Page 1

(1*,1((5,1* ,1&

CUSTOM CONFIGURABLE SIGNAL CONDITIONING MODULES

SignalPro

OMEGA ENGINEERING, INC. Tel: (203) 359-1660

Signal Conditioning System

Users Manual

One Omega Drive Fax: (203) 359-7700

P.O. Box 4047 Toll free:1-800-826-6342

Stamford, CT 06907-4047 E-mail:das@omega.com

http://www.dasieee.com

Page 2

WARRANTY WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC., warrants this unit to be free of defects in materials and workmanship fo r a period of 13

months from the date of purchase. OMEGA warranty adds an additional one (1) month grace period to the normal one (1)

year product warranty to cover shipping and handling time. This ensures that OMEGA’s customers receive maximum

coverage on each product. If the unit should malfunction, it must be returned to the factory for evaluation. OMEGA’s

Customer Service Department will issue an Authorized Return (AR) number im mediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective it will be repaired or replaced at no charge. OMEGA’s

warranty does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling,

improper interfacing, operation o utside design limits, impr oper repair or unauthorized modif ication. This WARRANTY is

VOID if the unit shows evidence of having been tampered with or shows evidence of being damaged as a result of excessive

corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Com ponents which wear are not warranted, including but not limited to contact

points, fuses and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes

responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its products

in accordance with information provided from OMEGA, either verbal or written. OMEGA warrants only that the parts

manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND

ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PU RPOSE ARE HEREBY D ISCLAIMED . LIMITA TION O F LIABILITY: The remedi es of purc haser set

forth herein are exclusive and the total liability of OMEGA with respect to this order, whether based on contract,

warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the component

upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or special damages.

CONDITION S: Equipment so ld by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Comp onent”

under 10 CFR 21 (NRC), used in or with any nuclear installation or activity, medical application or used on humans.

Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on humans or

misused in any way, OMEGA assum es no respo nsibility as set forth in o ur basic WA RRAN TY/DISCLAI MER language, and

additionally, the purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever

arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING

ANY PRODUCT(S) TO OMEGA, THE PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM

OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). THE ASSIGNED

NUMBER SHOULD THEN BE MARKED ON THE OUTSIDE OF THE RETURN PACKAGE AND ON ANY

CORRESPONDEN CE. THE PURCHASER IS RESPONSIBLE FOR SHIPPING C HARGES, FREIGHT, IN SURANCE AND

PROPER PACKAGING TO PREVENT BREAKAGE IN TRANSIT.

FOR WARRANTY

(1) P.O. Number under which the product was purchased,

(2) Model and serial number of the product under warranty, and

(3) Repair instructions and/or specific problems relative to the product.

FOR NON-WARRANTY

BEFORE contacting OMEGA:

(1) P.O. Number to cover the cost of the repair,

(2) Model and serial number of the product, and

(3) Repair instructions relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvem ent is possible. This af fords our

customers the latest in technology and engineering. OM EGA is a registered trademark of OMEGA EN GI N EERIN G, I N C. ©

Copyright 1999 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated or reduced to any electronic medium or machine readable form , in whole or in part, without prior

written consent of OMEGA ENGINEERING, INC.

RETURNS, please have the following information available BEFORE contacting OMEGA:

REPAIRS, consult OMEGA fo r current repair charges. Have the fo llowing information available

Page 3

OMEGAnet On-line Service: Internet e-mail:

http://www.omega.com

Servicing North America

: One Omega Drive, Box 4047 E-mail: info@omega.com

USA

ISO 9001 Certified

Canada

: 976 Bergar E-mail: info@omega.com

Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

info@omega.com

:

For immediate technical or application assistance

USA and Canada

Mexico and Latin America

: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378/ 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

:Tel: (001) 800-826-6342 FAX: (001) 203-359-7807

En Espanol: (001) 203-359-7803

E-mail: espanol@omega.com

SM

:

SM

SM

Benelux

Czech Republic

France:

Germany/Austria

: Postbus 8034, 1180 LA Amstelveen, The Netherlands

: ul.Rude armady 1868, 733 01 Karvina-Hraniee

9, rue Denis Papin, 78190 Trappes

Servicing Europe

Tel: (31) 20 6418405

Toll Free in Benelux: 0800 0993344

E-mail: nl@omega.com

Tel: 42 (69) 6311899 FAX: 42 (69) 6311114

Toll Free: 0800-1-66342 E-mail: czech@omega.com

Tel: (33) 130-621-400

Toll Free in France: 0800-4-06342

E-mail: france@omega.com

: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017

Toll Free in Germany: 0130 11 21 66

E-mail: germany@omega.com

:

Page 4

United Kingdom: One Omega Drive, River Bend Technology Drive

ISO 9002 Certified

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that app ly.

OMEGA is constantly pursuing certification of it’s products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc.

accepts no liability for any errors it contains, and reserves the right to alter specifications without

notice. WARNING: These products are not designed for use in, and should not be used for, p atient

connected applications.

Northbank, Irlam, Manchester

M44 5EX, England

Tel: 44 (161) 777-6611

FAX: 44 (161) 777-6622

Toll Free in England: 0800-488-488

E-mail: info@omega.co.uk

Page 5

Table of Contents

29

4.3.4 Differential Thermocouple Measurements

29

4.3.3 Single Ended Thermocouple Measurements

29

4.3.2 Software Zero Correction

28

4.3.1 Cold Junction Compensation (CJC) Sensor

4.3 Basic Principles

26

4.2.2 QTC-200T Terminal Board Configuration

26

4.2.1 QTC-200 Interface Board Configuration

4.2 Hardware Configuration

25

4.1.2 QTC-200T Terminal Board Description

25

4.1.1 QTC-200 Interface Board Description

4.1 Circuit Board Description

4 QTC-200 Thermocouple Input Module

3.2 QTC-100 Specifications

22

3.1.2 Power Jack and Switch

22

3.1.1 AC/DC Power Supply Priority

3.1 Circuit Board Description

3 QTC-100 DC Voltage Power Adapter Module

2.4 Physical Dimensions

2.3 Power Requirements

19

2.2.3 Multiple Enclosures

19

2.2.2 External TTL Trigger Connector

19

2.2.1 Data Acquisition Adapter Connection

2.2 External Connections

2.1 Multiple Module Enclosures

2 SignalPro™ Series Racks and Enclosures

16

1.3.3 Expansion Channel Numbering

15

1.3.2 Board Selection Jumper Configuration

14

1.3.1 Main A/D Channel Selection and Jumper Configuration

1.3 Hardware Configuration

14

1.2.2 Terminal Board Description

13

1.2.1 Interface Board Description

1.2 Hardware Description

12

1.1.4 Analog-to-Digital Converter (ADC)

12

1.1.3 Multiplexer

12

1.1.2 Signal Conditioner

12

1.1.1 Transducers

1.1 Functional Description

1 SignalPro™ Series Overview

...............................

SignalPro Series Users Manual 5

......................................................

......................................................

.............................................

................................................

..................................

..............................................

.........................................

........................................

...........................................

................

................................

.....................................

11

11

13

14

...............

........................................

...............................................

................................

.....................................

...............................................

...............................................

...............................................

..........

..........................................

......................................

.............................................

.............................................

..................

..........................................

.................................

...............................

...........................................

..............................

.............................

....................................................

............................

...........................................

...........................

............................

18

19

19

20

20

21

22

23

24

25

26

28

Page 6

7.4 QTC-350/QTC-350S Specifications

7.3 Field Wiring

60

7.2.1 QTC-350 Interface Board Configuration

7.2 Hardware Configuration

7.1 Circuit Board Description

7 QTC-350 Accelerometer/Dynamic Signal Input

6.6 QTC-300S/QTC-300T Specifications

6.5 Configuration Examples

53

6.4.4 Quarter Bridge Strain Gage Measurements

52

6.4.3 Half Bridge Strain Gage Measurements

51

6.4.2 Full Bridge Strain Gage Measurements

51

6.4.1 Basic Principles

6.4 Strain Gage Measurements

50

6.3.2 Calibration Mode

49

6.3.1 Normal Mode

6.3 Calibration Modes

47

6.2.2 QTC-300T Terminal Board Configuration

43

6.2.1 QTC-300 Interface Board Configuration

6.2 Hardware Configuration

42

6.1.2 QTC-300T Terminal Board Description

42

6.1.1 QTC-300 Interface Board Description

6.1 Circuit Board Description

6 QTC-300 Strain Gage Input Signal

5.5 QTC-250/QTC-250T Specifications

38

5.4.3 Four-Wire RTD Measurements

38

5.4.2 Three-Wire RTD Measurements

37

5.4.1 Two-Wire RTD Measurements

5.4 Basic Principles

5.3 RTD Measurements

34

5.2.2 QTC-250T Terminal Board Configuration

34

5.2.1 QTC-250 Interface Board Configuration

5.2 Hardware Configuration

33

5.1.2 QTC-250T Terminal Board Description

33

5.1.1 QTC-250 Interface Board Description

5.1 Circuit Board Description

5 QTC-250 RTD Signal Conditioning Module

4.4 QTC-200/QTC-200T Specifications

.................................

SignalPro Series Users Manual 6

30

................................................

...................................................

Conditioning Module

.................................................

....................................................

.................................................

..................................................

............

..........................................

.................................

...............................

...........................................

..............................

.............................

......................................

.....................................

......................................

.................................

...........................................

..........................................

.................................

...............................

...........................................

..............................

.............................

.........................................

...............................

...............................

............................

............................................

................................

32

33

34

37

37

39

41

42

43

49

51

54

57

Module

..............................................................

..........................................

...........................................

..............................

.......................................................

..................................

59

60

60

65

67

Page 7

10.4 QTC-500/QTC-500T/QTC-500TC Specifications

10.3 Field Wiring

86

10.2.2 QTC-500T / QTC-500TC Terminal Board Configuration

85

10.2.1 QTC-500 Interface Board Configuration

10.2 Hardware Configuration

85

10.1.2 QTC-500T/QTC-500TC Terminal Board Description

85

10.1.1 QTC-500 Interface Board Description

10.1 Circuit Board Description

10 QTC-500 5B Module Multipurpose Isolated

9.5 QTC-450 Specifications

81

9.4.3 Low Pass Filter Design Examples

80

9.4.2 Filter Block Configuration

79

9.4.1 Filter Parameter Selection

9.4 Filter Design Program

9.3 Field Wiring

74

9.2.1 QTC-450 Interface Board Configuration

9.2 Hardware Configuration

9.1 Circuit Board Description

9 QTC-450 Low/High Bandpass Filter Input

8.3 QTC-400/400T Specifications

70

8.2.1 QTC-400 Interface Board Configuration

8.2 Hardware Configuration

70

8.1.2 QTC-400T Terminal Board Description

70

8.1.1 QTC-400 Interface Board Description

8.1 Circuit Board Description

8 QTC-400 Universal Current/Voltage Input

Module

SignalPro Series Users Manual 7

..............................................................

..........................................

.................................

...............................

...........................................

..............................

.......................................

69

70

70

72

Module

..............................................................

.......................................................

Signal Input Card

......................................................

..........................................

...........................................

..............................

..............................................

..........................................

..........................................

....................................

.............................................

................................................

.........................................

................................

...................

..........................................

..............................

................

...................

73

74

74

78

79

82

84

85

85

86

88

Page 8

List of Figures

61

Figure 7-4. Filter Selection Jumpers

61

Figure 7-3. QTC-350/QTC-350S SSH Selection Jumper

60

Figure 7-2. QTC-350 Interface Board Jumper and Switch Locations

59

Figure 7-1. QTC-350 Accelerometer/Dynamic Signal Input Module

53

Figure 6-15. Quarter Bridge Wiring Configuration

52

Figure 6-14. Half Bridge Wiring Configuration

52

Figure 6-13. Full Bridge Wiring Configuration

51

Figure 6-12. Full Wheatstone Bridge Strain Gage Measurement

49

Figure 6-11. Calibration Modes

48

Figure 6-10. External Excitation Power Supply Connections

48

Figure 6-9. Excitation Current Selection

47

Figure 6-8. QTC-300T Terminal Board

46

Figure 6-7. AC/DC Coupling Jumper

45

Figure 6-6. Low-Pass Filter Block

45

Figure 6-5. Filter Selection Jumper

44

Figure 6-4. A/D Gain Selection Jumpers

44

Figure 6-3. QTC-300/QTC-300S SSH Selection Jumper

43

Figure 6-2. QTC-300 Jumper and Filter Block Locations

41

Figure 6-1. QTC-300 Strain Gage Input Module

38

Figure 5-8. Four-Wire RTD Measurement

38

Figure 5-7. Three-Wire RTD Measurement

37

Figure 5-6. Two-Wire RTD Measurement

36

Figure 5-5. Excitation Current Selection Jumpers

36

Figure 5-4. A/D Gain Selection Switches

34

Figure 5-3. QTC-250 Interface Board Jumper Locations

33

Figure 5-2. QTC-250T Terminal Board

32

Figure 5-1. RTD Signal Conditioning Module

29

Figure 4-6. Differential Thermocouple Measurement

29

Figure 4-5 Single Ended Thermocouple Measurement

27

Figure 4-4. Thermocouple Input Mode Selection Switches

27

Figure 4-3. QTC-200T Terminal Board

26

Figure 4-2. QTC-200 Main A/D Channel Jumper Block Location

24

Figure 4-1. QTC-200 Thermocouple Input Module

22

Figure 3-2. QTC-100 Block Diagram

21

Figure 3-1. QTC-100 DC Voltage Power Adapter Module

19

Figure 2-2. Multiple Module Enclosure Block Diagram

18

Figure 2-1. SignalPro Series Data Acquisition Racks and Enclosures

17

Figure 1-5. Expansion Channel Numbering in a Multiple Module System

16

Figure 1-4. SignalPro Series Board Selection Jumpers

15

Figure 1-3. SignalPro Series Main A/D Channel Selection Jumpers

13

Figure 1-2. SignalPro Portable Signal Conditioning System (QTC-250-PCS)

11

Figure 1-1. SignalPro Data Acquisition System Block Diagram

......................

SignalPro Series Users Manual 8

............

...................

..............................

..................

.............................

...........................

.............................................

................................

.....................

...........................................

..........................

.............................

..............................

.....................................

...........................................

.............................

........................................

..................................

........................................

.......................................

........................................

...................................

............................

............................

.........................................

..............................................

...............................................

...........................................

...........................................

..........................................

..........................

..................................................

.......................

.....................................

....................................

.................................

..................

...................

............................

.............................................

.............

Page 9

87

Figure 10-4. Field Wiring of 5B Series Modules

86

Figure 10-3. QTC-500T /QTC-500TC Terminal Board

85

Figure 10-2. QTC-500 Jumper Block Locations

84

Figure 10-1. QTC-500 5B Module Multipurpose Isolated Input Card

80

Figure 9-10. Corresponding Component Values of LP, HP and PP1

80

Figure 9-9. Low-pass, Band-pass and High-pass Filter Block Diagram

78

Figure 9-8. QTC-450 Wiring Diagram

77

Figure 9-7. Analog Ground Option Switch

76

Figure 9-6. Filter Block Socket Designations

76

Figure 9-5. SSH Selection Jumper

75

Figure 9-4. Filter Selection Jumpers

75

Figure 9-3. A/D Channel Gain Selection Jumpers

74

Figure 9-2. QTC-450 Jumper Block, Filter Block and Switch Locations

73

Figure 9-1. QTC-450 Low/High Bandpass Filter Input Module

71

Figure 8-3. Analog Ground Option Jumper

70

Figure 8-2. Current Measurement Resistor Sockets

69

Figure 8-1. QTC-400 Universal Voltage/Current Module

65

Figure 7-11. Dynamic Sensor Configuration

65

Figure 7-10. ICP Sensor Configuration

64

Figure 7-9. Excitation Current Selection

63

Figure 7-8. A/D Gain Selection Switch

63

Figure 7-7. AC/DC Coupling Selection Jumper

63

Figure 7-6. Sensor Type Selection Jumper

........................................

62

Figure 7-5. Filter Block Socket Designations

......................................

SignalPro Series Users Manual 9

....................................

...........................................

..........................................

............................................

.......................................

...........................

.................................

.......................................

......................

.................

..................................

..............................................

...............................................

......................................

........................................

............................................

................

....................

...................

......................................

...............................

.....................................

Page 10

List of Tables

81

Table 9-2. Butterworth Low Pass Filter Design Examples

77

Table 9-1. Omega Pre-Configured Filter Blocks

66

Table 7-4. Maximum Driving Capability of a Coaxial Cable with 30pF/ft. Capacitance

64

Table 7-3. Expansion Channels versus A/D Gain Selection

62

Table 7-2. Butterworth Low Pass Filter Design Examples

62

Table 7-1. Omega Pre-Configured RC Filter Blocks

50

Table 6-3. QTC-300 Calibration Modes

46

Table 6-2. Butterworth Low Pass Filter Design Examples

46

Table 6-1. Omega Pre-Configured RC Filter Blocks

35

Table 5-1. Suggested Gain and Excitation Current Values for Supported RTD Types

20

Table 2-1. Data Acquisition Enclosure Physical Dimensions

15

Table 1-2. Main A/D Channel Jumper Block Designators

14

Table 1-1. Expansion Channel Availability

.......................................

SignalPro Series Users Manual 10

...........................

.........................

.................................

...........................

..........................................

.................................

...........................

..........................

....................................

...........................

....

..

Page 11

1 SignalPro Series Overview

SignalPro Series Users Manual 11

Electrical measurement of physical quantities is often performed using a “transducer”.

Transducers, i n the context of this discussi on, are d evices that convert physical quantities such

as acceleration, strain or temperature to an electrical output signal. An example of a

transducer is the thermocouple, which is used to measure temperature. Transducers are

available in a wide variety of shapes, sizes and specifications for most applications.

The Omega SignalPro signal conditioning system provides a complete solution for data

acquisition using transducers. The SignalPro system provides the transducer with excitation

or biasing when required and then performs the necessary “conditioning” of the electrical

output signal from the transducer prior to measurement by an analog-to-digital converter

(ADC).

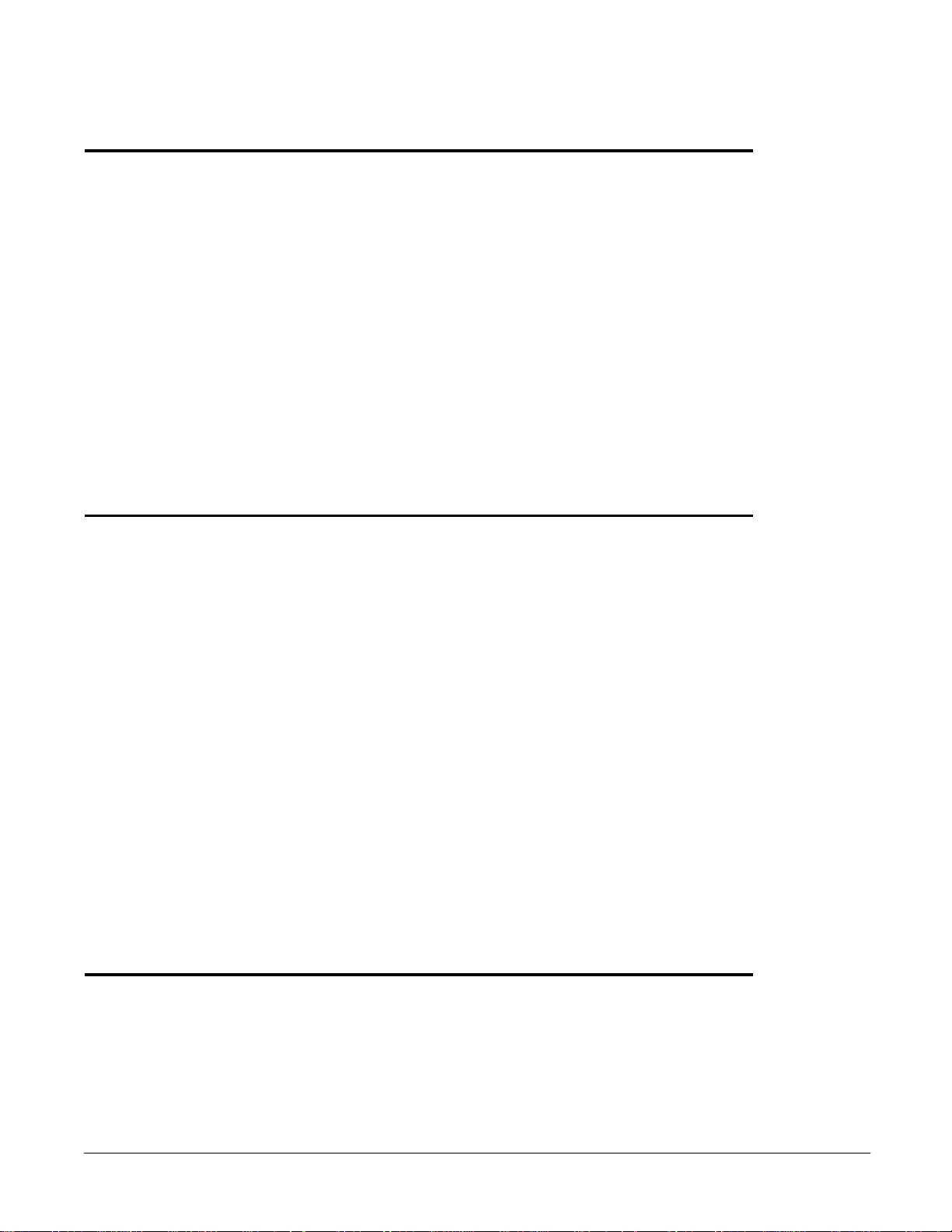

1.1 Functional Description

The SignalPro signal conditioning system covers a wide range of transducers and

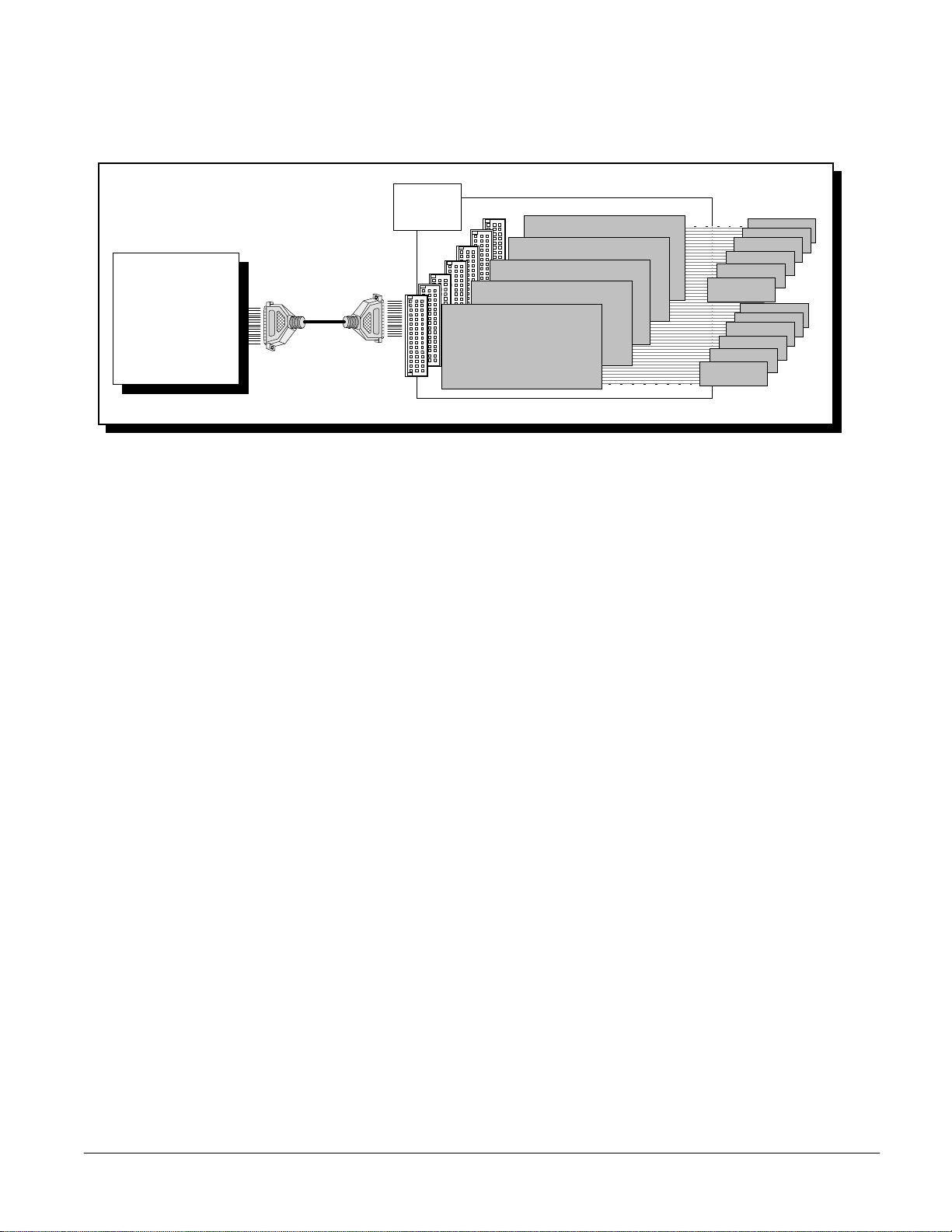

applications, ye t most of the modul es shar e some common elements. F i gur e 1-1 shows a bl ock

diagram of a typical data acquisition system using SignalPro series signal conditioning

modules.

Transducer

Signal

Conditioner

Transducer

Signal

Conditioner

Multiplexer

ADC

Computer

Transducer

Signal

Conditioner

Transducer

Signal

Conditioner

Figure 1-1. SignalPro Data Acquisition System Block Diagram

Page 12

1.1.1 Transducers

The SignalPro series includes signal conditioning modules that enable the user to create data

SignalPro Series Users Manual 12

acquisition systems for transducers such as thermocouples, resistance temperature detectors

(RTDs), strain gages and accelerometers. Multiple transducers can be attached to a single

module, the number of which depends on the specific module selected.

1.1.2 Signal Conditioner

The electri ca l output signal generated b y a transducer of te n nee d s “conditioni ng ” b e f or e it can

be measured by an ADC. The signal may require amplification, filtering, linearization and

more before the ADC can accurately read it. Additionally, some transducers require an

excitation source or proper bia sing to complete me asurements. The Signal Pro syste m provid es

the transducer with any required excitation or biasing and performs all necessary

conditioning of the electrical output signal.

1.1.3 Multiplexer

SignalPro ser ies modul es can pr ovide up to 16 cha nnels of tr ansducer input b y mul tipl exi ng a

single main analog-to-digital (A/D) channel off the data acquisition adapter in the host

computer. The mul tiplexers on a SignalPro seri es module work like a switch, scanning each

transducer input channel and connecting the input to the selected main A/D channel.

The multipl exed input channels on the SignalPro modul e may be mapped back to any main

A/D channel on the data acquisition adapter in the host computer via jumper configuration.

Some modules provide less than 16 input channels, yet allow multiple modules to share a

single main A/D channel. For example, the QTC-250 RTD signal conditioning module has

eight input channels. Two QTC-250 modules may share one main A/D input channel to

provide 16 transducer input channels per main A/D channel. Multiplexing of all 16 main

A/D channels, (provided the A/D adapter type supports 16 channels), from the host

computer data acquisition adapter results in a maximum of 256 A/D transducer input

channels (16 x 16) per adapter.

1.1.4 Analog-to-Digital Converter (ADC)

The analog output si gnal from the tra nsducer is converted to di gital inf ormation by the ADC

in the data acquisition adapter in the host computer. Omega offers a complete line of data

acquisition adapters with both 12 and 16 bit resolution.

Page 13

1.2 Hardware Description

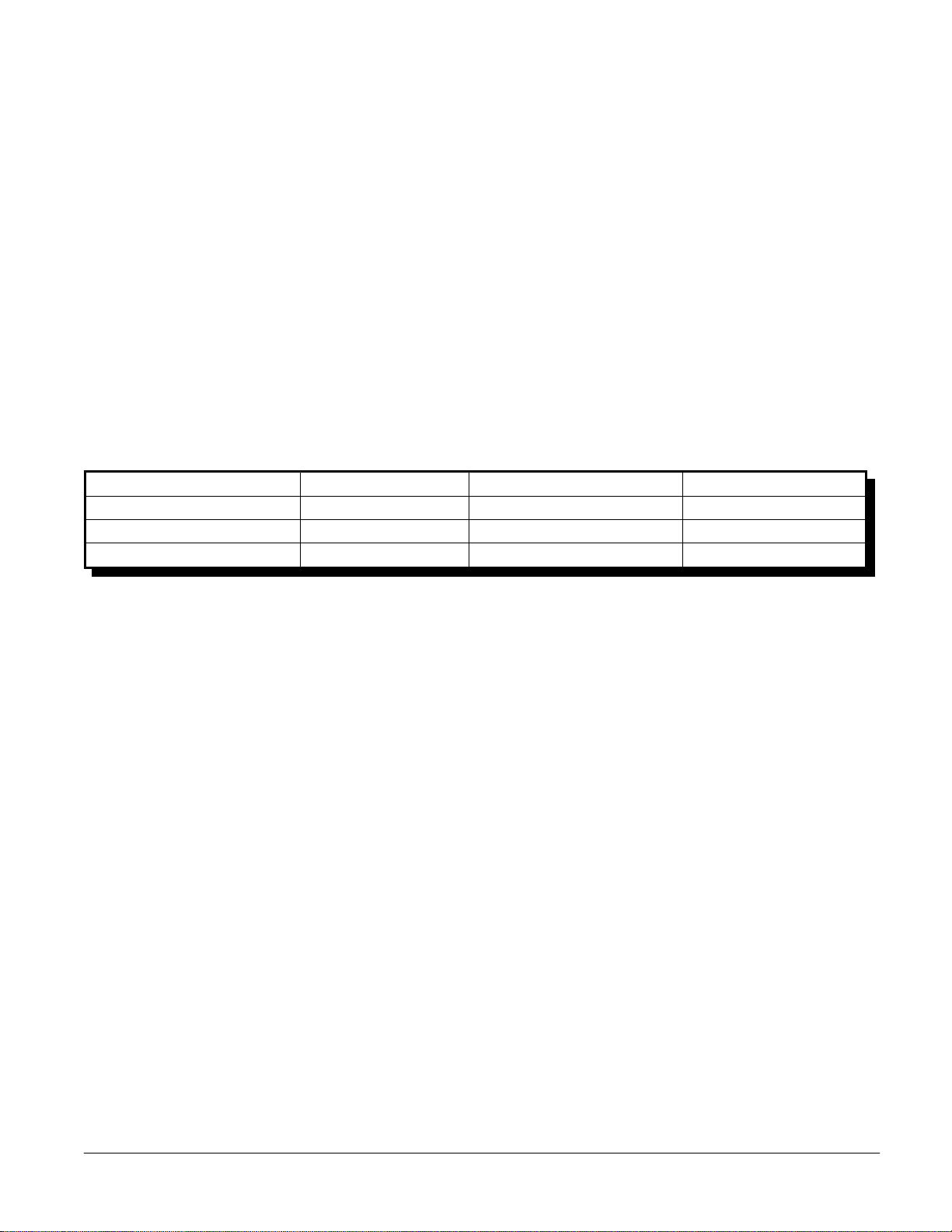

SignalPro series modules come in several configurations. The QTC-100 is a self-contained

SignalPro Series Users Manual 13

power adapter module. The QTC-350 and QTC-450 are self contained interface boards with

BNC connectors. The remaining modules consist of two circuit boards: an interface board and

a removable terminal board. The interface boards are standard 3U size and easily mount in

the QTE-7 (seven modules), QTE-14 (fourteen modules) or QTC-xxx-PCS (one module) data

acquisition enclosures. The SignalPro terminal boards contain the transducer input screw

terminal blocks and most of the user configurable switches and jumper blocks. Figure 1-2

depicts a two board configuration with a single module data acquisition enclosure.

Terminal Box

QTC-250 Terminal Board

QTC-250 Interface Board

QTC-250-PCS Enclosure

SignalPro Series

Portable Signal Conditioning

System

Figure 1-2. SignalPro Portable Signal Conditioning System (QTC-250-PCS)

1.2.1 Interface Board Description

SignalPro i nterface board s operate with the following transducers and sensor s: thermocouple

(QTC-200/200T), RTD (QTC-250/250T), strain gage (QTC-300/300T), accelerometer

(QTC-350), voltage/current (QTC-400/400T) and analog signal filter (QTC-450). The

QTC-500/500T is a multipurpose interface board that provides isolated input signals utilizing

5B modules. The SignalPro DC voltage adapter module, QTC-100, provides a versatile means

to power signal conditioning modules mounted in the QTE-7 half rack housing unit using

automobile battery power. After the initial configuration and mounting of an interface circuit

board, it rarely requires removal from the QTE-7, QTE-14 or QTC-xxx-PCS enclosure. For

information on interface board data acquisition enclosures, see Chapter 2: SignalPro Series

Racks and Enclosures.

Page 14

1.2.2 Terminal Board Description

SignalPro series modules QTC-200, 250, 300, 400 and 500 use the removable terminal board to

8

QTC-500

4

QTC-450

16

QTC-400

4

QTC-350

4

QTC-300

8

QTC-250

14

QTC-200

Number of Expansion

Signal Conditioning Module

SignalPro Series Users Manual 14

facilitate the quick connection of transducer lead wires. Lead wires easily attach to the screw

blocks on the portable terminal board. SignalPro series terminal boards slide into their own

protective enclosur e which connects externally to the inte rface board and is secur ed with two

thumb screws.

1.3 Hardware Configuration

For the purpose of this discussion, it is presumed the user is configuring the SignalPro signal

conditioning system using an Omega sixteen channel data acquisition adapter, product

number: DAQP-12 or DAQP-16 (PCMCIA) or DAQ-1201/02 (ISA).

1.3.1 Main A/D Channel Selection and Jumper Configuration

There are sixteen analog input channels on the main connector of a Omega data acquisition

adapter. Each analog input channel of the adapter can connect to either one signal

conditioning module or multiple modules of the same type and thus be expanded up to 16

signal condi tioning channel s. Th e number of mod ules that can be connected to a singl e analog

input channel varies depending on the number of expansion channels the specific module

supports. For example, the QTC-300 supports four expansion channels, so four modules can

be connected to one analog input channel (4 x 4 = 16). The QTC-250 supports eight expansion

channels, so two modul es can be connecte d to one anal og input channel (8 x 2 = 16 ). Ta ble 1-1

lists available expansion channels.

Channels Supported

Table 1-1. Expansion Channel Availability

SignalPro series modules can occupy any analog input channel on the data acquisition

adapter. Which channel the module(s) will occupy is dependent on the configuration of the

main A/D channel selection jumper. Note that if multiple modules occupy the same main

A/D channel, then each module must have the same jumper setting. Figure 1-3 depicts the

main A/D channel selection jumper. The factory default setting is channel zero (CH0) for all

SignalPro series modules installed in the QTC-xxx-PCS portable data acquisition enclosure.

For modules installed in the QTE-7 and QTE-14 rack enclosures, the factory default setting for

the main A/D channel jumper will vary depending on the number of modules in each system.

See section 1.3.3 for a system configuration example.

Page 15

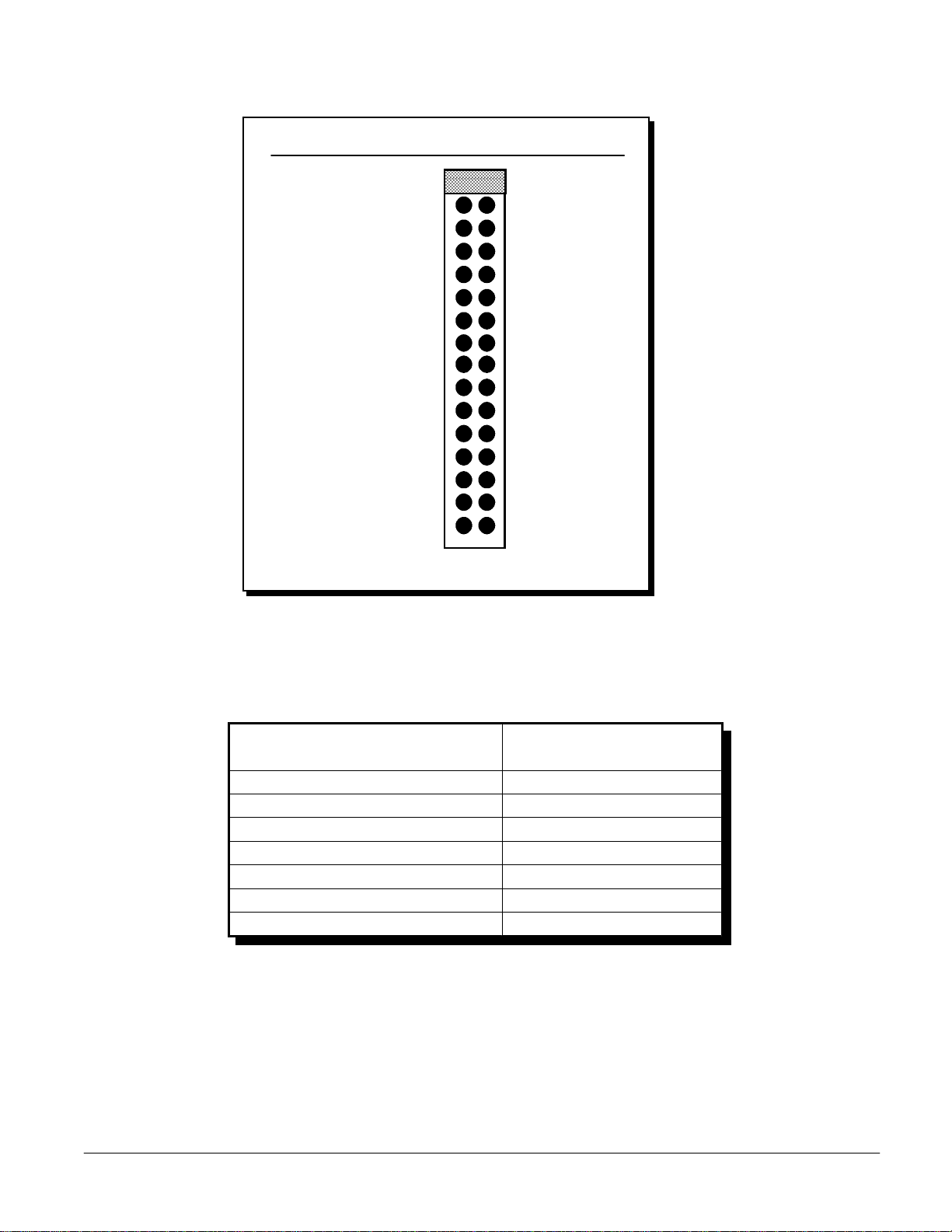

Main A/D C hannel Selection J umper

J1

QTC-500

J11

QTC-450

SignalPro Series Users Manual 15

CH0

CH1

CH2

CH3

CH4

CH5

CH6

CH7

CH8

CH9

CH10

CH11

CH12

CH13

CH14

CH15

Figure 1-3. SignalPro Series Main A/D Channel Selection Jumpers

The numerical designator for the main A/D channel jumper block varies from module to

module. Table 1-2 lists the designator for each specific module.

Signal Conditioning Module

Main A/D Channel

Jumper Designation

J1QTC-200

J10QTC-250

J5QTC-300

J15QTC-350

J1QTC-400

Table 1-2. Main A/D Channel Jumper Block Designators

1.3.2 Board Selection Jumper Configuration

Board selection jumper configuration options vary from module to module depending on the

number of expansion channels the module will support. Figure 1-4 depicts the board selection

jumpers with factory default settings and the numerical designator for each jumper block.

Note the factory default for all board selection jumpers is the lowest board number.

Page 16

SignalPro Series Users Manual 16

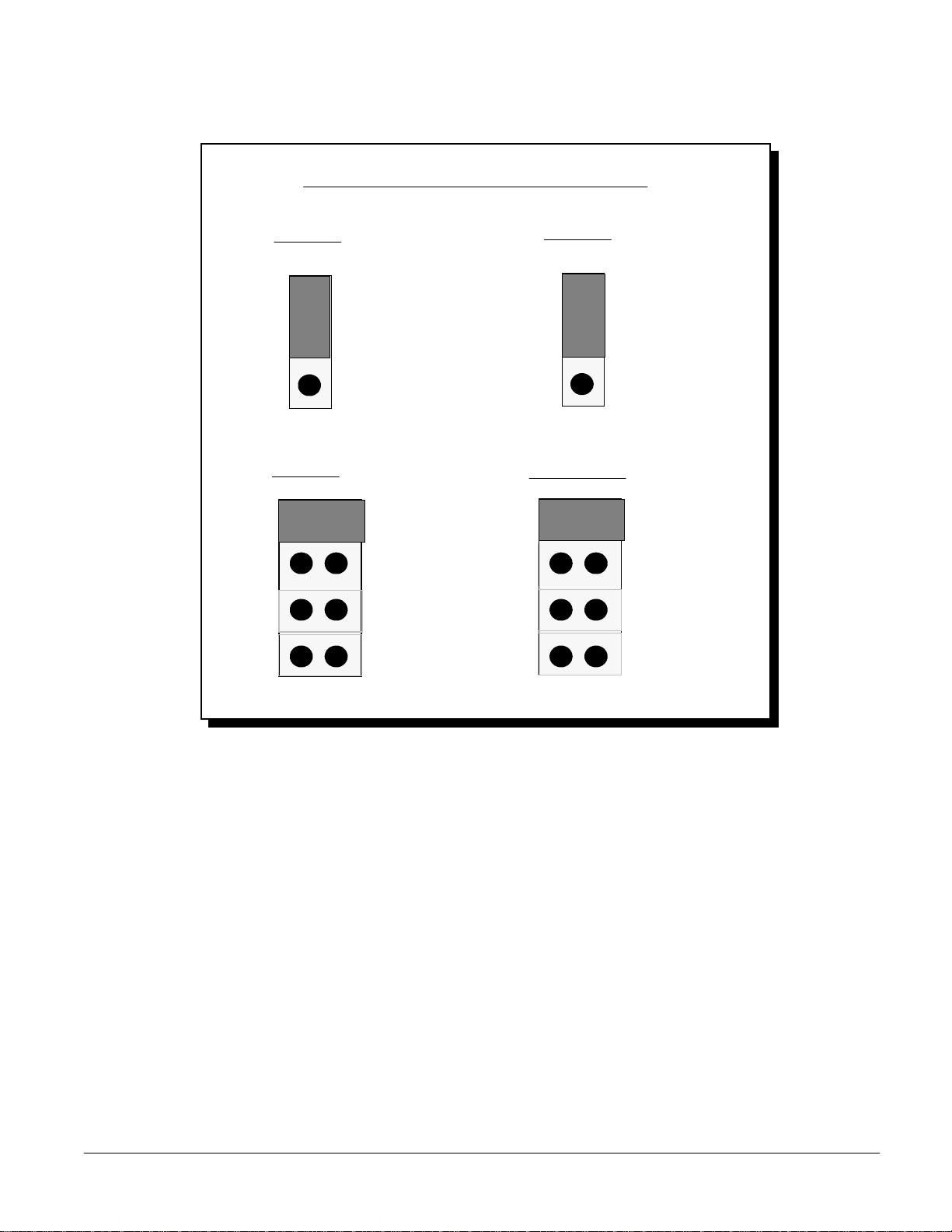

Board Selection Jumper Configurations

QTC-250

QTC-300

(J9)

BD0

BD1

(J6)

BD0

BD1

BD2

BD3

QTC-500

QTC-350/450

(J2)

BD1

BD2

(J14/J9)

BD1

BD2

BD3

BD4

Figure 1-4. SignalPro Series Board Selection Jumpers

When configuri ng multiple Signa lPro modules to one main A/D channel, the position of the

board selection jumper will determine which module is connected to a specific numerical

section of the sixteen available expansion channels. For example, if two QTC-250 modules

were connected to one main A/D channel, the first QTC-250 module would use the “BD0”

configuration and would occupy expansion channels 0 - 7. The second QTC-250 module

would use the “BD1” configuration and would occupy expansion channels 8 - 15.

1.3.3 Expansion Channel Numbering

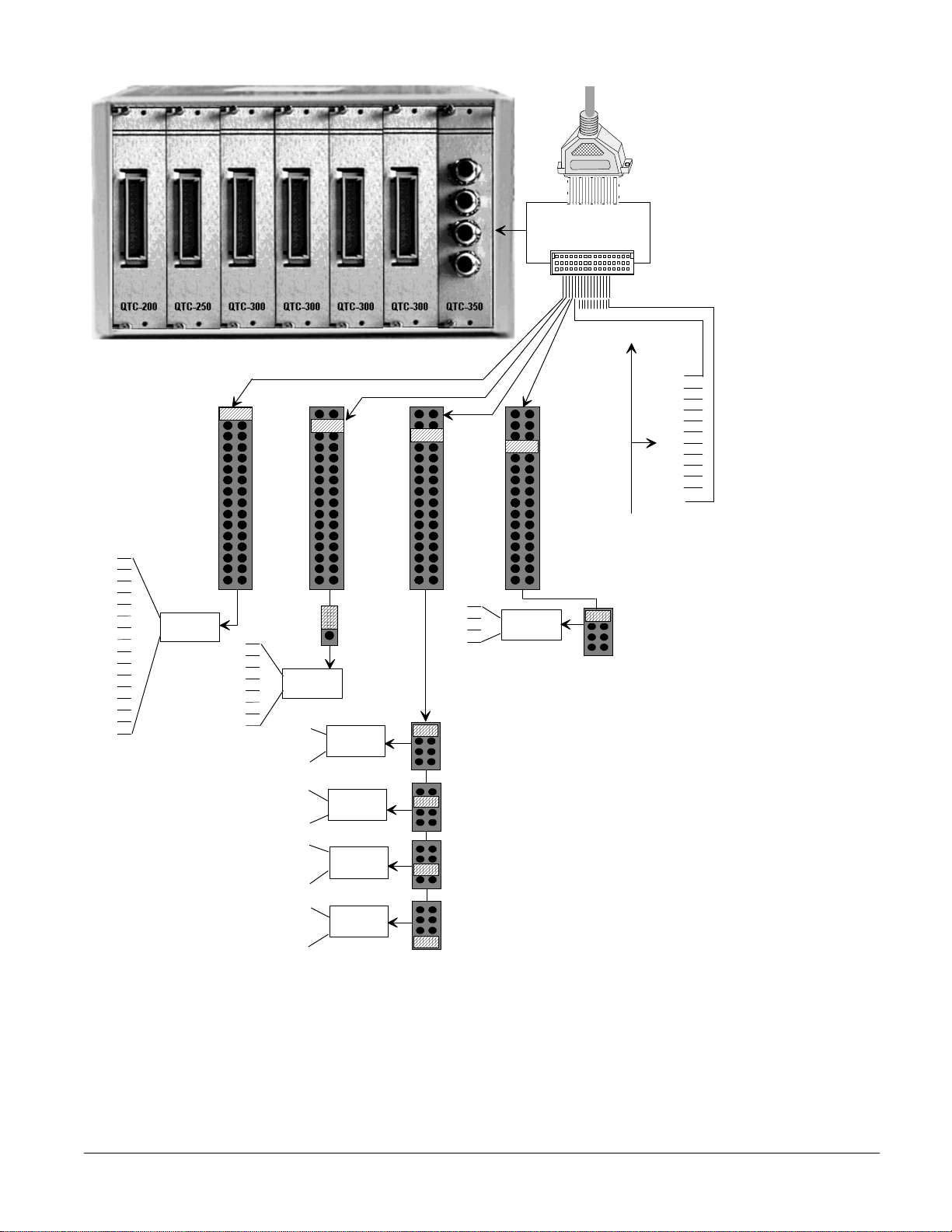

Figure 1-5 depicts the logical channel numbering for a signal conditioning system in which

four main A/D channels from the host computer data acquisition adapter are expanded. (The

QTC-200 module actually only has fourteen data acquisition channel s. Channels one and two

are utilized for cold junction and offset information).

Page 17

QTC-200/QTC-250/QTC-300/QTC-300/QTC-300/QTC-300/QTC-350

SignalPro Series Users Manual 17

10

11

12

13

14

15

CH0

0

1

2

3

4

5

6

7

8

9

QTC-200

16

17

18

19

20

21

22

23

BD0

QTC-250

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

CH1

QTC-300

QTC-300

QTC-300

QTC-300

CH2

40

41

42

43

BD0

BD1

BD2

BD3

To Data Acquisition

adapter: DAQ P-12/16

or DAQ-1201/1202

QTE-7

015

44

45

46

47

48

CH3

Main A/D channels

unused. Channels 4 - 15

not multiplexed into

subchannels.

QTC-350

BD0

One QTC-200: 14 channels thermo couple input

One QTC -250: 8 channels RTD input

Four QT C-300s: 16 ch an nels strain gage input

One QTC -350: 4 channels acceler ometer i n put

49

50

51

52

53

54

55

Figure 1-5. Expansion Channel Numbering in a Multiple Module System

Page 18

2 SignalPro™ Series Racks and Enclosures

Enclosure Features

SignalPro Series Users Manual 18

Flexibility to combine multiple types of modules in a single unit

Ruggedized aluminum, metal, and plastic enclosures

External trigger source input with BNC connector

Compatible with all SignalPro Series modules

Multiple enclosures can be linked together using only one data acquisition adapter for

up to 256 channels in a system.

Power can be supplied by a flexible range of either AC or DC voltage with appropriate

options installed

The SignalPro series interface boards are a standard 3U size and mount easily into the QTE-7,

QTE-14 or QTC-xxx-PCS data acquisition enclosures. Each of these enclosures is equipped

with a DIN -48 female connector(s) to mate with the interf ace boards and a standar d Omega

D-37 data acquisition connector which mates with the data acquisition adapter in the host

computer.

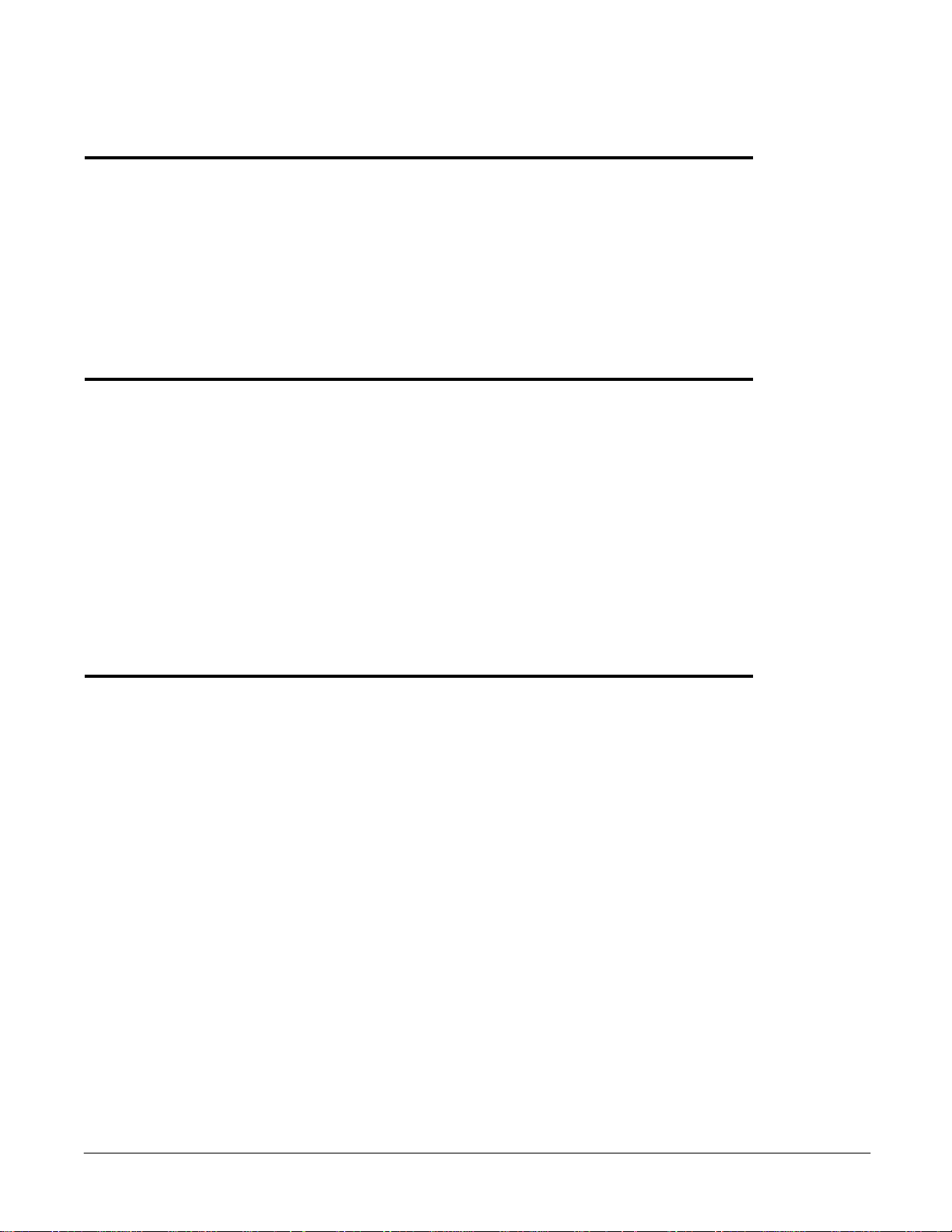

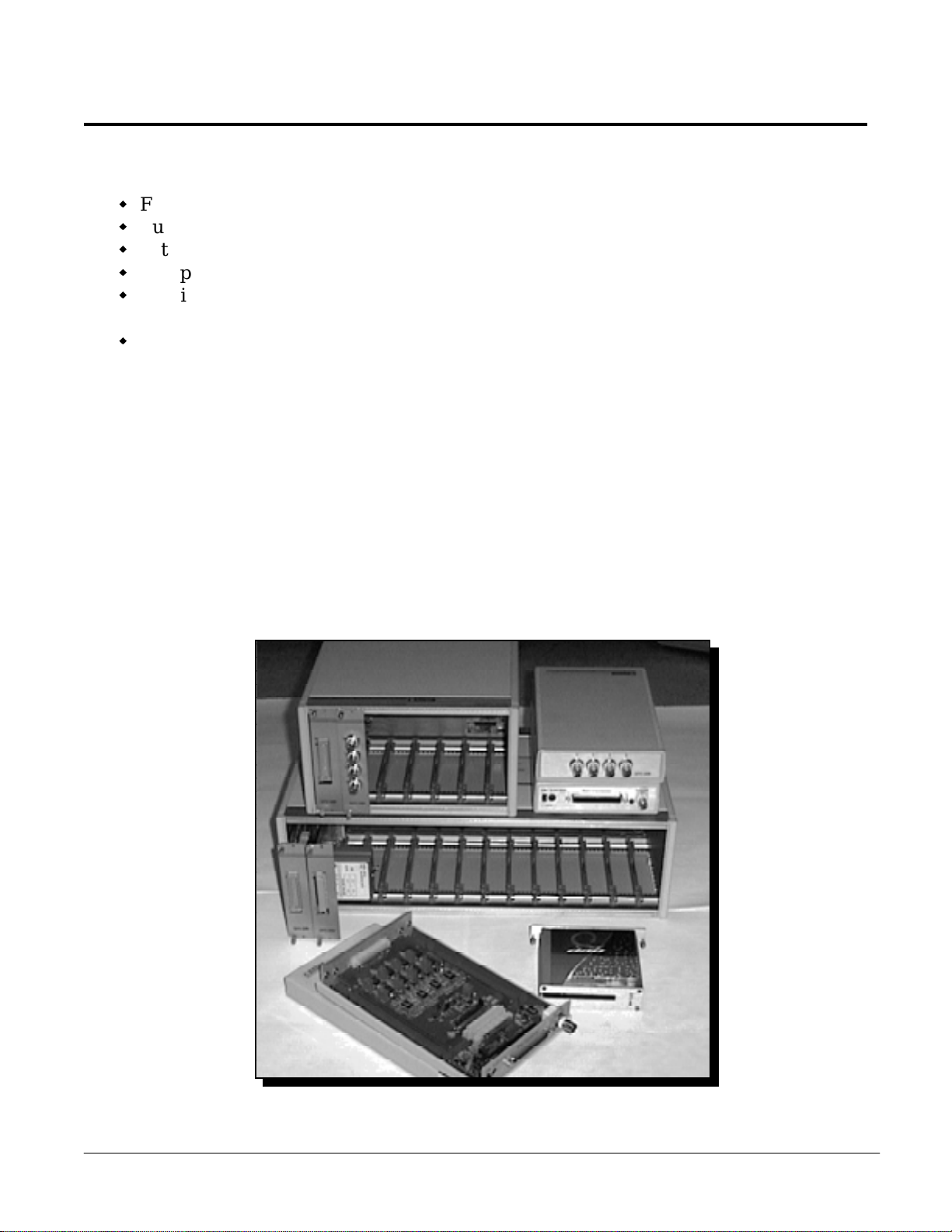

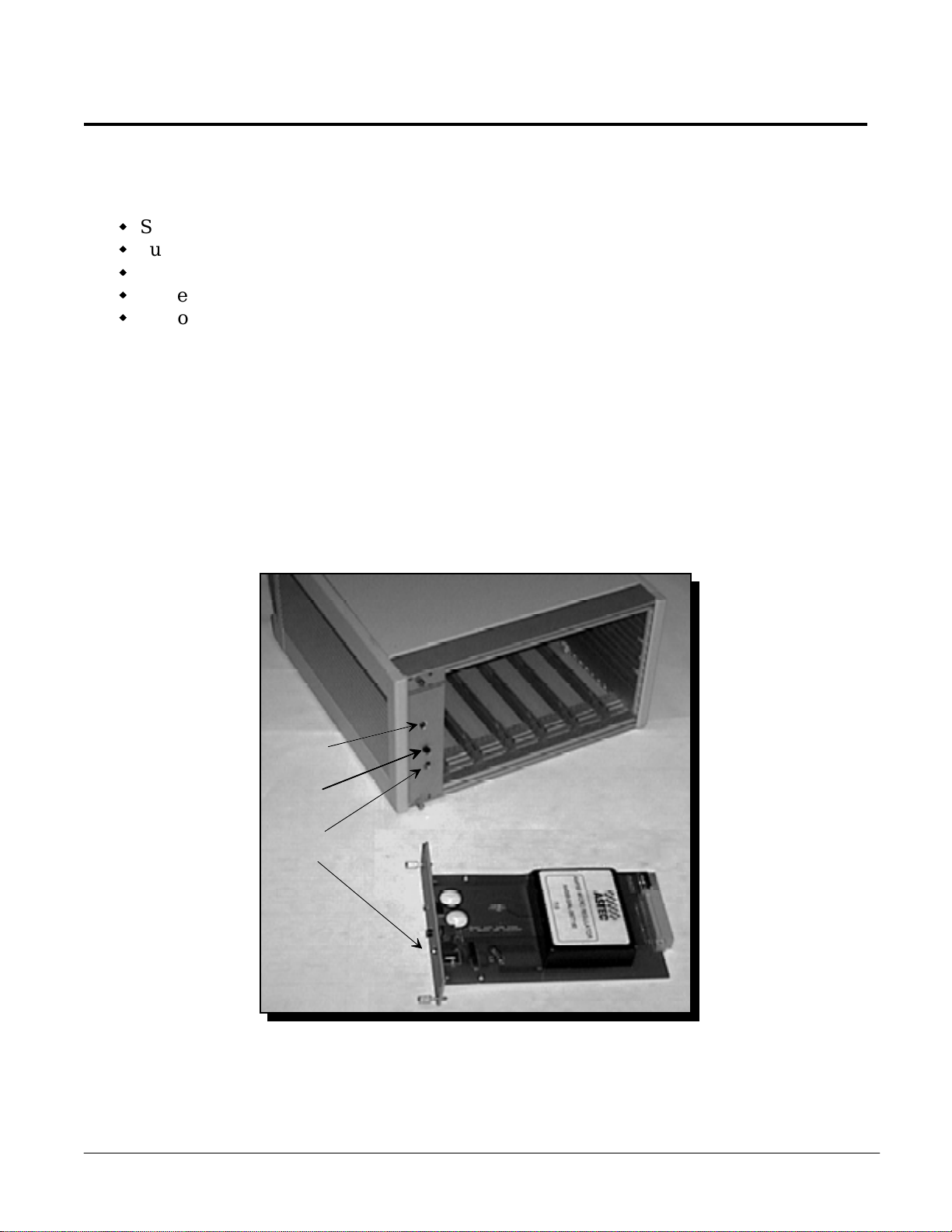

There are three housing options a vailable for Si gnalPro modules: (1) the QTE-14 rack mount

enclosure which holds up to 14 modules, (2) the QTE-7 half rack enclosure which holds up to

7 modules and (3) the QTC-xxx-PCS portable unit which accommodates a single module. (See

Figure 2-1).

QTE-7

QTC-xxx-PCS

QTE-14

Figure 2-1. SignalPro Series Data Acquisition Racks and Enclosures

Page 19

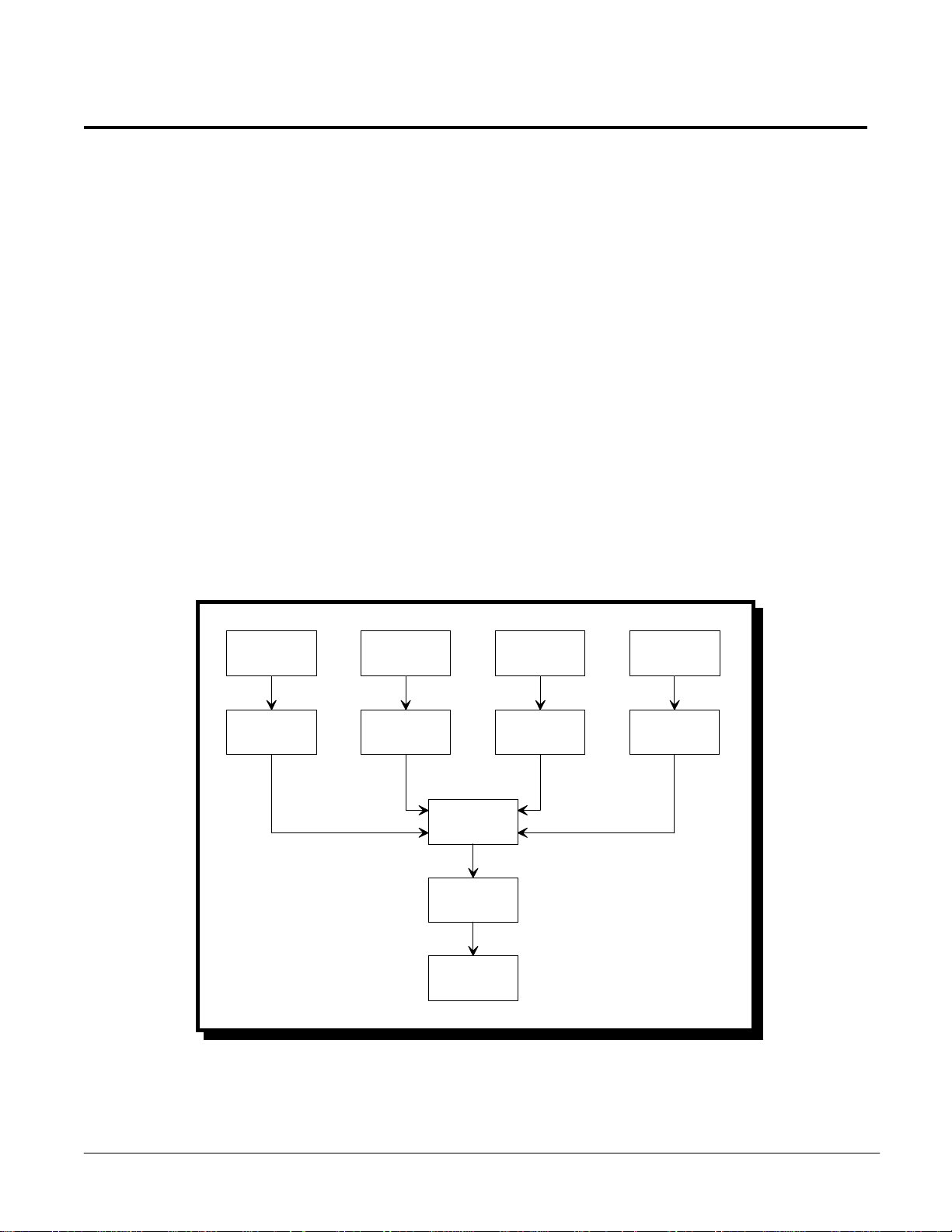

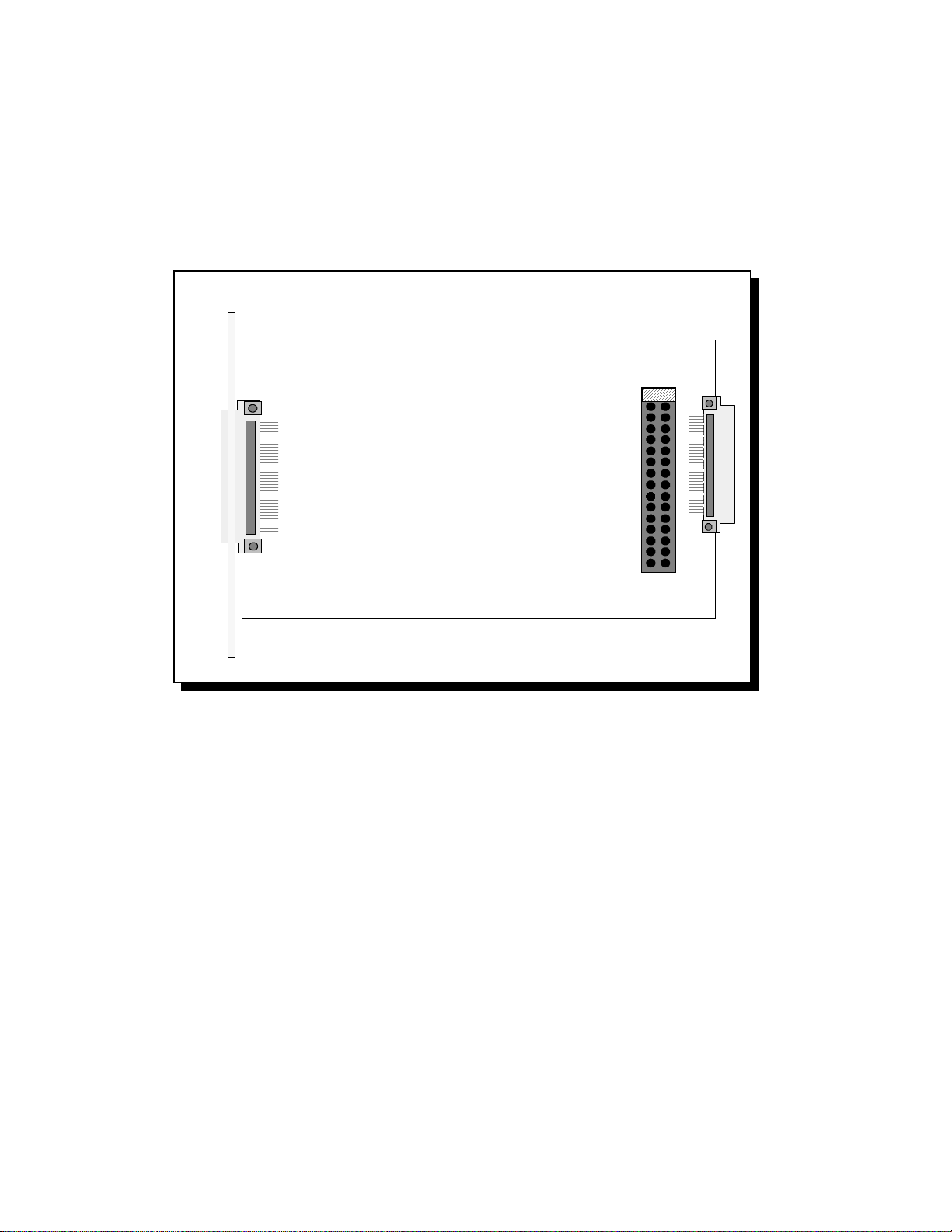

2.1 Multiple Module Enclosures

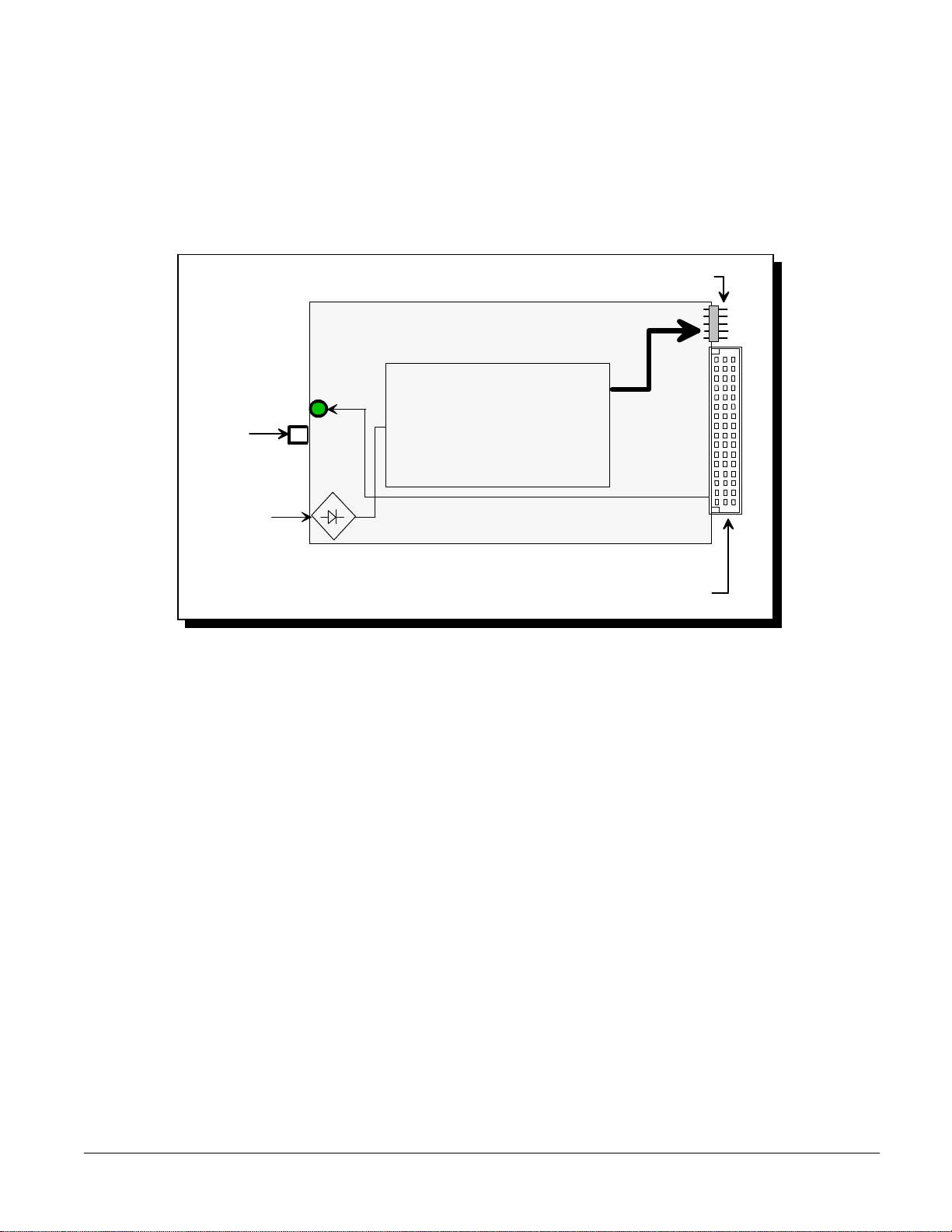

Figure 2-2 shows the block diagrams for the QTE-7 and QTE-14 data acquisition enclosures.

SignalPro Series Users Manual 19

Data

Acquisition

Adapter

Power

Module

QTC-200

QTC-250

QTC-350

QTC-500

QTE-7 / QT E -14

QTC-200

QTC-200

QTC-200

QTC-200

QTC-300

QTC-400

QTC-450

QTC-300

QTC-300

......

QTC-300

QTC-300

Sensor

Sensor

Figure 2-2. Multiple Module Enclosure Block Diagram

SignalPro modules may be mounted into any slot in the data acquisition enclosures. (The

QTC-100 power adapter module will only mount in the first slot of the QTE-7 and are not

available for the QTE-14).

2.2 External Connections

2.2.1 Data Acquisition Adapter Connection

Each of the SignalPr o series enclosures is equipped with a D-37 female connector that is pin

compatible with Omega data acquisition adapters. Omega data acquisition adapters are

available with 12 and 16 bit resolution.

2.2.2 External TTL Trigger Connector

The data acquisition adapter in the host computer requires an initial signal to start A/D

conversions. Depending on the software configuration, A/D conversions will be initiated by

either a software trigger or an external hardware trigger. Each of the SignalPro series data

acquisition enclosures provides a BNC connector for a hardware TTL trigger input. The TTL

trigger starts A/D conversions on either the rising or falling edge of a TTL signal. The BNC

connector maps the TTL input back to pin 25, (digital input channel 0), on the Omega D-37

data acquisition adapter.

2.2.3 Multiple Enclosures

Multiple SignalPro series enclosures can be linked together using only one data acquisition

adapter to expand a signal conditioning system from sixteen up to 256 channels. An Omega

D-37 adapte r cable, prod uct number: CP-D AQ, is requ ired to link multiple enclosures in your

system.

Page 20

2.3 Power Requirements

The QTE-7 and QTE -14 enclosures require an AC input voltage from 90 to 260 VAC @ 60 Hz.

5.22” (132.7mm)

9.39” (238.7mm)

17.68” (449.1mm)

QTE-14

5.22” (132.7mm)

9.39” (238.7mm)

9.28” (235.7mm)

QTE-7

1.56” (39.62mm)

8.78” (233.0mm)

5.57” (141.5mm)

QTC-xxx-PCS

Height

Depth

Width

SignalPro Enclosure

SignalPro Series Users Manual 20

With the QTE-7, the user has the option of using an Omega QTC-100 power module. The

power module allows the user to power a remote data acquisition system with automobile

battery power. The QTC-xxx-PCS requires a DC input voltage from 9 to 25 VDC and is

shipped with a 12v, 2.92A power supply module included.

All three enclosure models have a +5V and +/-15V DC power supply mounted inside the

enclosure to provide power for SignalPro series modules. The QTC-xxx-PCS internal power

supply automatically corrects the pola rity of the input vol tage to pr ovide maximum f lexi bility

in choosing a power source for the portable enclosure.

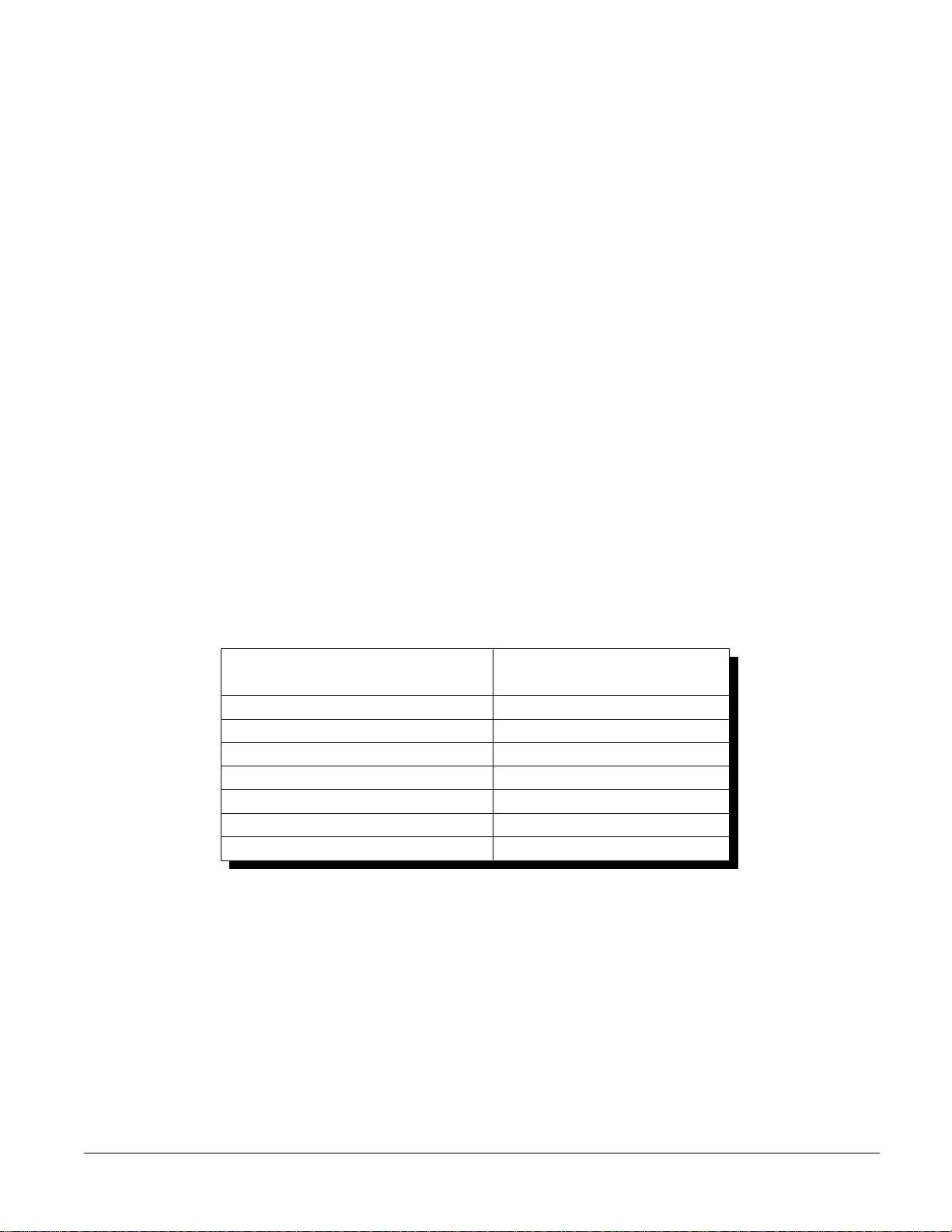

2.4 Physical Dimensions

Table 2-1 lists the physical dimensions of each enclosure in the SignalPro series.

Table 2-1. Data Acquisition Enclosure Physical Dimensions

Page 21

3 QTC-100 DC Voltage Power Adapter Module

QTC-100 Features

SignalPro Series Users Manual 21

Standard 3U interface board for use with the QTE-7 half-rack housing unit

Supplies 25 watts of total power to the QTE-7

No polarity required on the DC input voltage - Center pin can be positive or negative

Power LED to indicate slot status

Optional power cord allows system to be powered from a standard automobile

cigarette lighter

The QTC-100 is a DC voltage power adapter module which provides a convenient way to

power SignalPro series modules using an automobile battery. For use with the QTE-7

half-rack housing unit, the QTC-100 accepts DC input voltage from 10 to 28vdc and generates

the +5 and ±15vdc output require d to powe r a remote d ata acquisi tion syste m. An optional six

foot cord, ( product number: QTC-PWR-DC), is availa ble to al low the user to gene rate system

power using a standard automobile cigarette lighter. (See Figure 3-1).

Power

Indicator

Power

Switch

Input Jack

DC 9~28V

Figure 3-1. QTC-100 DC Voltage Power Adapter Module

QTC-100 DC Voltage

QTE-7

Power Adapter

Page 22

3.1 Circuit Board Description

The QTC-100 is a standard 3U size board designed for use with the QTE-7 half rack data

SignalPro Series Users Manual 22

acquisition enclosure. A block diagram of QTC-100 is shown in Figure 3-2. The DC to DC

converter accepts input voltage from 10 to 28vdc and in turn generates +5, +15 and -15vdc.

The 14-pin male power connector and the DIN-48 male connector on the QTC-100 interface

board will only connect to the first slot of the QTE-7.

14-Pin Power Connector

+5v, +/-15v

LED

Power

Switch

DC/DC

Converter

10~28 vdc

QTC-100

Figure 3-2. QTC-100 Block Diagram

3.1.1 AC/DC Power Supply Priority

With the QTC-100 DC Voltage Power Adapter Module, the QTE-7 half rack enclosure can

accept either AC power (90~260 vac) or DC power (9~28 vdc). If both power supplies are

available simultaneously, the QTE-7 will use AC power to generate the +5, +15 and -15VDC

power required for all SignalPro series modules in the QTE-7 system. If the AC power supply

is unavailable or failed, the QTE-7 will automatically switch to DC power from QTC-100

power module.

DIN-48

Connector

3.1.2 Power Jack and Switch

The QTC-100 power jack accepts 9~28vdc through a 2.5 x 5.5mm DC plug in which the center

pin can be either positive or negative. A push button switch on the front panel is used to

control power to the QTE-7 and a green LED indicates the power status. (Refer to Figure 3-1

for locations of the power jack, switch and indicator).

Page 23

3.2 QTC-100 Specifications

0.3 Kg

Weight:

100mm X 166.4mm

Dimension:

500 VDC

Isolation:

50mV p-p (+5V), 100mV p-p (+/-15V)

Noise/Ripple:

0.25% (+5V), 3% (+/-15V)

Load Regulation:

0.25% for +5V, 2% for +/-15V

Line Regulation:

+5V+/-1%@3.50A, +15V+/-3%@0.50A, -15V+/-3%@0.50A

Output Voltage:

25 Watts

Total Power:

<100 mA p-p 80-85% typical

Input Ripple Current:

No Polarity required (Center pin can be either positive or

Input Polarity:

Suitable for 2.5 x 5.5mm DC plug

Power Jack:

DIN-48 male and 14-pi n right angle male, mates with fi rst slot

Connectors:

SignalPro Series Users Manual 23

of QTE-7

negative)

Page 24

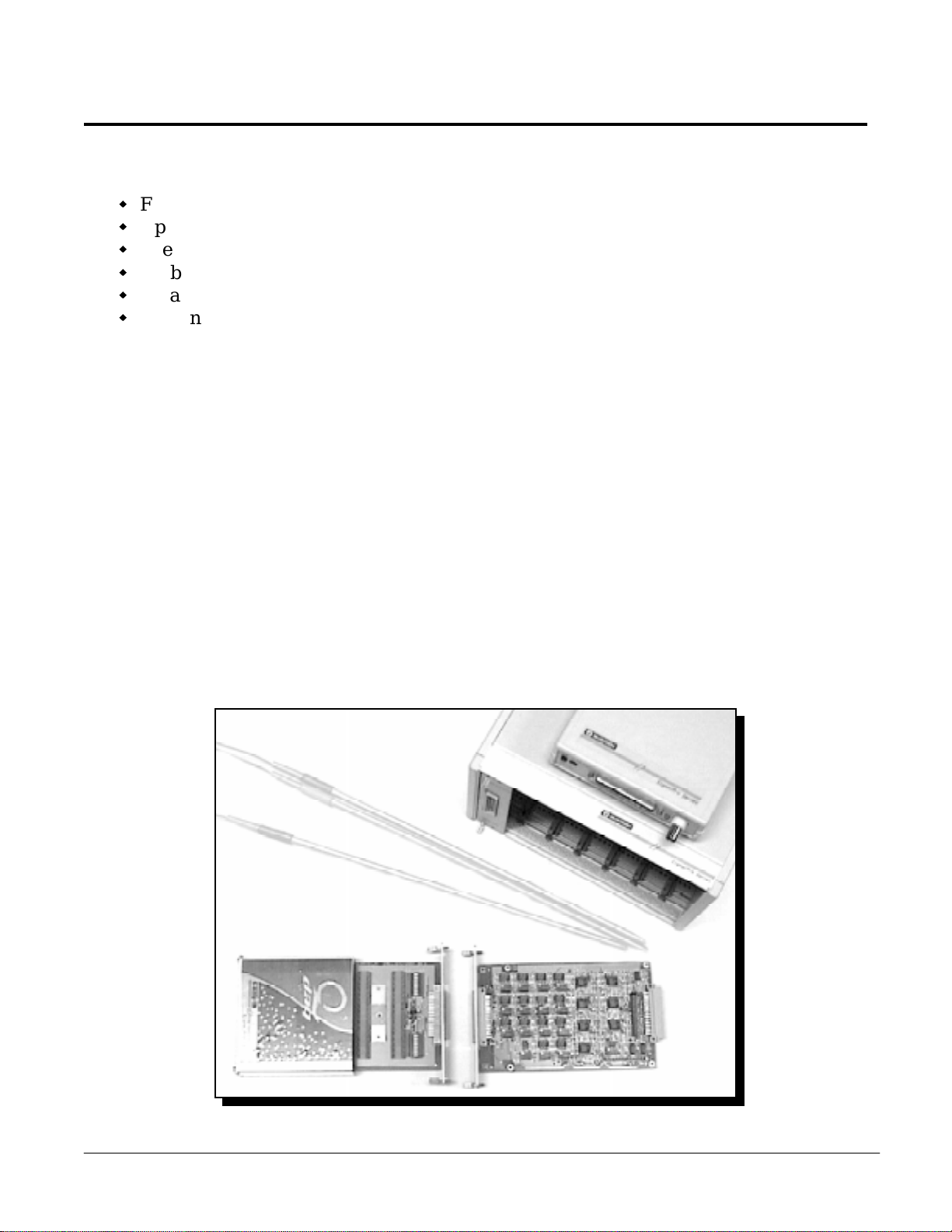

4 QTC-200 Thermocouple Input Module

QTC-200 Features

SignalPro Series Users Manual 24

Fourteen Thermocouple input channels

Up to 224 Analog Input Channels can be configured in a system

Thermocouple types J, K, T, E, S or R, N & B supported

On board Low Pass Filter for each channel (-80dB @ 50Hz)

Isolated Cold Junction Compensation

Terminal block for quick, easy signal connections

The QTC-200 is a fourteen channel thermocouple input module. Each channel is equipped

with a separate instrument amplifier, offset adjustment and low pass filter. Up to sixteen

QTC-200 modules can be configured in an Omega signal conditioning and data acquisition

system for a total of 224 analog input channel s. The QTC-200 can also be coupled with other

modules in Quatech’s SignalPro™ series to provide a versatile data acquisition system.

The QTC-200 module consists of two circuit boards: the QTC-200 interface board and the

QTC-200T terminal board. The interface board is a standard 3U size board which can be

mounted in the QTE-7, QTE-14 or QTC-200-PCS data acquisition enclosures. The QTC-200T

terminal board contains the thermocouple input screw blocks, Cold Junction Compensation

(CJC) sensor and the mode selection switches. This two board configuration allows quick and

easy connection of the thermocouple lead wires. After the initial configuration of the interface

board, it can be mounted in a data acquisition enclosure and will rarely require removal. All

connections are completed on the screw terminals of the portable QTC-200T, which is then

plugged into the interface board and secured using two thumb screws. (See Figure 4-1).

Thermocouple

Sensors

QTC-200 Terminal Board

Figure 4-1. QTC-200 Thermocouple Input Module

QTE-7

QTC-200 Interface Board

QTC-200-PCS

Page 25

4.1 Circuit Board Description

SignalPro Series Users Manual 25

4.1.1 QTC-200 Interface Board Description

The QTC-200 interface board shown in Figure 4-1 can be mounted in SignalPro series data

acquisition racks and enclosures. (See Chapter 2 for information on SignalPro series racks).

Each rack enclosure i s equipped wi th a DIN-4 8 female connector which mate s to the QTC-200

and other SignalPro series signal conditioners. The rack also contains a standard Omega D37

connector which attaches to the host computer data acquisition adapter.

The QTC-200 provides sixteen channels; one channel for CJC input, one channel for zero offset

input and fourteen channels for thermocouple input; by multiplexing a single main A/D

channel off the host computer data acquisition adapter. The mul ti pl exer on the QTC-200 scans

the sixteen input channels sequentially and connects each input to the single main A/D

channel. The sixteen multiplexed input channels may be mapped back to any main A/D

channel on the data acquisition adapter depending on the configuration of jumper J1.

Multiplexi ng of all 16 main A/D channel s from the host computer results in a maximum of

256 channels consisting of 224 A/D input channels (14 x 16) and 32 CJC/zero offset input

channels (2 x 16) per data acquisition adapter.

4.1.2 QTC-200T Terminal Board Description

The QTC-200T terminal board contains the thermocouple input screw blocks and the mode

selection switches which configure either differential or single ended input for each channel.

The terminal board DIN-48 female connector plugs into the QTC-200 interface board and is

equipped with a strain relief bracket to secure external thermocouple wiring.

Page 26

4.2 Hardware Configuration

SignalPro Series Users Manual 26

For system configuration options see Chapter 1: SignalPro Series Overview, section 1.3:

Hardware Configuration.

4.2.1 QTC-200 Interface Board Configuration

QTC-200

Main A/D Channel

Selection Jumper J1

CH0

CH1

CH2

CH3

CH4

CH5

CH6

CH7

CH8

CH9

CH10

CH11

CH12

CH13

CH14

CH15

Figure 4-2. QTC-200 Main A/D Channel Jumper Block Location

Figure 4-2 shows the location of the main A/D channel selection jumper block J1. System

configuration options for J1 are discussed extensively in Chapter 1, section 1.3

4.2.2 QTC-200T Terminal Board Configuration

Figure 4-3 depicts the location of the thermocouple input screw blocks, differential or

single-ended mode selection switches (SW1 and SW2), CJC sensor and the thermocouple lead

wire strain relief bracket.

Page 27

ST1

SignalPro Series Users Manual 27

TC8

TC7

TC6

TC5

TC4

TC3

TC2

-

+

CJC

Sensor

-

+

-

+

-

+

-

+

-

+

-

+

TC9

TC10

TC11

TC12

TC13

TC14

TC15

-

+

-

+

-

+

-

+

-

+

SW2

-

+

-

+

QTC-200T

Figure 4-3. QTC-200T Terminal Board

SW1

O

N

1 2 3 4 5 6 7 8

O

N

1 2 3 4 5 6 7 8

4.2.2.1 Thermocouple Input Mode Selection Switches

Figure 4-4 depicts the mode selection switches for thermocouple input channels 2 through 15.

12345678

Thermocouple

12345678

Switch OFF (Open) - - - Differential Input

Switch ON (Closed) - - - Single Ended

All Switches shown with factory default setting:

OFF (Differential Input)

ON

ON

CH15

CH14

CH13

CH12

CH11

CH10

CH9

CH8

CH7

CH6

CH5

CH4

CH3

CH2

CH1

CH0

OFFSET

CJC

Figure 4-4. Thermocouple Input Mode Selection Switches

Page 28

4.3 Basic Principles

Thermocouples measure temperature using the Seebeck Effect which occurs at the junction

SignalPro Series Users Manual 28

connection of two dissimilar metals. A voltage difference is generated at the junction that

changes with temperature over a given range. This voltage is not a linear function of

temperature and theref ore cannot be rela ted dir ectly to temperature. Linear ization table s and

polynomial appr oximation are two methods used to transform thermocouple input into real

temperature measurement.

One problem experienced with thermocouple temperature measurement is when the junction

between thermocouple lead wires and terminal blocks creates, in essence, another

thermocouple. The QTC-200 signal conditioning module provides a practical solution to this

problem by using a built in cold junction compensation circuit to neutralize the voltage

created at the terminal block junction.

Damaged thermocouples can introduce another significant source of measurement error by

becoming open or extremely resistive. The QTC-200 si gnal conditioning modul e uses an open

thermocouple detection circuit on each thermocouple input to guard against this possibility.

The detection circuit drives a low level current through the thermocouple causing the input

amplifiers to be driven to rails whenever an open or highly resistive thermocouple is present.

4.3.1 Cold Junction Compensation (CJC) Sensor

The QTC-200T uses an isolated CJC sensor to detect temperature at the thermocouple

terminals with high accuracy and minimize any temperature difference between the CJC

sensor and thermocouple terminal junctions.

The first channel (CH0) is used to measure temperature at the CJC sensor.

Temperature in °C : TC and in °F : TF is calculated as follows:

TC = - 273

(A+Bln(R)+C(ln(R))

1

3

)

R = VCH0 * 5000 / (10 - VCH0)

TF = Tc * 9 / 5 + 32

where A=0.00128974451631 VCH0: Voltage reading at CH0 in volts

B=0.00023530184288 R: Resistance of the sensor in ohms

C=0.00000009729702

Page 29

4.3.2 Software Zero Correction

SignalPro Series Users Manual 29

Since most thermocouple signals are within the 100mV range, offset voltage between the

QTC-200T and the data acquisition adapter must be monitored. QTC-200 channel 1 (CH1) is

used to check the zero reference of the QTC-200T, then the data acquisition system software

subtracts this offset.

4.3.3 Single Ended Thermocouple Measurements

A single ended thermocouple measurement is shown in Figure 4-5. The thermocouple input

channel must be configured for single ended operation as discussed in section 4.2.2.1 of this

chapter.

ST1

GND

+

+

Thermocouples

Strain Relief

Bracket

Thermocouple

Terminal Block

Figure 4-5 Single Ended Thermocouple Measurement

4.3.4 Differential Thermocouple Measurements

A differential thermocouple measurement is shown in Figure 4-6. The thermocouple input

channel must be configured for differential operation as discussed in section 4.2.2.1 of this

chapter.

ST1

Wire Shield

GND

-

Thermocouple

Strain Relief

Bracket

+

Thermocouple

Terminal Block

Figure 4-6. Differential Thermocouple Measurement

Page 30

4.4 QTC-200/QTC-200T Specifications

SignalPro Series Users Manual 30

Connector: DIN-48 male, mates with QTE-7, QTE-14 and QTC-200-PCS

Signal Connection: DIN-48 female, mates with terminal block

Number of TC Channels: 14 (CH0: CJC; CH1: Zero offset; CH2-15: Thermocouple inputs)

Input Type: Differential/Single-ended ( DIP Switch Select-able)

Precision Thermistor: 5000 Ohm @ 25 °C

Supported Thermocouple Type, Temperature Range

Type

J Thermocouple: -200°C to 760°C

K Thermocouple: -100°C to 1350°C

T Thermocouple: -200°C to 400°C

E Thermocouple: -200°C to 1000°C

S or R Thermocouple: 0°C to 1760°C

N Thermocouple: 0°C to 1300°C

B Thermocouple: 0°C to 1800°C

Voltage Input Range: ±100 mVDC

Maximum Input Voltage: -20V to +15V DC

Input Bias Current: 6 nA typ

Input Offset Voltage: ± 0.07 mV typ, ± 0.25 mV max (Adjustable to zero)

Range

Input Offset Drift: ± 0.4 lV/°C typ, ± 2.0 lV/°C max

Gain Range: 100 fixed

Gain Error: X100

Input Impedance: 12 GW

Gain Nonlinearity : X100

Gain Error Drift: X100

Common Mode Rejection: X100

Cutoff Frequency (-3dB): 5 Hz (4 Poles Butterworth, -3dB@5Hz, -80dB@50Hz)

Page 31

Dimension: 160mm X 100 mm for QTC-200;

SignalPro Series Users Manual 31

100mm X 100mm for QTC-200T

Weight: QTC-200 0.29Kg;

QTC-200T (with enclosure): 0.36Kg

Power Consumption: +5V/20mA typ; +15V/40mA typ; -15V/40mA typ

Temperature Range: 0 ~ +70°C

Page 32

5 QTC-250 RTD Signal Conditioning Module

QTC-250 Features

SignalPro Series Users Manual 32

Eight channel Resistor Temperature Detector (RTD)

On board low-pass filter for each channel (-80dB @ 50Hz)

Per channel jumper selectable excitation current source of 1mA, 0.5mA or 0.25mA

Supports 2, 3 and 4 wire RTD configurations

Up to 256 channels can be configured in a system

Terminal block for quick, easy signal connections

The QTC-250 is an eight channel Resistance Temperature Detector (RTD) input signal

conditioning module. Each channel is equipped with separate instrument amplifiers, three

excitation cur rent source options and a fourth ord er low pass f ilter . Up to thirty- two QTC-250

modules can be configured in an Omega signal conditioning and data acquisition system for a

total of 256 analog input channels. The QTC-250 can also be coupled wi th other modules in

Omega’s SignalPro™ series to provide a versatile data acquisition system.

The QTC-250 module consists of two circuit boards: the QTC-250 interface board and the

QTC-250T terminal board. The interface board is a standard 3U size board which can be

mounted in the QTE-7, QTE-14 or QTC-250-PCS data acquisition enclosures. The QTC-250T

terminal board contai ns the RTD i nput screw bl ocks, channel gain sel ect switches and channel

excitation current sources. T his two board configuration allows qui ck and easy connection of

the RTD lead wires. After the initial configuration of the interface board, it can be mounted in

a data acquisition enclosure and will rarely require removal. All connections are completed on

the screw terminals of the portable QTC-250T, which is then plugged into the QTC-250

interface board and secured using two thumb screws. (See Figure 5-1).

QTC-250T

Terminal Block

Figure 5-1. RTD Signal Conditioning Module

QTC-250-PCS

QTE-7

QTC-250

Interface Bo a rd

Page 33

5.1 Circuit Board Description

5.1.1 QTC-250 Interface Board Description

SignalPro Series Users Manual 33

The QTC-250 interface board shown in Figure 5-1 can be mounted in SignalPro series data

acquisition racks and enclosures. (See Chapter 2 for information on SignalPro series racks).

Each rack enclosure i s equipped wi th a DIN-4 8 female connector which mate s to the QTC-250

and other SignalPro series signal conditioners. The rack also contains a standard D37

connector which attaches to the host computer data acquisition adapter.

Eight RTD input channels are provided by multiplexing a single main A/D channel off the

host computer data acquisition adapter. The multiplexer on the QTC-250 scans the eight RTD

input channels sequentially and connects each input to the single main A/D channel. The

eight multipl exed input channe ls may b e mapped back to any main A/D channel on the data

acquisition adapter depending on the configuration of jumper J10. Two interface boards may

share one single ended A/D input from the host computer to provide a maximum of 16

multiplexed channels per main A/D channel. Multiplexing of all 16 main A/D channels from

the host computer results in a maximum of 256 A/D input channels, (16 x 16), per data

acquisition adapter.

5.1.2 QTC-250T Terminal Board Description

The QTC-250T terminal board shown in Figure 5-2 contains the input terminal blocks,

excitation current sources and input gain amplifiers for each of the eight RTD inputs. The

terminal board DIN-48 female connector plugs into the QTC-250 interface board and is

equipped with a strain relief bracket to secure external RTD wiring.

ST1

IRR+

I+

IRR+

I+

IRR+

I+

IRR+

I+

IRR+

I+

IRR+

I+

IRR+

I+

IRR+

I+

J8 - RTD8

J7 - RTD7

J6 - RTD6

J5 - RTD5

J4 - RTD4

J3 - RTD3

J2 - RTD2

J1 - RTD1

Figure 5-2. QTC-250T Terminal Board

Page 34

5.2 Hardware Configuration

For system configuration options see Chapter 1: SignalPro Series Overview, section 1.3:

SignalPro Series Users Manual 34

Hardware Configuration.

5.2.1 QTC-250 Interface Board Configuration

Figure 5-3 depicts the location of the main A/D channel and board selection jumpers (J9/J10).

System configuration options for J9 and J10 are discussed extensively in Chapter 1, section 1.3.

Board Selection Jumper

J9

Main A/D Channel

Selection Jumper J10

Figure 5-3. QTC-250 Interface Board Jumper Locations

5.2.2 QTC-250T Terminal Board Configuration

The QTC-250T terminal board contains the excitation current selecti on jumpers and the input

gain selecti on switches for each of the eight RTD inputs. The user must configur e two settings:

Input gain (GAI N) and ex citati on current source (I ). The gai n and curre nt source settings are

determined according to the following two considerations:

I * RRTDMAX * GA IN shoul d b e as cl ose as possi ble to, bu t not ex ceed , the f ull scale value of

10 Volts, where RRTDMAX is the maximum RTD r esistance in the specific measuring rang e.

The excitation current “I” should be the smallest possible value, (0.25mA, 0.5mA or 1.0mA),

that will satisfy the first consideration.

Note that resistive heating must be consider e d w he n determining the excitati on current source

amplitude. The RTD dissi pates power at the ra te of Power = I x R, where I is the excitati on

2

current and R is the RTD resi stance. The heat genera ted by the excitation cur rent through the

RTD is a source of error in temperature measurements. Since lower current options will

generate less heat, a combination of low current with a high A/D input gain is desirable.

Page 35

Table 5-1 lists the suggested gain and excitation current values for all supported RTD types.

9.81

10

0.25 mA

1133.158/ 3922.784

-100 to 200

1,816.81(0.00527)

9.81

10

0.5 mA

566.576 / 1961.381

-100 to 200

908.4 (0.00527)

6.51

10

0.5 mA

372.789 / 1301.86

-100 to 200

604 (0.00518)

9.51

100

0.25 mA

66.6 / 380.31

-80 to 260

120 (0.00672)

5.58

100

0.25 mA

69.528 / 223.221

-60 to 180

100 (0.00618)

1.91

100

1.0 mA

5.128/ 19.116

-100 to 260

9.035 (0.00427)

7.84

10

0.25 mA

185.201 / 3137.08

-200 to 600

1,000 (0.00385)

7.84

10

0.5 mA

92.6 / 1568.54

-200 to 600

500 (0.00385)

7.47

10

0.5 mA

79.881 / 1494.393

-200 to 600

470 (0.00392)

6.27

10

1.0 mA

37.04 / 627.416

-200 to 600

200 (0.00385)

9.39

100

0.25 mA

18.52 / 375.704

-200 to 800

100 (0.00385)

8.36

100

1.0 mA

4.334 / 83.575

-200 to 630

25.5 (0.00392)

Full

Gain

Excitation

Resistance

Temperature

RTD Types

SignalPro Series Users Manual 35

W @0°C(a)

1

Platinum

Copper

Nickel

Range

(°C)

Range

(W )

Current

mA

Setting

2

Scale

Output

(Volts) 3

Nickel-Iron

Notes:

1. (a) is the temperature coefficient in W / W / º C .

2. The gai n setting li sted in Ta ble 5-1 is the hardw are setting f or each supported RTD sensor.

If using DaqEZ, the QTC-250 module gain should be set to 1. The hardware configuration,

(gain and current settings), for each RTD channel will be determined by the DaqEZ signal

conditioner database.

3. The full scale output is from the QTC-250 to the data acquisition card.

5.2.2.1 A/D Gain Selection Switches

The A/D input gain for each of the RTD inputs is individually selectable using SW1 and SW2

as shown in Figure 5-4. Each of the input amplifiers can be configured for gains of x1, x10 or

x100. Configuring the gain setting on the QTC-250T terminal board input amplifiers will

result in less signal noise than using the A/D configuration options available on the data

acquisition adapter in the host computer.

Table 5-1. Suggested Gain and Excitation Current Values for Supported RTD Types

Page 36

SW1

SignalPro Series Users Manual 36

12345678

ON

RTD5

SW2

12345678

ON

RTD1

Gain = X1

(factory default)

RTD6

RTD7

RTD8

Gain = X10 Gain = X100

RTD2

RTD3

RTD4

Figure 5-4. A/D Gain Selection Switches

5.2.2.2 Excitation Current Selection Jumpers

The QTC-250T provides a stable, constant current source for each of the eight RTD input

channels. The excitation current value of 1.0mA, 0.5mA or 0.25mA for each channel can be

selected using jumper blocks J1 through J8 as shown in Figure 5-5.

RTD Exci tation Current Sele cti on J umpe r s

J1 - J8

(configures RTD1 - RTD8 respectively)

1.0 mA

(factory default)

0.5 mA

0.25 mA

Figure 5-5. Excitation Current Selection Jumpers

Page 37

5.3 RTD Measurements

SignalPro Series Users Manual 37

5.4 Basic Principles

The basic principle behind RTD measurements is that resistance of an RTD increases with

temperature. By supplying the RTD with a constant current source and measuring the voltage

drop across the RTD, the change in resistance can be monitor ed. The re lationship betw een the

change in temperature and the change in RTD resistance can be defined as follows:

∆T→∆R = ∆V ÷ I

RTD RTD

where:

∆T = the change in temperature

∆R = the change in RTD resistance

RTD

∆V = the voltage drop across the RTD

RTD

I = the RTD excitation current source value

Note: RTD resistance is measured in units of voltage or current where the current amplitude

from the QTC-250 is constant.

5.4.1 Two-Wire RTD Measurements

The configuration of a two-wire measurement circuit is shown in Figure 5-6. The RTD

resistance in this circuit is read at the current source. If the lines connected to the RTD are

short, this method may b e acceptable. H owever, this method is g enerally inaccur ate since the

resistance and thermal heating characteristics of long lead wires ( ) connected to the RTD

R

line

introduce some measurement error.

R

line

I R I +

RTD

Excitation

Current

R +

R

line

Strain Relief

Bracket

RTD

Terminal Block

Figure 5-6. Two-Wire RTD Measurement

Page 38

5.4.2 Three-Wire RTD Measurements

SignalPro Series Users Manual 38

The configuration of a three-wire measurement circuit is shown in Figure 5-7. T he advantage

of this circui t over the two-wire method i s the elimination of one current car rying lead w ire.

However, the resistance and thermal heating characteristi cs of the remaining lead wir e (R )

line

to the RTD may still introduce some measurement error.

R

line

I -

RTD

Excitation

Current

R I +

R

R

line

line

Strain Relief

Bracket

RTD

Terminal Block

R +

Figure 5-7. Three-Wire RTD Measurement

5.4.3 Four-Wire RTD Measurements

The configuration of a four-wi re measurement circuit is shown in Figure 5-8. The advantage

of this circuit over the previous two and three-wire methods is that greater accuracy is

obtained. By measuring the change in the RTD voltage d rop directly at the RTD resistor, the

error introduced from the lead wires (R ) to the RTD is removed. The measurement error

introduced due to resistance of the A/D lead wires (R ) is insignificant. The input

line

lead

impedance of the A/D is very high and thus minimizes current flow through the lead wires.

R

line

R

line

I -

RTD

Excitation

Current

R I +

R +

R

line

R

line

Strain Relief

RTD

Terminal Block

Bracket

Figure 5-8. Four-Wire RTD Measurement

Page 39

5.5 QTC-250/QTC-250T Specifications

Connector: DIN-48 male, mates with QTE-7, QTE-14, and QTC-250-PCS

SignalPro Series Users Manual 39

Signal Connection: DIN-48 female, mates screw terminal block for easy connection

Number of Channels: 8

RTD type: Platinum 25.5W, 100W, 200W, 470W, 500W, 1000W

Copper 10W

Nickel 100W, 120W

Nickel-Iron 604W, 908.4W, 1816.81W

Accuracy and Resolution:

Type

100 W Platinum -100°C to +600°C 0.4 °C 0.3 °C/ 0.1 °C

120 W Nickel 0°C to 260°C 0.15 °C0. 3 °C/ 0.1 °C

Excitation Current: 1.0 mA, 0.5mA, 0.25 mA

Output Impedance: 1990K Compliance: 10V

Range Accuracy Resolution(12-bit/16-bit)

RTD Configuration: 2-wire, 3-wire, 4-wire

Input Type: Differential

Voltage Input Range: ±10 V

Input Bias Current: ±0.5 pA typ; ±2 pA max

Input Offset Voltage: ± (0.01+0.02/G) mV typ, ± (0.05+0.1/G) mV max

(Adjustable to zero)

Input Offset Drift: ± (0.1+0.5/G) lV/°C typ, ± (0.25+100/G) lV/°C max

Gain Range: 1, 10, 100

Gain Error: X1 0.005% typ, 0.024% max

X10, X100 0.01% typ, 0.024% max

Input Impedance: 10 GW

Gain Non linearity : X1,X10, X100 ± 0.0004% of FS typ, ± 0.001% of FS max

Gain Temp. Coefficient: X1, X10, X100 ± 2.5 ppm/°C typ, ± 10 ppm/°C max,

Page 40

Common Mode Rejection: X1 80 dB min 99 dB typ

X10 96 dB min 114 dB typ

SignalPro Series Users Manual 40

Cutoff Frequency: 5 Hz (4 Poles Butterworth, -3dB@5Hz, -80dB@50Hz)

Power Requirement: + 5V ±5% 70mA typ

Dimension: 160mm X 100mm for QTC-250; 100mm X 100mm for QTC-250T

Weight: 0.13Kg for QTC-250; 0.35Kg for QTC-250T.

X100 110 dB min 123 dB typ

+15V ±5% 50~70mA typ

-15V ±5% 50mA typ

Page 41

6 QTC-300 Strain Gage Input Signal Conditioning Module

QTC-300 Features

SignalPro Series Users Manual 41

Four Strain Gage input channels (Up to 256 channels can be configured in system)

Custom configurable excitation current source which readily converts to vendor

specified Strain Gage Excitation Voltage

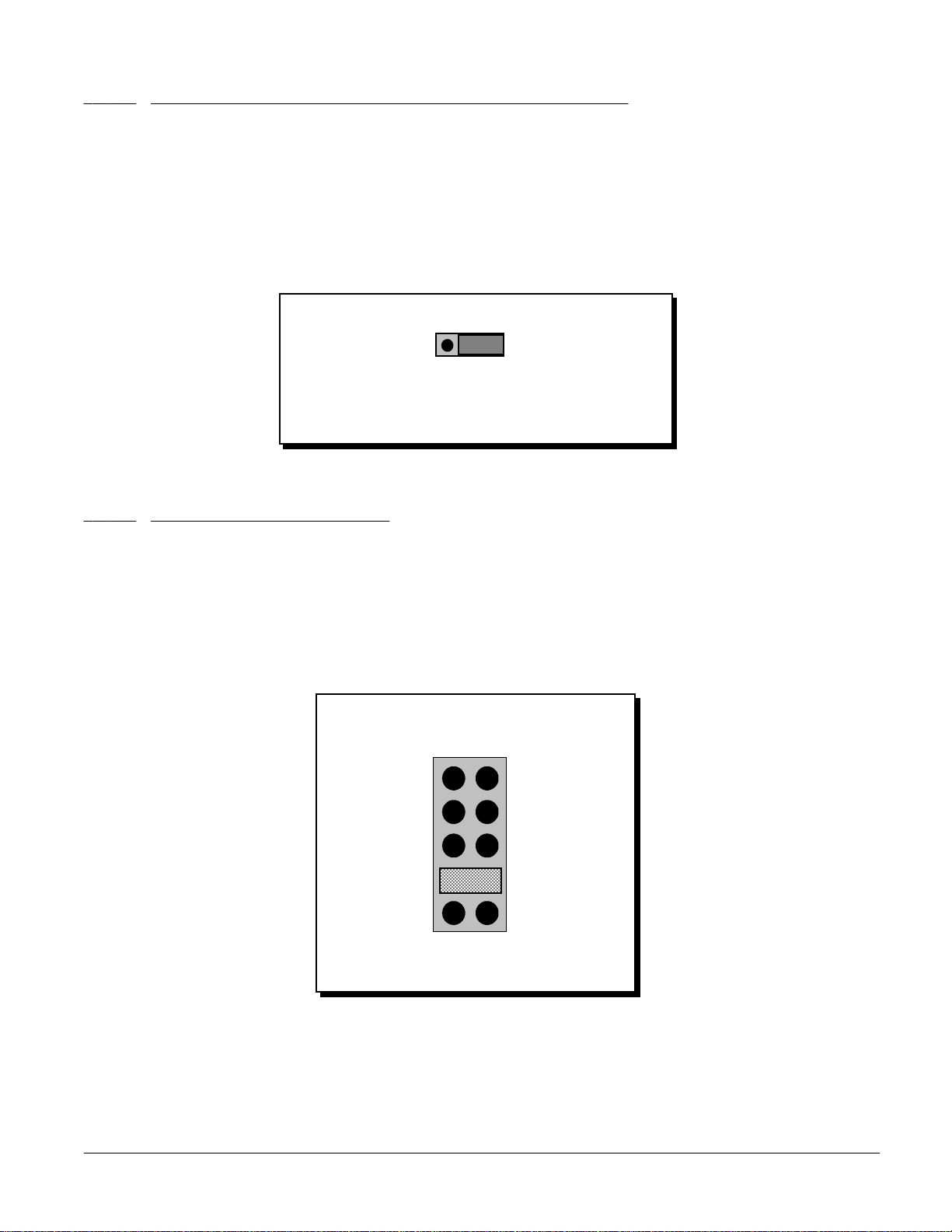

Supports full, half and quarter bridge gage configurations

On board low-pass filter for each channel (10Hz, 100Hz or 1KHz cut off frequency)

Easy zero and shunt calibration

Terminal block for quick, easy signal connections

The QTC-300 is a four channel strain gage input signal conditioning module. Each channel is

equipped wi th separate instrument ampl ifiers, multiple excitati on current source options and

a fourth order low pass filter. Up to 64 QTC-300 modules can be configured in an Omega

signal condi tioning and data acquisiti on system for a total of 256 analog input channels. Each

channel has selectable gain of 1, 10, 100, 200 or 500. The QTC-300 can also be coupled with

other modules in Omega’s SignalPro series to provide a versatile data acquisition system.

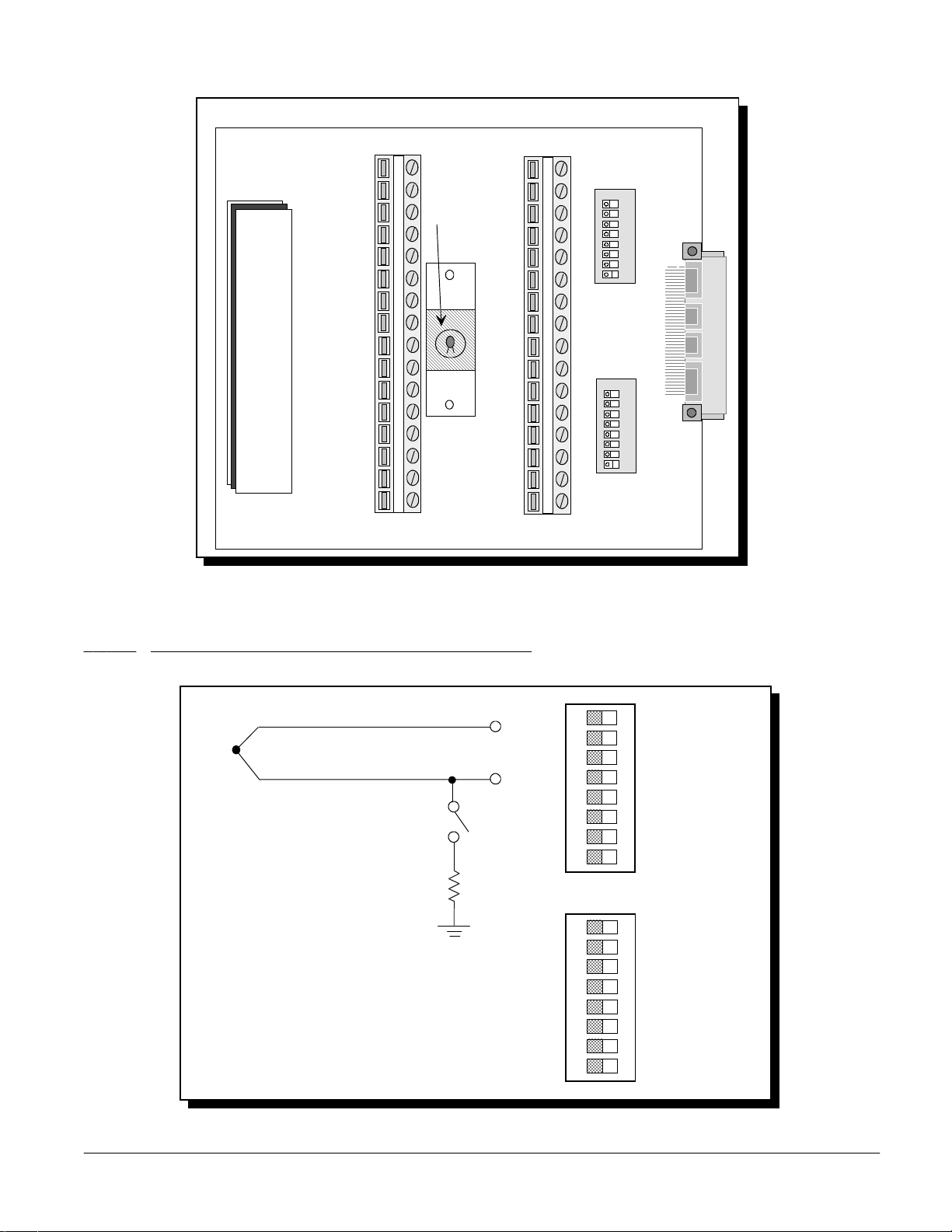

The QTC-300 module consists of two circuit boards: the QTC-300 interface board and the

QTC-300T terminal board. The interface board is a standard 3U size board which can be

mounted in the QTE-7, QTE-14 or QTC-300-PCS data acquisition enclosures. The QTC-300T

terminal b oard conta ins the strai n gage input scre w bl ocks, b rid ge comple tion cir cuits and the

calibration switch. This two board configuration allows quick and easy connection of the

strain gage lead wires. After the initial configuration of the interface board, it can be mounted

in a data acquisition enclosure and will rarely require removal. All connections are completed

on the screw terminals of the portable QTC-300T, which is then plugged into the QTC-300

interface board and secured using two thumb screws. (See Figure 6-1).

QTC-300-PCS

QTE-7

QTC-300 Terminal Board

QTC-300

Interface Board

Figure 6-1. QTC-300 Strain Gage Input Module

Page 42

6.1 Circuit Board Description

6.1.1 QTC-300 Interface Board Description

SignalPro Series Users Manual 42

The QTC-300 interface board shown in Figure 6-1 can be mounted in SignalPro series data

acquisition racks and enclosures. (See Chapter 2 for information on SignalPro series racks).

Each rack enclosure i s equipped wi th a DIN-4 8 female connector which mate s to the QTC-300

and other SignalPro series signal conditioners. The rack also contains a standard D37

connector which attaches to the host computer data acquisition adapter.

Four strain gage input channels are provided by multiplexing a single main A/D channel off

the host computer data acquisition adapter. The multiplexer on the QTC-300 scans the four

strain gage input channels sequentially and connects each input to the single main A/D

channel. The four multi plexed input channel s may b e mapped back to any main A/D channel

on the data acquisition adapter depending on the configuration of jumper J5. Four interface

boards may share one singl e e nd e d A/D input fr om the host computer to provid e a maximum

of 16 multiplexed channels per main A/D channel. Multiplexing of all 16 main A/D channels

from the host computer resul ts in a maximum of 256 A/D i nput channels, (16 x 16) , per data

acquisition adapter.

6.1.2 QTC-300T Terminal Board Description

The QTC-300T terminal board shown in Figure 6-1 contains the strain gage input terminal

blocks, bridge connection LEDs, calibration switch, offset null potentiometers, excitation

current selection resistor sockets, external ex citation power supply connector and the bridge

completion circuits. The terminal board DIN-48 female connector plugs into the QTC-300

interface board and is equipped with a strain relief bracket to secure external strain gage

wiring.

Page 43

6.2 Hardware Configuration

SignalPro Series Users Manual 43

For system configuration options see Chapter 1: SignalPro Series Overview, section 1.3:

Hardware Configuration.

6.2.1 QTC-300 Interface Board Configuration

QTC-300

SHC298

J7

J8

J9

J10

J1

J2

J3

J4

F1

F2

F3

F4

U15

SHC298

U23

SHC298

U30

SHC298

U29

BB

J11

BB

J12

J13

BB

J14

BB

J15

J5

CH0

CH1

CH2

CH3

CH4

CH5

CH6

CH7

CH8

CH9

CH10

CH11

CH12

CH13

CH14

CH15

J6

Figure 6-2. QTC-300 Jumper and Filter Block Locations

Figure 6-2 depicts the location of the main A/D channel and board selection jumper blocks

(J5/J6), SSH option jumper block (J11), A/D gain selection jumper blocks (J1 through J4), filter

selection jumper blocks (J12 through J15), filter blocks (F1 through F4) and the AC/DC

coupling selection jumpers (J7 through J10). System configuration options for J5 and J6 are

discussed extensively in Chapter 1, section 1.3.

Page 44

6.2.1.1 Simultaneous and Sample Hold Jumper ( QTC-300S only)

The simultaneous sample and hold f eature on the QTC-300S eliminates time skew across the

SignalPro Series Users Manual 44

four analog input channels. At the beginning of an A/D channel scan, the SSH device

simultaneously samples all four of the QTC-300S input channels and holds the input signals.

The A/D multiplexer then scans each of the channels in sequence and performs the A/D