Page 1

Page 2

OMEGAnet®On-Line Service Internet e-mail

www.omega.com info@omega.com

omega.com

TM

®

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA

is constantly pursuing certification of its products to the European New Approach Directives. OMEGA will add

the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts no

liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected

applications.

Benelux:

Postbus 8034, 1180 LA Amstelveen

The Netherlands

TEL: +31 (0)20 6418405 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic:

Rude´arma´dy 1868, 733 01 Karvina´ 8

TEL: +420 (0)69 6311899 FAX: +420 (0)69 6311114

Toll Free in Czech Republic: 0800-1-66342

e-mail: czech@omega.com

France:

9, rue Denis Papin, 78190 Trappes

TEL: +33 (0)130 621 400 FAX: +33 (0)130 699 120

Toll Free in France: 0800-4-06342 e-mail: france@omega.com

Servicing Europe:

USA and Canada:

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN® TELEX:

996404 EASYLINK: 62968934 CABLE: OMEGA

USA: ISO 9001 Certified

One Omega Drive, P.O. Box 4047

Stamford CT 06907-0047

TEL: (203) 359-1660

FAX: (203) 359-7700

e-mail: info@omega.com

Servicing North America:

For immediate technical or application assistance:

Mexico:

TEL: (001) 800-826-6342

FAX: (001) 203-359-7807

En Espan~ol: (001) 203-359-7803

e-mail: espanol@omega.com

info@omega.com.mx

Germany/Austria:

Daimlerstrasse 26, D-75392

Deckenpfronn, Germany

TEL: +49 (0)7056 3017 FAX:+49 (0)7056 8540

Toll Free in Germany: 0800 TC-OMEGA

SM

e-mail: germany@omega.com

United Kingdom: ISO 9002 Certified

One Omega Drive

River Bend Technology Centre

Northbank, Irlam

Manchester M44 5EX United Kingdom

TEL: +44 (0)161 777 6611 FAX:+44 (0)161 777

6622

Toll Free in United Kingdom: 0800488488

e-mail: sales@omega.co.uk

Canada:

976 Bergar

Laval (Quebec) H7L 5A1

TEL: (514) 856-6928

FAX: (514) 856-6886

e-mail: info@omega.ca

Page 3

SCR POWER CONTROLLERS

TABLE OF CONTENTS

General Description

and Specifications .................1

Firing Modes .......................2

Installation and Wiring ...............4

Operation .........................9

Troubleshooting....................15

Parts Lists and

Ordering Codes ..................18

Page 4

1

OPERATING INSTRUCTIONS

Series 19 and 39 SCR Power Controllers

Series 91 and 93 SCR Power Controllers

Section 1. General Description

Introduction

SCR Power Controllers are designed to regulate ac power to electrical

heating processes, such as ovens, furnaces, heat sealers, etc. (Note:

They are not designed to drive transformers, coils or other inductivetype loads.)

The controller accepts an input signal, such as 4-20 mAdc from some

signal conditioning device, e.g., a temperature controller. For most

processes, the combination of a temperature controller and SCR

power controller will provide very accurate, automatic temperature

control. For manual operation, a manual control option with a remote

potentiometer is available.

General Specifications

Inputs: 4-20 mAdc standard, or as ordered (see

serial number) minimum voltage

requirements 10 Vdc; all inputs

electrically isolated via optical coupling

Supply Voltage: 110/120; 208/240; 440/480, 575/600

Vac, or as ordered (Phase connection

not critical on 3-phase units)

Frequency: 50/60 Hz

Ambient Temperature: 30

o

to 122oF for listed power ratings

Cooling: Convection

Protection: Sub-cycle, current-limiting fuse; transient

voltage suppresion

Load Resistive, 1- or 3-phase - 3-wire Wye or Delta

All specifications subject to change.

Page 5

2

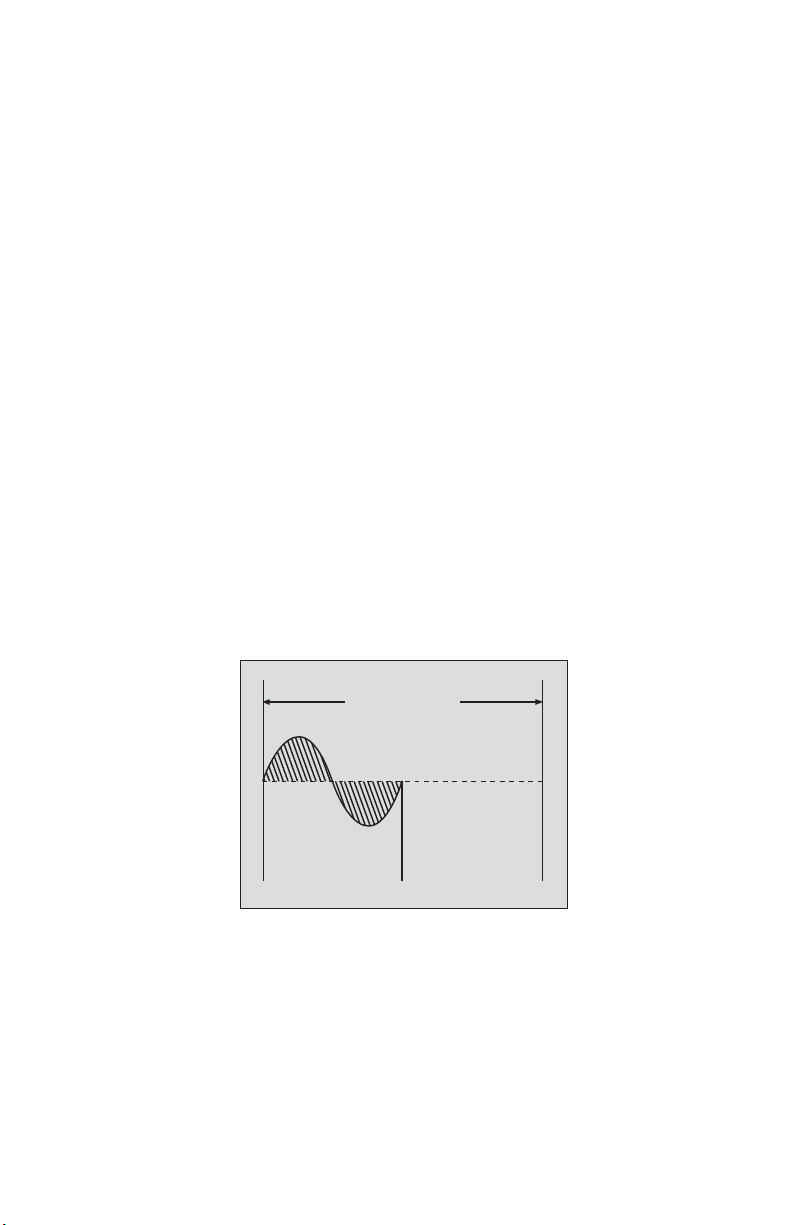

0.2 Second

Time Base

On

Off

Figure 1. Time-proportioned, zero-cross burst.

Section 1. Firing Modes

Zero-Crossing Control

A zero-crossing switched (zer-switched or burst fired) SCR

power controller works by triggering at the moment when the

value of the ac sine wave is at the baseline or “zero” voltage

point (Figure 1.) This results in a “burst” of full line voltage with

no RFI. SCR power controllers utilize a patented trigger

circuit that turns on the SCRs as close as possible to the ac

zero voltage point. Proportioning action is obtained by varying

the number of cycles on to the number of cycles off. The

output will vary from a few cycles on and a large number of

cycles off at low input, through halh the cycles on and half off

at half input, to all cycles on at maximum input. This output

is integrated by the heaters which produce a smoothly

proportioning heat output that varies directly with the input

signal.

Page 6

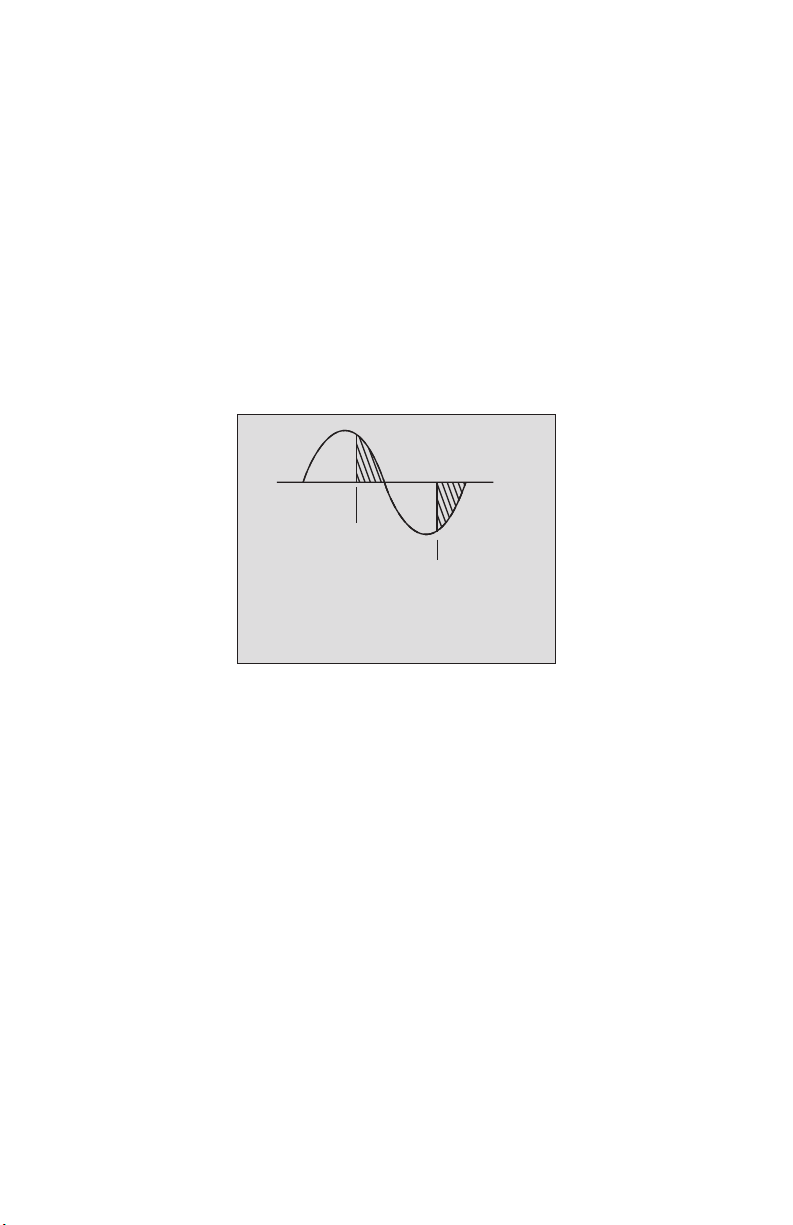

Phase-Angle Control

A phase-angle type SCR power controller works by delaying

the trigger pulse to some point in the half cycle of the ac

wave. This trigger point, from 0 to 180 degrees, is referred to

as the phase angle (Figure 2). The SCR will turn on when

triggerred, and remain on for the rest of the half cycle.

Increasing the control signal will cause the trigger pulse to

occur earlier in the half cycle, thus delivering a greater portion

of the wave to the load.

Because it provides an extremely fast response, phase-angle

control should be used in low-mass element applications that

require high switching speeds, such as tungsten elements,

quartz lamps, hot wires and other loads subject to high inrush

currents. (Note: Some RFI can be generated from the phaseangle controller) SCR phase-angle power controllers are available with a soft-start timing option that provides a ramp to

peak voltage, and are available with a voltage limit option that

“clamps” output voltage to a level lower than the supply

voltage.

3

Figure 2. Phase-angle changes and their effect on output power.

Phase angle = 113°, 293°

Power = 25%

0° 360°

180 °

11 3 °

293°

Page 7

4

Section 3. Installation

3.1 Mounting

Mount the controller, with the heat sinks in a vertical position,

in a reasonably cool location -- 50

o

C (122oF) maximum.

Some space should be left above and below the unit to allow

for air circulation. If the controller must be placed in an

environment where the ambient temperature exceeds 50oC

(122

o

F), it will be necessary to derate the unit. If derating is

not possible, venting or an exhaust fan must be used to keep

ambient temperatures at an acceptable level. (See Figure 3

for cooling calculations).

Formula for minimum metal enclosure size

for convection cooling

.72 x AMPS x # of Controlled Legs Min. Exposed

=

122

o

F - Ambient oF Sq. Ft.

.40 x AMPS x # of Controlled Legs Min. Exposed

=

50oC - Ambient oC Sq. Ft.

Formula for forced air cooling

2.2 x AMPS x # of Controlled Legs

= Min. CFM

50

o

C - Ambient oC

3.8 x AMPS x # of Controlled Legs

= Min. CFM

122oF - Ambient oF

Figure 3. Calculations for determining cooling requirements

Page 8

3.2 Wiring

The wiring components of SCR power controllers consists of

line voltage, heater, load, and signal input. Follow the wiring

diagrams on the following pages (Figures 4 and 5) and the

terminal labels on the unit. On three-phase controllers (Series

39), it is not necessary to connect the phases to any

particular terminal. Because the controllers are

phase-to-phase controllers, either Wye or Delta connected

loads may be used.

Wire gauge for power and load connections will vary depending on the size of the load. Standard electrical code

procedures should be followed. Do not exceed the voltage

and ampere ratings indicated on the controller’s label. Before

connecting the controller to a heater, we recommend that the

heater be connected directly to the power line to ensure that

the current rating is correct and that no shorts exist.

5

CAUTION

On Wye connected loads, do not connect the

center terminal to the line or to the ground.

Page 9

6

CAUTION:

Possible Shock Hazard -- Exposed high voltage exists on heat

sinks and other parts of these units.

To prevent possible electrocution, the

controller must be locked in a secure

enclosure during operation. Solid

state devices do not completely

remove power from the load, even in

the OFF state. This leakage current

presents a potential shock hazard at

all unit and load terminals. All power

must be completely off before servicing

.

Only qualified personnel should be

allowed access.

Possible Fire Hazard -- Because SCR power controls and

associated equipment are not fail-safe

devices, an approved temperature

and/or pressure safety control should

be used to ensure safe operation.

Page 10

7

Figure 4a. Wiring scheme for Series 19Z.

Figure 4b. Wiring scheme for Series 39Z.

3.21 Zero-Cross

Zero-cross mode power controllers may only be used with

constant resistance heating elements, such as Nichrome. They

are NOT intended for high-inrush loads. Depending on the type

of element used, you can oversize the load controller.

Figure 5a. Wiring scheme for Series 19P.

Figure 5b. Wiring scheme for Series 39P.

Page 11

8

3.23 Fuses and Safety Warnings

Only I2fuses should be used for protecting the power

controller’s SCRs. These fuses are especially designed to

protect the solid state devices under short-circuit conditions;

other fuses may not act quickly enough. If it becomes

necessary to replace a fuse, use only a Chase-Shawmut

Form 101 or semiconductor fuse, or equivalent.

IMPORTANT SAFETY WARNINGS - READ BEFORE

OPERATING CONTROLLER.

Standard fuses or a circuit breaker should be used on

all power lines for safety and to meet electrical code

requirements. The supplied fuses are for protecting the

SCRs only and are not acceptable as power line fuses.

SCR power controllers do not satisfy electrical code

disconnect requirements in the non-conducting or OFF

state. Because they are semiconductor devices, the

have a leakage current in the OFF state on the order of

10mA at rated line voltage. Therefore, the controller

should be connected to a circuit breaker or disconnect

switch.

SCRs can fail in a “shorted-closed” mode, resulting in

full application of power. Use of a seperate, thermally

protected safety contactor is strongly recommended.

Page 12

Section 4. Operation

4.1 Series 19Z/39Z

The Series 19Z and 39Z power controllers are designed to

control ac power to electrical heating processes, such as

ovens, furnaces, heat sealers, etc. (Note: They are NOT

intended to drive transformer coupled or inductive loads.)

The controllers consist of power semiconductors (SCRs),

properly sized heat sinks, and trigger circuitry. These

controllers accept a control signal (e.g., 4-20 mAdc) from a

signal conditioning device, such as a temperature controller.

The “Z” suffix designates the controller as operating in the

Zero Cross, Zero Voltage Switched, or Zero Burst firing mode.

A patented trigger circuit turns on the SCRs as close as

possible to the point at which the ac sine wave crosses

through zero. In effect, this turns the line voltage on and off

in full cycles. With an input of 4-20 mA , the output will be

FULL OFF below 4 mA and FULL ON at 20 mA.

Proportioning action is obtained by varying the number of

cycles ON to the number of cycles OFF. The resulting output

power is integrated by the heaters to produce smoothly

proportional heating that varies directly with the input signal.

9

Series

19/39

Page 13

4.2 Series 19P/39P

The Series 19P and 39P power controllers are designed to

control ac power to electrical heating processes, such as

ovens, furnaces, heat sealers, etc. (Note: They are NOT

designed to drive transformer-coupled loads.) The controllers

consist of power semiconductors (SCRs), properly sized heat

sinks, and trigger circuitry.

These controllers accept a control signal (e.g., 4-20 mAdc)

from a signal conditioning device, such as a temperature

controller.

The “P” Suffix designates the controller as operating in the

Phase-Angle firing mode. Providing full proportional control,

SCRs are turned ON during each 1/2 cycle at apoint (phase

angle) of the ac sine wave, remaining ON for the rest of the

1/2 cycle. By varying the phase angle setting, the amount of

voltage reaching the load may be adjusted. The output

voltage is proportional to the input signal. At 4 mA input, no

voltage will be applied to the load; at 20 mA input, the

output voltage will almost equal the line voltage.

10

Page 14

11

4.3 Voltage Limit Option (Phase-Angle Fired Units Only)

The output voltage of the controller can be limited by

adjusting the trimmer on the printed circuit board. Turning

the adjustment clockwise will increase the out put voltage

limit. This control will operate over a range of about 20% to

full output. Ordinarily, this adjustment is used to protect

heaters that cannot operate on full line voltage, or to limit the

maximum heating of a process.

4.4 Soft Start Option (Phase-Angle Fired Units Only)

The soft start circuitry is used to slowly turn on the voltage

from the controller to the load. It is used to protect the

controller when it is operating into loads having high-current,

turn-on characteristics, e.g., quartz or tungsten heaters. The

output voltage will rise from zero to full output over various

times, depending on the time option selected.

The soft start circuit presents an initial high impedance which

is inserted between the signal source and the controller. This

impedance decreases in value with time. Soft start action

can be seen as the input signal slowly changes from 4-20 mA

when full output is required.

Page 15

4.5 Manual Option

A module board is added to the standard controller which

converts a variable resistance potentiometer to a 0-20 mA

signal. This signal is then applied to the input of the standard

trigger board and operates the controller in the standard

manner (Figure 6). The input potentiometer can be any

three-lead pot from 100 to 1000 ohms. The pot supplied

with the manual option is 500 ohms. This pot has a 0-10

scale and knob. There will be no output at the “0” setting

and full output at the “10” setting.

12

Figure 6. Wiring diagram for manual control (Option module M required).

120/240/480/600Vac

RED

0 -20 dc

BLACK

+

–

TRIGGER

BOARD

(1000 Ω MAX)

Page 16

4.6 Thermostat Option

The module will also operate from a standard 135-ohm

thermostat. Connect the three output wires to the controller

as shown on the drawing (Figure 7) and on the terminal strip.

If the output terminals on the thermostat are not marked in

the same fashion, connect the center wire to the CT point on

the terminal strip, connect the other two wires to the CW

and CCW points. The controller should then provide an

output as the thermostat setpoint is increased. If the reverse

action occurs, interchange the CW and the CCW wires.

13

Figure 7. Wiring diagram for thermostatic control (Option H required).

120/240/480/600 Vac

Hot

Cold

0 -20 dc

+

–

TRIGGER

BOARD

(1000 Ω MAX)

Page 17

4.7 Maintenance

SCR power controllers require little, if any, maintenance.

However, as with all products exposed to industrial

environments, they should be cleaned periodically to prevent

corrosion and to remove any surface dust, dirt, and oil. We

also recommend inspecting, and re-tightening if necessary, all

electrical and mechanical connections (lugs, terminals, fuses,

buss bars, etc.)

14

WARNING: Before Touching Controller Parts,

Make Sure Power Is Disconnected.

Page 18

15

4.8 Troubleshooting

If the power controller is not functioning properly, refer to

these troubleshooting procedures.

Symptom: No heat or reduced heat output.

Possible Cause(s) Action

1. Loss of line voltage. Check power

supply.

2. Line fuse or controller fuse blown. Check heater for

short circuit and

correct problem.

3. No input signal. Check signal

conditioner.

4. Malfunction on trigger board. Consult factory.

5. Open SCR Consult factory.

Page 19

16

Trigger board

malfunction

Shorted SCR

Signal source

defective

Reconnect properly

Line and

load connections

reversed

Disconnect

input

signal wires

Output off?

Turn power

back on

Turn off power

and disconnect

gate wires

Heater

amps

present?

Yes

No

No

No

Yes

Yes

Troubleshooting Flowchart

Symptom: Heaters will not turn off.

Page 20

Input Signal Problems: In normal operation, the green LED will

illuminate if an input signal of proper polarity is present. Its

brightness indicates signal level.

Symptom: Red or amber input LED is lit

Red: Polarity of input signal is reversed (Change polarity).

Amber: AC on input signal (Check signal source).

Output Signal Problems: In normal operation, the amber LED

will illuminate if an output voltage is present. Its brightness

indicates output level.

Symptom: Output LED lit with no input.

Symptom: Output LED is red or green with input.

Check and correct the following conditions:

1. Gate wire unplugged or broken

2. Open SCR

3. Trigger board malfunction

4. Balance pot misadjusted (Phase-angle controllers only)

17

Trigger board malfunction

Heater circuit open

Shorted SCR

Reconnect properly

Line and load

connections reversed?

Turn off power

and disconnect

gate wires

Heater

amps

present?

Yes

No

Heater

amps

present?

Yes

No

No

Yes

Page 21

18

Section 5. Parts Lists

Series 19/39

MODEL # FUSES SCR MODULE SCR MODULE

(Voltage / Load) (19P, 19Z, 39Z) (39P)

24040/12040 A050F040 IRKT 57-10 IRKH 72-10

24060/12060 A050F060 IRKT 57-10 IRKH 72-10

24080/12080 A050URG080XAA IRKT 92-10 IRKH 92-10

48040 A050F040 IRKT 57-10 IRKH 72-10

48060 A070F060 IRKT 57-10 IRKH 72-10

48080 A070URGC080WA IRKT 92-10 IRKH 92-10

Page 22

19

Athena Model No:

9

SWITCHING MODE

Code

*P Phase angle firing

Z Zero switched

Ordering Example:

Model 39Z-24-040-P-0-00

Three phase, zero switched,

208/240 Vac line voltage, 40 amps,

pulsed dc input, no options, no timing.

(Use “0” for all spaces not used.)

ACCESSORIES

Manual Station with Remote Potentiometer

(Requires Input “A” on SCR unit)

90M001-120 (120 Vac supply voltage)

90M001-240 (240 Vac supply voltage)

90M001-480 (480 Vac supply voltage)

90M001-600 (600 Vac supply voltage)

SOFT START / VOLTAGE

LIMIT P SERIES ONLY

Code (Soft Start Timing

0 None

A9 Seconds

B 15 Seconds (Standard)

C 30 Seconds

D 60 Seconds

INPUTS

Code

A 4-20 mA

C 10-50 mA

D Other mA or Voltage (Specify)

P Pulsed dc (Z series only)

PHASE

Code

1 Single

3 Three

AC LINE VOLTAGE (50/60 HZ)

24 = 02 440/480 = 48

110/120 = 12 575/600 = 60

208/240 = 24

LOAD CURRENT

(AMPS)

Code

040 40 Amps

060 60 Amps

080 80 Amps

OPTIONS

Consult Factory

00 None

0A Fuses

*Specify voltage code

Section 6. Model Identification

Ordering Codes: Series 19/39

Page 23

Section 7. Dimensions

Series 19/39

Warranty

This equipment is warranteed to be free from defects of

material and workmanship. It is sold subject to our mutual

agreement that the liability of the manufacturer is limited to

replacement and/or repair at its factory, provided the

equipment is returned, transportation prepaid, within one (1)

year of purchase.

The purchaser agrees that the manufacturer shall assume no

liability for consequential damages resulting from its use or

from packaging of shipments returned to the factory.

Components that wear or are damaged by misuse are not

warranted. These include contact points, fuses and triacs.

Units that have been customer modified are not warranted.

Specifications are subject to change without notice.

20

19Z 19P 39Z 39P

Dimensions Dimensions Dimensions Dimensions

H x W x D H x W x D H x W x D H x W x D

(in) (in) (in) (in)

7 x 4.75 x 4 7 x 4.75 x 4 7 x 9.62 x 4 7 x 14.37 x 4

Notes: If fuses are added to unit, add 3 1/4". Overall depth is 4".

Page 24

21

NOTES

Page 25

22

NOTES

Page 26

23

NOTES

Page 27

24

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2004 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, trans-

lated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA

ENGINEERING, INC.

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for

a period of 13 months from date of purchase. OMEGA’s Warranty adds an additional one (1) month

grace period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other

operating conditions outside of OMEGA’s control. Components which wear are not warranted, including but not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with information provided by OMEGA,

either verbal or written. OMEGA warrants only that the parts

manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER

WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT

THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA with

respect to this order, whether based on contract, warranty, negligence, indemnification, strict liability

or otherwise, shall not exceed the purchase price of the component upon which liability is based. In

no event shall OMEGA be liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a

“Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2)

in medical applications or used on humans. Should any Product(s) be used in or with any nuclear

installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes

no responsibility as set forth in our basic WARRANTY / DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever

arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA,PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER

FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The

assigned AR number should then be marked on the outside of the return package and on any

correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR W

ARRANTY RETURNS, please have the following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTY REPAIRS,

consult OMEGA for

current repair charges. Have the following information available BEFORE

contacting OMEGA:

1. Purchase Order number to cover the

COST of the repair,

2. Model and serial number of the

product, and

3. Repair instructions and/or specific problems

relative to the product.

Page 28

M4100/1004

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERATURE

✓

Thermocouple, RTD & Thermistor Probes, Connectors,

Panels & Assemblies

✓

Wire:Thermocouple, RTD & Thermistor

✓

Calibrators & Ice Point References

✓

Recorders, Controllers & Process Monitors

✓

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

✓

Transducers & Strain Gages

✓

Load Cells & Pressure Gages

✓

Displacement T r ansducers

✓

Instrumentation & Accessories

FLOW/LEVEL

✓

Rotameters, Gas Mass Flowmeters & Flow Computers

✓

Air Velocity Indicators

✓

Turbine/Paddlewheel Systems

✓

Totalizers & Batch Controllers

pH/CONDUCTIVITY

✓

pH Electrodes, Testers & Accessories

✓

Benchtop/Laboratory Meters

✓

Controllers, Calibrators, Simulators & Pumps

✓

Industrial pH & Conductivity Equipment

DATA ACQUISITION

✓

Data Acquisition & Engineering Software

✓

Communications-Based Acquisition Systems

✓

Plug-in Cards for Apple, IBM & Compatibles

✓

Datalogging Systems

✓

Recorders, Printers & Plotters

HEATERS

✓

Heating Cable

✓

Cartridge & Strip Heaters

✓

Immersion & Band Heaters

✓

Flexible Heaters

✓

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

✓

Metering & Control Instrumentation

✓

Refractometers

✓

Pumps & Tubing

✓

Air, Soil & Water Monitors

✓

Industrial Water & Wastewater Treatment

✓

pH, Conductivity & Dissolved Oxygen Instruments

Loading...

Loading...