Page 1

Users Guide

http://www.dasieee.com

e-mail: das@omega.com

RTU Series

Radio Telemetry Systems

Page 2

OMEGAnet® On-Line Service Internet e-mail

http://www.omega.com info@omega.com

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGASM

Customer Service: 1-800-622-2378 / 1-800-622-BESTSM

Engineering Service: 1-800-872-9436 / 1-800-USA-WHENSM

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico and

Latin America: Tel: (95) 800-826-6342 FAX: (95) 203-359-7807

En Espanol: (95) 203-359-7803 e-mail: espanol@omega.com

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: ul. Rude armady 1868, 733 01 Karvina-Hranice

Tel: 420 (69) 6311899 FAX: 420 (69) 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5EX, England

Tel: 44 (161) 777-6611 FAX: 44 (161) 777-6622

Toll Free in the United Kingdom: 0800-488-488

e-mail: info@omega.co.uk

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly

pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every

appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship

for a period of 13 months from date of purchase. OMEGA Warranty adds an additional one (1)

month grace period to the normal one (1) year product warranty to cover handling and shipping

time. This ensures that OMEGAs customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGAs Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGAs WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence

of having been tampered with or shows evidence of having been damaged as a result of excessive

corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or

other operating conditions outside of OMEGAs control. Components which wear are not warranted,

including but not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither

assumes responsibility for any omissions or errors nor assumes liability for any damages that result

from the use of its products in accordance with information provided by OMEGA, either verbal or

written. OMEGA warrants only that the parts manufactured by it will be as specified and free of

defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND

WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED

WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies

of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this

order, whether based on contract, warranty, negligence, indemnification, strict liability or otherwise,

shall not exceed the purchase price of the component upon which liability is based. In no event shall

OMEGA be liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a

Basic Component under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or

(2) in medical applications or used on humans. Should any Product(s) be used in or with any nuclear

installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes

no responsibility as set forth in our basic WARRANTY / DISCLAIMER language, and, additionally,

purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever

arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN

AUTHORIZED RETURN (AR) NUMBER FROM OMEGAS CUSTOMER SERVICE DEPARTMENT

(IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked

on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

FOR WARRANTY RETURNS,

please have the following information available

BEFORE contacting OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the

product under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering. OMEGA is a registered trademark of OMEGA

ENGINEERING, INC.

© 2002 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced,

translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written

consent of OMEGA ENGINEERING, INC.

FOR NON-W ARRANTY REPAIRS, consult

OMEGA for current repair charges. Have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number to cover the

COST of the repair,

2. Model and serial number of the product,

and

3. Repair instructions and/or specific

problems relative to the product.

Page 4

Installation/Operation/Software/Programming Manual DATAFLOW RTU

OWNER INFORMATION

FCC REGULATIONS

LICENSING

The FCC requires you to obtain a station license for your DATAFLOW RT U system before using it, but does not require an

operation license or permit.

The station licensee is responsible for ensuring that the transmitter power, frequency and deviation are within the limits

specified by the station license. The licensee is also responsible for the proper operation and maintenance of the radio

equipment. This includes checking the transmitter frequency and deviation periodically, using appropriate methods.

You will need to obtain a FCC license to operate the DATAFLOW RT U. To get a FCC license for VHF or UHF frequencies,

submit FCC application Form 600.

SAFETY STANDARDS

The FCC (with its action in General Docket 79-144, March 13, 1985), has adopted a safety standard for human exposure to

radio frequency electromagnetic energy emitted by FCC regulated equipment. OMEGA observes these guidelines, and

recommends that you do also:

• DO NOT hold the DATAFLOW RTU so the antenna is very close to or touching exposed parts of the body,

especially the face or eyes, while transmitting.

• DO NOT operate radio equipment near electrical blasting caps or in an explosive atmosphere.

• DO NOT allow children to play with any radio equipment that contains a transmitting device.

REPAIR of OMEGA products should be performed only by OMEGA authorized personnel.

( iii )

Page 5

Installation/Operation/Software/Programming Manual DATAFLOW RTU

CAUTIONS

1. ALL DIGITAL INPUTS, ANALOG INPUTS, ANALOG OUTPUTS, AND

MEASUREMENTS OF THE DATAFLOW RTU ARE REFERENCED TO

GROUND. DO NOT USE THE DATAFLOW RTU WITH EQUIPMENT

THAT REQUIRES COMPLETE ISOLATION.

2. ALL DATAFLOW RTU DIGITAL OUTPUTS ARE ISOLATED LATCHING

RELAYS. DO NOT EXCEED CONTACT RATINGS OF THESE RELAYS.

3. EXCITATION VOLTAGE AND LOAD DRIVE VARY FROM MANUFACTURER

TO MANUFACTURER. CONSULT MANUFACTURER DOCUMENTATION

BEFORE CONNECTING THE SENSORS OR INDICATORS TO THE

DATAFLOW RTU.

4. THE DATAFLOW RTU CASE IS CONNECTED TO GROUND.

5. ALL DATAFLOW RTU SYSTEMS REQUIRE AN FCC LICENSE

6. THE FREQUENCY DEVIATION IS CONTROLLED BY VARIABLE

RESISTOR R131. THIS DEVIATION ADJUSTMENT SHOULD ONLY BE

PERFORMED BY AUTHORIZED OMEGA PERSONNEL USING THE

APPROPRIATE METHODS AND TEST EQUIPMENT.

7. · DO NOT SHORT THE RED WIRE (PIN 6) OF CONNECTOR J105 TO

GROUND.

· DO NOT SHORT THE RED WIRE (PIN 5) OF CONNECTOR J101 TO

GROUND.

· IF AN INTERNAL BATTERY IS INSTALLED DO NOT SHORT THE

ORANGE WIRE (PIN 7) OF CONNECTOR J105 TO GROUND.

PERFORMING ANY OF THESE ACTIONS WILL DESTROY THE FUSE

(F101)LOCATED ON THE DATAFLOW RTU CONTROL BOARD.

8. DO NOT OPERATE THE DATAFLOW RTU WITHOUT AN ANTENNA OR

SUITABLE LOAD. TO DO SO MAY DAMAGE THE TRANSMITTER.

( iv )

Page 6

Installation/Operation DATAFLOW RTU

Installation/ Operation Table of Contents

SECTION TITLE PAGE NO.

1 Introduction A-1

2 Operation A-1

3 Microprocessor Updates A-1

4 Part Number Definition A-2

5 Accessories A-2

6 Specifications A-3

7 Control Board Schematic A-5

8 Control Board Layout A-6

9 RF Board Schematic A-9

10 RF Board Layout A-9

11 Interconnects A-9

12 Hardware Configuration A-11

13 Software Configuration A-12

14 Mounting Information A-12

15 Power A-14

16 Serial Link A-15

17 I/O Mapping A-15

18 Digital Inputs A-15

19 Digital Outputs A-16

20 Analog Inputs A-16

21 Analog Outputs A-17

22 Antennas A-19

23 Alignment A-19

24 Theory of Operation A-19

25 Voltage Charts A-21

Installation/ Operation Table of Figures

TITLE PAGE NO.

Figure A1 - Control Board Schematic A-5

Figure A2 - Control Board Top Side Parts Placement

with Reference Designators A-6

Figure A3 - Circular Connector Pin Designations A-9

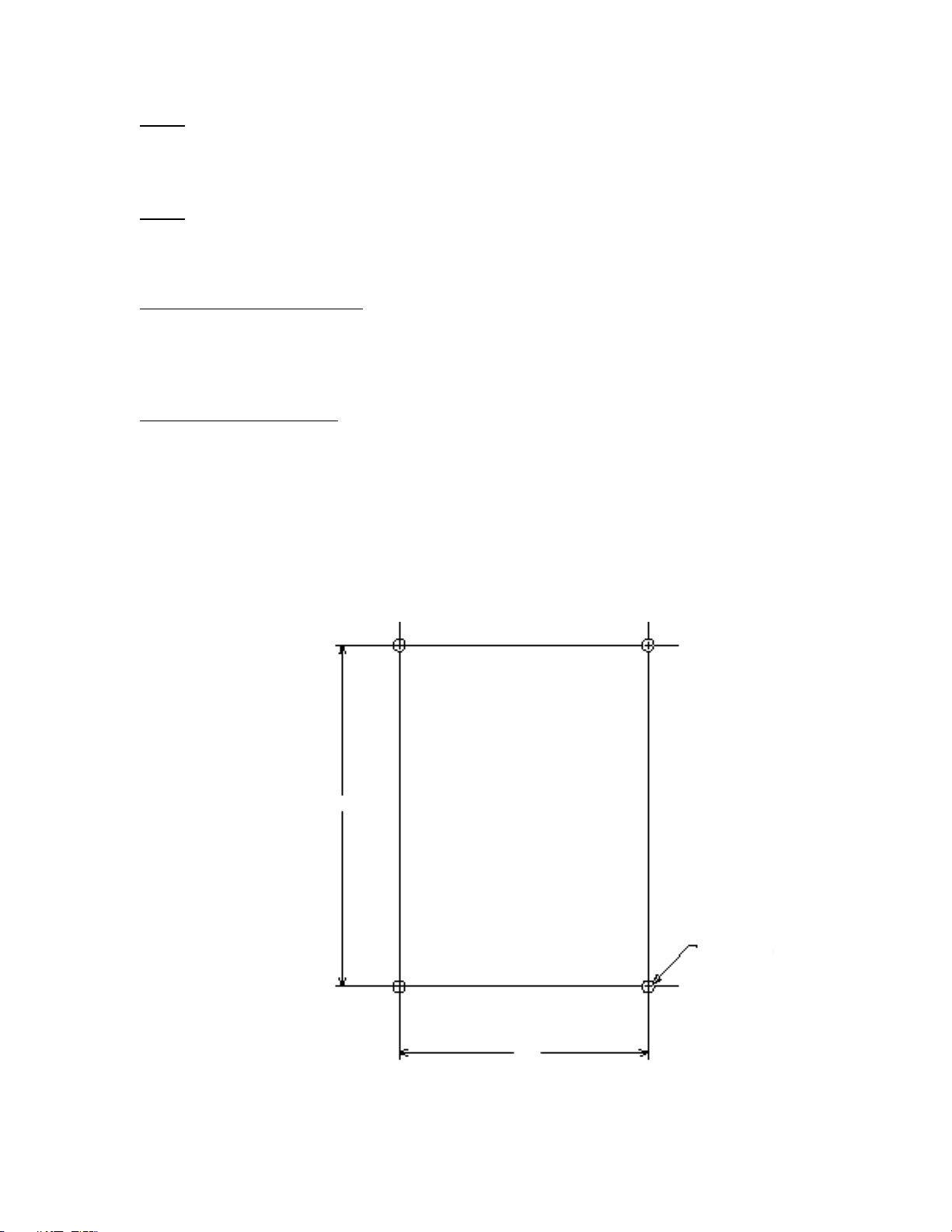

Figure A4 - Mounting Hole Pattern for Fastening

Directly to the DATAFLOW RTU Case A-12

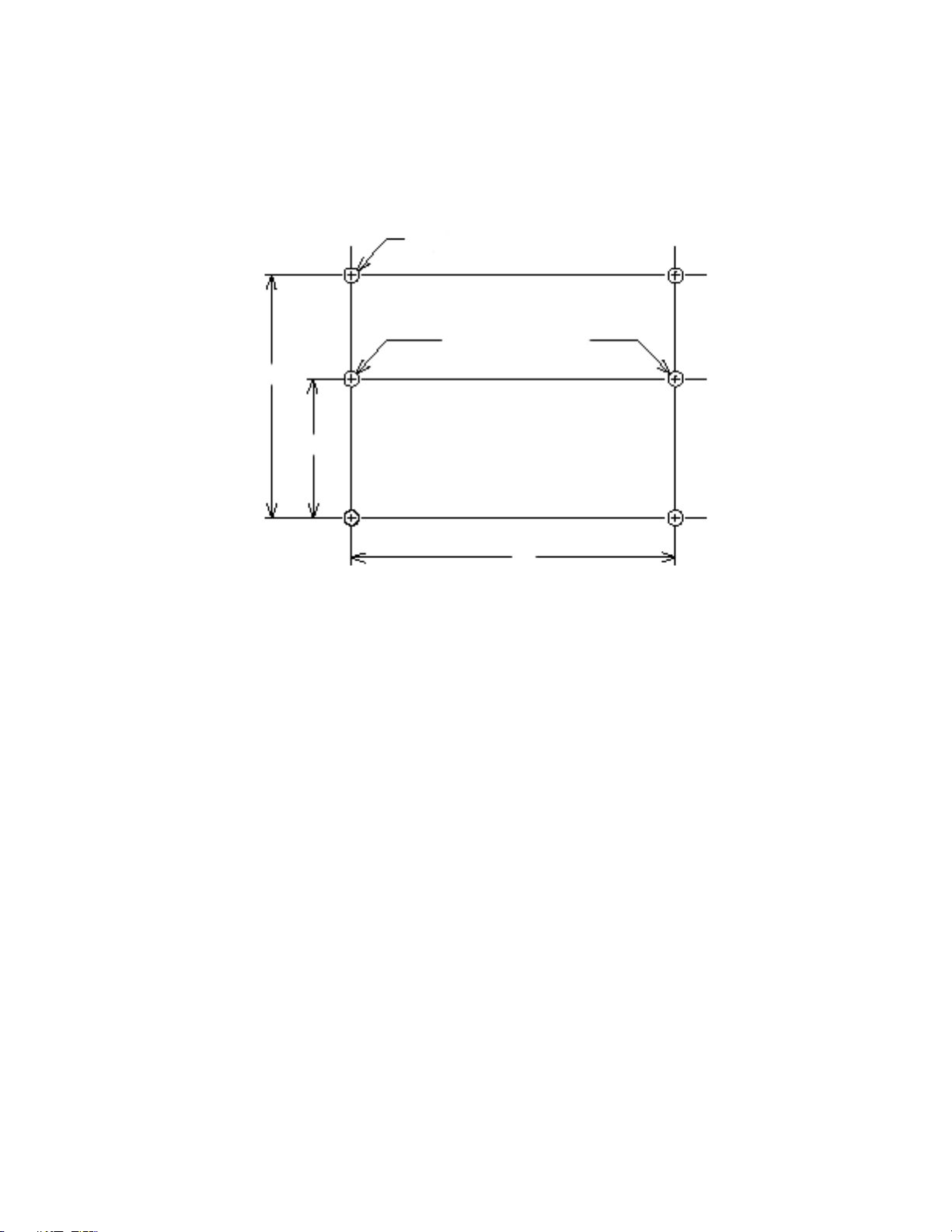

Figure A5 - Mounting Hole Pattern for Use with

Optional Mounting Bracket A-13

Figure A6 - Battery Connection Wiring Diagram A-14

Figure A7 - Connecting a Current Loop Sensor to a

DATAFLOW RTU Analog Input A-17

Figure A8 - Connecting a Current Loop Indicator to a

DATAFLOW RTU Analog Output A-18

Software/ Programming (Part B) Table of Contents B - i

( A-v )

Page 7

DATAFLOW RTU

1. INTRODUCTION

1.1 The DATAFLOW RTU from OMEGA is a complete wireless telemetry system designed to

deliver industrial instrumentation signals from a source to other instruments via radio frequency

communications. The DATAFLOW RTU allows you to access industrial measuring devices in

remote locations without running wires, installing microwave links or leasing a telephone line.

OMEGA DATAFLOW RTU and MODBUS radio communications equipment replaces these

methods.

1.2 Manual Part A is intended to provide information needed for the installation and operation of

DATAFLOW RTU systems. The intended readers are people familiar with industrial

instrumentation. A basic understanding of radio communications is helpful. The included

information is valid only for models listed on the cover.

2.

2.1 DATAFLOW RTU is a radio telemetry system. It operates on either 450-470 MHz with a

2.2 All DATAFLOW RTU systems require FCC licensing.

3.

3.1 A microprocessor, IC105, the main controlling device of a DATAFLOW RTU, is located in a

3.2 The microprocessor firmware version available when this manual was printed is Version 3.27.

OPERATION

transmitter power of 2 Watts or 5 Watts (UHF-FM), or 136 to 151 MHz, 150 to 165 MHz, 160 to

174 MHz with a transmitter power of 5 Watts (VHF-FM). An RTU system operating in the UHFFM band at 2 Watts with directional antennas and 50-foot towers has an effective range of 20

to 25 miles over level terrain. Changes in the frequency of operation, transmitter power, terrain

and antenna structure will affect the range of the link.

MICROPROCESSOR UPDATES

socket on the Control Board. Socket configuration provides ease in replacing or updating

microprocessor firmware.

(In Version 3.x, x represents the [number] designation of a minor revision.)

( A-1 )

Page 8

Installation/Operation

4. PART NUMBER DEFINITION

4.1 The following is a list of the part numbers available at the printing of this material.

RTU-X X X - X / / / /

Band Option

1 5 0 - E 136-151 MHz. RF Board (OMEGA # DTX-150-E0DD)

1 5 0 - 0 150-165 MHz. RF Board (OMEGA # DTX-150-00DD)

1 5 0 - F 160-174 MHz. RF Board (OMEGA # DTX-150-F0DD)

4 5 0 - 0 450-470 MHz. RF Board (OMEGA # DTX-450-00DD)

4 0 0 - G 400-430 MHz. RF Board (OMEGA # DTX-150-G0DD)

RTU-/ / / - / X / / /

RTU-/ / / - / / X / /

RTU-/ / / - / / / X /

RTU-/ / / - / / / / X

5. ACCESSORIES

5.1 The following list reflects available accessories.

OMEGA PART NO. DESCRIPTION

RTU-06001123 Power/ Serial Cable, 6 foot length for small (S) enclosure

RTU-06001124 User I/O Cable, 6 foot length for small (S) enclosure

RTU-25104600 Mounting Bracket for small (S) enclosure

RTU-25605100 Enclosure Cover Seal

RTU-BATNICD NiCad Rechargeable Battery Pack

RTU-BATHOLD Battery Holder

RTU-AFP-150 VHF Flexible Antenna

RTU-AFP-150H VHF Flexible Antenna for 164-174 MHz

RTU-RYA-15 VHF Directional Antenna, 6.5 dB Gain

RTU-AFP-450 UHF Flexible Antenna

RF Connection

U UHF Connector

Enclosure

S Small Enclosure

Power Option

1 One 8-cell AA battery holders (batteries not included)

2 Two 4-cell NiCad rechargeable battery packs

D No internal power

Data Encryption

C Clear

RTU-RYA-45 UHF Directional Antenna, 10 dB Gain

RTU-ROA-45 UHF Omnidirectional Antenna, 2.5 dB Gain

RTU-RAC-05 Coaxial Cable, 50 feet, RG-8A/U w/PL-250 Connectors

RTU-RAC-10 Coaxial Cable, 100 feet, RG-8A/U w/PL-250 Connectors

RTU-9/RTC-PAS Programming Cable for small (S) enclosure

RTU-PCPC Programming Cable for small (S) enclosure

RTU-PCPS-3.0 Programming software

(Version 3.03 for DOS & Windows PCs on 3.5" disk

RTU-PCPK Programming Kit

RTU-PS 1.5 Amp AC-to-DC Power supply

RPS-1 1 Amp AC to DC Power Supply

14800018-0 RTU Series Users Guide

( A-2 )

Page 9

6 SPECIFICATIONS

6.1 SYSTEM SPECIFICATIONS

FCC ID:......................................... RTU-150 - AIERIT04-150; RTU-450 - AIERIT04-450

Emission designator: 10K8FID

Digital Inputs:............................... Maximum of 6

LOW: Programmable from 0 to 5 V

HIGH: Programmable from 0 to 5 V

Digital Outputs:............................. Two (2) isolated latching relays

UL/CSA rating: 2A 30VDC

0.5A 110VDC

0.5A 125VAC

Analog Inputs: :............................. Maximum of 6

Voltage Mode Range: 0-5 VDC

Current Loop Mode Range: 0-20 mA

Resolution: 8 bits

Analog Outputs:............................ Maximum of 2

Analog Voltage Mode Range: 0-5 VDC

Current Loop Mode Range: 0-20 mA

Resolution: 8 bits

DATAFLOW RTU

Radio Communications:................. FSK, 1200 BPS, proprietary Manchester-Encoded data format

Serial Communications: ............... RS-485; 1200, 2400, 4800, or 9600 BPS; MODBUS RTU protocol;

for programming and external control

Power Requirements:..................... 10-16 VDC

300mA sleep, 100 mA receive

1.5A low power transmit, 2.5A high power transmit

Housing:........................................ Diecast Aluminum, Weather-resistant, (Enclosure S)

Dimensions (L x W x H):................ 4.5" x 3.5" x 2.2" (Enclosure option S)

Weight:.......................................... 1.4 lb. (Enclosure option S)

Operating Temperature:................. -30 to +60 degrees Centigrade

-22 to +140 degrees Fahrenheit

6.2 DTX SPECIFICATIONS

TRANSMITTER RECEIVER

Bandspread: 20 MHz Bandspread: 20 MHz

Freq. Stability: 5 PPM Freq. Stability: 5 PPM

RF Power Out: 5 W, programmable to 2 W Sensitivity: .3 mV

RF Output Z: 50 Ohms RF Input Z: 50 Ohms

Mod. Dist.: less than 4% Selectivity: 70 dB @ 30 kHz

65 dB @ 25 kHz

Mod. Input Z: 100 K Ohms Audio Dist.: less than 3%

( A-3 )

Page 10

Installation/Operation

N O T E S

.........................................................................................................................................................................

................................................................................................................................................

..............................................................................................................................................

............................................................................................................................................

...........................................................................................................................................

.................................................................................................................................................

......................................................................................................................................................

..........................................................................................................................................

..........................................................................................................................................

........................................................................................................................................

....................................................................................................................................................

..........................................................................................................................................

...........................................................................................................................................

................................................................................................................................................

......................................................................................................................................

....................................................................................................................................

........................................................................................................................................

....................................................................................................................................

.......................................................................................................................................

.............................................................................................................................................

.................................................................................................................................................

........................................................................................................................................................

..........................................................................................................................................

............................................................................................................................................

.....................................................................................................................................................

..................................................................................................................................................

............................................................................................................................................

......................................................................................................................................................

............................................................................................................................................

.............................................................................................................................................

..........................................................................................................................................

.........................................................................................................................................

.............................................................................................................................................

.................................................................................................................................................................

................................................................................................................................................

..........................................................................................................................................

.................................................................................................................................................

.......................................................................................................................................

..........................................................................................................................................

.................................................................................................................................................

.........................................................................................................................................

...........................................................................................................................................

.....................................................................................................................................

( A-4 )

Page 11

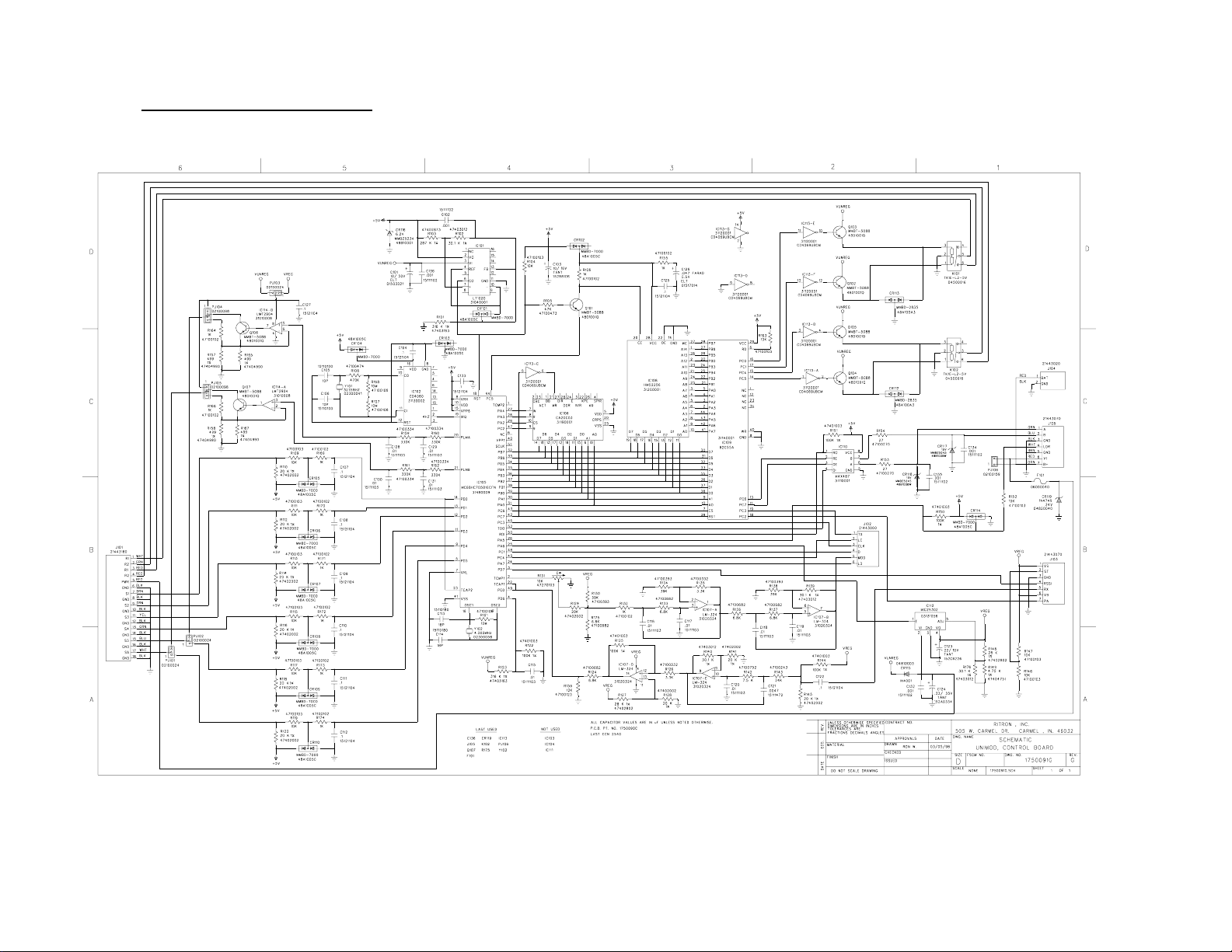

7. CONTROL BOARD SCHEMATIC

7.1 The following is the DATAFLOW RTU Control Board schematic.

Figure A1 - Control Board Schematic

( A-5 )

Page 12

Installation/ Operation

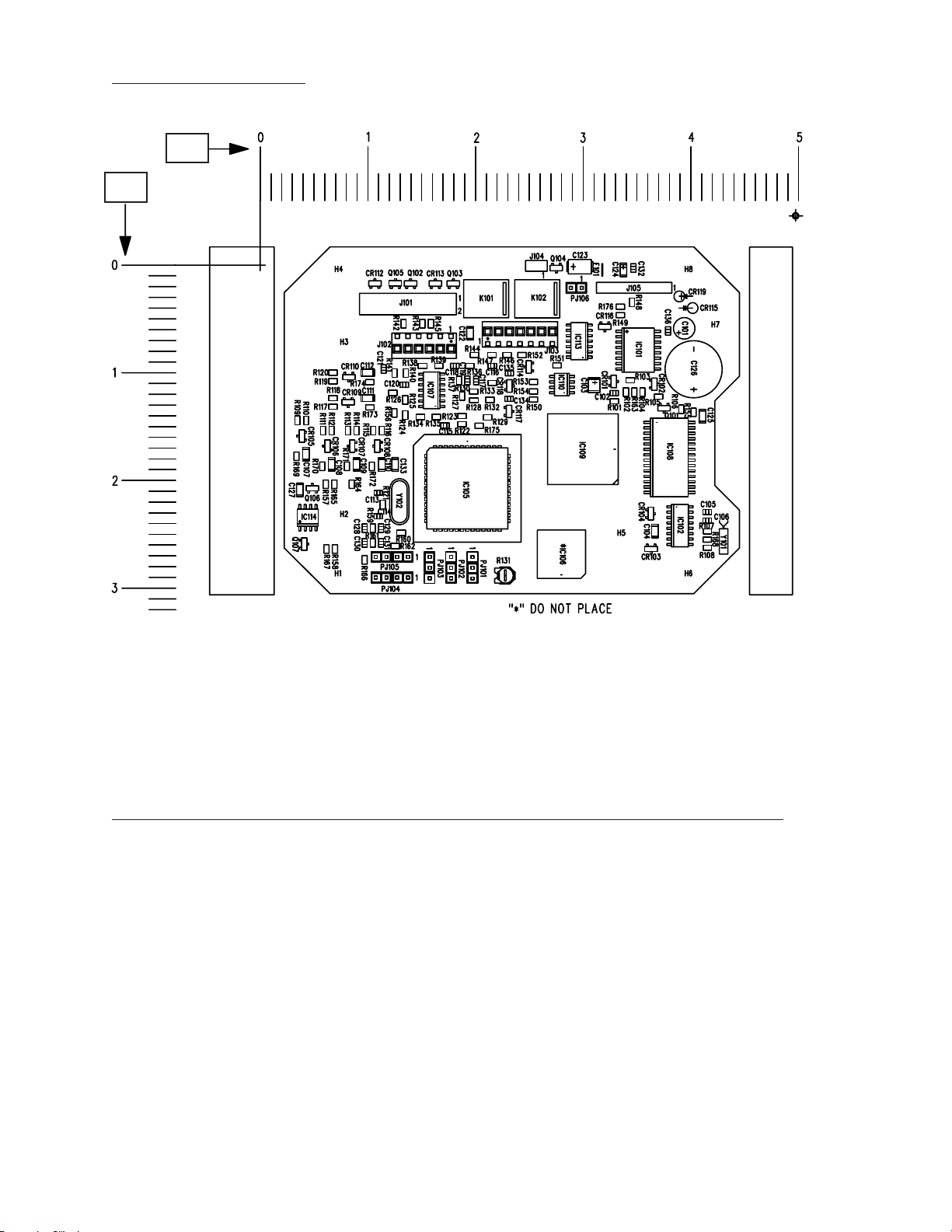

8. CONTROL BOARD LAYOUT

8.1 The following diagram shows the physical layout of the RTU control board

X

Y

1750090C 12/16/97 TOP SIDE PARTS PLACEMENT W/ REF. DES.

1750092G LAST ECN 2540

Figure A2 - Control Board top side parts placement with reference deisgnators.

8.2 EXAMPLE: The location of a particular component is given by the following notation - J101 PIN 1 (Y 0.3 - X 1.8).

This means the pin 1 of connector J101 is located at a horizontal (X) coordinate of 1.8 inches and a vertical

(Y) coordinate of 0.3 inches.

8.3 SCHEMATIC REFERENCE NUMBER PARTS LIST, RTU-CNTL, 03/05/98

REF. PART NO. DESCRIPTION Y X

CAPACITORS

C 101 01503021 10uf ELT CAP 50V .1" .2"x.46" r 0.585 3.939

C 102 15111102 .001MF X7R 0805 50V CHIP CAP 1.189 3.291

C 103 152B8106 CAP 10uF 16V 3.4 X 2.8 CHIP TANTALUM 1.113 3.104

C 104 15121104 .1MF X7R 1206 50V CHIP CAP 2.470 3.670

C 105 15110100 10PF NPO 0805 50V CHIP CAP 2.294 4.155

C 106 15110100 10PF NPO 0805 50V CHIP CAP 2.372 4.155

C 107 15121104 .1MF X7R 1206 50V CHIP CAP 1.755 0.428

C 108 15121104 .1MF X7R 1206 50V CHIP CAP 1.849 0.666

C 109 15121104 .1MF X7R 1206 50V CHIP CAP 1.850 0.897

C 110 15121104 .1MF X7R 1206 50V CHIP CAP 1.851 1.130

C 111 15121104 .1MF X7R 1206 50V CHIP CAP 1.234 1.001

C 112 15121104 .1MF X7R 1206 50V CHIP CAP 0.999 1.001

C 113 15110180 18PF NPO 0805 50V CHIP 2.114 1.100

C 114 15110180 18PF NPO 0805 50V CHIP 2.332 1.099

C 115 15111103 .01MF X7R 0805 50V CHIP 1.489 1.719

C 116 15111103 .01MF X7R 0805 50V CHIP 0.935 2.159

C 117 15111103 .01MF X7R 0805 50V CHIP 1.069 2.007

C 118 15111103 .01MF X7R 0805 50V CHIP 0.935 1.810

C 119 15111103 .01MF X7R 0805 50V CHIP 1.069 1.926

C 120 15111103 .01MF X7R 0805 50V CHIP 1.110 1.340

C 121 15111472 .0047MF X7R 0805 50V CHIP 0.964 1.149

C 122 15121104 .1MF X7R 1206 50V CHIP CAP 0.632 1.951

RITRON, INC.

( A-6 )

Page 13

DATAFLOW RTU

REF. PART NO. DESCRIPTION Y X

C 123 152C6226 22uf 10V 6.0 X 3.2 CHIP TANTALUM CAP 0.028 2.955

C 124 152AB334 .33MF 35V "3.2X1.6" CHIP TANTALUM 0.044 3.375

C 125 15121104 .1MF X7R 1206 50V CHIP CAP 1.402 4.111

C 126 01517014 CAPACITOR .047F 5.5V TANTALUM 1.065 4.027

C 127 15121104 .1MF X7R 1206 50V CHIP CAP 2.086 0.369

C 128 15111103 .01MF X7R 0805 50V CHIP 2.442 0.971

C 129 15111103 .01MF X7R 0805 50V CHIP 2.441 1.124

C 130 15111103 .01MF X7R 0805 50V CHIP 2.578 0.971

C 131 15111103 .01MF X7R 0805 50V CHIP 2.579 1.124

C 132 15111102 .001MF X7R 0805 50V CHIP CAP 0.026 3.469

C 133 15121104 .1MF X7R 1206 50V CHIP CAP 1.851 1.255

C 134 15111102 .001MF X7R 0805 50V CHIP CAP 1.241 2.313

C 135 15111102 .001MF X7R 0805 50V CHIP CAP 1.004 2.316

C 136 15111102 .001MF X7R 0805 50V CHIP CAP 0.610 3.791

DIODES

CR101 48A1005C MMBD7000 DUAL DIODE SOT-23 1.080 3.285

CR102 48A1005C MMBD7000 DUAL DIODE SOT-23 1.105 3.664

CR103 48A1005C MMBD7000 DUAL DIODE SOT-23 2.634 3.633

CR104 48A1005C MMBD7000 DUAL DIODE SOT-23 2.306 3.630

CR105 48A1005C MMBD7000 DUAL DIODE SOT-23 1.588 0.388

CR106 48A1005C MMBD7000 DUAL DIODE SOT-23 1.680 0.626

CR107 48A1005C MMBD7000 DUAL DIODE SOT-23 1.680 0.857

CR108 48A1005C MMBD7000 DUAL DIODE SOT-23 1.681 1.090

CR109 48A1005C MMBD7000 DUAL DIODE SOT-23 1.274 0.820

CR110 48A1005C MMBD7000 DUAL DIODE SOT-23 1.039 0.825

CR112 48A100A3 MMBD2835, DUAL DIODE SOT-23 0.170 1.067

CR113 48A100A3 MMBD2835, DUAL DIODE SOT-23 0.171 1.629

CR114 48A1005C MMBD7000 DUAL DIODE SOT-23 0.945 2.496

CR115 04810003 1N4001 DIODE 50 VOLT/1AMP 0.398 4.019

CR116 48B10001 DIODE, ZENER, 6.2V 5% 225MW SOT-23 0.572 3.203

CR117 48B1008W MMBZ 5245 ZENER DIODE SOT23 1.358 2.313

CR118 48B1008W MMBZ 5245 ZENER DIODE SOT23 1.121 2.316

FUSE

F 101 06000040 WIRE; #40AWG TINNED BUS (INCHES) 0.044 3.180

INTEGRATED CIRCUITS

IC101 31040001 IC, SO-16 WIDE VOLT. REG. LT1020 0.789 3.513

IC102 31130002 CD4060 COUNTER, SO-16, CD4060 2.419 3.901

IC105 314B0005 IC, PLCC-52 MICROPROCESSOR, 68HC705B16 2.073 1.926

IC107 31020324 LMT324AD/NJM324E QUAD OP-AMP 1.162 1.595

IC108 312G0001 IC, SO-28 WIDE 32KB STATIC RAM HM52256 1.785 3.803

IC109 311A0001 IC, PLCC-44, PERIPHERAL INTERFACE 82C55A 1.709 3.000

IC110 31110001 RS-485 TRANSCEIVER, SO-8, MAX487 1.109 2.805

IC112 03131056 IC, TO-220 5 PIN VOLT. REG. MIC29302 BOTTOM SIDE

IC113 31120001 INVERTER, HEX CD4069 0.706 2.966

IC114 31010008 LMT2904D DUAL OP AMP SO-8 2.345 0.444

JACKS

J 102 21443061 CONNECTOR; 6 POSITION PC VERT. GOLD

J 103 21443071 CONNECTOR; 6 POSITION PC VERT. GOLD

RELA YS

K 101 04500016 RELAY, SPDT 5V LATCHING 0.161 2.201

K 102 04500016 RELAY, SPDT 5V LATCHING 0.162 2.675

JUMPERS

PJ101 02100024 3 PIN STRAIGHT HEADER 2.810 1.975

PJ102 02100024 3 PIN STRAIGHT HEADER 2.809 1.775

PJ103 02100024 3 PIN STRAIGHT HEADER 2.809 1.575

PJ104 02100098 4 PIN 0.1" HEADER 2.902 1.375

PJ105 02100098 4 PIN 0.1" HEADER 2.709 1.375

PJ106 02100159 2 PIN .1" HEADER STRIP 0.211 2.888

TRANSISTORS

Q 101 4801001Q MMBT-5088 "SOT-23" 1.328 3.754

Q 102 4801001Q MMBT-5088 "SOT-23" 0.171 1.399

Q 103 4801001Q MMBT-5088 "SOT-23" 0.171 1.796

Q 104 4801001Q MMBT-5088 "SOT-23" 0.027 2.752

Q 105 4801001Q MMBT-5088 "SOT-23" 0.170 1.257

Q 106 4801001Q MMBT-5088 "SOT-23" 2.071 0.485

Q 107 4801001Q MMBT-5088 "SOT-23" 2.590 0.409

RESISTORS

R 101 47403163 316K OHM 1% 0805 CHIP 1.264 3.291

R 102 47403012 30.1K OHM 1% 0805 CHIP 1.180 3.399

R 103 47402873 287K OHM 1% 0805 CHIP 1.068 3.439

R 104 47100103 10K OHM 0805 CHIP RES 1.180 3.554

R 105 47100473 47K OHM 0805 CHIP RES. 1.219 3.702

( A-7 )

RITRON, INC.

Page 14

Installation/ Operation

REF. PART NO. DESCRIPTION Y X

R 106 47100102 1K OHM 0805 CHIP RES 1.337 3.914

R 107 47100106 RESISTOR, 10M OHM 0805 5% CHIP 2.473 4.155

R 108 47100474 470K OHM 0805 CHIP RES. 2.625 4.155

R 109 47100103 10K OHM 0805 CHIP RES 1.442 0.348

R 110 47402002 20K OHM 1% 0805 CHIP 1.443 0.428

R 111 47100103 10K OHM 0805 CHIP RES 1.537 0.586

R 112 47402002 20K OHM 1% 0805 CHIP 1.537 0.666

R 113 47100103 10K OHM 0805 CHIP RES 1.537 0.817

R 114 47402002 20K OHM 1% 0805 CHIP 1.537 0.897

R 115 47100103 10K OHM 0805 CHIP RES 1.537 1.050

R 116 47402002 20K OHM 1% 0805 CHIP 1.537 1.130

R 117 47100103 10K OHM 0805 CHIP RES 1.314 0.676

R 118 47402002 20K OHM 1% 0805 CHIP 1.234 0.676

R 119 47100103 10K OHM 0805 CHIP RES 1.079 0.676

R 120 47402002 20K OHM 1% 0805 CHIP 0.999 0.676

R 121 47100106 RESISTOR, 10M OHM 0805 5% CHIP 2.222 1.139

R 122 47401003 100K OHM 1% 0805 CHIP 1.477 1.877

R 123 47403163 316K OHM 1% 0805 CHIP 1.400 1.877

R 124 47100682 6.8K OHM 0805 CHIP RES. 1.391 1.350

R 125 47401003 100K OHM 1% 0805 CHIP 1.250 1.350

R 126 47100332 3.3K OHM 0805 CHIP RES. 1.187 1.234

R 127 47402802 28K OHM 1% 0805 CHIP 1.215 1.879

R 128 47402002 20K OHM 1% 0805 CHIP 1.255 1.986

R 129 47402002 20K OHM 1% 0805 CHIP 1.413 2.115

R 130 47100393 39K OHM 0805 CHIP RES. 1.175 1.985

R 131 47270103 VARIABLE RESISTOR 10K SEALED 2.882 2.265

R 132 47100102 1K OHM 0805 CHIP RES 1.252 2.134

R 133 47100682 6.8K OHM 0805 CHIP RES. 1.094 2.159

R 134 47100393 39K OHM 0805 CHIP RES. 1.410 1.491

R 135 47100332 3.3K OHM 0805 CHIP RES. 1.410 1.640

R 136 47100682 6.8K OHM 0805 CHIP RES. 0.935 1.947

R 137 47100682 6.8K OHM 0805 CHIP RES. 1.070 1.850

R 138 47100393 39K OHM 0805 CHIP RES. 0.935 1.510

R 139 47403012 30.1K OHM 1% 0805 CHIP 0.935 1.662

R 140 47403012 30.1K OHM 1% 0805 CHIP 1.002 1.354

R 141 47402002 20K OHM 1% 0805 CHIP 1.002 1.250

R 142 47100752 RESISTOR, 7.5K OHM 0805 CHIP 0.543 1.333

R 143 47100243 24K OHM 0805 CHIP RESISTOR 0.543 1.508

R 144 47401003 100K OHM 1% 0805 CHIP 0.835 1.990

R 145 47402002 20K OHM 1% 0805 CHIP 0.543 1.588

R 146 47100103 10K OHM 0805 CHIP RES 0.835 2.294

R 147 47100103 10K OHM 0805 CHIP RES 0.835 2.154

R 148 47402802 28K OHM 1% 0805 CHIP 0.346 3.455

R 149 47404751 4.75K OHM 1% 0805 CHIP 0.463 3.368

R 150 47401003 100K OHM 1% 0805 CHIP 1.248 2.540

R 151 47401003 100K OHM 1% 0805 CHIP 0.931 2.758

R 152 47100103 10K OHM 0805 CHIP RES 0.835 2.433

R 153 47100270 27 OHM 0805 CHIP RESISTOR 1.084 2.540

R 154 47100270 27 OHM 0805 CHIP RESISTOR 1.172 2.540

R 155 47100102 1K OHM 0805 CHIP RES 1.366 4.028

R 156 47100123 12K OHM 0805 CHIP RES. 1.373 1.249

R 157 47404990 RESISTOR, 499 OHM 1% 0805 CHIP 2.035 0.611

R 158 47404990 RESISTOR, 499 OHM 1% 0805 CHIP 2.636 0.695

R 159 47100334 330K OHM 0805 CHIP RES. 2.442 1.048

R 160 47100334 330K OHM 0805 CHIP RES. 2.485 1.310

R 161 47100334 330K OHM 0805 CHIP RES. 2.579 1.048

R 162 47100334 330K OHM 0805 CHIP RES. 2.608 1.253

R 163 47100103 10K OHM 0805 CHIP RES 1.180 3.477

R 164 47100102 1K OHM 0805 CHIP RES 2.035 0.852

R 165 47404990 RESISTOR, 499 OHM 1% 0805 CHIP 2.035 0.689

R 166 47100102 1K OHM 0805 CHIP RES 2.737 0.971

R 167 47404990 RESISTOR, 499 OHM 1% 0805 CHIP 2.636 0.617

R 168 47100106 RESISTOR, 10M OHM 0805 5% CHIP 2.549 4.155

R 169 47100102 1K OHM 0805 CHIP RES 1.775 0.339

R 170 47100102 1K OHM 0805 CHIP RES 1.868 0.578

R 171 47100102 1K OHM 0805 CHIP RES 1.868 0.807

R 172 47100102 1K OHM 0805 CHIP RES 1.869 1.040

R 173 47100102 1K OHM 0805 CHIP RES 1.321 1.020

R 174 47100102 1K OHM 0805 CHIP RES 1.085 1.019

R 175 47100682 6.8K OHM 0805 CHIP RES 1.492 2.036

R 176 47403012 30.1K OHM 1% 0805 CHIP RES

CRYST ALS

Y 101 02300041 32.768 KHz CRYSTAL 2.372 4.344

Y 102 02300058 CRYSTAL 4.000MHZ; AT-49 2.195 1.294

RITRON, INC.

( A-8 )

Page 15

9. RF BOARD SCHEMATIC

9.1 Contact Omega for more detailed information on the DTX RF board schematic.

DATAFLOW RTU

10.

RF BOARD LAYOUT

10.1 Contact Omega for more detailed information on the DTX RF board layout.

11. INTERCONNECTS

C A U T I O N

On DATAFLOW RTUs shipped before the 2nd quarter of 1998, do not exceed 6 volts

referenced to GNDon RS-485 connections (the GREEN and BLUE wires of the External

Power/Serial Cable: OMEGA Part No. 06001123). Exceeding 6 volts will damage

protection circuitry and render the units serial link inoperable.

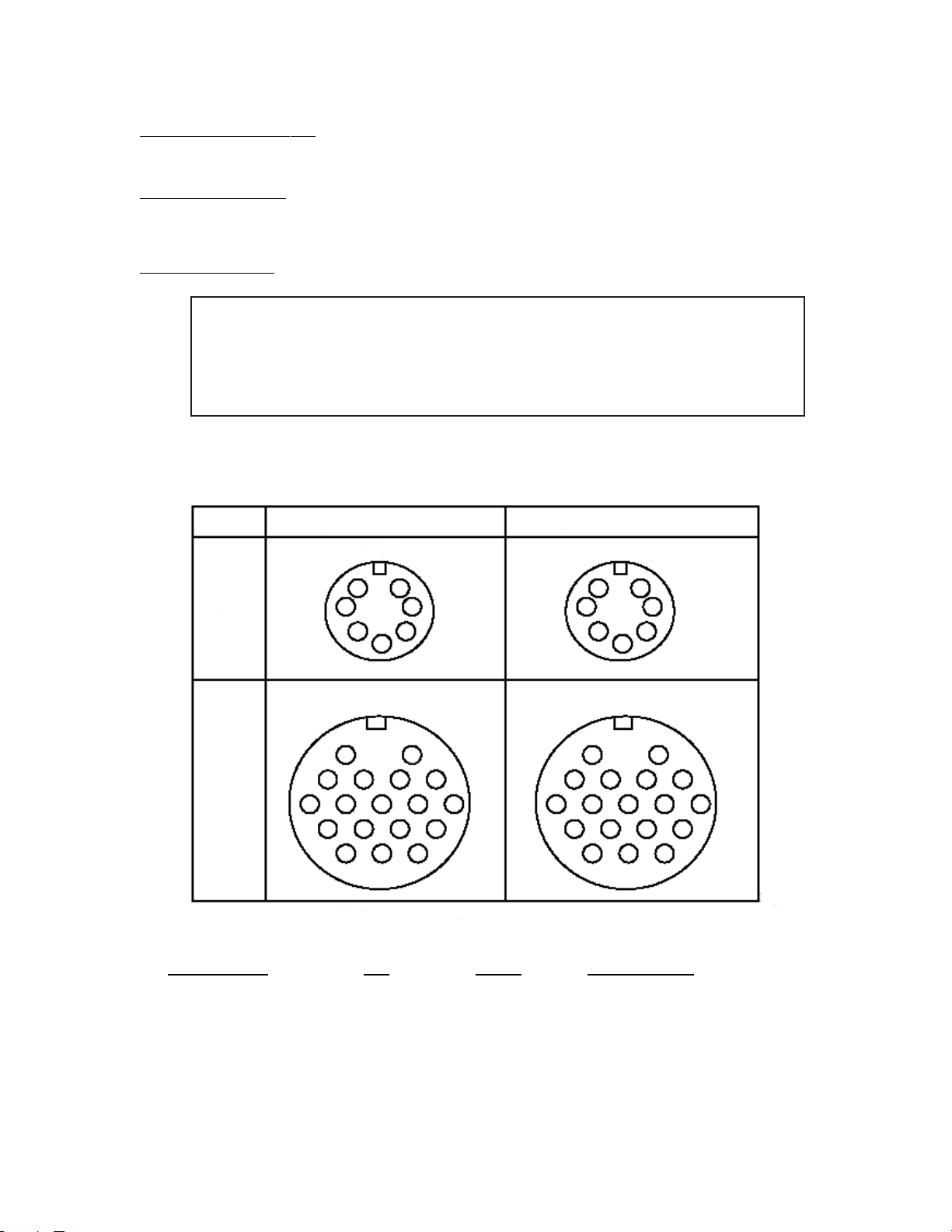

11.1 For a weather-resistant aluminum enclosure for DATAFLOW RTU, purchase it in a small (S) enclosure

option. This option also provides bulkhead circular connectors and one UHF antenna port. See Figure A3

for pin number designations of the circular connectors.

BULKHEAD CONNECTOR CABLE CONNECTOR

KEYING SLOT

1

7

6

55

2

3

4

7-PIN

KEYING PIN

1

7

2

3

6

4

3

18-PIN

7

12

Figure A3 - Circular connector pin designators

11.1.1 BULKHEAD CONNECTORS:

CONNECTOR PIN NAME DESCRIPTION

Ext. Power/ Serial: 1 A Serial Pair A

KEYING PIN

1

4

8

16 17

2

6

5

9

14

11

15

18

KEYING SLOT

2

6

11

10

15

18

14

1

3

4

5

8

910

1313

7

12

1617

2 B Serial Pair B

3 GND Loader Ground

4 LDR Loader Connected/Program Enable

5 GND Power Ground

6 VI Power In to Controller and Radio

7 B+ From Internal Battery

( A-9 )

Page 16

Installation/Operation

CONNECTOR PIN NAME DESCRIPTION

User Input/ Output: 1 R11 Relay 1 Contact 1

2 R12 Relay 1 Contact 2

3 R21 Relay 2 Contact 1

4 R22 Relay 2 Contact 2

5 PWR Power Out

6 GND Power Out Ground

7 S1 Input 1

8 GND Input 1 Ground

9 S2 Input 2

10 GND Input 2 Ground

11 S3 Input 3

12 GND Input 3 Ground

13 S4 Input 4

14 GND Input 4 Ground

15 S5 Input 5/ Output 1

16 GND Input 5/ Output 1 Ground

17 S6 Input 6/ Output 2

18 GND Input 6/ Output 2 Ground

11.1.2 OPTIONAL INTERFACE CABLES, part numbers RTU-06001123 and RTU-06001124, may be purchased

for use with the small (S) enclosure. These cables provide the user with 6-foot long, color-coded cables

designed specifically for use with DATAFLOW RTU.

11.1.3 INTERFACE CABLE CONNECTIONS:

CABLE PIN NAME COLOR CODE DESCRIPTION

Ext. Pwr./ Serial: 1 A GREEN Serial Pair A

Part # 06001123 2 B BLUE Serial Pair B

3 GND BLACK Loader Ground

4 LDR WHITE Loader Connected/Program Enable

5 GND BROWN Power Ground

6 VI RED Power In to Controller and Radio

7 B+ ORANGE From Internal Battery

User Input/ Output: 1 R11 WHITE Relay 1 Contact 1

Part # 06001124 2 R12 RED Relay 1 Contact 2

3 R21 GREEN Relay 2 Contact 1

4 R22 RED Relay 2 Contact 2

5 PWR RED Power Out

6 GND BLACK Power Out Ground

7 S1 BROWN Input 1

8 GND BLACK Input 1 Ground

9 S2 ORANGE Input 2

10 GND BLACK Input 2 Ground

11 S3 YELLOW Input 3

12 GND BLACK Input 3 Ground

13 S4 GREEN Input 4

14 GND BLACK Input 4 Ground

15 S5 BLUE Input 5/ Output 1

16 GND BLACK Input 5/ Output 1 Ground

17 S6 WHITE Input 6/ Output 2

18 GND BLACK Input 6/ Output 2 Ground

NOTE: The following pin groups are twisted pairs:

1-2, 3-4, 5-6, 7-8, 9-10, 11-12, 13-14, 15-16, 17-18

( A-10( A-3 ) )

Page 17

11.1.4 CONNECTIONS

CONNECTOR PIN NAME DESCRIPTION

Ext. Power/ Serial: 1 A Serial Pair A

J105 (X3.8 Y0.2) 2 B Serial Pair B

User Input/ Output: 1 R11 Relay 1 Contact 1

J101 (X1.8 Y0.3) 2 R21 Relay 2 Contact 1

DATAFLOW RTU

3 GND Loader Ground

4 LDR Loader Connected/ Program Enable

5 GND Power Ground

6 VI Power In to Controller and Radio

7 B+ From Internal Battery

3 R12 Relay 1 Contact 2

4 R22 Relay 2 Contact 2

5 PWR Power Out

6 GND Power Out Ground

7 S1 Input 1

8 GND Input 1 Ground

9 S2 Input 2

10 GND Input 2 Ground

11 S3 Input 3

12 GND Input 3 Ground

13 S4 Input 4

14 GND Input 4 Ground

15 S5 Input 5/ Output 1

16 GND Input 5/ Output 1 Ground

17 S6 Input 6/ Output 2

18 GND Input 6/ Output 2 Ground

12. HARDWARE CONFIGURATION

12.1 The DATAFLOW RTU has six hardware configurable jumpers. Jumper functions are described in the

following paragraphs 12.1.1 to 12.1.6. See Figure A2, page A-6, for location references.

12.1.1 PJ101 (Y 2.8 - X 2.0): This jumper setting determines whether configurable I/O 1 is an input or an analog

output. The jumper across pins 1 and 2 configures the pin to be an input. The jumper across pins 2 and 3

configures the pin to be an output, the default setting.

12.1.2 PJ102 (Y 2.8 - X 1.8): This jumper setting determines if configurable I/O 2 is an input or an analog

output. The jumper across pins 1 and 2 configures the pin to be an input. The jumper across pins 2 and 3

configures the pin to be an output, the default setting.

12.1.3 PJ103 (Y 2.8 - X 1.6): This jumper setting determines how the configurable analog outputs 1 and 2 are

powered. The jumper setting is valid only if PJ101 or PJ102 is set for output. The jumper across pins 2

and 3 configures the output to be powered by system power. The jumper across pins 1 and 2 configures

the output to be powered by regulated radio power, the default setting.

PJ104 (Y 2.9 - X 1.2): This jumper setting determines if configurable I/O 1 is set for voltage or current loop

analog output. This jumper setting is valid only if PJ101 is set for output. With one jumper across pins 1

and 2 and another jumper across pins 3 and 4, the output is configured for voltage, the default setting.

Only one jumper across pins 2 and 3 configures the output for current loop.

( A-11 )

Page 18

Installation/Operation

12.1.5 PJ105 (Y 2.7 - X 1.2): This jumper setting determines if configurable I/O 2 is set for voltage or current

loop analog output. This jumper setting is valid only if PJ102 is set for output. With one jumper across

pins 1 and 2 and another jumper across pins 3 and 4, the output is configured for voltage, the default

setting. Only one jumper across pins 2 and 3 configures the output for current loop.

12.1.6

PJ106 (Y 0.2 - X 2.9): This jumper connects the internal battery power to the power input of the control

board. This jumper setting is valid only when using the internal battery power. With the jumper installed,

the default condition, the internal battery is always connected to control board power, meaning the unit is

always ON with the internal batteries installed.

13. SOFTWARE CONFIGURATION

13.1 All DATAFLOW RTUs contain identical hardware; the software configuration of a unit makes it perform a

particular task. This programmable configuration can be changed using any PC compatible computer,

DATAFLOW RTU Programming Software and a DATAFLOW RTU Programming Cable.

14. MOUNTING INFORMATION

14.1 To provide DATAFLOW RTU with an aluminum enclosure, it may be purchased with the small enclosure

(S). The S enclosure has four pilot holes drilled into the back corners of the case; the holes are tapped

with four (4) #6 - 32 x 3/8 thread-forming screws. The DATAFLOW RTU is shipped with these screws

installed in the case. A T-15 Torx© drive tool is required to remove the screws.

14.1.1 You can use the holes in the back of the enclosure to mount the DATAFLOW RTU directly to a surface,

using the recommended hole pattern shown in Figure A4. The four thread-forming screws can be used to

secure the case to the surface, if desired, by removing the screws and reusing them. Alternately, four #6 32 machine screws may be used; ensure they do not extend more than 5/16" into the case.

4.050

.144 DIA. MIN. 4-PLACES

(CLEARANCE FOR #6-32 SCREW)

3.050

Figure A4 - Mounting hole pattern for fastening directly to the DATAFLOW RTU case

( A-12 )

Page 19

DATAFLOW RTU

14.1.2 Optional mounting bracket OMEGA part number RTU-25104600 is available for DATAFLOW RTU. To

install this bracket to the case, remove and save the four thread-forming screws described in paragraph

14.1 to attach the mounting bracket to the case. Be sure the narrow portion of the keyhole is positioned

towards the top (UHF antenna connector) of the DATAFLOW RTU. Use the recommended hole pattern

for the optional mounting bracket shown in Figure A5.

.201 DIA. MIN. TYP

(CLEARANCE FOR #10-32 SCREW)

OPTIONAL MOUNTING - 2-PLACES

3.250

1.882

4.437

Figure A5 - Mounting hole pattern for use with optional mounting bracket

14.2 Reassembling DATAFLOW RTU Cover/ Waterproofing the Antenna Connection

14.2.1 The DATAFLOW RTU is weather-resistant if it has been properly sealed. If you have opened or

disassembled the device, refer to the following instructions.

14.2.2 Sealing the Housing Cover: Inspect the seal and mating surfaces for flaws (tears, gaps, dents, etc.).

Repair the surface or replace the part as necessary. Purchase replacement cover gaskets through Omega: Part

No. RTU-25605100.

Insert the seal in the cover. Thread the four (4) screws through the cover, into the housing; do not tighten the

screws. Snug down the screws in an X sequence; i.e.: top left, then bottom right, then top right, then bottom

left. Then fully tighten the screws in this same sequence.

14.2.3 Replacing Connectors: OMEGA discourages the practice of removing and discarding the protective cap

from the connectors. Doing this may reduce the water-resistance of the unit. If you must remove a connector for

any reason, make sure it has been retightened properly finger-tight connector nuts will not provide an

effective water barrier.

14.2.4 Connecting the Antenna: Seal screws are used to secure the antenna to the housing. Always replace

with a new seal screw, not a common screw.

Do not remove the antenna connector from the housing; doing so will destroy the silicone rubber seal in the

interface. The screw securing the ground strap inside the housing must be fully tight.

14.2.5 If this device is to be used in a wet environment, use seal tape around the antenna connection. Use

Archer Connector Sealant, Radio Shack Number 278-1645 or an equivalent. Wrap the connection with the

sealant tape and press it securely in place.

( A-13 )

Page 20

Installation/Operation

15. POWER

15.1 The DATAFLOW RTU small enclosure (S) may be purchased with the delete internal power (D) option.

The RTU power source is a user-provided external power supply meeting the following criteria:

· Between 10 VDC and 16 VDC with 12 VDC nominal;

· Has less than 1 V peak-to-peak of ripple;

· Provides 1.5 A with the transmitter in low power setting;

· Provides 2.5 A with the transmitter in high power setting.

15.1.1 Connect the positive side of the power supply to J105 pin 6. Connect the negative side of the power

supply to J105 pin. The negative side of the power supply is considered to be GROUND and is the

REFERENCE to which all inputs, outputs and measurements are to be made. GROUND is connected to

the enclosure.

15.2 You can purchase the DATAFLOW RTU with an eight-cell internal battery holder (power option 1). In this

option, internal AA batteries are used as the power source.

CAUTION: When installing the batteries, be sure to match polarities of the batteries with the

battery holder. Not matching polarities can damage the RTU.

15.2.1 The negative side of the battery assembly is considered to be GROUND and is the REFERENCE by

which all inputs, outputs, and measurements are to be made. GROUND is connected to the case.

15.2.2 The battery voltage appears at pin 8 of J105 pin 8, and is not connected directly to the input power of the

RTU control board. With jumper PJ106 installed, the battery is jumpered to the input power. With jumper

PJ106 not installed, an external connection is required between pin 6 and 7, which allows the user to

install an external ON/OFF switch to the RTU while using internal power.

15.3 J101 pin 5 is connected to the RTU power source, and J101 pin 6 is connected to GROUND. This power

supply provides excitation voltage to external equipment with maximum current draw of .25 A.

15.4 Fuse F101 (X3.2 - Y0.1) is a 40-gauge tinned wire designed to open at 2.5A. If this fuse is destroyed,

replace it with nothing larger than 40-gauge wire.

15.5 Optional Internal Battery Back-up (Refer to 11.1.3 for the appropriate pin numbers.)

Either of the following two options may be used as an optional internal battery back-up:

a. A two 4-cell battery pack (OMEGA Part No. RTU-BATNICD),

b. An 8-cell AA battery holder (OMEGA Part No. RTU-BAT/HOLD).

OR

15.5.1 Connect the battery as shown in Figure A6:

CR1

NOTE: CR1and CR2

are to be 1N5817

CR2

V source

G N D

R1

Figure A6 - Battery Connection Wiring Diagram

15.5.2 The following equations define the values required for R1.

R1 = (Vsource - Vdiode - Vbattfull) / Icharge

PR1 = (Vsource - Vdiode - Vbattempty)2 / R1

WHERE: R1 is the value of R1 in Ohms

Vsource is the input voltage to the RTU.

Vdiode is the voltage drop of the diode (CR1).

Vbatfull is the fully charged voltage of the internal battery.

Icharge is the charge current to the battery.

PR1 is the power rating of R1 in Watts.

Vbattempty is the empty voltage of the internal battery.

( A-14 )

RTU 7-PIN

CONNECTOR

7 ORN

6 RED

5 BRN

B +

V 1

G N D

Page 21

DATAFLOW RTU

15.5.3 The following calculations apply to RTU-BATNICD, using a 14V source.

R1 = (14 - 0.4 - 12) / .05 = 32 W

PR1 = (14 - 0.4 - 8)2 / R1 = 0.98 W

15.5.4 For RTU-BATHOLD, use a rechargeable battery type. Confirm the manufacturers specification for full

charge voltage, empty voltage, and trickle charge current.

16.

16.1 J105 pins 1 and 2 comprises the pair of differential lines used for the RS-485 link. This link provides the

17. I/O MAPPING

17.1 I/O mapping is the connection of one DATAFLOW RTU input to (another) DATAFLOW RTU input via

17.2 A digital output used as a warning indicator is not available for mapping to an input of another unit.

17.3 Using the analog output as a warning indicator is not recommended. If used in this way, it is not available

18. DIGITAL INPUTS

18.1 The (up to) six digital inputs are pins 7, 9, 11, 13, 15 and 17 of J101. (NOTE: Pins 15 and 17 are inputs

SERIAL LINK

user access to change the software configuration, and allows the RTU to be controlled by an external

computer via MODBUS RTU Protocol. The baud rate of this link is programmable between 1200, 2400,

4800, and 9600 BPS.

radio communication. The current mapping scheme allows any input of any DATAFLOW RTU to be sent

to any output of any other DATAFLOW RTU.

Because of this, a DATAFLOW RTU having a digital output used as a warning indicator can have only

one digital signal sent to it.

to be mapped to an input of another unit, meaning a DATAFLOW RTU having an analog output used in

this manner can have only one analog signal sent to it. NOTE: Be sure to not exceed the load drive

capability if an analog output is used as a warning indicator.

only if jumpers PJ101 and PJ102 are configured as inputs.)

Inputs are to be considered either HIGH or LOW. The following table defines the characteristics of the

input pin. The absolute limits are the safe operating region. Operation outside of this region can damage

the device. A HIGH state may be obtained by letting the input pin float, and a LOW state may be obtained

by connecting the input pin to GROUND. The threshold level between HIGH and LOW is programmed

with DATAFLOW RTU Programming Software.

PARAMETER MINIMUM MAXIMUM

HIGH programmable V 5 V

programmable kΩ infinite Ω

LOW 0 V programmable V

0 Ω programmable kΩ

ABSOLUTE LIMITS -2 V 7 V

You can invert the input state of an RTU unit, which will cause a DATAFLOW RTU reading a switch as

HIGH to transmit the switch status as LOW to another DATAFLOW RTU. Inversion allows a NORMALLY

OPEN switch to control a NORMALLY CLOSED relay output without external circuitry.

( A-15 )

Page 22

Installation/Operation

19. DIGITAL OUTPUTS

19.1 The two digital outputs are defined to be pins 1-3 and 2-4. These outputs are two dry-contact closurelatching relays. They are controlled by the DATAFLOW RTU software, and are either OPEN or CLOSED.

The following table defines the characteristics of the relay. The UL/ CSA power rating is the safe

operating region. Operation outside of this region can damage the device.

PARAMETER MINIMUM MAXIMUM

OPEN 1 MΩ

CLOSED 1 Ω

UL/ CSA POWER RATING 2A 30VDC

.5A 110VDC

.5A 125VAC

19.1.1 The relays can be programmed to have both initial and fail-safe conditions. The initial condition forces the

relays to a desired state at power on of the device. The fail-safe condition forces the relays to a desired

state if a RF data link problem is detected. For details on how to set these conditions, see the

DATAFLOW RTU Software/Programmers Manual.

19.2 If a digital output is used for a warning indicator, it is not available to be mapped to the corresponding

digital input of the other unit. This means that if a digital output is used for a warning indicator, only one

digital signal may be sent to that DATAFLOW RTU.

19.3 Because the relays are latching relays, they retain the state they are in if power to the DATAFLOW RTU

is lost; they will not go to OPEN state during power outage.

20.

20.1 The (up to) six analog inputs are defined as pins 7, 8, 11, 13, 15 and 17. (NOTE: Pins 15 and 17 are

20.1.2 If the signal to be transmitted is a 0 - 20mA current source, the input pin must have a 250W resistor

ANALOG INPUTS

inputs only if PJ101 and PJ102 are configured as inputs.)

These inputs can be of two types: voltage or current loop. These inputs are used to digitize the analog

signal and transmit it to another DATAFLOW RTU.

20.1.1 If the signal to be read is a voltage source, the input pin is ready as is. The following table defines

the characteristics of the input pin working as voltage input. Absolute limits define the safe operating

region; operating outside this region can damage the device.

PARAMETER MINIMUM MAXIMUM

INPUT RANGE 0 V 5 V

SOURCE IMPEDANCE 1000 Ω

ABSOLUTE LIMITS -2 V 7 V

placed between the pin and GROUND. The following table defines the characteristics of the input pin

working as a current input. Absolute limits define the safe operating region. Operating outside this region

can damage the device.

See Figure A7, below, for an example of connecting a current loop sensor to the DATAFLOW RTU.

PARAMETER MINIMUM MAXIMUM

INPUT RANGE 0 mA 20 mA

SOURCE IMPEDANCE (Ev-5) / .02 Ω

ABSOLUTE LIMITS -8 mA 28 mA

NOTE: Ev is excitation voltage

( A-16 )

Page 23

DATAFLOW RTU

POWER OUT

ANALOG IN

ANALOG IN GND

RESISTOR

SENSOR

RESISTOR

DATAFLOW RTU

POWER OUT

ANALOG IN

ANALOG IN GND

SENSOR

V

EXCITATION

VOLTAGE

USING DATAFLOW RTU

AS THE EXCITATION VOLTAGE

Ω

250

USING AN EXTERNAL SOURCE

AS THE EXCITATION VOLTAGE

Ω

250

DATAFLOW RTU

Figure A7 - Connecting a Current loop sensor to a DATAFLOW RTU analog input.

20.2 All analog inputs are non-isolated. All analog measurements are referenced to GROUND. Take care

when connecting the DATAFLOW RTU to external sensors.

20.3 The user can invert the input state of a DATAFLOW RTU if desired, which will cause a DATAFLOW RTU

that reads an analog signal as full scale to transmit the signal status as zero scale to another

DATAFLOW RTU. This inversion allows a positive transfer function signal to control a negative transfer

function signal without external circuitry.

20.4 Sensor excitation voltage may be supplied by the DATAFLOW RTU, using the J101 Power Out pin. For

this configuration, make sure to not exceed the maximum current drive of the pin, and ascertain your

sensor will operate on a supply voltage of Vsupply-5Volts.

21. ANALOG OUTPUTS

21.1 The two analog outputs are defined to be pins 15 and 17. (NOTE: Pins 15 and 17 are outputs only if

PJ101 and PJ102 are configured as outputs.)

These outputs are two low power outputs hardware configured as either a voltage source or a current

sink. All analog outputs are referenced to GROUND.

21.1.1 If the output pin is desired to be a voltage source, correctly set the hardware configuration. The pin is to

be hardware-configured as an output and as a voltage source. The following table defines the

characteristics of the output pin set as a voltage source. Attempting to drive a load less than the minimum

will cause incorrect output and can possibly damage the device.

PARAMETER MINIMUM MAXIMUM

OUTPUT RANGE 0 V 5 V

LOAD RESISTANCE 1000 Ω

( A-17 )

Page 24

Installation/Operation

D

U

POWER O U T

ANALOG OUT

ANALOG OUT GND

IND IC ATOR

D

U

POWER O U T

ANALOG OUT

ANALOG OUT GND

V

21.1.2 If the output pin is to be a current sink, correctly set the hardware configuration. The pin is to be

hardware configured as an output and as a current source. The following table defines the characteristics

of the output pins set as a current sink. Attempting to drive a load less than the minimum will cause

incorrect output and possibly can damage the device.

See Figure A8, below, for an example of how to connect a current loop meter to the DATAFLOW RTU.

PARAMETER MINIMUM MAXIMUM

OUTPUT RANGE 0 mA 20 mA

LOAD RESISTANCE (Ev-5.5)/.02 Ω

NOTE: Ev is excitation voltage

USING DATAFLOW RTU

AS THE EXCITATION VO LTA G E

ATAFLOW RT

USING AN EXTERNAL SOURCE

AS THE EXCITATION VO LTA G E

ATAFLOW RT

INDICATOR

EXCITATION

VOLTAGE

Figure A8. - Connecting a Current loop indicator to a DATAFLOW RTU analog output

21.2 The analog outputs can be programmed to have both initial and fail-safe conditions. The initial condition

forces the output to a desired state at power ON of the device. The fail-safe condition forces the output to

a desired state if an RF data link problem is detected. Refer to DATAFLOW RTU Software/Programmers

Manual for details on setting these conditions.

21.3 Meter excitation voltage may be provided by the DATAFLOW RTU using the Power Out pin of connector

J101. If the Power Out pin is used as the excitation supply make sure that the maximum current drive of

the pin is not exceeded and that your indicator will operate on a supply voltage of Vsupply-5.5Volts.

21.4 It is not recommended to use the analog output as a warning indicator. If used, it is not available to be

mapped to the corresponding analog input of the other unit; meaning that a DATAFLOW RTU having an

analog output used in this manner can have only one analog signal sent to it. NOTE: Be sure to not

exceed the load drive capability if an analog output is used for a warning indicator.

( A-18 )

Page 25

Software/Programming DATAFLOW RTU

Software/ Programming Table of Contents

SECTION TITLE PAGE NO.

1 Introduction B-1

2 Operation B-1

3 Microprocessor Updates B-1

4 Programming Kit B-1

5 Programming Software B-3

6 MODBUS Memory Map B-11

7 Technical Notes B-13

8 Application Examples B-15

Software/ Programming Table of Figures

TITLE PAGE NO.

B1 - Configuration Screen B-13

B2 - Example 1 RTU ID 1 Wiring Diagram B-26

B3 - Example 1 RTU ID 2 Wiring Diagram B-27

B4 - Example 2 RTU ID 1 Wiring Diagram B-28

B5 - Example 2 RTU ID 2 Wiring Diagram B-29

B6 - Example 2 RTU ID 3 Wiring Diagram B-30

B7 - Example 4 RTU ID 1 Wiring Diagram B-31

B8 - Example 4 RTU ID 2 Wiring Diagram B-32

B9 - Example 5 RTU ID 1 Wiring Diagram B-33

B10 - Example 5 RTU ID 2 Wiring Diagram B-34

B11 - Example 5 RTU ID 3 Wiring Diagram B-35

B12 - Example 6 RTU ID 1 Wiring Diagram B-36

B13 - Example 6 RTU ID 1 Wiring Diagram B-37

( B-i )

Page 26

1. INTRODUCTION

DATAFLOW RTU

1.1 The DATAFLOW RTU from OMEGA is a complete wireless telemetry system designed to

deliver industrial instrumentation signals from a source to other instruments via radio frequency

communications. The DATAFLOW RTU allows you to access industrial measuring devices in

remote locations without running wires, installing microwave links or leasing a telephone line.

OMEGA DATAFLOW RTU and MODBUS radio communications equipment replaces these

methods.

1.2 Manual Part B is intended to provide information needed for the programming and MODBUS

control of OMEGA DATAFLOW® RTU systems. The intended readers are people familiar with

industrial instrumentation. A basic understanding of radio communi-cations is helpful. The

included information is valid only for models listed on the cover.

2.

2.1 DATAFLOW RTU is a radio telemetry system that operates on either UHF-FM (450-470 MHz

2.2 All DATAFLOW RTU systems require FCC licensing.

3.

3.1 A microprocessor, the main controlling device of a DATAFLOW RTU, is located in a socket on

3.2 The microprocessor firmware version available when this manual was printed is Version 3.27.

3.3 Custom software is also available. Call OMEGA for help in determining if custom software is

OPERATION

with transmitter power of 2 Watts or 5 Watts); or VHF-FM (150 - 165 MHz, 136 - 151 MHz,

160 - 174 MHz with transmitter power of 5 Watts). An RTU system operating in the UHF-FM

band at 2 Watts with directional antennas and 50-foot towers has an effective range of 20 to 25

miles over level terrain. Changes in the frequency of operation, transmitter power, terrain and

antenna structure will affect the range of the link.

MICROPROCESSOR UPDATES

the Control Board. Socket configuration provides ease in replacing or updating microprocessor

firmware.

(In Version 3.x, x represents the [number] designation of a minor revision.) OMEGA Users

Guide for DATAFLOW RTU is written for all 3.2 minor designation number DATAFLOW RTU

microprocessors.

cost-effective for you.

4.

4.1 A programming kit for user configuration, OMEGA part number RTU-PCPK, is available on

4.2 The programming kit RTU-PCPK, consists of:

PROGRAMMING KIT

separate purchase. It is for connecting and providing power to the DATAFLOW RTU, and for

connecting a MODBUS PC controller to the DATAFLOW RTU.

· (1) AC Power Supply, OMEGA part number RTU-PS

· (1) Computer Cable, OMEGA part number RTU-9/RTC-PAS

· (1) DATAFLOW RTU Cable, OMEGA part number RTU-PCPC

· (1) RTU Programming Software Disk, OMEGA part number RTU-PCPS-3.05

NOTE: You can download the RTU-PCPS-3.05 software from the OMEGA website at

<www.dasieee.com/>

( B-1 )

Page 27

Software/Programming

4.2.1 The AC Power Supply, OMEGA part number RTU-PS, converts 110 Volts AC to a DC voltage

for use by the DATAFLOW RTU. The power supply provides power to the RTU when RTU

programming software is being used, and also provides power to the RTU, if it is to be

connected to a MODBUS PC controller.

CAUTION:

Plug the power supply only into a 110 VAC outlet. AC Power Supply, OMEGA

part number RTU-PS is intended only for indoor use at normal room temperatures.

It is not intended to provide protection from water or any other contaminants; it is

not intended to function over the full temperature range of the DATAFLOW RTU.

To correctly use the power supply, plug the two-pronged end into a 110 VAC

50-60 Hz wall outlet. Plug the 2.1 mm power jack into the 2.1 mm power receptacle

of the RTU-PCPC cable.

NOTE: The AC Power Supply furnished with the programming kit is not guaranteed to provide

adequate current to the RTU in HIGH (5W) power mode. When the transceiver is operating in

the HIGH power mode, DC power supply of 12 Volts and 2.5 Amps minimum is required. For

external power supply connection, mate the coaxial power connector of the RTU-PCPC cable

to a coaxial power connector, Radio Shack part number 274-1569 or equivalent, having an

outer diameter of 5.5 mm and an inner diameter of 2.1 mm.

4.2.2 The Computer Cable, OMEGA part number RTU- 9/RTC-PAS, connects the 25-pin PC compatible

COM port to the RTU-PCPC cable. Plug the 25-pin connector into the computer port and the

modular telephone jack into the RTU-PCPC.

CAUTION:

Computer Cable, OMEGA part number RTU-9/RTC-PAS is intended to operate at normal room

temperatures; it is not intended to function over the full temperature range of the DATAFLOW RTU.

NOTE: If the COM port has a 9-pin connector, a 9-pin to 25-pin serial port adapter is required.

The adapter is not included with the programming kit.

4.2.3 DATAFLOW RTU Cable, OMEGA part number RTU-PCPC is used to connect the RTU to the

power supply and the computer cable. Plug the 7-pin circular connector of the RTU-PCPC into

the 7-pin connector of the RTU.

CAUTION:

DATAFLOW RTU Cable, OMEGA part number RTU-PCPC is intended to operate at normal room

temperatures, it is not intended to function over the full temperature range of the DATAFLOW RTU.

( B-2 )

Page 28

DATAFLOW RTU

4.2.4 RTU Programming Software Disk, OMEGA part number RTU-PCPS-3.0, provided with the

programming kit to facilitate configuration of a DATAFLOW RTU is version 3.0. To install it on

the computer hard drive, insert the 3.5" diskette into the floppy drive, select that drive and type

INSTALL.EXE. Follow the instructions on the computer monitor screen to load the software

onto the hard drive. DATAFLOW RTU programming software is not copy-protected; it may be

copied, or loaded onto more than one computer.

5.

5.1 The DATAFLOW RTU programming software is a DOS-based executable program. System

5.2 Menus and function keys are used for program navigation. Execute menu choices by pressing

5.3 The user interfaces the programming software by modifying highlighted fields of the monitor

5.4 The <F3> and <F4> function keys are used in several fields of the programming software. The

5.4.1 The <F3> UPLOAD key executes the upload function by causing the computer to read the RTU

DATAFLOW RTU PROGRAMMING SOFTWARE

requirement is a PC-compatible computer with a serial port. The availability of a mouse and a

printer is helpful, but not required.

the key of the corresponding menu choice number or by clicking the mouse on the menu

choice. Function key commands are executed when they are displayed by pressing the

corresponding function key or by clicking the mouse on the command.

screen display. Position the cursor in the chosen highlighted field, then type in the desired text.

The cursor can be moved using the mouse, or shifted to the next field by pressing the <TAB>

key. Press <SHIFT> <TAB> to shift the cursor to the previous field. The <ENTER> key, the

arrow keys and page control keys can also be used to move the cursor.

Press the <F1> FIELD HELP key at any time. A Help dialog box will appear on the monitor

screen with a brief explanation of the selected field.

<F3> UPLOAD key transfers configuration data from the DATAFLOW RTU to the computer.

The <F4> DOWNLOAD key transfers configuration data from the computer to the DATAFLOW

RTU. UPLOADed and DOWNLOADed data is transferred over the serial link.

configuration from the DATAFLOW RTU. When the configuration is successfully read, all

programming field values are updated to the current RTU configuration.

NOTE: If an upload is unsuccessfully attempted, none of the field values will update. The

computer indicates an unsuccessful upload by displaying a message in the lower right corner of

the monitor screen and by sounding a two-tone beep.

5.4.2 The <F4> DOWNLOAD key executes the download function by causing the computer to write

all current field values to the DATAFLOW RTU by sending 16 sequential messages.

NOTE: If one or more of these messages is unsuccessfully sent, the RTU configuration may

be corrupted. The computer indicates an unsuccessful download by displaying a message in

the lower right corner of the monitor screen and by sounding a two-tone beep.

When these signals of an unsuccessful download are given, attempt the download operation

again. When the download is successful, the current field values are successfully written so the

RTUs configurations are the same as the computer field values.

( B-3 )

Page 29

Software/Programming

5.5 The <F5>, <F6> and <F9> function keys are used in several fields of the programming

software to perform file functions. The <F5> READ DISK key transfers file data from the

computer hard disk to the computer screen field values. The <F6> WRITE DISK key transfers

file data from the computer-screen field values to the computer hard disk. The <F9> DIR key

displays all files of the proper type that are on the computer hard disk.

CAUTION:

To prevent loss of configuration data, save all RTU configuration files to the hard disk.

NOTE: Selecting a file with the <F9> DIR key DOES NOT LOAD the file. Use the <F5> READ

FILE key after the <F9> DIR key to load the selected file.

5.6 If a printer is connected to the computer system, press the <PRINT SCREEN> key at any time

during the operation of the programming software to generate a hard copy of the current

configuration data.

5.7 A Help file is available for several areas of the programming software. The user can display,

read and close the Help text file while running and programming the software. A copy of the

Help text is included in this manual on pages B-5 to B-10.

NOTE: In the event of a difference between the included text of this file and the actual file in

the software, the computer file supersedes.

5.8 Software Utilities Menu: refer to UTILITIES, Item 3, for system diagnostics and remote

monitoring, which is also covered on pages B-9 - B-10 of this manual.

( B-4 )

Page 30

>>> RTU PROGRAMMER VERSION 3.03 960724 HELP FILE <<<

1.0 RTU System Configuration Screen:

The system configuration screen provides an area for the user to configure

system parameters, send list, repeat list, and fail-safe states. It allows access to

RTU configuration and disk files. It also provides access to the input/output

configuration and the SCADA configuration.

1.1 System Parameters:

The frequency must be the same for all RTUs in a system. The frequency must

be a multiple of the channel spacing. The standard channel spacing for UHF

channels (RTU-450s) is 12.5kHz. VHF radios (RTU-150s) may operate at

either 5 kHz or 12.5 kHz channel spacing. UHF RTUs can be programmed to

operate on either high or low power. High power is approximately 5 Watts. Low

power is approximately 2 Watts. VHF RTUs can only operate on high power.

The ID must be unique for each RTU in the system. Other MODBUS devices in

the system must each also have a unique ID. All RTUs which communicate together

must have the same group number. For version 3.27 firmware, the group is limited to 1.

Multiple groups will be supported in a later version of the firmware.

DATAFLOW RTU

Each RTU can send periodic status messages that are not triggered by a change

on the inputs. The time between these periodic check-ins is variable from 1 second

to 48 days. A check-in time of zero indicates that the periodic check-in is not used,

and messages will be sent on input change only. The check-in interval must be larger

than the number of message attempts times the transmit time (about 180 ms) plus the

listen time. If an acknowledge is not received, the sending RTU tries to send the

message again until the number of message attempts has been exhausted. If, at the

end of these attempts, an acknowledge has not been received, the unit will set its

fail-safe condition.

Some of the variables particular to the radio operation of the RTU are displayed on

the System configuration screen. These values include the carrier detect level, back-off

time, cold start time, and attack time. These values are preset and should not be altered

without consultation with the factory.

The serial port baud rate is selectable between 1200, 2400, 4800, and 9600. Version 3.0

software locks the baud rate at 9600 baud. The radio communicates at a constant 1200

baud. This RF data rate is not selectable.

The RTU can be programmed to operate in sleep mode. In this mode, the RTU acts

as an input device only. The RTUs radio receiver is turned off during normal operation.

The RTU transmits only on status change or at a set check-in interval. After message

transmission, the RTU turns on the receiver and waits for an acknowledge. It then turns

off the receiver and goes back to sleep. The maximum time that the sleeping units

receiver stays on is equal to the awake time.

( B-5 )

Page 31

Software/Programming

>>> RTU PROGRAMMER VERSION 3.03 HELP FILE <<<(continued)

Enabling RF spy mode on one RTU allows that RTU to report all incoming RF

messages over the serial link. These messages can be displayed using the RF Spy

screen available from the Utilities menu. While the RF Spy feature is enabled, the

unit will only operate in RF Spy mode and will not respond to the RF messages.

1.2 Send List:

The send list indicates up to four other RTUs to which this RTU can send its status.

All inputs will be sent to each of the units on the list. Enter an ID of 0 (zero) for any

unused entries. If any of these listed units fail to acknowledge the message, the

fail-safe state indicated by the letter next to that units ID will be set. The lettered

fail-safe states are listed in the lower right corner of the system configuration screen.

1.3 Repeat List:

When this unit receives a message from another unit, it can use the message AND

send it along to other RTUs. This information is configured in the repeat list. Each

incoming message can be repeated to up to four RTUs. The first column indicates

the unit that originates the message and the next four columns show the IDs of the

units which will receive the message.

1.4 Fail-Safe States:

If a unit fails to receive an acknowledge a fail-safe condition can be set. Each of the

four outputs can be set to a distinct fail-safe condition. The analogs can be set to any

value from 0% to 100%. A no change option is also available. For the analog outputs,

the no change is indicated by a 999%. Any number over 101% will be interpreted as a

no change. The programmer will automatically replace this number with 999% when it

downloads the information to the RTU. For the digital outputs, the choices are: open on fail,

close on fail, or no change on fail. The R column indicates whether the output should revert

to its initial condition when the signal is re-acquired. The choices for the field are yes or no.

Example 1: Revert to initial condition is selected for a digital output.

The initial condition for this output is relay open.

The fail-safe condition for this output is relay closed.

This output is not actively controlled by any other RTU.

The relay will be open when the system is started.

The relay will close when the RF link is lost.

The relay will open when the RF link is regained.

Example 2: Revert to initial condition is NOT selected for digital output.

The initial condition for this output is relay open.

The fail-safe condition for this output is relay closed.

This output is not actively controlled by any other RTU.

The relay will be open when the system is started.

The relay will close when the RF link is lost.

The relay will remain closed after the RF link is regained.

( B-6 )

Page 32

DATAFLOW RTU

>>> RTU PROGRAMMER VERSION 3.03 HELP FILE <<<(continued)

1.5 Message Line

The third line from the bottom of the RTU system configuration screen is the message

line. This line displays important information about the status of uploads, downloads,

disk reads, and disk writes.

1.6 Function Keys

The last two lines of the RTU system configuration screen form the function key menu.

To perform one of the listed tasks either press the related function key or click the

command with your mouse. Field help will display a short help message for the field

where the cursor is. Full help will display this text file.

Upload will read the contents of the RTU currently connected to the serial programming

cable and display the configuration on the screen. Download will cause the currently

displayed configuration to be written to the RTU. Read disk will get the configuration

stored in the file named in the file name field at the top of the screen and display this

configuration on the screen. Write disk will save the currently displayed configuration to

the file named at the top of the screen.

Selecting I/O CONFIG will display the RTU input/output configuration screen. SCADA

CONFIG will display the RTU SCADA configuration screen. Press F9 to display a list of

.USR files which you can select. F10 will return the program to the main screen.

2.0 RTU Input/Output Configuration Screen: