Omega Products SV-600 Installation Manual

nn EP~.PI..,E

rhmxxJv=a~4

A

Lit

nrrt

L

Am

0-A

Tee~ml~&#

tim~amy

i’

SW600

Series

Anti-Water Hammer

Unpacking Instructions

Remove the Packing

have received all equipment, including the

following (quantities in parentheses):

SV-600 Series Hammer Solenoid Valve (1)

Operator’s Manual. (1)

If you have any quest ions about the ship-

ment, please call the OMEGA Customer

Service Department.

When you receive

container and equipment for signs of

damage. Note any

handling in transit. Immediately report any

damage to the shipping agent.

The carrier will not honor damage

claims unless all shipping material

is saved for inspection. After

examining and removing contents,

save packing

in the event reshipment is

necessary.

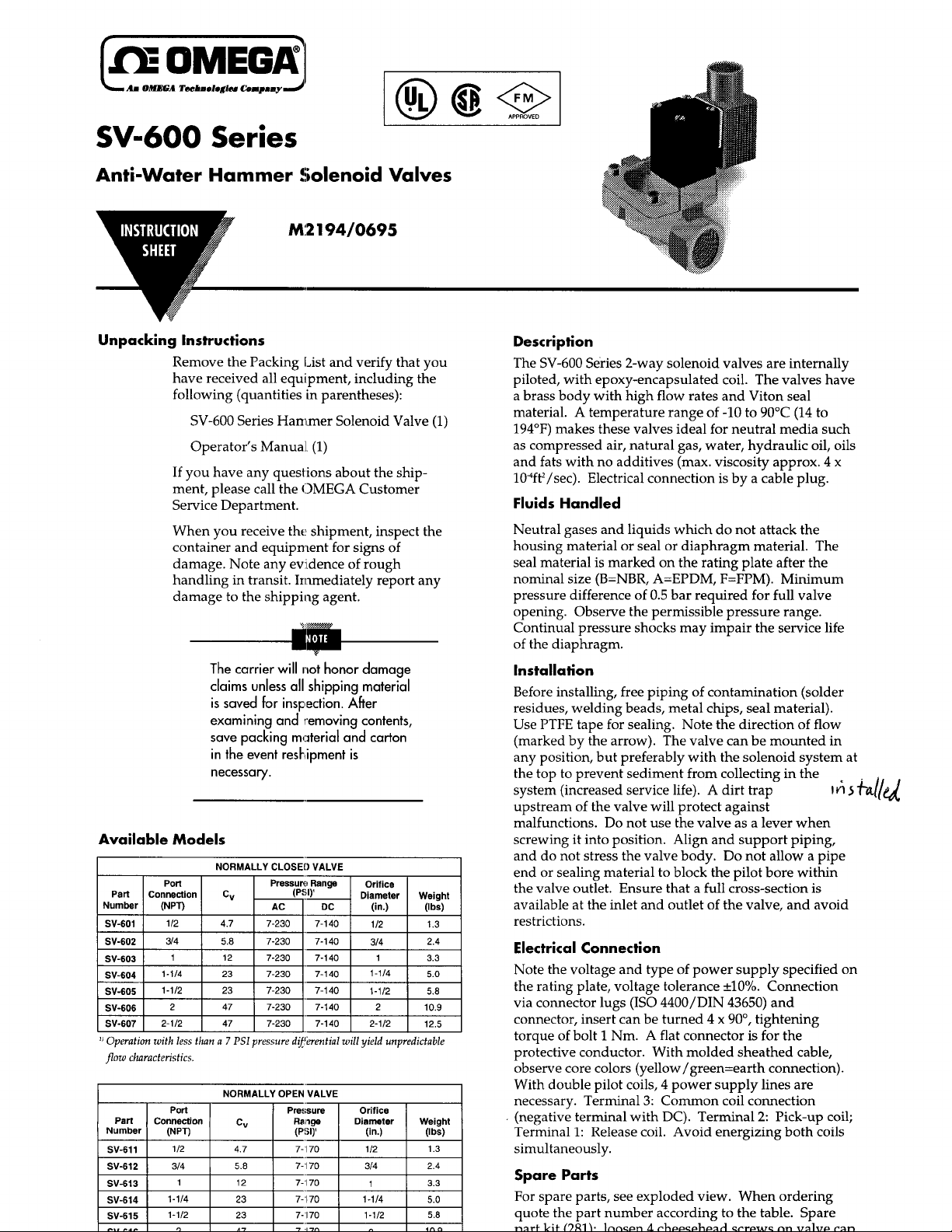

Available Models

NORMALLY

CLOSE;) VALVE

!iiolenoid

MY2

19410695

IList

and verify that you

the

shipment, inspect the

ev:ldence

mc:rterial

Valves

of rough

and carton

Description

The SV-600 Series 2-way solenoid valves are internally

piloted, with epoxy-encapsulated coil. The valves have

a brass body with high flow rates and Viton seal

material. A temperature range of -10 to 90°C (14 to

194°F) makes these valves ideal for neutral media such

as compressed air, natural gas, water, hydraulic oil, oils

and fats with no additives (max. viscosity approx. 4 x

10-4ft2/sec).

Electrical connection is by a cable plug.

Fluids Handled

Neutral gases and liquids which do not attack the

housing material or seal or diaphragm material. The

seal material is marked on the rating plate after the

nominal size (B=NBR, A=EPDM, F=FPM). Minimum

pressure difference of 0.5 bar required for full valve

opening. Observe the permissible pressure range.

Continual pressure shocks may impair the service life

of the diaphragm.

Installation

Before installing, free piping of contamination (solder

residues, welding beads, metal chips, seal material).

Use PTFE tape for sealing. Note the direction of flow

(marked by the arrow). The valve can be mounted in

any position, but preferably with the solenoid system at

the top to prevent sediment from collecting in the

system (increased service life). A dirt trap

lvl5

upstream of the valve will protect against

malfunctions. Do not use the valve as a lever when

screwing it into position. Align and support piping,

and do not stress the valve body. Do not allow a pipe

end or sealing material to block the pilot bore within

the valve outlet. Ensure that a full cross-section is

available at the inlet and outlet of the valve, and avoid

restrictions.

+ii((Ld

sv-604

SW605

SW606

W-607

PSI?

Number

SW61

1

l-114

1

l-112

I

Z-112

1

I

CO~tlXtiOll

2

(NW

Electrical Connection

23

23

I

47 7-230

47

1

1

1

7-230

7-230 i

7-1407-230

7-140

1’

7-140

7-140

l-114

l-1/2

I

2

Z-112

1

5.0

I

5.6

10.9

I

12.5

Note the voltage and type of power supply specified on

the rating plate, voltage tolerance

via connector lugs (IS0

4400/DIN

connector, insert can be turned 4 x

*lo%.

Connection

43650) and

90”,

tightening

torque of bolt 1 Nm. A flat connector is for the

protective conductor. With molded sheathed cable,

observe core colors (yellow/green=earth connection).

NORMALLY OPEN ’VALVE

I

cv

l/2

4.7

PWiSUWI Orifice Poll

I

With double pilot coils, 4 power supply lines are

necessary. Terminal 3: Common coil connection

(negative terminal with DC). Terminal 2: Pick-up coil;

Terminal 1: Release coil. Avoid energizing both coils

simultaneously.

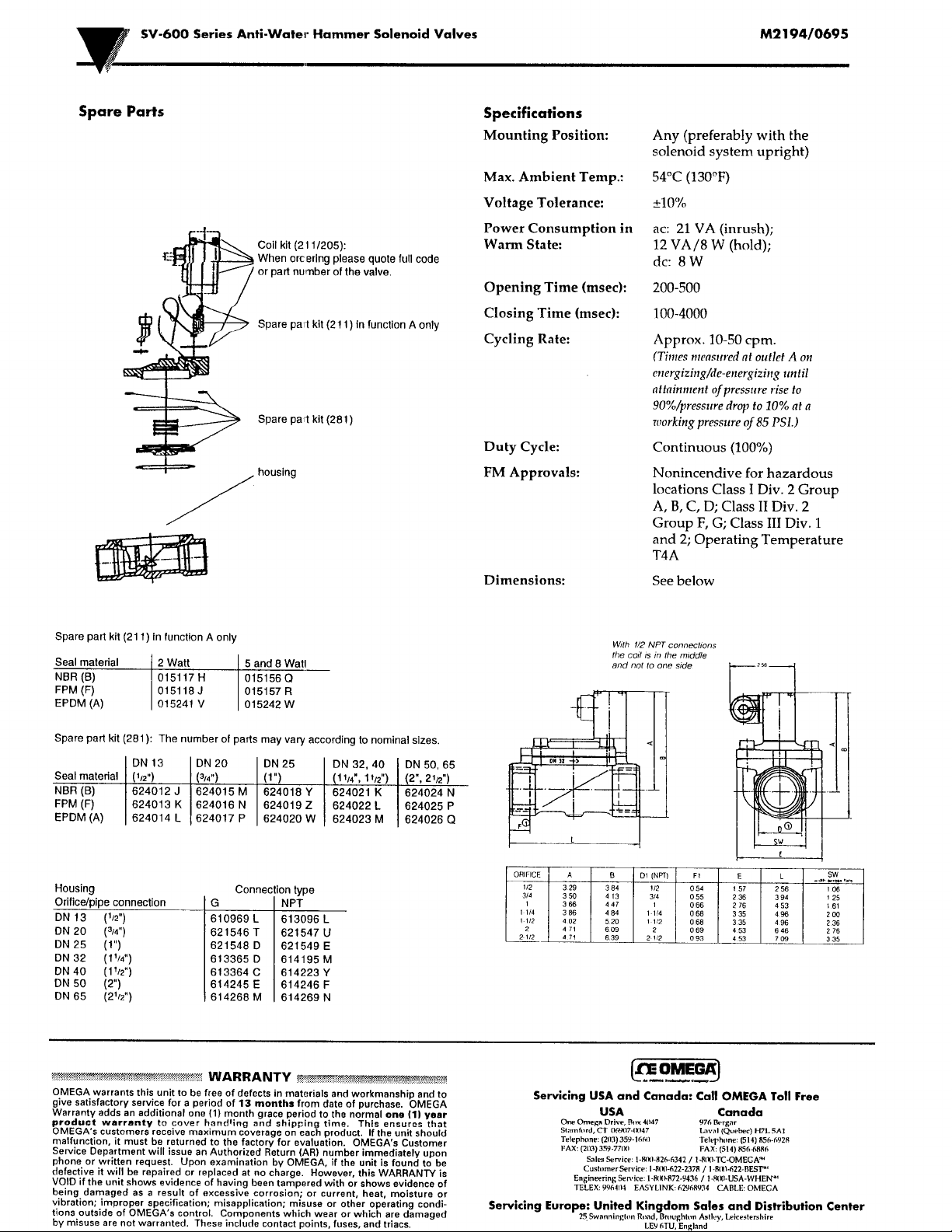

Spare Parts

For spare parts, see exploded view. When ordering

quote the part number according to the table. Spare

x,alx,~

/7Rl\.

lnnc~n

ran

SV-600

Series

Anti-Watemr

Hammer Solenoid Valves

M2

194/0695

Spare Parts

Specifications

Mounting Position:

Any (preferably with the

solenoid system upright)

Max. Ambient Temp.:

Voltage Tolerance:

Power Consumption

I

Coil kit (2

When

or

11205):

arc

ering please quote full code

nwnber of the valve.

part

Warm State:

Opening Time (msec):

pa? kit (211) in function A only

Spare

Closing Time (msec):

Cycling Rate:

pai-t

Spare

kit (261)

Duty Cycle:

housing

/

FM Approvals:

54°C (130°F)

+lO%

ac: 21 VA (inrush);

in

12 VA/8 W (hold);

dc: 8W

200-500

100-4000

Approx.

(Tirlres

nttninnzent

YO%/presswe

rootking

lo-50 cpm.

nt

ofpressure

drop to 10%

IlrPosl/ved

pressure of85 PSI.)

Continuous (100%)

Nonincendive for hazardous

locations Class I Div. 2 Group

A, B, C, D; Class II Div. 2

outlrf

rise to

A

0)~

rrntilcner~izing/~e-ener~gizirtg

nnt

Group F, G; Class III Div. 1

and 2; Operating Temperature

T4A

Dimensions:

See below

parl kit (21 1) in function A only

Spare

Spare part kit (261): The number of parts may vary according to nominal sizes.

DN

(2”.

624024 N

624025 P

624026

Housing

Orifice/pipe connection

DN 13

DN 20

DN

DN

DN

DN

DN

(1/z”)

&“j

(1”)

25

(II/d”)

32

(I’/$)

40

(2”)

50

(2’12’)

65

Connet

m

type

NPT

613096 L

621547 U

621549 E

614195 M

614223 Y

614246 F

614269 N

50,65

2’n”)

c~nnec,,~n~

f/Z

NPT

Wllh

COII the

nof

and

Q

lo

,n

the IS

one side

mrddle

OMEGA warrants this unit to be free of defects in materials and workmanship and to

give satisfactory service for a period of 13

Warranty adds an additional one

product warranty

OMEGA ’s customers receive maximum coverage on each product. If the unit should

malfunction, it must be returned to the factory for evaluation.

Service Department will issue an Authorized Return

phone or written request. Upon examination by OMEGA, if the unit is found to be

defective it will be repaired or replaced at no

VOID if the unit shows evidence of having been tampered with or shows evidence of

being damaged as a result of excessive corrosion; or current, heat. moisture or

vibration; improper specification; misapplication: misuse or other operating condi-

tions outside of OMEGA ’s control. Components which wear or which are damaged

by misuse are not warranted. These include contact points, fuses. and

cover

handling and shipping time. This ensures that

to

months

(1)

month grace period to the normal one

from

date of purchase. OMEGA

OMEGA’s

(AR) number immediately upon

charge. However, this WARRANTY is

Customer

triacs.

(1)

ysar

Servicing Europe: United Kingdom Sales and Distribution Center

Swannin~l,~ ”

25

&lad,

sro”~hton

hT”,

LEY

*r&y,

En+nd

Leicrrlerjhirr

Loading...

Loading...