

• IEEE 510 "IEEE Recommended Practices for Safety in High-Voltage and

High-Power Testing"

7

CT Analyzer User Manual

Conventions and Symbols Used

In this manual, the following symbols indicate paragraphs with special safety

relevant meaning:

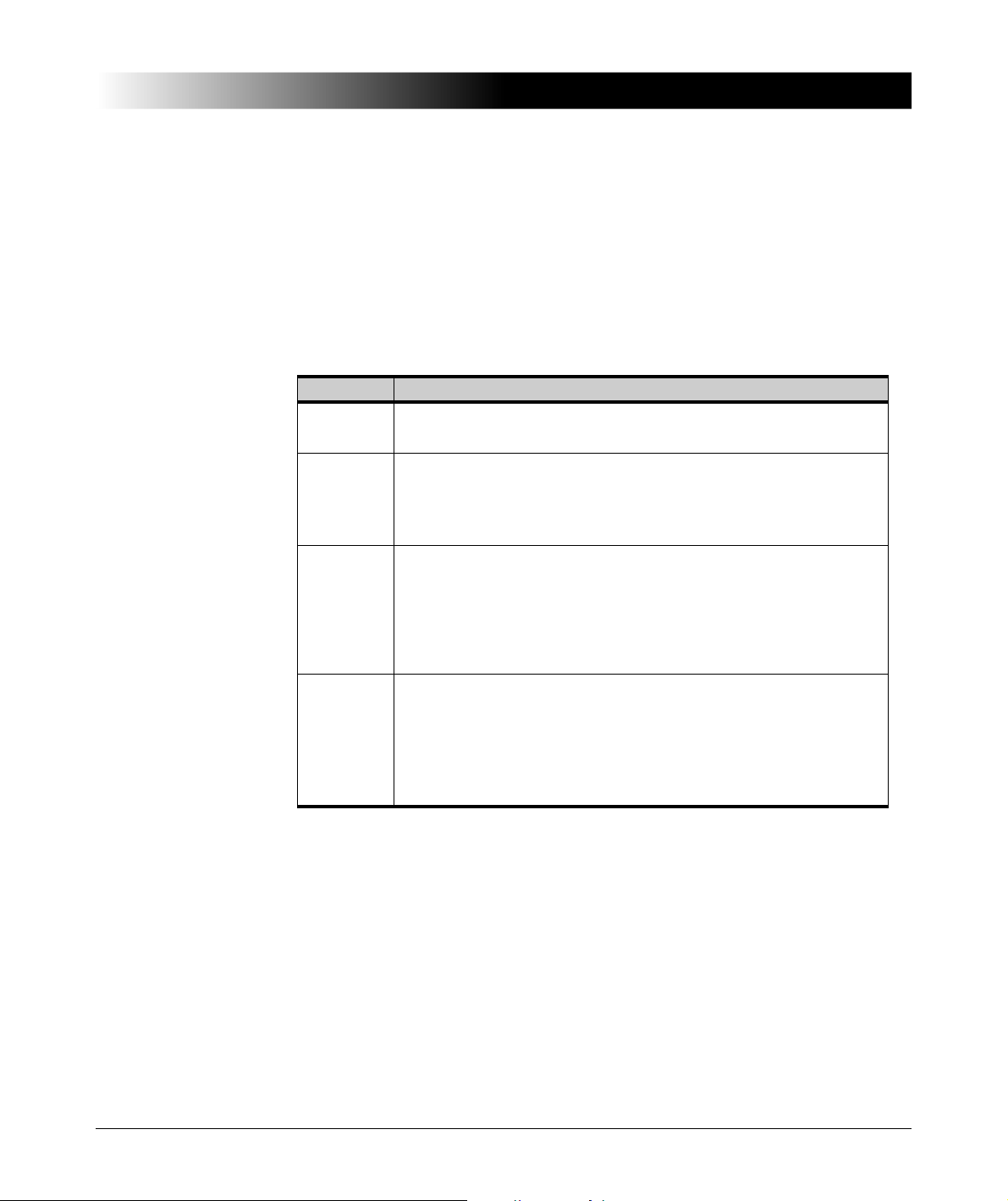

Symbol Description

Related Documents

The following documents complete the information covered in the CT Analyzer

User Manual:

Caution: Equipment damage or loss of data possible

Warning: Risk of electric shock!

Personal injury or severe damage to objects possible

Title Description

CT SB2 User Manual Contains information how to use and

operate the optional CT SB2 switch box for

multi-ratio CT measurement with the

CT Analyzer as well as safety instructions

for working with the CT SB2.

Help System for

CT Analyzer PC Toolset

Contains detailed information about the

software tools provided with the

CT Analyzer PC Toolset.

8

Safety Rules

Before operating the CT Analyzer, read the instructions in this section carefully.

If you do not understand some safety rules, contact OMICRON before

proceeding. When working with the CT Analyzer, observe the following safety

rules.

Maintenance and repair is only permitted by qualified experts at OMICRON

repair centers.

General Rules for Safe Operation

• Always observe the five safety rules:

– Disconnect completely

– Secure from reconnection

– Verify that the installation is dead

– Carry out grounding and short-circuiting

– Provide protection against adjacent live parts

• Do not touch any terminals without a visible connection to ground.

• Always be aware of the danger of the high voltages and currents associated

with this equipment. Pay attention to the information provided in this user

manual.

•Use the CT Analyzer and its accessories only in a technically sound

condition and when its use is in accordance with the safety regulations for the

specific job site and application.

• Use only original accessories available from OMICRON.

• If the CT Analyzer or any add-on device or accessory seems to be

functioning improperly, please call the OMICRON Hotline (refer to

chapter "OMICRON Service Centers" on page 185).

• Do not operate the CT Analyzer when explosive gas or vapors are present.

• Do not operate the CT Analyzer under wet or moist conditions

(condensation).

• Do not open the CT Analyzer. Opening the CT Analyzer invalidates all

warranty claims. Do not repair, modify, extend, or adapt the CT Analyzer or

any accessories.

• Do not insert objects (e.g. screwdrivers, etc.) into the ventilation slots or any

input/output sockets.

Safety Rules

9

CT Analyzer User Manual

• Do not stand right next to or directly underneath a connection point because

• Full compliance with the regulations also includes following the instructions

Orderly Measures

The CT Analyzer User Manual or the e-book version of the manual has always

to be available on the site where the CT Analyzer is being used. All users of the

CT Analyzer must read and observe the safety rules described in this section

and all relevant installation and operation instructions.

The CT Analyzer may be used only as described in this User Manual. Any other

use is not in accordance with the regulations. The manufacturer and the

distributor are not liable for damage resulting from improper usage. The user

alone assumes all responsibility and risk.

Disclaimer

the clamps may fall off and touch you.

provided in this User Manual.

If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

10

1 Introduction

1.1 Designated Use

The CT Analyzer is intended to perform automatic testing and calibration of low

leakage flux current transformers (i.e., CTs with non-gapped cores) in

laboratories as well as on-site in utilities. Testing of CTs with gapped cores is

also possible with restricted accuracy. The following tests can be performed

using the CT Analyzer:

• Burden measurement

• Residual magnetism measurement of CTs

• CT winding resistance measurement

• CT excitation characteristic measurement according to IEC 61869-2,

IEC 60044-1, IEC 60044-6 (TPS, TPX, TPY, TPZ) and IEEE C57.13.

• CT ratio measurement with consideration of a connected burden

• CT phase and polarity measurement

• Determination of accuracy limiting factor, instrument security factor,

secondary time constant, symmetrical short-circuit current factor, transient

dimensioning factor, remanence factor, knee point voltage/current, class,

saturated inductance and non-saturated inductance.

Introduction

Using the Quick Test feature it is also possible to use the CT Analyzer as a

versatile multimeter with included power source, e.g. for:

• Quick and easy resistance measurement, e.g. for wiring checks on the

secondary side of CTs.

• Quick voltage ratio checks for VTs.

• Measurement of burden values, e.g. to determine the new burden value after

changes of the relay equipment. This allows the re-calculation of the CT test

results for the new burden value by the CT Analyzer and thus makes it

unnecessary to run an additional CT test in order to determine the behavior

of the CT with the new burden.

• Quick wiring checks using the CPOL polarity checker from OMICRON. Using

the CPOL in combination with the specific test signal provided by the

CT Analyzer’s Quick Test feature you can check a series of test points (e.g.,

the burden wiring) for correct polarity.

The CT Analyzer is intended exclusively for the applications described above.

Any other use is deemed not to be according to the regulations. The

manufacturer and the distributor are not liable for damage resulting from

improper usage. The user alone assumes all responsibility and risk.

11

CT Analyzer User Manual

Compact Flash

card slot

Remote control interface

RS232 interface and USB

interface for connecting

the CT Analyzer to a PC

Grounding

terminal

Keyboard

with cursor keys and

card selection keys

Output

Generator output

Display

with context-dependent

keys ("soft keys")

Sec, Prim

Measurement inputs

I/0 key

with status LEDs

Mains connection unit

Mains socket with fuse and

ON/OFF switch

1.2 Functional Components of the CT Analyzer

1.2.1 Overview

Figure 1-1 provides an overview of the operating and display elements and the

connectors of the CT Analyzer.

Figure 1-1 CT Analyzer overview

12

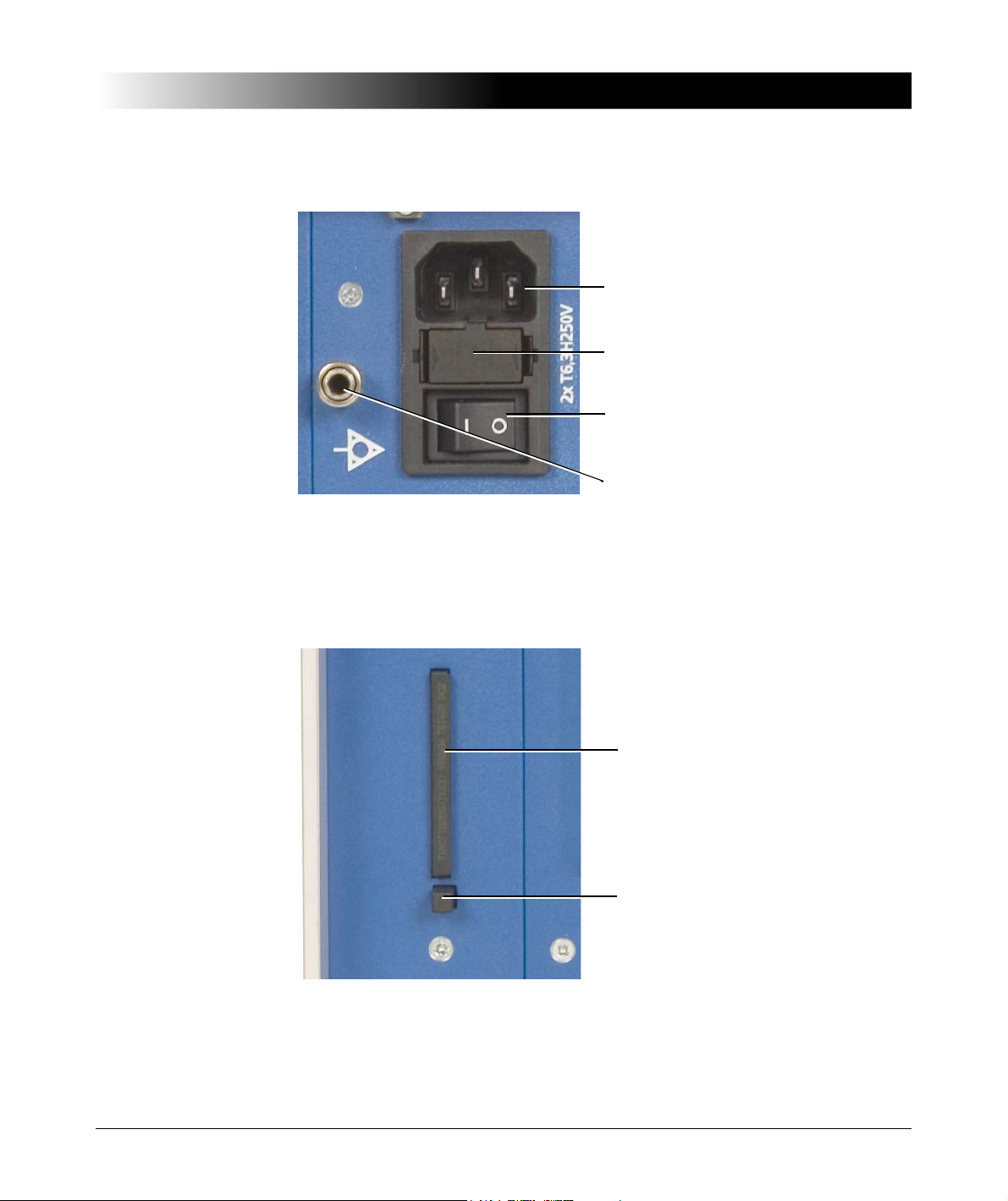

1.2.2 Mains Connection Unit and Grounding

Mains socket (IEC320)

ON/OFF switch

Grounding terminal

(4mm socket combined with knurled

nut for clamp connection)

Mains fuse: 2 x T6.3 A / 250 V,

high breaking capacity

Compact Flash card

Storage medium for test data.

Eject button

Press to eject the Compact Flash

card.

Figure 1-2 Mains connection unit and grounding terminal

Introduction

1.2.3 Compact Flash Card Slot

Figure 1-3 Compact Flash card slot

13

CT Analyzer User Manual

RS232 interface

USB interface

(type B connector)

1.2.4 Remote Control Interface (PC Connection)

CT Analyzer devices as of serial number JHxxxx or newer are equipped with a

USB interface and a RS232 interface. You can use both interfaces alternatively

to connect the CT Analyzer to a computer.

OMICRON recommends to use the USB interface since communication via USB

is considerably faster than communication via RS232.

14

Figure 1-4 Remote control interface (RS232 and USB)

Since in this case the CT Analyzer provides two alternative interfaces, the user

has to select the interface to be used (or check the selection) in the CT Analyzer

settings before connecting the CT Analyzer. The factory default setting for those

devices is USB.

1. Open the Main Menu on the CT Analyzer and select Settings.

2. In the Setting Menu page, select Remote Interface.

3. In the Select remote interface port page, select the interface actually used

to connect the CT Analyzer to the computer: USB or RS232.

The CT Analyzer will only communicate via the selected interface. It will not be

recognized by the computer if the CT Analyzer settings do not match the

interface used for connection.

Note: Please refer to the following sections for more information:

I/0

Output

Generator output.

AC: 40V

rms

, 5A

rms

DC: 120V, 15A

Sec

Measurement input for secondary side of CT,

150V

AC

max., 500kΩ input impedance

Prim

Measurement input for primary side of CT,

30V

AC

max., 150kΩ input impedance

• Section 2.3 on page 23 for information on how to connect the CT Analyzer to

a PC.

• Chapter 5 on page 59 for general information on how to operate the

CT Analyzer.

• Section 5.7 on page 65 for more detailed information about the

Setting Menu page.

1.2.5 Inputs and Outputs

Warning: While the red LED of the key is flashing, voltage is applied at

the output and the measurement inputs.

Introduction

Figure 1-5 Inputs and outputs of the CT Analyzer

15

CT Analyzer User Manual

I/0

1.2.6 I/0 Key with Status LEDs

Red LED on the left, green LED on the right.

I/0 key to start the test.

During the boot process after switching the CT Analyzer on, both

LEDs are on. The red LED is switched off when the boot process is

finished and the CT Analyzer is ready for operation.

Green LED on: The CT Analyzer is switched on and ready for

Red LED flashing: Test is running.

Red LED steadily on: Device error.

operation.

Warning: While the red LED is flashing,

voltage is applied at the output and the

measurement inputs.

16

1.2.7 Display with Soft Keys

Card area with tab

Soft key description

fields

Soft keys, labelled by the soft

key description fields

If 3 points are visible in the lowermost soft

key description field (see dashed arrow),

this key can be used to open an additional

set of soft keys

Edit fields

(underlined by

dotted lines)

Status

line

Display field

(not underlined)

A scrollbar is displayed if the content of a

card is too long to be displayed at a time.

Use the up/down cursor keys on the

keyboard to scroll through the card.

Introduction

Figure 1-6 Display with context-dependent soft keys

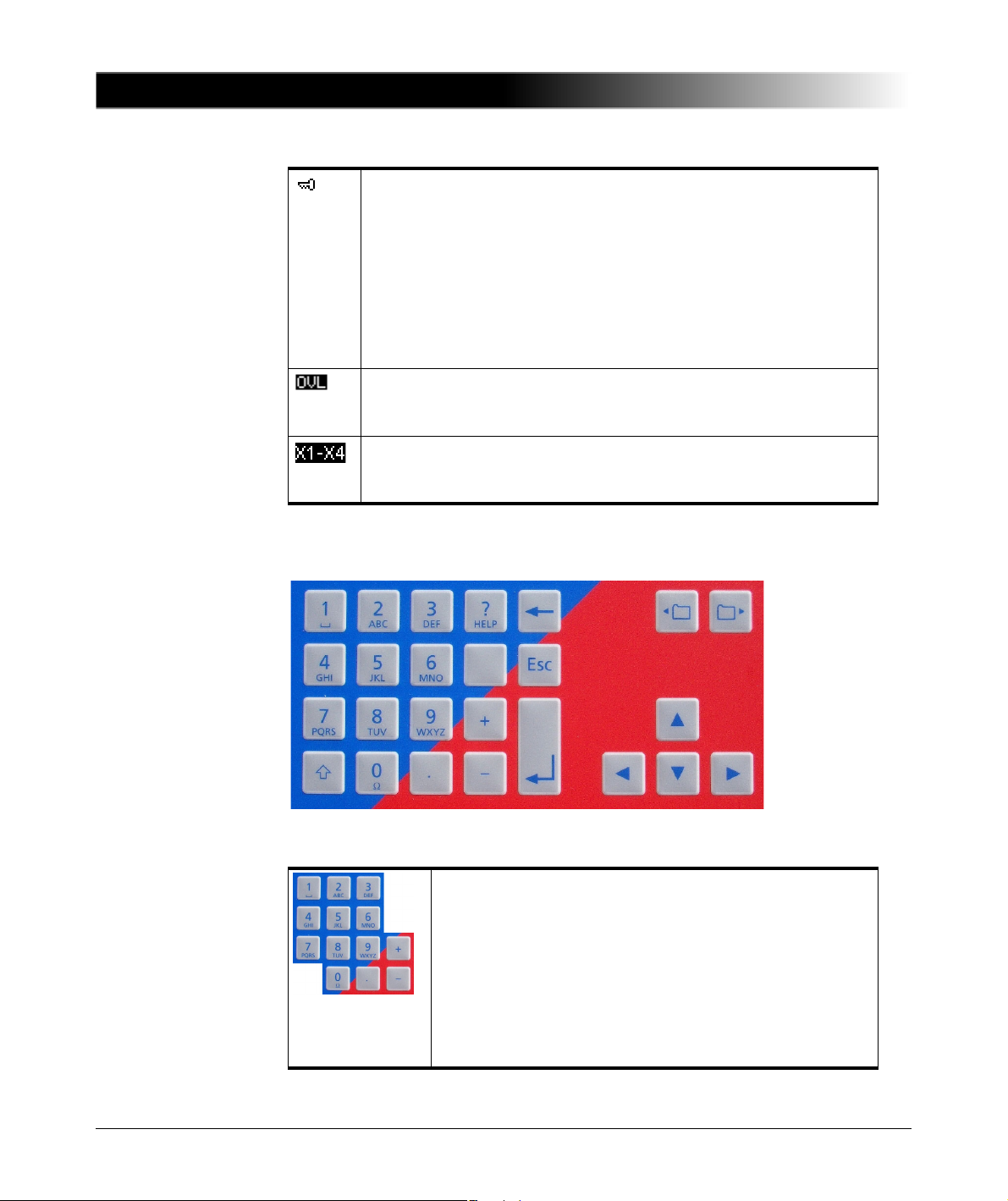

The following icons may be displayed in the status line:

Remote control. The CT Analyzer is connected to a computer and a

software tool of the CT Analyzer PC Toolset (e.g. the

CTA Remote Excel File Loader) running on that computer has

established connection to the CT Analyzer.

The keyboard on the CT Analyzer is locked until the running test is

finished.

17

CT Analyzer User Manual

1.2.8 Keyboard

Security key. The data measured with the CT Analyzer can be

stored in XML files. Stored files are protected by a security

checksum to prevent the data within these files from being edited.

If the CT Analyzer displays the data of a previously stored test, and

the data in this file are valid, a key is shown in the status line. If the

file data are invalid since someone tried to edit them later, a broken

key is displayed.

Note: When loading older files containing no security checksum, no

security information is shown.

Overload indication. The CT Analyzer could not output the required

test current or take all necessary measurement points due to an

overload.

Multi-ratio CT measurement. Indicates that a multi-ratio CT test

using the optional CT SB2 switch box has been initialized on the

CT Analyzer (here: full tap combination X1-X4).

18

Figure 1-7 Keyboard

Numeric / character keys for entering values and text.

After pressing a key, the status line displays the character

set available for the key. Press the key as often as

required to scroll through the displayed character set. After

1 second or after pressing another key, the character

selected in the status line is entered into the edit field in

the display.

Note: To quickly change between letters and numerics,

hold the button pressed for a second.

Introduction

HELP

?

ESC

Press this key to enter capital letters.

Press this key to display the context-sensitive help system

(see section 5.9 on page 76).

Press this key to delete the character left of the cursor

position.

Press this key to leave an edit field without applying a

change or to leave the edit mode of a card or to go one

level back in the user interface level.

The CT-Object card is the top user interface level.

Pressing this key several times will always bring you back

to the CT-Object card.

Press this key to apply a change for an edit field.

When working in the CT Analyzer file system, use this key

to open a selected folder or to confirm to move back to the

next higher level in the file structure.

Use the card selector keys to display a specific card.

Use the cursor keys to select an edit field in the user

interface or to move the cursor within an edit field.

Use the cursor key to enter the edit mode of a

displayed card.

1.3 License-Depending Functional Scope

The functional scope provided by the CT Analyzer depends on the licenses

actually available on the device.

This User Manual describes the full functional scope provided when the

complete set of licenses is available on the CT Analyzer. A lack of licenses may

primarily result in functional restrictions regarding the selectable standards,

classes, core types and frequencies as well as the availability of individual

measurement functions and/or test cards.

For up-to-date information about the licenses and packages available for the

CT Analyzer please refer to the OMICRON website.

19

CT Analyzer User Manual

1.4 Scope of Delivery, Accessories, Available Licenses

For up-to-date information about the scope of delivery and available accessories

and licenses for the CT Analyzer please refer to the OMICRON website or the

OMICRON office nearest you.

20

Setup and Connection

2 Setup and Connection

2.1 General Safety Rules for Connecting and Operating the CT Analyzer

Observe the following general safety rules when connecting and operating the

CT Analyzer. The safety rules given here are supplemented by further notes and

warnings applicable for specific actions only. Such specific notes and warnings

are given where necessary in this user manual.

• Before putting the CT Analyzer into operation, check the test set for visible

damages.

• When taking the CT Analyzer into operation, make sure that the air slots, the

power switch and the power supply plug at the test set are not obstructed.

• Only use wires with 4mm safety "banana" connectors and plastic housing for

connection to the front panel input/output sockets.

• During the test always connect one terminal of the transformer’s primary side

to protective earth.

Warning: Make sure that the terminals of the test object to be connected to the

CT Analyzer do not carry any voltage potential. During a test, the CT Analyzer

is the only permitted power source for the test object.

Warning: Do not touch the equipment under test or the measurement leads

while the red LED on the CT Analyzer is flashing. Never connect or disconnect

measurement leads while the red LED on the CT Analyzer is flashing.

As long as the red LED is flashing, the output is active and lethal voltages can

occur due to the high energy stored in external inductors.

Warning: Always make sure that the CT Analyzer output is connected to the

correct side of the current transformer according to the wiring instructions given

in sections 2.4 to 2.5 below. Accidentally mixing up the windings can cause lifethreatening voltages within the transformer and/or destroy the connected CT

or the CT Analyzer!

21

CT Analyzer User Manual

Warning: Feeding test voltage to a tap of a multi-ratio CT can cause life-

threatening voltages on other taps with higher ratios. Do not touch these taps!

Using the optional CT SB2 switch box can make the testing of multi-ratio CTs

much safer. If necessary, the CT Analyzer then reduces the test voltage in a

way that the maximum possible voltage within the measurement setup (i.e., the

voltage occurring at the tap combination with the highest ratio) is limited to

200V.

2.2 Setting Up the CT Analyzer

Proceed as follows to set up the CT Analyzer:

1. Make sure to position the CT Analyzer on dry, solid ground.

2. Connect the grounding terminal on the CT Analyzer’s side panel (see section

1.2 on page 12) to protective ground (PE). Use the original cable supplied by

OMICRON or alternatively a solid connection of at least 6mm

point as close as possible to the test object.

3. Connect the CT Analyzer to mains using the supplied power cord. Supply the

CT Analyzer only from a power outlet that is equipped with protective ground

(PE). An error message (901) appears if the PE connection is defective or if

the power supply has no galvanic connection to ground.

2

. Use a ground

22

Warning: The error message 901 is a safety relevant message! This

message may appear if protective ground or equipotential ground is not

connected properly or if the power supply does not have galvanic

connection to ground, which can be the case in very special grid

applications or if the CT Analyzer is supplied by a generator or an isolating

transformer. For safe operation always make sure that protective ground

and equipotential ground are connected properly.

4. Connect the equipment under test according to the instructions given in this

manual. Refer to sections 2.4 and 2.5 for detailed descriptions how to

connect the CT Analyzer for a specific measurement and/or application.

Setup and Connection

to PC

USB A/B

CT Analyzer settings:

Main Menu -> Settings ->

Remote Interface -> USB

CT Analyzer settings:

Main Menu -> Settings ->

Remote Interface -> RS232

to PC

RS232

(crossover)

RS232/USB

adapter

CT Analyzer settings:

Main Menu -> Settings ->

Remote Interface -> RS232

to PC

RS232

(crossover)

2.3 Connecting the CT Analyzer to a PC (optional)

CT Analyzer devices as of serial number JHxxxx or newer are equipped with a

USB interface and a RS232 interface. You can use both interfaces alternatively

to connect the CT Analyzer to a computer.

Proceed as follows to connect the CT Analyzer to a PC:

1. Select the interface to be used (or check the selection) in the CT Analyzer

settings:

– Open the Main Menu on the CT Analyzer and select Settings.

– In the Setting Menu page, select Remote Interface.

– In the Select remote interface port page, select the interface actually

used to connect the CT Analyzer to the computer: USB or RS232.

2. Connect the CT Analyzer to the PC using a RS232 cable or a USB cable as

shown in the following figure.

CT Analyzer connected via USB

CT Analyzer connected via RS232 interface and a RS232/USB adapter on

the PC side

CT Analyzer connected via RS232 interface

Figure 2-1 Connecting the CT Analyzer to a PC

23

CT Analyzer User Manual

2.4 Connection for Usual Applications

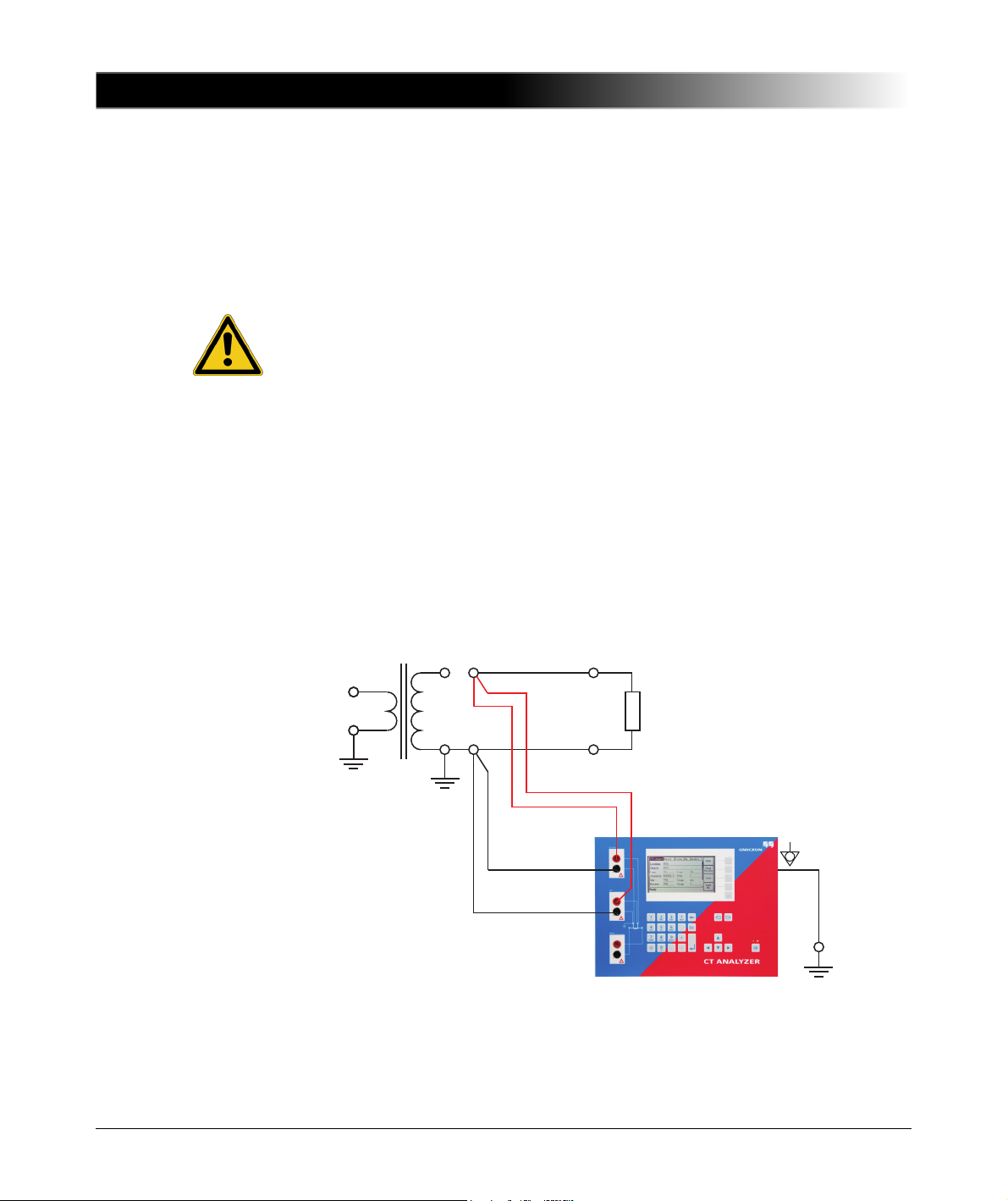

2.4.1 Wiring for a CT Test

This section shows the basic wiring of the CT Analyzer for a CT test.

Observe the general safety rules in section 2.1 on page 21 and the hints and

instructions for improving the quality of the measurement results given in section

2.7 on page 42.

Warning: Feeding test voltage to a tap of a multi-ratio CT can cause lifethreatening voltages on other taps with higher ratios. Do not touch these taps!

Caution: The grounded terminal on the secondary side of the CT always has

to be connected to the black sockets of input "Sec" and the "Output" of the

CT Analyzer. Connecting the red sockets of the CT Analyzer to PE can result

in incorrect measurement and/or cause an automatic abortion of the

measurement with an error message.

Caution: If it is necessary to use clamps for the connection of the

measurement leads to the secondary side of the test object, always use the

4-wire connection technique as described in section 2.7.1 on page 42 in order

to avoid measurement errors.

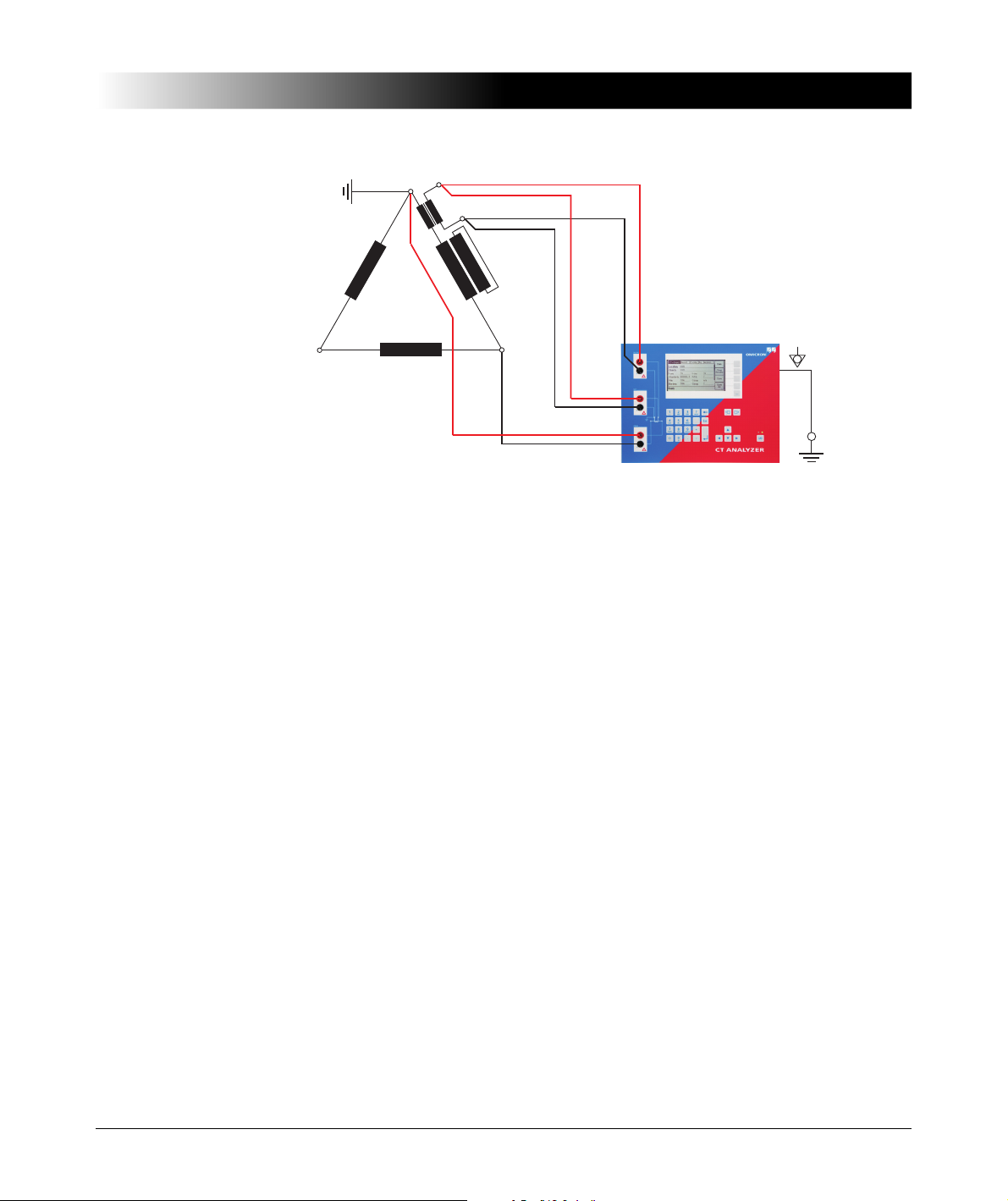

For a CT test, connect the CT Analyzer as shown in Figure 2-2:

1. Make sure that the primary side of the CT is connected to PE on one side and

open on the other side.

Caution: It is absolutely important to avoid coupling of interferences into the

primary circuit during measurement. Therefore, connect the side of the primary

circuit that is able to receive more interferences to PE (e.g. the side with the

longer line length). The ungrounded side should be the side that receives less

interferences (refer to Figure 2-2).

2. Disconnect the hot side of all secondary windings of the CT in order to

remove any load from the CT. Every kind of load remaining on the secondary

side of the CT during measurement leads to incorrect measurement results

or error messages.

3. Connect the black socket of CT Analyzer input "Prim" to the grounded side

of the CT’s primary circuit and the red socket of this input to the open

(ungrounded) side.

24

Setup and Connection

Utility line

Prevent coupling of interferences into the primary circuit (e.g. by

disconnecting the utility line, switching off the breaker, etc).

Coupling of interferences into the ungrounded connection

influences the measurement results.

The side that is able

to receive more

interferences has to

be connected to PE.

4. Connect the black "Output" socket and the black socket of input "Sec" of the

CT Analyzer to that terminal on the secondary side of the CT that is

connected to PE.

5. Connect the red "Output" socket and the red socket of input "Sec" of the

CT Analyzer to the other (ungrounded) terminal on the secondary side of the

CT.

Figure 2-2 Basic wiring for a CT test

Note: The CT may make humming or buzzing noises of varying frequency

during the CT test. This is completely normal and does not indicate a defective

CT.

25

CT Analyzer User Manual

CT Burden

2.4.2 Wiring for a Burden Test

For a burden test, connect the CT Analyzer as shown in Figure 2-3. Observe the

general safety rules in section 2.1 on page 21.

1. Open the connection line to the ungrounded side of the CT (refer to Figure

2-3).

Caution: If you do not disconnect the CT for the burden test, the

CT Analyzer measures the parallel impedance of the burden and the CT

winding instead of the burden itself. Although in many cases the impedance

of the CT is many times higher than the burden impedance, this will cause a

measuring error.

The CT Analyzer does not perform demagnetization after burden

measurement. Therefore, CT saturation could occur if you do not disconnect

the CT prior to the burden test.

2. Connect the black "Output" socket and the black socket of input "Sec" of the

CT Analyzer to that side of the burden that is connected to PE.

3. Connect the red "Output" socket and the red socket of input "Sec" of the

CT Analyzer to the other (ungrounded) side of the burden.

Figure 2-3 Basic wiring for a burden test

26

Setup and Connection

Utility line Utility line

2.4.3 Wiring for Primary Resistance Measurement

For the primary winding resistance measurement, connect the CT Analyzer as

shown in Figure 2-4. Observe the general safety rules in section 2.1 on page 21.

1. Make sure that the primary side of the CT is connected to PE on one side and

open on the other side.

2. Disconnect the hot side of all secondary windings of the CT in order to

remove any load from the CT. Every kind of load remaining on the secondary

side of the CT during measurement leads to incorrect measurement results

or error messages.

3. Connect the black socket of CT Analyzer input "Prim" to the grounded side

of the CT’s primary winding and the red socket of this input to the open

(ungrounded) side.

4. Connect the black "Output" socket of the CT Analyzer to the grounded side

of the CT’s primary winding and the red "Output" socket to the ungrounded

side of the primary winding.

Figure 2-4 Basic wiring for primary winding resistance measurement

27

CT Analyzer User Manual

Air gap

Position 2

Ratio error measured: +5%

Position 1

Ratio error measured: +0.5%

Position 3

Ratio error measured: -15%

Primary wire

2.5 Connection for Special Applications

2.5.1 Measurement on a Gapped Core

For gapped cores, the position of the primary wire inside the core has a large

influence on the ratio measurement results.

Therefore, in order to obtain correct measurement results, it is very important to

arrange the primary wire during measurement to the same position inside the

core as it is during real operation. Depending on the position of the primary wire

inside the core, the measured ratio can differ by up to 20%.

The figure below shows how the ratio error can differ depending on the position

of the primary wire inside the core.

28

Figure 2-5 Ratio error depending on the position of the primary wire inside

As shown in Figure 2-5, the measured ratio error may differ considerably

depending on the position of the primary wire. Best measurement results are

obtained if the primary wire is positioned exactly in the center of the core. As an

alternative, a copper foil formed to a ring and placed to the inner side of the core

can be used as shown in Figure 2-6.

the gapped core

Setup and Connection

Copper foil

Figure 2-6 Using a copper foil formed to a ring as primary wire

Note: Exact measurement results are only possible if the primary wire is

positioned exactly in the center of the core.

The CT Analyzer does not consider leakage inductances. The leakage

inductances are neglected instead. This way, the CT Analyzer is able to reach a

measurement error of approx. 0.1% for class PR and class TPY CTs and

approx. 0.8% for class TPZ CTs.

2.5.2 Excitation Curve Measurement for an Unwound Iron Core

Using the CT Analyzer it is possible to measure the magnetic properties of an

empty, unwound iron core. For this purpose, it is necessary to apply an "auxiliary

winding" of at least 20 turns to the core.

For this purpose, OMICRON offers a special cable with 23 turns (VEHK0658)

and a special Microsoft Excel template for the required calculations.

Proceed as follows to perform the measurement (refer to Figure 2-7 and Figure

2-8). Observe the general safety rules in section 2.1 on page 21.

1. Apply the "auxiliary winding" cable to the unwound core.

2. Connect the "Output" sockets and input "Sec" of the CT Analyzer to the cable

as shown in Figure 2-7. For cores that require high currents to reach the knee

point, several cables can be cascaded to increase the number of turns, see

Figure 2-8.

3. Start the CTA Remote Excel File Loader with the special Excel template

mentioned above.

4. Enter the iron parameters to the template.

29

CT Analyzer User Manual

Iron core without winding

23 turns auxiliary

winding

Figure 2-7 Excitation curve measurement using one "auxiliary winding"

cable

Figure 2-8 Excitation curve measurement using several cascaded

"auxiliary winding" cables

2.5.3 Measurement on a GIS (SF6) Switch Gear

Proceed as follows to perform measurements on a GIS (SF6) switch gear (refer

to Figure 2-9). Observe the general safety rules in section 2.1 on page 21.

1. Disconnect all utility lines.

2. Open all circuit breakers to the bus bars.

3. Close the earthing switch.

4. Connect one secondary side terminal of the CT to protective earth.

30

Setup and Connection

Utility line

disconnected

100m max.

Gas insulated busbar

Earthing switch

Circuit breaker

3m max.

Burden

Coax measurement cables

5. Connect the secondary side of the CT to the "Output" sockets and input "Sec"

of the CT Analyzer:

• Connect that side of the CT that is connected to PE to the black sockets

of the CT Analyzer.

• Connect that side of the CT that is open to the red sockets of the

CT Analyzer.

6. Connect the primary side of the CT to CT Analyzer input "Prim". Make sure

that the polarity is correct (same colors on same polarity).

Figure 2-9 Measurement on a GIS (SF6) switch gear

31

CT Analyzer User Manual

2.5.4 Measurement on Bushing-Type CTs

Measurement on a Bushing-Type CT

Proceed as follows to perform measurements on a bushing-type CT (refer to

Figure 2-10). Observe the general safety rules in section 2.1 on page 21.

1. Disconnect all utility lines from the transformer (i.e., isolate the transformer

from the energized power system).

2. Connect all transformer terminals that are not used for measurement (in this

example H2 and H3) to protective earth (PE) in order to minimize the external

disturbances. External disturbances can influence the measurement results

because the bushings are acting as an antenna.

3. Connect terminal H0 to protective earth.

4. Connect one secondary side terminal of the CT to protective earth.

5. Connect the secondary side of the CT to the "Output" sockets and the "Sec"

sockets of the CT Analyzer:

• Connect that side of the CT that is connected to PE to the black sockets

of the CT Analyzer.

• Connect that side of the CT that is open to the red sockets of the

CT Analyzer.

6. Connect the primary side of the CT to CT Analyzer input "Prim". Make sure

that the polarity is correct (same colors on same polarity).

7. Short-circuit and ground the free winding on the measured transformer leg to

reduce the impedance of the winding that is connected in series to the

primary side of the CT. The input impedance of CT Analyzer input "Prim" is

only approx. 330k

winding of that leg is short-circuited.

8. If the transformer has a tap changer installed, the position of the tap changer

should be changed to a position where the regulation winding is completely

bridged in order to ensure that the regulation winding cannot act as a voltage

divider together with the main winding of the transformer.

Ω and can thus influence the measurement results, if no

32

Setup and Connection

H0

(Mp)

(N)

H3

(C)

(W)

H2

(B)

(V)

H1

(A)

(U)

CT

Coax measurement cables

Figure 2-10 Measurement on a bushing-type CT

Note: Primary terminal H1 must be open. Otherwise the primary side is shorted

and the CT Analyzer cannot obtain proper results.

Measurement on a Y (Wye) Winding Transformer

For measurements on current transformers in Y-connected transformer

windings it has to be assured that the main impedance of the transformer does

not influence the measurement results.

The CT Analyzer has an input impedance of approx. 330kΩ. This measurement

impedance can be low enough to influence the measurement results. In order to

prevent any influence of the CT Analyzer's input impedance to the measurement

results, the transformer winding at the same leg should be short-circuited. Shortcircuiting the windings on all legs of the transformer is even better.

Furthermore, all bushing terminals that are not connected to the CT Analyzer

should be connected to protective earth in order to prevent influence of external

disturbances (see Figure 2-11).

33

CT Analyzer User Manual

Figure 2-11 Measurement on a Y winding transformer

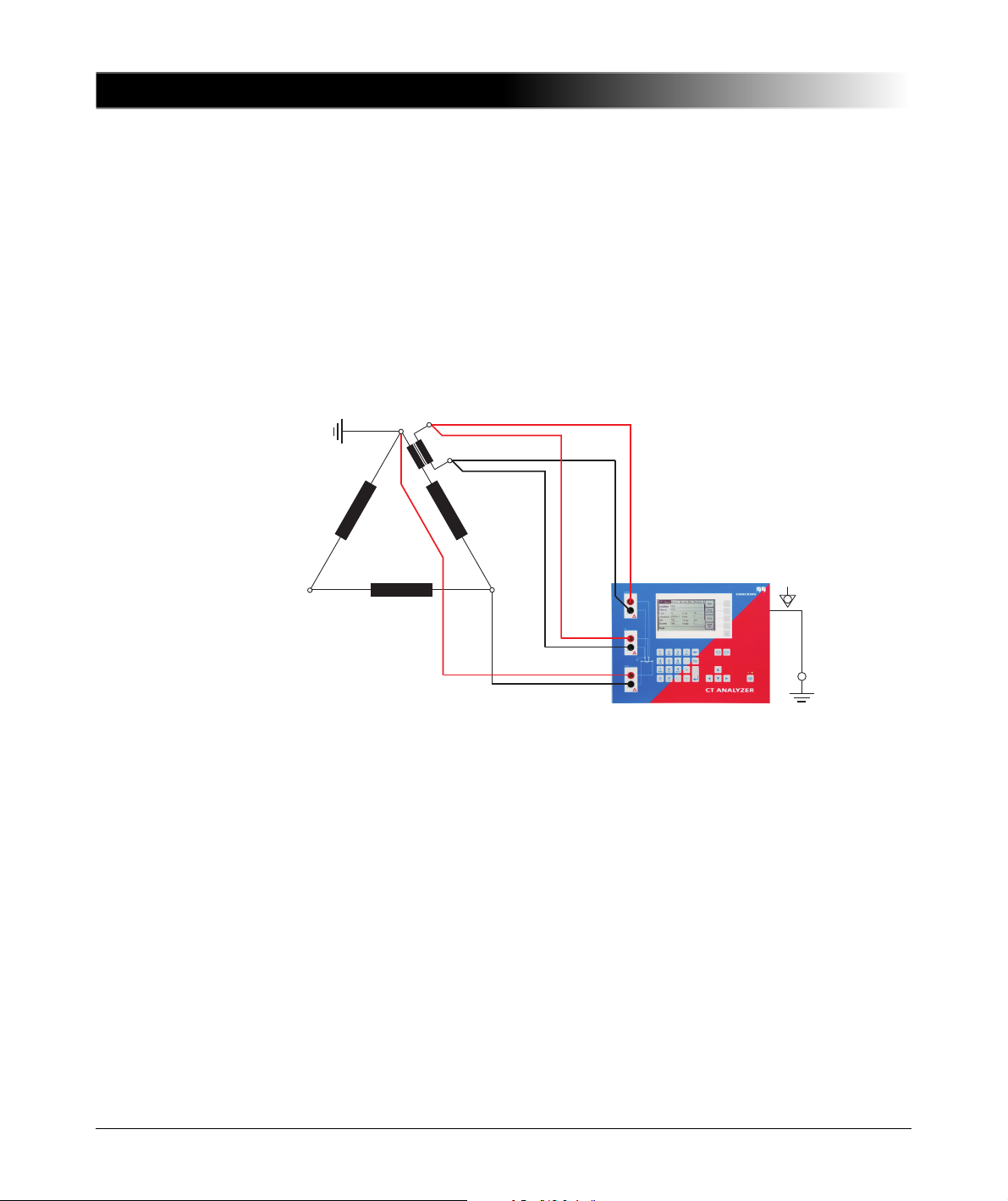

Measurement on a Δ (Delta) Winding Transformer

CTs outside the delta winding

For CTs that are located in the bushing outside of the delta winding (Figure

2-12), no delta compensation is needed.

In this case, only two parallel transformer windings are connected in series to

the CT. This connection method provides least possible influence to the

measurement result for the winding resistance of the CT.

The Y winding and the remaining windings of the power transformer's delta

winding are short-circuited to avoid influence of the induced flux of the power

transformer's core to the measurement.

34

Setup and Connection

Figure 2-12 Bushing-type CT outside the delta winding power transformer

CTs inside the delta winding

For CTs that are integrated in the delta winding of the transformer, it is not

possible to read the CT ratio directly since the delta winding acts as a voltage

divider. In order to obtain the correct CT ratio, the ratio value determined by the

CT Analyzer has to be corrected.

For this purpose, the CT Analyzer provides a "Delta Compensation" field on the

CT- Object card where you can select the delta compensation factor depending

on the bushing terminals that are used for primary signal measurement.

Figure 2-13 Setting the delta compensation on the CT-Object card

35

CT Analyzer User Manual

L2

L3

L1

If it is possible to short-circuit the transformer winding at the same leg as the

primary measurement is done (see Figure 2-15), the measurement should be

performed with the winding short-circuited. In this case, no delta compensation

is required since the voltage induced on the transformer’s secondary winding is

zero and thus the voltage induced on the primary side of the transformer is also

zero.

For the measurement setup shown in Figure 2-14, the delta compensation factor

on the CT-Object card has to be set to "Ratio 2/3" (see Figure 2-13).

If input "Prim" is connected between L1 and L2, the delta compensation has to

be set to "Ratio 1/3".

Figure 2-14 Measurement setup for delta compensation "Ratio 2/3"

In the configuration shown in Figure 2-15, no delta compensation is required

since the main winding of the power transformer is short-circuited on the other

side. This avoids the induction of flux in the main winding of the power

transformer that could influence the measurement results.

36

Setup and Connection

L2

L3

L1

Figure 2-15 Measurement setup for delta compensation "Ratio 1"

37

CT Analyzer User Manual

a

n

A

N

2.5.5 VT Ratio Measurement Using QuickTest

To measure the ratio of VTs using the CT Analyzer, you can either use the

Quick Test function of the CT Analyzer (see chapter 8 on page 135) or the

CTA QuickTest PC tool which is part of the CT Analyzer PC Toolset.

Observe the general safety rules in section 2.1 on page 21.

Warning: For VT ratio measurement using the Quick Test feature, the

CT Analyzer output has to be connected to the primary side of the VT.

Connecting the CT Analyzer output to the secondary side of the VT by mistake

will cause hazardous voltages on the primary side!

For VT ratio measurements using Quick Test, connect the CT Analyzer as

shown in Figure 2-16. For a detailed description on how to perform such

measurements, please refer to section 8.7 on page 151.

1. Connect the "Output" sockets and input "Sec" of the CT Analyzer to the

primary side of the VT.

2. Connect input "Prim" of the CT Analyzer to the secondary winding of the VT.

Figure 2-16 Connecting the VT for ratio measurement using the

CT Analyzer

38

Setup and Connection

a

n

A

N

2.5.6 VT Winding Resistance Measurement Using QuickTest

To measure the winding resistance of VTs using the CT Analyzer, you can either

use the Quick Test function of the CT Analyzer (see chapter 8 on page 135) or

the CTA QuickTest PC tool which is part of the CT Analyzer PC Toolset.

Observe the general safety rules in section 2.1 on page 21.

For VT winding resistance measurements using Quick Test, connect the

CT Analyzer as shown in Figure 2-17. For a detailed description on how to

perform such measurements, please refer to section 8.8 on page 154.

Connect the "Output" sockets and input "Sec" of the CT Analyzer to the winding

to be measured.

Figure 2-17 Connecting the VT for winding resistance measurement using

the CT Analyzer

2.5.7 Polarity Check Using QuickTest and the CPOL Polarity Checker

Observe the general safety rules in section 2.1 on page 21.

For the polarity check using Quick Test, connect the CT Analyzer as shown in

Figure 2-18. For a detailed description on how to perform the polarity check,

please refer to section 8.5 on page 145.

1. Ensure that the ungrounded side of the CT winding is not connected to the

wiring to be checked.

2. Connect the black "Output" socket and the black socket of input "Sec" of the

CT Analyzer to that side of the burden that is connected to PE.

39

CT Analyzer User Manual

CT

Burden

CPOLCPOL

3. Connect the red "Output" socket and the red socket of input "Sec" of the

CT Analyzer to the other (ungrounded) side of the burden.

Figure 2-18 Wiring for a polarity check of the burden wiring using Quick Test

and the CPOL polarity checker

Note: The CT Analyzer measures the voltage of the injected signal using input

"Sec". Therefore, you should always connect this input when using the Polarity

Check measurement type. The higher the resistance of the wiring checked (i.e.,

the burden wiring) or the current amplitude set on the CT Analyzer, the higher

the terminal voltage generated by this current!

40

2.6 Disconnection

Proceed as follows to disconnect the CT Analyzer:

1. Wait until the red LED on the CT Analyzer is off.

Warning: Never disconnect measurement leads while the red LED on the

CT Analyzer is flashing. As long as the red LED is flashing, the output is active

and lethal voltages can occur due to the high energy stored in external

inductors.

2. Disconnect the measurement leads starting at the CT Analyzer.

Setup and Connection

41

CT Analyzer User Manual

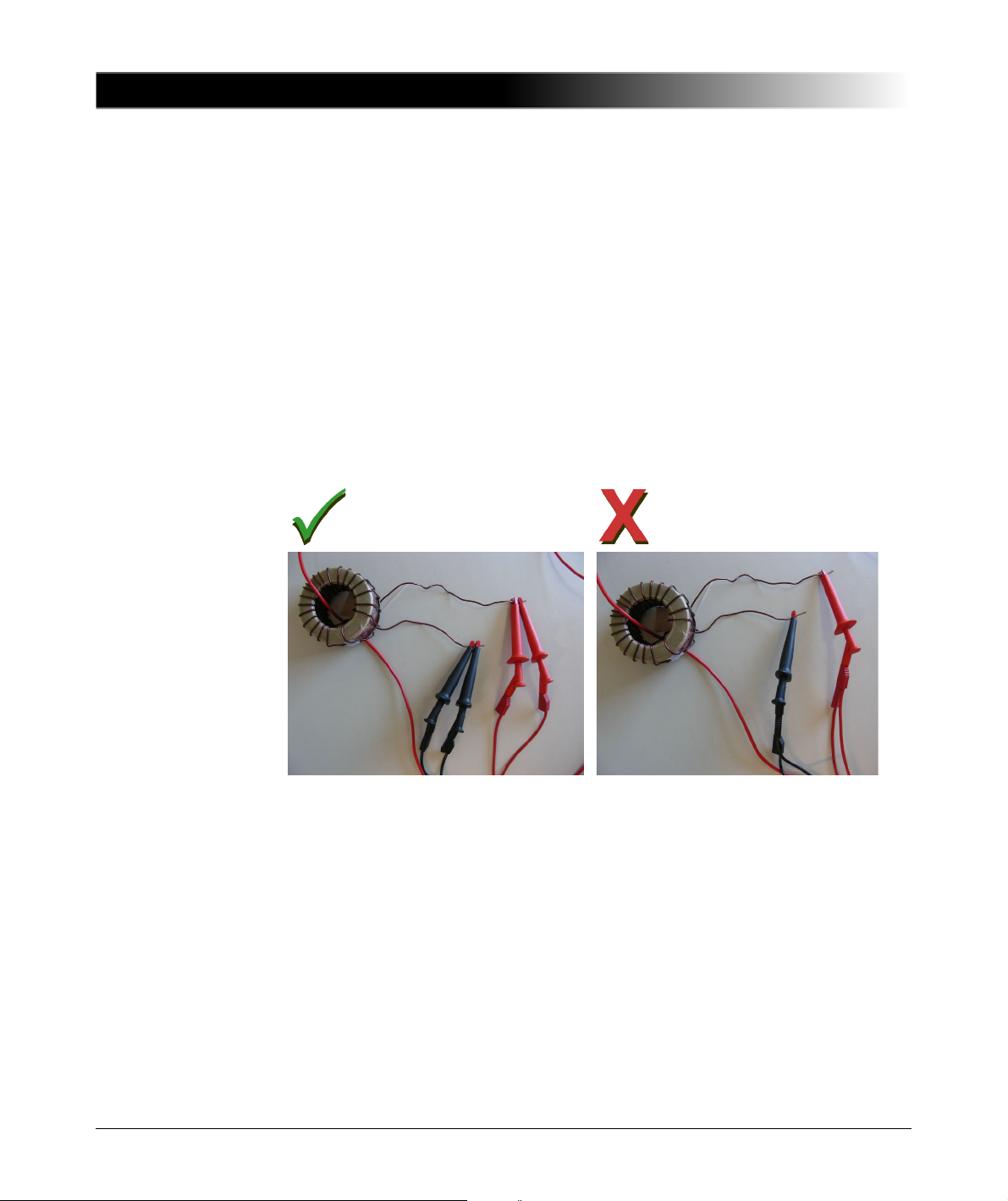

The measurement leads from the

"Output" sockets and input "Sec" of

the CT Analyzer are connected to the

test object via separate clamps.

One clamp is used for each

measurement lead! Correct!

Separate measurement leads are

used for the "Output" sockets and

input "Sec" of the CT Analyzer, but

the measurement leads are

connected to the test object via a

common clamp.

Two measurement leads use one

single clamp! Do not use!

Do not use!

OK

4-wire connection 2-wire connection

2.7 Improving the Quality of Measurement Results

2.7.1 4-Wire Measurement vs. 2-Wire Measurement

If the secondary side of the test object does not provide screw terminals for

connecting the delivered terminal adapters or banana sockets to insert the

measurement leads directly, and it is therefore necessary to use clamps (e.g.

crocodile clamps or Kelvin clamps) for the connection of the measurement

leads, always use the 4-wire connection technique as described below.

Otherwise, the possibly existing contact resistance of the clamps could

affect the measurement results, i.e., the CT Analyzer possibly delivers

incorrect measurement results.

Both connection techniques are shown in the following figure.

42

Figure 2-19 Demonstration of 2-wire and 4-wire connection technique

2.7.2 Noise Reduction Techniques

For proper test results it is important to consider the following:

• If possible, disconnect both primary terminals of the CT from the utility lines.

• If possible, always use the original coax measurement cables delivered by

OMICRON. If it is necessary to use loose single-wire measurement cables,

twist the wires to a twisted-pair line. Avoid open loops consisting of individual

single-wire measurement cables in order to prevent interference voltages

caused by magnetic fields.

• Connect one terminal of the CT’s primary side to protective earth. If it is not

possible to disconnect the utility lines from both primary terminals, connect

that side of the primary circuit that is able to receive more interferences to PE

(the primary side that is still connected to the utility lines or the side with the

longer line length, respectively). The ungrounded side should be the side that

receives less interferences.

• When testing a CT in a utility, take care that one side of the CT is connected

to PE and at least the ungrounded terminal is disconnected from all utility

lines.

Refer to Figure 2-20.

Setup and Connection

Note: Do not connect both primary terminals to PE! This would cause

incorrect measurement results. Connecting both primary terminals to PE has the

same effect as a short-circuit in the CT.

43

CT Analyzer User Manual

Utility line

Utility line

Connection required if

secondary side

terminal cannot be

disconnected

Burden

Use coax measurement cables!

Figure 2-20 Noise reduction for CT measurement

44

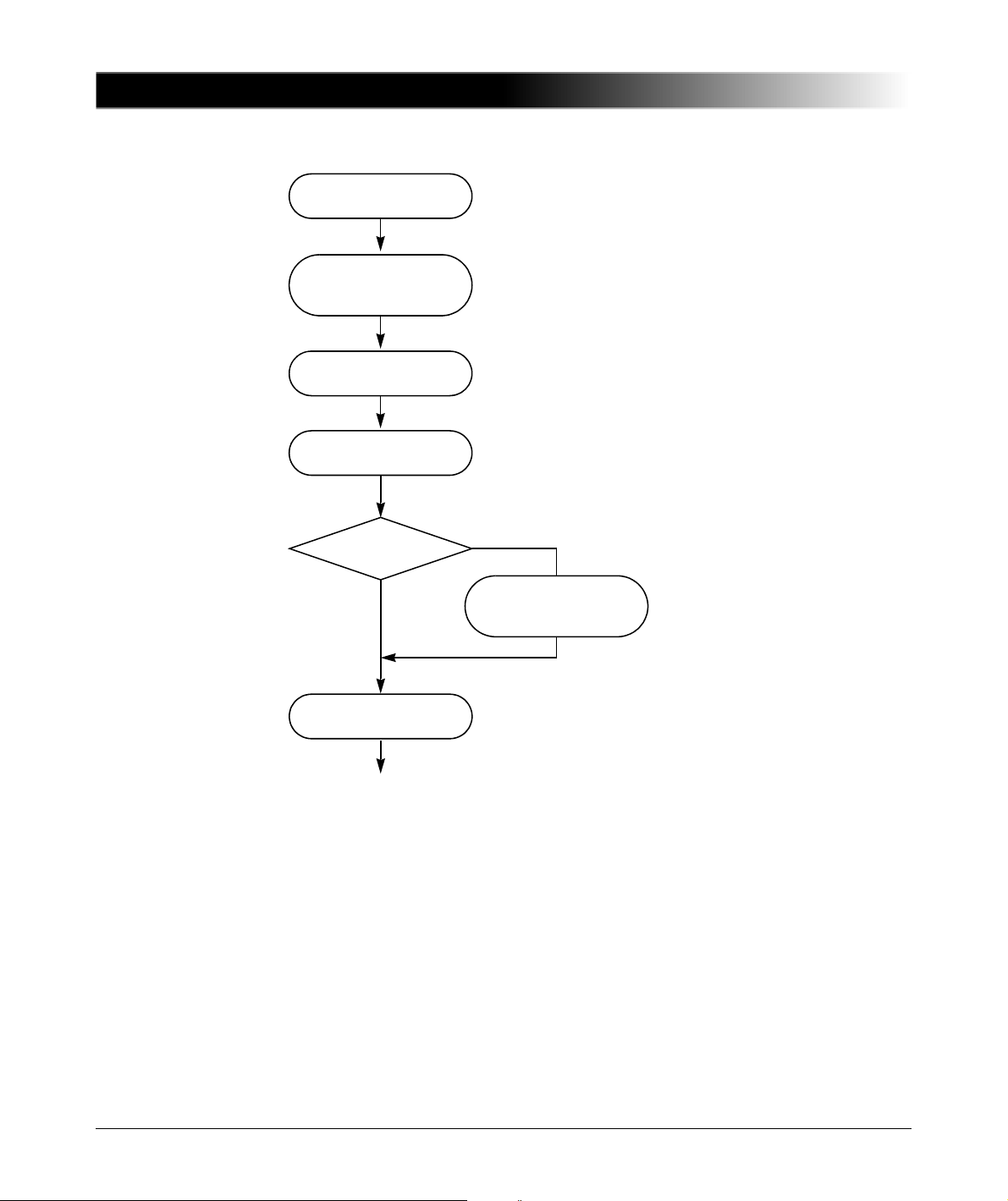

Short Guide for Running a CT Test

3 Short Guide for Running a CT Test

This chapter provides a short guide for running a CT test using the CT Analyzer.

This short guide is intended as an overview of a complete test procedure. For

more detailed information, please refer to chapter 4 on page 49.

This short guide does not consider the residual magnetism measurement (see

section 6.4 on page 102) and does not use the guesser function of the

CT Analyzer (see chapter 7 on page 131).

When working with the CT Analyzer, always observe the safety rules given in

section 2.1 on page 21.

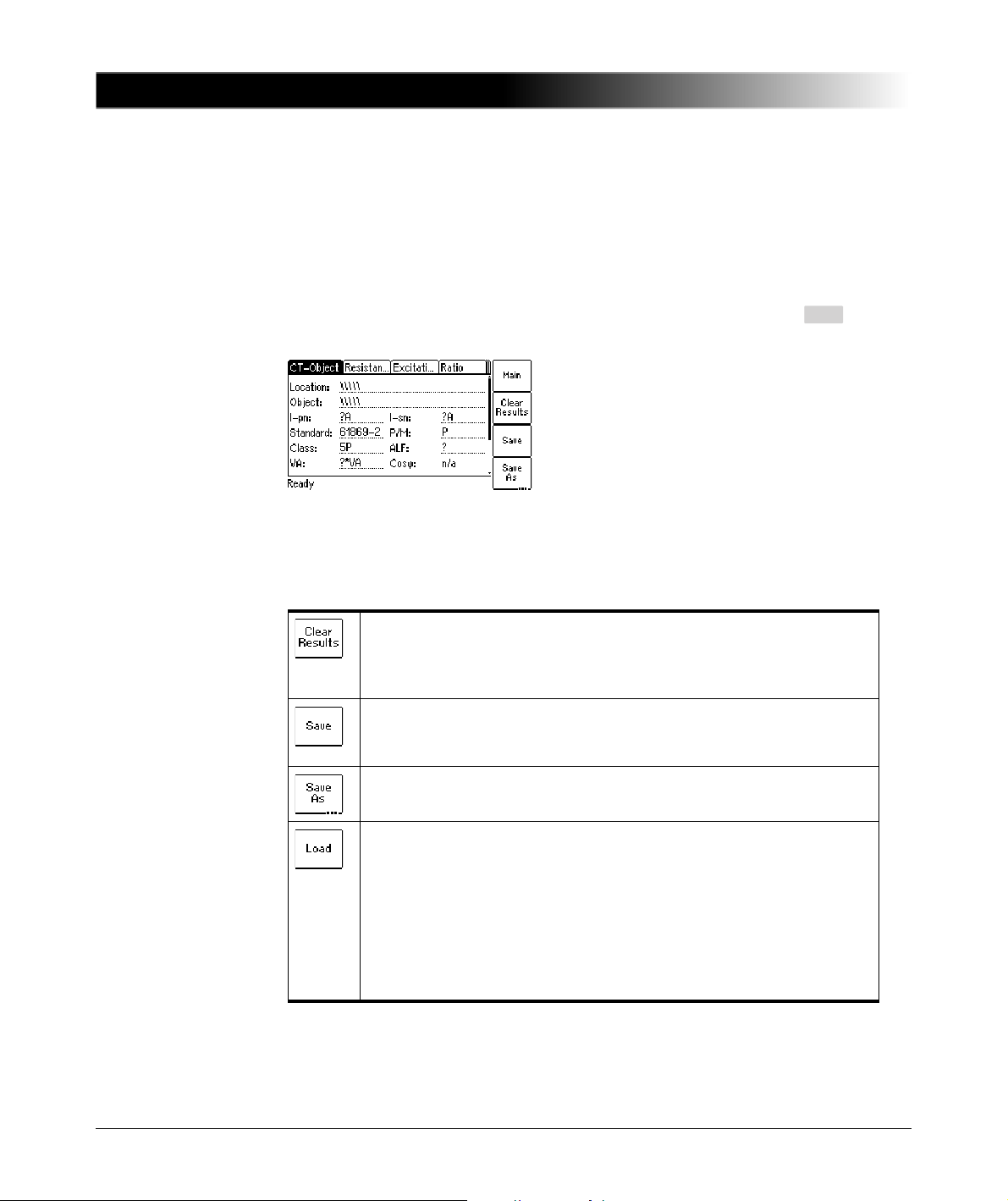

Note: The CT may make humming or buzzing noises of varying frequency

during the CT test. This is completely normal and does not indicate a defective

CT.

Warning: Do not touch the equipment under test or the measurement leads

while the red LED on the CT Analyzer is flashing. Never connect or disconnect

measurement leads while the red LED on the CT Analyzer is flashing.

As long as the red LED is flashing, the output is active and lethal voltages can

occur due to the high energy stored in external inductors.

Warning: Always make sure that the CT Analyzer output is connected to the

correct side of the current transformer according to the wiring instructions given

in sections 2.4 and 2.5. Accidentally mixing up the windings can cause lifethreatening voltages within the transformer and/or destroy the connected CT

or the CT Analyzer!

Warning: Feeding test voltage to a tap of a multi-ratio CT can cause lifethreatening voltages on other taps with higher ratios. Do not touch these taps!

45

CT Analyzer User Manual

Set up the CT Analyzer

-> 2.2 on page 22

Switch the CT Analyzer on and

display the CT-Object card

-> 4.2 on page 50

Select test cards

-> 4.2, step 2. on page 50

Enter CT name plate data

-> 4.2, step 3. on page 51

Burden test card

enabled?

Select test current for

burden test

-> 4.2, step 4. on page 52

Start test

-> 4.3, step 1. on page 52

see next page

Yes

No

46

Test execution:

Burden test

Test finished message

-> 4.3, step 11. on page 54

Disconnect or perform new test

-> 4.5 on page 57

Burden test card

enabled?

Connect CT Analyzer

for burden test

-> 2.4.2 on page 26

Start Test

soft key

Skip Test

soft key

Cancel Test

soft key

Connect CT Analyzer

for CT test

-> 2.4.1 on page 24

Prim.

Winding Resistance

measurement

enabled?

Connect CT Analyzer for

primary winding resistance

measurement

-> 2.4.3 on page 27

Start Test

soft key

Skip Test

soft key

Cancel Test

soft key

View results

-> 4.4 on page 55

Start Test

soft key

Skip Test

soft key

Cancel Test

soft key

Test execution:

CT test

from previous page

Yes

No

Yes

No

Test execution:

Prim. winding resistance

measurement

Residual Magnetism

measurement if enabled

-> 6.4 on page 102

Short Guide for Running a CT Test

47

CT Analyzer User Manual

48

Running a CT Test (Detailed)

4 Running a CT Test (Detailed)

This chapter provides a detailed description how to run a CT test using the

CT Analyzer. Follow the sections 4.1 to 4.5 in the given order.

The example CT test described below does not use the guesser function, which

is an aid for the user to find out single unknown name plate data of a CT, for

example if parts of the CT’s name plate are unreadable. For detailed information

about the guesser function, please refer to chapter 7 on page 131.

When working with the CT Analyzer, always observe the safety rules given in

section 2.1 on page 21.

Note: The CT may make humming or buzzing noises of varying frequency

during the CT test. This is completely normal and does not indicate a defective

CT.

Warning: Do not touch the equipment under test or the measurement leads

while the red LED on the CT Analyzer is flashing. Never connect or disconnect

measurement leads while the red LED on the CT Analyzer is flashing.

As long as the red LED is flashing, the output is active and lethal voltages can

occur due to the high energy stored in external inductors.

Warning: Always make sure that the CT Analyzer output is connected to the

correct side of the current transformer according to the wiring instructions given

in sections 2.4 and 2.5. Accidentally mixing up the windings can cause lifethreatening voltages within the transformer and/or destroy the connected CT

or the CT Analyzer!

Warning: Feeding test voltage to a tap of a multi-ratio CT can cause lifethreatening voltages on other taps with higher ratios. Do not touch these taps!

49

CT Analyzer User Manual

I/0

4.1 Setting Up the CT Analyzer

1. Set up the CT Analyzer as described in section 2.2 on page 22.

4.2 Preparing and Configuring the Test

1. Proceed as follows to display the CT-Object card with a new CT test.

If the CT Analyzer is already switched on:

– If necessary, display the CT-Object card and then press the Main soft key

to display the main menu.

– In the main menu, select "New CT Test" and press the OK soft key to

initialize a new CT test.

– The display shows the CT-Object card, ready to start a test.

If the CT Analyzer is switched off:

– Switch the CT Analyzer on.

– After the boot process is finished, the green LED is on and the red LED is

off.

– The display shows the CT-Object card, ready to start a test.

2. For reasons of simplicity, we do not want to perform a residual magnetism

measurement in our example CT test described here. Press the Select

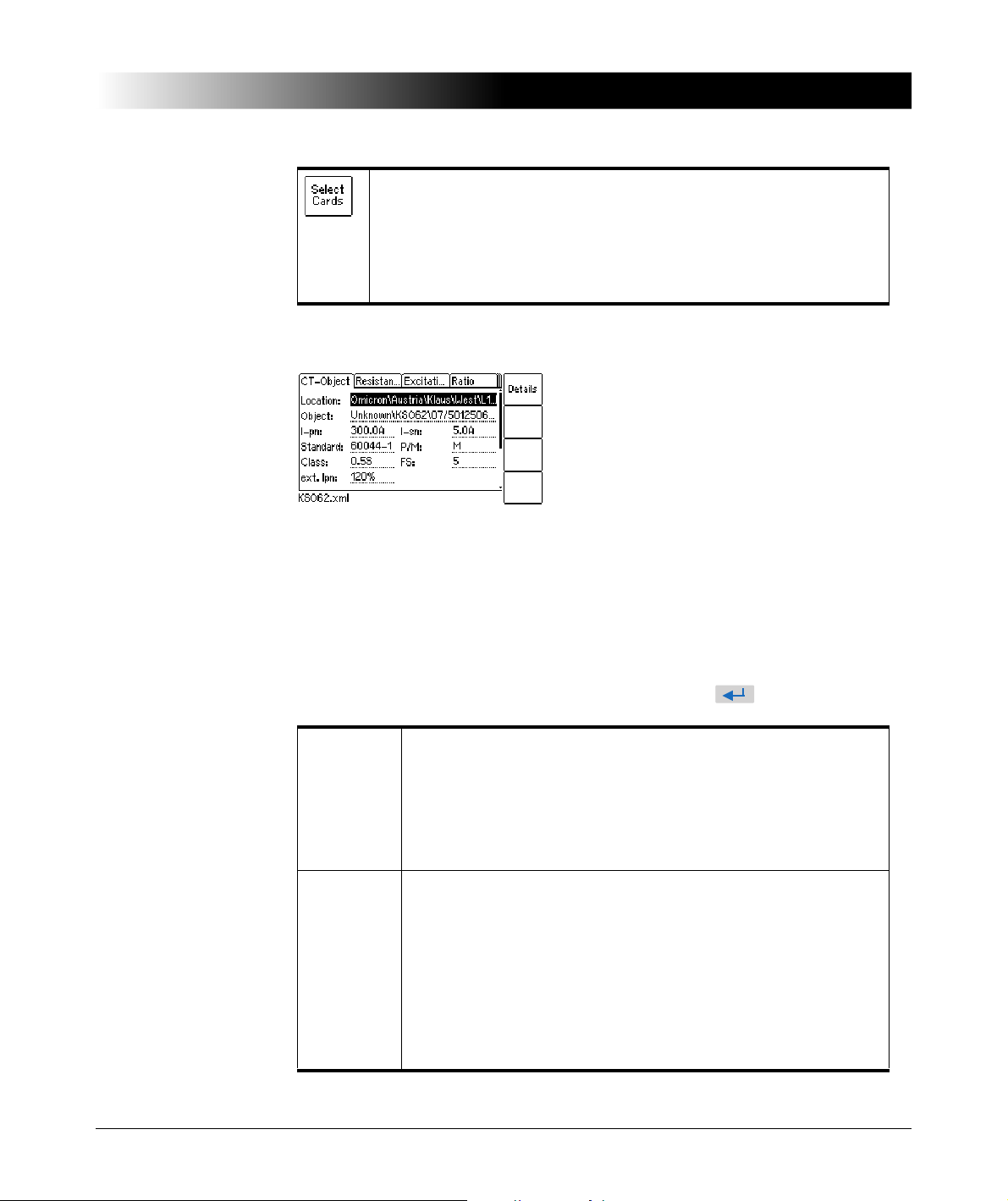

Cards soft key in the CT-Object card to open the Select Cards page. Check,

and if necessary make the following test card selection (see Figure 4-1):

The following test cards are required: CT-Object, Burden, Primary Winding

Resistance, Secondary Winding Resistance, Excitation, Ratio and

Assessment.

The Residual Magnetism test card is not required. Deselect it if necessary.

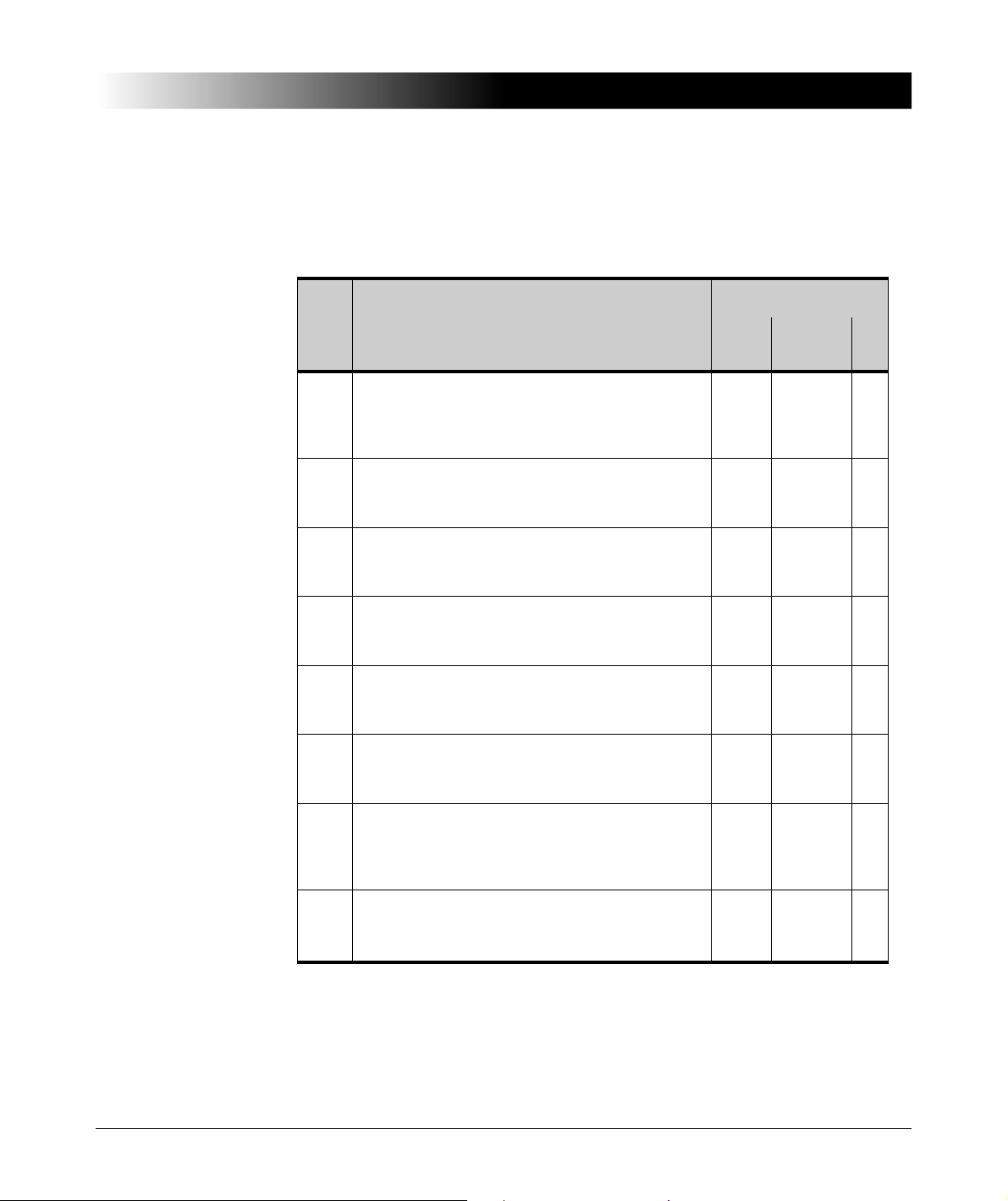

Figure 4-1 Select Cards page

When finished, press the Back soft key to return to the CT-Object card.

50

Running a CT Test (Detailed)

3. Enter the CT name plate data listed in the table below to the CT-Object card

(see Figure 4-2).

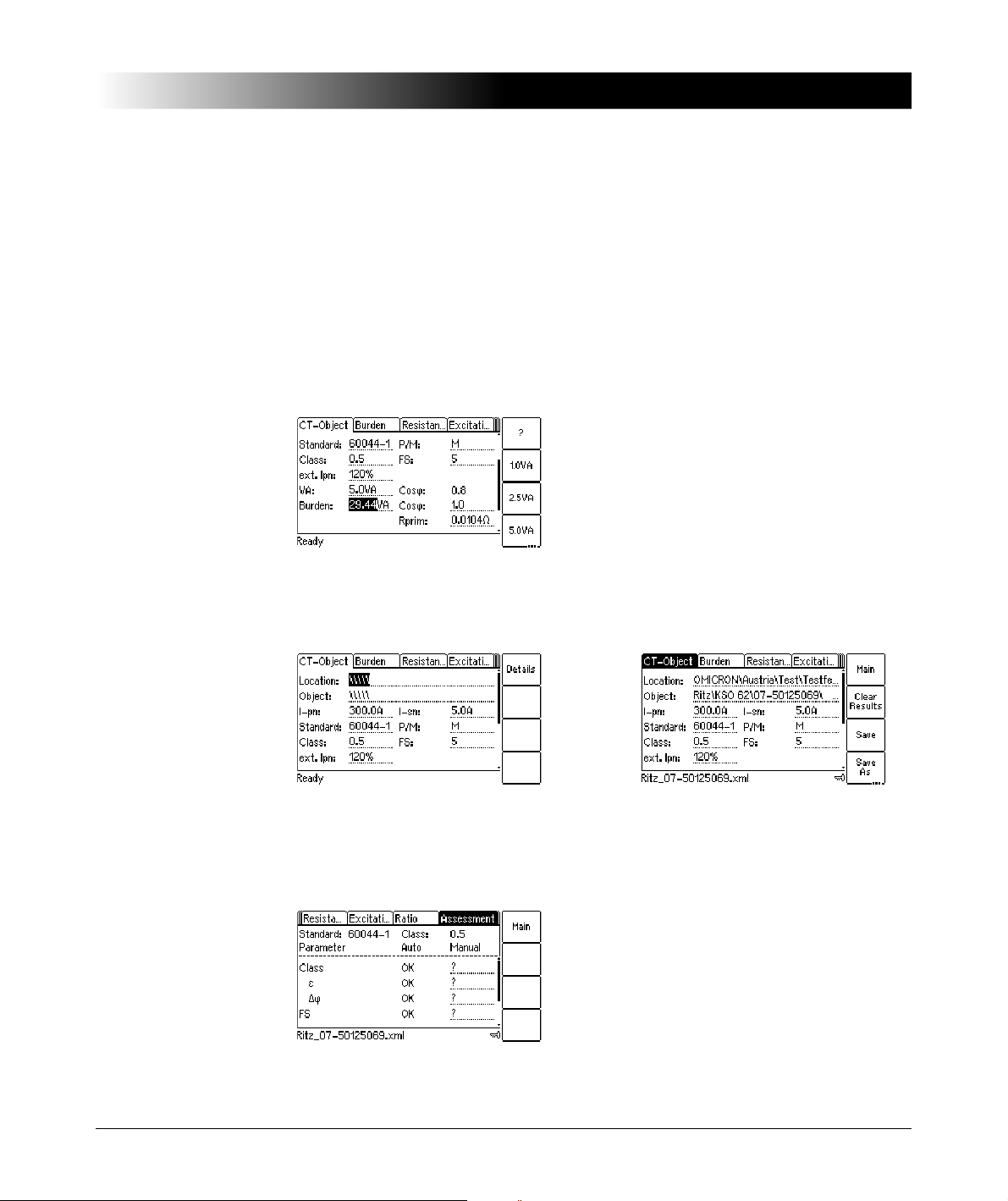

Figure 4-2 CT-Object card with name plate data entered

I-pn Rated primary current of the CT.

I-sn Rated secondary current of the CT.

Standard Standard to be used for the CT test and the test assessment.

P/M CT type. Set "P" for a protection CT or "M" for a metering CT.

Class Rated accuracy class of the CT. This field becomes available

after selecting the CT type (protection CT or metering CT).

VA Rated power of the CT.

Note: For protection CTs of the IEEE C57.13 classes C, K

and T, the VA parameter is not available. Enter the rated

secondary terminal voltage V

instead (see also "Specific

b

parameters and settings displayed for IEEE C57.13

protection CTs" on page 98).

Note: Depending on the selected standard and CT type, other or further CT

data may be necessary for a correct assessment. If the "Check "*" settings

before start" option is enabled in the default test settings (see section

5.7.3 on page 70), all parameters that are required for assessment are

marked by a star "*" in the CT-Object card. In this case, no automatic

assessment will be available if you do not enter data for one or more

parameters marked by a star "*" (see section 6.2.3 on page 82).

51

CT Analyzer User Manual

I/0

I/0

?

4. If you enabled the Burden test card in step 2., display the Burden card and

specify the test current for the burden measurement. Use the default test

current derived from the I

a test current of your choice to the "I-test" parameter.

Figure 4-3 Defining the test current in the Burden card

previously entered in the CT-Object card or enter

sn

4.3 Running the Automatic Test and Connecting the CT Analyzer

1. Start the test by pressing the key. The red LED flashes to indicate that

the CT test is running.

2. If you enabled the Burden test card in section 4.2, step 2. on page 50 a

message is displayed, asking you to change the wiring for the burden test.

Connect the burden as described in chapter 2.

– Make sure that the red LED on the CT Analyzer is off.

– Refer to section 2.4.2 on page 26 for detailed information on how to

connect the CT Analyzer for the burden test.

– You can display the connection diagram by pressing the key while

the wiring check message is displayed.

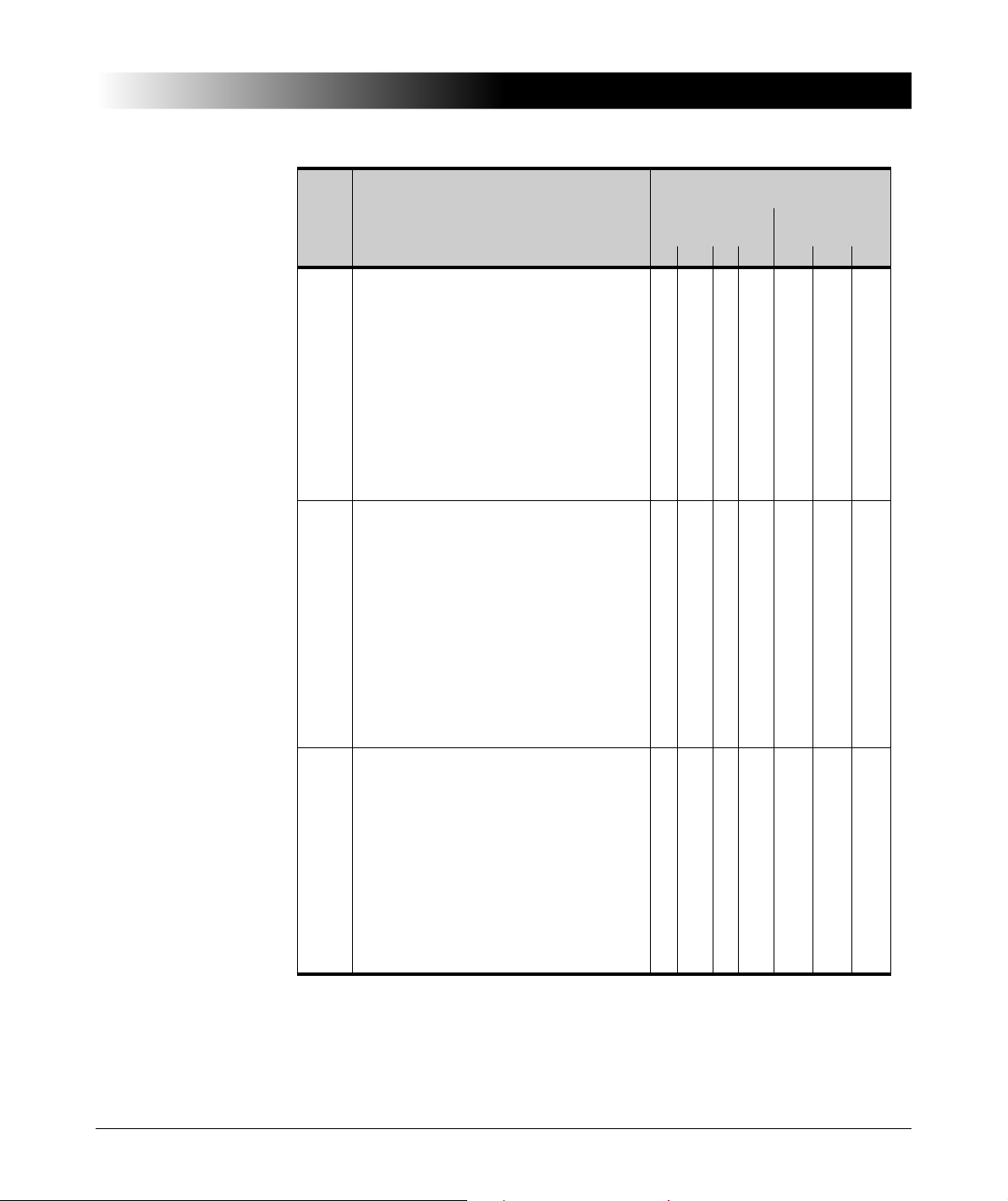

Figure 4-4 Burden test: Wiring check message (left) and wiring diagram

(right)

3. Press the Start Test soft key to execute the automatic burden test.

Note: If you do not want to perform the burden test, press Skip Test to skip

the burden test and continue with the next test step or Cancel Test to abort

the complete test.

52

Running a CT Test (Detailed)

I/0

?

?

Note: If the "Continuous burden measurement" option is enabled in the

Settings (see section 5.7.3 on page 70), the burden test has to be stopped

manually by pressing the key.

4. If you enabled the Primary Winding Resistance test card in section 4.2,

step 2. on page 50, a message is displayed, asking you to change the wiring

for the primary winding resistance measurement. Connect the primary

winding of the CT as described in chapter 2.

– Make sure that the red LED on the CT Analyzer is off.

– Refer to section 2.4.3 on page 27 for detailed information on how to

connect the CT Analyzer for the primary resistance measurement.

– You can display the connection diagram by pressing the key while

the wiring check message is displayed.

Figure 4-5 Primary winding resistance measurement: Wiring check

message (left) and wiring diagram (right)

5. Press the Start Test soft key to execute the automatic primary winding

resistance measurement.

Note: If you do not want to perform the primary winding resistance

measurement, press Skip Test to skip the primary winding resistance

measurement and continue with the CT test or Cancel Test to abort the

complete test.

6. A message is displayed asking you to change the wiring for the CT test.

Connect the CT to the CT Analyzer as described in chapter 2.

– Make sure that the red LED on the CT Analyzer is off.

– Refer to section 2.4.1 on page 24 for detailed information on how to

connect the CT Analyzer for the CT test.

– Be sure that the polarity of all wires is correct.

– You can display the connection diagram by pressing the key while

the wiring check message is displayed.

Note: If you do not want to execute the CT test, press the Skip Test soft key

instead of changing the wiring. This will skip the CT test and immediately

perform the demagnetization cycle to finish the test.

53

CT Analyzer User Manual

I/0

7. Press the Start Test soft key to execute the automatic CT test.

8. Automatic test step 1: CT resistance measurement

9. Automatic test step 2: Determination of the excitation characteristic

Figure 4-6 CT test: Wiring check message (left) and wiring diagram

(right)

Note: If you do not want to perform the CT test, press Skip Test to skip the

CT test or Cancel Test to abort the complete test.

The CT Analyzer measures the secondary winding resistance of the CT.

The CT Analyzer measures the excitation curve and determines the knee

point and other important CT data.

10.Automatic test step 3: Ratio measurement

The CT Analyzer then measures the current ratio error, the phase error, the

composite error and the polarity. The CT Analyzer calculates the ratio error

for the operating burden (parameter "Burden" in the CT-Object card) and the

nominal burden (parameter "VA" in the CT-Object card).

11."Test finished" message

When the test is over, the red LED stops flashing and the green LED is on.

The CT Analyzer displays a "Test finished" message showing the status of

the test execution and the overall test assessment (see Figure 4-7).

Press any key on the keyboard to close this message.

Figure 4-7 Test finished message when the test is over

54

Note: The test results and settings of each test finished with the "Test ok"

status are automatically stored to the file OMICRON\AutoSave\

CTAnalyzer.xml on the Compact Flash card. The existing CTAnalyzer.xml

file is overwritten with each successful test. Tests that could not be finished

successfully or that were aborted by the user are not stored and thus do not

overwrite the existing CTAnalyzer.xml file.

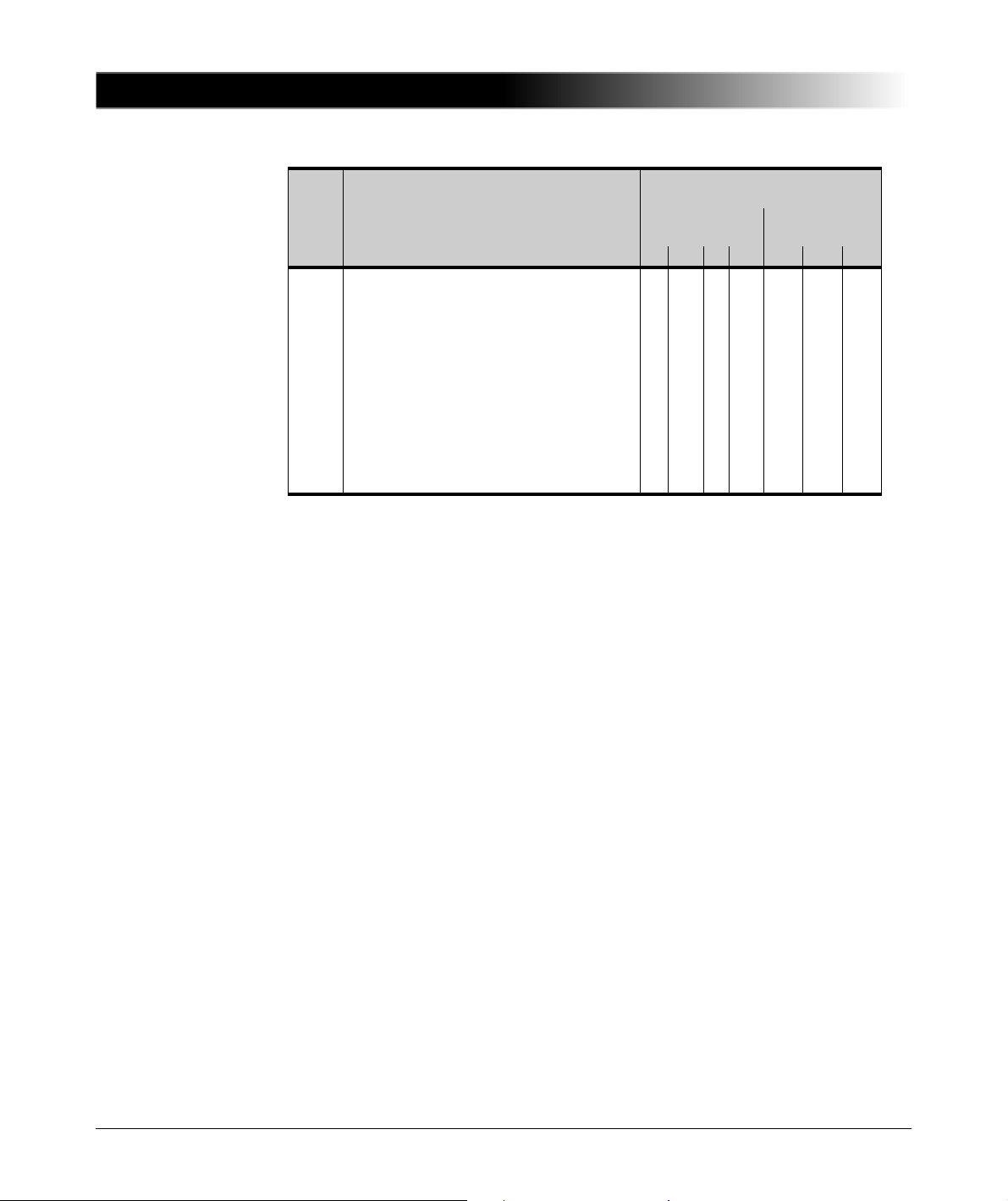

4.4 After the Test is Finished

After the test is finished, the CT-Object card displays the CT data determined

during the test (refer to Figure 4-8).

Figure 4-8 CT-Object card after the test is finished

Running a CT Test (Detailed)

Now, you can enter the "Location" and "Object" details and save the test (use

the cursor keys to scroll within the card and select edit fields).

Figure 4-9 CT-Object card after the test, ready to enter location details

(left) and after saving the test (right)

The assessment of the individual parameters can be viewed on the

Assessment card (Figure 4-10).

Figure 4-10 Assessment card after the test is finished

55

CT Analyzer User Manual

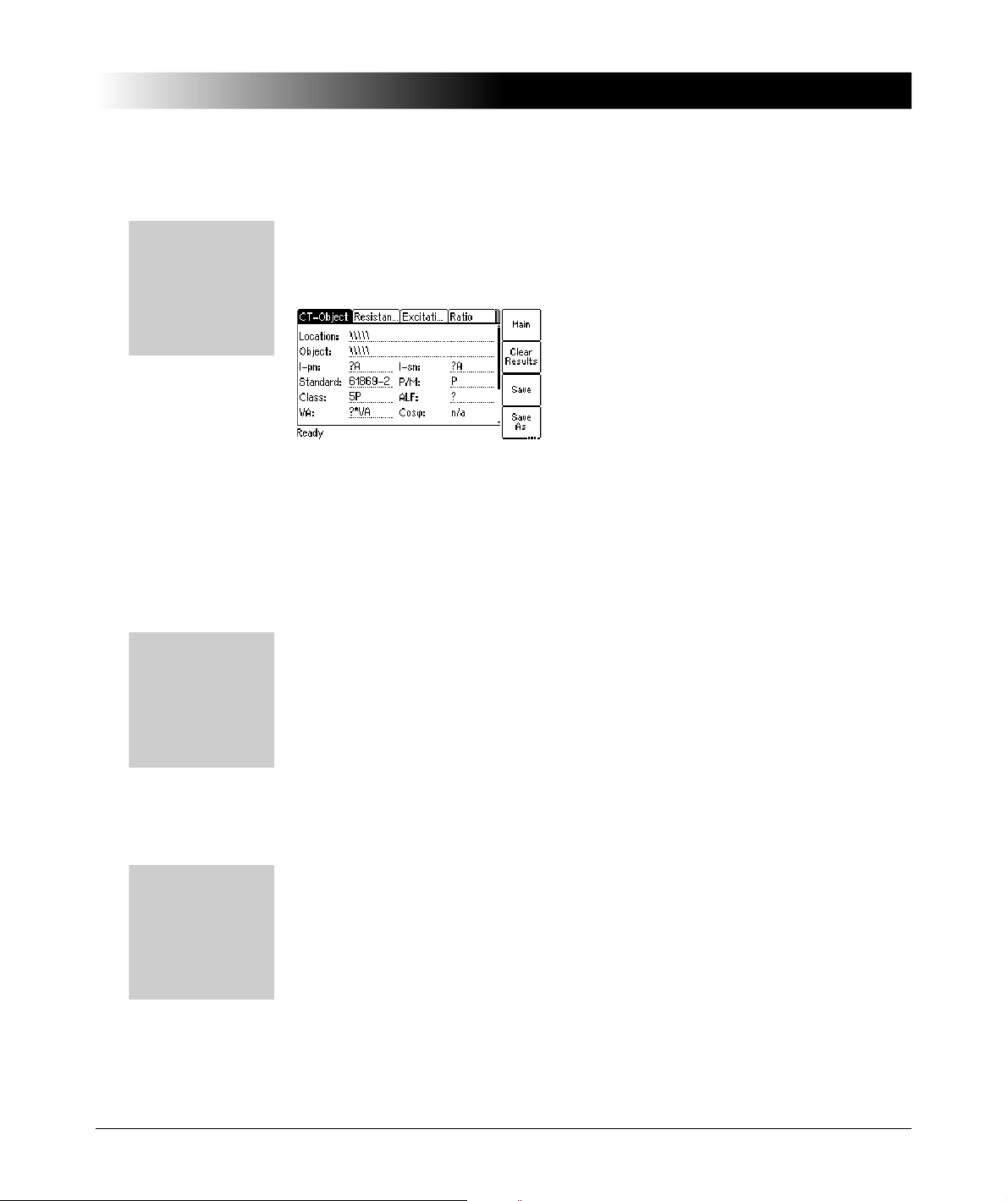

If desired, you can view the individual measurement results acquired during the

test by viewing the Burden, Resistance, Excitation and Ratio cards, as shown

in the following figures 4-11 to 4-14.