Page 1

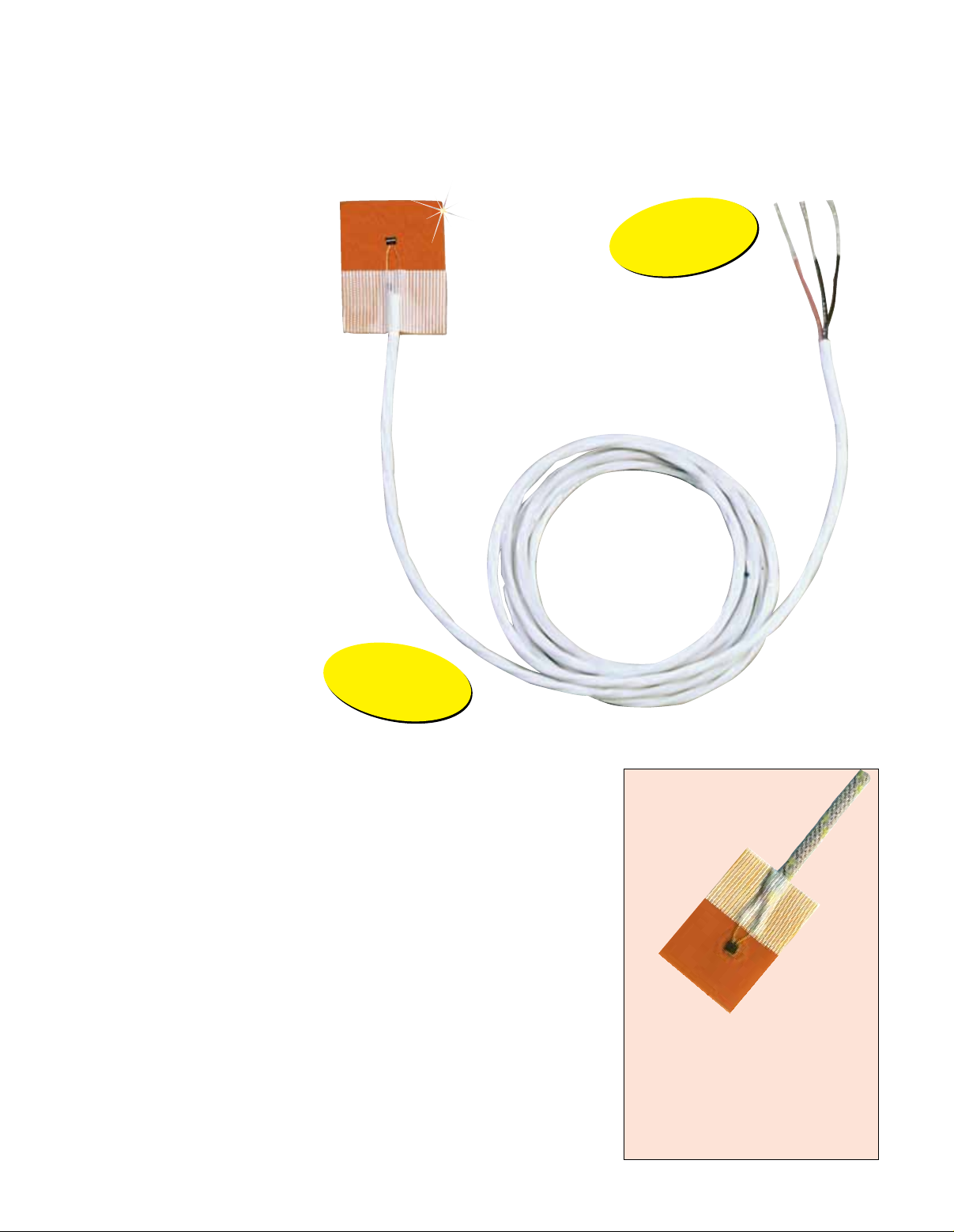

Advanced-Design Surface-Mount RTD

Provides Class A Accuracy

“Stick-On” or “Cement-On” to Target Device

260°C (500°F) Continuous Operation Self-Adhesive or Cement-On! Use on Flat or Curved Surfaces

SA1-RTD

U 100 Ω DIN Class A

(±0.06 Ω or ±0.15°C at 0°C)

Accuracy Standard

U Easy-Installation

Silicone-Based,

Self-Adhesive Backing

Rated to 260°C (500°F)

U Sensor Can be Reapplied

U 290°C (554°F) Short-

Term Operation When

Used as a “Cement-On”

(OMEGABOND

Set Cements)

U Stripped 3- or

4-Wire Leads Standard

(Connectors Optional)

U Stocked in 1 m

(40") Lengths; Also

Available in 2 and 3 m

(80 and 120") and Custom

Length Lead Wires

U Other Resistances/

Accuracies Available

on Request

The SA1-RTD surface-mount RTD

temperature sensor mounts on flat

or curved surfaces and provides

Class A accuracy for critical

temperature monitoring applications.

Based on a 2 x 2 x 0.8 mm thin-film

platinum RTD and supplied in

PFA-insulated 3- or 4-wire

configurations (connectors optional),

it can be customized for use in

a wide variety of applications.

The sensor can be easily applied

using its self-adhesive backing,

or permanently mounted using

OMEGABOND® cements.

Use the SA1-RTD to monitor chip,

heat sink, and environmental

temperatures in electronic devices;

check piping or ducting temperatures;

monitor motor and transformer core

®

Air

Class A accuracy

of ±0.06Ω at 0°C.

Thin film element

is 2 x 2 x 0.8 mm

in a 25 x 19 mm

self-adhesive carrier.

Quick Delivery

on Custom Lead

Wire Lengths

heat; test insulation capabilities; and

check other applications in which

surface and/or gradient temperatures

need to be monitored or controlled.

Specifications

Minimum/Maximum Temperature:

-73°C to 260°C (-100°F to 500°F)

continuous, 290°C (554°F) short-term

(when cemented in place)

Sensing Element: 100 Ω at 0°C (32°F),

temp coefficient of 0.00385 Ω/Ω/°C

(IEC60751)

Accuracy:

±0.06Ω at 0°C (DIN Class A)

Stability: Less than 0.2°C drift/year

Response Time: Less than 0.9 s (63%

response time in water immersion), less

than 2 s response time on a hot plate

Self-Heating Effect: 2.5 mW/°C

Lead Wire: 1 m (40"), 26 AWG stranded

nickel-plated copper, PFA-insulated and

jacketed cable

Extra Accuracy

for Critical

Measurements!

1 m (40"), 26 AWG

stranded nickelplated copper,

PFA-insulated and

jacketed cable.

SA1-RTD shown

actual size.

Available with

Stainless Steel

Overbraid!

For applications where electrical noise

is prevalent, or where the sensor

lead wires may be routed around

sharp objects, consider the stainless

steel overbraid option. To specify this

option, add “-SB” to the end of the

model number for an additional cost

per meter (foot). Ordering example:

SA1-RTD-80-SB.

C-107

Page 2

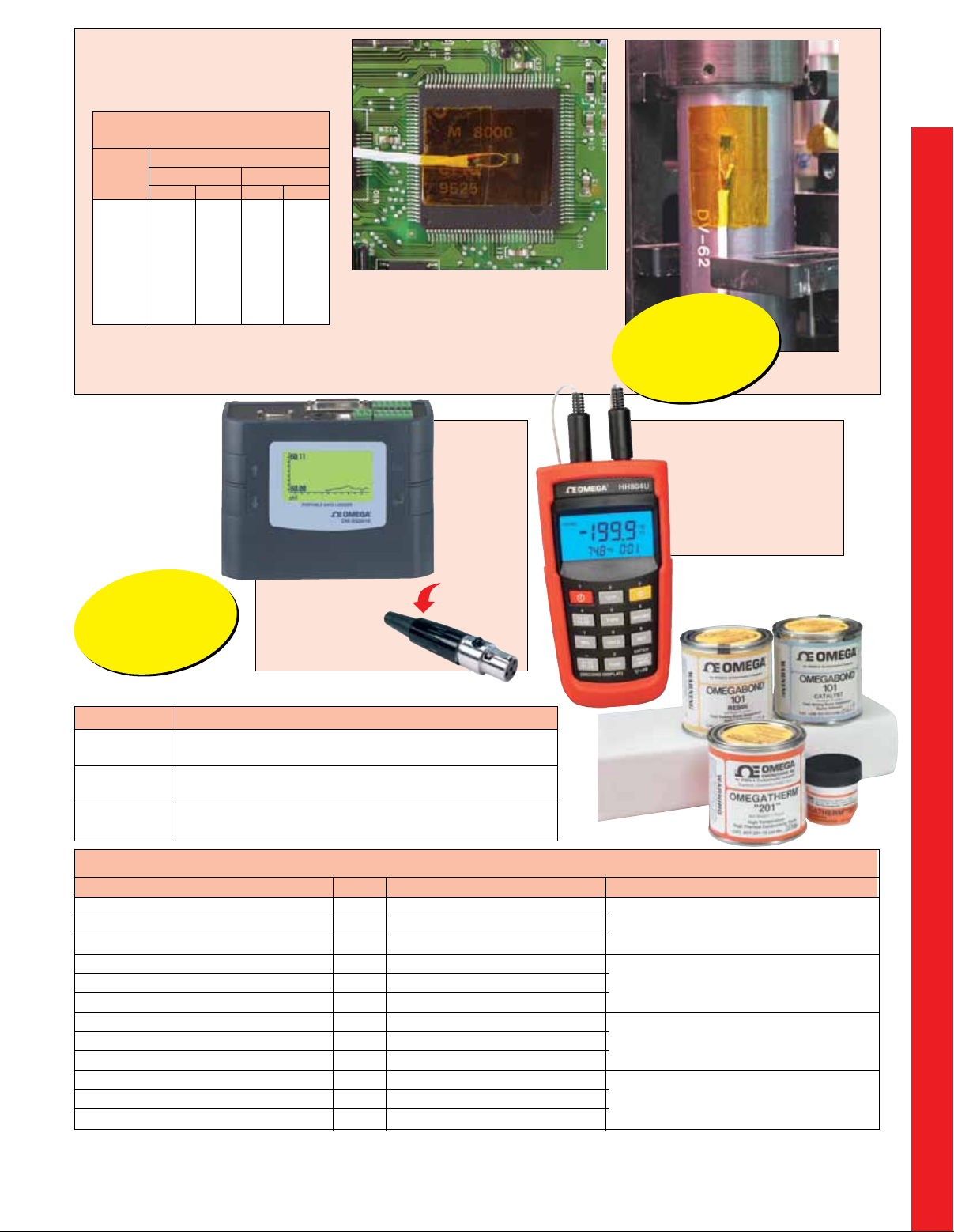

The Self-Adhesive Backing

is Ideal for Targeted

Class A Sensor Elements on

Curved and Flat Surfaces.

IEC 751 Class A/B

Standard Tolerances

Tolerance

Temp. Class A Class B

in °C ±°C ±Ω ±°C ±Ω

-200 0.55 0.24 1.3 0.56

-100 0.35 0.14 0.8 0.32

0.0 0.15 0.06 0.3 0.12

100 0.35 0.13 0.8 0.30

200 0.55 0.20 1.3 0.48

300 0.75 0.27 1.8 0.64

400 0.95 0.33 2.3 0.79

500 1.15 0.38 2.8 0.93

600 1.35 0.43 3.3 1.06

The IEC-751/BS EN60751 1996 standard

tolerances for Pt 100 Ω RTD elements.

Class A devices have an accuracy of

±0.35° at 100°C.

All products

shown smaller

than actual size.

OM-SQ2010 data

Make Your Sensor

Into a Complete

Measurement

System!

logger shown

smaller than

actual size, visit

omega.com/

om-sq2010

The self-adhesive sensor is ideal for

“targeted” placement on curved or flat

surfaces. Once in place, it can be used

“as is” for measuring temperatures in

applications such as machine tools,

electronic products, structures or other

places where temperatures need to be

monitored and controlled.

TA4F

connector

included

with meter.

Thin-Film RTDs Ensure

Trouble-Free Connection

to Flat or Curved Surfaces.

Perfect for High-Vibration

Environments!

HH804U

handheld, shown

smaller than actual

size, visit omega.com/

hh804_805

OMEGABOND®,

Visit omega.com

C

OMEGABOND

®

for Permanent Mounting Options

Model No. Description

OB -100-16 OMEGABOND® 100: 1 lb kit, fast-setting, 2-part

epoxy (sets in 8 to 12 min); 130°C (265°F) max

OB -200-16 OMEGABOND® 200: 1 lb kit, high temperature,

2-part epoxy; 260°C (500°F) max

OB-700 OMEGABOND® 700: powder, 8 fluid oz (one part

cement; just mix with water); 871°C (1600°F)

To Order Visit omega.com/sa1-rtd for Pricing and Details

Model Number Style

SA1-RTD 3-wire 1 (40)

SA1-RTD-80 3-wire 2 (80)

SA1-RTD-120 3-wire 3 (120)

SA1-RTD-MTP 3-wire 1 (40)

SA1-RTD-80-MTP

2 (80)

3-wire

SA1-RTD-120-MTP 3-wire 3 (120)

SA1-RTD-4W 4-wire 1 (40)

SA1-RTD-4W-80 4-wire 2 (80)

SA1-RTD-4W-120 4-wire 3 (120)

SA1-RTD-4W-TA4F 4-wire 1 (40)

SA1-RTD-4W-80-TA4F 4-wire 2 (80)

SA1-RTD-4W-120-TA4F

Ordering Examples: SA1-RTD-80-MTP, Class A, surface-mount RTD sensor, 3-wire leads, 2 m (80") lead-wire length with a miniature 3-pin

MTP connector. SA1-RTD-4W-80-TA4F, Class A, surface-mount RTD sensor, 4 wire leads, 2 m (80") lead-wire length with a 4-pin

audio-style connector. For special lengths, add additional cost. For the “-SB” option, add additional cost.

4-wire 3 (120)

Length: m (inch)

Cold End Termination

Stripped leads, 11⁄2

singles

1

⁄2

" bare), 3 wires

" (1" insulated,

“MTP” style miniature flat 3-pin

connector

Stripped leads, 11⁄2" (1" insulated,

singles 1 ⁄2" bare), 4 wires

TA4F Connector; Pins 1 and 2,

common 3 and 4 common

C-108

Loading...

Loading...