Page 1

SPRTX-SS SERIES

Industrial RTD Connector/Transmitter

INSTRUCTION

SHEET

M4755/0311

Shop online at: omega.com e-mail: info@omega.com

For latest product manuals: omegamanual.info

General Description

The OMEGA®2-wire SPRTX-SS Series temperature transmitters are high

performance, low cost, industrial transmitters designed for direct connection

to most CIP (clean-in-place) sanitary Pt100 probes and sensors that

incorporate a M12 style connector. All models feature an encapsulated micro

miniature signal conditioner built into a sealed connector housing. The signal

conditioner converts the resistive change of a 100 , 0.00385 RTD probe or

sensor into an industry-standard 2 wire, 4 to 20 mA analog output across a

dedicated temperature range. This analog output can be sent hundreds of feet

away from the location of your sensor (probe) to an indicating device,

controller, PLC, computer, data logger or chart recorder. Your SPRTX-SS

temperature transmitter has been factory calibrated to provide maximum

performance and requires no field adjustments.

Omega’s SPRTX-SS transmitters are available in M12-1 and M12-2 models,

allowing for more flexible international use. The SPRTX-SS1-M12-1 and

SPRTX-SS2-M12-1 are designed for use commonly in North America. The

SPRTX-SS1-M12-2 and SPRTX-SS2-M12-2 are geared towards European

applications.

Unpacking

Remove the packing list and verify that you have received all your

equipment. If you have any questions about the shipment, please call

Customer Service at: 1-800-622-2378 or 203-359-1660.

On the web you can find us at: omega.com e-mail: cservice@omega.com

When you receive the shipment, inspect the container and equipment for

any signs of damage. Note any evidence of rough handling in transit.

Immediately report any damage to the shipping agent.

NOTE:

The carrier will not honor any damage claims unless all shipping material is

saved for inspection. After examining and removing contents, save packing

material and carton in the event reshipment is necessary.

The following items are supplied in the box with your SPRTX

Connector/Transmitter.

• This User's Manual, # M-4755 (1 ea.)

Page 2

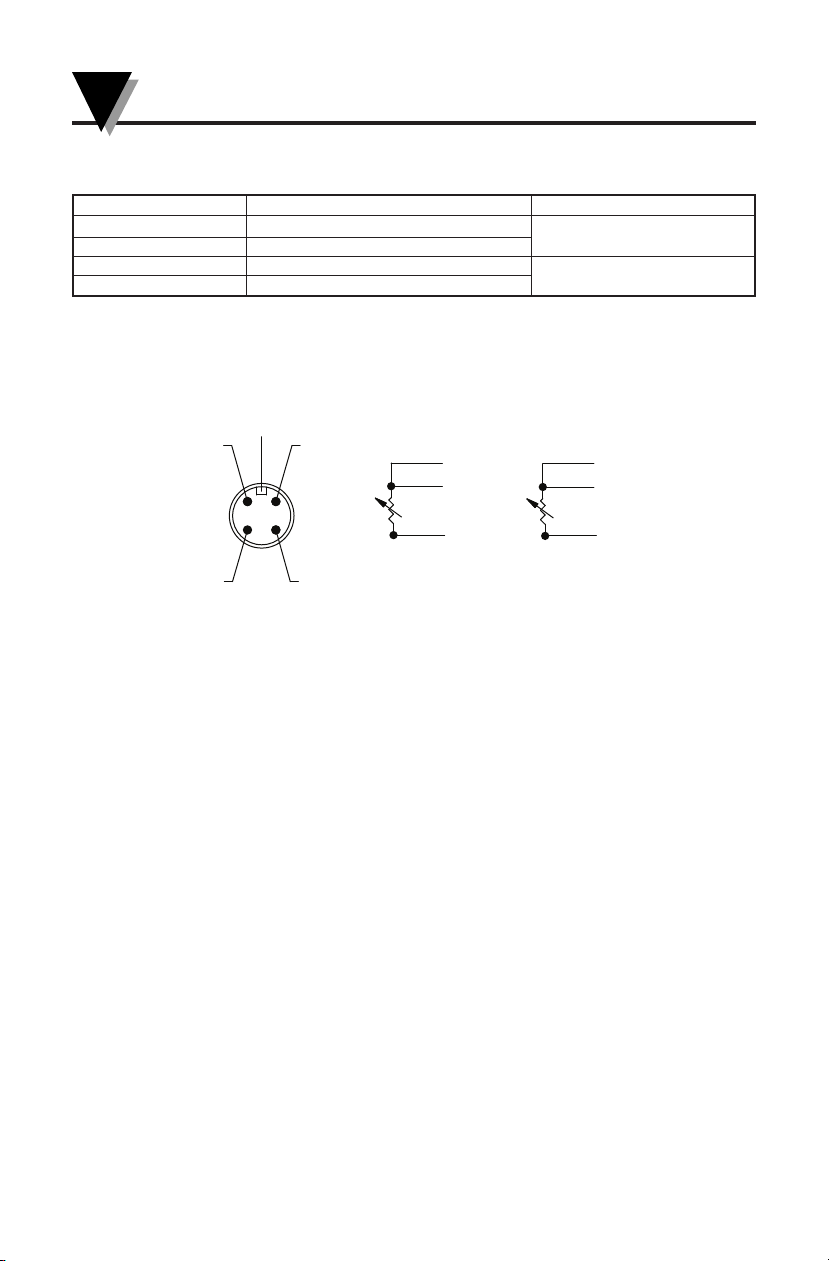

PIN #2

PIN #1

PIN #3

PIN #4

KEYWAY

PIN #1

PIN #2

PIN #3

WIRING OPTION #2

PIN #1

PIN #4

PIN #3

WIRING OPTION #1

SPRTX-SS Series Industrial RTD Connector/Transmitter

SPRTX-SS Temperature Transmitter

Model No. Description* Range

SPRTX-SS1-M12-1 Pt100 Transmitter, Wiring Option 1

SPRTX-SS1-M12-2 Pt100 Transmitter, Wiring Option 2

SPRTX-SS2-M12-1 Pt100 Transmitter, Wiring Option 1

SPRTX-SS2-M12-2 Pt100 Transmitter, Wiring Option 2

* See Figure 1 for Wiring Option information

Recommended Accessories

Power Supply, OMEGA Part No.: PSU-93

Shielded 2-conductor cable (100 ft), OMEGA Part No.: TX2-100

Figure 1. Wiring Options

Introduction/Safety

Your SPRTX-SS Temperature Transmitter has been designed for ease of use

and flexibility. It is important that you read this Users Manual completely

and follow all safety precautions before operating your unit.

Precautions

1. FOLLOW ALL SAFETY PRECAUTIONS AND OPERATING

INSTRUCTIONS OUTLINED IN THIS MANUAL.

2. INSURE PROBE/M12 CONNECTOR CONNECTION IS ALWAYS

FULLY TIGHTENED DURING USE.

3. ADD ADDITIONAL SAFE GUARDS TO YOUR SYSTEM IN

CRITICAL APPLICATIONS WHERE DAMAGE OR INJURY MAY

RESULT FROM PROBE/CONNECTOR SEPARATION OR FAILURE.

4. NEVER EXPOSE THE CONNECTOR/MODULE BODY TO

AMBIENT TEMPERATURES ABOVE 85ºC (185ºF) OR BELOW -40°C

(-40°F). DAMAGE MAY RESULT.

5. DO NOT OPERATE IN FLAMMABLE OR EXPLOSIVE

ENVIRONMENTS.

2

6. DO NOT USE IN HUMAN MEDICAL OR NUCLEAR

APPLICATIONS.

7. NEVER OPERATE WITH A POWER SOURCE OTHER THAN WHAT

IS SPECIFIED IN THIS MANUAL.

-99 to 20°C (-146 to 406°F)

2 to 569°C (36 to 1056°F)

Page 3

SPRTX-SS Series Industrial RTD Connector/Transmitter

500.1C

24V

+

+

–

–

CONTROL ROOM

MA NU FAC TU RI NG AR EA

SPRTX-SS

CONNECTOR/

TRANSMITTER

PT-100

SANITARY RTD PROBE

a=0.00385

PROCESS METER

OR CONTROLLER

DC POWER SUPPLY

1000 FT. MAX

8. REMOVE AND OR DISCONNECT POWER SOURCE BEFORE

ATTEMPTING INSTALLATION OR MAINTENANCE.

9. ALWAYS OPERATE YOUR UNIT WITH THE SHIELD WIRE

CONNECTED TO EARTH GROUND.

10. INSTALLATION AND WIRING SHOULD BE DONE BY TRAINED

PROFESSIONALS ONLY.

11. DO NOT OPEN OR DISASSEMBLE YOUR UNIT.

There are no user serviceable parts inside your unit. Attempting to open, repair

or service your unit will void your warranty.

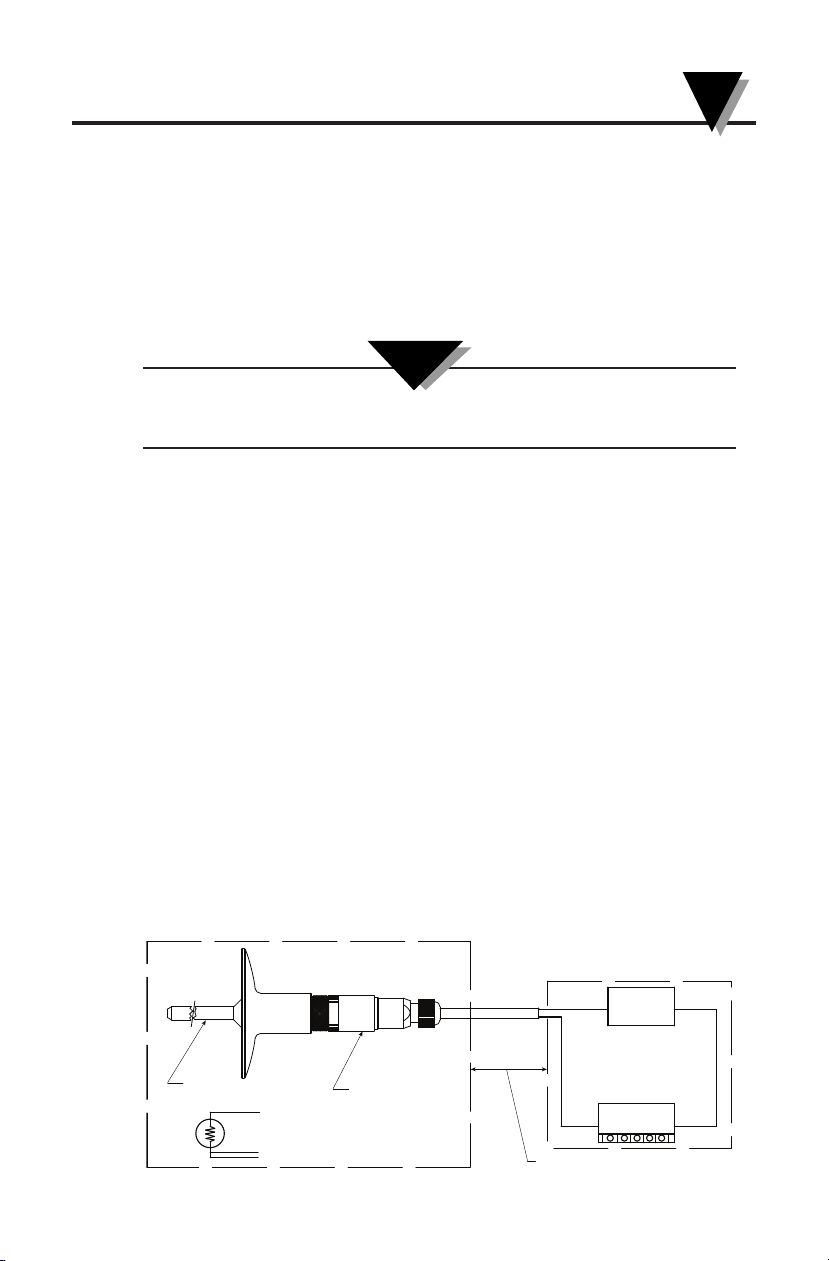

Theory of Operation

A 4-20 mA loop is a series loop in which a transmitter will vary the current

flow depending on the input to the transmitter. With the SPRTX-SS the

amount of current allowed to flow in the loop will vary depending on the

resistance change, due to changes in the temperature being measured by the

Sanitary RTD sensor (probe). Some advantages of a current output over a

voltage output is that the signal measured is less susceptible to electrical

noise interference and the loop can support more than one measuring

instrument as long as the maximum loop resistance is not exceeded.

A typical application utilizing a current loop will normally consist of a

power supply, the transmitter and a meter, recorder or controller to

measure the current flow. The loop resistance is the sum of the measuring

instruments and wire used. The maximum allowable loop resistance for the

SPRTX-SS to function properly is found by using the following formula:

Rmax = (power supply voltage – 9 volts)/.02 amps

For applications that require a voltage output, the 4-20mA signal from the

SPRTX-SS can be converted in the field by adding a 250 Ohm shunt

resistor that will convert the transmitters output to a 1-5 Vdc signal when

wired correctly.

NOTE:

Figure 2. SPRTX-SS Operation

3

Page 4

SPRTX-SS Series Industrial RTD Connector/Transmitter

PATENTED CONNECTOR/TRANSMITTER

WITH M12 CONNECTION

PT-100 SANITARY

RTD PROBE

MANUFACTURING AREA

85°C (185°F) AMBIENT TEMP. MAX

SPRTX-SS

CONNECTOR/TRANSMITTER

RTD

PROBE

3" (76mm) MIN.

SHIELD

(E.G., WALL)

HEAT

SOURCE

Mounting Your SPRTX to Probes

The SPRTX-SS Series of connector/transmitters are designed for quick

connection to Sanitary RTD sensors and probes. See below for correct usage.

Figure 3. SPRTX-SS Connection

Protection from High Ambient Temperatures

NOTE:

Your SPRTX-SS Connector/Transmitter Assembly can be damaged if exposed to

ambient temperatures above 85°C (185°F). Some applications may require that

you shield the SPRTX-SS unit from radiated heat as shown below. You should

always use a probe where the length allows for a safe distance of 76 mm (3")

or more between the body of the SPRTX-SS and your source of heat.

Figure 4. SPRTX-SS Temperature/Protection

4

Page 5

SPRTX-SS Series Industrial RTD Connector/Transmitter

500.1C

24V

+

–

+

–

P

OWER SUPPLY

DC VOLTAGE INPUT METER

B

ARE WIRE

RED WIRE

BLACK WIRE

MUST BE

CONNECTED

T

O EARTH

GROUND

S

PRTX-SS

250 RESISTER

500.1C

24V

+

–

+

–

POWER SUPPLY

DC VOLTAGE INPUT METER

BARE WIRE

RED WIRE

BLACK WIRE

MUST BE

CONNECTED

TO EARTH

GROUND

SPRTX-SS

Transmitter Wiring Examples

Figure 5. Transmitter Wiring: 2-Wire, 4 to 20mA Output

Converting from 4 to 20mA Output to 1 to 5Vdc Output (3-wire)

Figure 6. Transmitter Wiring: 3-Wire, Converting From 4 to 20mA Output to 1-5Vdc Output

WHEN WIRED FOR 1-5 Vdc OPERATION THE MINIMUM OPERATING

VOLTAGE MUST BE INCREASED TO 15 Vdc.

NOTE:

5

Page 6

SPRTX-SS Series Industrial RTD Connector/Transmitter

Temperature to Analog Output Calculations

Models: SPRTX-SS1-M12-1, SPRTX-SS1-M12-2

Temp deg. C Temp deg. F RTD Resistance Output mA

-99 -146 60.67 4.00

-50 -58 80.31 6.55

0 32 100.00 9.16

25 77 109.73 10.46

50 122 119.40 11.77

75 167 128.99 13.07

100 212 138.51 14.37

125 257 147.95 15.67

150 302 157.33 16.98

175 347 166.62 18.28

208 406 178.80 20.00

Models: SPRTX-SS2-M12-1, SPRTX-SS2-M12-2

Temp deg. C Temp deg. F RTD Resistance Output mA

-18 0 92.95 3.54

2 36 100.78 4.00

25 77 109.73 4.65

50 122 119.40 5.35

100 212 138.51 6.77

150 302 157.33 8.18

200 392 175.86 9.59

250 482 194.10 11.00

300 572 212.05 12.41

400 752 247.09 15.23

500 932 280.98 18.10

569 1056 303.68 20.00

Calibration/Service

Your transmitter has been factory calibrated to meet or exceed the

specifications outlined in this manual. No field adjustments are needed or

possible on your unit. If your unit should become damaged or malfunction,

please contact Omega Customer Service at:

On the web you can find us at:

omega.com e-mail: cservice@omega.com

6

Page 7

Specifications

Supply Voltage: 9 to 24 Vdc @ 30mA max

Max Load: Rmax () = (V supply – 9V)/0.02 A

Max Input Lead Resistance: 50V

Output: Linearized 4 to 20 mA

Accuracy: ±0.5% of full scale @ 23ºC (73ºF)

Repeatability: ± 0.25ºC (± 0.5ºF)

Temperature Effect: ±0.00022 mA/ºC (±0.00012 mA/ºF)

Temperature Input Range by model

SPRTX-SS1: -99 to 208ºC (-146 to 406ºF)

SPRTX-SS2: 2 to 569ºC (36 to 1056ºF)

Input: 3-wire, Pt100 (=0.00385) 4-wire compatible

Probe/Sensor Input Connection

Transmitter Operating Temp: -40 to 85ºC (-40 to 185ºF)

Output Connection: 2-wire, Shielded, polyurethane cable 4 m

Approvals: CE Marked

Max Loop Resistance: Ohms = (V supply – 9 V)/0.02 A

Dimensions: 76 L x 20 mm D (3 x 0.8") without cable

Weight: 110 g (0.25 lb) max with cable

SPRTX-SS Series Industrial RTD Connector/Transmitter

M12, 4-pin female, (connects to RTD probes

having a 12M, 4-pin male connection)

(12') included

7

Page 8

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

U.S.A.: Omega Engineering, Inc., One Omega Drive, P.O. Box 4047

SO 9001 CertifiedStamford, CT 06907-0047

I

Canada: 9

Toll-Free: 1-800-826-6342 Tel: (203) 359-1660

AX: (203) 359-7700 e-mail: info@omega.com

F

76 Bergar

Laval (Quebec), H7L 5A1 Canada

oll-Free: 1-800-826-6342 TEL: (514) 856-6928

T

AX: (514) 856-6886 e-mail: info@omega.ca

F

For immediate technical or application assistance:

U.S.A. and Sales Service: 1-800-826-6342/1-800-TC-OMEGA

Servicing North America:

Canada: Customer Service: 1-800-622-2378/1-800-622-BEST

Mexico/ E

Latin Ameica info@omega.com.mx e-mail:espanol@omega.com

t is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing

I

certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any errors it contains, and reserves the

right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

n Español: 001 (203) 359-7803 FAX: 001 (203) 359-7807

Benelux: Managed by the United Kingdom Office

zech

C

epublic:

R

France: M

Germany/ Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

®

®

Austria Toll-Free: 0800 6397678 TEL: +49 (0) 7056 9398-0

®

nited

U

Kingdom: O

ISO 9001

ertifiedToll-Free: 0800-488-488 TEL: +44 (0) 161 777-6611

C

Servicing Europe:

Toll-Free: 0800 099 3344 TEL: +31 20 347 21 21

FAX: +31 20 643 46 43 e-mail: sales@omegaeng.nl

Frystatska 184

733 01 Karviná, Czech Republic

Toll-Free: 0800-1-66342 TEL: +420-59-6311899

AX: +420-59-6311114 e-mail: info@omegashop.cz

F

anaged by the United Kingdom Office

oll-Free: 0800 466 342 TEL: +33 (0) 161 37 29 00

T

FAX: +33 (0) 130 57 54 27 e-mail: sales@omega.fr

FAX: +49 (0) 7056 9398-29 e-mail: info@omega.de

OMEGA Engineering Ltd.

ne Omega Drive, River Bend Technology Centre, Northbank

Irlam, Manchester M44 5BD United Kingdom

FAX: +44 (0) 161 777-6622 e-mail: sales@omega.co.uk

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 13 months from

WARRANTY/ DISCLAIMER

date of purchase. OMEGA’s WARRANTY adds an additional one (1) month grace period to the normal one (1) year product

warrant y t o cover ha ndling and shippi ng time. T his ensures that OM EGA’s customers receive maximum coverage on each

product.

If the unit malfunctions, it must be returned to the factory for evaluation. O MEGA’s Customer Service Department will issue an

Authorized Return (AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be

defective, it will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the

purchaser, including but not limited to mishandling, improper interfacing, operation outside of design limits, improper repair, or

unauthorized modification. This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence of

havi ng been damag ed as a resu lt of exc essi ve corro sion ; or c urr ent, hea t, moistu re or vib rati on; impr ope r specifi cat ion;

misapplication; misuse or other operating conditions outside of OMEGA’ s control. Components in which wear is not warranted,

include but are not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes responsibility

for any omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with

information provided by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by the

company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY

KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY

WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION

OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this

order, whether based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the

purchase price of the component upon which liability is based. In no event shall OMEGA be liable for consequential,

incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under 10 CFR

21 (NRC), used in or with any nuclear installation or activity; or (2) in medical applications or used on humans. Should any Product(s)

be used in or with any nuclear installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes

no responsibility as set forth in our basic WARRANTY/ DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and

hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.

Dire ct all warr anty and repair requests /inqu irie s to t he OMEGA Custom er Service Depa rtme nt. BEFORE RETU RNIN G ANY

PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER

SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the

outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

FOR WARRANTY

tion available BEFORE contacting OMEGA:

1. Purchase Order number under which the product was

PURCHASED,

2. Model and serial number of the product under warranty, and

3. Repair instructions and/or specific problems relative to the

product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in

technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2011 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or

reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.

RETURNS, please have the following informa-

RETURN REQUESTS/INQUIRIES

FOR NON-WARRANTY REPAIRS,

rent repair charges. Have the following information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems relative to

the product.

consult OMEGA for cur-

Loading...

Loading...