Page 1

Q-I-PUTS

(nnn-sw~~wd\

7

the

.

- - - -_ .

.

. . . .

SV-

10 Series

PVC Solenoid Valves

M2 19510695

Unpacking Instructions

Remove the Packing List and verify that you

have received all equipment, including the

following (quantities in parentheses):

SV-10 Series PVC Solenoid Valves (1)

Operator’s Manual (1)

If you have any questions about the ship-

ment, please call the OMEGA Customer

Service Department.

When you receive the shipment, inspect the

container and equipment for signs of

damage. Note any evidence of rough

handling in transit. Immediately report any

damage to the shipping agent.

The carrier will not honor damage

claims unless all shipping material

is saved for inspection. After

examining and removing contents,

save packing material and carton

in the event reshipment is

necessary.

Fluids Handled

Neutral or aggressive gases or liquids which do not attack

the valve body material PVDF and PVC (rigid PVC in

accordance with DIN 8061 and 8062, resistant) or the

=

selected seal material. Seal material: A = EPDM, B

F

= FPM; see the rating plate. Seal materials is marked on

NBR,

the rating plate after nominal size.

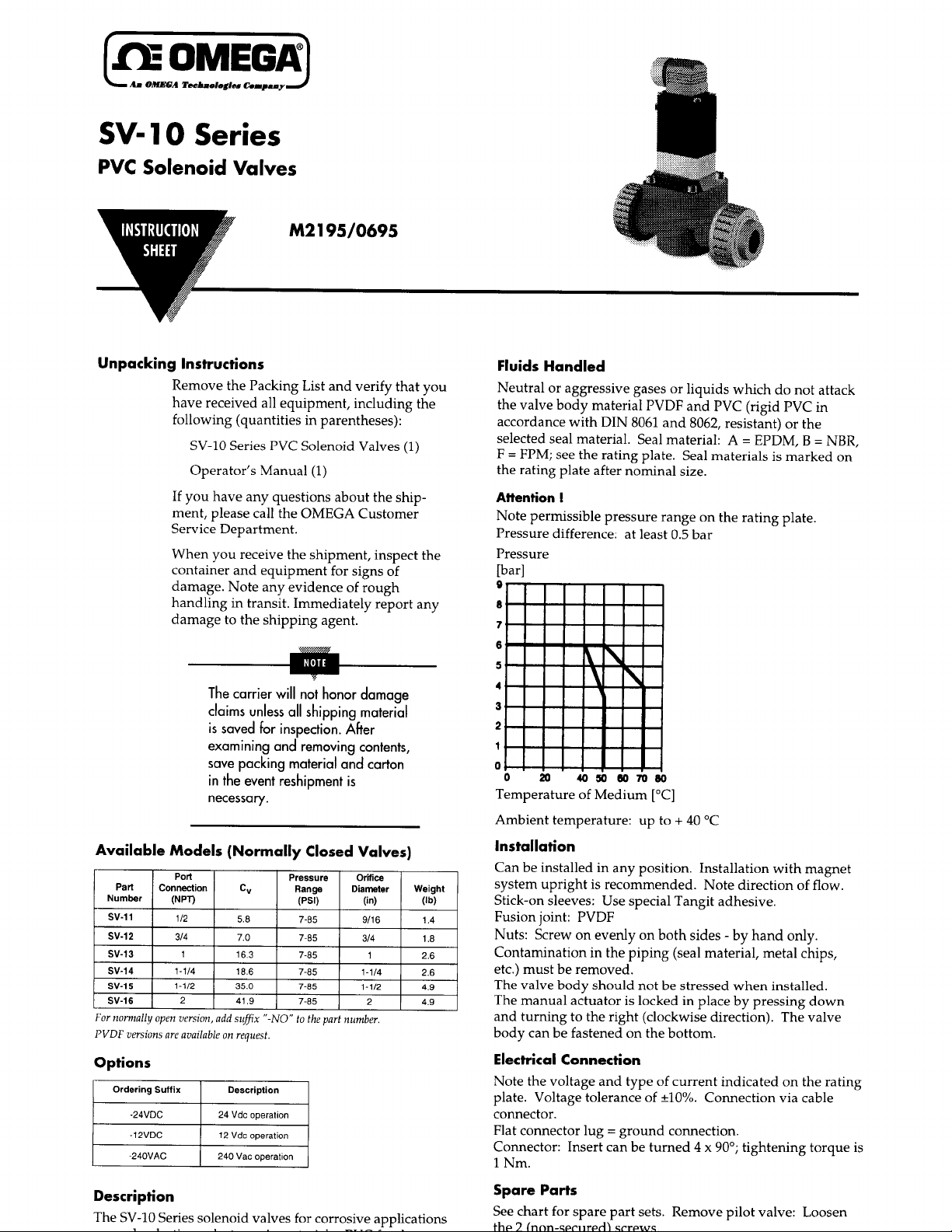

Attention

!

Note permissible pressure range on the rating plate.

Pressure difference: at least

0.5

bar

Pressure

Ibar1

9

8

4030

:0 ; :

aomeo

[“Cl

+

40

“C

20

:;

01;

Temperature of Medium

Ambient temperature: up to

Available Models (Normally Closed Valves)

Part

Number

sv-11

sv-12

sv-13

sv-14

sv-15

sv-16

For normally open

PVDF versions are available on request

POrt

Connection

(NPT)

l/Z

314

I

l-1/4

l-l/2

2

vrrsion,

CV

5.6

7.0

1

1

16.3

16.6

35.0

41.9

sufiix “-NO” to the

add

1

Pressure

Range

(PSI)

7-65

7-65

7-85

7-65

7-85

7-65

part

Orifice

Diameter

(in)

9/16

II

314

1

l-l/4

l-112

number.

Weight

(lb)

1.4

I

1.6

2.6

I

1

2.6

4.9

2

4.9

Options

Ordering Suffix Description

-24VDC

I

-12VDC

I

-24QVAC

I

24 Vdc operation

12 Vdc operation

operation

Vat

240

Description

The SV-10 Series solenoid valves for corrosive applications

Installation

Can be installed in any position. Installation with magnet

system upright is recommended. Note direction of flow.

Tangit

Stick-on sleeves: Use special

adhesive.

Fusion joint: PVDF

Nuts: Screw on evenly on both sides

-

by hand only.

Contamination in the piping (seal material, metal chips,

etc.) must be removed.

The

valve body should not be stressed

The manual actuator is locked

in place by pressing

when installed.

down

and turning to the right (clockwise direction). The valve

body can be fastened on the bottom.

Electrical Connection

Note

the voltage and type of current indicated on the rating

+lO%.

plate. Voltage tolerance of

Connection via cable

connector.

Flat connector lug = ground connection.

Connector: Insert can be turned 4 x 90”; tightening torque is

1 Nm.

Spare Parts

See

chart for spare part sets. Remove pilot valve: Loosen

Page 2

W-1

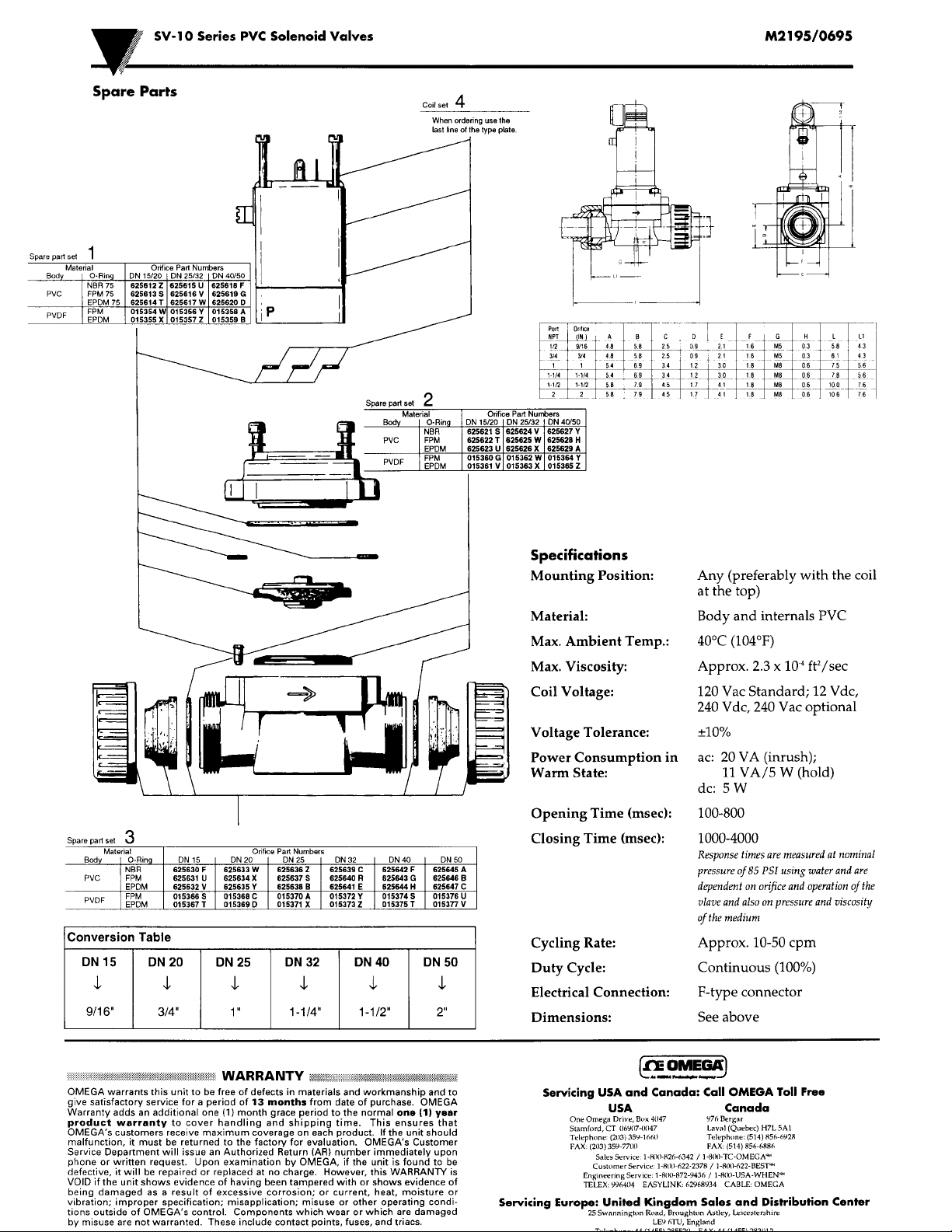

Spare Parts

0 Series PVC

Solenoid Valves

M2

195/0695

\

1

Conversion Table

DN15

1

9/l 6”

DN 20

314”

Specifications

Mounting Position:

Any (preferably with the coil

at the top)

Material:

Max. Ambient Temp.:

Max. Viscosity:

Coil Voltage:

Voltage Tolerance:

Power Consumption in

Warm State:

\\

I

,

I

Opening Time (msec):

Closing Time

(msec):

Cycling Rate:

DN 25

11

In

1

DN 32

1

l-114”

DN 40

1

l-1/2”

DN 50

1

2”

Duty Cycle:

Electrical Connection:

I

Dimensions:

Body and internals PVC

40°C (104°F)

ft’/sec

10.’

Approx. 2.3 x

120

Vat Standard; 12 Vdc,

240 Vdc, 240

Vat optional

+lO%

ac: 20 VA (inrush);

11 VA/5 W (hold)

dc: 5W

100-800

1000-4000

Response times are measured at nominal

of

are

the

pressure

of

85 PSI using water and

dependent on orifice and operation

vlave

and also on pressure and viscosity

of

the medium

Approx.

lo-50 cpm

Continuous (100%)

F-type connector

See above

-,.~~~~~:lliiiiiiiiiiiiii:i~ii:iii:i:i::

OMEGA warrants this unit to be free of defects in materials and workmanship and

give satisfactory service for a period of 13

Warranty adds an additional one

product warranty to cover handling and shipping time. This ensures that

OMEGA’s customers receive maximum coverage on each product. If the unit should

malfunction, it must be returned to the factory for evaluation. OMEGA ’s Customer

Service Department will issue an Authorized Return

phone or written request. Upon examination by OMEGA, if the unit is found to be

defective, it will be repaired or replaced at no charge. However, this WARRANTY is

VOID if the unit shows evidence of having been tampered with

being damaged as a result of excessive corrosion; or current, heat, moisture or

vibration; improper specification; misapplication;

tions outside of OMEGA ’s control. Components which wear or which are damaged

by misuse are not warranted. These include contact points, fuses, and

WARRANTY

months

(I)

month grace period to the normal one

,~~~,ri:iii~~~i~~~~~~

~, :

my,,

from date of purchase. OMEGA

SARI

number immediately upon

or shows evidence of

mwse

or other operating condi-

triacs.

to

(1) year

Loading...

Loading...