Bode 100

User Manual

Smart Measurement Solutions

®

Version: ENU1006 05 02 — Year: 2017

© OMICRON Lab, OMICRON electronics. All rights reserved.

This manual is a publication of OMICRON electronics.

All rights including translation reserved. Reproduction of any kind, e.g., photocopying, microfilming,

optical character recognition and/or storage in electronic data processing systems, requires the explicit

consent of OMICRON electronics. Reprinting, wholly or in part, is not permitted.

The product information, specifications, and technical data embodied in this manual represent the

technical status at the time of writing and are subject to change without prior notice.

Windows is a registered trademark of Microsoft Corporation. OMICRON Lab and Smart Measurement

Solutions are registered trademarks of OMICRON electronics.

2

OMICRON Lab

Contents

Contents

1 Safety instructions 5

1.1 Operator qualifications ................................................................................................................ 5

1.2 Rules for use ............................................................................................................................... 6

1.3 Designated use ........................................................................................................................... 6

1.4 Disclaimer ................................................................................................................................... 6

1.5 Cleaning ...................................................................................................................................... 6

2 Compliance statements and recycling 7

2.1 Compliance statement ................................................................................................................ 7

2.2 Information for disposal and recycling ......................................................................................... 7

3 Bode 100 and accessories 8

3.1 Delivered items ........................................................................................................................... 8

3.2 Optional accessories ................................................................................................................... 9

4 Technical data 10

4.1 Absolute maximum ratings .......................................................................................................... 10

4.2 Bode 100 specifications .............................................................................................................. 11

4.3 Power requirements .................................................................................................................... 12

4.4 System requirements .................................................................................................................. 12

4.5 Environmental requirements ....................................................................................................... 13

4.6 Mechanical data .......................................................................................................................... 13

5 Device overview 14

5.1 Connectors .................................................................................................................................. 14

5.2 Block diagram ............................................................................................................................. 16

5.3 Functional description ................................................................................................................. 17

5.4 Hardware revisions ..................................................................................................................... 17

6 Bode Analyzer Suite introduction 18

6.1 Start screen ................................................................................................................................. 18

6.2 Main window ............................................................................................................................... 19

6.2.1 Measurement configuration .......................................................................................... 21

6.2.2 Trace configuration ....................................................................................................... 23

6.2.3 Ribbon controls ............................................................................................................. 25

6.2.4 Status bar ..................................................................................................................... 27

6.3 Chart context menu ..................................................................................................................... 28

6.4 Options menu .............................................................................................................................. 29

6.5 Hardware setup ........................................................................................................................... 32

7 Measurement types and applications 34

7.1 Gain measurement introduction .................................................................................................. 35

7.2 Impedance measurement introduction ........................................................................................ 37

7.3 Vector Network Analysis ............................................................................................................ 41

7.3.1 Transmission / Reflection ............................................................................................ 41

7.3.2 Gain / Phase ................................................................................................................. 47

7.3.3 Reflection with external coupler .................................................................................... 48

7.4 Impedance analysis ................................................................................................................... 49

7.4.1 One-Port ....................................................................................................................... 49

7.4.2 Impedance Adapter ...................................................................................................... 59

7.4.3 Shunt-Thru .................................................................................................................... 64

7.4.4 Shunt-Thru with series resistance ............................................................................... 65

7.4.5 Series-Thru ................................................................................................................... 66

7.4.6 Voltage/Current ............................................................................................................. 67

OMICRON Lab

3

7.4.7 External Bridge ............................................................................................................. 68

8 Calibration 69

8.1 Internal device calibration ........................................................................................................... 69

8.2 Performing a Gain Calibration ..................................................................................................... 70

8.2.1 Calibrating a Transmission (S21) measurement .......................................................... 71

8.2.2 Calibrating a Gain/Phase measurement ....................................................................... 73

8.3 Performing an Impedance Calibration ........................................................................................ 75

8.3.1 Calibrating a Reflection or One-Port Impedance measurement ................................... 78

8.3.2 Calibrating an External Coupler or External Bridge measurement ............................... 80

8.3.3 Calibrating an Impedance Adapter measurement ........................................................ 82

8.3.4 Calibrating a Shunt-Thru or Series-Thru measurement ............................................... 84

8.3.5 Calibrating a Voltage/Current measurement ................................................................ 86

8.4 Further calibration information ................................................................................................... 87

8.4.1 Difference between Full-Range and User-Range calibration ....................................... 87

8.4.2 Enabling and disabling a calibration ............................................................................. 89

8.4.3 Re-performing a calibration .......................................................................................... 90

8.4.4 Full-Range calibration below 10 Hz .............................................................................. 90

8.4.5 Automatic deletion of calibration ................................................................................... 91

8.4.6 Saving calibration data ................................................................................................. 91

9 Bode Analyzer Suite functions 92

9.1 Exporting and saving measurement data or settings .................................................................. 92

9.1.1 Loading and saving the equipment configuration ........................................................ 92

9.1.2 Use the copy to clipboard functions to export data ....................................................... 92

9.1.3 Exporting measurement data to CSV or Excel files ...................................................... 94

9.1.4 Generating a Touchstone file ........................................................................................ 96

9.1.5 Generate a PDF report ................................................................................................. 97

9.2 Signal source settings ................................................................................................................. 98

9.3 Using the interactive chart ........................................................................................................... 101

9.3.1 Configure the diagrams ................................................................................................ 101

9.3.2 Zooming the measurement curve ................................................................................ 103

9.3.3 Optimize the axis scaling ............................................................................................. 106

9.4 Working with cursors and the cursor grid .................................................................................... 109

9.5 Using the memory traces ............................................................................................................ 111

9.6 Using the trace configuration ...................................................................................................... 114

9.7 Cursor calculations ...................................................................................................................... 116

9.7.1 Non-Invasive Stability Measurement ............................................................................ 116

9.7.2 Fres-Q Calculation ........................................................................................................ 118

9.8 Using probes ............................................................................................................................... 120

9.9 Unwrapped phase ....................................................................................................................... 123

9.10 Check for updates ....................................................................................................................... 125

10 Automation interface 126

11 Troubleshooting 127

Support 128

Index 129

4

OMICRON Lab

Safety instructions

1 Safety instructions

Before operating Bode 100 and its accessories, read the following safety instructions carefully. If you

do not understand some safety instructions, contact OMICRON Lab before proceeding. When working

with Bode 100, observe all safety instructions in this document. You are responsible for every

application that makes use of an OMICRON or OMICRON Lab product. Any miss-operation can result

in damage to property or persons. Maintenance and repair of Bode 100 and its accessories is only

permitted by qualified experts either at OMICRON Lab or at certified repair centers.

Following these instructions will help you to prevent danger, repair costs and possible down time due

to incorrect operation. Furthermore, it ensures the reliability and life-cycle of Bode 100.

Use Bode 100 in observance of all existing safety requirements from national standards for

accident prevention and environmental protection.

Reading the Bode 100 manual alone does not release you from the duty of complying with all national

and international safety regulations relevant for working with Bode 100, for example, the regulation

EN50191 "Erection and Operation of Electrical Test Equipment”.

WARNING

Bode 100 is a SELV device (SELV = Safety Extra Low Voltage according to IEC

60950).

► Do not apply hazardous voltage levels >50 VDC or >25 VAC to the inputs of

Bode 100.

► Ensure that voltage and current probes used with Bode 100 are properly grounded

in accordance with their manufacturer's guidelines.

► When working with voltage or current probes, always connect the Bode 100's

ground terminal (available for HW Rev. 2 or higher) with a solid connection of at

least 3.6 mm² cross-section and not longer than 10 m to the ground terminal in the

laboratory.

► Be aware that no indication on Bode 100 shows that the output is active. This could

be especially critical if amplifiers are connected to Bode 100.

1.1 Operator qualifications

• Testing with Bode 100 must only be carried out by qualified, skilled and authorized personnel.

• Personnel receiving training, instructions, directions, or education on Bode 100 must be under

constant supervision of an experienced operator while working with the equipment.

• Testing with Bode 100 must comply with the internal safety instructions as well as additional

relevant documents.

OMICRON Lab

5

1.2 Rules for use

• Bode 100 is exclusively intended for the application area specified in this document. The

manufacturer/distributors are not liable for damage resulting from a use other than the specified

operation. The user alone assumes all responsibility and risk.

• Use Bode 100 only when it is in a technically sound condition.

• Do not open Bode 100 or remove any of its housing components.

• Do not carry out any modifications, extensions or adaptations to Bode 100.

• Use Bode 100 in observance of all existing safety requirements from national and international

standards for accident prevention and environmental protection.

• Always keep the manual either printed or as PDF file at the site where Bode 100 is used. The

manual must be read by all people working with Bode 100. In addition to the manual and the

applicable regulations for accident prevention in the country and at the site of operation, heed the

accepted technical procedures for safe and competent work.

1.3 Designated use

Bode 100 and its accessories are especially designed for swept frequency measurements of

electronic circuits in laboratory and manufacturing environments.

Examples for typical applications are:

• Measurement of the complex transfer function of amplifiers, filters and attenuators

• S-Parameter measurement in the 50 Ohm domain

• Stability assessment of control loops

• Determination of resonance frequencies of piezo elements and quartz crystals

• Impedance measurement of inductors, capacitors and resistors

1.4 Disclaimer

The advisory procedures and information contained within this document have been compiled as a

guide to the safe and effective operation of Bode 100. It has been prepared in conjunction with

application engineers and the collective experience of the manufacturer.

The in-service conditions for the use of Bode 100 may vary between customers and end-users.

Consequently, this document is offered as a guide only. It shall be used in conjunction with the

customers own safety procedures, maintenance program, engineering judgment, and training

qualifications.

Using Bode 100 or its accessories in a manner not specified by the manufacturer may result in

damage to property or persons.

1.5

Cleaning

Use a cloth dampened with isopropanol alcohol to clean Bode 100 and its accessories.

6

OMICRON Lab

Compliance statements and recycling

2 Compliance statements and recycling

2.1 Compliance statement

Declaration of Conformity (EU)

The equipment adheres to the guidelines of the council of the European Community for meeting the

requirements of the member states regarding the electromagnetic compatibility (EMC) directive and

the RoHS directive.

FCC compliance (USA)

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which case

the user will be required to correct the interference at his own expense. Changes or modifications not

expressly approved by the party responsible for compliance could void the user's authority to operate

the equipment.

Declaration of compliance (Canada)

This Class A digital apparatus complies with Canadian ICES-003. Cet appareil numérique de la classe

A est conforme à la norme NMB-003 du Canada.

2.2 Information for disposal and recycling

Bode 100 and all of its accessories are not intended for household use. At

the end of its service life, do not dispose of the test set with household

waste!

For customers in EU countries (incl. European Economic Area)

OMICRON test sets are subject to the EU Waste Electrical and Electronic

Equipment Directive (WEEE directive). As part of our legal obligations

under this legislation, OMICRON offers to take back the test set and to

ensure that it is disposed of by an authorized recycling facility.

For customers outside the European Economic Area

Please contact the authorities in charge for the relevant environmental

regulations in your country and dispose Bode 100 and all of its

accessories only in accordance with your local legal requirements.

OMICRON Lab

7

3 Bode 100 and accessories

3.1 Delivered items

Bode 100

multi functional test set

Bode Analyzer Suite on DVD Wide-range AC power supply

including mains input plugs for

different national standards

4 pc. BNC 50 Ω cable (m-m)

Test objects

(Quartz filter and IF filter) on

PCB

BNC straight adapter (f-f)

BNC 50 Ω load (m)

The delivered items may vary a bit from the look shown above. Please refer to the packing

list received with the Bode 100 for further information

Bode 100 Quick Start Guide

USB Cable

BNC T adapter (f-f-f)

BNC short circuit (m)

Multilingual safety instructions

8

OMICRON Lab

3.2 Optional accessories

B-WIT 100 Wideband Injection Transformer

The B-WIT 100 is used to inject signals into control loops. Its main

application is in the stability analysis of switched mode power

supplies and linear voltage regulators.

B-SMC impedance adapter for surface mount components

The B-SMC extends the impedance measurement range of

Bode 100. It enables you to easily measure components for

surface mounting such as ceramic capacitors or chip resistors.

B-WIC impedance adapter for thru hole type components

The B-WIC extends the impedance measurement range of

Bode 100. It enables you to perform impedance measurements for

thru hole type components such as inductors or crystal oscillators.

Bode 100 and accessories

B-AMP 12 amplifier

12 dB amplifier to boost the output signal of Bode 100 for

applications where more than 13 dBm are needed.

B-RFID measurement adapters

The B-RFID adapters allow standard compliant measurement of

the resonance frequency and Q-factor of RFID antennas.

For more information on the above mentioned Bode 100 accessories and recommended

accessories manufactured by partner companies visit www.omicron-lab.com.

OMICRON Lab

9

4 Technical data

In this section you can find the most important technical data for the Bode 100 Revision 2.

Technical data can change without notice.

You can download a detailed technical data sheet for Bode 100 from the OMICRON Lab website

www.omicron-lab.com → Bode 100 → Technical Data

4.1

NOTICE

Exceeding the absolute maximum ratings listed below might result in a permanent damage of the

device.

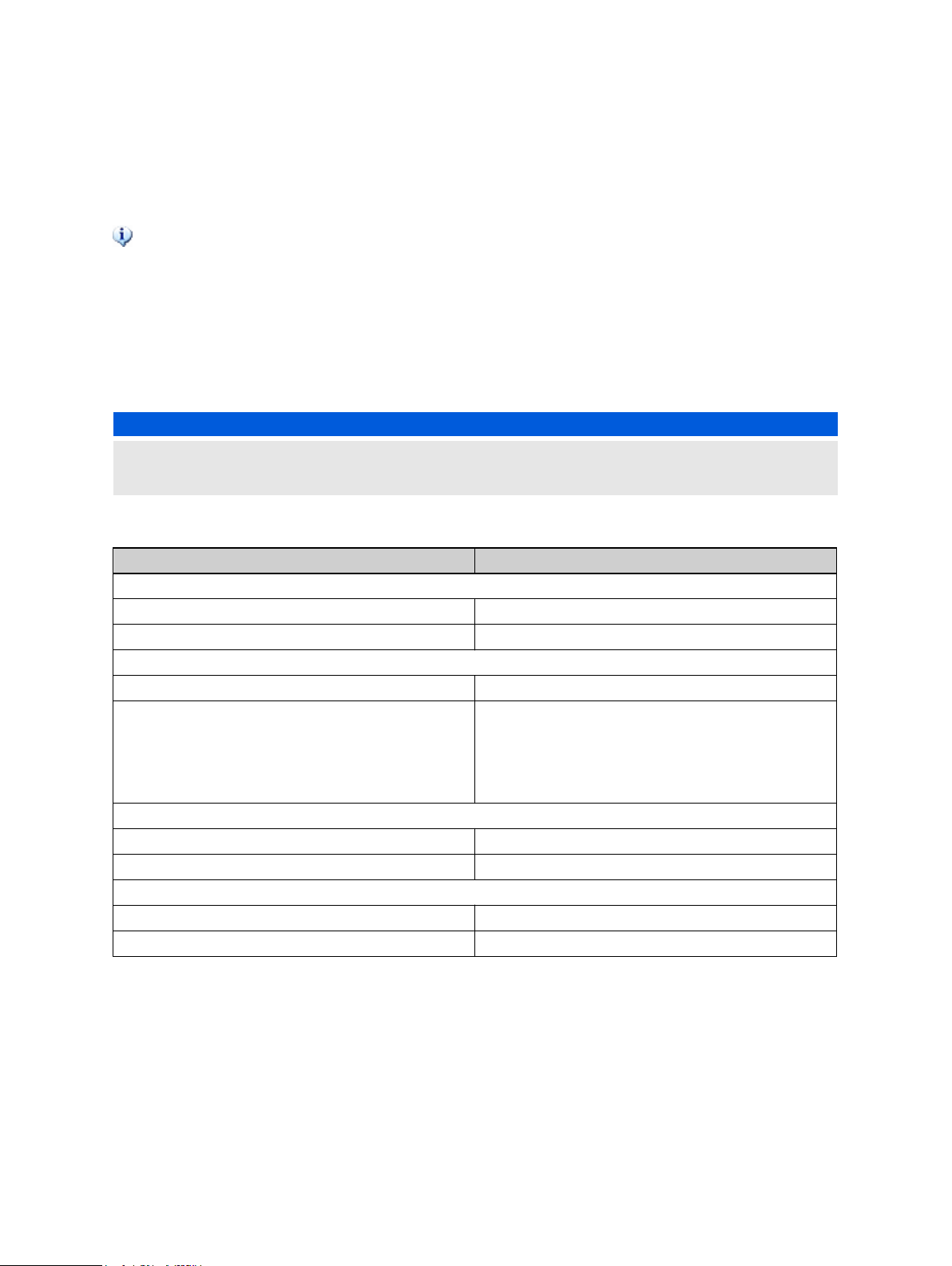

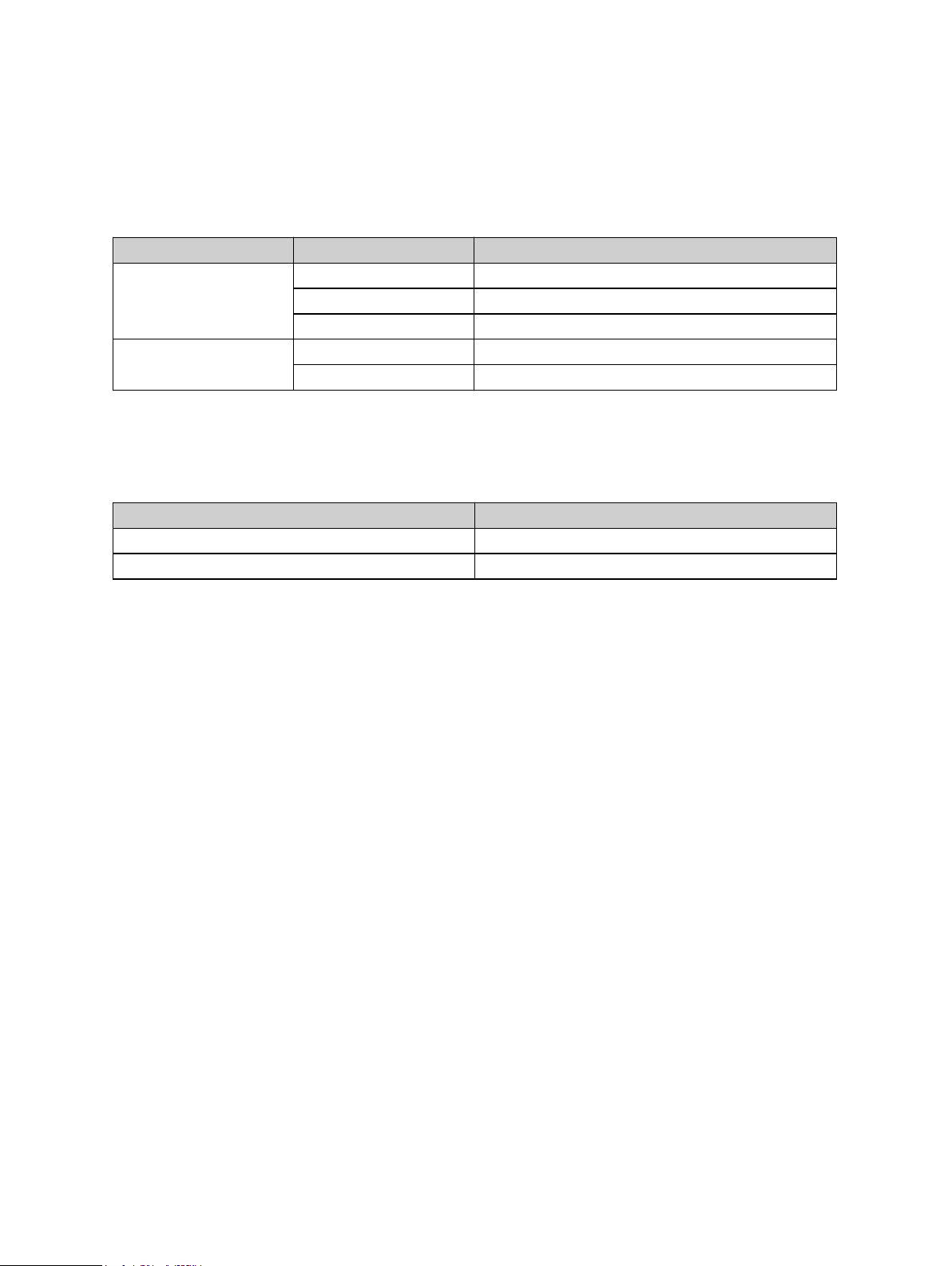

Table 4-1: Absolute maximum ratings

Characteristic Absolute Maximum Rating

DC Power Input

DC supply voltage +28 V

Max. DC supply reverse voltage -28 V

INPUT CH 1, INPUT CH 2 connectors (high Z input impedance selected )

Maximum DC input signal 50 V

Maximum AC input signal 1 Hz...10 MHz: 50 Vrms

INPUT CH 1, INPUT CH 2 connectors (50 Ω input impedance selected)

Maximum input power 1 W

Maximum input voltage 7 Vrms

OUTPUT connector

Maximum reverse power 0.5 W

Maximum reverse voltage 3.5 Vrms

Absolute maximum ratings

1 MHz...2 MHz: 30 Vrms

2 MHz...5 MHz: 15 Vrms

5 MHz...10 MHz: 10 Vrms

10 MHz ... 50 MHz: 7 Vrms

10

OMICRON Lab

Technical data

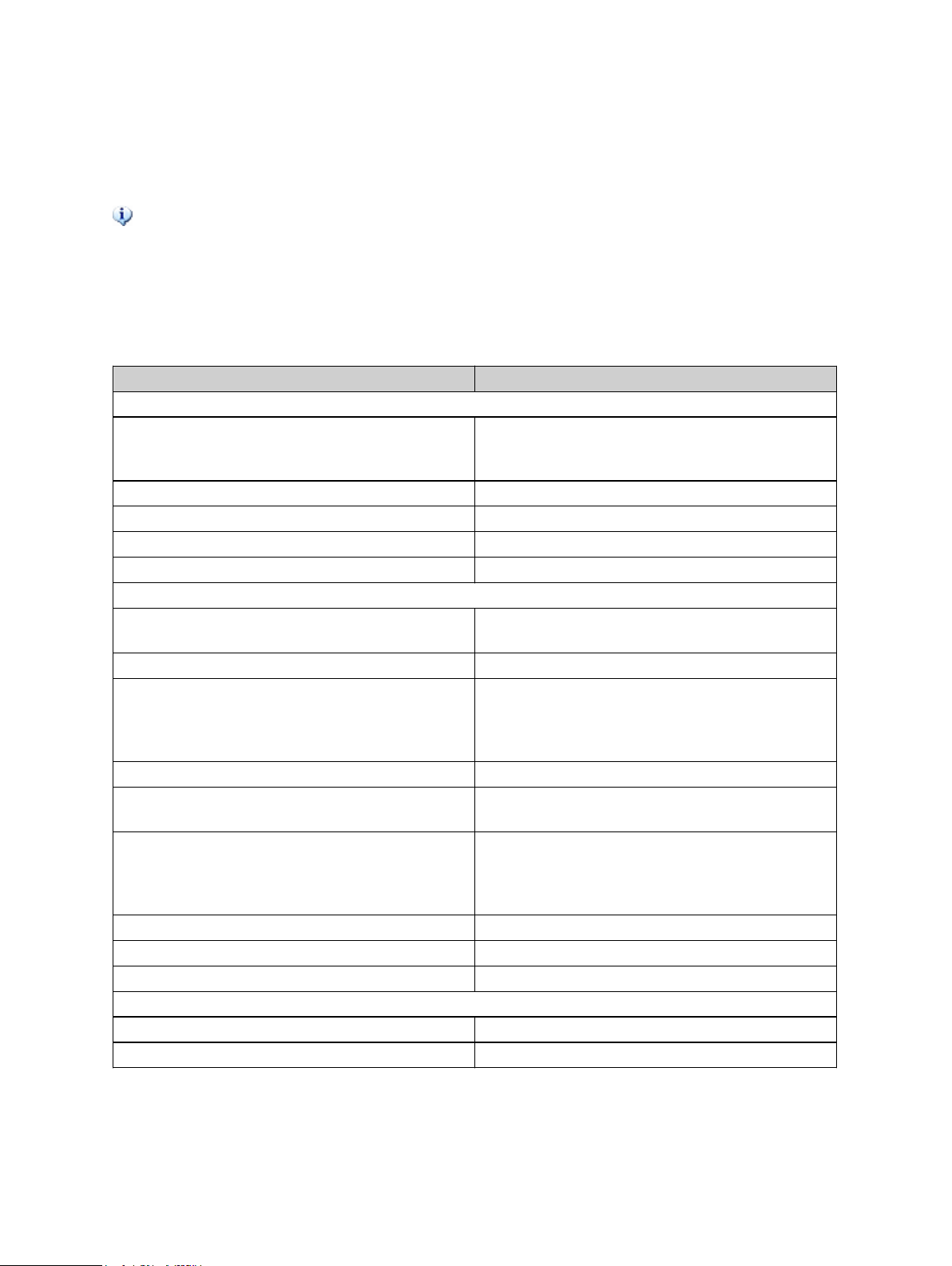

4.2 Bode 100 specifications

In this section you can find the most important technical data for the Bode 100. This

technical data is valid for Bode 100 R2 (Hardware revision 2). To find out what hardware

revision you use, please check 5.4 Hardware revisions on page 17.

Technical data can change without notice. You can download a detailed technical data sheet

from the OMICRON Lab website www.omicron-lab.com → Bode 100 → Technical Data

Table 4-2: Bode 100 specifications

Characteristic Rating

OUTPUT

Voltage range -30 dBm...13 dBm

7 mVrms...1 Vrms at 50 Ω load

14 mVrms...2 Vrms at high impedance load

Frequency range 1 Hz...50 MHz

Wave form sinusoidal

Source impedance 50 Ω

Connector BNC

INPUT CH 1, INPUT CH 2

AC measurement range 100 mVrms full scale with 0 dB input attenuation

10 Vrms full scale with 40 dB input attenuation

Frequency range 1 Hz...50 MHz

Input impedance Selectable via software:

• 50 Ω

• 1 MΩ ±2% || 40...55 pF

Connectors BNC

Input attenuators Selectable via software:

0 dB, 10 dB, 20 dB, 30 dB, 40 dB

Receiver bandwidth Selectable via software:

1 Hz, 3 Hz, 10 Hz, 30 Hz, 100 Hz, 300 Hz, 1 kHz,

3 kHz , 5 kHz*

*only Bode 100 R2

Dynamic Range > 100 dB (10 Hz receiver bandwidth)

Gain Error < 0.1 dB (calibrated)

Phase Error < 0.5 ° (calibrated)

PC interface

Universal serial bus USB 2.0 or higher

Connector USB type B socket

OMICRON Lab

11

4.3 Power requirements

Table 4-3: Power requirements

Characteristic Rating

DC input

Supply voltage range +9 ... 24 V

Minimum DC supply power 10 W

Connector Coaxial power socket

Inner Diameter: 2.5 mm

Outer Diameter: 5.5 mm

Polarity

Inner conductor: Positive voltage

Outer conductor: Ground

We strongly recommend you to use the power supply delivered with Bode 100.

4.4 System requirements

Table 4-4: System requirements

Characteristic Minimum PC Configuration

Processor Intel Core-I Dual-Core (or similar)

Memory (RAM) 2 GB, 4 GB recommended

Graphics resolution Super VGA (1024x768)

higher resolution recommended

Graphics card DirectX 11 with Direct2D support

USB interface USB 2.0

Operating System Microsoft Windows 7 SP1 or higher

12

OMICRON Lab

Technical data

4.5 Environmental requirements

Table 4-5: Environmental requirements

Characteristic Condition Rating

Temperature Storage -35 ... +60 °C / -31...+140 °F

Operating +5 ... +40 °C / -41...+104 °F

For specification 23 °C ±5 °C / 73 °F ±18 °F

Relative humidity Storage 20 ... 90 %, non-condensing

Operating 20 ... 80 %, non condensing

4.6 Mechanical data

Table 4-6: Mechanical data

Characteristic Rating

Dimensions (w x h x d) without connectors 26 cm x 5 cm x 26.5 cm / 10.25 " x 2 " x 10.5 "

Weight < 2 kg / 4.4 lbs

OMICRON Lab

13

5 Device overview

Bode 100 is a USB controlled vector network analyzer. The system consists of the Bode 100 hardware

and the Bode Analyzer Suite software. In the following the Bode 100 hardware is described in detail.

To learn more about the Bode Analyzer Suite, please check out 6.1 Start screen on page 18 ff.

5.1

NOTICE

To avoid damage of Bode 100 make sure that the absolute maximum ratings defined in chapter

4.1 Absolute maximum ratings on page 10 are not exceeded at any time.

For save operation it is strongly recommended only to use the power supply delivered with

Bode 100.

Bode 100 provides the following three connectors at the front panel:

• OUTPUT: signal output (BNC socket)

• CH 1: channel 1 signal input (BNC socket)

• CH 2: channel 2 signal input (BNC socket)

Connectors

CAUTION

To ensure save operation and to prevent injuries it is recommended to connect

Bode 100 to ground using the ground connector at the rear panel at all times.

Figure 5-1: Bode 100 front view

14

OMICRON Lab

Device overview

Bode 100 provides the following three connectors at the rear panel:

• DC power input:

input for DC voltages from 10 V to 24 V (5.0 mm power supply plug with 2.5 mm pin)

• USB: data interface (USB type B port)

• : Equipotential ground connector for external ground connection (4 mm banana-socket)

Figure 5-2: Bode 100 rear view

OMICRON Lab

15

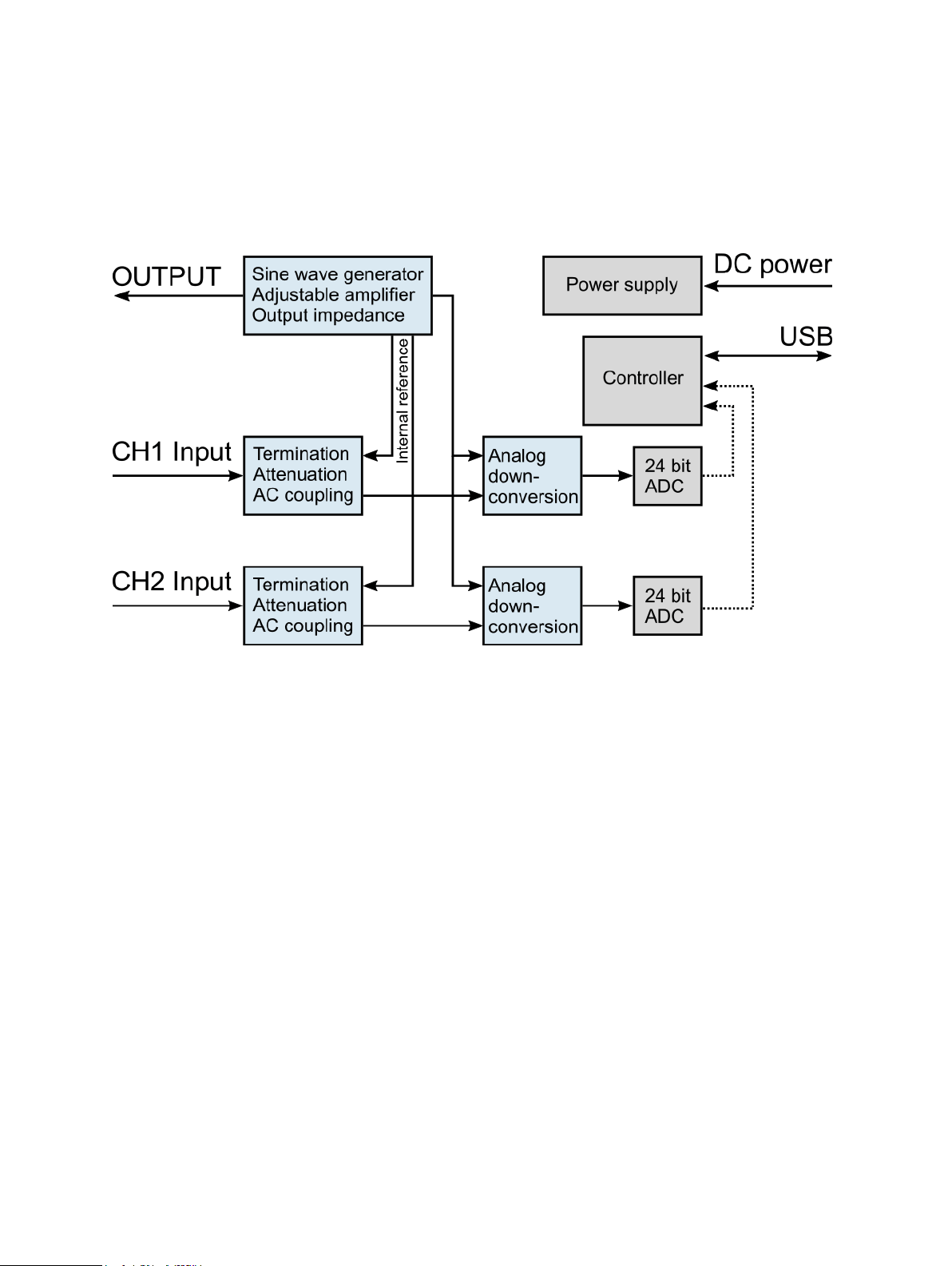

5.2 Block diagram

Bode 100 is a flexible device that features the following mayor building blocks:

Figure 5-3: Bode 100 block diagram

• Signal source:

The signal source of Bode 100 consists of an adjustable DDS sine-wave generator and adjustable

amplifiers. The output impedance of Bode 100 is 50 Ω.

Internal reference connections allow to directly connect the source signal to the receivers.

• Channel inputs:

Each of the Bode 100 input features adjustable attenuators for best signal / noise ratio and

software-switchable termination. Channel termination can be either 50 Ω or 1 MΩ. Without 50 Ω

terminations the inputs are AC coupled.

• Down conversion & sampling:

The input signal is down-converted to an intermediate frequency and sampled by a 24bit ADC.

The sampled data is sent to the PC and evaluated by the Bode Analyzer Suite.

More details on the hardware configuration can be found in 6.5 Hardware setup on page 32.

16

OMICRON Lab

Device overview

5.3 Functional description

The flexible hardware concept of Bode 100 allows to use it for several applications such as:

• Transmission / Reflection measurements

• Gain / Phase (transfer function) measurements

• Impedance measurements

The device operates in a wide frequency range from 1 Hz to 50 MHz. Bode 100 creates a sine-wave

at a frequency and measures two voltages. The creation of the sine wave and both voltage

measurements are synchronized such that magnitude and phase relation of the two measured

voltages can be derived.

From the magnitude and phase ratio of the two voltages, the Bode Analyzer Suite calculates

Impedance, Reflection, Admittance, Transmission or complex Gain values of the DUT (Device Under

Test).

For a complete list of all possible measurements that you can perform with Bode 100

see 7 Measurement types and applications on page 34.

5.4 Hardware revisions

Currently there are two mayor hardware revisions of Bode 100 available. Revision 1 and Revision 2.

To find out if you are using a Bode 100 R1 or a Bode 100 R2, check the identification plate on the

bottom of the device.

Below typical identification plates for a Bode 100 R1 and a Bode 100 R2 are shown.

Bode 100 R1 Bode 100 R2

Your identification plate might look slightly different. The important information is visible in the

Option field. If Option is Rev. 2, you are using a Bode 100 R2. If Option is empty, you are

using a Bode 100 R1.

OMICRON Lab

17

6 Bode Analyzer Suite introduction

In this section you will learn the basics of the Bode Analyzer Suite. The window structure and the main

functionality is explained.

Step-by-step examples

Hint: Get a quick introduction to the Bode Analyzer Suite and how to use Bode 100 by following the

step-by-step examples. The following examples are available in this manual:

• Perform a Transmission / Reflection measurement on the IF filter DUT,

see Transmission / Reflection measurement example on page 42.

• Perform a one-port impedance measurement on the Quartz filter DUT,

see One-Port measurement example on page 51

• Measure impedance of an inductor using the impedance adapter,

see Impedance Adapter example on page 59

6.1 Start screen

When starting the Bode Analyzer Suite, the Start screen is shown.

Figure 6-1: Bode Analyzer Suite Start screen.

18

OMICRON Lab

Bode Analyzer Suite introduction

The Start screen allows the following user interactions:

• Choose the device to use (1.). This field is only visible if you have a Bode 100 device connected to

your PC.

• Open a recent file or other file (2.). On your first start-up the demo-files are listed here. Check out

the examples that explain the content of the demo-files.

• Select one of the available measurement modes (3.) and start a measurement.

Hint: If you prefer to automatically start a measurement instead of entering the Start screen,

choose your default startup measurement mode by clicking on Set default startup and

choosing your preferred startup mode. You can also choose a .bode3 file to be your default

startup configuration.

6.2 Main window

After starting a measurement the Main window of the Bode Analyzer Suite is opened.

Figure 6-2: Bode Analyzer Suite Main window.

OMICRON Lab

19

The Main window is structured into six main regions:

1. Measurement configuration

The measurement configuration allows to configure the measurement frequencies and some

hardware setup elements such as the source level, the attenuators and the receiver bandwidth.

2. Chart region

In the chart region the measurement results are displayed. You can use the Trace settings on the

right hand side to choose the result that shall be displayed. Different formats such as Magnitude or

Phase as well as different diagrams such as Polar, Nyquist or Smith can be selected. To learn

more about the result diagrams, have a look at 9.3 Using the interactive chart on page 101.

3. Trace settings

Choose what measurement and which result format is displayed in a trace. Additional memory

traces or math traces are also controlled in this region. Lear more about how to configure traces

and memories in 9.5 Using the memory traces on page 111 and 9.6 Using the trace

configuration on page 114.

4. Ribbon bar

The ribbon bar contains the file operation commands as well as the buttons to start and stop a

measurement. Further possibilities are the hardware setup, calibration, view settings, memory

operations and cursor commands.

5. Cursor grid

The cursor grid displays the values of the movable cursors that are attached to the traces shown in

the result diagrams. To learn more about how to use the cursors, check out 9.4 Working with

cursors and the cursor grid on page 109.

6. Status bar

The status bar shows the connection state of the hardware and the receiver levels. Further

possibilities are signal source control and internal device calibration control.

20

OMICRON Lab

6.2.1 Measurement configuration

Frequency

In Frequency sweep mode you can change either Start

frequency and Stop frequency or Center and Span.

Get from zoom updates Start frequency and Stop

frequency with the current zoom window range.

Furthermore, the sweep mode can be Linear or

Logarithmic and the number of points in the sweep can

be chosen.

In Fixed Frequency mode only the Source frequency

can be adjusted. In this case the Bode 100 will display a

vector chart instead of a frequency dependent chart.

Source level

Choose between a constant or variable output level

(shaped level) and set the source level. The variable

output level feature is only available in Frequency

sweep mode. It allows to define different source levels

for different frequency points. To learn more about the

source control, refer to 9.2 Signal source settings on

page 98.

Attenuators

Set the input attenuators for Receiver 1 (Channel 1) and

Receiver 2 (Channel 2). If the measurement mode

supports two measurements (Transmission and

Reflection) you can set the attenuators for each

measurement. Possible attenuator values are 0 dB,

10 dB, 30 dB and 40 dB. Increase the attenuators when

you experience an overload, reduce the attenuators to

improve signal to noise ratio.

Receiver bandwidth

Set the maximum Receiver bandwidth used for the

measurement. Receiver bandwidth will be reduced

internally if the measurement frequency is smaller than

the Receiver bandwidth setting.

Select a high Receiver bandwidth to increase

measurement speed.

Reduce Receiver bandwidth to reduce noise and to

catch narrow-band resonances.

Bode Analyzer Suite introduction

OMICRON Lab

21

Nominal impedance

The nominal impedance or characteristic impedance

value is used to calculate the Reflection factor. See also

7.2 Impedance measurement introduction on page 37.

Note that this field is only visible if a reflection

measurement is performed.

Measurement mode

Shows what measurement mode is currently used. All

available measurement modes are explained in

7 Measurement types and applications on page 34.

22

OMICRON Lab

Bode Analyzer Suite introduction

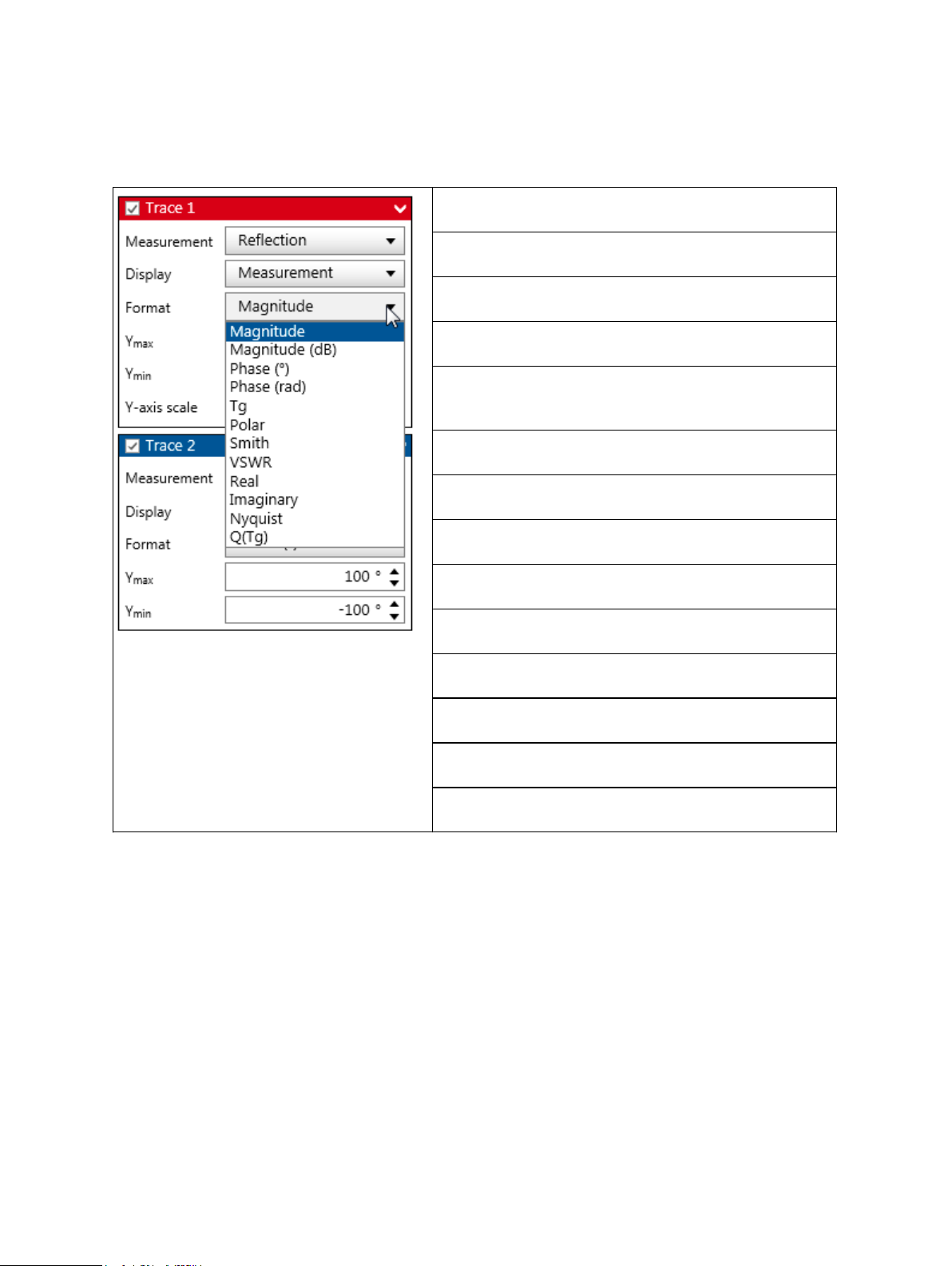

6.2.2 Trace configuration

In a Frequency Sweep measurement, the right hand side of the Bode Analyzer Suite shows the Trace

configuration. The Trace configuration allows to choose what measurement (Gain, Impedance,

Reflection, Admittance) is performed and how it is displayed in the chart.

Trace configuration box: The Trace configuration box displays the trace-name

and contains the following trace-display settings:

Measurement: Impedance, defines that Trace 1

measures impedance.

Display: Measurement, indicates that the chart shows

the measured trace.

Note that memory curves are displayed as well.

Format: Magnitude, defines that Trace 1 displays the

Magnitude of Impedance.

Ymax: 100 Ω, The upper limit of the y-axis displayed in

the diagram.

Ymin: 1 mΩ, The lower limit of the y-axis displayed in

the diagram.

Y-axis scale : Log(Y), Currently the y-axis is set to a

logarithmic scaling.

Learn more about the trace configuration box in

9.6 Using the trace configuration on page 114.

Memory configuration box: The memory configuration box allows to control the

memory curves:

Click to copy the current measurement data to

Memory 1.

Click to delete the Memory 1 trace.

Click to link the cursors to Memory 1.

Furthermore it can be selected with which trace (in

which diagram) the memory is shown.

Learn more about the memory curves in 9.5 Using the

memory traces on page 111.

Hint: By clicking the inner border of the Measurement configuration or Trace configuration

you can collapse these configuration areas to create a bigger chart area. You can fold out

the configurations anytime by clicking the respective areas at the side of the chart area. For

more details refer to the figure below.

OMICRON Lab

23

Figure 6-3: Collapsing the measurement and trace configuration areas

24

OMICRON Lab

6.2.3 Ribbon controls

The Bode Analyzer Suite ribbons feature the following commands:

Home ribbon

• New: Create a new measurement

• Open: Open a different measurement file

• Save: Save the current file

• Save as: Choose a different file name to save file

• Export: Export measurement data

• Report: Create a PDF print-report

A detailed explanation on the single file operations can be found in

9.1 Exporting and saving measurement data or settings on

page 92.

• Continuous: Starts a continuous measurement

• Single: Performs one single measurement

Bode Analyzer Suite introduction

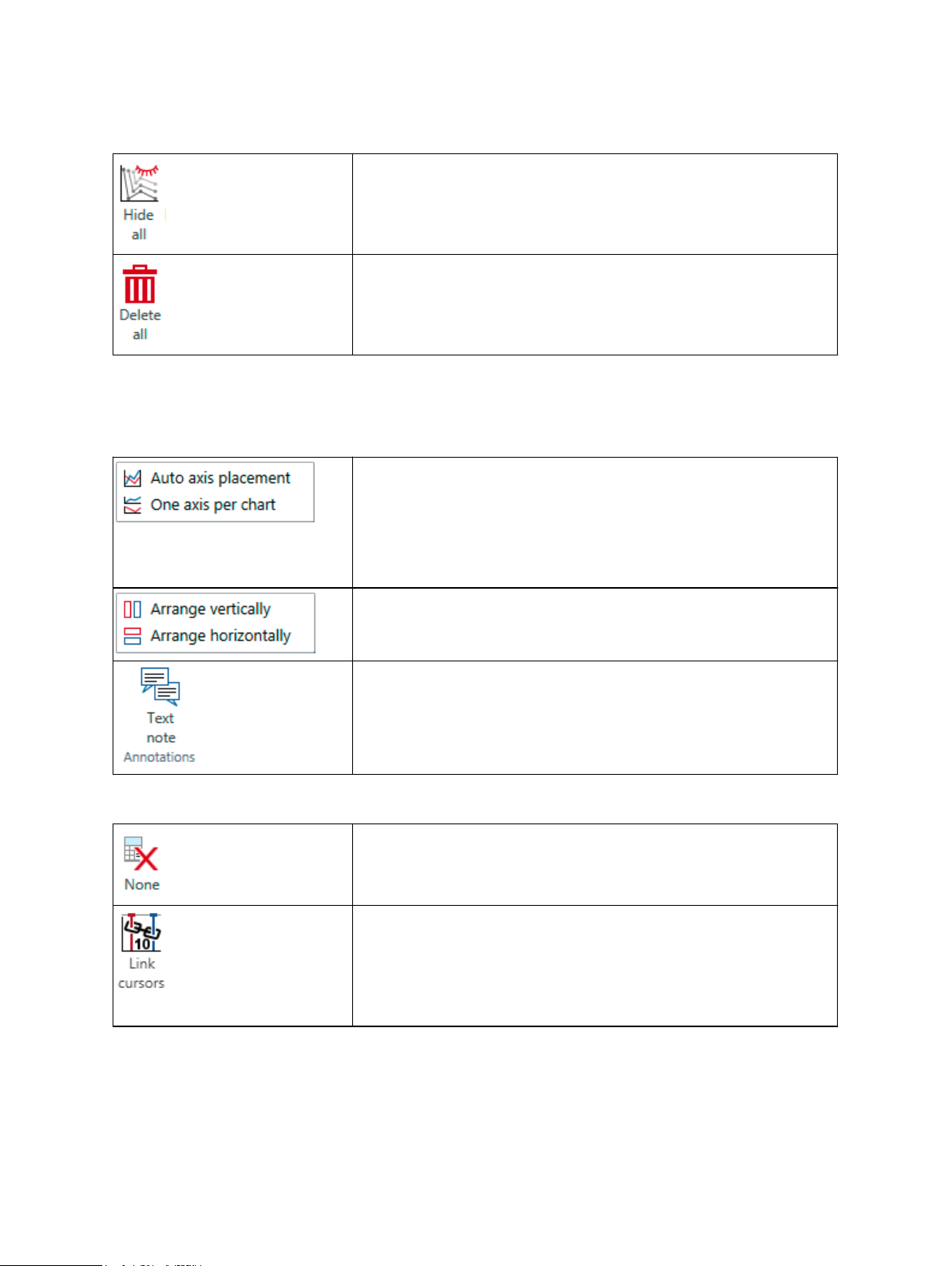

Memory ribbon

• Stop: Stops a running measurement

• Transmission/Gain: Open the hardware setup used for the gain

measurement

• Impedance/Reflection: Open the hardware setup used for the

impedance measurement

For more information regarding the hardware setup, please check

out Hardware setup .

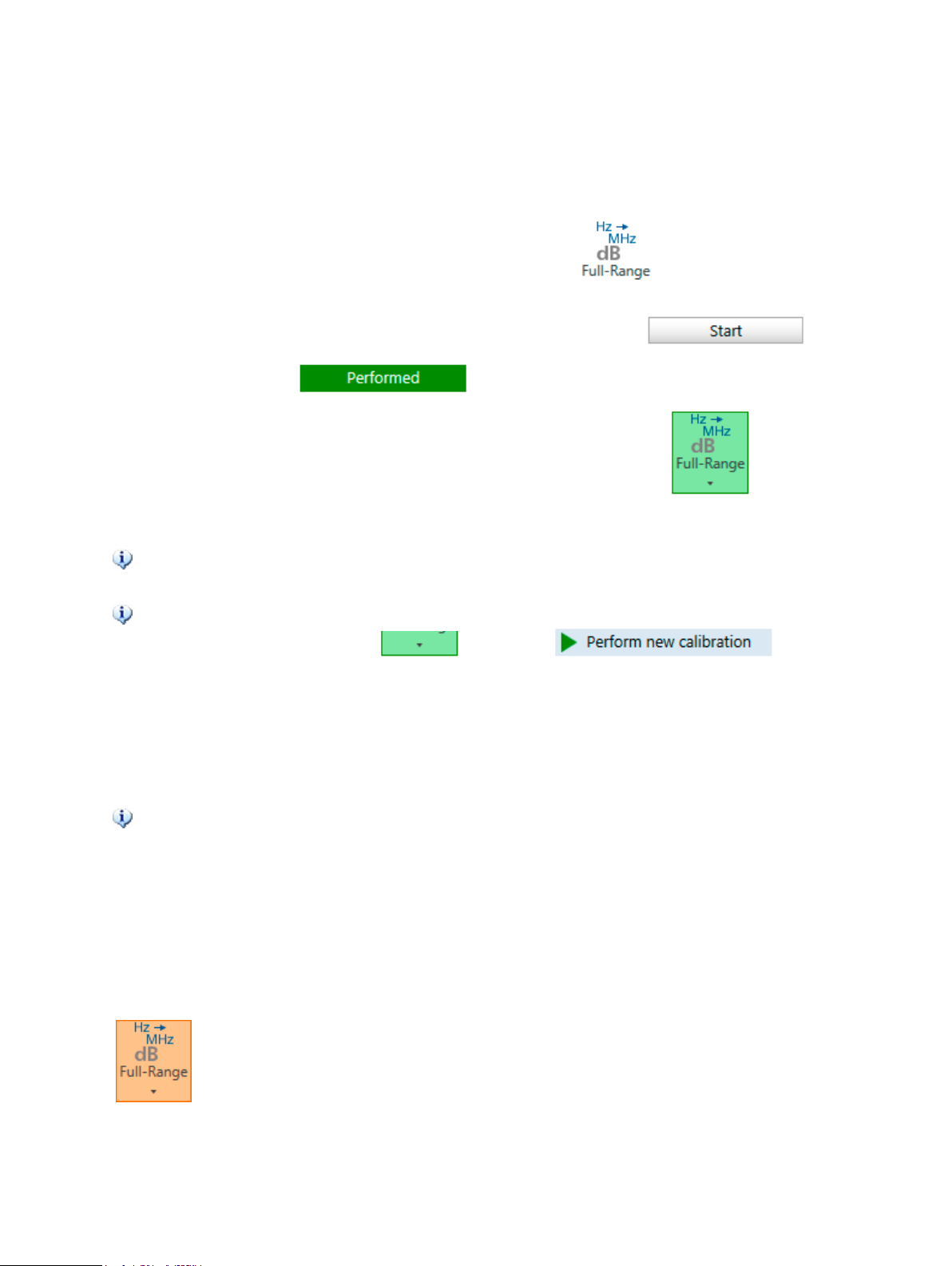

• Full-Range: Perform a Full-Range calibration

• User-Range: Perform a User-Range calibration

For more information regarding the calibration, please check out

8 Calibration on page 69

Copy the current measurement data to a new or existing memory

trace.

OMICRON Lab

Show all available memory traces in the diagram.

25

Hide all available memory traces. They will not be shown in the

diagram.

Delete all memory traces.

You can find more information about the use of the memory traces in 9.5 Using the memory traces on

page 111.

View ribbon

• Auto axis placement attempts to merge two traces with two

axes into one diagram.

• One axis per chart places only one trace into one diagram. So

for every trace there is an own diagram. You can find more

information about this setting in 9.3.1 Configure the

diagrams on page 101.

• Arrange multiple diagrams side by side.

• Arrange multiple diagrams from top to bottom other.

Cursor ribbon

Open a text field to add text notes to the current measurement.

Activate a cursor calculation. For more details please check out

cursor calculations.

Activate cursor linking. Cursor linking maintains a constant distance

between two cursors. By moving one cursor, the second one will

follow automatically. Use this feature to e.g. measure the slope at

crossover frequency in a bode plot. You can select either decade

(x10) or octave (x2) or constant linear distance which will maintain

the current frequency delta value.

26

OMICRON Lab

Bode Analyzer Suite introduction

6.2.4 Status bar

The Status bar has several displays and interactive control elements. These are:

Source indicator

The source indicator shows if the signal source of Bode 100 is

switched on. By moving the mouse over the indicator, a pop-up

allows to change between Auto off and Always on setting. More

details regarding the source setting can be found in 9.2 Signal

source settings on page 98.

Overload indicators

The overload indicators show the signal level at the receivers of

Bode 100. Red color indicates an overload of the receiver. An

overload warning will be shown in the chart in such a case.

Internal device calibration indicator

Shows the date of the last performed internal device calibration.

Move the mouse over the indicator in order to perform a new

internal device calibration.

Device connection indicator

Displays the serial number of the connected device. If no device is

connected, "No device" is shown. Move the mouse over the

indicator in order to search or re-connect to a Bode 100 device.

OMICRON Lab

27

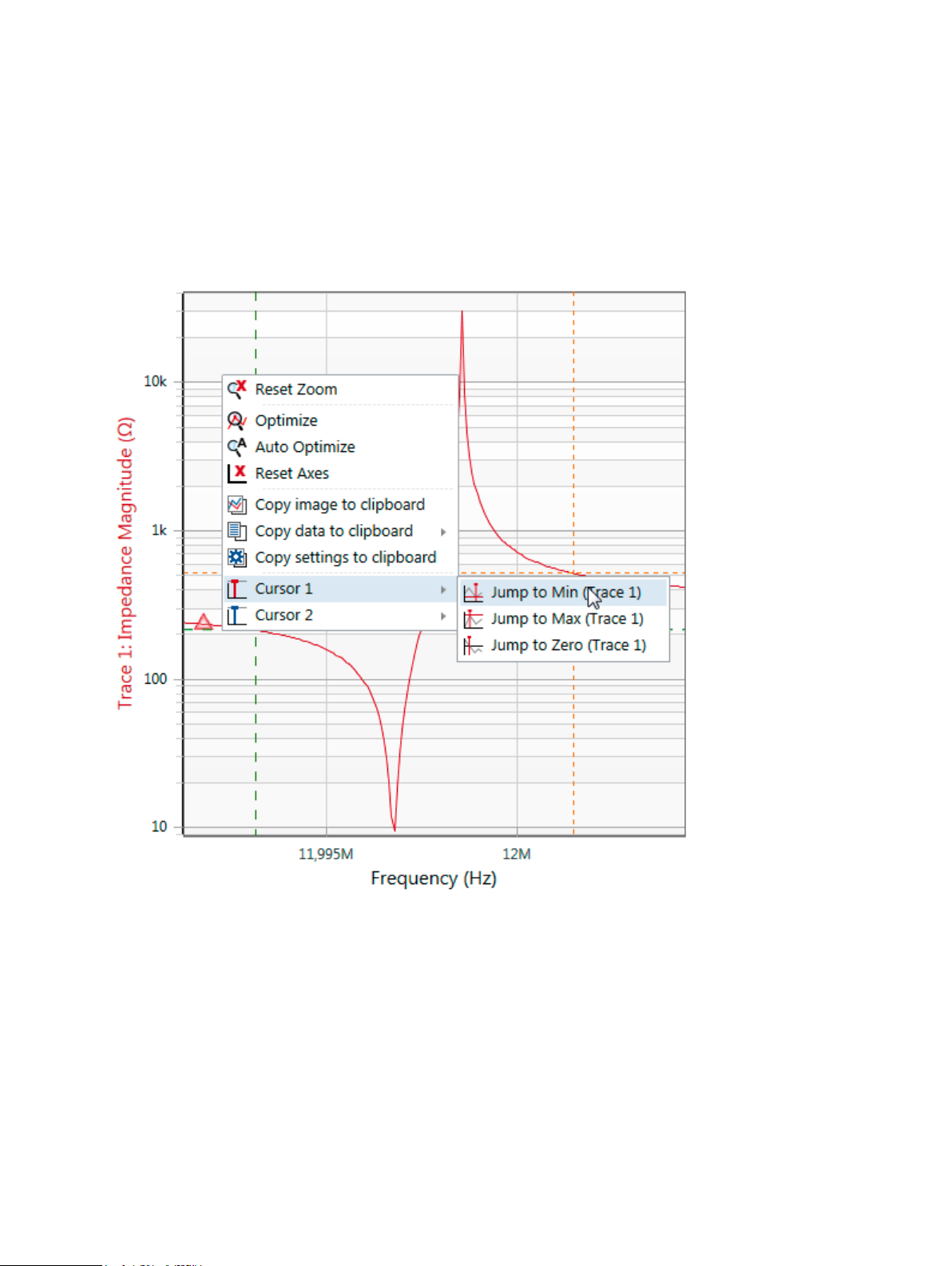

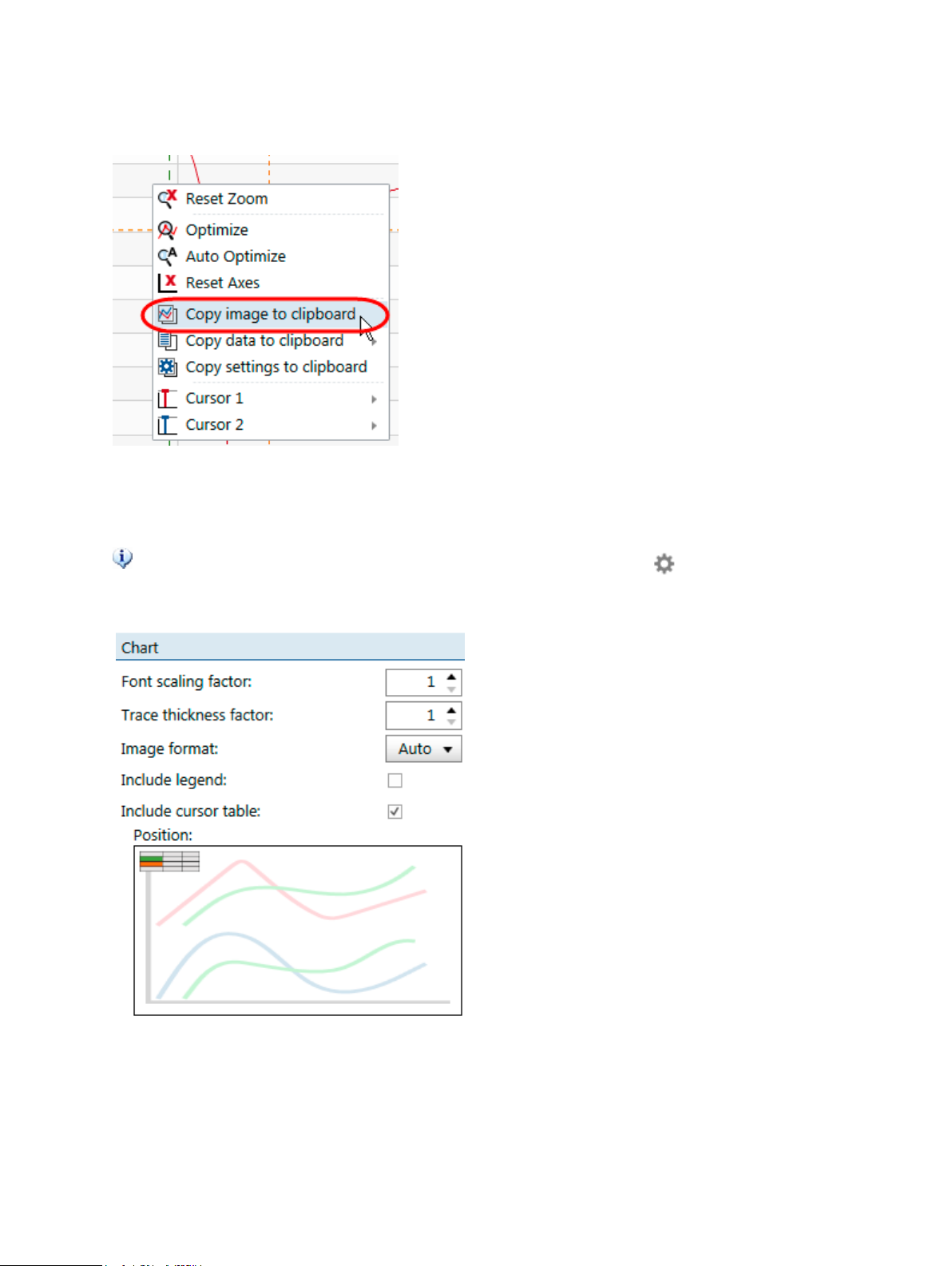

6.3 Chart context menu

By right clicking into the chart you get access to a context menu that allows quick access to several

functions:

Reset Zoom: Resets the x-axis to the start and

stop frequency and the y-axes to the predefined

Ymin and Ymax values. See 9.3.2 Zooming the

measurement curve on page 103 for details.

Optimize: Optimizes the Ymin and Ymax values

once to ensure that the current measurement

curve fills the chart area in an optimum way.

Auto Optimize: Optimizes the Ymin and Ymax

values continuously to ensure that the

measurement curve always fills the chart area in

an optimum way.

Reset Axes: Resets the Y-axes to their predefined startup values.

See 9.3.3 Optimize the axis scaling on page 106

for detail on these functions.

Copy image to clipboard: Copies a image of the

current chart to the clipboard.

Copy data to clipboard: Copies all

measurement points of Trace 1 or Trace 2 to the

clipboard for further processing in a spread sheet

software.

Copy settings to clipboard: Copies all

measurement settings to the clipboard in text

format.

See 9.1.2 Use the copy to clipboard functions to

export data on page 92 for details on these

functions.

Cursor 1 & Cursor 2: Allows to access several

cursor functions to position the cursors to the

maximum, minimum or zero crossing of the

measurement traces.

See 9.4 Working with cursors and the cursor

grid on page 109 for details on these functions.

28

OMICRON Lab

Bode Analyzer Suite introduction

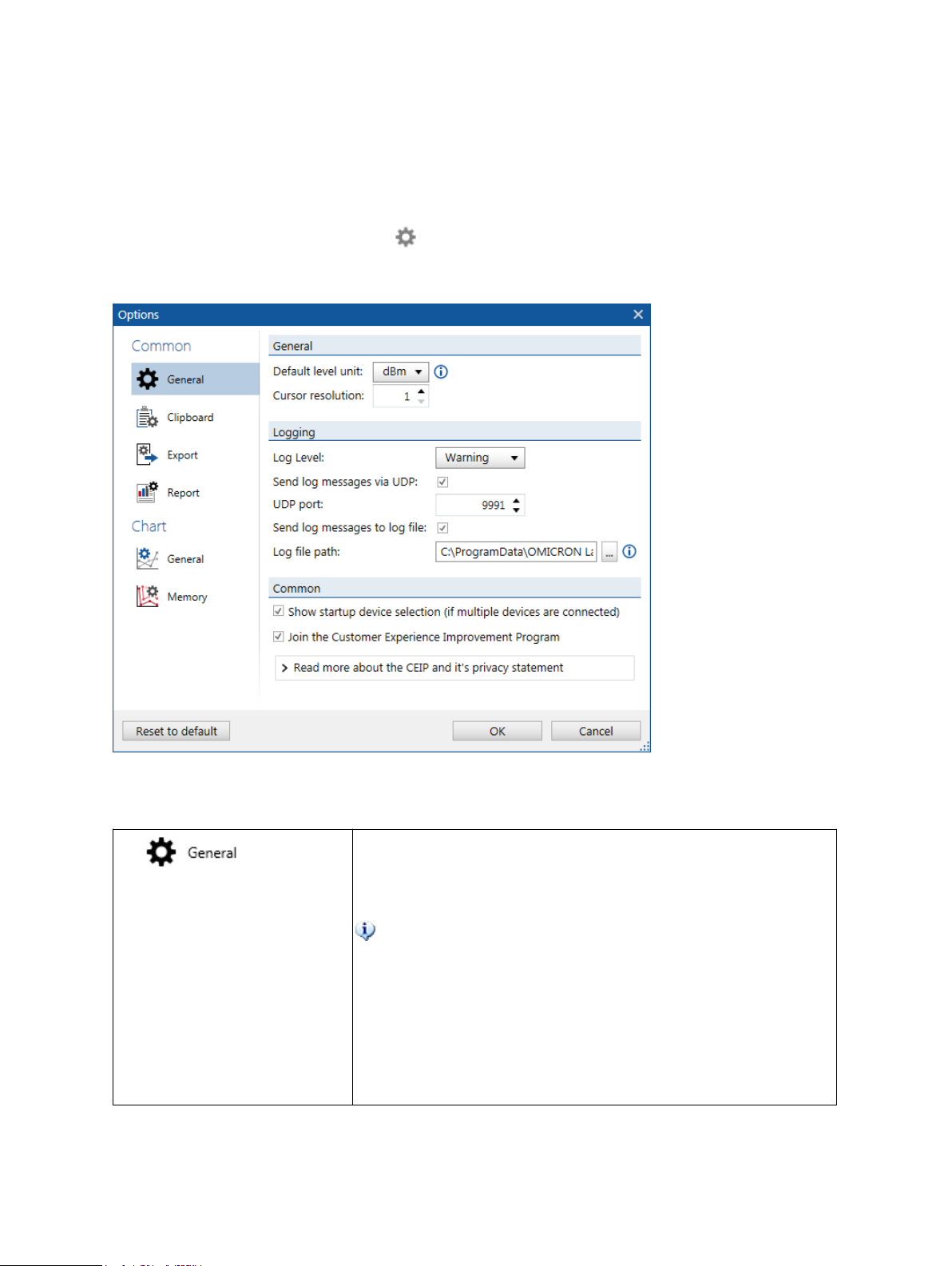

6.4 Options menu

The Options menu allows you to modify several functions of the Bode Analyzer Suite. You can access

the Options menu by either clicking the icon in the top right corner of the Bode Analyzer Suite's

main window or by clicking File → Options.

Figure 6-4: Bode 100 Options menu

In the Common section of the Options Menu you can change the following settings:

General:

Default level unit: allows you to change the unit for Bode 100's

source level setting. You can choose dBm, Vpp or Vrms.

dBm defines the power dissipated into 50 Ω load.

Vpp and Vrms are the voltage output levels present when

a 50 Ω load is connected at the output. Due to the

source's output impedance the output voltage will change

depending on the impedance of the connected load. See

more in 9.2 Signal source settings on page 98.

Cursor resolution: Defines the number of digits behind the

decimal separator for all values shown in the cursor grid.

OMICRON Lab

29

Logging:

Log Level:This function allows you to define the severity level of

the events stored in the log-file. Default is Warning.

Do not use the log-levels Verbose or Debug, except if told

by the OMICRON Lab support team.

UDP Logging: allows you to enable event logging via UDP and to

define the used UDP port.

Logging to a file: allows you to enable the logging of events to a

log file and to define the location of the log file on your computer's

hard drive.

Common:

Allows you to enable the device selection in the start up screen and

to change your preference in relation to the Customer Experience

Improvement Program.

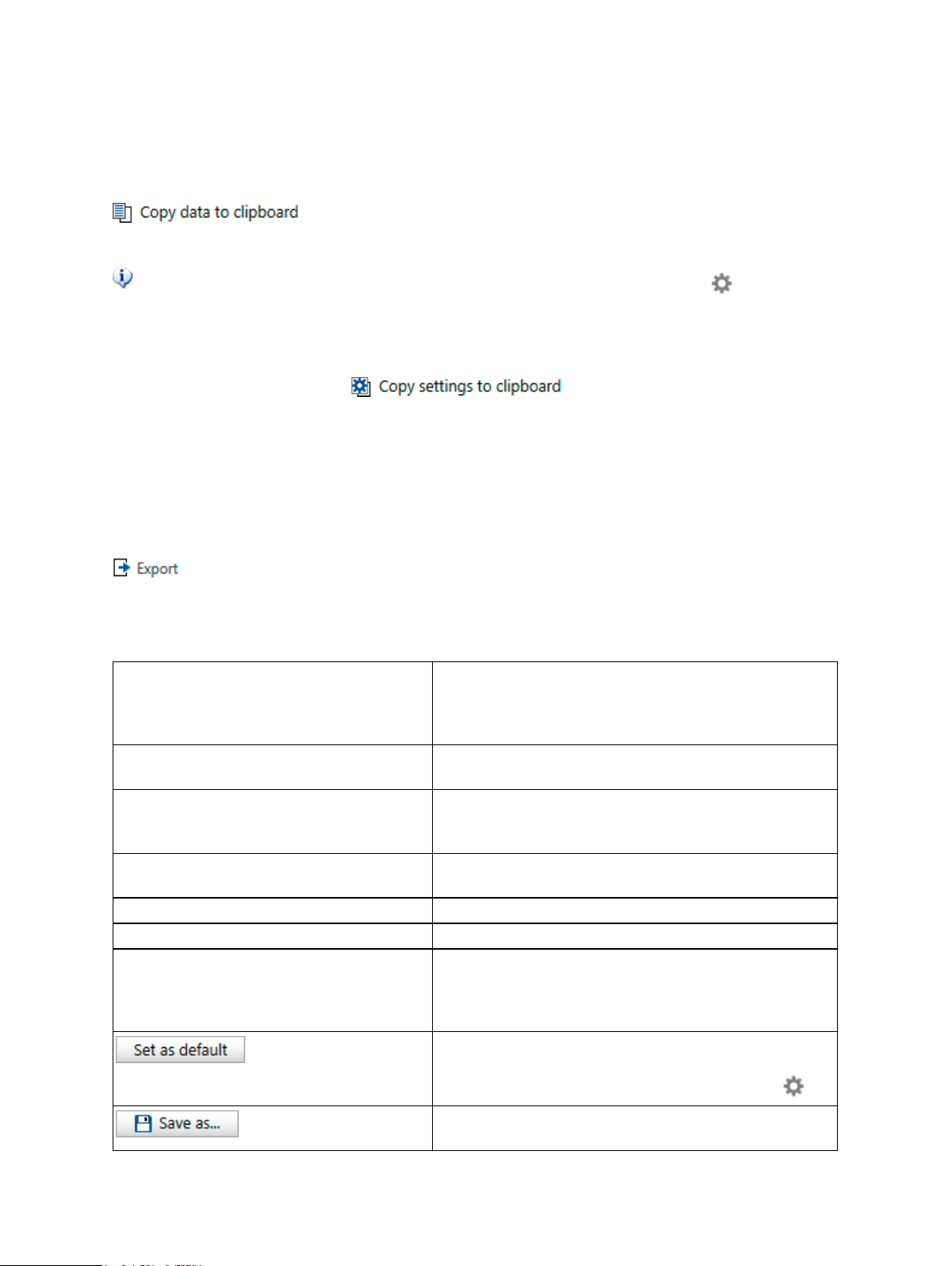

Chart:

In this section you can optimize the size of the text fonts and the

thickness of the measurement traces in the exported chart .

Further on, you can enable the inclusion of the chart legend and

the cursor grid. In addition the position of the cursor grid in the

exported chart and the image file format can be defined.

Data:

In this section you can choose the decimal separator and the field

separator for the clipboard export.

Find more information in 9.1.2 Use the copy to clipboard functions

to export data on page 92.

In this section you can define several parameters for the CSV-

Export, Excel-Export and Touchstone-Export of the measured

data. These parameters are the default values that will be used for

all future exports you perform.

Find out more in 9.1.3 Exporting measurement data to CSV or

Excel files on page 94.

Here you can choose if comments, the cursor table, the chart

legend or shaped level are included in the report or not.

Additionally, you can choose if you want to use a custom report or

the standard report. Finally you can select if the report should be

opened after its generation and the program that should be used to

display the report.

Detailed information is available in 9.1.5 Generate a PDF report on

page 97.

30

OMICRON Lab

Bode Analyzer Suite introduction

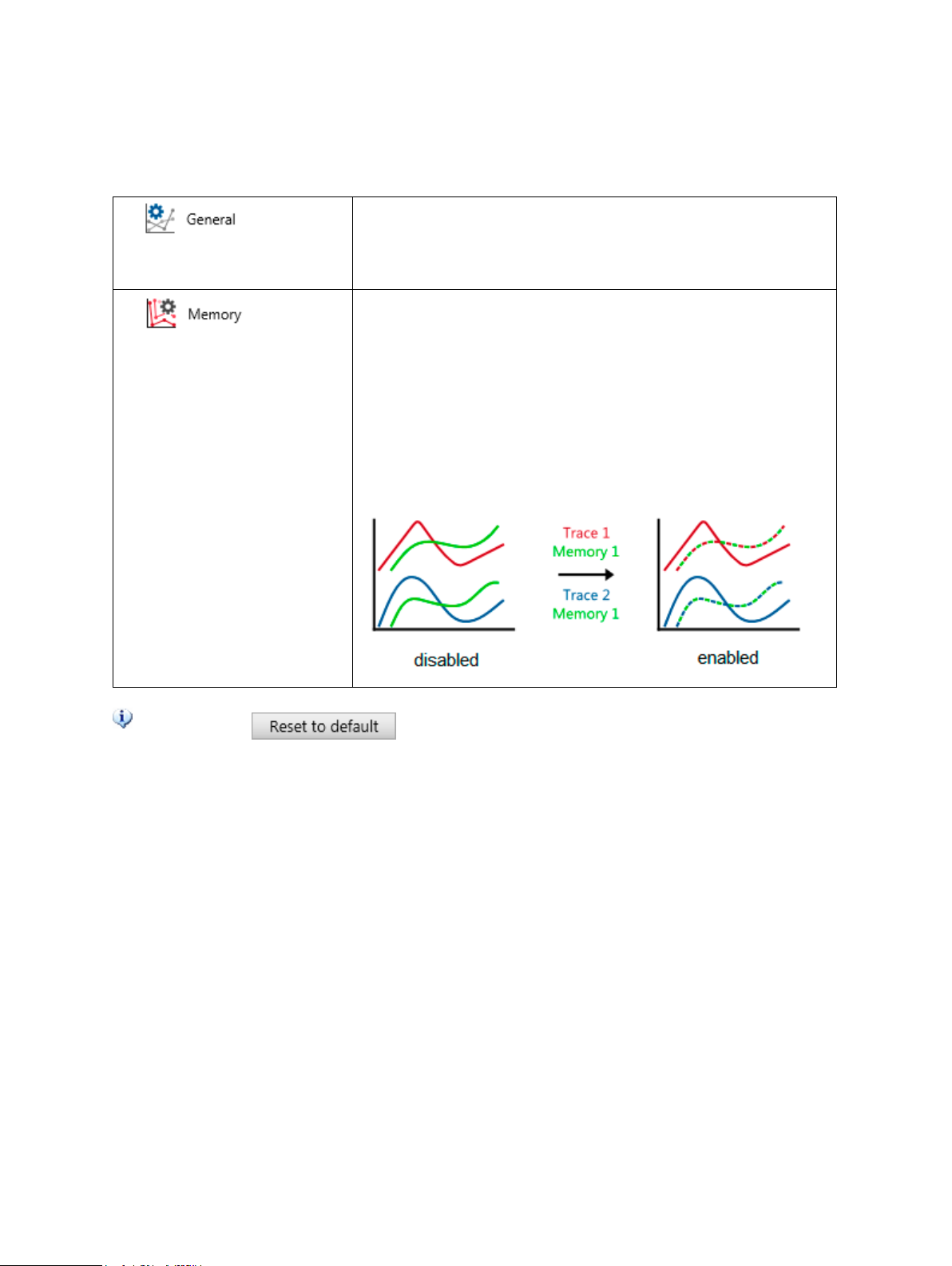

In the Chart section of the Options Menu you can change the following settings:

The sections in this unit allow you to optimize the quality and

appearance of the charts displayed in the Bode Analyzer Suite.

Further on, you can select if the axis labels are displayed in

scientific or engineering format.

General:

Here you can select the maximum number of memory traces,

the default memory line pattern (e.g. solid or dashed) as well as

if the deletion of a memory trace needs to be confirmed or not.

Alternating memory trace color mode:

By enabling this mode you can make it easier to find out to which

trace a memory belongs. If activated each memory alternates the

memory color and the color of the trace it belongs to as shown

below:

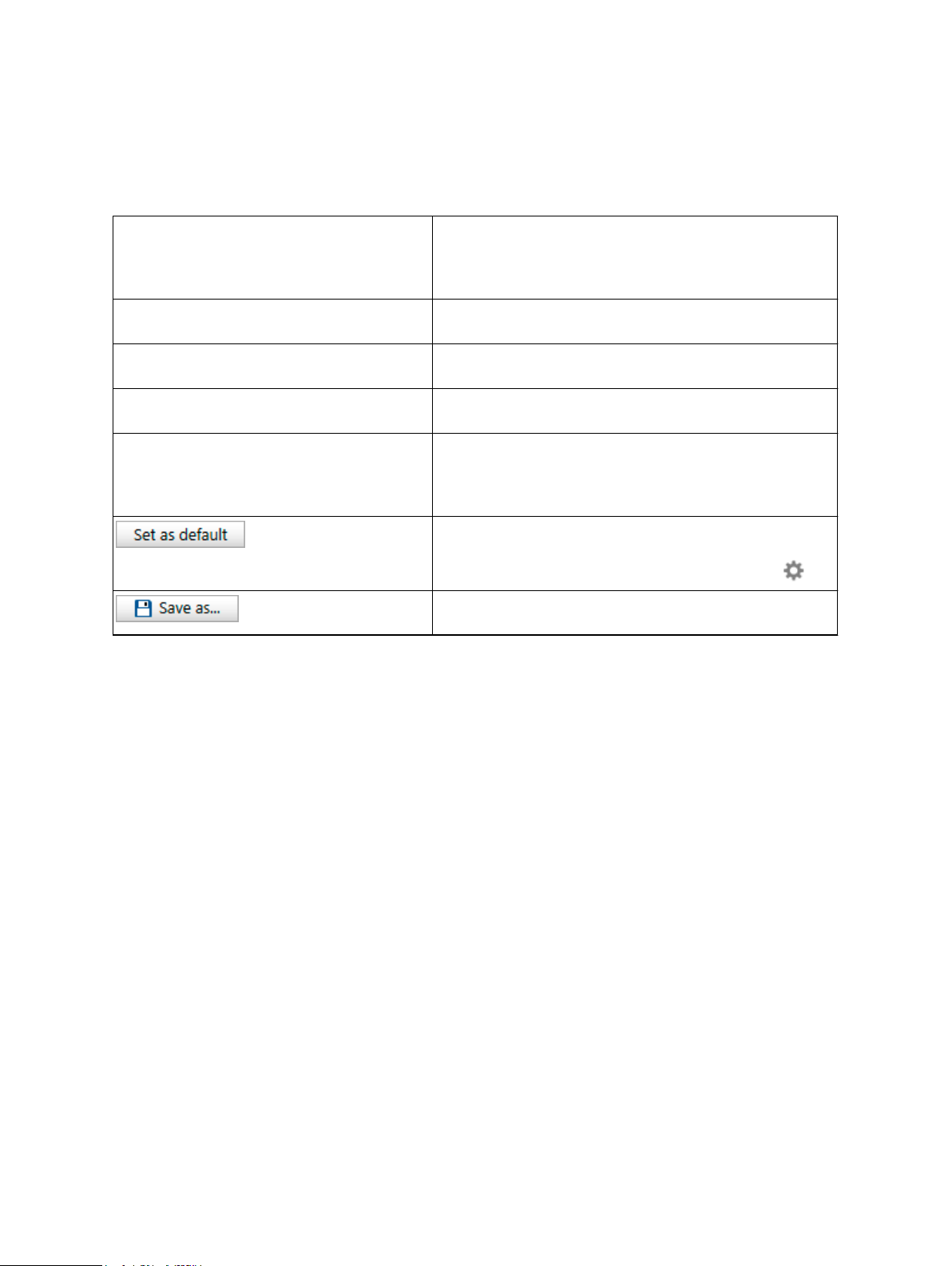

Hint: Click to switch back to the default settings of all options at any

time.

OMICRON Lab

31

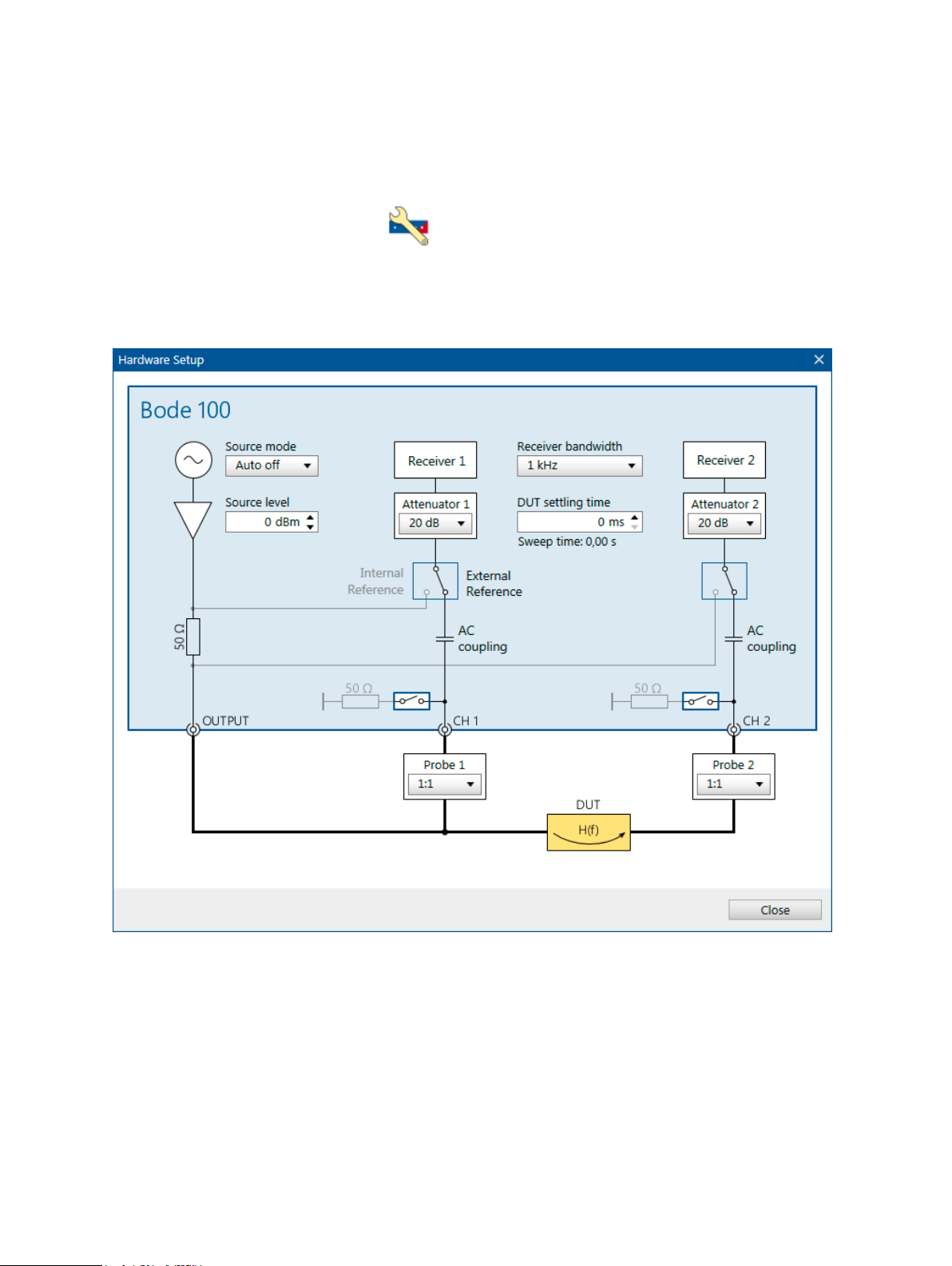

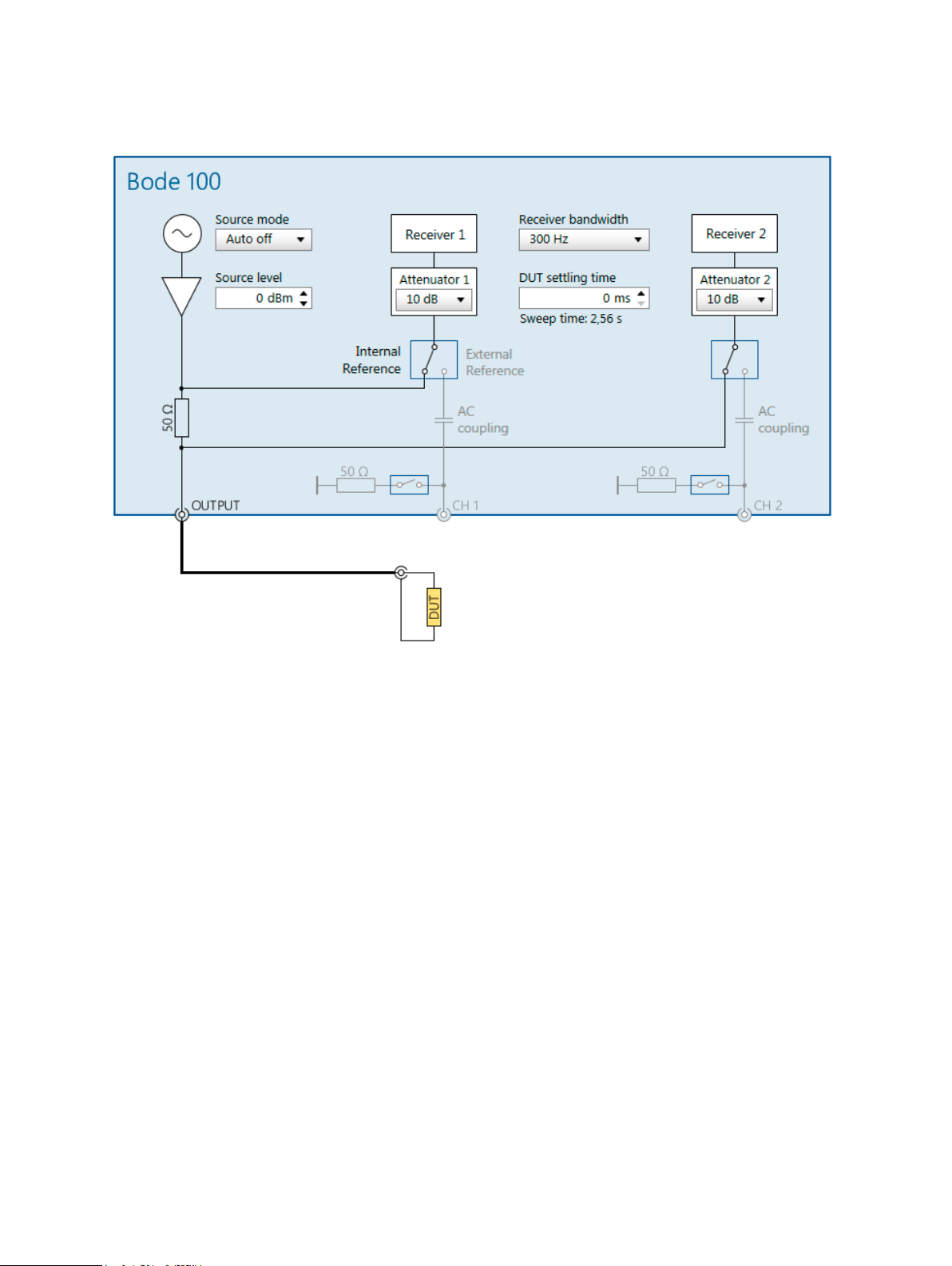

6.5 Hardware setup

By clicking on the Hardware setup icon , the hardware setup dialog is opened.

The hardware setup dialog shows the internal connections of Bode 100 as well as the external

connection to the DUT. Depending on the selected measurement mode, hardware settings such as

Channel termination, Receiver connection or an external Probe factor can be changed by clicking on

the icons shown in the Hardware setup dialog.

Figure 6-5: Hardware setup dialog in Gain/Phase measurement mode.

Depending on the measurement mode, some of the following settings can be changed by the user:

• Source mode: Choose between Auto off or Always on. More details on the source behavior of

Bode 100 can be found in 9.2 Signal source settings on page 98.

• Source level: Set the constant source level or the reference level when the shaped level function

is used.

• Receiver bandwidth: Select the receiver bandwidth used for the measurement.

32

OMICRON Lab

Bode Analyzer Suite introduction

• DUT settling time: Time between applying the measurement signal and starting to measure at the

receiver. A DUT settling time is needed if the DUT introduces a significant time delay before the

output reaches its final reaction to the input stimulus.

• Attenuator 1 and Attenuator 2: Select the input attenuators.

• Reference switch: Receiver 1 and Receiver 2 can be connected either internally or externally

depending on the measurement mode.

• Termination switch: When switched on, the Channel 1 and Channel 2 inputs are terminated with

50 Ω. If the switch is open, the input impedance is 1 MΩ.

• Probe 1 and Probe 2: Some measurement modes allow you to manually enter a probe factor. For

more details on using probes see 9.8 Using probes on page 120.

OMICRON Lab

33

7 Measurement types and applications

Bode 100 allows measuring Gain as well as Impedance, Reflection and Admittance. The following

chapters introduce you to the basics of the Gain and Impedance / Reflection / Admittance

measurements.

For an easy use, the Bode Analyzer Suite supports different measurement types / modes for different

applications. The available measurements are listed in the start screen of the Bode Analyzer Suite

(see 6.1 Start screen on page 18).

The available measurement modes are grouped in the Vector Network Analysis Tab and the

Impedance Analysis Tab:

Vector Network Analysis

The Vector Network Analysis Tab contains the following measurement types:

1. Transmission / Reflection

2. Gain / Phase

3. Reflection with external coupler

Impedance Analysis

The Impedance Analysis Tab contains the following measurement types:

1. One-Port

2. Impedance Adapter

3. Shunt-Thru

4. Shunt-Thru with series resistance

5. Series-Thru

6. Voltage / Current

7. External Bridge

In the following chapters all measurement types are explained in detail.

34

OMICRON Lab

Measurement types and applications

7.1 Gain measurement introduction

Bode 100 offers two different ways of measuring Gain. Either with the internal reference or the

external reference. Internal reference means that Receiver 1 is internally connected to the Bode 100

signal source picking up the source voltage. External reference means that Receiver 1 is routed to the

front panel input Channel 1.

Depending on the Receiver 1 connection, Gain is measured as shown in the following table:

Receiver 1 is set to internal reference Receiver 1 is set to external reference

Bode 100 measures

Bode 100 measures

Where V0 is the internal source voltage. If

Channel 2 is terminated with 50 Ω (default), Gain

equals the scattering parameter S21 of a two-port

DUT (Port 1 is connected to Bode 100 output and

port 2 is connected to Bode 100 Channel 2).

If Channel 2 is set to high-impedance, a

Thru-connection from Output to

Channel 2 will result in +6 dB. To

normalize to 0 dB you can use Thrucalibration.

The following two measurement modes can be used to perform a Gain measurement:

1. Transmission / Reflection: This mode allows both, measurements with internal and external

reference connection.

2. Gain / Phase: Is used to measure Gain from Channel 1 to Channel 2 (Frequency Response

Measurement).

Since the gain result is a complex number you can choose how gain shall be displayed. You can

select the result formats by clicking the drop down Format in the trace configuration box.

Gain therefore equals the transfer function of a 2port DUT if Channel 1 is connected to the DUT

input port and Channel 2 is connected to the DUT

output port.

OMICRON Lab

35

In a gain measurement the following result formats are available:

Gain Result Formats

Magnitude: Displays the magnitude of the measured

Gain.

Magnitude (dB): Displays the magnitude of the

measured Gain in dB

Phase (°): Displays the phase of the measured Gain in

degrees.

Phase (rad): Displays the phase of the measured Gain

in radians.

Tg: Displays the group delay of the measured Gain in

seconds (see Gain result format equations for details).

Polar: Displays the measured Gain in a polar chart.

Real: Displays the real part of the measured Gain.

Imaginary: Displays the imaginary part of the

measured Gain.

Nyquist: Displays the measured Gain in a Nyquist

chart.

Q(Tg): Displays the Q-factor derived from group delay.

This value is used for NISM (see cursor calculations on

page 116 for details).

Gain result format equations

The Gain results are calculated based on the following equations:

Gain H:

where h is the magnitude of gain H and φ the phase of H.

ω is the angular frequency with the frequency f.

Group delay Tg is calculated by symmetric difference quotient

Q(Tg) is the quality factor derived from the group delay

36

OMICRON Lab

Measurement types and applications

7.2 Impedance measurement introduction

Bode 100 offers several ways of measuring Impedance, Reflection or Admittance. Impedance,

Reflection and Admittance are directly related to each other by the following equations:

Admittance Y is the reciprocal of the impedance Z.

The reflection coefficient Γ is calculated from the measured

impedance Z and the nominal impedance Z0.

Z0 can be changed by the user in the measurement configuration. The nominal impedance

Z0 field is only visible if a measurement trace is set to Reflection.

The Impedance Analysis modes allow you to display the measurement results in various formats. You

can select the result formats by clicking the drop down Format in the trace configuration box.

Depending on the chosen measurement the following result formats are available:

Impedance Result Formats

Magnitude: Displays the magnitude of the measured

impedance in Ohms.

Magnitude (dB): Displays the magnitude of the

measured impedance in dBΩ.

Phase (°): Displays the phase of the measured

impedance in degrees.

Phase (rad): Displays the phase of the measured

impedance in radians.

Tg: Displays the group delay of the measured

impedance in seconds (see Gain result equations for

details).

Polar: Displays the measured impedance in a polar

chart.

Real: Displays the resistance of the measured

impedance in Ohms.

Imaginary: Displays the reactance of the measured

impedance in Ohms.

Rs: Displays the equivalent series resistance (ESR) of

the measured impedance in Ω. This value equals the

Real part of impedance.

Ls: Displays the equivalent series inductance (ESL) of

the measured impedance in Henry.

OMICRON Lab

37

Admittance Result Formats

Cs: Displays the equivalent series capacitance (ESC) of

the measured impedance in Farad.

Q: Displays the Q-factor of the measured impedance

(see Impedance result equations for details).

Nyquist: Displays the measured impedance in a

Nyquist chart

Q(Tg): Displays the Q-factor derived from group delay.

This value is used for NISM (see Cursor calculations for

details).

tan(δ): Displays the tan(δ) of the measured admittance.

(see Impedance result equations for details).

Magnitude: Displays the magnitude of the measured

admittance in Siemens.

Magnitude (dB): Displays the magnitude of the

measured admittance in dBS.

Phase (°): Displays the phase of the measured

admittance in degrees

Phase (rad): Displays the phase of the measured

admittance in radians

Tg: Displays the group delay of the measured

admittance in seconds (see Gain result equations for

details).

Polar: Displays the measured admittance in a polar

chart.

Real: Displays the conductance of the measured

admittance in Siemens.

Imaginary: Displays the susceptance of the measured

admittance in Siemens

Rp: Displays the equivalent parallel resistance of the

measured admittance in Ohms.

Lp: Displays the equivalent parallel inductance of the

measured admittance in Henry.

Cs: Displays the equivalent parallel capacitance of the

measured admittance in Farad.

Q: Displays the Q-factor of the measured admittance

(see Impedance result equations for details).

Nyquist: Displays the measured admittance in a

Nyquist chart.

Q(Tg): Displays the Q-factor derived from group delay

(see Cursor calculations for details).

tan(δ): Displays the tan(δ) of the measured admittance.

(see Impedance result equations for details)

38

OMICRON Lab

Reflection Coefficient Result Formats

Measurement types and applications

Magnitude: Displays the magnitude of the measured

reflection coefficient.

Magnitude (dB): Displays the magnitude of the

measured reflection coefficient in dB

Phase (°): Displays the phase of the measured

reflection coefficient in degrees.

Phase (rad): Displays the phase of the measured

reflection coefficient in radians.

Tg: Displays the group delay of the measured reflection

coefficient in seconds (see Gain result equations for

details).

Polar: Displays the measured reflection coefficient in a

polar chart.

Smith: Displays the measured reflection coefficient

respectively impedance in a Smith chart.

VSWR: Displays the voltage standing wave ratio of the

measured reflection coefficient.

Real: Displays the real part of the measured reflection

coefficient.

Imaginary: Displays the imaginary part of the

measured reflection coefficient.

Nyquist: Displays the reflection coefficient in a Nyquist

chart.

Q: Displays the Q-factor of the measured reflection (see

Impedance result equations for details).

Nyquist: Displays the measured reflection in a Nyquist

chart.

Q(Tg): Displays the Q-factor derived from the group

delay (see Cursor calculations for details).

OMICRON Lab

39

Result format equations

The Impedance / Admittance / Reflection results are calculated based on the following equations:

ImpedanceZ:

where R is the real part of the impedance (resistance) and X the imaginary part of the

impedance (reactance).

ω is the angular frequency with the frequency f.

Series equivalent resistance Rs equals the real part of impedance

Series equivalent capacitance Cs

Series equivalent inductance Ls

Series circuit quality factor Q

tan(d) of impedance

Admittance Y:

where G is the real part of the admittance (conductance) and B the imaginary part of

the admittance (susceptance).

ω is the angular frequency with the frequency f.

Parallel equivalent resistance Rp

Parallel equivalent capacitance Cp

Parallel equivalent inductance Lp

Parallel circuit quality factor Q

tan(d) of admittance

40

OMICRON Lab

Measurement types and applications

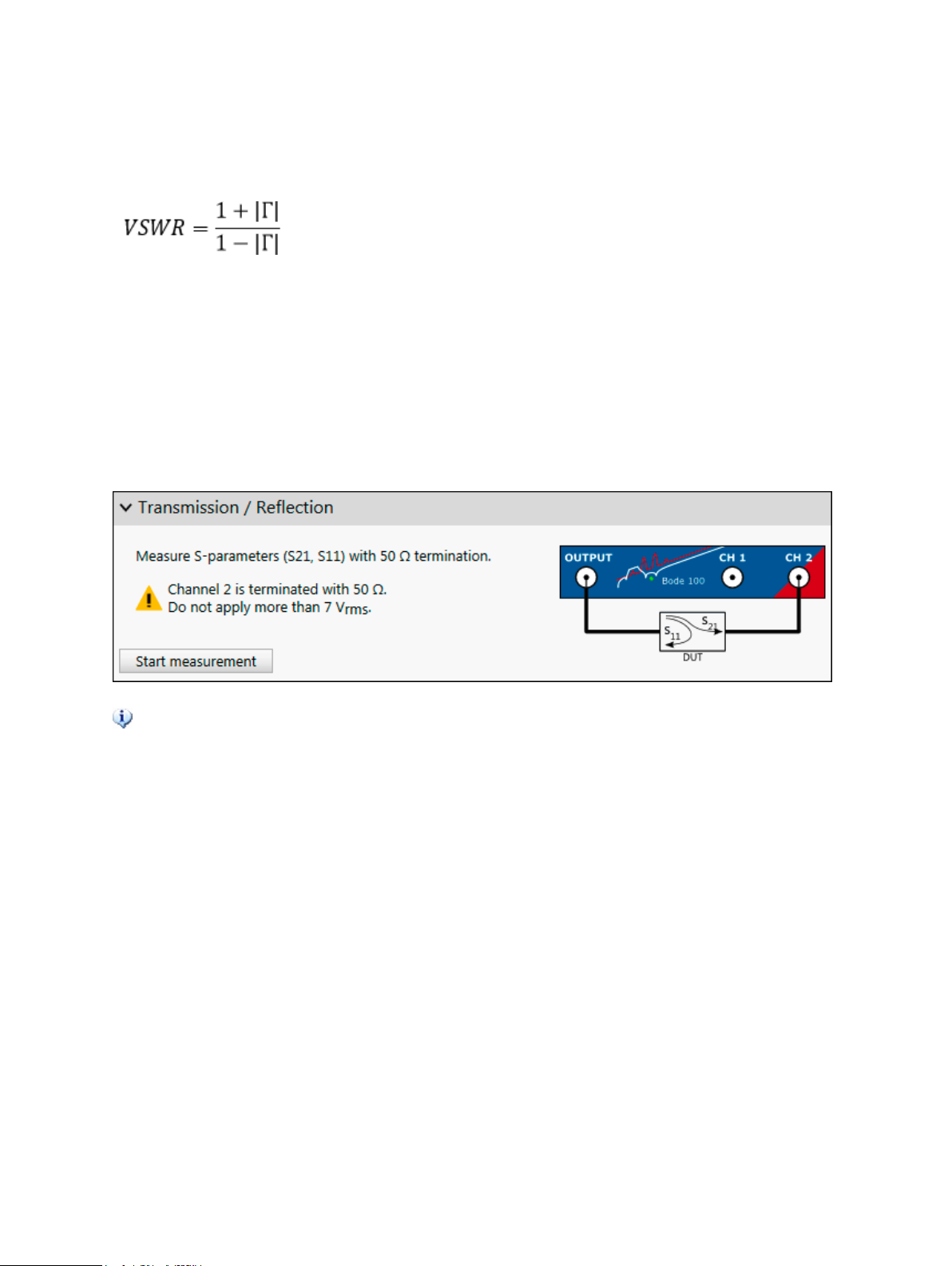

Reflection Coefficient Γ:

Voltage Standing Wave Ratio VSWR

Tg as well as Q(Tg) are calculated in the same way as for the gain measurement (see 7.1 Gain

measurement introduction on page 35).

7.3

Vector Network Analysis

7.3.1 Transmission / Reflection

The Transmission / Reflection measurement mode is designed to measure the S-parameters S21 and

S11 in the 50 Ω domain.

The Transmission / Reflection measurement mode allows to measure both, Transmission

(Gain) and Reflection (Impedance). It is possible to select e.g. a Gain measurement in Trace

1 and an Impedance measurement in Trace 2. Bode 100 will then sequentially measure Gain

and Impedance.

Therefore some hardware settings are available twice. Once for the Gain measurement and once for

the Impedance measurement.

Also the hardware setup dialog is available twice. Once for the Gain measurement and once for the

impedance measurement.

For details on how the Gain is calculated, please check 7.1 Gain measurement introduction on

page 35.

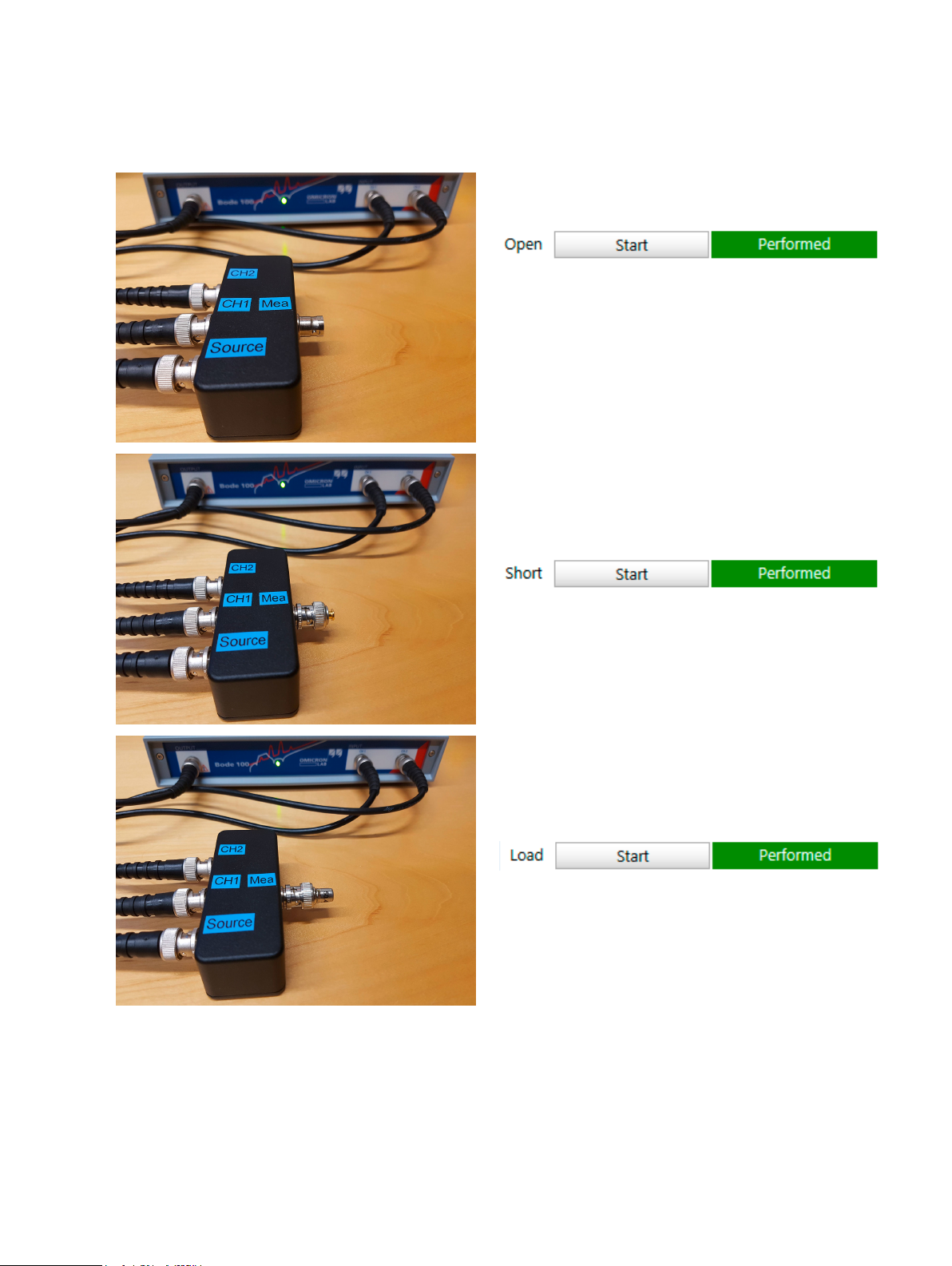

Calibration in the Transmission / Reflection measurement mode

The Transmission / Reflection measurement mode does not require calibration to perform a

measurement. However, to remove the influence of your connection cables the measurement mode

offers Gain (Thru) as well as Impedance (Open, Short, Load) calibration. Gain calibration applies to a

Gain measurement and Impedance calibration applies to a Impedance/Reflection/Admittance

measurement. When measuring at high frequency or with long cables it is strongly recommended to

perform a calibration. For more details regarding the Gain calibration please refer to 8 Calibration on

page 69.

OMICRON Lab

41

Typical applications

Typical applications for the Transmission / Reflection measurement mode are:

• Measuring Transmission and Reflection of filters such as IF filters or EMI filters.

• Comparing results from measurements with internal and external reference connection

(the Transmission / Reflection measurement mode is the only measurement mode that allows

changing the Receiver 1 connection).

• Measuring Gain of RF amplifiers in the 50 Ω domain.

Transmission / Reflection measurement example

Follow the steps described below to perform a Transmission / Reflection measurement:

Connect the test object "IF Filter" to Bode 100 using two BNC cables as shown in the figure below.

Figure 7-1: Connecting the test object IF Filter to Bode 100

42

OMICRON Lab

Measurement types and applications

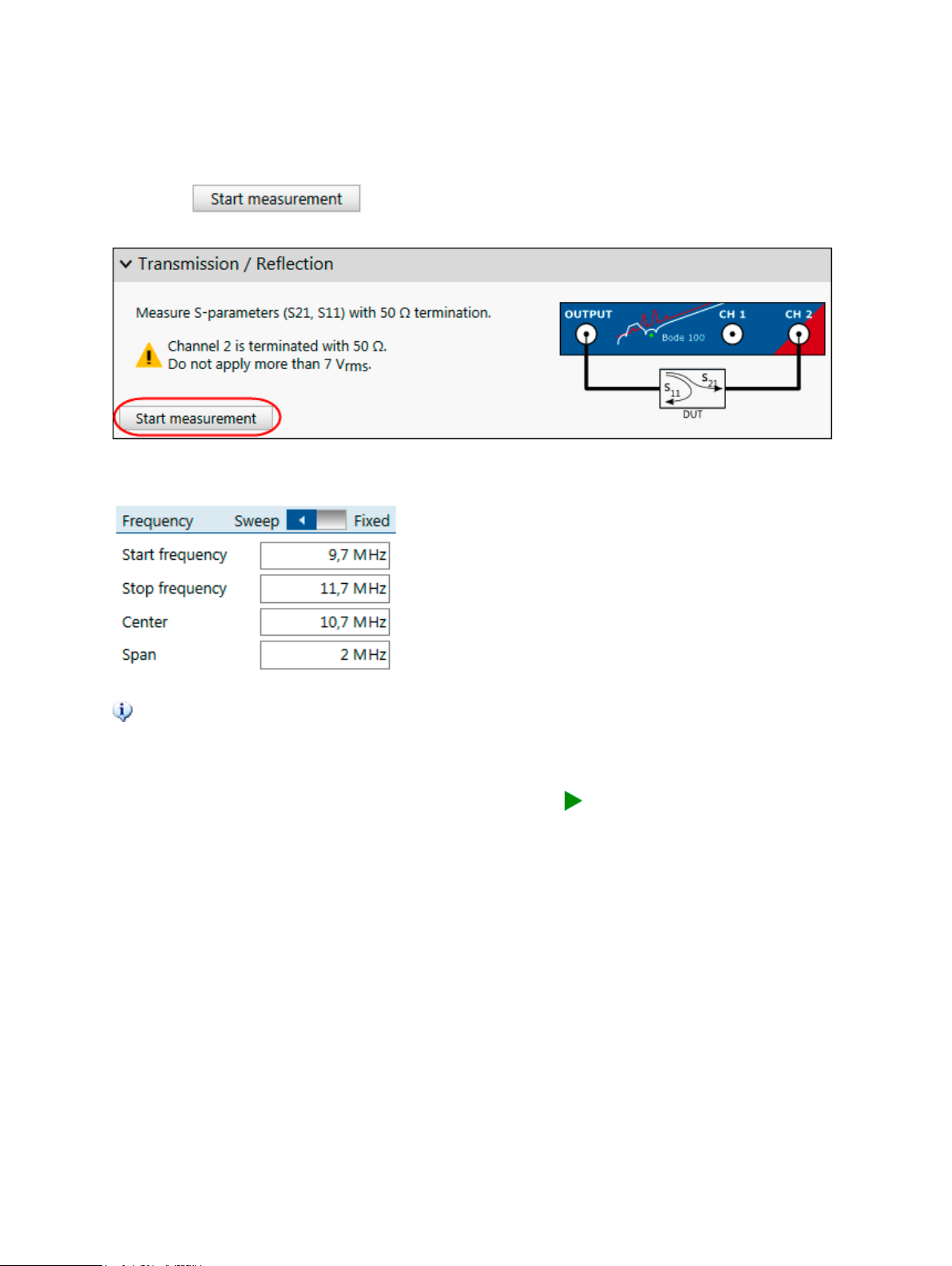

Now start the Bode Analyzer Suite and enter the Transmission / Reflection measurement mode by

clicking on .

Before starting the measurement set the Start and Stop frequency to the values shown below:

After setting the Start and Stop frequency the Center frequency as well as the frequency

Span are set automatically. Alternatively you can enter the Span and Center and the Start

and Stop frequency are updated accordingly

Now you are ready to start your first measurement. Simply click in the home ribbon. As a result you

will see a first measurement comparable to the one shown in the figure below.

OMICRON Lab

43

Figure 7-2: S-Parameter measurement of a 10.7 MHz IF filter

Trace 1 (red curve) shows the Magnitude of the Gain (= Magnitude of S21) while Trace 2 (blue curve)

shows the Magnitude of Reflection (= Magnitude of S11). You can change Format for both traces to

display other results such as Phase or Real and Imaginary components

To optimize the chart you can right click onto the chart and select Optimize as shown below. For more

information on the chart's context menu check out 6.3 Chart context menu on page 28.

44

OMICRON Lab

Measurement types and applications

Figure 7-3: Context menu of chart

OMICRON Lab

45

Further on you can use the cursors to perform measurements. To do so simply drag the cursors to the

point you want to measure (1.) and check out the results in the cursor grid (2.) as shown in 7-4 on

page 46. For more cursor functions visit 9.4 Working with cursors and the cursor grid on page 109.

Figure 7-4: Use of cursors and cursor grid

Congratulations you have performed your first measurement with the Bode 100. You can load the

settings for the measurement by clicking File → Open → and then navigating to: "%APPDATA%

\OMICRON Lab\Bode Analyzer Suite\Demo Files\". The file you will need is: TransRefl_IF-

Filter.bode3

Hint: The Transmission / Reflection is the most flexible measurement setup for the

Bode 100. By selecting this setup you can switch between internal and external reference.

Further on, you can switch the input impedance of input CH1 and input CH2 between 50 Ω

and high impedance.

46

OMICRON Lab

Measurement types and applications

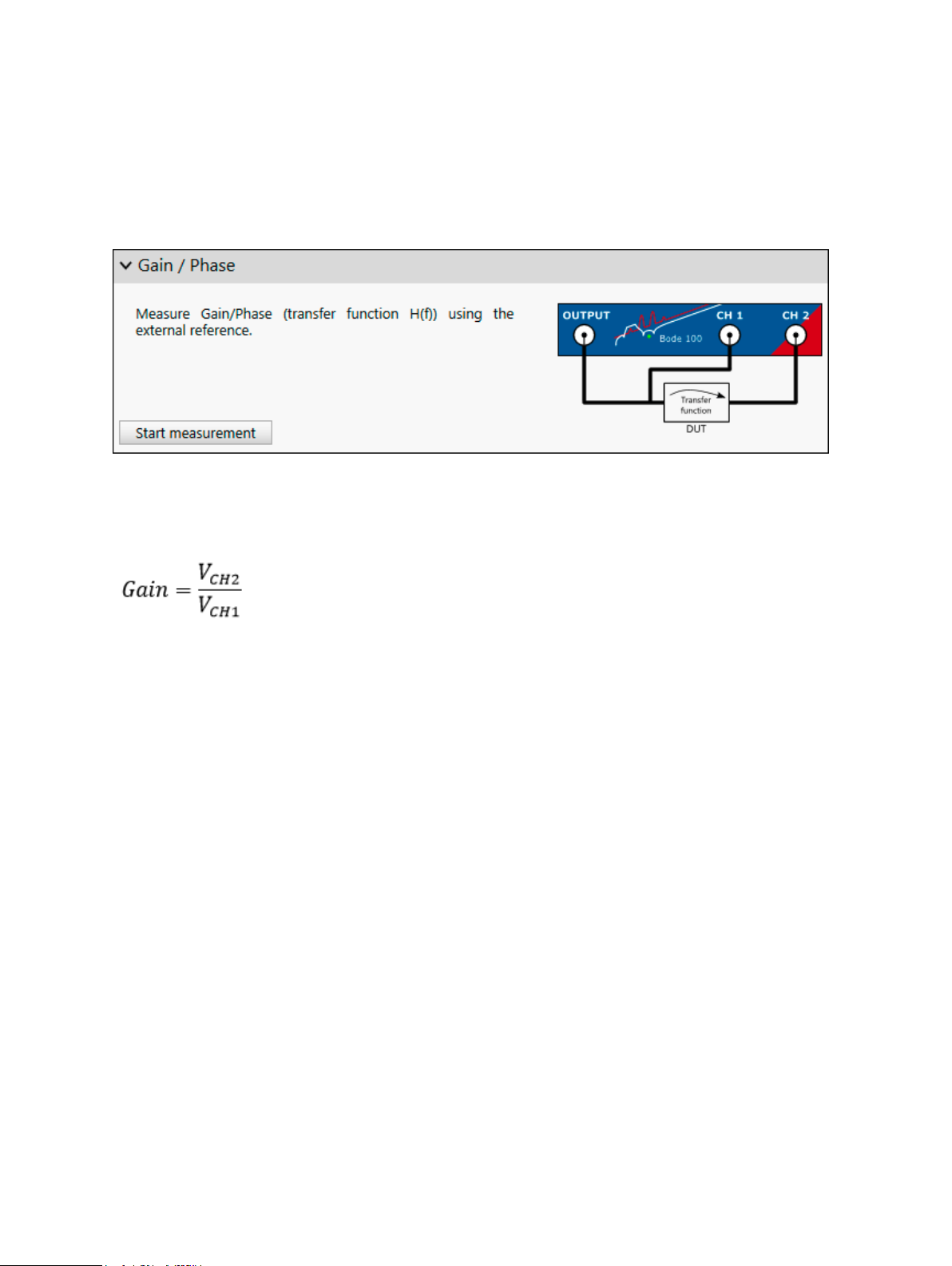

7.3.2 Gain / Phase

The Gain / Phase measurement mode is designed to measure the transfer function of a DUT using the

external reference connection. This means that both Channel 1 and Channel 2 are active.

The Gain Measurement

Bode 100 measures

Gain therefore equals the transfer function of a 2-port DUT if Channel 1 is connected to the DUT input

port and Channel 2 is connected to the DUT output port. The inputs Channel 1 and Channel 2 are set

to 1 MΩ by default.

Details on the gain measurement can be found in 7.1 Gain measurement introduction on page 35.

Calibration

The Gain / Phase measurement mode does not require calibration to perform a measurement.

However, to remove the influence of probes and cables Gain (Thru) calibration is recommended. For

more details regarding the Gain calibration please refer to 8 Calibration on page 69.

Typical applications

Typical applications for the Gain / Phase measurement mode are:

• Measuring the transfer function of filters or other circuits.

• Measuring in-circuit transfer functions using high-impedance probes.

• Measuring the transfer function of amplifiers etc.

• Measuring loop stability of power supplies.

OMICRON Lab

47

Measurement example

For detailed measurement examples using the Gain / Phase measurement mode, please check out

the application notes at www.omicron-lab.com/BodeManualAppNotes. The following application notes

use the Gain / Phase measurement mode:

• DC/DC Converter Stability Measurements

• Bipolar Transistor AC Current Gain Measurement

• Op-Amp measurements

• PSRR Measurement

• And many more...

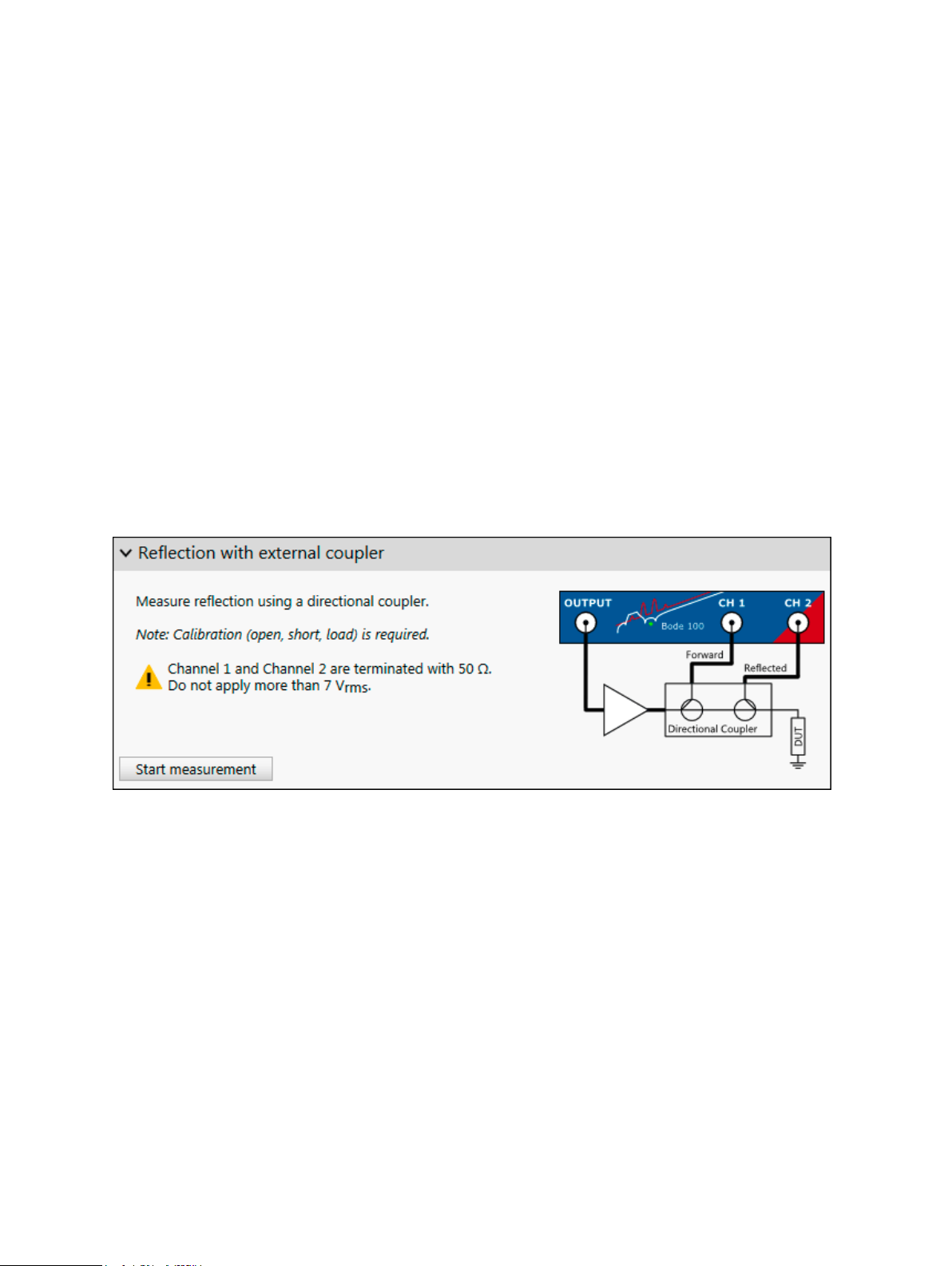

7.3.3 Reflection with external coupler

The External coupler measurement mode is designed to measure reflection using an external coupler.

This offers the possibility to use an external amplifier and protect the inputs of Bode 100 by using an

external directional coupler.

Calibration

Please note that the external coupler measurement mode requires an impedance calibration (Open,

Short, Load). For more details on how to perform an impedance calibration see 8.3.2 Calibrating an

External Coupler or External Bridge measurement on page 80.

Typical applications

Typical applications for the external coupler measurement mode are:

• Measuring medium-wave antennas.

• Measuring impedance with high-power amplifiers.

Measurement example

For a detailed measurement example using the external coupler measurement mode, please check

out the medium wave antenna measurement application note at

www.omicron-lab.com/BodeManualAppNotes.

48

OMICRON Lab

Measurement types and applications

7.4 Impedance analysis

7.4.1 One-Port

The One-Port measurement mode is designed to perform quick impedance, admittance and reflection

measurements. One advantage of the One-Port impedance measurement mode is that no external

calibration is required. Bode 100 can measure impedance directly at the output port.

Measurement information

Bode 100 derives the impedance by evaluating the internal source voltage and the output voltage.

Receiver 1 as well as Receiver 2 are internally connected. General details on impedance

measurements with Bode 100 can be found in 7.2 Impedance measurement introduction on page 37.

OMICRON Lab

49

Figure 7-5: Hardware setup of the One-Port measurement mode.

Since the output impedance of Bode 100 is 50 Ω, the one-port measurement provides highest

sensitivity for a DUT having an impedance close to 50 Ω. The method is generally suitable to measure

impedance values between roughly 500 mΩ and 10 kΩ.

For measurements close to the limits of this method it is highly recommended to perform a careful

User-Range calibration to achieve best results.

Calibration

The One-Port impedance measurement mode does not require calibration to perform a measurement.

However, to achieve highest accuracy a calibration is recommended. Furthermore a calibration allows

to move the reference plane from the output port of Bode 100 to the end of a connection cable. This

compensates the effect of the connection cable.

For more details on how to perform an Impedance calibration please refer to 8.3.1 Calibrating a

Reflection or One-Port Impedance measurement on page 78.

Typical applications

Typical applications for the One-Port impedance measurement mode are:

• Measuring impedance of passive components.

• Measuring impedance of cables, piezo-elements or any one-port DUT.

50

OMICRON Lab

Measurement types and applications

One-Port measurement example

In this measurement example we will determine the series ans parallel resonance frequency of a 12

MHz quartz filter. Further on, we will display the quartz filter's reflection curve in a Smith chart.

Connect the input IN 2 of the test object "Quartz Filter" to the OUTPUT of Bode 100 using a BNC

cable. Further on, connect the BNC short delivered with Bode 100 to the corresponding output OUT 2.

The complete setup is shown in the figure below.

Figure 7-6: Connecting the test object Quartz Filter to Bode 100

Now start the Bode Analyzer Suite and enter the One-Port measurement mode by clicking Impedance

Analysis and then .

OMICRON Lab

51

Before starting the measurement set the Center frequency, frequency Span and the Number of

points to the values shown below.

Further on, select sweep linear:

Now click in the home ribbon. As a result you will see a first measurement comparable to the one

shown in the figure below.

52

OMICRON Lab

Measurement types and applications

Figure 7-7: Impedance measurement of the test object Quartz Filter

Trace 1 (red curve) shows the Magnitude of the Quartz Filter's impedance while Trace 2 (blue curve)

shows the Phase of the Quartz Filter's impedance.

Before continuing the measurement please switch of Trace 2 by unchecking the corresponding check

box .

To determine the parallel and series resonance of the Quartz filter we need to zoom in. You can do this

by clicking into the chart on the top left corner of the intended zoom area, keep the mouse button

pressed and pull it to the lower right corner of the intended zoom area as shown.

OMICRON Lab

53

In the zoomed window you will see that you are not having enough frequency points. By pressing

you can set the start and stop frequency of the measurement to

match the zoomed window. Right Click into the chart and select Optimize. Repeat these steps until

you achieve a chart as shown in 7-8 on page 54

Figure 7-8: Optimizing the frequency resolution with Get from zoom

For more information on the zoom functions and optimizing check out 9.3.2 Zooming the

measurement curve on page 103 and 6.3 Chart context menu on page 28.

54

OMICRON Lab

Measurement types and applications

After you have optimized the chart you can measure the series resonance and parallel resonance

using the cursors. To do so right-click into the chart area close to the red curve and choose Cursor 1

and then Jump to Min (Trace 1). Then right-click into the chart area once more and choose Cursor 2

and then Jump to Max (Trace 1)

Figure 7-9: Using the cursor jump functions

For more information on cursor functions visit 9.4 Working with cursors and the cursor grid on

page 109.

OMICRON Lab

55

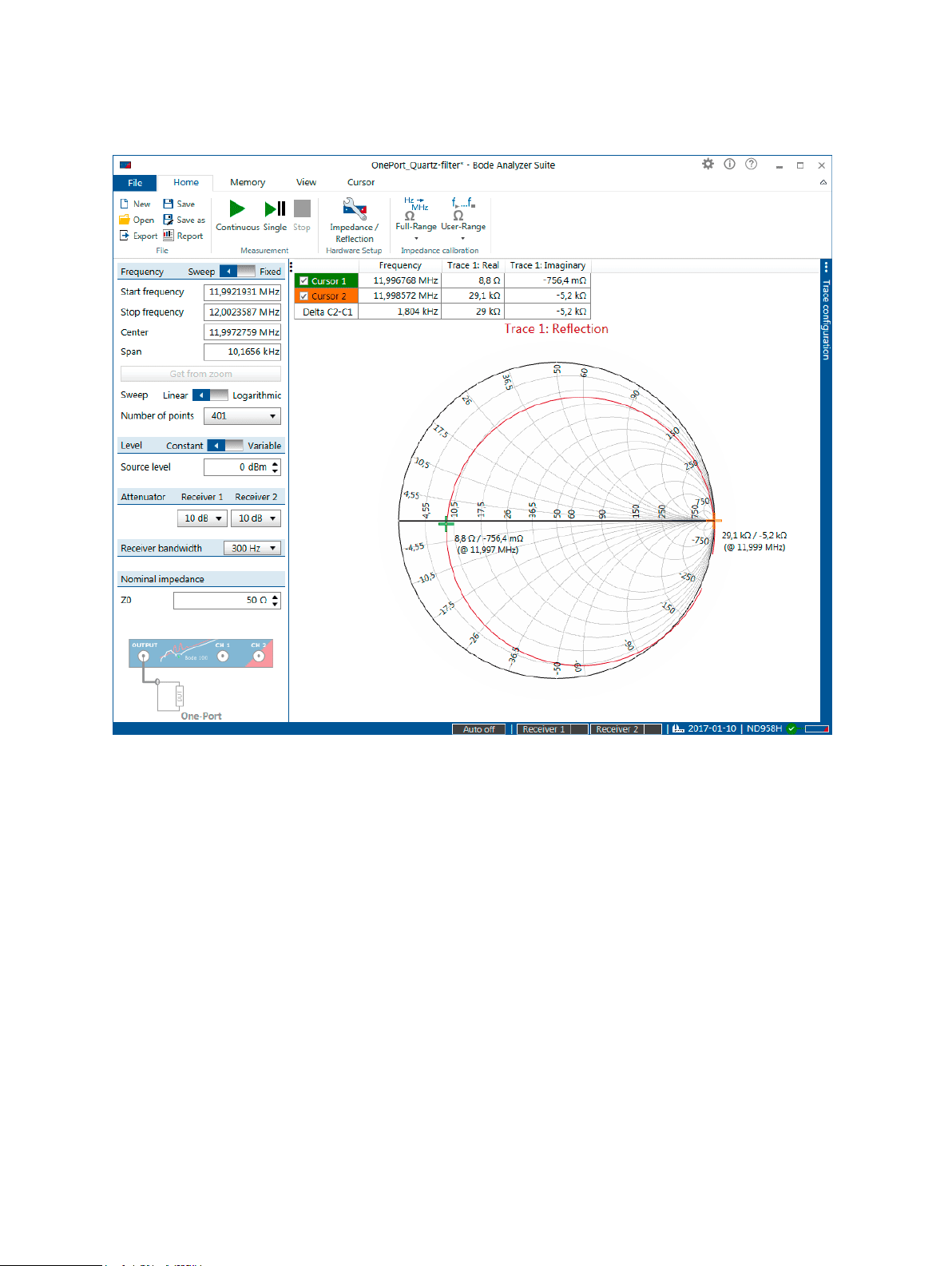

Now let's have a look at the measurement result:

Figure 7-10: Series and parallel resonance frequency of the quartz filter

To determine the series and parallel resonance frequencies check out the cursor grid as shown in

7-8 on page 54:

• Series resonance frequency (Cursor 1 - green): 11.996768 MHz

• Parallel resonance frequency (Cursor 2 - orange): 11.998572 MHz

• Offset between the series and parallel resonance frequency (Delta C2-C1): 1.8 kHz

Your measurement results can be slightly different since each quartz filter behaves a little bit

different.

One characteristic of resonance frequencies is that the inductances and capacitances compensate

each other. This means that at the series and parallel resonance the impedance of our quartz filter

should be purely resistive. An elegant way to check this is to display the quartz filters reflection curve

as a Smith chart.

56

OMICRON Lab

Measurement types and applications

Smith charts were developed at a time when it was still difficult to directly measure the frequency

swept impedance of measurement objects. The Smith chart is used to determine the impedance at a

certain point of the reflection curve. To display the Smith chart of our quartz filter's impedance apply

the settings shown below to Trace 1:

After applying the settings a smith chart like the one shown below will be displayed:

OMICRON Lab

57

Figure 7-11: Smith chart of the 12 MHz Quartz Filter

As you can see both cursors are very close to the horizontal (=resistive) axis of the Smith chart.

However, you can also see that the imaginary part for both measurements is not exactly 0 Ω. The

reason for this is the chosen number of frequency points and the frequency resolution resulting from it.

Fell free to use more points and zooming to determine the exact frequencies at which the imaginary

part of the impedance becomes 0 Ω

Congratulations you have performed your impedance measurement with the Bode 100. You can

load the settings for the measurement by clicking File → Open → and then navigating to:

"%APPDATA%\OMICRON Lab\Bode Analyzer Suite\Demo Files\".

The file you will need is: OnePort_Quartz-Filter.bode3.

58

OMICRON Lab

Measurement types and applications

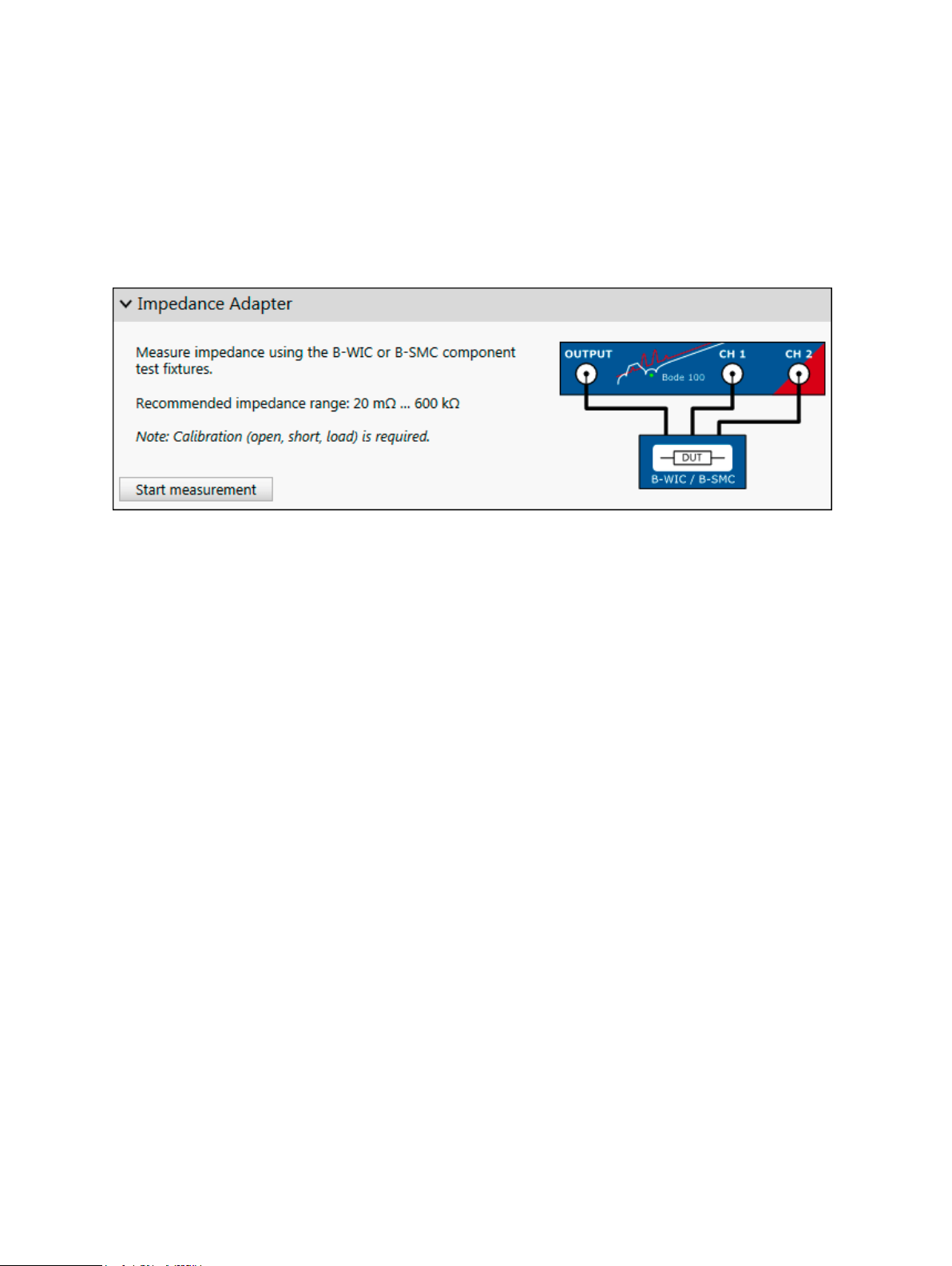

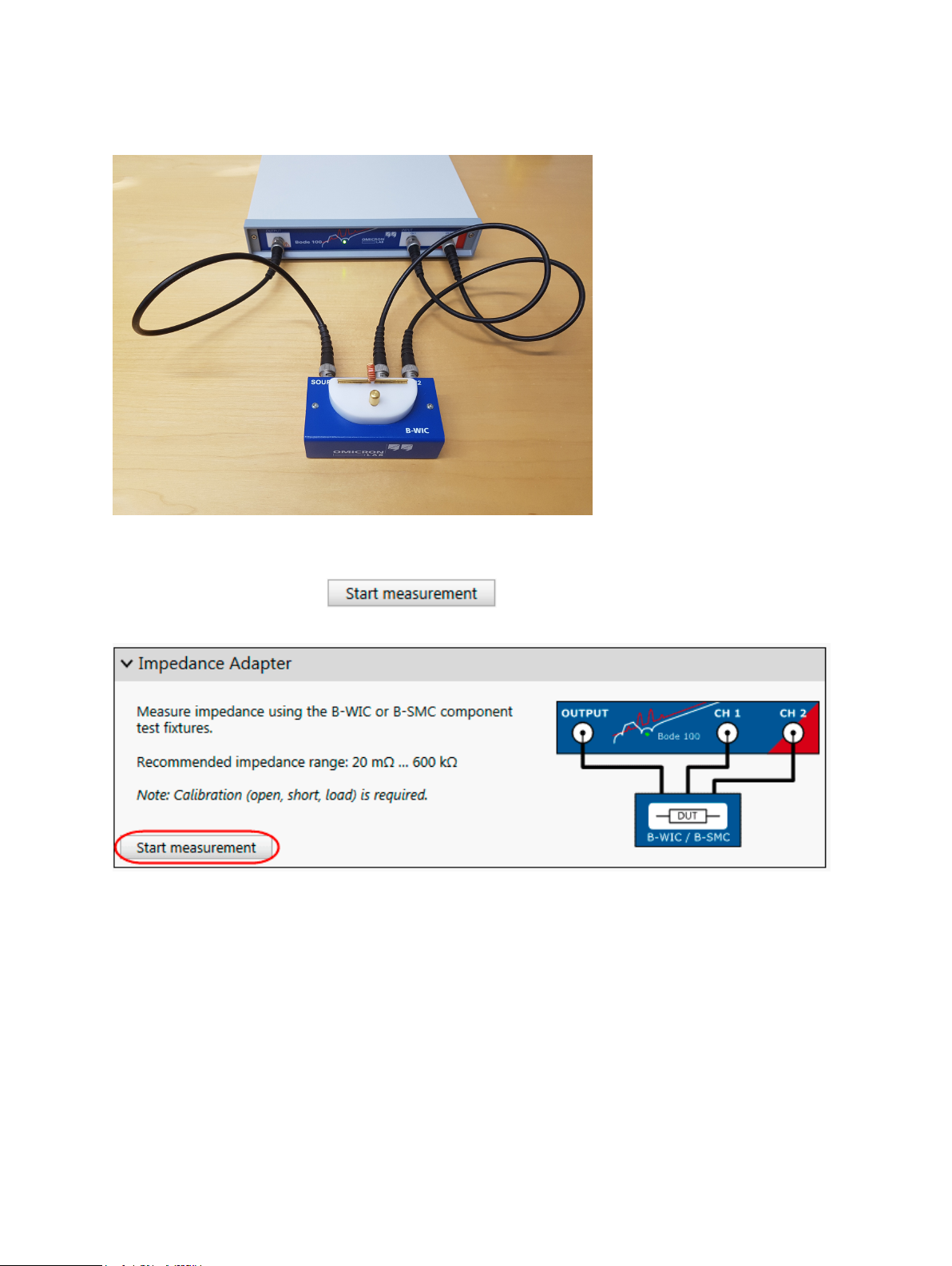

7.4.2 Impedance Adapter

The impedance adapter measurement mode is especially designed for measurements with the

OMICRON Lab impedance test fixtures B-WIC and B-SMC. The impedance adapter measurement

mode ensures that Bode 100 is configured correctly to achieve best results when measuring with both

B-WIC and B-SMC.

Calibration

The impedance adapter measurement mode requires impedance (open, short, load) calibration.

For more details on how to calibrate the B-WIC or B-SMC impedance adapter, please refer to

8.3.3 Calibrating an Impedance Adapter measurement on page 82.

Measurement information

With B-WIC and B-SMC, the dynamic range of both input channels is used. This widens the usable

impedance measurement range to 20 mΩ to 600 kΩ.

It is recommended to use the 0.5 m BNC cables delivered with Bode 100 to connect B-WIC or B-SMC

to the Bode 100.

B-WIC and B-SMC are designed to measure physically small DUTs. Stray-fields between the DUT and

the grounded housing of the impedance adapters might introduce a systematic measurement error.

The error is negligible when measuring physically small objects. To measure physically big DUTs it is

recommended to use a grounded measurement configuration such as shown in 7.2.1 One-Port on

page 49.

Typical applications

Typical applications for the impedance adapter measurement mode are:

• Measuring impedance of capacitors, inductors and other passives (THT and SMC).

• Measuring impedance piezo-elements or quartz elements.

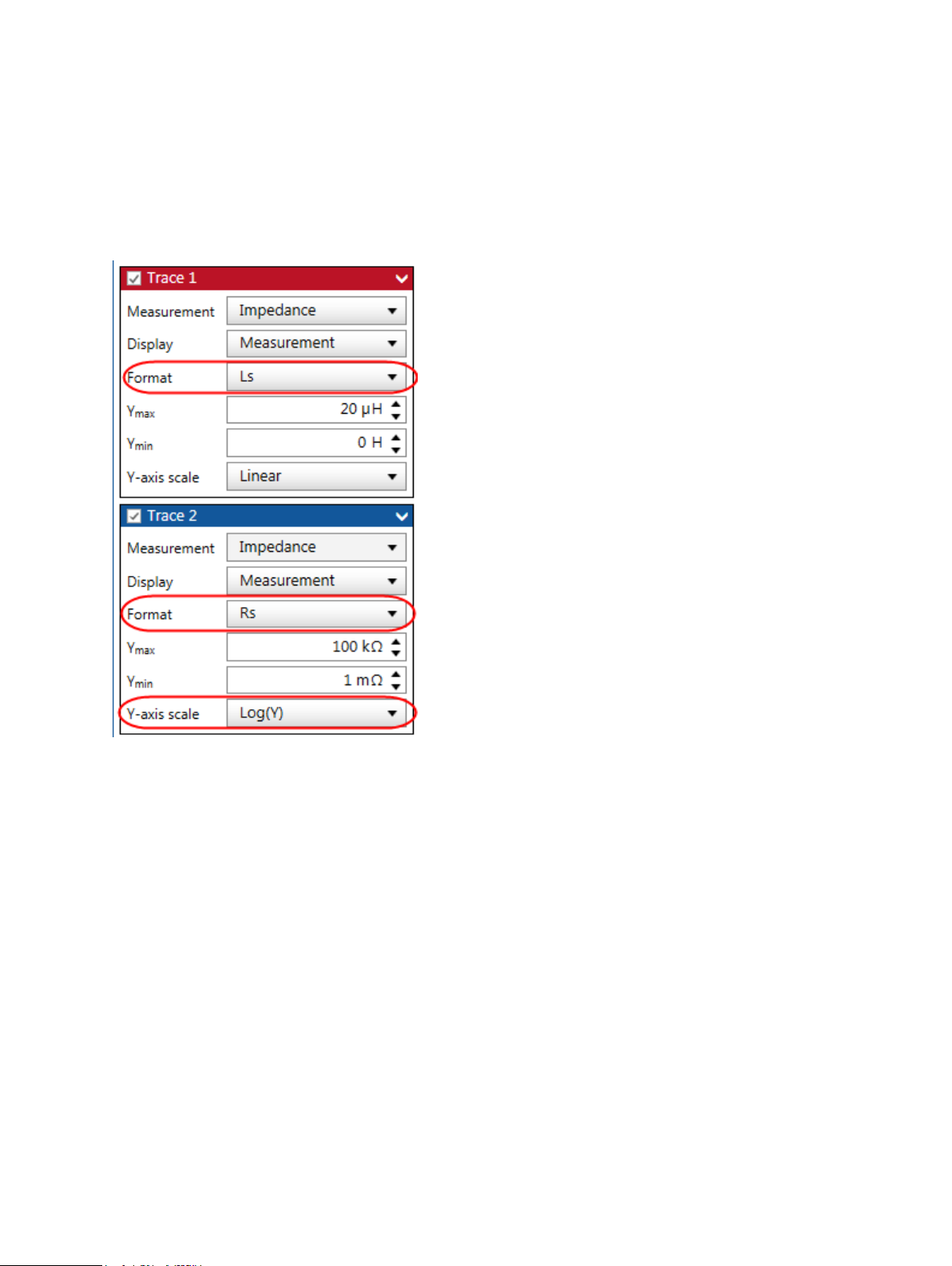

Impedance Adapter measurement example

In this measurement example we will determine the inductance (Ls) and the equivalent series

resistance (Rs) of an inductance with the B-WIC impedance measurement adapter for through-holetype components. Connect the B-WIC to Bode 100 using three BNC cables as shown below.

OMICRON Lab

59

Figure 7-12: Connecting the B-WIC to Bode 100

Now start the Bode Analyzer Suite and enter the Impedance Adapter measurement mode by clicking

Impedance Analysis and then .

Before you can start a measurement you have to perform a Full range calibration. To do so please

follow the steps described in Impedance Adapter Calibration on page 82.

After having performed the calibration please put the inductor you want to measure into the

impedance measurement adapter as shown in 7-12 on page 60.

Since it is not known in what frequence range the examined inductor is working please change the

stop frequency to 50 MHz.

60

OMICRON Lab

Measurement types and applications

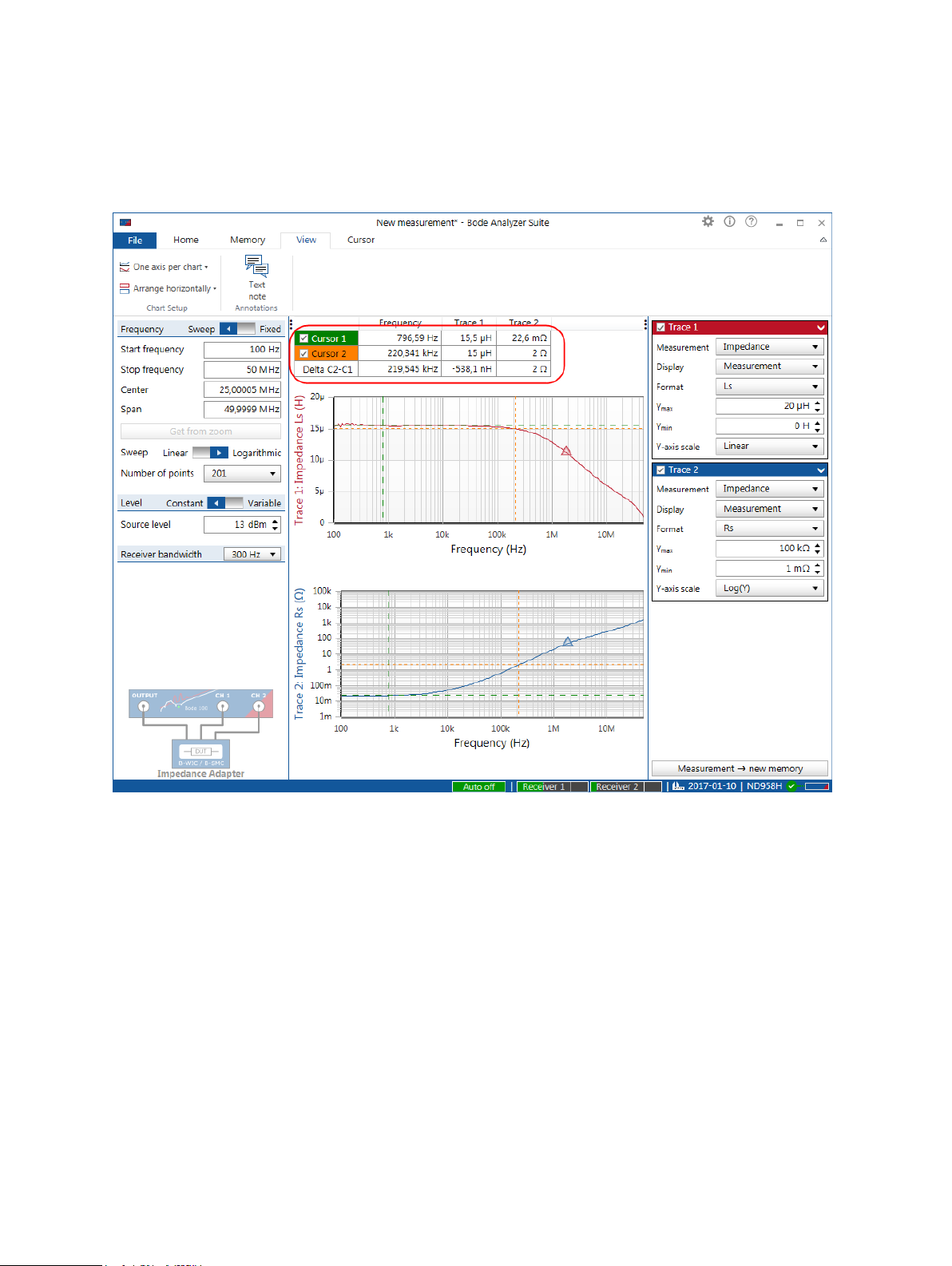

Now click in the home ribbon. As a result you will see a first measurement comparable to the one

shown in the figure below. For sure your result will look different since you are using a different

inductor.

Figure 7-13: Impedance measurement of an Inductor

OMICRON Lab

61

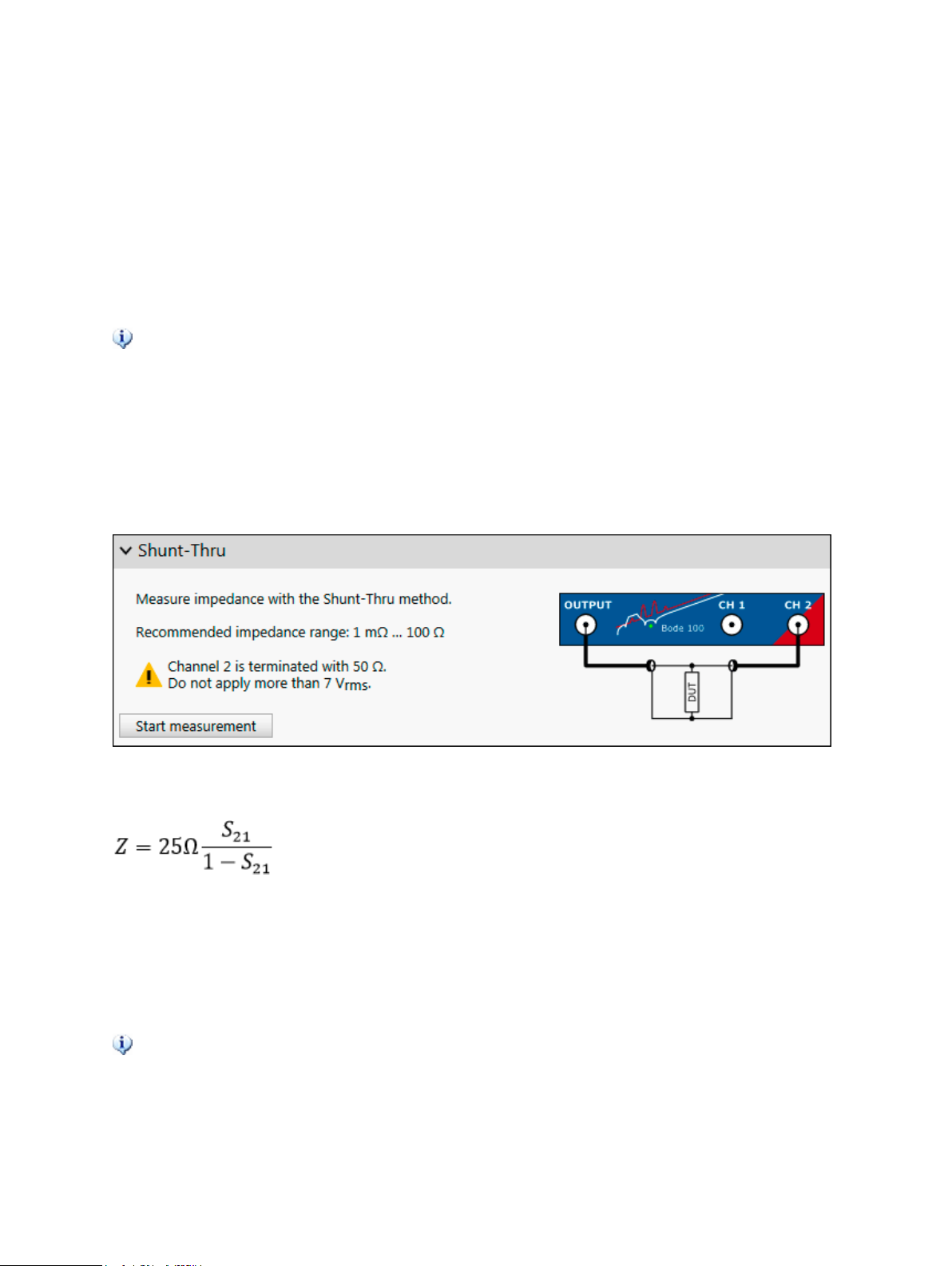

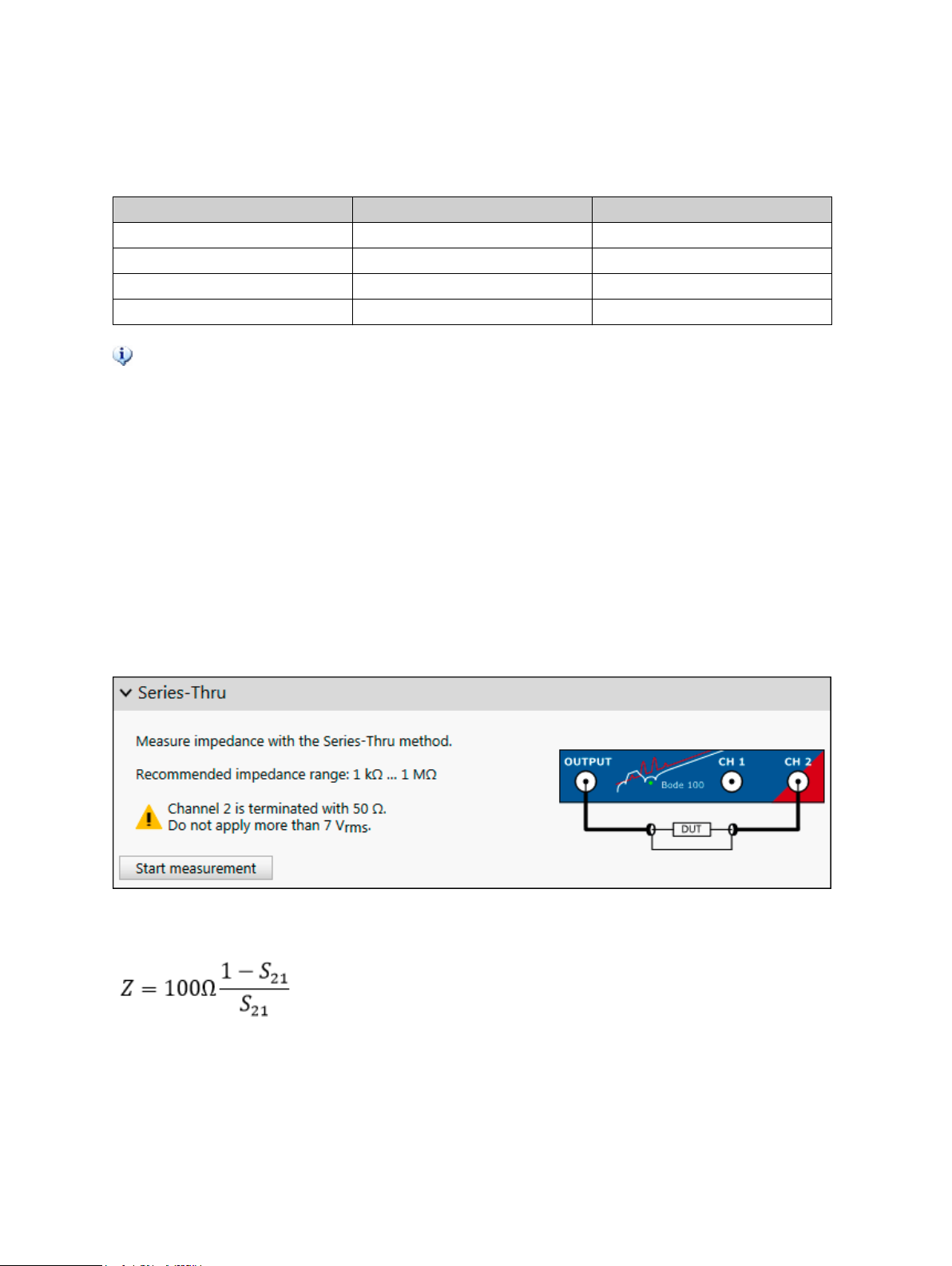

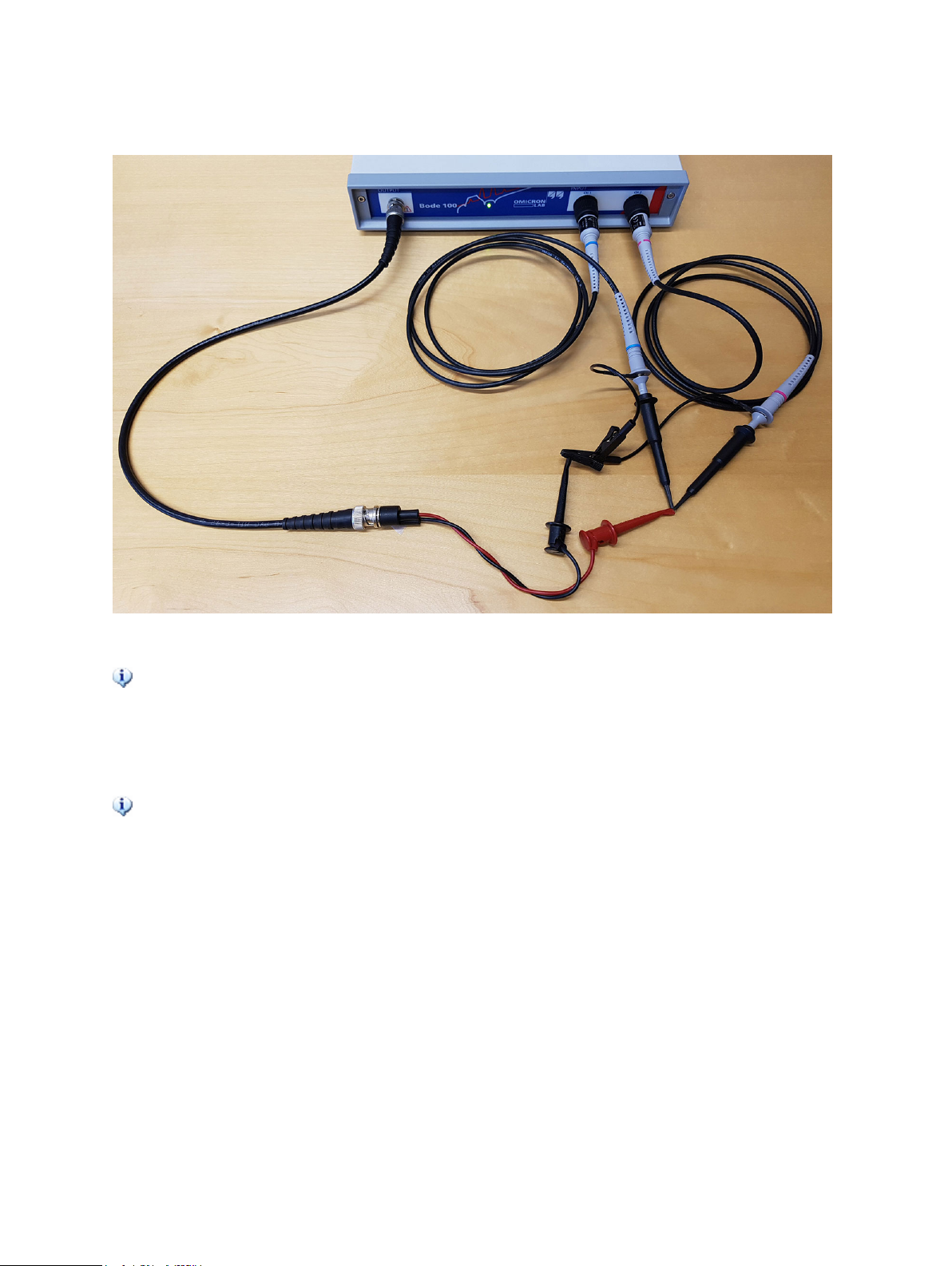

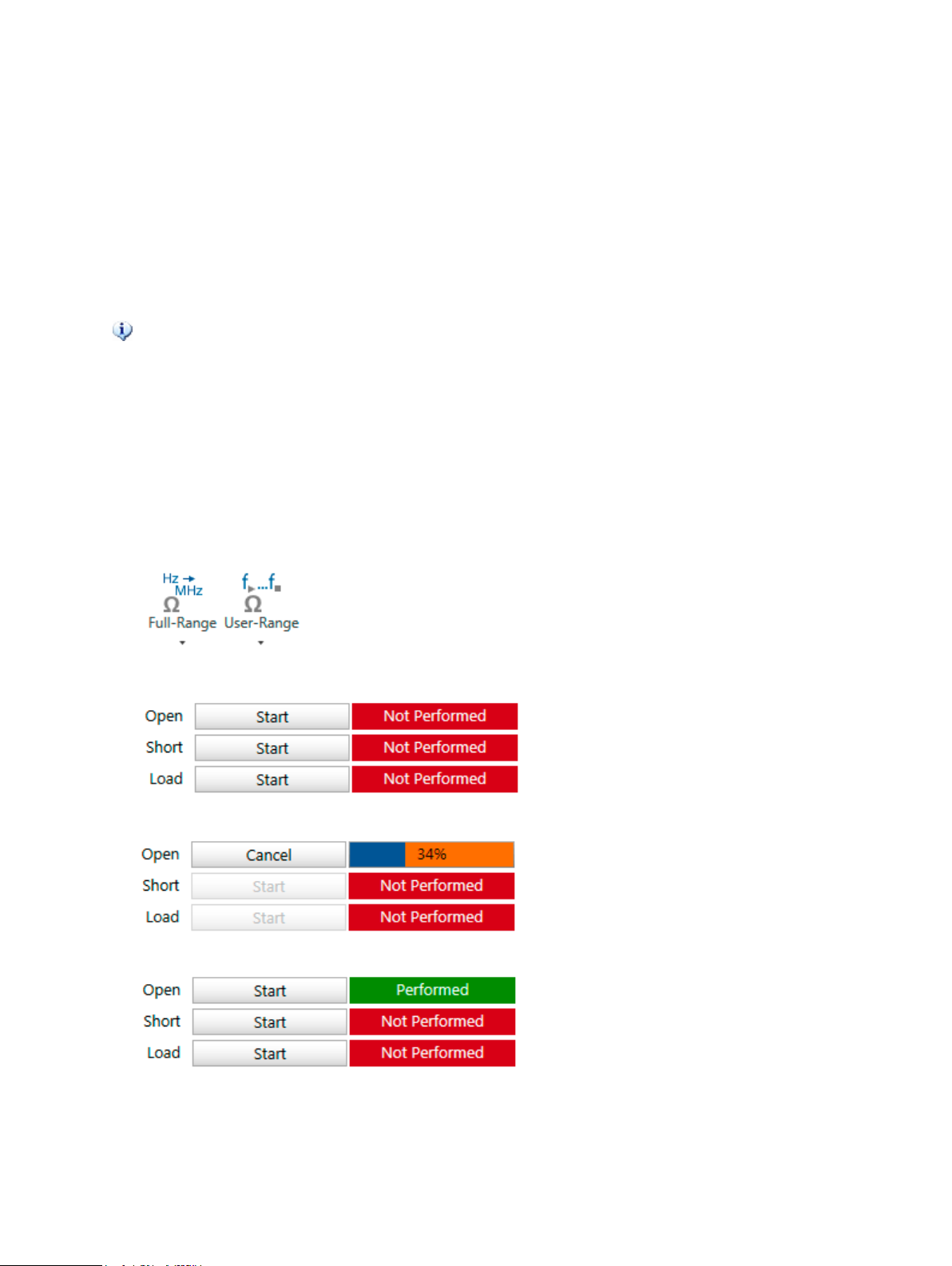

Trace 1 (red curve) shows the Magnitude of the inductor's impedance while Trace 2 (blue curve)