Page 1

MPS40

Melting Point Apparatus

®

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

Shop online at

omega.com

®

User’s Guide

®

MADE IN UNITED KINGDOM

Page 2

Servicing North America:

U.S.A.: OMEGA Engineering, Inc.

ISO 9001 Certified One Omega Drive

P.O. Box 4047

Stamford, CT 06907-0047 USA

Toll-Free: 1-800-826-6342 TEL: (203) 359-1660

FAX: (203) 359-7700 e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec), H7L 5A1 Canada

Toll-Free: 1-800-826-6342 TEL: (514) 856-6928

FAX: (514) 856-6886 e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 /1-800-622-BEST

®

Engineering Service: 1-800-872-9436/1-800-USA-WHEN

®

Mexico/ En Español: 001 (203) 359-7803 FAX: 001 (203) 359-7807

Latin America info@omega.com.mx e-mail: espanol@omega.com

Servicing Europe:

Benelux: Managed by the United Kingdom Office

Toll-Free: 0800 099 3344 TEL: +31 20 347 21 21

FAX: +31 20 643 46 43 e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184

733 01 Karviná, Czech Republic

Toll-Free: 0800-1-66342 TEL: +420-59-6311899

FAX: +420-59-6311114 e-mail: info@omegashop.cz

France: Managed by the United Kingdom Office

Toll-Free: 0800 466 342 TEL: +33 (0) 161 37 29 00

FAX: +33 (0) 130 57 54 27 e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26

D-75392 Deckenpfronn, Germany

Toll-Free: 0800 6397678 TEL: +49 (0) 7056 9398-0

FAX: +49 (0) 7056 9398-29 e-mail: info@omega.de

United Kingdom: OMEGA Engineering Ltd.

ISO 9001 Certified

One Omega Drive, River Bend Technology Centre, Northbank

Irlam, Manchester M44 5BD United Kingdom

Toll-Free: 0800-488-488 TEL: +44 (0) 161 777-6611

FAX: +44 (0) 161 777-6622 e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

®

Page 3

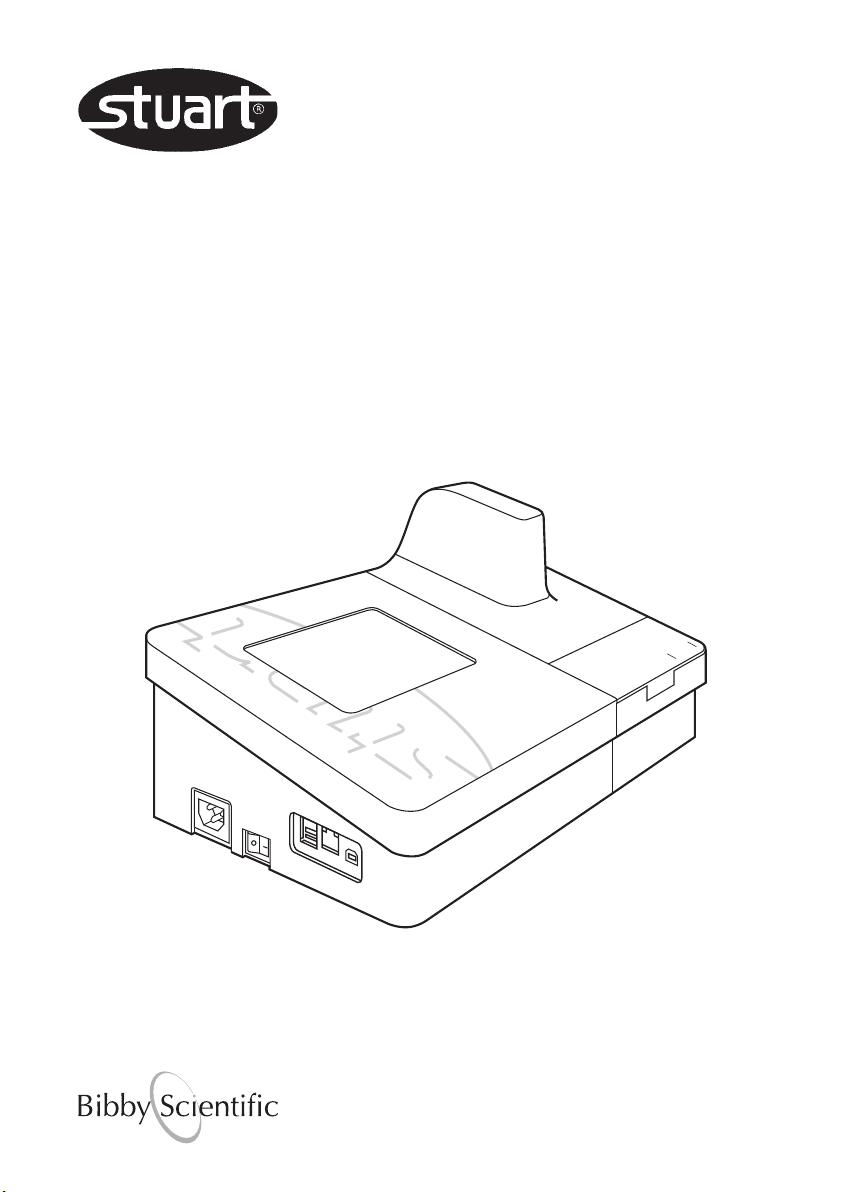

Melting Point

automatic melt ing point

SMP40

Apparatus SMP40

Instructions for use

Version 1.0

Page 4

1. Introduction 1

2. Safety Advice Before Use 1

3. General Description 1

3.1 Module Separation 2

3.2 Melting Point Determination 3

3.3 Temperature Settings 3

3.4 Sample Preparation 3

4. Preparation for Use 4

4.1 Electrical Installation 4

4.2 Installation 4

5. Instrument and Software Controls 5

5.1 Instrument 5

5.2 Main Menu Screen 6

6 Setting up New Methods 10

6.1 Creating a New Method 11

6.2 Preset Methods 12

6.3 Carry out a Rapid-Melt 13

7 Performing Melt Determinations 14

8 Results 17

8.1 View Previous Results 17

8.2 Re-use Result Parameters 25

9 File Management 26

9.1 Manage Files 26

9.2 View Storage Information 28

10 Settings and Calibration 29

10.1 User Settings 29

10.2 Maintenance Settings 31

10.3 Instrument Calibration 31

11 Maintenance & Servicing 36

11.1 Repairs and Support 36

11.2 Cleaning the Sample Block 36

11.3 Accessories 36

12 Warranty 37

13 Specification 37

Page 5

1. Introduction

Thank you for purchasing this piece of Stuart

equipment. To get the best performance from the

SMP40 please read these instructions carefully

before use. Before discarding the packaging

check that all parts are present and correct.

For your own safety and that of others please

read and understand the safety advice given

below before using the equipment.

2. Safety Advice Before

Use

! If the equipment is not used in the manner

described in this manual and with accessories

other than those recommended by Stuart, the

protection provided might be impaired.

This equipment is designed to operate under the

following conditions:

❖ For indoor use only

❖ Use in a well ventilated area

❖ Ambient temperature range +5°C to +40°C

❖ Altitude to 2000m

❖ Relative humidity not exceeding 80%

❖ Mains supply fluctuation not exceeding 10%

❖ Over-voltage category II IEC 60364-4-443

❖ Pollution degree 2

Never move or carry the unit when in use or

connected to the mains electricity supply.

The unit should be carried using both hands with

fingers under each side of the frame.

The ventilation slots at the back or side of the

device should not be sealed or obstructed.

*

The number of result files that can be stored on the SMP40 is largely dependant upon the runtime and size of

the video file for each sample.

The user is able to review the result file and video, reprocessing the automatically determined results if required.

3. General Description

The device is designed to automatically measure

and record the melting temperatures of crystalline

samples held within capillary tubes. Up to three

tubes can be accommodated in an illuminated

chamber within an aluminium block. The tubes

are monitored by a digital camera; the image of

which can be viewed on the instruments display

during the melting process. The device is

designed to be independently operated using the

colour touch screen allowing all operational and

data management functions to be performed

without the need to attach an external computer

or keyboard. The unit can be split into two

modules to allow the heating module to be

located in an environment suitable for the types

of samples being tested, while the control

module can be kept in a more convenient

location.

The temperature range of the device is ambient

to 400°C and the heating rate is variable

between 0.1°C and 20°C/minute. Temperature

data and information on the instruments status is

displayed on the screen at all times. All of the

instruments functions and menus are accessed

using the colour touch screen interface which

allows fast and intuitive navigation throughout a

substance’s melting point determination (melt

determination). The instrument has sufficient

internal storage capacity for an almost unlimited

number of preset method programs and typically

between 100 and 200 result files*. When

required, result files can be transferred from the

instrument to a PC or USB flash drive for external

storage and archiving.

When a melt cycle is started the SMP40 heats up

to the pre-programmed plateau temperature at

the maximum rate before stabilising at the

plateau temperature for 60 seconds. The SMP40

will then start to heat at the pre-programmed

rate until the melt is complete or until the device

reaches a pre-determined end temperature. Once

a melt determination has been completed,

cooling is automatically engaged until the

instrument reaches 50°C.

1

Page 6

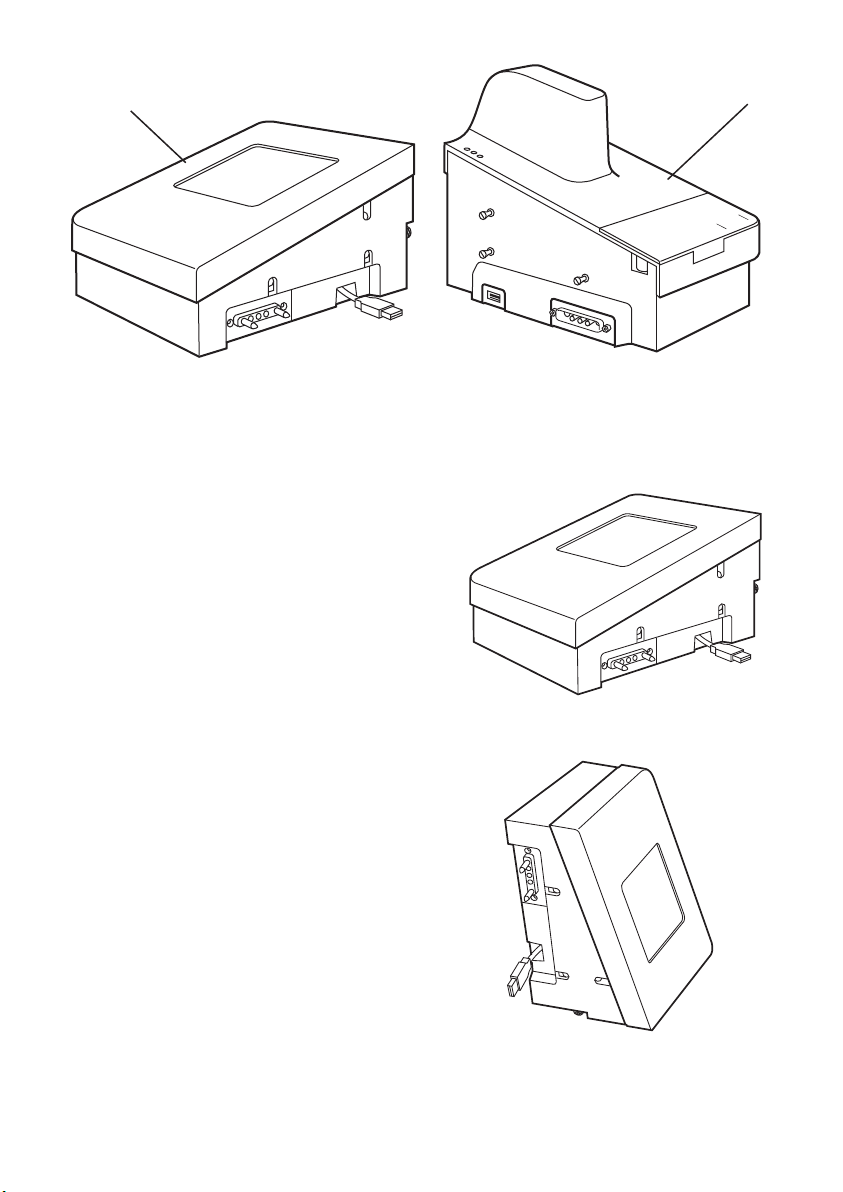

3.1 Module Separation

automatic melting point

SMP40

automatic melting point

SMP40

automatic melting point

SMP40

Control module

Figure 1: SMP40 module separation

The SMP40 can be split into two separate

modules using the split module release

mechanism located at the rear of the “Control”

module. Using the supplied accessory cables the

modules can be placed in separate locations up

to 1m apart.

Please ensure that the instruments electrical

power supply is switched off or disconnected

before commencing the following procedure.

1. Rotate the split module release mechanism

clockwise until it cannot be turned any further.

2. Gently pull the “Control” and “Melt” modules

apart taking care not to strain the connecting

USB cable.

3. Disconnect the USB cable on the control

module that connects the two modules.

4. Using the accessory cables supplied with your

SMP40 reconnect the power and USB

connections between the modules.

5. Once the devices power supply is

re-established the unit can then be used as

described in this manual.

6. Reconnecting the modules is the reverse of the

above.

Please ensure that the extension cables are

not removed from their connections when

the unit is connected to the electrical power

supply and switched on.

Melt module

The SMP40s touchscreen display is fitted with an

accelerometer device.

Flat

Upright

2

Page 7

3.2 Melting Point Determination

The capillary technique is a standard method for

determining the melting point of a substance. In

this method, thin glass capillary tubes containing

prepared samples of a substance are introduced

into the heating block of a suitable device. The

block is then heated at a fixed rate over a

temperature range that brackets the expected

melting temperature of the substance, until the

substance is completely melted (i.e. clear point).

During the heating cycle the substance under test

will often undergo a number of observable

physical changes:

1. Fine droplets adhere uniformly to the inside of

the capillary tube.

2. A clearance between the sample and the

capillary wall becomes visible.

3. The substance collapses and begins to liquefy.

4. A meniscus is visible at the samples surface

but solid particles remains visible. (Meniscus

Point)

5. The sample is a clear liquid and no solid

particles remain visible. (Clear Point)

When determining the melting point of a

substance it is necessary to select one stage in

the melting process which will be used to define

the melting point. The meniscus point or clear

point is commonly used to define the melting

point of a substance.

The SMP40 automatically reports the Clear

Point (5); the point at which the sample is a

clear liquid and no solid particles remain, as

the melting point of a substance.

Other changes in the physical appearance of the

substance are sometimes observed, such as

sublimation (transition from the solid to gas

phase with no intermediate liquid stage) or

decomposition (the separation of a substance

into its elements or smaller compounds). These

changes (if observed) should be recorded

manually.

Where a single melting point is difficult to define

for a substance it is often useful to report a

substances melting range. The melting range of a

substance is defined as the interval between the

start of a melt and the clear point.

3.3 Temperature Settings

The temperature settings used to determine a

substances melting point are critical to the

accuracy of the determination.

Start or

Plateau

Temperature:

End

Temperature:

Ramp

Rate:

Ramp rate is the most important instrument

parameter with regards to the accuracy of a

substances melt determination. The use of

fast ramp rates is the most common cause of

inaccurate melt determinations.

3.4 Sample Preparation

For accurate melting point determinations the

substance being tested should be in a dry and

uniformly powdered form. Coarse crystalline and

non-homogeneous samples should be crushed

into a fine powder using a pestle and mortar

before the substance is introduced into a capillary

tube.

Each capillary tube in a substances melt

determination should be prepared in the same

way. The open end of a capillary tube is pressed

gently into a small amount of powdered

substance until the capillary contains sufficient

material to form a compact layer of 2.5-4.5mm in

height. The powder is then forced to the bottom

of the tube by repeatedly tapping the bottom of

the capillary against a hard surface.

Excessive amounts of sample in the capillary

tubes will result in inaccurate melt

determinations.

The start temperature is usually

set 5 or 10˚C below the

expected melting point of the

substance.

The end temperature is set at a

temperature where all physical

changes in the substance are

expected to be complete.

The ramp rate is the rate at

which the sample block is

heated during the melt

determination. For accurate

determinations a rate of

between 0.5˚C/min and 2.0˚C/

min is recommended.

3

Page 8

The SMP40 can accommodate up to three sample

capillaries. For accurate melting point

determinations it is recommended that three

samples of the same material are prepared in the

same way and analysed at the same time. The

average of the three capillaries results can then

be reported as the substances melting point.

The appropriate mains lead should be connected

to the instrument BEFORE connection to the

mains supply. Should the mains lead require

replacement, a cable of 1mm

code H05VV-F connected to an IEC320 plug

should be used. The UK mains lead is protected

by a 10A fuse mounted in the plug top.

2

of harmonised

4. Preparation for Use

4.1 Electrical Installation

THIS EQUIPMENT MUST BE EARTHED

Before connecting the instrument, please read

and understand these instructions and ensure

that the electrical supply corresponds to that

shown on the rating plate. This unit is designed

for use with a supply rated at 115/230V,

50-60Hz. The power consumption of the unit is

60W. The unit is fitted with an IEC socket at the

side of the instrument for connection of the

mains lead.

Caution: Fuses are fitted in both live and

neutral lines.

The unit is supplied with two mains leads fitted

with IEC plugs. One lead has a UK 3 pin plug and

the other has a 2 pin “Shuko” plug for

connection to the mains supply. Choose the lead

appropriate for your electrical installation and

discard the other. Should neither lead be suitable

take the lead with the UK plug and replace the

plug with a suitable alternative. This involves

cutting off the moulded plug, preparing the cable

and connecting to the rewireable plug in

accordance with its instructions.

IT IS IMPORTANT THAT THIS OPERATION

SHOULD ONLY BE UNDERTAKEN BY A

QUALIFIED ELECTRICIAN.

Refer to the equipment’s rating plate to ensure

that the plug and fusing are suitable for the

voltage and wattage stated. The wires in the

mains cable are coloured as follows:

LIVE BROWN

NEUTRAL BLUE

EARTH GREEN/YELLOW

4.2 Installation

Connect the unit to the electricity supply but DO

NOT SWITCH ON. Place the unit on a firm, level,

non-slip surface ensuring that there is sufficient

free space on all sides without coming into

contact with anything else during use. Switch the

unit ON at the mains On/Off switch on the side

of the instrument. When switched ON, the touch

screen display will illuminate and the interface

software will load within 30 seconds.

IF IN DOUBT CONSULT A QUALIFIED

ELECTRICIAN

The sample block will become hot during

operation.

4

Page 9

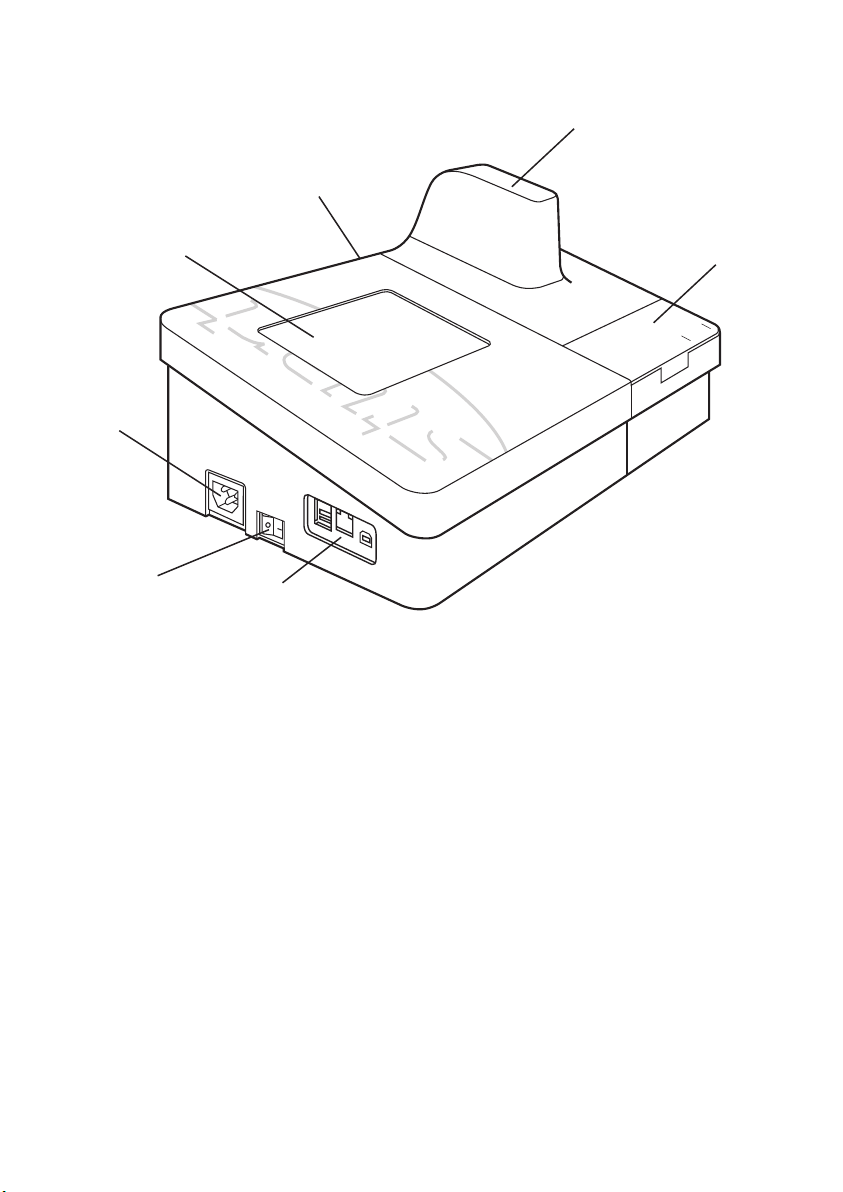

5. Instrument and Software

automatic melt ing point

SMP40

Controls

5.1 Instrument

Touch Screen

Interface and

Display

A/C power

input

Split Module Release

Mechanism

Sample Compartment

Capillary Storage

and Cutter

ON/OFF Switch

Mains On/Off: This is a rocker type switch found on the left hand side of the

unit. Pressing the “I” switches the unit ON. Pressing the “O”

switches the unit OFF.

Sample Compartment: This lifts to provide access to the sample block which is capable of

holding three capillary sample tubes.

Capillary tubes must be a minimum of 5.0cm in length to

ensure that they can be retrieved from the sample block.

Capillary Storage and Cutter: A compartment is provided for the storage of the glass capillaries

used in the melt determinations and incorporates a device to cut

capillary tubes.

Touch Screen Interface The touch screen interface is used to perform all control

and Display: functions on the SMP40. Live images of the sample compartment,

real-time data on the instrument’s status and the sample block’s

temperature can also be viewed on this display.

USB and Ethernet A USB flash drive can be inserted into the one of the USB ports,

Connections: allowing result files to be copied or moved from the device. If the

unit is to be connected directly to a PC please contact the technical

support department for advice. See page 35 for contact details.

The ethernet port is for service and support use only.

USB and Ethernet

Connections

Figure 2: SMP40 front view

5

Page 10

5.2 Main Menu Screen

Figure 3:

Main Menu

When the instrument is first switched on the display will show “LOADING PLEASE WAIT” message.

After 30 seconds the display will show the main menu screen and the four main menu options:

Measurement: This menu gives access to options that allow a new melt determination to be

performed using new, previously stored or preset method parameters.

Results: This menu gives access to the result files stored on the device. The result files report and

video file can be accessed from this menu.

File Management: This menu allows result files on the device to be copied or moved to an inserted

USB flash drive. The devices storage information is also displayed in this menu.

Settings and Calibration: This menu gives access to the devices user adjustable settings and also

allows the device to be recalibrated if required.

The Stuart SMP40 is controlled solely through the touch screen interface of the instrument. The

header bar is located at the top of the screen in most menus within the software interface.

Back button

Figure 4: The

Touchscreen

Header Bar

Back Button: Used to return to the previous screen at anytime

Block Temperature: Displays the actual temperature reading from the sample block

Time and Date: Displays the current time and date in the format specified in the user settings

Menu Title/Name: Displays the current menus title or name

Instrument Status: Displays the current instrument status

Home Button: Used to return to the main menu at anytime

Menu title/name Instrument status

Home button

6

Page 11

The command toolbar is located at the bottom of the screen in most menus within the software

interface. The command toolbar will give the user either one or two options based upon the menu

shown.

Figure 5: The Command Toolbar

If the number of options available in a menu exceeds the number that can be displayed on the screen,

a scrollbar will be displayed on the right hand side. Pressing the arrows at the top and bottom of the

scrollbar enables the list of options available in the menu to be seen.

The following controls are used to input data and adjust settings on the instrument:

Alphanumeric: Alphanumeric data can be

entered.

Numerical: Numerical data can be entered.

Date: Calender date information can be entered.

Time: 12/24hr time information can be entered.

Listed Options: Setting specific options can be

selected.

Drop Down List: Field specific options can be

selected.

Toggle Selection Field: Option is not selected or

selected respectively.

Other keys used:

BCK Removes the character directly behind the cursor or the highlighted characters.

DEL Removes the character directly in front of the cursor or the highlighted characters.

SHIFT Toggles the keypad between higher and lower case letters for one character entry.

CAPS Toggles the keypad between higher and lower case letters for all characters entered.

CLR Clears the characters in the current entry.

To change the data in each of these fields the screen should be pressed within the border of the control.

The interface used to add or change the setting depends on the type of control.

7

Page 12

5.2.1 Alphanumeric Entry Field

1 Selecting an Alphanumeric Entry Field opens

the text keypad interface.

2 The alphanumeric entry field can be

populated with letters (Abc), numbers (123)

or symbols (SYM). Text, numbers and symbols

are accessed using the Abc, 123 and SYM

keys on each of the respective keypads.

3 Entries are confirmed by pressing the “Accept

this text” button on the command toolbar.

5.2.2 Numerical Entry Field

8

1 Selecting a Numerical Entry Field opens the

numeric keypad interface.

2 The numeric entry field can only be populated

with numbers.

3 Entries are confirmed by pressing the “Accept

this number” button on the command

toolbar.

Page 13

5.2.3 Date Entry Field

5.2.4 Time Entry Field

1 Selecting a Date Entry Field opens the date

keypad interface.

2 The date entry field is displayed in the

format specified in the User Settings menu.

3 Press the arrows above and below each

number to increase or decrease the value

displayed.

4 Entries are confirmed by pressing the

“Accept this date” button on the

command toolbar.

1 Selecting a Time Entry Field opens the time

keypad interface.

2 The Time Entry Field is displayed in the 24

hour format.

3 Press the arrows above and below each

number to increase or decrease the value

displayed.

4 Entries are confirmed by pressing the “Accept

this time” button on the command toolbar.

5.2.5 Listed Options Field

1 Selecting a Listed Options Field opens the

listed options keypad interface.

2 The options available in the Listed Options

entry field is specific to each individual

setting. e.g. The Temperature Units setting

gives the options Celsius (˚C), Fahrenheit (˚F)

and Kelvin (K).

3 Use the scrollbar to view the full list of

available options for each setting.

4 The option that is required is selected by

pressing on the required option button.

9

Page 14

5.2.6 Drop Down List Field

5.2.7 Toggle Selection Field

6. Setting up New Methods

1 Selecting a Drop Down List Field displays the

options available for that field.

2 Arrows keys may be displayed to indicate that

further options are available. Use the arrow

buttons to view the additional options.

3 Press the required option from the list to

select it.

1 Pressing a Toggle Selection Field will add or

remove the check mark in that field.

2 A check mark indicates that the option is

active.

Touching the measurement section on the main menu screen will open the measurement menu where

three options are available:

Create a new measurement: This option

allows a new melt determination to be started.

Measurement parameters such as the Sample

Name, Start Temperature and Ramp Rate need to

be entered when using this option.

Use a preset from the library: This option

allows a new melt determination to be started

using measurement parameters stored previously

on the device.

Carry out a rapid-melt: The device will roughly

determine the melting point of the sample using

preset measurement parameters.

10

Page 15

6.1 Creating a New Method

In the Measurement menu screen touch the “Create a new measurement” section of the screen.

1 Enter a sample name for the samples by

selecting the Sample Name field

2 Enter an appropriate start or plateau

temperature for the sample by selecting the

Start Temperature field.

3 Enter the required temperature ramp rate for

the samples by selecting the Ramp Rate field.

4 Optional sample and method information is

accessed by pressing the “Touch here to enter

additional information” button. If this is not

required press “Continue” and go to step 8.

5 The SMP40 will automatically detect the end

of the melt when the toggle selection field

has an X in the Automatically detect the melt

end field. Removing this check mark allows a

value to be entered into the End Temperature

field.

6 Enter any batch or reference details in the

Batch/Reference alphanumeric entry field.

7 To proceed to the melt determination select

“Go back to main information” and then

select “Continue”.

8 The option of saving this new method as a

preset method will be given. Select “Yes” to

save the method for future use or select

“No” to proceed without saving the method.

11

Page 16

6.2 Preset Methods

In the Measurement menu screen touch the “Use a preset from the library” section of the screen.

1 In the preset methods screen select the

method to be used for the melt

determination by pressing on the method

details.

2 Press “Select preset and continue”.

3 Method parameters such as the Sample

Name, the Start Temperature and the Ramp

Rate can then be adjusted if required by

selecting the relevant field.

4 Optional sample and method information is

accessed by pressing the “Touch here to enter

additional information” button.

12

5 Method parameters can be adjusted if

required. The SMP40 will automatically detect

the end of the melt when the toggle selection

field has an X in the “Automatically detect

the melt end” field. Removing this check

mark allows a value to be entered into the

End Temperature field.

6 Enter any batch or reference details in the

Batch/Reference alphanumeric entry field.

7 To proceed to the melt determination, select

“Go back to main information” and then

select “Continue”.

Page 17

8 The option of saving this new method as a

new preset method will be given if the

sample name has been changed. Select “Yes”

to save the method for future use or select

“No” to proceed without saving the method.

9 If changes are made to the temperature

settings the user will be asked whether they

wish to overwrite the existing preset method

of that name. Select “Yes” to save the new

method settings for future use or select “No”

to proceed without saving the new settings.

6.3 Carry out a Rapid-Melt

If the user is unsure of the start temperature that should be specified in a melt determination method

they can use the rapid melt function to quickly determine an approximate melting temperature.

In the Measurement menu screen touch the “Carry out a rapid-melt” section of the screen.

1 The rapid melt function will heat the sample

from 50.0˚C at 20.0˚C/min until the sample

has melted.

2 The results will be reported on the screen as

shown in the example opposite.

3 The results from the rapid melt analysis can

then be used to facilitate the setting of the

start temperature on a more accurate melt

determination.

13

Page 18

7. Performing Melt Determinations

Once the analysis method and sample information have been entered into the SMP40 software the

instrument will display the New Measurement screen.

Current block

temperature

Sample name

Method

information

Live image

of the

sample

compartment

Figure 6: New Measurement Screen

The Capillary tubes melt status is for Information Only. An accurate analysis of the data is

performed after the melt determination has been completed.

Capillary

tubes melt

status

14

1 Place 1-3 prepared melting point capillaries

into the SMP40 sample compartments sample

block.

The external surface of the sample

capillaries must be wiped clean before being

placed into the sample block as chemical

residues may build up and affect the

performance of the device.

2 Press “Start the melt” to initiate the melting

protocol.

Page 19

3 The instrument status will change to

“Heating” and the command toolbar options

will change.

4 The SMP40 will quickly heat the sample block

to the set start temperature.

5 When the sample block reaches the start

temperature the SMP40 status will change to

“Stabilising” and the temperature of the

sample block will remain constant for 60

seconds.

6 After the instrument has stabilised at the start

temperature the status will change

automatically to “Analysing” and the

instrument will begin to heat the sample

capillaries at the specified ramp rate.

7 The Capillary tubes melt status is shown to

indicate the melt determinations progress.

The Capillary tubes melt status is shown for

Information Only.

15

Page 20

8 As the melt determination progresses the

capillary tube melt status changes through:

Solid: No changes have been detected in the

samples physical form.

Melting: The sample is showing the first signs of

a change in its physical form.

Liquid: The change in the samples physical form

is complete.

Finished: Once a capillary tube displays

“finished” the melt determination is complete.

Once all of the sample capillaries are deemed to

have finished, or the instrument reaches the

previously specified end temperature, the

instrument will complete the measurement and

display the samples analysis report.

At any time in the melt determination pressing

the “Stop and go back” button will end the melt

determination and save any data collected up

until that point.

16

Once the melt determination is complete the

analysis report will be displayed. The analysis

report displays the following information:

Statistical Analysis: The mean and standard

deviation are calculated for the clear point values

in the melt determination.

Method Information: Sample name, Filename,

Batch reference, Start and end temperatures,

Ramp rate, Time created, Date created, and

Calibration factor.

Individual Capillaries Results: Intensity graph,

melting range and clear point.

Page 21

8. Results

Touching the results section on the main menu screen will open the results menu. Two options are

now available:

View previous results: Displays the result files

of melt determinations previously carried out on

the device which are currently located on internal

storage.

Re-use result parameters: A result can be

selected and a repeat melt determination carried

out using the method settings from that result.

8.1 View Previous Results

In the Results menu screen touch the “View previous results” section of the screen. The View Results

screen allows the user to perform a number of actions with the result files stored on the instrument.

The actions available are displayed in the Results Toolbar.

Results

toolbar

Individual

sample results

Figure 7: View

Results Screen

The View Results screen allows the user to perform a number of actions with the result files stored

on the instrument. The actions available are displayed in the Results Toolbar.

Sort/Search: The Sort/Search function is used to display the stored result files in accordance with

the rules specified in this option.

Open: The Open action is used to display the Report screen for the selected result.

View Video: The View Video action is used to display the Video Replay screen for the selected

result.

17

Page 22

Rename: The Rename action is used to change the Sample Name for the selected result.

Delete: The Delete action is used to delete the selected result from the instruments internal storage.

8.1.1 Sort/Search Function

In the menus that display the stored methods and

results the user has the option to organise the

displayed data using either a sort by or search for

function.

Sort:

1 Pressing the “Sort/Search” button will change

the tool bar to allow the user to specify which

function is required.

2 Pressing the “Sort By” button will display the

sort toolbar options.

3 The sort toolbar allows a method or

parameter to be selected to organise the

displayed data.

4 Select the parameter to be used to organise

the displayed data by pressing the

appropriate button.

5 Pressing the button twice will reverse the

order or the displayed data.

6 Highlight the required result file and press the

“Select result (or preset) and continue”

button.

7 The “Other” button on the toolbar can be

used to access additional parameters such as

Filename, Start Temperature, End Temperature

and Ramp Rate with which to sort the

displayed files.

18

Search

1 Pressing the “Sort/Search” button will change

the tool bar to allow the user to specify

which function is required.

2 Pressing the “Search By” button will display

the search options screen.

3 Pressing on a data entry field allows the user

to define the search criteria for that field.

Page 23

4 The required option should be selected from

the displayed list or alternatively enter the

search criteria using the keypad that is

displayed.

5 When the search criteria have been finalised,

press “Apply this search”.

6 Only the results that match the search criteria

specified will now be displayed.

7 Pressing the “Sort/Search” and “Search”

buttons again will display the search results

summary and allow a new search to be

started.

8 Press the “Search again” button to apply new

search criteria.

9 Press the “Clear search” button to remove

the specified search criteria.

19

Page 24

8.1.2 Opening Results Files

When a melt determination is complete or a

result file is opened, the screen will display the

Report Screen.

The report displays the following information:

The mean clear point: The average of the

sample capillaries clear point values is

automatically calculated.

The standard deviation of the clear points:

The standard deviation of the sample capillaries

clear point values is automatically calculated.

Method information: The Sample name,

Filename, Batch reference (if entered), Analysed

temperature range, Ramp rate, Time created,

Date created, and Calibration factor are all

displayed in the analysis report.

Intensity graphs for each capillary tube: The

device continuously measures each capillary tubes

image intensity value during the melt

determination. These graphs show how the

intensity value changes throughout the melt

determination. Coloured lines indicate the start

(green) and end (red) of the melting range.

Recorded events for each capillary tube:

Automatic and any manually recorded events are

displayed for each capillary tube.

Use the scrollbar to review the data

contained in the report: Use the arrows to

scroll up and down the report.

If a video record of the melt determination has

been stored it can be reviewed by pressing the

“View the video” button on the command

toolbar.

20

Page 25

8.1.3 Viewing Videos

When a video record is accessed the Video Replay screen is displayed.

Block

temperature

at specific

time

Selected

capillary

Video replay

window

Displays report

information

summary

Tagged event

selection

Video

controls

Figure 8: Video Replay Screen

The Video Replay screen is designed to allow the user to review the recorded video of a melt

determination and reprocess the results if required.

Block temperature at specific time: The temperature of the sample block at the specific timeframe

displayed in the video replay window.

Report information: Pressing the “Touch for automatically calculated values” button displays the

screen below. Each capillary tube has its start temperature, end temperature and clear point displayed.

In addition, the mean value of the start and end temperatures is calculated and displayed.

Press the “Hide” button to return to the Video Replay screen.

Tagged event selection: During the melt determination additional events may occur that are

required to be recorded in the report. Pressing this button accesses the list of available events that can

be added to the analysis report.

Capillary selection: In order to record a manual event you must first select the number of the

capillary tube it applies to by using these buttons.

Video replay window: The Video replay window displays the images that were recorded during the

substances melt determination. To view the image in full screen mode press the video replay window.

Pressing the screen again will return the device to the normal Video Replay screen.

Video controls: The Video controls are used to control the playback of the substances melt

determination video.

Capillary

selection

buttons

21

Page 26

1 To start the video replay press the play button

(

) in the video replay controls. Once the

play button has been pressed it will change to

a pause symbol (

2 The video replay scrollbar will move and

display the elapsed time in the format

mins:seconds.

3 The scrollbar can be used to quickly move to

any timeframe within the video file. Touch the

scrollbar and whilst still touching the screen,

drag the scrollbar to the required timeframe.

4 Pressing the X2 button will double the speed

at which the video is replayed.

).

❙❙

5 The restart button (

return the beginning of the video file.

Manual Events

Each melt determination may contain events of interest that require highlighting in the report. The

SMP40 allows the user to review the melt video and add defined event information to specific

timeframes for each individual capillary tube. Both the automatically determined events and any

manually added events are shown in the analysis report.

The Tagged Events field can be used to add the following events:

Clear point: The sample is a clear liquid. Solid particles are no longer visible.

Collapse point: The substance collapses and begins to liquefy.

Decomposition point: The separation of a substance into its elements or smaller compounds. Often

seen as discolouration or charring of the sample.

End of melt: The point at which no further changes in the physical form of the substance are being

seen.

Start of melt: Droplets of liquid are clearly visible for the first time.

Meniscus point: A meniscus becomes clearly visible at the surface of the sample but solid particles

remain visible in the liquid.

Sublimation point: The substance undergoes a transition from the solid to gas phase with no

intermediate liquid stage.

Other: Use this tag if an event occurs that is not accurately described by the events listed previously.

❙) can be pressed to

22

Page 27

1 Select the capillary tube to which the manual

event is to be added by pressing the relevant

“Capillary selection” button.

2 Select the timeframe in the video file, where

the manual event is to be added, using the

video replay scrollbar and the video controls.

3 A manually determined event is added to the

timeframe by pressing the “Tagged Events”

field and selecting the required event from

the drop down list.

Manual events can only be used once in each

capillaries report. e.g. A capillary cannot

have more than one Meniscus Point.

4 Additional manual events can be added by

repeating the process described in steps 2

and 3.

5 If a manual event needs to be deleted,

pressing the X next to the manual event will

delete that event.

6 After the manual events have been added for

each capillary tube select “Save manual

overridden tags”. The screen will then go

back to the previously displayed screen.

23

Page 28

8.1.4 Renaming Result Files

The melt determination report is updated with

any manual events that are added and saved. An

asterisk next to the event name is used to denote

that it has been manually added by the user.

CAUTION: IF A MANUAL CLEAR POINT EVENT

IS ADDED BY THE USER, THE TEMPERATURE

VALUE IN THE MANUAL EVENT WILL BE USED

TO CALCULATE THE SAMPLES REPORTED

MELTING POINT.

1 When the “Rename” button is pressed for a

result a rename dialogue box is opened.

2 Press the alphanumeric entry field (Abc) in the

dialogue box to enter a new Sample Name for

the selected result.

24

3 The new Sample Name is then displayed in

the alphanumeric entry field. Select “OK” to

confirm the change to the results Sample

Name. Select “Cancel” to retain the current

Sample Name.

Page 29

8.1.5 Deleting Result Files

8.2 Re-use Result Parameters

1 To delete individual results from the

instruments memory highlight the result to be

deleted and press the “Delete” button on the

Result Toolbar.

2 A confirm delete dialogue box will appear

asking the user to confirm the action. Select

“Yes” to confirm or “No” to cancel.

In the Results menu screen touch the “Re-use

result parameters” section of the screen.

1 In the Repeat Measurement screen highlight

the result file to be repeated.

2 Press “Select result and continue”.

3 The method parameters used previously will

be loaded into the Create New Method

screen.

4 Method parameters and information can be 4

adjusted and a new measurement initiated as

described on page 14.

25

Page 30

9 File Management

Touching the File Management section on the main menu screen will open the File Management

menu. Two options are now available:

Manage files: Result files can be copied, moved

or deleted from the devices internal storage.

View storage information: Displays status

information on the internal storage or an inserted

USB flash drive.

9.1 Manage Files

In the File Management menu screen touch the Manage files section of the screen.

Manage files

toolbar

Individual

sample

results

Figure 9:

Manage Files

Screen

The View Results screen allows the user to perform a number of actions with the result files stored on

the instrument. The actions available are displayed in the Result Toolbar:

Sort/Search: See page 18

Select All/Clear Selection: The Select All/Clear Selection action is used to select all of the result files

on the instrument or it can be used to deselect the result files currently highlighted.

Copy: The Copy action is used to copy the selected result files to the inserted USB flash drive.

Move: The Move action is used to move the selected result files to the inserted USB flash drive.

Delete: The Delete action is used to delete the selected result files from the instruments memory.

26

Page 31

9.1.1 Select All/Clear Selection

9.1.2 Copying Files

1 Pressing the “Select All” button in the Manage

Files toolbar will highlight all of the result

files.

2 If any of the result files in the Manage Files

screen are selected, the “Select All” button

will change to a “Clear Selection” button.

Pressing the “Clear Selection” button will

deselect all the highlighted result files.

1 Result files can be copied to an inserted USB

flash drive by highlighting the files to be

copied and pressing the “Copy” button in

the Manage Files toolbar.

2 A window is displayed to show the progress

of the copy action.

Copying a typical 5MB result and video file will

take approximately 10 seconds.

9.1.3 Moving Files

1 Result files can be moved to an inserted USB

flash drive by highlighting the files to be

moved and pressing the “Move” button in

the Manage Files toolbar.

2 A window is displayed to show the progress

of the move action.

Moving a typical 5MB result and video file will

take approximately 10 seconds.

27

Page 32

9.1.4 Deleting Files

3 Once the move action has been completed

the files will no longer be available on the

instrument so ensure that no further

reprocessing of the results is required before

using the move action as it is not possible to

move the file back, from the USB flash drive

to the instrument, once the action is

complete.

1 To delete results from the instruments

memory highlight the results to be deleted

and press the “Delete” button on the

Manage Files Toolbar.

2 A confirm delete dialogue box will appear

asking the user to confirm the action. Select

“Yes” to confirm or “No” to cancel.

9.2 View Storage Information

In the File Management menu screen touch the View storage information section of the screen.

1 The Storage Details screen displays

information on the status of the internal

memory.

Information displayed includes:

Total storage capacity.

Available storage capacity.

Details on the types of files stored on the

instrument.

2 If a USB flash drive is inserted, a summary of

the flash drives storage information can be

displayed by pressing the Change to inserted

USB flash drive section of the screen.

28

Page 33

10 Settings and Calibration

Touching the Settings and Calibration section on the main menu screen will open the Settings and

Calibration menu. There are three options available:

Change user settings: Settings that relate to

how the device operates and displays information

can be viewed and adjusted in this menu.

Change maintenance settings: The devices

software can be upgraded and the touch screen

can be recalibrated in this menu.

Manage device calibration: This menu can be

used to recalibrate the device and view stored

information on the devices calibration history.

10.1 User Settings

The following user settings can be accessed and adjusted by pressing the Change user settings section

of the Settings and Calibration screen.

Date format: The devices displayed date can be set to UK or US format.

Time format: The devices displayed time can be set to 12 or 24 hour format.

Temperature unit: The devices displayed temperature unit can be set to centigrade (˚C), fahrenheit

(˚F) or Kelvin (K).

Camera gain: The devices camera gain can be adjusted to make the image of the sample capillaries

darker or brighter. Three settings of Low, Normal and High are available. The “Low” settings will

reduce the brightness of the image compared to the “Normal” setting and the “High” setting will

increase the brightness of the image compared to the “Normal” setting. The “Normal” setting should

be suitable for most melt determinations.

Calibration frequency: The frequency at which the device is recommended to be recalibrated can be

specified using this option. The available options are Never, Weekly, Monthly, Bi-annually and Yearly.

When a melt determination is initiated, the dialogue box below will be displayed if the time period

specified in this setting has elapsed since the previous calibration. Pressing “OK” will allow the user to

continue with the melt determination.

The dialogue box will be displayed each time a melt determination is initiated, until the device is

recalibrated or the calibration frequency setting is changed.

29

Page 34

Set time: The devices displayed time can be set using the time keypad interface.

Set date: The devices displayed date can be set using the date keypad interface.

Save melt video: If the video files of the devices melt determinations do not need to be stored,

remove the check mark in this Toggle Selection field.

Use sounds for events: If sounds are not required for events that occur on the device, remove the

check mark in this Toggle Selection field.

Use sounds for screen touches: If a sound is not required to confirm each time the touch screen is

pressed, remove the check mark in this Toggle Selection field.

In the Settings and Calibration menu screen

touch the Change user settings section of the

screen.

1 The Change User Settings screen displays the

current status of all the user adjustable

instrument settings.

2 To adjust any of the displayed settings, touch

the individual settings control field and a new

setting can be entered by following the

control instructions on pages 11 and 12.

3 When the required adjustments have been

made press “Save these settings” on the

command toolbar to apply them.

30

Page 35

10.2 Maintenance Settings

In the Settings and Calibration menu screen touch the Change maintenance settings section of the

screen. The Maintenance screen allows the user to upgrade the version of software on the instrument

and to recalibrate the touch screen.

1 To upgrade the instruments software, firstly

download the new software version onto a

USB flash drive. Insert the USB flash drive into

one of the SMP40’s USB ports and touch the

“Press to upgrade” button. The new software

version will be automatically installed onto

the instrument.

Do not switch off the device or attempt to

remove the USB flash drive during this

process.

2 To recalibrate the touch screen touch the

“Press to enter screen calibration” button and

follow the on-screen instructions.

10.3 Instrument Calibration

To ensure that the instrument is operating correctly, periodic checks on the accuracy of the instruments

temperature readings are commonly performed. If the accuracy of the instrument is found to deviate

from the specification or if it is a requirement of your local quality policy, the following procedure can

be used to recalibrate the displayed temperature on the instrument.

It is recommended that the recalibration procedure is performed using suitable certified reference

materials (CRM’s), as this will ensure the highest levels of confidence is maintained in the results

generated with the instrument. The World Health Organisation (WHO) gives a list of suitable CRM’s

which includes the following materials:

Material Nominal Melting Point

Azobenzene 69 °C

Vanillin 83 °C

Benzil 96 °C

Acetanilide 116 °C

Phenacetin 136 °C

Benzanilide 165 °C

Sulfanilamide 166 °C

Sulfapyridine 193 °C

Dicyanodiamide 210 °C

Saccharin 229 °C

Caffeine 237 °C

Phenolphthalein 263 °C

31

Page 36

For information on where to purchase suitable certified reference materials please contact us:

stuarthelp@bibby-scientific.com

Tel: +44 (0)1785 810433

In the Settings and Calibration menu screen touch the Manage device calibration section of the screen.

Current

calibration

factor

Current calibration

type

Time and type

of current

calibration

Date of next

calibration

Figure 10: Calibration Screen

The Calibration screen shows the following information:

Current calibration factor: The current calibration factor of the device

Calibration type of the current calibration: Three types of calibration are possible: Single, Dual

and Factory.

Time and date of current calibration: Displays the time and date of the current calibration.

Date when next calibration is due: Displays the date when the next calibration is due to be

performed as specified in the user settings.

Previous calibration history: Displays a summary of the devices historical calibrations including the

time, date, type and calibration factor.

Calibration

history

window

32

Page 37

10.3.1 Current Calibration Factor

Results Calibration Factor

�

�

The current calibration factor shows the factor which is used to calculate the displayed block

temperature on the device.

Displayed Block Temperature = Instruments Sensor Temperature x Calibration Factor

To calculate a new calibration factor the instrument uses the following equation.

New Calibration Factor Calculation:

Calibribration = Expected Melting Point

Factor

Please see the following calibration procedure for more details on calibrating the instrument.

10.3.2 Calibration Procedure

The SMP40 allows the user to perform either a single or dual point calibration by using the following

procedure.

1 Using a suitable certified reference material,

perform a melt determination as described in

section 7.

2 If a dual point calibration is required, perform

a second melt determination on a certified

reference material with a different melting

point to that used in step 1.

3 If manual events need to be added to a result

file, they should be added using the steps

described on page 22 before starting the

recalibration procedure below.

4 In the Settings and Calibration screen select

the Manage device calibration section of the

screen.

5 In the Calibration screen press the “Calibrate

this device” button on the Command toolbar.

6 The Set Calibrated Values screen is used to

select the result files that will be used to

calibrate the instrument.

7 Select the first result to be used by pressing the

“Choose Result” field next to Value 1.

33

Page 38

8 In the Select Calibration screen highlight the

result file to be used for the first calibration

point.

9 Press the "Select result and continue" button

on the Command toolbar.

10 The results melting point (mean clear point) is

now displayed in the field. If the selected

result needs to be changed press this field

again and go to step 8.

11 If a dual point calibration is required press the

“Choose Result” field next to Value 2 and

repeat the selection process described in

steps 8 to 10.

34

12 Enter the certified melting point (clear point)

of the reference material/s in the respective

“Expected” numerical entry field/s.

13 The new calibration factor is calculated and

displayed on the screen.

14 To accept the new calibration factor press the

“Apply this calibration” button on the

Command toolbar.

Page 39

15 The calibration screen is now updated to

show the new calibration details. The

Calibration history window will now update

to display details of the previous calibration.

16 If a calibration record needs to be deleted,

pressing the X next to the calibration record

will display a confirm deletion dialogue box.

Press “YES” to confirm or “NO” to cancel.

35

Page 40

11. Maintenance

& Servicing

WARNING: Ensure the unit is disconnected

from the mains electricity supply before

attempting maintenance or servicing.

This equipment does not require routine

servicing. The only maintenance required is to

clean internal and external surfaces using a damp

cloth and mild detergent solution. Do not use

harsh or abrasive cleaning agents.

11.1 Repairs and Support

Any repairs or replacement of parts MUST be

undertaken by suitably qualified personnel. Only

spare parts supplied or specified by Stuart or its

agents should be used. Fitting of non-approved

parts may affect the performance and safety

features designed into the instrument. For a

comprehensive list of parts required by service

engineers conducting internal repairs please

contact the service department quoting the

model and serial number:

Email: service@bibby-scientific.com

Tel. +44 (0)1785 810475

Fax: +44 (0)1785 810471

For any other technical enquiries please contact

the Technical Support Department at;

Email: stuarthelp@bibby-scientific.com

Tel: +44 (0)1785 810433

2 Remove the plastic cover from the

instruments melt module.

3 Remove the ceramic sample block cover

and the metal plate covering the

sample block chamber by lifting them

clear of the instrument.

4 Unscrew the two thumbscrews on

either side of the sample block and lift

it out of the instrument. Take care not

to damage the wiring that is connected

to the sample block during its removal.

5 Using a pair of long nosed pliers or

small tweezers remove the circlip from

the sample blocks glass window.

6 The glass window is removed by gently

agitating the sample block until the

window is dislodged form the sample

block.

7 Debris can now be removed from the

sample block. Please ensure the

window is clean before reassembly as

any grease or dirt on the glass could be

detrimental to the instruments

performance.

11.2 Cleaning the Sample Block

Occasionally it may be necessary to gain access to

the sample block to allow broken capillary tubes

or other debris to be removed.

Please ensure that the sample block is cooled

to room temperature and the instruments

electrical power supply is switched off or

disconnected before commencing the

following procedure.

1 Lift the cover of the capillary storage

compartment and remove the two

screws on either side of the recess.

36

8 Reassembly is the reverse of the above.

11.3 Accessories

The following accessories are available from your

local distributor.

Description Catalogue No.

Capillaries, open at both ends

(pack of 100) SMP1/4

Capillaries, open at one end

(pack of 100) SMP10/1

Capillaries, closed at both ends

(pack of 100) SMP2/1

Page 41

12. Warranty

Stuart warrants this instrument (excluding the

VGA touch screen) to be free from defects in

material and workmanship when used under

normal laboratory conditions, for a period of 3

years (the VGA touch screen warranty period

is 12 months). In the event of a justified claim

Bibby Scientific Ltd will replace any defective

component or replace the unit free of charge.

This warranty does NOT apply if damage is

caused by fire, accident, misuse, neglect,

incorrect adjustment or repair, damage caused by

incorrect installation, adaptation, modification,

fitting of non-approved parts or repair by

unauthorised personnel.

Bibby Scientific Ltd.

Stone

Staffordshire, ST15 0SA

United Kingdom

Tel: +44 (0) 1785 812121

Fax: +44 (0) 1785 813748

E-mail: equipment@bibby-scientific.com

Website: www.bibby-scientific.com

13. Specification

Overall Dimensions:

Height: 180mm

Depth: 210mm

Width: 340mm

Weight: 3.9kg

Technical Specifications:

Temperature range Ambient to 400°C

Temperature resolution 0.1°C

Ramp rate 0.1°C to 10°C/minute

Cooling time 350°C to 50°C

in 10 minutes

Number of samples Up to three

Display 5.7” Colour VGA touch

screen

Sensor PT1000

Memory storage 1GB

Electrical supply 115V / 230V, 50-60Hz

37

Page 42

Notes

38

Page 43

Notes

39

Page 44

Page 45

This product meets the applicable EC

harmonized standards for radio frequency

interference and may be expected not to

interfere with, or be affected by, other equipment with

similar qualifications. We cannot be sure that other

equipment used in its vicinity will meet these standards

NEW DEC

and so we cannot guarantee that interference will not

occur in practice. Where there is a possibility that injury,

damage or loss might occur if equipment malfunctions

due to radio frequency interference, or for general advice

before use, contact the Technical Department of Bibby

Scientific Ltd.

TO COME

Page 46

INSPECTION REPORT

MODEL SMP40

ELECTRICAL SAFETY

1. Earth continuity

✓

❏

2. Insulation ❏

3. Flash test ❏

✓

✓

FUNCTIONAL

1. Indicators

2. Temperature control ❏

3. Visual acceptance ❏

✓

❏

✓

✓

QUALITY CONTROL INSPECTOR

Bibby Scientific France SAS

ZI du Rocher Vert - BP 79

77793 Nemours Cedex

France

Tel: +33 1 64 45 13 13

Fax: +33 1 64 45 13 00

e-mail: bsf@bibby-scientific.fr

www.bibby-scientific.com

Bibby Scientific Italia Srl

Via Alcide de Gasperi 56

20077 Riozzo di Cerro al Lambro

Milano Italia

Tel: +39 (0)2 98230679

Fax: +39 (0)2 98230211

e-mail: marketing@bibby-scientific.it

www.bibby-scientific.it

Bibby Scientific Ltd

Beacon Road Stone

Staffordshire ST15 0SA

United Kingdom

Tel: +44 (0)1785 812121

Fax: +44 (0)1785 813748

e-mail: info@bibby-scientific.com

www.bibby-scientific.com

Bibby Scientific US Ltd

3 Terri Lane Suite 10

Burlington NJ 08016

USA

Tel: 800-225-9243

Fax: 609-589-2571

www.bibby-scientific.com

Bibby Scientific (Asia) Ltd

Room 607 Yen Sheng Centre

64 Hoi Yuen Road Kwun Tong

Kowloon Hong Kong

Tel: +852 3583 1581

Fax: +852 3583 1580

e-mail bibby@bibby-scientificasia.com

www.bibby-scientificasia.com

Page 47

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship

for a period of 37 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1)

month grace period to the normal three (3) year product warranty to cover handling and

shipping time. This ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer

Service Department will issue an Authorized Return (AR) number immediately upon phone or

written request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired

or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action

of the purchaser, including but not limited to mishandling, improper interfacing, operation outside

of design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit

shows evidence of having been tampered with or shows evidence of having been damaged as a

result of excessive corrosion; or current, heat, moisture or vibration; improper specification;

misapplication; misuse or other operating conditions outside of OMEGA’s control. Components in

which wear is not warranted, include but are not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability

for any damages that result from the use of its products in accordance with

information provided by OMEGA, either verbal or written. OMEGA warrants only that

the parts manufactured by the company will be as specified and free of defects.

OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND

WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED

WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The

remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA

with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a

“Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or

(2) in medical applications or used on humans. Should any Product(s) be used in or with any

nuclear installation or activity, medical application, used on humans, or misused in any way,

OMEGA assumes no responsibility as set forth in our basic WARRANTY / DISCLAIMER language,

and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability

or damage whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN

AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN

ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the

outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to

prevent breakage in transit.

FOR WARRANTY

RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the product

under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the

COST of the repair,

2. Model and serial number of the

product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2012 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, repro-

duced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior

written consent of OMEGA ENGINEERING, INC.

Page 48

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

SM

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

䡺⻬

Transducers & Strain Gages

䡺⻬

Load Cells & Pressure Gages

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters & Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators & Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition & Engineering Software

䡺⻬

Communications-Based Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM & Compatibles

䡺⻬

Data Logging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater Treatment

䡺⻬

pH, Conductivity & Dissolved Oxygen Instruments

M5096/0112

Loading...

Loading...