Page 1

SBG111950, SBG111954,

SBG111956, SBG113000, SBG114166

Single Channel Zener Barrier

Instruction Sheet M1779/1199Instruction Sheet M1779/1199

Instruction Sheet M1779/1199

Instruction Sheet M1779/1199Instruction Sheet M1779/1199

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

These shunt diode, safety barriers are one channel devices

which pass a unidirectional signal (D.C.) and limit the energy to a

level that cannot ignite an explosive atmosphere.

Approvals include FM, UL and CSA.

UNPACKINGUNPACKING

UNPACKING

UNPACKINGUNPACKING

Remove the Packing List and verify that you have received all

equipment. If you have any questions about the shipment,

please call the OMEGA Customer Service Department at

1-800-622-2378 or (203) 359-1660. When you receive the

shipment, inspect the container and equipment for any signs of

damage. Note any evidence of rough handling in transit. Immediately report any damage to the shipping agent.

NOTENOTE

NOTE

NOTENOTE

The carrier will not honor any claims unless all shipping material

is saved for their examination. After examining and removing

contents, save packaging material and carton in the event

reshipment is necessary.

Important: Read carefully and completely beforeImportant: Read carefully and completely before

Important: Read carefully and completely before

Important: Read carefully and completely beforeImportant: Read carefully and completely before

installing or connecting the solid-state relays.installing or connecting the solid-state relays.

installing or connecting the solid-state relays.

installing or connecting the solid-state relays.installing or connecting the solid-state relays.

INSTALLATION REQUIREMENTS

Location: Barriers must be installed and grouped in a non-

hazardous location. If necessary to locate in a hazardous area,

barriers must be mounted in a suitable enclosure which, along

with its installation, must be suitable for that location.

Environment: Environment:

Environment: The operating temperature range for these

Environment: Environment:

barriers is -40°F to +140°F (-40°C to +60°C). They should be

mounted in a clean, dry environment and be well ventilated, so

that the maximum temperature is not exceeded. If an enclosure

is used, it must be suitable for the location.

Earth Connection:Earth Connection:

Earth Connection: The bracket on which the barrier is mounted

Earth Connection:Earth Connection:

must be connected to an earth ground. Grounding should be

adequate for conduction of line-generated fault currents and

should have a resistance of less than one ohm. (See Figures 1

and 2.)

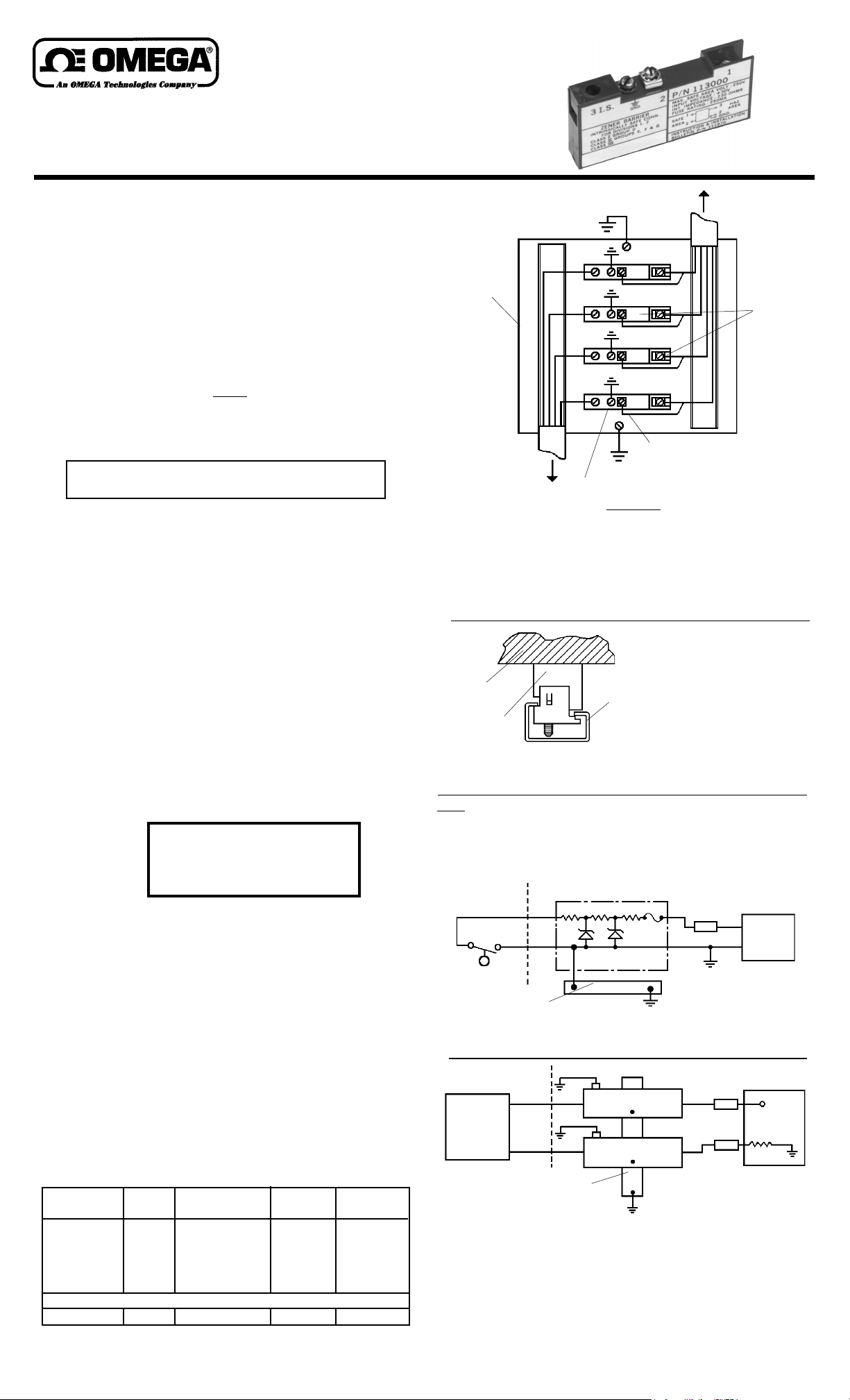

Non-Intrinsically

Safe Wiring

Earth Ground

Mounting

Panel

Resistance to ground must

Intrinsically

Safe Wiring

1. All barriers used for multiple barrier mounting must be of the

same polarity.

2. All intrinsically safe wiring must be segregated from

non-intrinsically safe wiring and shall have a minimum

insulation thickness of 0.010".

Zener

Barrier

Mounting

Clip

Protective Cover

ImportantImportant

Important

ImportantImportant

Fig. 1. Multiple Barrier MountingFig. 1. Multiple Barrier Mounting

Fig. 1. Multiple Barrier Mounting

Fig. 1. Multiple Barrier MountingFig. 1. Multiple Barrier Mounting

be less than one ohm.

**

Rail

*

**

**

*

6" Mounting Rail:

**

SBG-RAIL-6

12" Mounting Rail:

SBG-RAIL-12

18" Mounting Rail:

SBG-RAIL-18

Zener

Barriers

Safe Area Apparatus:Safe Area Apparatus:

Safe Area Apparatus: Safe area apparatus must not generate

Safe Area Apparatus:Safe Area Apparatus:

or be connected to sources having voltages greater than

250Vrms or VDC.

Product must be maintained and installed

in strict accordance with the National Electrical Code. Failure to observe this warning

could result in serious injuries or damages.

INSTALLATIONINSTALLATION

INSTALLATION

INSTALLATIONINSTALLATION

It is expected that the installation will be in accordance with ISA RP-

12.6, NEC Chapters 5 and 7 and FM Standards

Approval. The following specific points should be kept in mind:

WARNING

• Check that the barrier is of specified type and polarity.

• For multiple barrier installation, the barrier's safe area sides

should face one side of the enclosure and the intrinsically safe

sides should face the opposite side (see Fig. 1). Wiring must be

channeled and segregated as shown, so that no mis-wiring can occur

during servicing, testing or when replaced.

• Connect hazardous area equipment to terminals marked "3" and "2"

(Fig. 3). Common, commercially available signal wire may be used

provided its capacitance and inductance are below the following

maximum values:

- TABLE 1 -- TABLE 1 -

- TABLE 1 -

- TABLE 1 -- TABLE 1 -

ModelModel

Model

ModelModel

NumberNumber

Number

NumberNumber

SBG111950SBG111950

SBG111950

SBG111950SBG111950

SBG111954SBG111954

SBG111954

SBG111954SBG111954

SBG111956SBG111956

SBG111956

SBG111956SBG111956

SBG113000SBG113000

SBG113000

SBG113000SBG113000

SBG114166SBG114166

SBG114166

SBG114166SBG114166

RatedRated

Rated

RatedRated

VoltageVoltage

Voltage

VoltageVoltage

+15

+24

+30

+30

Signal Return Barriers

+30

GroupGroup

Group

GroupGroup

A, B, C, D, E, G

A, B, C, D, E, G

A, B, C, D, E, G

C, D, E, G

A, B, C, D, E, G

Parallel

Capac - uF

0.32

0.12

0.07

0.20

0.07

Series

Induct - mH

2.0

3.0

1.8

3.0

0.35

• Safety depends on earth continuity. The resistance to earth

ground must be less than 1 ohm.

Fig. 2. Optional Mounting ClipFig. 2. Optional Mounting Clip

Fig. 2. Optional Mounting Clip

Fig. 2. Optional Mounting ClipFig. 2. Optional Mounting Clip

(SBG113530)(SBG113530)

(SBG113530)

(SBG113530)(SBG113530)

NoteNote

: :

Note

: Positive signal channel shown. Sensor switch may be any

NoteNote

: :

non-voltage producing, essentially resistive device; containing no

energy storing components. Flow and level switches, temperature

switches, pressure switches or resistive transducers or transmitters

are typical devices.

Hazardous

Area

Sensor

Earth Ground

Bus Bar

Hazardous Area

Resistive

Transducer

****

**Littelfuse type 3AG or equal (optional). External fuses are

****

recommended to protect barrier from incorrect wiring or

equipment faults at start-up.

Note: Note:

Note: Redundant grounding required by CSA.

Note: Note:

Supply and Signal Return Barrier Type InstallationSupply and Signal Return Barrier Type Installation

Supply and Signal Return Barrier Type Installation

Supply and Signal Return Barrier Type InstallationSupply and Signal Return Barrier Type Installation

Safe Area

3

2

Fig. 3. Positive Signal Barrier InstallationFig. 3. Positive Signal Barrier Installation

Fig. 3. Positive Signal Barrier Installation

Fig. 3. Positive Signal Barrier InstallationFig. 3. Positive Signal Barrier Installation

(See Figure 2)

(4-20mA Transducer with Both Leads Floating

Zener Barrier12

Max. Line Voltage Input

Not To Exceed 250 Vrms.

GNDGND

GND

GNDGND

3

3

Rail

and Neg.Signal Common)

Supply

2

GNDGND

GND

GNDGND

Signal Return

(SBG114166)

2

Earth Ground

Fig. 4.Fig. 4.

Fig. 4.

Fig. 4.Fig. 4.

****

Fuse

**

****

(+)

Fuse

1

Fuse

1

4-20mA

(_)

****

**

****

****

**

****

Receiver

Input

Voltage

P.S.

Load

Earth

Ground

Page 2

INSPECTIONINSPECTION

INSPECTION

INSPECTIONINSPECTION

A routine inspection should be made at intervals of not more than

two years. Harsh locations should be inspected more frequently to:

1. Check integrity of earth grounding (Less than one ohm).

2. Check unit labeling for legibility.

3. Check all interconnections for good electrical connections.

CautionCaution

Caution

CautionCaution

Never conduct tests while circuit is active. Use of

instruments between input and output will bypass barrier.

TESTINGTESTING

TESTING

TESTINGTESTING

• All testing is to be done with circuit inactive and all but earth

grounding disconnected.

• With a suitable ohmmeter (resolution to 1 ohm), measure the

resistance between terminals 1 and 3. The total resistance readings shown in

Table 2 Table 2

Table 2 indicate a good unit.

Table 2 Table 2

ModelModel

Model

ModelModel

NumberNumber

Number

NumberNumber

SBG111950SBG111950

SBG111950

SBG111950SBG111950

SBG111954SBG111954

SBG111954

SBG111954SBG111954

SBG111956SBG111956

SBG111956

SBG111956SBG111956

SBG113000SBG113000

SBG113000

SBG113000SBG113000

SBG114166SBG114166

SBG114166

SBG114166SBG114166

RatedRated

Rated

RatedRated

VoltageVoltage

Voltage

VoltageVoltage

+15

+24

+30

+30

+30

- TABLE 2 -- TABLE 2 -

- TABLE 2 -

- TABLE 2 -- TABLE 2 -

**

TotalTotal

*

Total

TotalTotal

**

Resist.Resist.

Resist.

Resist.Resist.

OhmsOhms

Ohms

OhmsOhms

183

390

750

303

Signal Return Barriers

33.9

*All resistance values are ±5%

LimitLimit

Limit

LimitLimit

Resist.Resist.

Resist.

Resist.Resist.

OhmsOhms

Ohms

OhmsOhms

153

360

720

273

30

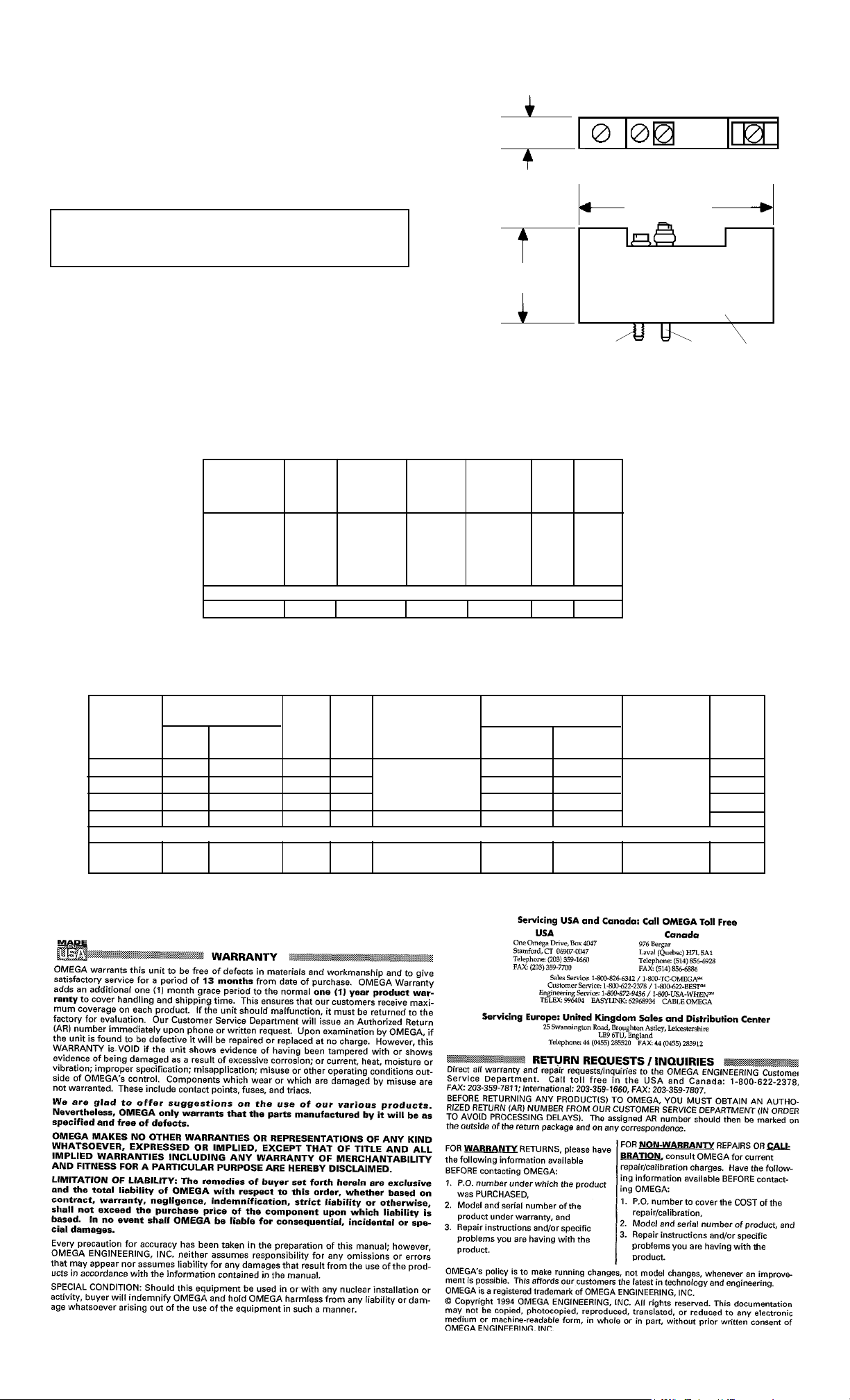

Red Polysulfone Housing

11

1

11

Output

Terminal

Cover

31/64"

(12.3mm)

1-7/16"

(36.5mm)

33

3

33

Mounting

Screw

22

2

22

3-3/16" (81mm)

Locating

Pin

Fig. 5. Dimensions

FuseFuse

**

Fuse

*

FuseFuse

**

Max.Max.

RatingRating

Rating

RatingRating

mAmA

mA

mAmA

250

62

62

250

250

Max.

Max.Max.

VocVoc

Voc

VocVoc

17.3

26.2

33.1

36.1

36.1

II

SCSC

I

SC

II

SCSC

mAmA

mA

mAmA

112.8

72.7

46.0

132.3

0

DC Input toDC Input to

DC Input to

DC Input toDC Input to

Barrier, Max.Barrier, Max.

Barrier, Max.

ModelModel

Model

ModelModel

NumberNumber

Number

NumberNumber

SBG111950SBG111950

SBG111950

SBG111950SBG111950

SBG111954SBG111954

SBG111954

SBG111954SBG111954

SBG111956SBG111956

SBG111956

SBG111956SBG111956

SBG113000SBG113000

SBG113000

SBG113000SBG113000

SBG114166SBG114166

SBG114166

SBG114166SBG114166

Housing material is polysulfone.

Barrier, Max.Barrier, Max.

VoltageVoltage

Voltage

VoltageVoltage

+15

+24

+30

+30

+30

Fuse Rating

Current, mA

250

62

62

250

250

Signal

Polarity

Positive

Positive

Positive

Positive

Positive

- TABLE 3 -- TABLE 3 -

- TABLE 3 -

- TABLE 3 -- TABLE 3 -

(Specifications)(Specifications)

(Specifications)

(Specifications)(Specifications)

ApplicationsApplications

Applications

ApplicationsApplications

SeriesSeries

Series

SeriesSeries

Resist.Resist.

Resist.

Resist.Resist.

ΩΩ

Ω

ΩΩ

183

390

750

303

33.9

Class I & II,Class I & II,

Class I & II,

Class I & II,Class I & II,

Groups A, B, C,

D, E, F, G

Groups C, D, E, F, G

Signal Return Barrier

Groups A, B, C,

D, E, F, G

GroupsGroups

Groups

GroupsGroups

Div 1, 2Div 1, 2

Div 1, 2

Div 1, 2Div 1, 2

Reactive LimitsReactive Limits

Reactive Limits

Reactive LimitsReactive Limits

Capacitance

µµ

µF

µµ

0.32

0.12

0.07

0.20

0.07

Inductance

mHmH

mH

mHmH

2.0

4.9

11.1

3.0

0.35

AmbientAmbient

Ambient

AmbientAmbient

OperatingOperating

Operating

OperatingOperating

TemperatureTemperature

Temperature

TemperatureTemperature

-40° to +140°F

(-40° to +60°C)

-40° to +140°F

(-40° to +60°C)

WeightWeight

Weight

WeightWeight

66g

66g

66g

66g

66g

P/N 158353

Rev. E

Loading...

Loading...