Page 1

SELECTION GUIDE FOR OMEGA®ZENER

FM

APPROVED

BARRIERS FOR INTRINSIC SAFETY

OMEGA®Solid State

Relays and Zener

Barriers for

Intrinsic Safety

The maximum energy

possible at the switch

terminals of the OMEGA

zener barriers is far below the

explosive point of the most

volatile surrounding gas

conditions. The type of

non-voltage-producing

switch or sensor best

fitted for the application

can be used, since

the entire switching

circuit is rendered

intrinsically safe by the

OMEGA®zener barrier.

Because the switching

circuit is low voltage, there

is no shock hazard to

operating or maintenance

personnel.

Installation

and Maintenance

OMEGA®zener barrier

units are normally

installed in a safe area

and connected to the

sensor in a hazardous location;

no explosion-proof or protective

housings are needed. Units install

singly in any position, or can be

grouped on a common earthgrounded plate with mounting tabs

to provide electrical grounding.

Between 6 and 32 threaded

electrical terminals are conveniently

placed atop the unit housings.

®

Single- and dualchannel zenner

barriers, shown

smaller than

actual size.

OMEGA®zener barriers must be installed in conformance with the National Electrical

Code and the Instruction, Installation and Service Bulletin supplied with all units.

Periodic checks of ground bonding and cleanliness of units and terminals constitute

the only maintenance required.

Approvals Hazardous Locations

Group

Model No. UL FM CSA Class Division ABCD EFG

SBG111950 XXX I,II 1,2 XXXX XXX

Single

Channel SBG111956 XXX I,II 1,2 XXXX XXX

Zener Barriers

Dual Channel

Zener Barriers

Note: Zener barrier model numbers SBG54803 and SBG54806 are certified by CSA for mounting inside a suitable enclosure in Div. 2 or

non-hazardous locations and must be connected by means of the 2 studs provided to a grounded copper busbar or equivalent.

SBG111954 XXX I,II 1,2 XXXX XXX

SBG113000 XXX I,II 1,2 XXXXX

SBG114166 XXX I,II 1,2 XXXX XXX

SBG54803 XXX I,II 1,2 XXXX

SBG54806 XXX I,II 1,2 X

K-105

Page 2

POWER

SUPPLY

ANNUNC.

POWER

SUPPLY

ANNUNC.

(+)

(–)

(+)

(–)

FUSE

FUSE

1

2

1

3

4

2

7

5

6

8

HAZARDOUS AREA SAFE AREA

HAZARDOUS AREA SAFE AREA

SENSOR

SIGNAL

CONDITIONER

ZENER BARRIER

EARTH GROUND

(2 PLACES)

ZENER

BARRIER UNITS

EARTH GROUNDED

MOUNTING PLATE

INTRINSICALLY

SAFE WIRING

RESISTANCE TO GND.

MUST BE LESS THAN

1 FROM

MOUNTING SCREW

OR BRACKET TO

EARTHING MEMBER

TO ENSURE INTEGRITY

NON-INTRINSICALLY

SAFE WIRING

INTRODUCTION TO SOLID STATE SINGLE-

FM

APPROVED

AND DUAL-CHANNEL ZENER BARRIERS

FOR INTRINSIC SAFETY

OMEGA®SingleChannel and DualChannel Zener

Barriers Feature

Intrinsic Safety

With Solid State

Reliability—And

These Additional

Advantages:

⻬ Installation

Economy

⻬ No Explosion-

Proof Enclosures of

any Kind Needed for

Sensor Wiring

⻬ Compact Size—

Streamlines Multiple

Installations

⻬ Encapsulated

Construction—

Impervious to Dust and

Moisture, Shock and

Vibration Resistant

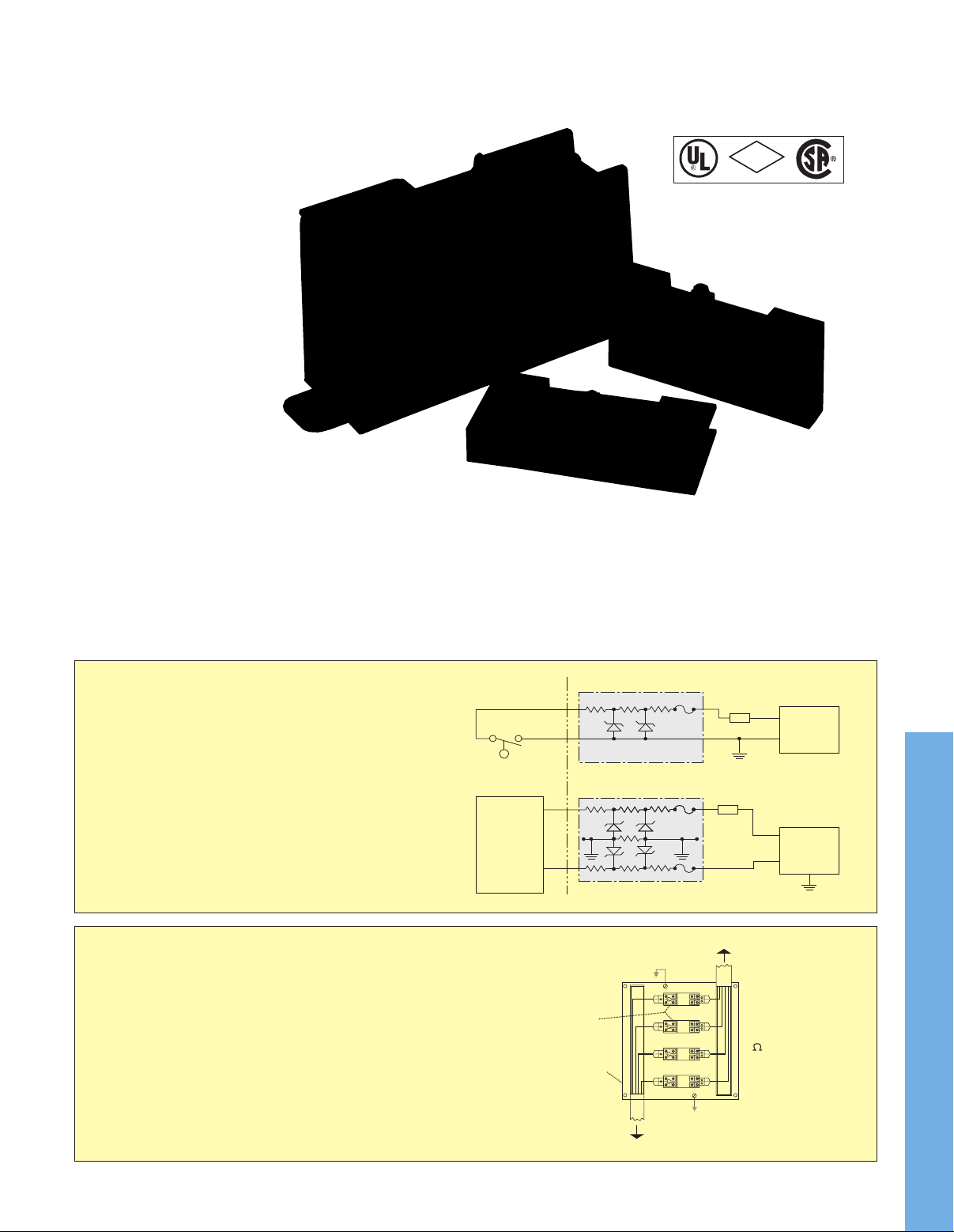

Single- and DualChannel Barriers

For most non-voltage-producing

devices located in a hazardous

area, a single zener barrier that is

negative-earth-grounded (see figure

1) can be used for intrinsic safety.

Instrumentation that produces an

output (signal conditioners) usually

SBG54803 dual-channel zener

barrier, $315, shown smaller

than actual size.

SBG111950 single-channel

zener barrier, $132, shown

smaller than actual size.

requires two barriers,

one for each “floating”

lead. Here, a dual-channel barrier can

be provided (see figure 2), or for

applications in which the instrument

signal return level cannot be

reduced, a supply barrier and a low

resistance return barrier can be

supplied (see diagram 2B on

page K-110).

Sensor switch may be any non-voltage-producing

device. Flow and level switches, temperature

switches (thermostats), pressure switches, or

passive, resistive transducers or transmitters are

typical.

Fig. 1 Positive single-channel zener barrier with

Fig. 2 Positive dual-channel zener barrier with

Note: Terminals 3, 4, 5, and 6 are common and

Installation and Maintenance

OMEGA®Zener barriers are installed in non-hazardous

(safe) locations, and may be grouped on a common,

earth-grounded mounting plate. Intrinsically safe sensor

wiring must be separated from non-intrinsically-safe input

wiring in separate conduits or raceways to prevent by-pass

during testing or servicing. Routine inspections every two

years or less to check integrity of earth-grounding and

electrical connections, and to make sure the unit is clean,

constitute the only maintenance normally required.

Installation and maintenance must be in accordance with the

National Electrical Code and the applicable OMEGA

operator’s manual.Ω

negative ground.

floating leads.

are bonded to the mounting tabs for positive

redundant grounding.

Figure 1

K

Figure 2

®

K-106

Page 3

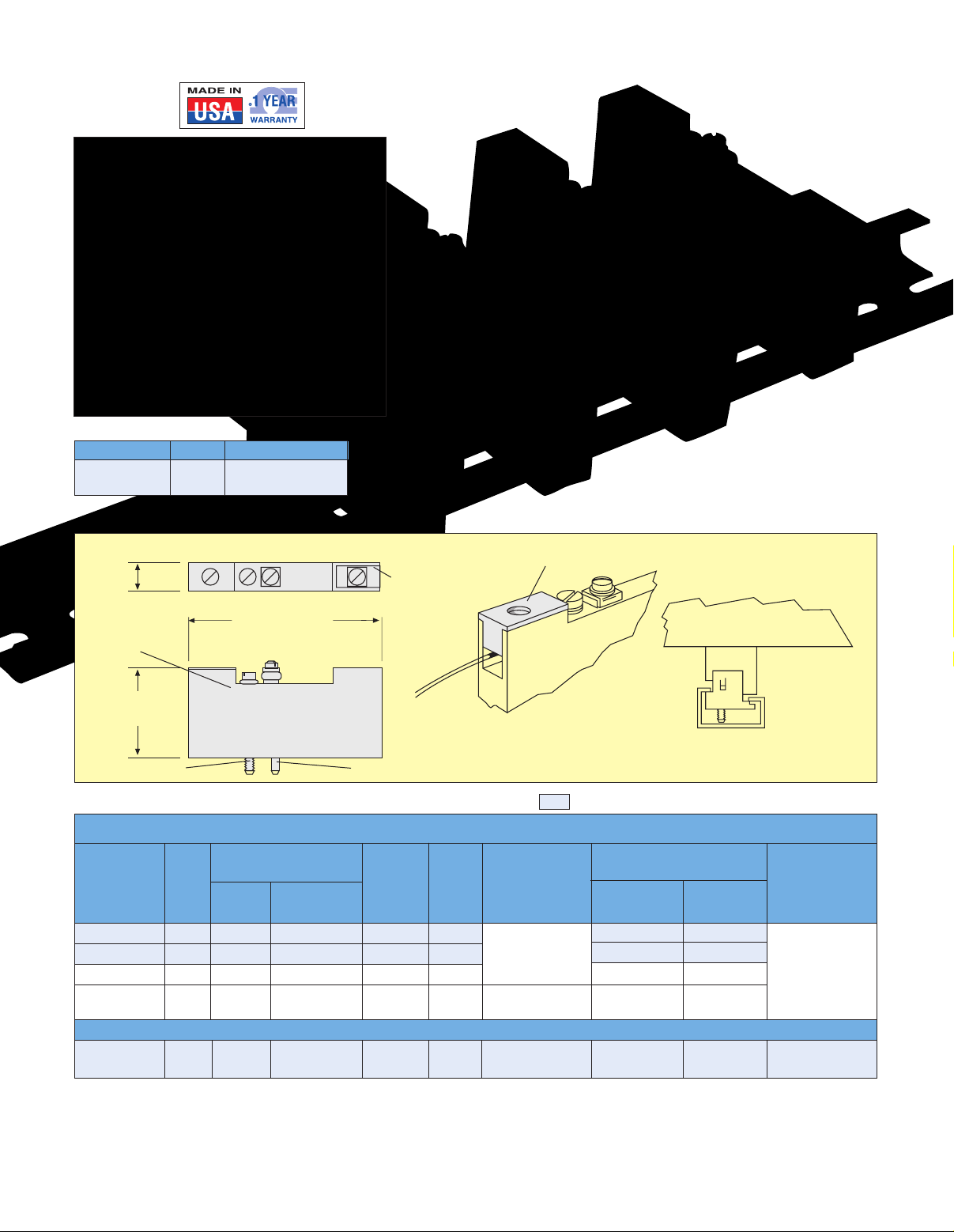

SINGLE-CHANNEL ZENER BARRIERS, DC

81 (3-3/16)

36.5

(1-7/16)

12.3

(31/64)

2

3

1

Mounting Accessories

Model No. Price Description

SBG113530 $20 TS32 style rail

mounting clip

SBG111950 single-channel

zener barrier, $132, shown

smaller than actual size.

Output

terminal cover

Mounting screw

Red polysulfone

housing

Locating Pin

Protective cover over the

output terminal (3).

SBG113530 optional rail

mounting clip, $20.

Single-channel zener barriers can

be supplied with a clip for rail

mounting. Clip attaches to barrier

with mounting screw supplied.

Dimensions: mm (in)

MOST POPULAR MODELS HIGHLIGHTED!

To Order (Specify Model Number)

DC Input to

Barrier, Max

Model No. Price Voltage Current, mA Polarity Ω Div. 1, 2 µF mH Temperature

SBG111950 $132 +15 250 Positive 183 0.32 2.0

SBG111954 132 +24 62 Positive 390

SBG111956 132 +30 62 Positive 750

SBG11300 132 +30 250 Positive 303

SBG114166 132 +30 250 Positive 33.9

The exceptionally compact, almost "wafer-thin" design single-channel zener barriers save space and simplify installation, especially in multiples

on a common mounting plate. Single-screw mounting is standard; units can be supplied with an optional clip for rail mounting. The single

through-mounting screw also provides an electrical connection to ground through the earth-grounded mounting surface.

Ordering Example: SBG111954, zener barrier, 24 V, 62 mA and SBG113530, rail mounting clip, $132 + 20 = $152.

Note: Order rail mounting clip separately.

Fuse Rating Signal Resist. Class I & II, Capacitance Inductance Operating

Series

Signal Return Barrier

Applications

Groups

Groups A, B, C,

D, E, F, G

Groups C, D,

E, F, G

Groups A, B, C, -40 to 60°C

D, E, F, G

Reactive Limits

0.12 3.0 -40 to 60°C

0.07 1.8 (-40 to 140°F)

0.20 3.0

0.07 0.35

(-40 to 140°F)

K-107

Ambient

Page 4

DUAL-CHANNEL ZENER BARRIERS, DC

8 7 6

5

4 7 2

1

152.4 (6)

139.7 (5-1/2)

OUTPU T TERMINALS

NO. 6-32 TH D

MOUNTING TA B

5.6 (7/22) DIA.

3 MTG HOLES

INPU T TERMINALS

NO.6-32 THD.

120.6 (4-3/4)

69.8 (2-3/4)

HOUSIN G R AIL MOUNTING

OPTIONA L

41.3

(1-5/8)

OUTPU T

TERMINA L

COVER

SBG61783, $20,

shown smaller

than actual size.

Mounting Accessories

Model No. Price Description

SBG61783 $20 Rail mounting clips

for dual-channel

zener barriers

SBG54803, $315,

shown smaller

than actual size.

Typical applications for dual-channel zener barriers include solenoids, switches or 4 to 20 mA DC transmitters. When applicable, using a

dual-channel barrier can save money in installation over 2 single-channel barriers.

Ordering Example: SBG54803, 20 V, 100 mA zener barrier, and SBG61783, mounting clips, $315 + 20 = $335.

Note: Order rail mounting clips SBG61783 separately.

Dimensions: mm (in)

Dual-channel zener

barriers can be

mounted with a clip

for rail mounting.

Standard tabs on

barrier allow

surface mounting.

A protective cover

ensures intrinsic

safety integrity of

sensor terminals

and wiring.

To Order (Specify Model Number)

DC Input to

Barrier, Max

Fuse Rating Signal Resist. Class I & II, Capacitance Inductance Operating

Note 1: Dual-channel zener barriers are internally fused.

Note 2: Housing material is blue Lexan

Note 3: For typical wiring diagrams,

Applications

Series Groups

If a "fault" or abnormal signal level continues for

a sustained period, the internal fusing within the

barrier will open, disconnecting the barrier.

External fuses (Littlefuse Type 3AG or equal) are

recommended to protect the barrier from

incorrect wiring at start-up, or from other

equipment fault.

see pages K-109 and K-110.

®

.

MOST POPULAR MODEL HIGHLIGHTED!

Reactive Limits

Ambient

Model No. Price Voltage Current, mA Polarity Ω Div. 1, 2 µF mH Temp.

SBG54803 $315 20 100 Positive 270 Groups A, B, C, D -3.2 -10 -40 to 60°C

SBG54806 315 30 60 Positive 270 Group D 2.4 6.0 (-40 to 140°F)

K-108

K

Page 5

32 1

NON-HAZARDOUS

AREA

HAZARDOUS

AREA

OPTO

COUPLER

32 1

+5 VDC

SUPPLY

RETURN

RETURN

OPTO

COUPLER

MICROPROCESSOR

ZENER

BARRIERS

32 1

876

5

432

1

TERM. EQUIP.

(BY CUST.)

V+

COM.

R

L

AC

INPUT

SOURCE**

ZENER BARRIER

** INPUT POWER FROM

SOURCE NOT GREATER

THAN 250 VAC

STUD COVER MUST BE IN PLACE

WHEN BARRIER IS IN USE.

SENSOR

SWITCH

HAZARDOUS

LOCATION

NON-H AZARDOU S AREA

32 1

NON-HAZARDOUS

AREA

HAZARDOUS

AREA

SENSOR,

SINGLE

STATION

SWITCH

DC POWER

SUPPLY

ANNUNC.

(–)

(+)

FUSE*

SUPPLY

BARRIER

32 1

NON-HAZARDOUS

AREA

HAZARDOUS

AREA

FLOW

SWITCH

NO

FLOW

32 1

SUPPLY

BARRIER

COM.

FLOW

(+)

DUAL CHANNEL ZENER BARRIERS, DC

Choosing a suitable barrier for a particular

application involves a number of

considerations

1. Select a barrier that has the Agency

Approvals and Hazardous Location

Ratings required (see page K-109).

2. Choose the barrier by the Loop or Entity

concept, whichever applies. If the

associated equipment has been approved

under the loop concept, then the specified

barrier must be used. If the associated

equipment is approved under the entity

concept, then the barrier can be chosen

using the entity parameters. The entire

loop or system should be evaluated

including possible failures or miswiring

causing shorts or open loops.

Intrinsic Safety barriers are chosen based

on the following parameters as defined by

Testing Agencies

1. Maximum Open Circuit Voltage

2. Maximum Short–Circuit Current

3. End to End Resistance–this is the total

resistance of the barrier. The entire circuit

loop resistance should be evaluated, to

make sure the loop will still function with

the barrier installed.

4. Maximum allowed external series inductance

5. Maximum allowance capacitance.

Typical Intrinsic Safety Barrier Wiring Diagrams

I. Switches

1A

A Dual Channel zener barrier in a circuit where the load is

activated from a switch in the hazardous area.

1C

Two Single Channel zener barriers used with an OMEGA®flow

switch located in a hazardous area for flow/no flow indication.

APPLICATION DATA

1B

A Single Channel zener barrier used with an OMEGA®level

switch or any other non-voltage producing device located in a

hazardous area.

1D

Three zener barriers for an optically coupled microprocessor.

One Single Channel supply barrier with two return barriers for

the SPDT switch.

K-109

Page 6

II. Two-wire, 4-20 mA Transmitters

32 1

NON-HAZARDOUS

AREA

HAZARDOUS

AREA

TRANSDUCER

OR

CONVERTER

DC POWER

SUPPLY

(–)

(+)

FUSE*

32 1

LOAD

SIGNAL

RETURN

BARRIER

SUPPLY

BARRIER

876

5

432

1

TERM. EQUIP.

(BY CUST)

V+

COM.

R

L

AC

INPUT

SOURCE**

ZENER BARRIER

SAFE-PAK

(POSITIVE TYPE)

** INPUT POWER FROM

SOURCE NOT GREATER

THAN 250 VAC

STUD COVER MUST BE IN PLACE

WHEN BARRIER IS IN USE.

PROCESS

CONTROL

TRANSMITTER

HAZ ARDOUS A REA NON- HAZARDO US ARE A

32 1

NON-HAZARDOUS

AREA

HAZARDOUS

AREA

INTRINSICALLY

SAFE SOLENOID

OR OTHER LOAD

DC POWER

SUPPLY

(–)

(+)

FUSE*

5

4

321

DC

POWER

SUPPLY

INTRINSICALLY

SAFE SOLENOID

OR OTHER LOAD

HAZARDOUS

LOCATION

NO N-HAZ ARDOU S AR EA

68

7

DC

POWER

SUPPLY

(–)

(+)

FUSE*

2A 2B

A Dual Channel zener barrier in a current loop used with an

approved intrinsically safe transmitter in a process control

system.

III. Intrinsically-Safe Solenoids

3A

A Dual Channel zener barrier used for supply & return voltage

leads. This circuit is used whenever a floating power system

must be maintained. For optimum power transfer, the total

resistance of the barrier must be matched to the resistance of

the solenoid.

HAZARDOUS AREA

NON-HAZARDOUS AREA

Two Single Channel zener barriers for a floating system in a

current loop with an approved intrinsically safe transducer.

The signal return barrier is used to minimize the total

resistance in the loop.

3B

A Single Channel zener barrier used where the load in a

hazardous area can function with a negative signal that is

earth-grounded.

INTRINSICALLY SAFE

APPARATUS

Maximum Open Circuit Voltage Vmax ≥ Maximum Open Circuit Voltage Voc

Maximum Short Circuit Current Imax ≥ Maximum Short Circuit Current Isc

Maximum Unprotected Capacitance Ci ≤ Maximum Allowed Capacitance Ca

Maximum Unprotected Inductance Li ≤ Maximum Allowed Inductance La

Ci and Li Must Also Take Into Account The Interconnecting Wiring

Inductance Lw And The Interconnecting Wiring Capacitance Cw.

INTRINSIC SAFETY

BARRIER

K-110

Warning

Product must be maintained and

installed in strict accordance with

the National Electrical Code and

the applicable OMEGA

operator’s manual. Failure to

observe this warning could result

in serious injuries or damages.

®

K

Page 7

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...