Page 1

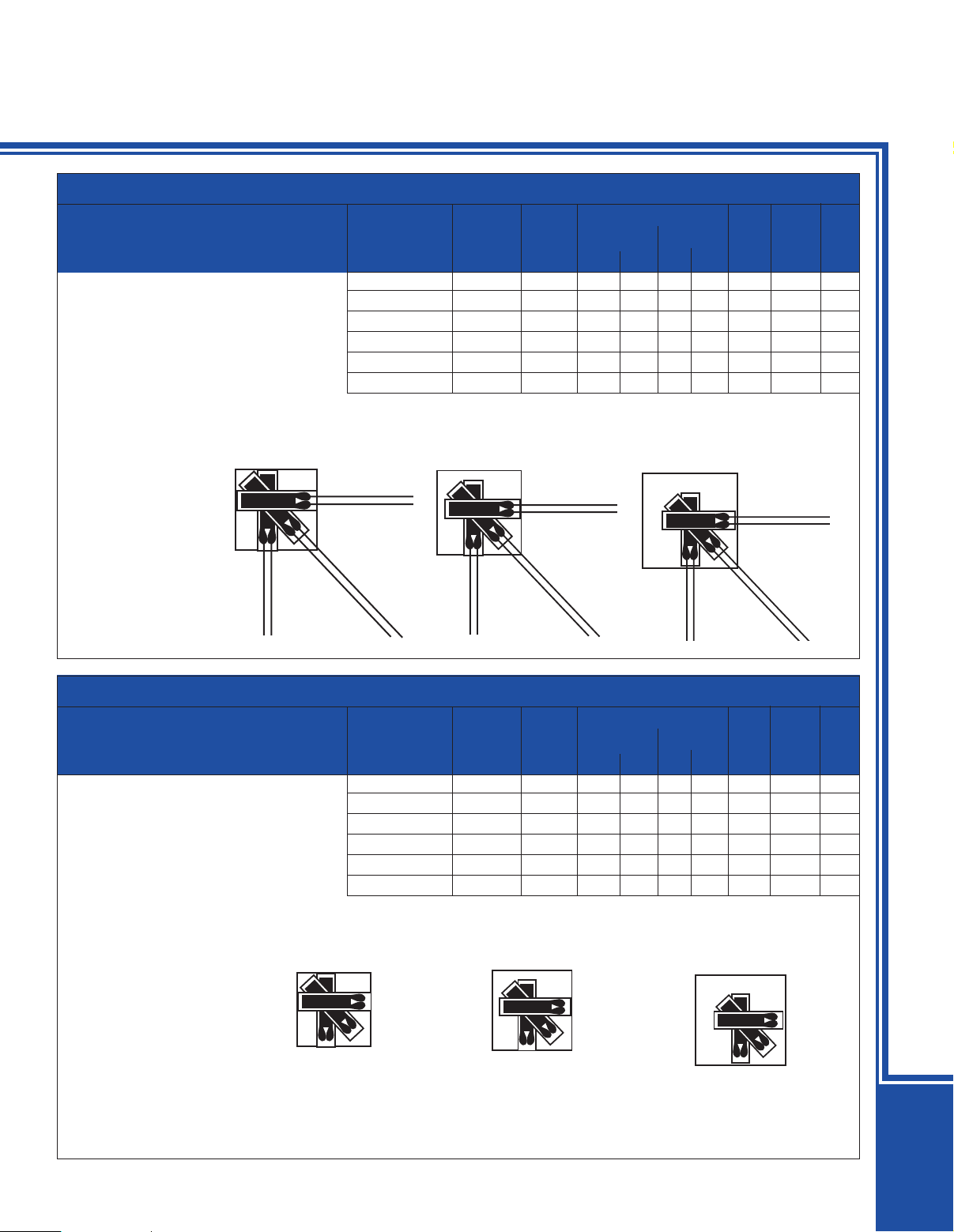

ROSETTE STRAIN GAGES

To Order

TYPE SERIES PRICE GRID CARRIER

U 0°/45°/90° Encapsulated with

Ribbon Leads

RY51

Temperature characteristics

matched to carbon steel

RY53

Temperature characteristics

matched to aluminum

(Specify Model Number)

Diagrams Shown Larger

Than Actual Size

Fig. 1

DIMENSIONS [MM]

PER PKG MAX TERM

MODEL NO. OF 5 OHMS A B C D EXC PADS FIG

SG-2/120-RY51 $125 120 2.0 1.8 6.3 5.0 5 TP-1 1

SG-3/350-RY51 139 350 3.0 1.6 7.0 6.8 8 TP-2 2

SG-7/120-RY51 165 120 6.0 3.0 12.0 11.0 10 TP-3 3

SG-2/120-RY53 125 120 2.0 1.8 6.3 5.0 5 TP-1 1

SG-3/350-RY53 139 350 3.0 1.6 7.0 6.8 8 TP-2 2

SG-7/120-RY53 165 120 6.0 3.0 12.0 11.0 10 TP-3 3

Fig. 2 Fig. 3

For Accessory

Terminal Pads,

see page E-25.

To Order

TYPE SERIES PRICE GRID CARRIER

U 0°/45°/90° Encapsulated with

Solder Tabs

RY61

Temperature characteristics

matched to carbon steel

RY63

Temperature characteristics

matched to aluminum

Ordering Example:

SG-7/120-RY61, package of

five rosette strain gages

encapsulated with solder tabs,

with temperature characteristics

matched to carbon steel and

max. excitation of 9 V, $165.

(Specify Model Number)

DIMENSIONS [MM]

PER PKG MAX TERM

MODEL NO. OF 5 OHMS A B C D EXC PADS FIG

SG-2/120-RY61 $125 120 2.0 1.8 6.3 5.0 5 TP-1 1

SG-3/350-RY61 139 350 3.0 1.6 7.0 6.8 8 TP-2 2

SG-7/120-RY61 165 120 6.0 3.0 12.0 11.0 9 TP-3 3

SG-2/120-RY63 125 120 2.0 1.8 6.3 5.0 5 TP-1 1

SG-3/350-RY63 139 350 3.0 1.6 7.0 6.8 8 TP-2 2

SG-7/120-RY63 165 120 6.0 3.0 12.0 11.0 9 TP-3 3

Diagrams Shown Larger

Than Actual Size

Fig. 1 Fig. 2 Fig. 3

STRAIN GAGES

For Accessory

Terminal Pads,

see page E-25.

E

E-16

Page 2

a

b

c

a

b

c

a

b

c

ab c

a

c

b

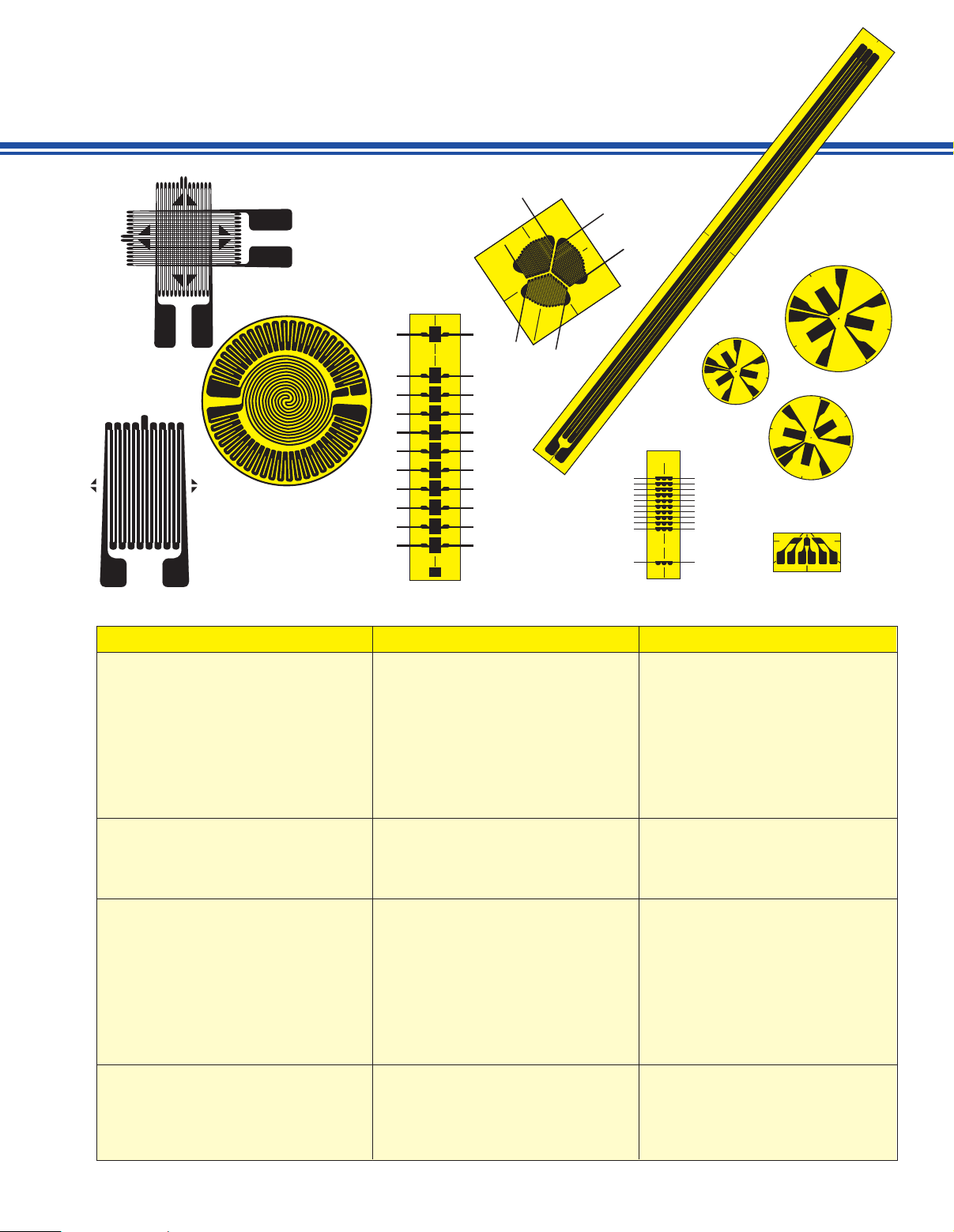

OMEGA®STRAIN GAGES

SPECIFICATIONS CHART

SG SERIES KFG SERIES

Foil strain gages are constructed by

embedding a foil measuring element into

a carrier.

Foil measuring grid Constantan foil 5 µm thick Constantan foil 6 µm thick

Carrier Polyimide Kapton

Substrate thickness 50 µm 15 µm

Cover thickness 25 µm 9 µm

Connection dimensions in (mm) [in] Solder pads or ribbon leads 27 AWG strand polyvinyl insulation

(30 long x.05 thick x 3 wide) (1 x 2) [.04 x .08]

[1.2 long x .002 thick x .012 wide]

Nominal resistance Stated in “to order” box 120 ±0.4 ohms

Resistance tolerance per package 0.5% 03%

Gage factor (µΩ/µ/µΩ) Approximately 2.0 2.10 ±10%

(actual value printed on each package)

Gage factor tolerance per package 1.0% 1.0%

Thermal Properties

Reference temperature 23°C/73°F 23°C/73°F

Service temperature:

Temperature characteristics:

Static measurements -30 to 250°C (-22 to 482°F) -20 to 100°C (-4 to 212°F)

Dynamic measurements -30 to 300°C (-22 to 572°F) -20 to 100°C (-4 to 212°F)

Steel 11 ppm°C (6.1 ppm°F) 10.8 ppm°C (6 ppm°F)

Aluminum 23 ppm°C (12.8 ppm°F) —

Uncompensated ±20 ppm°C (±11.1 ppm°F) —

Temperature compensated range -5 to 120°C (5 to 248°F) 10 to 80°C (50 to 176°F)

Tolerance of temp. compensation 1 ppm°C (0.5 ppm°F) 1 ppm°C (0.5 ppm°F)

Mechanical Properties

Maximum strain 3% or 30,000 µe 5% or 50,000 µe

Hysteresis Negligible Negligible

Fatigue (at ±1500 µe) > 10,000,000 cycles > 10,000,000 cycles

Smallest bending radius 3 mm (1⁄8 inch) 3 mm (1⁄8 inch)

Transverse sensitivity — Stated on each package

E-7

Page 3

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...