Page 1

Page 2

Page 3

CONTENTS

1. Introduction --------------------------------------------------------------- 2

2. Specifications (Turbine)------------------------------------------------- 3

3. Specifications (Transmitter)-------------------------------------------- 4

4. Model Number------------------------------------------------------------ 5

5. Principal of Operation--------------------------------------------------- 6

Signal Transmitter ------------------------------------------------------- 7

Material Selection and Construction ---------------------------------- 8

Flowmeter Calibrations ------------------------------------------------- 8

6. Installation----------------------------------------------------------------- 9

7. Transmitter Wiring -----------------------------------------------------11

Flowmeter Input -------------------------------------------------------- 12

Analog Output----------------------------------------------------------- 13

Alarm Output------------------------------------------------------------ 14

RS232 Communications Port------------------------------------------ 16

8. Maintenance and Troubleshooting-----------------------------------17

Pickup Coil Testing----------------------------------------------------- 17

Bearing Testing --------------------------------------------------------- 17

Bearing Replacement--------------------------------------------------- 18

9. Communication Protocols ---------------------------------------------19

Message Format and Timeout----------------------------------------- 19

Messages----------------------------------------------------------------- 21

-1-

Page 4

1. Introduction

The following information is provided for the proper installation and

maintenance of your instrument.

-2-

Page 5

2. Specifications (Turbine)

Over-range: 150% of maximum flow (intermittently)

Turn Down Range: Dependent on gas density at user’s operating

conditions.

Linearity: ±1% of reading typical

Repeatability: ±0.25% of reading over repeatable range

Temperature Range: -157 to 150 C (-250 to 300 F)

End Fittings: Standard: NPT

Optional: MS flared and flanged styles

Bearing Styles: Self lubricating, ceramic hybrid ball bearings

Materials: 316/316L dual rated stainless steel with

17.4 pH rotor.

Consult OMEGA Flow Engineering

for other available materials.

-3-

Page 6

3. Specifications (Transmitter)

Input Signal Type: MCP pickup

Input frequency range: 0.2 Hz to 4 KHz

Signal level: 10 mV rms to 30 Vdc

Power supply: 13-30 Vdc, 50mA max, reverse polarity protection

100-240 Vac, (optional)

Analog Output: 4 to 20mA, 1 to 5V, (dip switch selectable)

24mA overflow condition

Load resistance: Max 650 Ω at 24 Vdc

Accuracy: ±0.02% of full scale

Temperature drift: 40 ppm °C

Pulse output: 0 to 5V

Recommended Minimum

Load Resistance: 50kΩ

Pulse Scaling: Divide by 1, 10, 100 per flow unit of measure

Hi/Lo Alarm (Optional): Relay (2A, 30 Vdc), 0 to 5V, Open

Collector (0.5A, 30 Vdc)

Communications RS232 port for configuration and diagnostics

Linearization: Up to 20 points

Operating temperature: -40 to 85

o

C (-40 to 185CoF)

Humidity: 0 to 90% non-condensing

Enclosure: Explosion-Proof

FM: Class I, Div. 1, Gr. ABCD

Class II/III, Div. 1, Gr. EFG

CSA: Class I, Div. 1, Gr. ABCD

Class II, Div 1, Gr. EFG, Class III

Type 4X

Ex d IIC, Class I, Zone 1, IP 66

ATEX: Ex II 2GD Ex d IIC

IEC: Ex d IIC IP68

Regulatory: CE compliant

-4-

Page 7

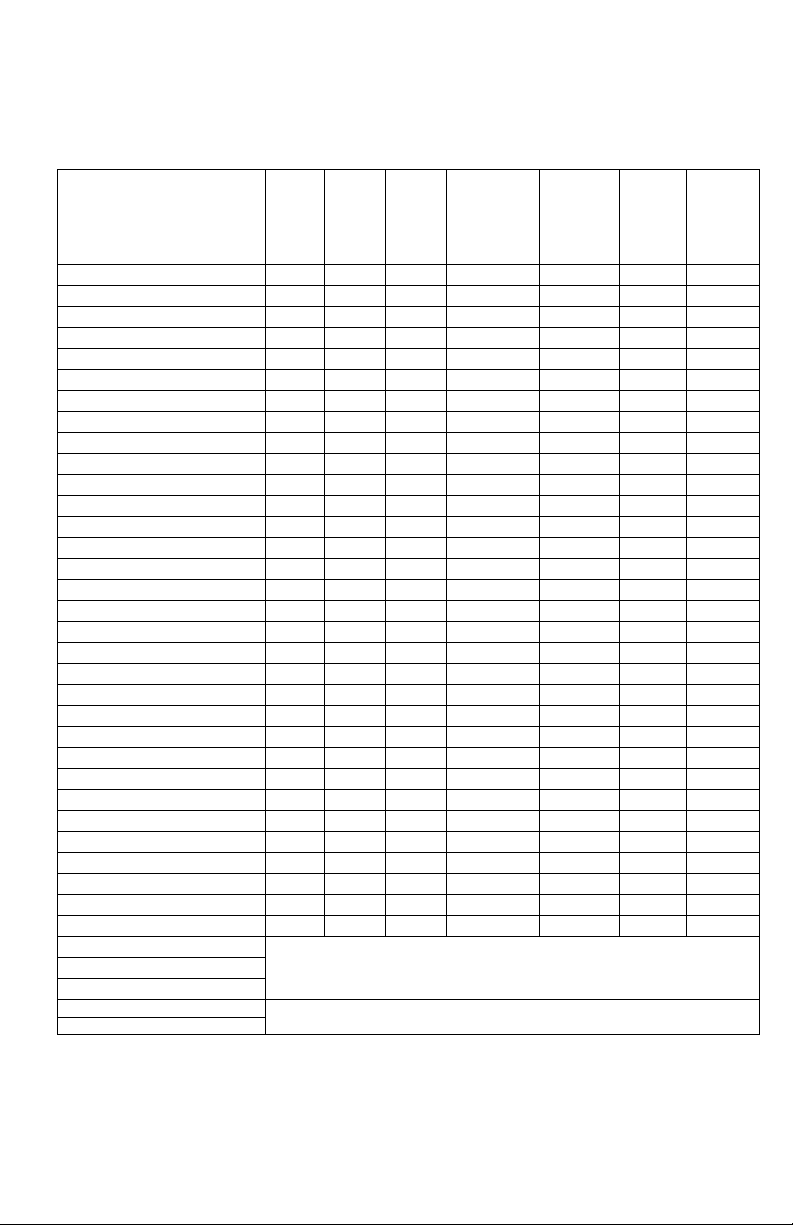

4. Model Number

Press.

Omega

Model Number

SYS/FTBG-101/FLSC-C3 1/4 1/2 30° 0.3-1.6 .13-1.6 0.1 0.5

SYS/FTBG-102/FLSC-C3 1/4 1/2 15° 0.65-3.5 .35-3.5 0.02 0.1

SYS/FTBG-103/FLSC-C3 3/8 1/2 30° 0.6-2.3 .27-2.3 0.1 0.5

SYS/FTBG-104/FLSC-C3 3/8 1/2 15° 1.3-5 .6-5 0.02 0.1

SYS/FTBG-105/FLSC-C3 5/8 3/4 30° 1-4.4 .45-4.4 0.1 0.5

SYS/FTBG-106/FLSC-C3 5/8 3/4 15° 2.17-9.5 1-10 0.025 0.125

SYS/FTBG-107/FLSC-C3 3/4 3/4 30° 1.2-9.2 .54-9.2 0.1 0.5

SYS/FTBG-108/FLSC-C3 3/4 3/4 15° 2.6-20 1.2-20 0.02 0.1

SYS/FTBG-109/FLSC-C3 1 1 30° 1.6-20 .72-20 0.2 1

SYS/FTBG-110/FLSC-C3 1 1 15° 3.5-43 1.6-43 0.04 0.2

SYS/FTBG-111/FLSC-C3 11/2 11/2 30° 3.5-55.5 1.6-55.6 0.15 0.75

SYS/FTBG-112/FLSC-C3 11/2 11/2 15° 7.6-120 3.5-120 0.035 0.175

SYS/FTBG-113/FLSC-C3 2 2 30° 7-93 3.1-93 0.3 1.5

SYS/FTBG-114/FLSC-C3 2 2 15° 15-200 7-200 0.0625 0.3125

SYS/FTBG-115/FLSC-C3 3 3 30° 15-363 6.7-363 0.4 2

SYS/FTBG-116/FLSC-C3 3 3 15° 35-600 15-600 0.1 0.5

SYS/FTBG-101/FLSC-C3-AL 1/4 1/2 30° 0.3-1.6 .13-1.6 0.1 0.5

SYS/FTBG-102/FLSC-C3-AL 1/4 1/2 15° 0.65-3.5 .35-3.5 0.02 0.1

SYS/FTBG-103/FLSC-C3-AL 3/8 1/2 30° 0.6-2.3 .27-2.3 0.1 0.5

SYS/FTBG-104/FLSC-C3-AL 3/8 1/2 15° 1.3-5 .6-5 0.02 0.1

SYS/FTBG-105/FLSC-C3-AL 5/8 3/4 30° 1-4.4 .45-4.4 0.1 0.5

SYS/FTBG-106/FLSC-C3-AL 5/8 3/4 15° 2.17-9.5 1-10 0.025 0.125

SYS/FTBG-107/FLSC-C3-AL 3/4 3/4 30° 1.2-9.2 .54-9.2 0.1 0.5

SYS/FTBG-108/FLSC-C3-AL 3/4 3/4 15° 2.6-20 1.2-20 0.02 0.1

SYS/FTBG-109/FLSC-C3-AL 1 1 30° 1.6-20 .72-20 0.2 1

SYS/FTBG-110/FLSC-C3-AL 1 1 15° 3.5-43 1.6-43 0.04 0.2

SYS/FTBG-111/FLSC-C3-AL 11/2 11/2 30° 3.5-55.5 1.6-55.6 0.15 0.75

SYS/FTBG-112/FLSC-C3-AL 11/2 11/2 15° 7.6-120 3.5-120 0.035 0.175

SYS/FTBG-113/FLSC-C3-AL 2 2 30° 7-93 3.1-93 0.3 1.5

SYS/FTBG-114/FLSC-C3-AL 2 2 15° 15-200 7-200 0.0625 0.3125

SYS/FTBG-115/FLSC-C3-AL 3 3 30° 15-363 6.7-363 0.4 2

SYS/FTBG-116/FLSC-C3-AL 3 3 15° 35-600 15-600 0.1 0.5

FLSC-C1-LIQ

FLSC-C3-LIQ

FLSC-C3-AL-LIQ

FLSC-C3

FLSC-C3-AL

Meter

Fitting

Size

Size

For use with FTB liquid turbines 1" riser, to be phased in as replacements

for FLSC-18, FLSC-28, FLSC-34, FLSC-35 and FLSC-51 series.

Replacement signal conditioner ONLY for gas turbine system 3/4" riser.

Blade

Angle

0.05#/FT3

Range

ACFM

0.25#/FT

3 Range

ACFM

Drop

(PSID)

0.05#

/FT3

Press.

Drop

(PSID)

@

@

0.25#

/FT3

-5-

Page 8

5. Principal of Operation

Omega Engineering Turbine Flowmeter includes integrally mounted

microprocessor-based signal transmitter. The transmitter is mounted in

an explosion proof enclosure.

Pickup Coil

Riser

(Threaded)

Flowmeter

Housing

Flow

Straightener

Deflector

Cones

The turbine flow sensor consists of a rotor assembly which is supported

on a shaft held in place by triple tube clusters and secured with locking

nuts within the flowmeter housing.

The rotor is free to spin on a self lubricated ceramic ball bearing. A

modulated carrier pickup coil (MCP) is attached on the exterior of the

flowmeter housing.

A low mass rotor design allows for rapid dynamic response. The

deflector cones eliminate downstream thrust on the rotor and allows for

dynamic positioning of the rotor between deflector cones.

The dynamic positioning of the low mass rotor provides wider

rangeability and longer bearing life than that of conventional turbine

flowmeters. Integral flow straightening tubes minimize the effects of

upstream flow turbulence.

As the gas flows through the flowmeter the rotor spins at rate

proportional to the volumetric gas flowrate.

Each rotor blade passing through the pickup coil generates an electrical

pulse. The frequency of the pulses is proportional to flowrate. The

summation of pulses represents total amount of gas volume passed

through the meter.

-6-

Page 9

The number of pulses generated per cubic foot is called the calibration

factor or K-Factor. This calibration factor is programmed into the

electronic transmitter to calculate correct flowrate.

The MCP pickup is a type of coil which eliminates pickup drag and

requires a Modulated Carrier Signal Conditioner circuit. The MCP

works on a principle where the motion of the rotor modulates a high

frequency signal. The conditioner demodulates, filters, amplifies, and

shapes the resulting signal prior to sending it to the microcontroller.

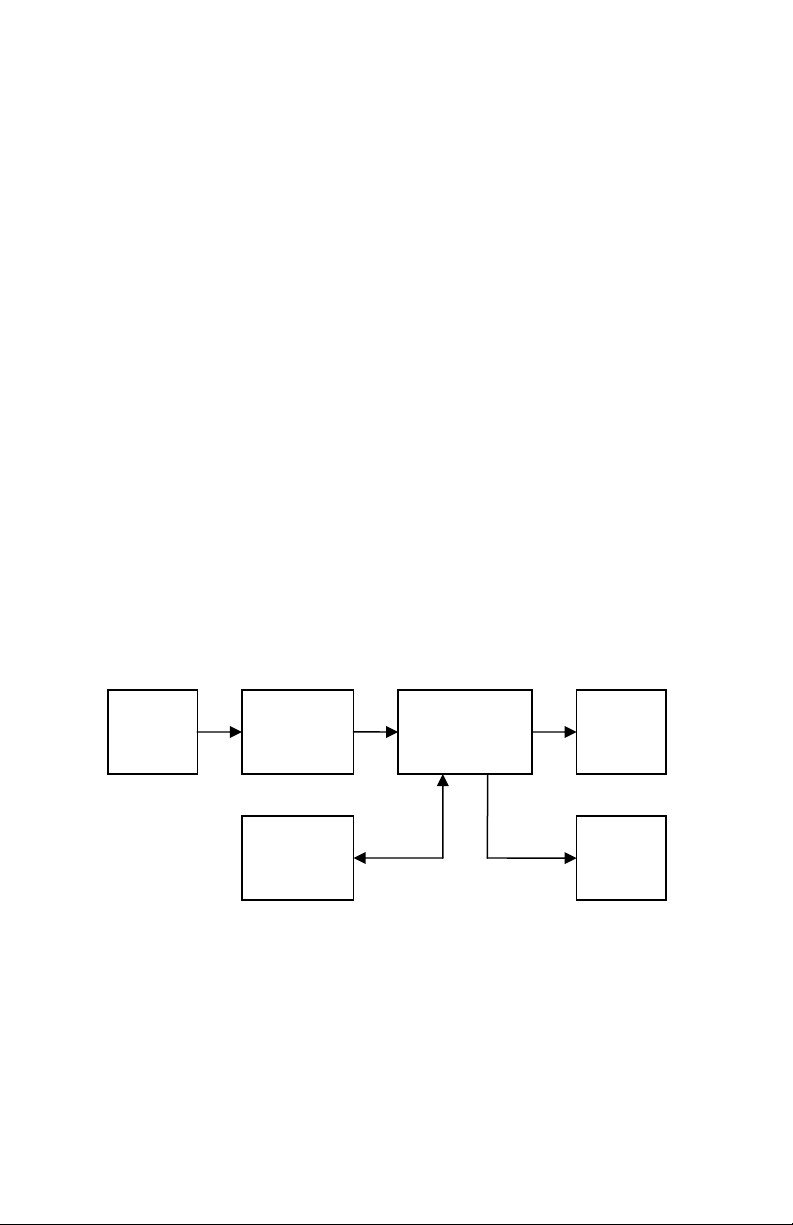

Signal Transmitter

The transmitter is a DC or AC powered microprocessor-based unit,

which provides a 0 – 5 V, TTL/CMOS pulse output, a 4 to 20 mA

analog output and optional High/Low flow alarm output. Optional 20point linearization is available to correct for flowmeter non-linearities,

improving overall system accuracy.

An RS232 communications port is located under the top plate of the

transmitter. It allows unit to be configured using a Windows based

program included with the unit. Configuration and remote monitoring

may also be performed using any PC based communications program

(e.g., HyperTerminal) or ASCII terminal.

Pickup

Coil

Amplifier Microprocessor

RS232

Port

Signal Transmitter Block Diagram

-7-

Pulse

Output

Analog

Output

Page 10

Material Selection and Construction

The housing is made of 316 stainless steel. The rotor is made of 17.4

pH stainless steel. Bearings are shielded, ceramic hybrid ball bearings

and are made of 440C stainless steel. Bearings are self lubricating type

and do not require any external lubrication.

Flowmeter Calibrations

The standard calibration provided with an Omega gas turbine

flowmeter consists of a 10-point water calibration that is traceable to

NIST. Based on this water calibration, we derive an average k-factor

for water for the flowmeter. The average k-factor for water is then

converted to ACF by using the following equation.

K-Factor / .134 = pulses/ACF

The uncertainty of this calibration methodology is +/-2%

The gas flowmeters are optionally available with actual gas calibrations

at an additional charge. The uncertainty of an actual gas calibration is

+/-0.5%. Actual gas calibrations are generally recommended for

custody transfer (billing) applications.

The k-factor on turbine flowmeters used on gas service is NOT density

dependent. The flowmeter “turndown” range is density dependent.

The higher the operating density; the better the flow turndown range is

on any Omega gas turbine flowmeter.

-8-

Page 11

6. Installation

Inspect all packages for any indications of damage which may have

occurred during shipment.

Verify that all meter parts or auxiliary components have arrived with

the shipment. Refer to the packing list/invoice for a detailed list of

items included in the shipment.

The flowmeter should be installed horizontally for proper operation.

It is required to install meter with a minimum straight run of pipe

approximately 10 pipe diameters ahead of the inlet and 5 pipe

diameters following the outlet.

The meter housing is marked by a flow direction arrow and the inlet is

marked ‘IN’ and the outlet is marked ‘OUT’. The meter must be

installed in the piping in the correct orientation to ensure the most

accurate and reliable operation.

Install meter with adequate distance and isolation from electric motors,

transformers, welding equipment and solenoids to avoid any

electromagnetic interference from ambient electrical field.

-9-

Page 12

A typical flowmeter installation is shown below:

BYPASS RUN

Bypass Valve

Flow Straighener

Turbine FlowmeterStrainer

METER RUN

Blocking ValveBlocking Valve

Figure 1: Typical Flowmeter Installation

Blocking and Bypass valves should be installed if it is necessary to do

preventive maintenance on the flowmeter without shutting down the

flow system. The Bypass valve can be opened before the Blocking

valves allowing the flow to continue while removing the turbine

flowmeter for service.

IMPORTANT: All flow lines should be purged prior to installing the

meter. To prevent possible damage to the meter, install the

meter ONLY in flow lines that are clean and free of debris.

Upon initial start-up of the system a spool piece should be installed in

place of the flowmeter so that purging of the system can be performed

to remove all particle debris which could cause damage to the meter

internals.

CAUTION: Avoid over-spinning the meter. Over-spinning the meter

may cause damage to the meter internals and lead to

needless meter failure.

-10-

Page 13

N/CN

P

-

N/CA

S

SIG-+ DC+DC-- P

DC-

DC+SIG-

P

-

N/CN/CP

S

A

N

L1L

7. Transmitter Wiring

Shielded cables are recommended for all input and output signals. The

shield should be connected to the earth ground lug on the transmitter.

The shield on the opposite end of the cable should be left unconnected.

This wiring practice is required for electromagnetic compatibility, as per

EMC-Directive 89/336/EEC of the Council of European Community.

DC Power Supply (13-30 VDC)

IG+

DC

POWER

SUPPLY

AC Power Supply (100-240 VAC)

AC power for TRANSMITTER requires an optional circuit board, PCA182. The

Alarm option (PCA184) is not available when the AC Power option is equipped.

IG+

NLG

ULSE+

ULSE

/C

2

NLG

ULSE+

ULSE

/C

NEUTRAL

PLUG AC MALE

HOT

-11-

Page 14

A

N/CP

-

N/CN/CS

A

SIG-

DC+

DC-

P

N/CP

-

N/CN/CS

A

SIG-

DC+DC-

P

Flowmeter Input

B

C

Modulated Carrier Pickup (RF)

IG+

NLG

ULSE+

ULSE

1

DIP switch settings for

MCP pickup coil

PCA180

SW1

The flowmeter input is wired at the factory and does not require user

wiring.

Pulse Output (0-5V)

USER DCS

PULSE

INPUT

+

-

IG+

NLG

ULSE+

ULSE

1

Pulse Output option that is scaled according to the least significant digit

of the internal total amount. A scaling factor of 1, 10 or 100 is available

to reduce or increase the resolution of the pulse output. For example, if

the Total Decimal Point is set to 0000000.0, and the Pulse Scale is 1, then

1 pulse will be output for each tenth (0.1) of a unit of measure. Changing

the Pulse Scale to 10, would result in an output pulse for each 1.0 unit of

measure. The output must be scaled so that the pulse frequency does not

exceed the Pulse Frequency setting (100 Hz. Max) at the maximum flow

rate

DIP switch settings for

0-5V pulse output

PCA180

SW2

-12-

Page 15

Analog Output

DC

POWER

+

DC+

DCSIG+

SIGANLG

PULSE+

+

PULSEN/C

N/C

N/C

SUPPLY

LOAD

1

PCA183, SW1

4–20 mA Output

Analog Output is proportional to the flow rate. Default settings are

4mA (1V) at zero flow and 20mA (5V) at max flow rate of the turbine.

1

PCA183, SW1

1-5 V Output

The following equations are used to compute the flow rate and analog

output current.

Where:

flowrate

frequency

Kfactor

Kfactor = Is dependent on the Flow Calculation Method setting and

is either the Average K-Factor or the Linearized K-Factor

from the Frequency / K-Factor table.

FM = Is the Flow rate Units setting of 0, 1, or 2. Where “0” is

For Seconds, “1” is for Minutes, and “2” is for Hours.

CF = Is the Correction Factor setting.

Where:

AF = Is the 20 mA maximum Flow rate value.

mAxmAcurrent 164

FM

60

flowrate

xCFx

AF

-13-

Page 16

If the calculated flowrate is greater than the AF setting, the current

will be set to 24mA to indicate an “Over-range” condition.

The analog output response time to reach steady state due to a change

in the flow rate is approximately 0.25 seconds. When flow stops, the

time for the analog output to return to 4 mA will be between 3 and 12

seconds, depending on the Maximum Sample Time (MST) setting.

MST is adjusted using the NB= (DATA) command, where NB is a

value between 1 and 80. The default MST setting is NB= 1. Adjusting

the MST is only recommended for low flow applications where the

minimum input frequency is below 1 Hz.

Alarm Output

Optional High/Low Flow Alarm feature requires an optional circuit

board, PCA184. The Alarm option is not available when the AC

Power option is equipped.

Hi/Lo Alarm (Relay)

DC+

DCSIG+

SIGANLG

PULSE+

PULSEN/C

N/C

N/C

NC1

COM1

NO1

High/Low-Nomally Closed

High/Low-COM

High/Low-Nomally Open

1

DIP switch settings

PCA184

SW1

for relay alarm

-14-

Page 17

Hi/Lo Alarm (0-5V)

DC+

DCSIG+

SIGANLG

PULSE+

PULSEN/C

N/C

N/C

ALARM1

COM

USER DCS

+

Alarm

Indicator

-

1

DIP switch settings for 0-5V alarm

PCA184

SW1

Hi/Lo Alarm (Open Collector)

V+

USER DCS

2.7K

DC+

ALARM1

DCSIG+

SIGANLG

PULSE+

PULSEN/C

N/C

N/C

COM

+

-

Alarm

Indicator

1

PCA184

DIP switch settings

for open collector alarm

SW1

-15-

Page 18

RS232 Communications Port

The RS232 serial port connector is located under the top plate of

transmitter and may be accessed by removing the two screws from the

top plate. A matching connector is provided with Communications

Cable supplied with transmitter.

Transmitter unit has to be powered from external supply in order to be

able to communicate. Additional power for TRANSMITTER

communication circuitry is supplied by the RS232 serial port of the

computer/terminal.

COM port settings must be set as follows:

Baud Rate: 2400

Data Bits: 8

Parity: None

Stop bits: 1

Handshaking: None

Communications Cable

CD 1

Rx 2

Tx 3

DTR 4

SIG COM 5

DB9

6 DSR

7 RTS

8 CTS

9 NC

VDC1

VDC2

-16-

Pin 1

Molex

0511100660

or

Equivalent

Pin 2

Page 19

8. Maintenance and Troubleshooting

Pickup Coil Testing

Testing the MCP pickup coil requires measuring the resistance with an

ohmmeter.

1. Measure the resistance between pin A and pin B. The resistance

should be approximately 11.5 10% Ohms.

2. The resistance from any pin to the case should be greater than 1

mega Ohm.

If either resistance measurement fails, replace the pickup coil. When

installing a coil, make sure to firmly seat the coil in the flowmeter

housing.

Bearing Testing

It is recommended that the shielded, self lubricating ceramic ball

bearings be checked periodically for wear. The cleanliness of the gas

affects the life expectancy of the bearings.

It is recommended that the bearings be replaced if any signs of wear are

apparent. An unexplained shift in the output accuracy could be a sign of

worn bearings.

CAUTION: If bearings are allowed to operate without replacement at

the recommended interval, the accuracy of the device may

drift from the original calibration and if left long enough

severe damage to the rotor and/or internals may occur.

The shielded, self lubricating 440c SS ball bearings may be changed in

the field.

Lock N ut

Cone Shaft

Han ger/Flow Straightener

Bearing

Rotor

Figure 1 Exploded View - Flowmeter Internals

-17-

Page 20

Bearing Replacement

1. Move the flowmeter to a clean stable work surface.

2. Using two “Spin-Tite” wrenches, remove one lock nut from the shaft.

3. Place a small head stove bolt in a vise. Guide the bolt head gently

through one of the hanger/flow straightener tubes and in a smooth

firm stroke remove the hanger from the housing.

4. With the shaft placed vertically downward, carefully remove a cone,

two bearings, and the rotor.

5. Remove the other hanger in a similar manner.

6. Examine the shaft and cones for scoring. If scoring is present,

replacement is necessary.

7. Obtain new bearings of the same type from stock or the manufacturer.

Discard old bearings.

8. Reassemble one hanger in the housing with the shaft, a cone, and lock

nut.

9. Place the bearings into the rotor. Guide the bearings and rotor onto

the shaft making sure to reassemble with the “IN” side of rotor facing

the “IN” side of the housing.

10. Place the remaining cone on the shaft. Gently “rattle” the flowmeter

to seat the internals on the shaft.

11. When properly seated, gently push the hanger onto the shaft. Be sure

to properly align the hanger on the shaft. The hangers seat against a

shoulder machined into the housing.

12. Gently tighten the self-locking lock nuts until they make contact with

the spring clip hanger. “Two Finger” tight on a “Spin-Tite” is more

than adequate.

13. Holding the meter horizontally, gently blow into it (DO NOT use

compressed air). The rotor should turn freely. With a magnetic coil

the rotor should gradually slow down and then “quiver” to a stop with

one of its blades aligning with the pickup coil. With a MCP (RF) coil

the rotor should “coast” smoothly to a stop.

14. Clean the flowmeter assembly with ISOPROPYL ALCOHOL or an

alternately approved cleaning solution.

-18-

Page 21

9. Communication Protocols

Message Format and Timeout

Communication messages consist of a string of ASCII characters

terminated by a carriage return character. The maximum message length

coming to the unit is 20 characters, including the carriage return. The

unit will transmit no more than 35 characters before transmitting a

carriage return.

If a message longer than 20 characters sent, the instrument responds with

“Command Sequence is Too Long!<NL>”

If an unrecognized or invalid command is sent, the instrument responds

with

“Invalid Command! <NL>”

The

UNIT echoes all received messages and then transmits a response

string terminated with a carriage return. If the sending unit takes longer

than one minute to send a message,

the receive buffer.

If the sending unit (PC or other such device) wishes to change a setting

on the

sign (“=”) with the data following immediately after the equal sign. The

carriage return terminates the message.

UNIT, the sending unit shall follow the command with an equal

UNIT aborts the message by clearing

Any

UNIT response that sends data back to the sending unit shall have an

equal sign (“=”) followed by the data. Space is allowed between the

equal sign and the data on the return message, but the total message

length is limited to 35 characters.

READ Example:

To read the number of points that the

UNIT has in the K factor table, send

“NP<CR>”

The UNIT echoes the sent message, and responds with

“NUM PTS=2<CR>”

WRITE Example:

To change the number of points to 20 in the K factor table, the sending

unit shall send

“NP=20<CR>”

-19-

Page 22

UNIT echoes the sent message and responds with

The

“NUM PTS=20<CR>”.

The UNIT checks the ranges for data and rejects writes that are not within

the allowed range. If the sending unit sends data that is not within the

allowed range, the

value that is currently stored in the

UNIT echoes the sent message and responds with the

UNIT.

Example:

If the sending unit wishes to change the max sample time to 2000 from

the previous setting of 10, the sending unit shall send

“NB=2000<CR>”

The UNIT echoes the sent message, and responds with

“MAX M TIME=10<CR>”.

-20-

Page 23

Messages

Command Description/Allowed Data/Response

DN

FC

KD

AK

Tag Number

“0” to “99999999”

“TAG NUM = (DATA)”

The first three digits are the units code for total.

Changing these digits will change the TU settings.

Linearization

“0” = Average K factor

“1” = Linearization table

“F C METHOD = AVG” for Average K factor

or

“F C METHOD = LIN” for Linearization table

K Factor Decimal Point Location

“0” for 00000000.

“1” for 0000000.0 and all K Factors are less than

9999999.9, otherwise not allowed

“2” for 000000.00and all K Factors are less than

999999.99, otherwise not allowed

“3” for 00000.000 and all K Factors are less than

99999.999, otherwise not allowed

“K-FAC DECL=(DATA)”

Average K Factor

“0.001” to

“99999.999” if KD = 3

“999999.99” if KD = 2

“9999999.9” if KD = 1

“ 99999999” if KD = 0

“AVG KFAC =(DATA)”

NP

Number Points in the Table

“2” to “20”

“NUM PTS =(DATA)”

-21-

Page 24

Command Description/Allowed Data/Response

F##

K##

CF

TU

Frequency 1-20

F01 has a range of “0.000” to the value of F02

minus 0.001; F20 has a range of the value from F19

plus 0.001 to “5000.000”; Frequencies F02 to F19

must be 0.001 greater than the previous frequency and

0.001 less than the next frequency.

“FREQ ## =(DATA)” for F01 through F20. Data

to fixed three decimal places.

K-Factor 1-20

“K-FACT # =(DATA)” for K01 through K09.

“K-FACT ## =(DATA)” for K10 through K20.

DATA to decimal places as per KD command.

Correction Factor

“0.001” to “9999999.999”

“CORR FACT =(DATA)”

Total Units

“100” for gallons

“140” for liters

“110” for cubic feet

“150” for cubic meters

“180” for barrels

All other integer values from 0 and less than 999 will

map to custom units

“TOT UNITS =(DATA)”

(DATA) shall be:

“GAL” for gallons

“LIT” for liters

“FT3” for cubic feet

“M3 ” for cubic meters

“BBL” for barrels

“CUS” for custom

These three numbers will be the same as the first three

digits of the tag number. Changes to this menu shall

cause the changes to the tag number.

-22-

Page 25

Command Description/Allowed Data/Response

FM

NB

LF

AF

Rate Units

“0” for seconds

“1” for minutes

“2” for hours

“3” for days

“FLOW UNITS=(DATA)”

(DATA) shall be:

“SEC” for seconds

“MIN” for minutes

“HR ” for hours

“DAY” for days

Max Sample Time

“1” to “80”

“MAX M TIME=(DATA)”

Out Low

“0.000” to a maximum value of the Out High setting

“4mA FLOW =(DATA)”

Out High

Minimum is the Out Low Setting (LF) to a maximum of

the following:

“99999.999” if RD = 3

“999999.99” if RD = 2

“9999999.9” if RD = 1

“ 99999999” if RD = 0

“20mA FLOW =(DATA)”

-23-

Page 26

Command Description/Allowed Data/Response

PS

FO

UA

Pulse Scale

“0” for OFF

“1” for 1

“10” for 10

“100” for 100

“PULS SCALE=(DATA)”

(DATA) shall be:

“OFF” for OFF

“1” for 1

“10” for 10

“100” for 100

Pulse Frequency

“1”

“2”

“4”

“8”

“PULS FREQ =(DATA)”

Alarm Function

“0” for OFF

“1” for RATE

“2” for TOTAL

“ALARM FUNC=(DATA)”

(DATA) shall be:

“OFF” for OFF

“RAT” for RATE

“TOT” for TOTAL

-24-

Page 27

Command Description/Allowed Data/Response

AL

OC

PR

Alarm Out

“0.001” to a maximum defined as follows:

If UA is RATE:

“99999.999” if RD = 3

“999999.99” if RD = 2

“9999999.9” if RD = 1

“ 99999999” if RD = 0

If UA is Total or Off:

“99999.999” if TD = 3

“999999.99” if TD = 2

“9999999.9” if TD = 1

“ 99999999” if TD = 0

“ALARM OUT =(DATA)”

Current Out

“0” - Current output follows rate.

“1” - Current output set to 4mA.

“2” - Current output set to 12mA.

“3” - Current output set to 20mA.

For “0”, response = “ Output equal to

input.”

For “1”, response = “ Output is 4mA.”

For “2”, response = “ Output is 12mA.”

For “3”, response = “ Output is 20mA.”

Pulse Output Controlled By PS and FO

“ Pulse Output Released ”

The PS and FO menus shall control the pulse output.

Used to terminate the TP command.

-25-

Page 28

Command Description/Allowed Data/Response

TP

RA

AS

OI

MO

OM

OF

Output 1Hz Test Frequency for Pulse Output

“ Test Pulse Output ”

Sets output to 1Hz, 50% duty cycle signal. This mode is

for factory test.

Release Alarm Output for Control According to Menu

Settings

“ Alarm Released ”

Releases alarm output for control by the alarm output

settings.

Alarm Output Test

“0” – Alarm output is set low.

“1” - Alarm output is set high.

For “0”, response = “ Alarm Active ”

For “1”, response = “ Alarm Released ”

After using the “AS” command, you must initiate a RA

command to allow HIT-2A to return to normal operation.

Output 4mA

“ Output is 4mA.”

Current output set to 4mA.

Output 12mA

“ Output is 12mA.”

Current output set to 12mA.

Output 20mA

“ Output is 20mA.”

Current output set to 20mA.

Output = Rate (Input)

“ Output equal to input.”

Current output follows rate.

-26-

Page 29

Command Description/Allowed Data/Response

AA

DA

UI

RR

Auto Data

“F (DATA) R (DATA) T (DATA)”

The response, not the echo, is sent every two seconds

until it receives another message from the master. The

(DATA) following the F denotes the frequency of the

pulses to a precision of three places past the decimal, the

(DATA) following the R denotes the rate to a precision

of three places past the decimal, and the (DATA)

following the T denotes the total to a precision of three

places past the decimal.

Dump All

All of the responses in previous table.

The

UNIT gives all responses except for the CL

command.

Unit Identification

“UNIT MODEL= XX YY.ZZ”

Model and software number for the unit. XX is the

hardware revision number, YY.ZZ is the software

revision where YY is the major software revision and ZZ

is the minor software revision.

Read Rate

“FLOW = (DATA)”

(DATA) = “0” to the following maximums:

“99999.999” if RD = 3

“999999.99” if RD = 2

“9999999.9” if RD = 1

“ 99999999” if RD = 0

-27-

Page 30

Command Description/Allowed Data/Response

CN

CM

SA

Adjust 4mA output point

“CN=#(DATA)”

(DATA) is the integer value that the unit sends to the 4-

20mA converter to output 4mA

This parameter is passed to the unit to adjust the 4mA

output point of the device. This value is used in

production at the test step to calibrate the 4mA output

point. “CN” will cause an Invalid Command response

and absence of the # symbol will cause the unit to ignore

the data.

Adjust 20mA output point

“CM=#(DATA)”

(DATA) is the integer value that the unit sends to the 4-

20mA converter to output 20mA

This parameter is passed to the unit to adjust the 20mA

output point of the device. This value is used in

production at the test step to calibrate the 20mA output

point. “CM” will cause an Invalid Command response

and absence of the # symbol will cause the unit to ignore

the data.

Set Alarm Output On

“ Alarm Active ”

Sets the alarm output active regardless of the settings.

-28-

Page 31

-29- -30-

Page 32

M5116/0312

Loading...

Loading...