Page 1

PARALLEL PNEUMATIC

GRIPPERS MINIATURE SERIES RPMC

CLEAN ROOM AND HARSH ENVIRONMENTS

DESIGNED FOR MANIFOLD MOUNTING

RPMC Series

l Precision Gripping—Preloaded V Roller Bearings

Eliminate Side Play Resulting in Excellent

Part Positioning

l Clean Room Grease and Corrosion Resistant

Shields Allow for Use in Clean Room and

Harsh Environments

l Accuracy of 0.05 mm (0.002") and Repeatability

of 0.03 mm (0.001")

l Rated Grip Force @ 7 Bar (100 psi), 36 N (8 lbs)

l Compact Design for Gripping Small Parts in

Small Places

l Rigid and Low Friction Design Allows for Longer

Finger Lengths for Use on Delicate Parts

l Group Multiple Grippers in Close Array Using Top

Manifold Mounting Surface

l Up to 5 Million Cycles in Typical Operation and

10 Million with Maintenance

l Operating Temperature -35 to 80°C (-30 to 180°F)

l System Requires 3 to 7 bar (5 to 100 psi)

Dry Filtered (40 Micron or Better) Air Supply

l Requires 4-Way, 2 Position Valve and Regulator

for Delicate Parts

Small Part

Handling

RPMC-3M, holding a 25.4 mm (1")

long 1PT100KN2515CLA ceramic

wire-wound class A platinum RTD

element shown larger than actual size.

Note: Grippers and

manifold are shown for

reference only. Tooling is

customers responsibility.

PRODUCT FEATURES

Preload Bearings

Bearings are preloaded for maximum

support and zero side play

Hard Coat Anodize

The body has hard-coat anodize

60 RC with PTFE impregnation

Purge/Scavenge Port

Purge/Scavenge port for extreme

environments from dirty and gritty to

clean-room Class 10 or better

Adjustable Preload Screw

Adjustable preload screw allows for adjustment

of preload on roller bearings

Contaminants

Units are lubricated with a

C-52

Clean-Room

clean-room

grade grease

Quality Components

External components are made from corrosion

resistant materials for resistance to de-ionized

water or for use in FDA and medical parts

handling applications

One Piece Body

One piece lightweight

aluminum body

Slip Fit Dowel Pin Holes

Located in body and jaws

Stainless Steel Cover

Stationary and non-contacting

cover eliminates the possibility

of particle generation

Roller Bearings

Patented Dual-“V” roller

bearings provide low friction

rolling motion and maximum

rigidity for fingers

Page 2

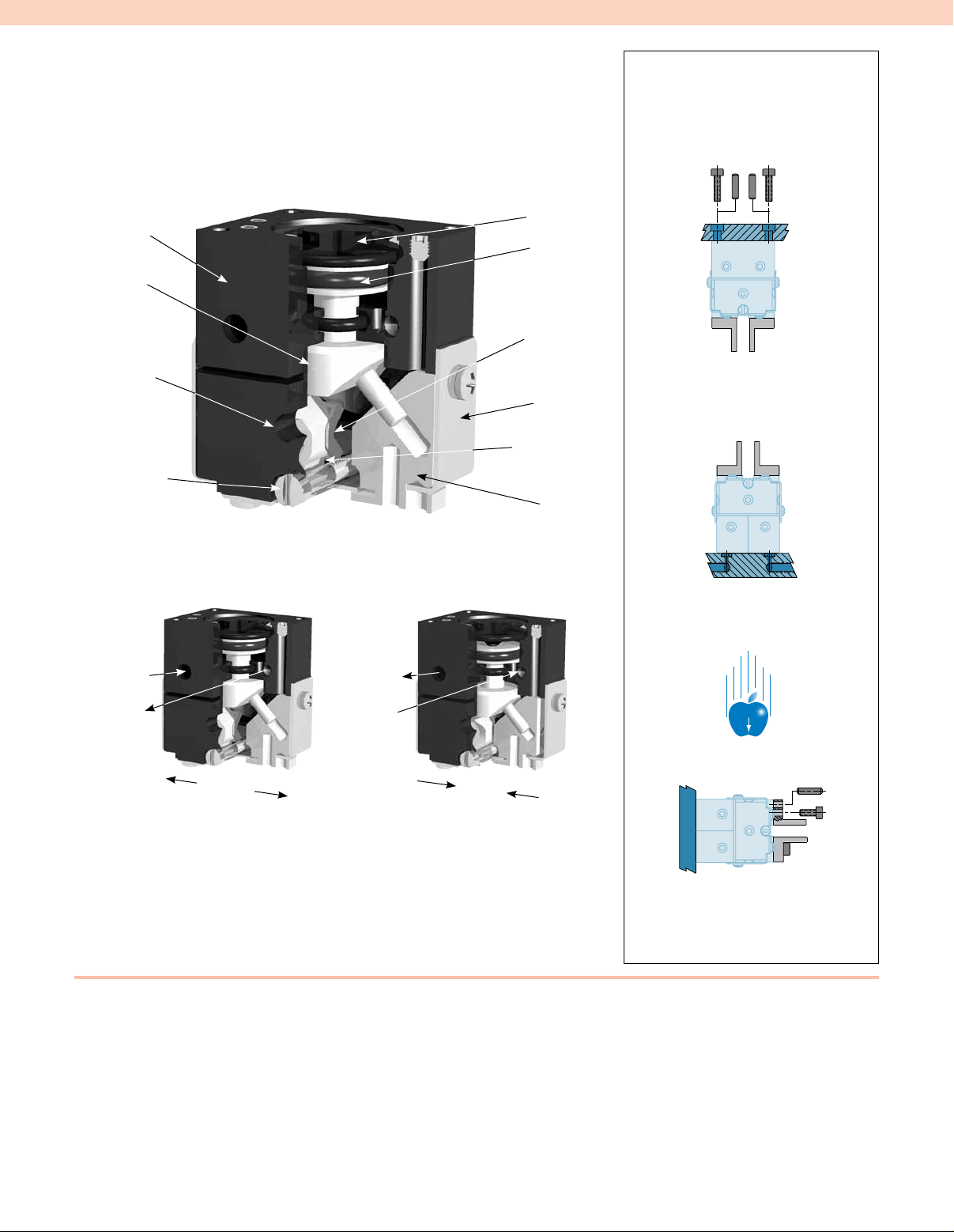

OPERATING PRINCIPLE

Body

Double Pin

Wedge

Purge/Scavenger

Port

MOUNTING INFORMATION

Grippers can be mounted and

operated in any orientation.

Cap

Piston

Roller

Bearings

and Cages

Body mounts with screws and locates

with slip-fit dowel pins for accuracy.

Shield

Preload

Roller Way

Adjustment

Screw

Pressure

Exhaust

Open

Position

Exhaust

Pressure

Closed

Position

Jaw

l A double acting piston is connected by a shaft to a double sided pin wedge.

l The pin wedge slides in a hole located in each of the jaws converting vertical

motion of the wedge into horizontal synchronous motion of the jaws.

l This gripper is suitable for internal or external gripping.

Unit has top manifold ports.

G

Fingers attach to jaws with screws and

locate with dowel pins or by keying.

TECHNICAL SPECIFICATIONS

Pneumatic Specifications

Pressure Operating Range: 3 to 7 bar

(40 to 100 psi)

Cylinder Type: Double acting

Dynamic Seals:

Internally lubricated Buna-N

Valve Required to Operate:

4-way, 2-position

Air Quality Requirements

Air Filtration: 40 micron or better

Air Lubrication: Not necessary*

Air Humidity: Low moisture content (dry)

Temperature Operating Range

Buna-N Seals (Standard): -35 to 80°C

(-30 to 180°F)

FKM Seals (Optional): -30 to 120°C

(-20 to 250°F)

C-53

Maintenance Specifications

Expected Life:

Normal Application: 5 million cycles

With Preventative Maintenance:

10+ million cycles*

Field Repairable: Yes

Seal Repair Kits Available: Yes

*Addition of lubrication will greatly increase

service life.

Page 3

2 X Ø 2H7 X 1.5 DP

(0.0787 SF X 0.06 DP)

2 X M2 X 0.4 X .09 DP

(0.315)

8.0

2 X M2 X 0.4

PURGE OR

SCAVENGE

PORTS

WITH

REMOVEABLE

PLUGS

OPEN

2 X M2 X 0.4

AUX. AIR PORT

(CLOSE)

2 X Ø 2H7 X 1.5 DP

(0.0787 SF X 0.06 DP)

2 X M2 X 0.4 X .09 DP

VIEW A-A

2 X Ø (0.0787 SF X .13) DP

Ø 2 H7 X 3.3 DP

2 X M2 X 4.5 (0.18) DP

19.5

(0.768)

23

(0.89)

12.00

(0.4724)

16.0

(0.630)

16.00

(0.6300)

2.5

(0.098)

(.224 .001)

5.69 .03

(0.315)

8.0

4 X 2.8

(0.112)

6.50

(0.2559)

3.5

(0.138)

13.4

(0.528)

C

L

C

L

C

L

Third Angle

Projection

Dimensions are

symmetrical about

centerline

Metric mm

All Dowel Holes are SF (Slip Fit).

Locational Tolerance

±.0005" or [±.013mm]

UNLESS OTHERWISE NOTED ALL

TOLERANCES ARE AS SHOWN BELOW

Metric Threads

Course Pitch

Imperial (inch)

(0.00) = (±.01)

(0.000) = (±.005)

(0.0000) = (±.0005)

0. = ±.25

0.0 = ±.13

0.00 = ±.013

OPEN

2 X Ø 2H7 X 1.5 DP

(0.0787 SF X 0.06 DP)

2 X M2 X 0.4 X .09 DP

A A

VIEW A-A

2 X Ø (0.0787 SF X .13) DP

Ø 2 H7 X 3.3 DP

2 X M2 X 4.5 (0.18) DP

CLOSE

2 X M3 X 0.5 AIR PORT

(OPEN)

19.5

(0.768)

23

(0.89)

12.00

(0.4724)

16.0

(0.630)

16.00

(0.6300)

4.5

(0.177)

10.5

(0.414)

2.5

(0.098)

(.224 .001)

5.69 .03

(0.315)

8.0

4 X 2.8

(0.112)

6.50

(0.2559)

3.5

(0.138)

13.4

(0.528)

19.2 (0.76) OPEN

16 (0.63) CLOSE

C

L

C

L

C

L

C

L

(0.630)

16.0

M3 X 0.5

PURGE OR

SCAVENGE

PORTS

(0.92)

23

2X (0.32)

8

Third Angle

Projection

Dimensions are

symmetrical about

centerline

Metric mm

All Dowel Holes are SF (Slip Fit).

Locational Tolerance

±.0005" or [±.013mm]

UNLESS OTHERWISE NOTED ALL

TOLERANCES ARE AS SHOWN BELOW

Metric Threads

Course Pitch

Imperial (inch)

(0.00) = (±.01)

(0.000) = (±.005)

(0.0000) = (±.0005)

0. = ±.25

0.0 = ±.13

0.00 = ±.013

2 X Ø 2H7 X 1.5 DP

(0.0787 SF X 0.06 DP)

2 X M2 X 0.4 X .09 DP

VIEW A-A

2.5

(0.098)

(.224 .001)

5.69 .03

(0.315)

8.0

4 X 2.8

(0.112)

6.50

(0.2559)

C

L

Third Angle

Projection

Dimensions are

symmetrical about

centerline

Metric mm

All Dowel Holes are SF (Slip Fit).

Locational Tolerance

±.0005" or [±.013mm]

UNLESS OTHERWISE NOTED ALL

TOLERANCES ARE AS SHOWN BELOW

Metric Threads

Course Pitch

Imperial (inch)

(0.00) = (±.01)

(0.000) = (±.005)

(0.0000) = (±.0005)

0. = ±.25

0.0 = ±.13

0.00 = ±.013

2 X Ø 2H7 X 1.5 DP

(0.0787 SF X 0.06 DP)

2 X M2 X 0.4 X .09 DP

VIEW A-A

(0.315)

8.0

6.50

(0.2559)

C

L

PORTS

WITH

PLUGS

OPEN

2 X M2 X 0.4

(CLOSE)

2 X Ø 2H7 X 1.5 DP

(0.0787 SF X 0.06 DP)

2 X M2 X 0.4 X .09 DP

A A

VIEW A-A

2 X Ø (0.0787 SF X .13) DP

Ø 2 H7 X 3.3 DP

2 X M2 X 4.5 (0.18) DP

CLOSE

2 X M3 X 0.5 AIR PORT

(OPEN)

19.5

(0.768)

23

(0.89)

12.00

(0.4724)

16.0

(0.630)

16.00

(0.6300)

24.0

4.5

(0.177)

10.5

(0.414)

2.5

(0.098)

(.224 .001)

5.69 .03

(0.315)

8.0

4 X 2.8

(0.112)

6.50

(0.2559)

3.5

(0.138)

13.4

(0.528)

19.2 (0.76) OPEN

16 (0.63) CLOSE

C

L

C

L

C

L

C

L

(0.630)

16.0

M3 X 0.5

PURGE OR

SCAVENGE

PORTS

(0.92)

23

2X (0.32)

8

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

20

18

16

13

11

9

7

4

2

0

lbs.

N

EFFECTIVE FINGER LENGTH - L

- E C R O F R E G N I F 2 / F

GRIP FORCE PER FINGER

0

0

.5

13

.25

6

.75

19 1 25

1.5 in.

38mm

WARNING!

DO NOT EXCEED

MAXIMUM EFFECTIVE

FINGER LENGTHS

1.25

32

40 PSI [2.7 bar]

20 PSI [1.4 bar]

80 PSI [5.5 bar]

60 PSI [4.1 bar]

100 PSI [7 bar]

Third Angle

Projection

Dimensions are

symmetrical about

centerline

Metric mm

All Dowel Holes are SF (Slip Fit).

Locational Tolerance

±.0005" or [±.013mm]

UNLESS OTHERWISE NOTED ALL

TOLERANCES ARE AS SHOWN BELOW

Metric Threads

Course Pitch

Imperial (inch)

(0.00) = (±.01)

(0.000) = (±.005)

(0.0000) = (±.0005)

0. = ±.25

0.0 = ±.13

0.00 = ±.013

PARALLEL PNEUMATIC GRIPPER—

MINIATURE CLEAN ROOM SERIES RPMC-1M

Dimensions: mm (inch)

2 X M2 X 0.4

PURGE OR

SCAVENGE

PORTS

WITH

REMOVEABLE

PLUGS

(0.138)

2 X M2 X 0.4

AUX. AIR PORT

(CLOSE)

C

L

3.5

N

20

18

16

13

- E C R O F R E G N I F 2 / F

11

9

7

4

2

0

24.0

(0.945)

lbs.

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

0

0

23

(0.89)

19.5

(0.768)

C

L

13.4

(0.528)

16.00

(0.6300)

8

2X (0.32)

GRIP FORCE PER FINGER

.5

.25

13

6

EFFECTIVE FINGER LENGTH - L

RPMC-1M shown

larger than actual size.

4.5

(0.177)

100 PSI [7 bar]

80 PSI [5.5 bar]

60 PSI [4.1 bar]

40 PSI [2.7 bar]

20 PSI [1.4 bar]

.75

19 1 25

2 X M2 X 4.5 (0.18) DP

12.00

16.0

(0.630)

(0.4724)

Ø 2 H7 X 3.3 DP

2 X Ø (0.0787 SF X .13) DP

CLOSE

10.5

(0.414)

C

L

19.2 (0.76) OPEN

16 (0.63) CLOSE

DO NOT EXCEED

MAXIMUM EFFECTIVE

FINGER LENGTHS

1.25

32

O-RING FOR MANIFOLD OPTION:

(C’BORE Ø.125 X .022.001 DP)

FOR RPMC-3M TOP PURGE PORTS:

(C’BORE Ø.188/.183

X .029.001 DP)

M3 PLUG FOR

MANIFOLD OPTION

OPEN

(0.630)

A A

WARNING!

1.5 in.

38mm

4 X 2.8

(0.112)

5.69 .03

(.224 .001)

2 X M3 X 0.5 AIR PORT

(OPEN)

(0.92)

23

M3 X 0.5

PURGE OR

SCAVENGE

PORTS

16.0

UNLESS OTHERWISE NOTED ALL

TOLERANCES ARE AS SHOWN BELOW

Dimensions are

symmetrical about

centerline

Metric Threads

Course Pitch

2.5

(0.098)

8.0

(0.315)

6.50

(0.2559)

2 X M2 X 0.4 X .09 DP

2 X Ø 2H7 X 1.5 DP

(0.0787 SF X 0.06 DP)

C

L

SPECIFICATIONS RPMC-1M

Total Rated Grip Force

F @ 100 psi, 7 bar 36 N (8 lb)

Stroke 3.2 mm (0.13")

Weight 0.024 Kg (0.052 lb)

Pressure Range 3 to 7 bar (40 to 100 psi)

Cylinder Bore Ø 10 mm (0.394")

Displacement 0.13 cm3 (0.008"3 )

Temp Range

(Standard Seals) -35 to 80°C (-30 to 180°F)

Temp Range

(Viton® Seals) -30 to 120°C (-20 to 250°F)

Actuation 0.10 sec

Accuracy ±0.05 mm (±0.002")

Repeatability ±0.03 mm (±0.00")

Valve Required to Actuate 4-way, 2-position

L

Z

T

C

M

LOADING CAPACITY† STATIC DYNAMIC

Maximum Tensile T 89 N (20 lbs) 31 N (7 lbs)

Maximum Compressive C 89 N (20 lbs) 31 N (7 lbs)

Maximum Moment Mx 1 Nm (12"/lbs) 0.5 Nm (4"/lbs)

Maximum Moment My 2 Nm (15"/lbs) 0.6 Nm (5"/lbs)

Maximum Moment Mz 1 Nm (12"/lbs) 0.5 Nm (4"/lbs)

C-54

†

Capacity are per set of jaws and not simultaneous.

Third Angle

Projection

Metric mm

0. = ±.25

0.0 = ±.13

0.00 = ±.013

Y

F/2

X

All Dowel Holes are SF (Slip Fit).

Locational Tolerance

±.0005" or [±.013mm]

Imperial (inch)

(0.00) = (±.01)

(0.000) = (±.005)

(0.0000) = (±.0005)

Z

M

Z

X

F/2

Y

M

Page 4

2 X Ø 2H7 X 1.5 DP

(0.0787 SF X 0.06 DP)

2 X M2 X 0.4 X .09 DP

VIEW A-A

(0.315)

8.0

6.50

(0.2559)

C

L

2 X M2 X 0.4 X .18 DP

2 X M2 X 0.4

PURGE OR

SCAVENGE

PORTS

WITH

REMOVEABLE

PLUGS

OPEN

VIEW A-A

2 X M2 X 0.4

(CLOSE)

2 X Ø 2 H7 X 3.3 DP

(Ø .0787 SF X .13 DP)

2 X M2 X 0.4 X .09 DP

2 X Ø 2H7 X 1.5 DP

(Ø 0.0787 SF X 0.06 DP)

21.0

(0.827)

24.0

(0.94)

12.00

(0.4724)

16.0

(0.630)

13.4

(0.528)

16

(0.6300)

2X 3.5

(0.138)

8.0

(0.315)

2.8

(0.112)

5.69 .03

(0.224 0.100)

2.5

(0.098)

6.50

(0.2559)

C

L

C

L

C

L

2 X M2 X 0.4 X .18 DP

2 X M2 X 0.4

PURGE OR

SCAVENGE

PORTS

WITH

REMOVEABLE

PLUGS

M3 X 0.5

PURGE OR

SCAVENGE

PORT

OPEN

VIEW A-A

AA

2 X M2 X 0.4

A

UX. AIR PORT

(CLOSE)

2 X Ø 2 H7 X 3.3 DP

(Ø .0787 SF X .13 DP)

CLOSE

2 X M3 X 0.5 AIR PORT

(OPEN)

2 X M2 X 0.4 X .09 DP

2 X Ø 2H7 X 1.5 DP

(Ø 0.0787 SF X 0.06 DP)

21.0

(0.827)

24.0

(0.94)

12.00

(0.4724)

16.0

(0.630)

13.4

(0.528)

16

(0.6300)

2X 3.5

(0.138)

25.5

(1.005)

10.5

(0.414)

5.2

(0.206)

8.0

(0.315)

2.8

(0.112)

5.69 .03

(0.224 0.100)

2.5

(0.098)

6.50

(0.2559)

20.8 (0.82) OPEN

16 (0.63) CLOSE

C

L

C

L

C

L

C

L

17.0

(0.669)

2X .36

(9)

25

(0.98)

Viton

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

20

18

16

13

11

9

7

4

2

0

lbs.

N

EFFECTIVE FINGER LENGTH - L

- ECROF REGNIF 2/F

GRIP FORCE PER FINGER

0

0

.5

13

.25

6

.75191

25

1.5 in.

38mm

WARNING!

DO NOT EXCEED

MAXIMUM EFFECTIVE

FINGER LENGTHS

1.25

32

40 PSI (2.7 bar)

20 PSI (1.4 bar)

80 PSI (5.5 bar)

60 PSI (4.1 bar)

100 PSI (7 bar)

2 X M2 X 0.4 X .18 DP

PORTS

WITH

PLUGS

M3 X 0.5

PURGE OR

SCAVENGE

PORT

OPEN

VIEW A-A

AA

2 X Ø 2 H7 X 3.3 DP

(Ø .0787 SF X .13 DP)

CLOSE

2 X M3 X 0.5 AIR PORT

(OPEN)

2 X M2 X 0.4 X .09 DP

2 X Ø 2H7 X 1.5 DP

(Ø 0.0787 SF X 0.06 DP)

21.0

(0.827)

24.0

(0.94)

12.00

(0.4724)

16.0

(0.630)

13.4

(0.528)

16

(0.6300)

2X 3.5

(0.138)

25.5

(1.005)

10.5

(0.414)

5.2

(0.206)

8.0

(0.315)

2.8

(0.112)

5.69 .03

(0.224 0.100)

2.5

(0.098)

6.50

(0.2559)

20.8 (0.82) OPEN

16 (0.63) CLOSE

C

L

C

L

C

L

C

L

17.0

(0.669)

2X .36

(9)

25

(0.98)

2 X Ø 2H7 X 1.5 DP

(0.0787 SF X 0.06 DP)

2 X M2 X 0.4 X .09 DP

VIEW A-A

2.5

(0.098)

(.224 .001)

5.69 .03

(0.315)

8.0

4 X 2.8

(0.112)

6.50

(0.2559)

C

L

Third Angle

Projection

Dimensions are

symmetrical about

centerline

Metric mm

All Dowel Holes are SF (Slip Fit).

Locational Tolerance

±.0005" or [±.013mm]

UNLESS OTHERWISE NOTED ALL

TOLERANCES ARE AS SHOWN BELOW

Metric Threads

Course Pitch

Imperial (inch)

(0.00) = (±.01)

(0.000) = (±.005)

(0.0000) = (±.0005)

0. = ±.25

0.0 = ±.13

0.00 = ±.013

2 X M2 X 0.4 X .09 DP

2 X Ø 2H7 X 1.5 DP

8.0

(0.315)

PARALLEL PNEUMATIC GRIPPER—

MINIATURE CLEAN ROOM SERIES RPMC-2M

AUX. AIR PORT

Dimensions: mm (inch)

2 X M2 X 0.4

PURGE OR

SCAVENGE

2 X M2 X 0.4

PORTS

WITH

PLUGS

2X 3.5

(0.138)

C

L

REMOVEABLE

(CLOSE)

N

20

18

16

13

- ECROF REGNIF 2/F

11

9

7

4

2

0

(1.005)

lbs.

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

0

0

24.0

(0.94)

21.0

(0.827)

C

L

25.5

13.4

(0.528)

16

(0.6300)

5.2

(0.206)

2X .36

(9)

GRIP FORCE PER FINGER

100 PSI (7 bar)

80 PSI (5.5 bar)

60 PSI (4.1 bar)

40 PSI (2.7 bar)

20 PSI (1.4 bar)

.5

.25

13

6

EFFECTIVE FINGER LENGTH - L

RPMC-2M shown

larger than actual size.

(0.4724)

2 X Ø 2 H7 X 3.3 DP

(Ø .0787 SF X .13 DP)

(0.414)

2 X M2 X 0.4 X .18 DP

12.00

10.5

OPEN

16.0

(0.224 0.100)

(0.630)

CLOSE

2 X M3 X 0.5 AIR PORT

(OPEN)

17.0

(0.669)

C

L

20.8 (0.82) OPEN

16 (0.63) CLOSE

.75191

25

AA

WARNING!

DO NOT EXCEED

MAXIMUM EFFECTIVE

FINGER LENGTHS

1.25

1.5 in.

32

38mm

O-RING FOR MANIFOLD OPTION:

(C’BORE Ø.125 X .022.001 DP)

FOR RPMC-3M TOP PURGE PORTS:

(C’BORE Ø.188/.183

X .029.001 DP)

M3 PLUG FOR

MANIFOLD OPTION

5.69 .03

2.8

(0.112)

2.5

(0.098)

25

(0.98)

M3 X 0.5

PURGE OR

SCAVENGE

PORT

8.0

(0.315)

6.50

(0.2559)

VIEW A-A

2 X M2 X 0.4 X .09 DP

2 X Ø 2H7 X 1.5 DP

(Ø 0.0787 SF X 0.06 DP)

C

L

TOLERANCES ARE AS SHOWN BELOW

Dimensions are

symmetrical about

Metric Threads

SPECIFICATIONS RPMC-2M

Total Rated Grip Force

F @ 100 psi, 7 bar

Stroke 4.8 mm (0.19")

Weight 0.026 Kg (0.058 lb)

Pressure Range 3 to 7 bar (40 to 100 psi)

Cylinder Bore Ø 10 mm (0.394")

Displacement 0.20 cm

Temp Range

(Standard Seals)

LOADING CAPACITY† STATIC DYNAMIC

Temp Range

®

(Viton

Seals)

Actuation 0.10 sec

Accuracy ±0.05 mm (±0.002")

Repeatability ±0.03 mm (±0.001")

Valve Required to Actuate 4-way, 2-position

Z

L

C

Maximum Tensile T 89 N (20 lbs) 31 N (7 lbs)

Maximum Compressive C 89 N (20 lbs) 31 N (7 lbs)

Maximum Moment Mx 1 Nm (12"/lbs) 0.5 Nm (4"/lbs)

Maximum Moment My 2 Nm (15"/lbs) 0.6 Nm (5"/lbs)

Maximum Moment Mz 1 Nm (12"/lbs) 0.5 Nm (4"/lbs)

†

Capacity are per set of jaws and not simultaneous.

C-55

UNLESS OTHERWISE NOTED ALL

All Dowel Holes are SF (Slip Fit).

Third Angle

centerline

Course Pitch

Projection

Metric mm

0. = ±.25

0.0 = ±.13

0.00 = ±.013

Locational Tolerance

±.0005" or [±.013mm]

Imperial (inch)

(0.00) = (±.01)

(0.000) = (±.005)

(0.0000) = (±.0005)

36 N (8 lb)

3

(0.012"3 )

-35 to 80°C (-30 to 180°F)

-30 to 120°C (-20 to 250°F)

Z

M

Z

Y

T

M

F/2

X

M

X

F/2

Y

Page 5

2 X Ø 2H7 X 1.5 DP

(0.0787 SF X 0.06 DP)

2 X M2 X 0.4 X .09 DP

VIEW A-A

2.5

(0.098)

(.224 .001)

5.69 .03

(0.315)

8.0

4 X 2.8

(0.112)

6.50

(0.2559)

C

L

Third Angle

Projection

Dimensions are

symmetrical about

centerline

Metric mm

All Dowel Holes are SF (Slip Fit).

Locational Tolerance

±.0005" or [±.013mm]

UNLESS OTHERWISE NOTED ALL

TOLERANCES ARE AS SHOWN BELOW

Metric Threads

Course Pitch

Imperial (inch)

(0.00) = (±.01)

(0.000) = (±.005)

(0.0000) = (±.0005)

0. = ±.25

0.0 = ±.13

0.00 = ±.013

2X M2 X 0.4 X .09 DP

10.0

(0.394)

2 X Ø 2H7 X 1.5 DP

(0.0787 SF X 0.06 DP)

2 X M2 X 0.4 X .09 DP

VIEW A-A

(0.315)

8.0

6.50

(0.2559)

C

L

PARALLEL PNEUMATIC GRIPPER—

PORTS

WITH

PLUGS

2X M3 X 0.5 X .20 DP

OPEN

VIEW A-A

(CLOSE)

2X Ø3H7 X 5.0 DP

(Ø.1181SF X .20 DP)

2X Ø 2H7 X 1.5 DP

(Ø .0787SF X .06 DP)

2X M2 X 0.4 X .09 DP

26.5

(1.043)

30.0

(1.16)

11.00

(0.4330)

16.0

(0.630)

13.4

(0.528)

20.00

(0.7874)

2X 3.5

(0.138)

10.0

(0.394)

2.5

(0.098)

7.50

(0.2953)

(0.224±.001)

5.69±.03

2.8

(0.112)

C

L

C

L

C

L

2 X M2 X 0.4 X .18 DP

2 X M2 X 0.4

PURGE OR

SCAVENGE

PORTS

WITH

REMOVEABLE

PLUGS

M3 X 0.5

PURGE OR

SCAVENGE

PORT

OPEN

VIEW A-A

AA

2 X M2 X 0.4

A

UX. AIR PORT

(CLOSE)

2 X Ø 2 H7 X 3.3 DP

(Ø .0787 SF X .13 DP)

CLOSE

2 X M3 X 0.5 AIR PORT

(OPEN)

2 X M2 X 0.4 X .09 DP

2 X Ø 2H7 X 1.5 DP

(Ø 0.0787 SF X 0.06 DP)

21.0

(0.827)

24.0

(0.94)

12.00

(0.4724)

16.0

(0.630)

13.4

(0.528)

16

(0.6300)

2X 3.5

(0.138)

25.5

(1.005)

10.5

(0.414)

5.2

(0.206)

8.0

(0.315)

2.8

(0.112)

5.69 .03

(0.224 0.100)

2.5

(0.098)

6.50

(0.2559)

20.8 (0.82) OPEN

16 (0.63) CLOSE

C

L

C

L

C

L

C

L

17.0

(0.669)

2X .36

(9)

25

(0.98)

Viton

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

20

18

16

13

11

9

7

4

2

0

lbs.

N

EFFECTIVE FINGER LENGTH - L

- ECROF REGNIF 2/F

GRIP FORCE PER FINGER

0

0

.5

13

.25

6

.75191

25

1.5 in.

38mm

WARNING!

DO NOT EXCEED

MAXIMUM EFFECTIVE

FINGER LENGTHS

1.25

32

40 PSI (2.7 bar)

20 PSI (1.4 bar)

80 PSI (5.5 bar)

60 PSI (4.1 bar)

100 PSI (7 bar)

2 X M2 X 0.4 X .18 DP

PORTS

WITH

PLUGS

M3 X 0.5

PURGE OR

SCAVENGE

PORT

OPEN

VIEW A-A

AA

2 X Ø 2 H7 X 3.3 DP

(Ø .0787 SF X .13 DP)

CLOSE

2 X M3 X 0.5 AIR PORT

(OPEN)

2 X M2 X 0.4 X .09 DP

2 X Ø 2H7 X 1.5 DP

(Ø 0.0787 SF X 0.06 DP)

21.0

(0.827)

24.0

(0.94)

12.00

(0.4724)

16.0

(0.630)

13.4

(0.528)

16

(0.6300)

2X 3.5

(0.138)

25.5

(1.005)

10.5

(0.414)

5.2

(0.206)

8.0

(0.315)

2.8

(0.112)

5.69 .03

(0.224 0.100)

2.5

(0.098)

6.50

(0.2559)

20.8 (0.82) OPEN

16 (0.63) CLOSE

C

L

C

L

C

L

C

L

17.0

(0.669)

2X .36

(9)

25

(0.98)

MINIATURE CLEAN ROOM SERIES RPMC-3M

Dimensions: mm (inch)

30.0

2X M3 X 0.5

PURGE OR

SCAVENGE

PORTS

WITH

REMOVEABLE

PLUGS

C

L

2X 3.5

(0.138)

2X M2 X 0.4

AUX. AIR PORT

(CLOSE)

To Order Visit omega.com/rpmc_series for Pricing and Details

MODEL NO. LENGTH mm (inch) DEPTH mm (inch) HEIGHT mm (inch) STROKE mm (inch)

RPMC-1M 23 (0.89) 16 (0.630) 23 (0.92) 3.2 (0.13)

RPMC-2M 24 (0.94) 16 (0.630) 25 (0.98) 4.8 (0.19)

RPMC-3M 30 (1.16) 16 (0.630) 25 (0.98) 6.3 (0.25)

Ordering Example: RPMC-2M mini gripper clean-room series with maximum stroke of 4.8 mm (0.19").

Recommended accessories SLKT-143V top air port manifold seal kit for remote air fitting use.

2X 10

(.38)

25.5

(1.005)

lbs.

N

20

4.5

18

4.0

16

3.5

13

3.0

- ECROF REGNIF 2/F

11

2.5

9

2.0

7

1.5

4

1.0

2

0.5

0

ACCESSORIES

MODEL NO. DESCRIPTION

SLKT-121 Standard seal repair kit

SLKT-143V Top air port manifold seal kit (FKM only)

(1.16)

26.5

(1.043)

C

L

13.4

(0.528)

20.00

(0.7874)

CLOSE

10.5

8.0

(0.414)

(0.314)

26.4 (1.04) OPEN

20 (0.79) CLOSE

C

L

GRIP FORCE PER FINGER

100 PSI (7 bar)

80 PSI (5.5 bar)

60 PSI (4.1 bar)

0

0

0

40 PSI (2.7 bar)

20 PSI (1.4 bar)

.5

.25

6

.75191

13

EFFECTIVE FINGER LENGTH - L

2X M3 X 0.5 X .20 DP

11.00

(0.4330)

2X Ø3H7 X 5.0 DP

(Ø.1181SF X .20 DP)

2X M3 X 0.5 AIR PORTS

(OPEN)

18.0

(0.709)

(0.98)

M3 X 0.5

PURGE OR

SCAVENGE

PORTS

AA

MAXIMUM EFFECTIVE

1.25

32

25

O-RING FOR MANIFOLD OPTION:

(C’BORE Ø.125 X .022.001 DP)

FOR RPMC-3M TOP PURGE PORTS:

(C’BORE Ø.188/.183

X .029.001 DP)

M3 PLUG FOR

MANIFOLD OPTION

OPEN

16.0

(0.630)

25

WARNING!

DO NOT EXCEED

FINGER LENGTHS

1.5 in.

38mm

5.69±.03

(0.224±.001)

(0.112)

(0.098)

10.0

(0.394)

2.8

2.5

7.50

(0.2953)

VIEW A-A

2X M2 X 0.4 X .09 DP

C

L

2X Ø 2H7 X 1.5 DP

(Ø .0787SF X .06 DP)

UNLESS OTHERWISE NOTED ALL

TOLERANCES ARE AS SHOWN BELOW

Dimensions are

symmetrical about

centerline

Metric Threads

Course Pitch

Third Angle

Projection

Metric mm

0. = ±.25

0.0 = ±.13

0.00 = ±.013

All Dowel Holes are SF (Slip Fit).

Locational Tolerance

±.0005" or [±.013mm]

Imperial (inch)

(0.00) = (±.01)

(0.000) = (±.005)

(0.0000) = (±.0005)

SPECIFICATIONS RPMC-3M

Total Rated Grip Force

F @ 100 psi, 7 bar

36 N (8 lb)

Stroke 6.3 mm (0.25")

Weight 0.034 Kg (0.074 lb)

Pressure Range 3 to 7 bar (40 to 100 psi)

Cylinder Bore Ø 10 mm (0.394")

3

Z

Z

Displacement 0.25 cm

Temp Range

(Standard Seals)

Temp Range

®

(Viton

Seals)

Actuation 0.10 sec

-35 to 80°C (-30 to 180°F)

-30 to 120°C (-20 to 250°F)

Accuracy ±0.05 mm (±0.002")

Repeatability ±0.03 mm (±0.001")

Valve Required to Actuate 4-way, 2-position

L

Z

M

Y

T

C

M

F/2

X

LOADING CAPACITY† STATIC DYNAMIC

Maximum Tensile T 89 N (20 lbs) 31 N (7 lbs)

Maximum Compressive C 89 N (20 lbs) 31 N (7 lbs)

Maximum Moment Mx 1 Nm (12"/lbs) 0.5 Nm (4"/lbs)

Maximum Moment My 2 Nm (15"/lbs) 0.6 Nm (5"/lbs)

Maximum Moment Mz 1 Nm (12"/lbs) 0.5 Nm (4"/lbs)

†

Capacity are per set of jaws and not simultaneous.

C-56

(0.015"3 )

X

F/2

Y

M

Loading...

Loading...