Page 1

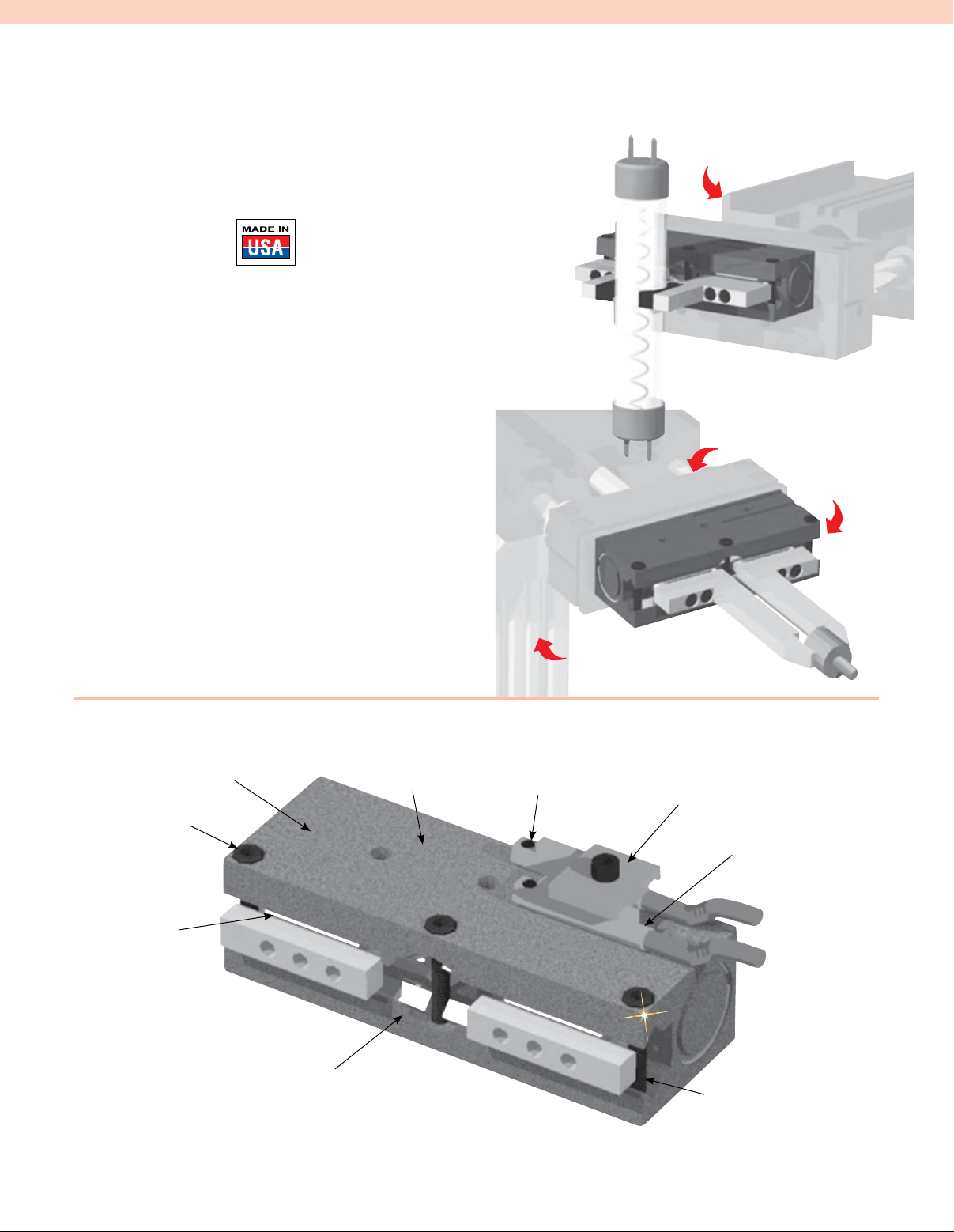

Parallel PNeUMaTIC

GrIPPerS PreCISION lOW PrOFIle SerIeS—

lONG FINGer aPPlICaTIONS

RPL Series

l Precision Gripping–Preloaded V Roller Bearings

Eliminate Side Play Resulting in Excellent

Part Positioning

l Gripper Force 116 to 160 N (26 to 36 lbs)

Stroke 6.4 to 19.1 mm (0.25 to 0.75")

l Accuracy of 0.05 mm (0.002") and Repeatability

of 0.03 mm (0.001")

l Rigid and Low Friction Design Allows for Longer

Finger Lengths for Use on Delicate Parts

l Non-Synchronous Motion Option Provides

Independent Jaw Operation

l Up to 5 Million Cycles in Typical Operation and

10 Million with Maintenance

l Operating Temperature -35 to 80°C (-30 to 180°F)

l System Requires 0.3 to 7 bar (5 to 100 psi)

Dry Filtered (40 Micron or Better) Air Supply

l Requires 4 Way, 2 Position Valve and Regulator

for Delicate Parts

All models

shown smaller

than actual size.

DMEX-16 mounting stanchions,

multiple sizes available.

Visit omega.com

DLT-08M-E-C-44

visit omega.com

RPL-1M

Note: Gripper fingers and

adapter plate shown are for

reference only. Tooling is

customers responsibility.

DLT-10M-L-C-100 visit

omega.com

RPL-2M

PrOdUCT FeaTUreS

Hard Coat Anodize

The body has hard-coat anodize 60 RC with

PTFE impregnation

Pre-Load

Adjustment

Screws

Adjustable preload

screws allow for

adjustment of preload

on roller bearings

Preloaded

Bearings

Roller bearings

are preloaded for

maximum support

and zero side play

Non-Synchronous

Operation Available

Self Lubricating Seals

Self lubricating dynamic seals

(Buna-N only)

High grip force with respect to

weight due to extremely efficient

High Grip Force

drive mechanism

One Piece Body

One piece lightweight

aluminum body

Dowel Holes

Slip fit dowel pin holes

C-37

in body

Accessory Mounting

Bracket

Sensors

Reads position of jaw

(sold separately)

Quality

Components

Internal components are

made from hardened

bearing and tool steels

Patented Bearing Support

“Dual-V” roller bearings provide low

friction rolling motion

Page 2

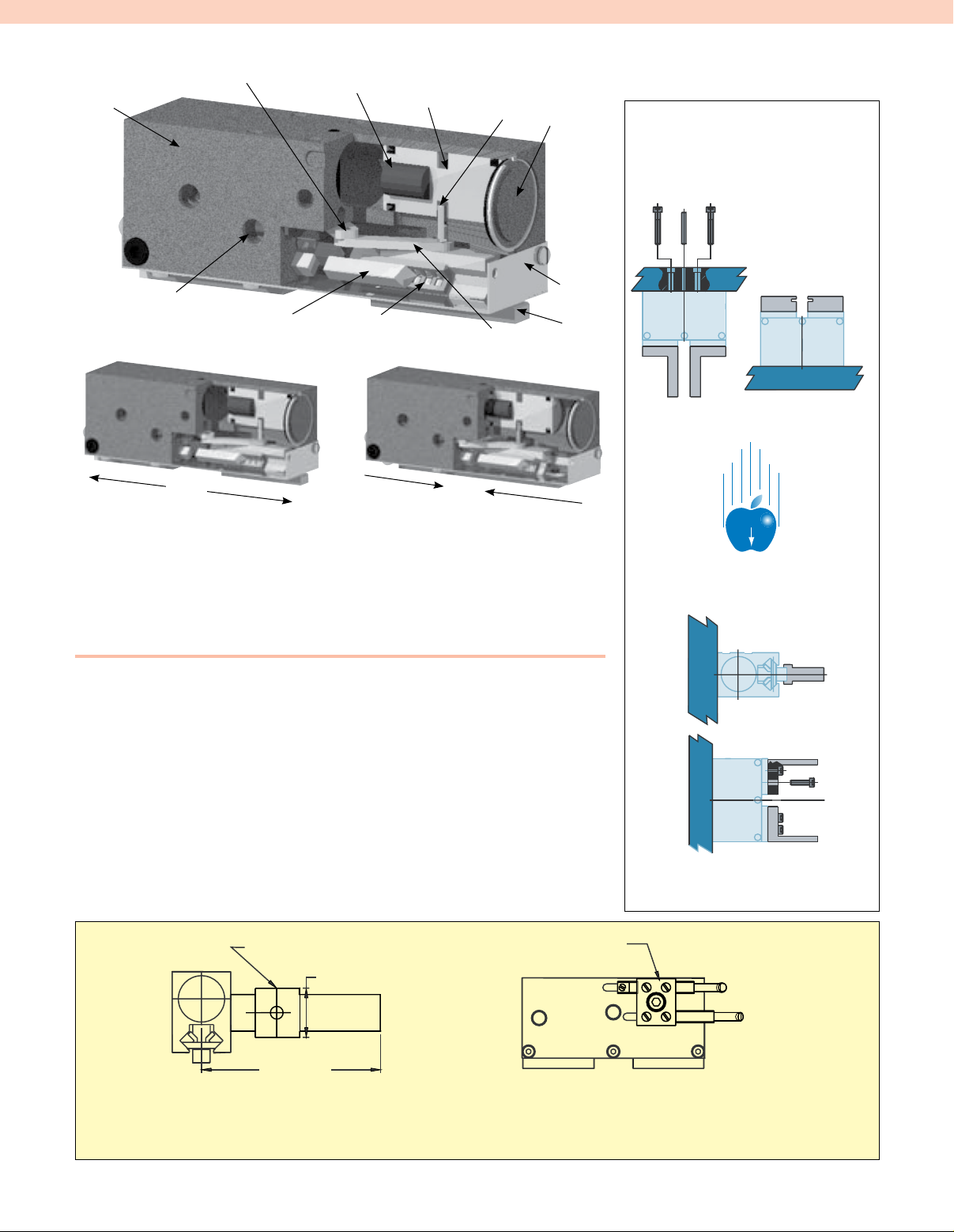

Magneto

Resistive Sensor

OHSP-017

OHSN-017

Body

G

Equalizer

OPeraTING PrINCIPle

Sensor Magnet

Standard

Piston

Drive

Pin

Cap

MOUNTING INFORMATION

Grippers can be mounted and

operated in any orientation.

Scavenge or

Purge Port

For clean-room or harsh

environments

Open

Position

Roller Way

Roller Bearings

and Cages

Synchronizing

Bar

Closed

Position

Shields

Jaw

l Dual double acting opposed pistons, connected to both a jaw and a synchronizing

bar by a drive pin, actuate in opposite directions.

l The synchronizing bars are connected to the equalizer which synchronizes

the motion.

l The purge/scavenge port can be used to expel or retain contaminates using

pressure or vacuum respectively.

l Suitable for internal or external gripping.

l The synchronizing elements can be removed for non-synchronous operation.

TECHNICAL SPECIFICATIONS

Pneumatic Specifications

Pressure Operating Range: 0.3 to 7 bar

(5 to 100 psi)

Cylinder Type: Dual double acting

Dynamic Seals:

Internally lubricated Buna-N

Valve Required to Operate:

4-way, 2-position

Air Quality Requirements

Air Filtration: 40 micron or better

Air Lubrication: Not necessary*

Air Humidity: Low moisture content (dry)

Temperature Operating Range

Buna-N Seals (Standard): -35 to 80°C

(-30 to 180°F)

FKM Seals (Optional): -30 to 120°C

(-20 to 250°F)

Maintenance Specifications

Expected Life:

Normal Application: 5 million cycles

With Preventative Maintenance:

10+ million cycles*

Field Repairable: Yes

Seal Repair Kits Available: Yes

*Addition of lubrication will greatly increase

service life.

Body mounts with screws and locates

with slip-fit dowel pins for accuracy.

G

Warning! Protect drive and bearing

mechanism from falling debris when

mounted upside down.

Fingers attach to jaws with screws and

locate by keying

Dimensions: mm (inch)

Fail Safe Valve

OFSV-004

16 (0.63)

58 (2.30) Min

l Position Sensors Available–PNP or NPN Magneto

Resistive Style, 2 per Gripper Recommended

l Sensors are Slot Mounted with Mounting Kit

and Easily Adjusted with Hex Key

Magneto

Resistive Sensor

l Built-In LED for Ease of Positioning and

Troubleshooting with Quick Disconnect Fitting

l Sensor Extension Cables Available in 2 or 5 m

G-38

(6.6 or 16') Long

OHSP-017

OHSN-017

C-38

Page 3

L

C

(1.164)

29.6

(1.031)

26.2

44.5

L

C

L

C

L

C

(0.750)

19.1

(1.750)

44.5

(0.750)

19.1

(2X)

Ø 3 SF X 4 DP

(1.164)

29.6

(1.031)

26.2

(0.594)

15.09

(4X)

M3 X 4 DP

L

C

L

C

L

C

L

C

(0.750)

19.1

(1.750)

44.5

(0.750)

19.1

(2X)

Ø 3 SF X 4 DP

(0.22)

(1.164)

29.6

(1.031)

26.2

M3 X 3 DP

(SENSOR MNTG HOLE,

DO NOT EXCEED DEPTH)

(0.594)

15.09

(4X)

M3 X 4 DP

OPEN

M5 (2X) AIR PORTS (CLOSE)

44 (1.75) (OPEN)

38 (1.50) (CLOSED)

(0.52)

13

(0.44)

11

(0.45)

11

8 (0.31)

Y

X

L

Z

Z

F/2

F/2

T

C

M

Z

6

L

C

L

C

L

C

L

C

L

C

JAW MOUNTING PATTERN

(SHOWN IN OPEN POSITION)

(0.750)

19.1

(1.750)

44.5

(0.750)

19.1

(2X)

Ø 3 SF X 4 DP

(0.22)

(1.164)

29.6

(0.750)

19.1

(1.031)

26.2

M3 X 3 DP

(SENSOR MNTG HOLE,

DO NOT EXCEED DEPTH)

(0.594)

15.09

(4X)

M3 X 4 DP

(4X)

M3 X 4 DP

(0.224 0.001)

5.69 0.03

OPEN

M5 (2X) AIR PORTS (CLOSE)

(0.250)

6.4

(0.250)

6.4

44 (1.75) (OPEN)

38 (1.50) (CLOSED)

(0.52)

13

(0.44)

11

(0.45)

11

8 (0.31)

L

C

FAIL SAFE

VALVE OPTION

58 (2.30)

16 (0.63)

MAGNETO RESITIVE

SENSOR OPTION

8 (0.30)

MAX

9 (0.36)

Y

X

L

Z

Z

F/2

F/2

T

C

M

MM

X

Y

Z

6

L

C

(1.164)

29.6

(1.031)

26.2

Y

X

L

Z

Z

F/2

F/2

T

C

M

MM

X

Y

Z

Parallel PNeUMaTIC GrIPPerS

lOW PrOFIle SerIeS rPl-1M

RPL-1M shown larger

than actual size.

Dimensions: mm (inch)

C

L

26.2

(1.031)

29.6

(1.164)

(0.52)

62

53

44

- ECROF REGNIF 2/F

35

26

18

9

0

FAIL SAFE

VALVE OPTION

58 (2.30)

Ø 3 SF X 4 DP

lbs.N

14

12

10

8

6

4

2

0

0

0

16 (0.63)

GRIP FORCE PER FINGER

80 PSI [5.5 bar]

60 PSI [4.1 bar]

40 PSI [2.7 bar]

20 PSI [1.4 bar]

25

EFFECTIVE FINGER LENGTH - L

6

13

(0.22)

(0.44)

11

44 (1.75) (OPEN)

38 (1.50) (CLOSED)

(1.750)

19.1

(0.750)

C

L

(2X)

ISP 001 ]rab 7[

WARNING!

DO NOT EXCEED

MAXIMUM EFFECTIVE

FINGER LENGTHS

1

9 (0.36)

2

50

MAGNETO RESITIVE

SENSOR OPTION

M5 (2X) AIR PORTS (CLOSE)

OPEN

11

(0.45)

C

L

8 (0.31)

19.1

15.09

C

(4X)

L

3 in.

75mm

(0.594)

M3 X 4 DP

(0.750)

8 (0.30)

MAX

5.69 0.03

(0.224 0.001)

M3 X 3 DP

(SENSOR MNTG HOLE,

DO NOT EXCEED DEPTH)

SPECIFICATIONS RPL-1M

Total Rated Grip Force

F @ 100 psi, 7 bar

Stroke 6.4 mm (0.25")

Weight 0.07 Kg (0.16 lb)

Pressure Range 0.3 to 7 bar (5 to 100 psi)

Cylinder Bore Ø 11.1 mm (0.438")

Displacement 0.6 cm

Temp Range

(Standard Seals)

Temp Range

(FKM Seals)

Actuation 0.10 sec

Accuracy ±0.05 mm (±0.002")

Repeatability ±0.03 mm (±0.001")

Valve Required to Actuate 4-way, 2-position

L

LOADING CAPACITY† STATIC DYNAMIC

Maximum Tensile T 222 N (50 lbs) 67 N (15 lbs)

Maximum Compressive C 222 N (50 lbs) 67 N (15 lbs)

Maximum Moment Mx 3.4 Nm (30"/lbs) 1.1 Nm (10"/lbs)

Maximum Moment My 4.5 Nm (40"/lbs) 1.4 Nm (12"/lbs)

Maximum Moment Mz 3.4 Nm (30"/lbs) 1.1 Nm (10"/lbs)

†

Capacities are per set of jaws and are not simultaneous

C-39

19.1

(0.750)

JAW MOUNTING PATTERN

(SHOWN IN OPEN POSITION)

Z

C

T

C

6.4

L

(0.250)

M3 X 4 DP

(4X)

C

L

6.4

(0.250)

116 N (26 lb)

3

(0.038"3 )

-35 to 80°C (-30 to 180°F)

-30 to 120°C (-20 to 250°F)

Z

M

Z

Y

X

F/2

X

F/2

Y

MM

Page 4

(4X)

Y

X

L

Z

Z

F/2

F/2

T

C

M

Z

L

C

L

C

L

C

(2.344)

59.5

(1.031)

26.2

(1.164)

29.6

(2X)

Ø 3 SF X 4 DP

(0.5940)

15.09

(4X)

M3 X 4 DP

(0.750)

19.1

(0.750)

19.1

Y

X

L

Z

Z

F/2

F/2

T

C

M

MM

X

Y

Z

L

C

L

C

L

C

L

C

(2.344)

59.5

6 (0.22)

16 (0.62)

8 (0.31)

(0.44)

11

57 (2.25) (OPEN)

44 (1.75) (CLOSED)

(1.031)

26.2

(1.164)

29.6

OPEN

M5 (2X) AIR PORTS (CLOSE)

M3 X 3 DP

(SENSOR MNTG HOLE,

DO NOT EXCEED DEPTH)

(2X)

Ø 3 SF X 4 DP

(0.5940)

15.09

(4X)

M3 X 4 DP

(0.750)

19.1

(0.750)

19.1

Y

X

L

Z

Z

F/2

F/2

T

C

M

MM

X

Y

Z

Y

X

Z

Z

F/2

F/2

T

C

M

MM

X

Y

Z

L

C

L

C

L

C

L

C

L

C

(2.344)

59.5

6 (0.22)

16 (0.62)

8 (0.31)

(0.44)

11

57 (2.25) (OPEN)

44 (1.75) (CLOSED)

(0.224 0.001)

5.69 0.03

(0.875)

22.2

(0.250)

6.4

(0.250)

6.4

(1.031)

26.2

(1.164)

29.6

OPEN

M5 (2X) AIR PORTS (CLOSE)

(4X)

M3 X 4DP

M3 X 3 DP

(SENSOR MNTG HOLE,

DO NOT EXCEED DEPTH)

(2X)

Ø 3 SF X 4 DP

(0.5940)

15.09

(4X)

M3 X 4 DP

(0.750)

19.1

(0.750)

19.1

L

C

Y

X

L

Z

Z

F/2

F/2

T

C

M

MM

X

Y

Z

MAGNETO RESITIVE

SENSOR OPTION

9 (0.36)

58 (2.30) MIN.

16 (0.63)

FAIL SAFE

VALVE OPTION

3 (0.12)

L

C

(1.031)

26.2

(1.164)

29.6

Y

X

L

Z

Z

F/2

F/2

T

C

M

MM

X

Y

Z

3 (0.12)

Parallel PNeUMaTIC GrIPPerS

lOW PrOFIle SerIeS rPl-2M

RPL-2M shown larger

than actual size.

Dimensions: mm (inch)

C

L

26.2

(1.031)

lbs.N

14

62

12

53

10

44

- ECROF REGNIF 2/F

8

35

6

26

4

18

2

9

0

0

FAIL SAFE

VALVE OPTION

16 (0.63)

58 (2.30) MIN.

13

(0.52)

29.6

(1.164)

Ø 3 SF X 4 DP

(2X)

80 PSI [5.5 bar]

60 PSI [4.1 bar]

40 PSI [2.7 bar]

20 PSI [1.4 bar]

0

0

EFFECTIVE FINGER LENGTH - L

6 (0.22)

11

(0.44)

59.5

(2.344)

19.1

(0.750)

C

L

GRIP FORCE PER FINGER

ISP 001 ]rab 7[

MAXIMUM EFFECTIVE

1

25

9 (0.36)

2

50

MAGNETO RESITIVE

SENSOR OPTION

M5 (2X) AIR PORTS (CLOSE)

C

L

57 (2.25) (OPEN)

44 (1.75) (CLOSED)

15.09

C

L

(0.5940)

M3 X 4 DP

WARNING!

DO NOT EXCEED

FINGER LENGTHS

3 in.

75mm

OPEN

(0.750)

16 (0.62)

8 (0.31)

M3 X 3 DP

(SENSOR MNTG HOLE,

DO NOT EXCEED DEPTH)

19.1

LOADING CAPACITY† STATIC DYNAMIC

Maximum Tensile T 289 N (65 lbs) 89 N (20 lbs)

Maximum Compressive C 289 N (65 lbs) 89 N (20 lbs)

Maximum Moment Mx 5.1 Nm (45"/lbs) 1.7 Nm (15"/lbs)

Maximum Moment My 6.8 Nm (60"/lbs) 2.3 Nm (20"/lbs)

Maximum Moment Mz 5.1 Nm (45"/lbs) 1.7 Nm (15"/lbs)

†

Capacities are per set of jaws and are not simultaneous

C-40

5.69 0.03

(0.224 0.001)

22.2

(0.875)

6.4

(0.250)

C

L

6.4

(0.250)

M3 X 4DP

(4X)

C

L

SPECIFICATIONS RPL-2M

Total Rated Grip Force

F @ 100 psi, 7 bar

116 N (26 lb)

Stroke 12.7 mm (0.50")

Weight 0.09 Kg (0.20 lb)

Pressure Range 0.3 to 7 bar (5 to 100 psi)

Cylinder Bore Ø 11.1 mm (0.438")

Displacement 1.2 cm

Temp Range -35 to 80°C

(Standard Seals) (-30 to 180°F)

Temp Range -30 to 120°C

(FKM Seals) (-20 to 250°F)

Actuation 0.13 sec

3

(0.075"3)

Accuracy ±0.05 mm (±0.002")

Repeatability ±0.03 mm (±0.001")

Valve Required to Actuate 4-way, 2-position

L

Z

Z

M

Z

Y

C

T

F/2

X

X

F/2

Y

MM

Page 5

L

C

L

C

L

C

L

C

(3.150)

80.0

(1.0)

25.4

(0.875)

22.2

(0.6560)

16.66

(0.53)

13

(0.44)

11

(0.76)

19

76 (3.00) (OPEN)

57 (2.25) (CLOSED)

(1.125)

28.6

(1.283)

32.6

OPEN

M5 (2X) AIR PORTS (CLOSE)

(4X)

M3 X 8 DP

M3 X 3DP

(SENSOR

MNTG HOLE)

(2X)

Ø 3 SF X 6 DP

8 (0.31)

15 (0.58)

L

C

L

C

L

C

L

C

(3.150)

80.0

(1.0)

25.4

(0.875)

22.2

(0.6560)

16.66

11

(0.76)

19

76 (3.00) (OPEN)

57 (2.25) (CLOSED)

(1.125)

28.6

(1.283)

32.6

OPEN

M5 (2X) AIR PORTS (CLOSE)

(4X)

M3 X 8 DP

M3 X 3DP

(SENSOR

MNTG HOLE)

(2X)

Ø 3 SF X 6 DP

8 (0.31)

15 (0.58)

L

C

(1.125)

28.6

(1.283)

32.6

L

C

(1.125)

28.6

(1.283)

32.6

L

C

(1.125)

28.6

(1.283)

32.6

FAIL SAFE

VALVE OPTION

MAGNETO RESITIVE

SENSOR OPTION

16 (0.63)

60 (2.36) MIN.

9 (0.36)

L

C

JAW MOUNTING PATTERN

(SHOWN IN OPEN POSITION)

L

C

L

C

L

C

L

C

(3.150)

80.0

(1.0)

25.4

(0.875)

22.2

(0.6560)

16.66

(0.44)

11

(0.76)

19

76 (3.00) (OPEN)

57 (2.25) (CLOSED)

(0.224 0.001)

5.69 0.03

(1.125)

28.6

(0.25)

6.4

(0.250)

6.4

(0.25)

6.4

(1.125)

28.6

(1.283)

32.6

(6X)

M3 X 4 DP

OPEN

M5 (2X) AIR PORTS (CLOSE)

(4X)

M3 X 8 DP

M3 X 3DP

(SENSOR

MNTG HOLE)

(2X)

Ø 3 SF X 6 DP

8 (0.31)

L

C

15 (0.58)

Y

X

L

Z

Z

F/2

F/2

T

C

M

MM

X

Y

Z

FAIL SAFE

VALVE OPTION

MAGNETO RESITIVE

SENSOR OPTION

16 (0.63)

60 (2.36) MIN.

9 (0.36)

Parallel PNeUMaTIC GrIPPerS

lOW PrOFIle SerIeS rPl-3M

Dimensions: mm (inch)

5.69 0.03

(0.224 0.001)

28.6

(1.125)

JAW MOUNTING PATTERN

(SHOWN IN OPEN POSITION)

SPECIFICATIONS RPL-3

80.0

(3.150)

25.4

(1.0)

Total Rated Grip Force

F @ 100 psi, 7 bar

Stroke 19.1 mm (0.75")

Weight 0.15 Kg (0.32 lb)

Pressure Range 0.3 to 7 bar (5 to 100 psi)

Cylinder Bore Ø 12.7 mm (0.500")

Displacement 2.4 cm

Temp Range -35 to 80°C

(Standard Seals) (-30 to 180°F)

Temp Range -30 to 120°C

Ø 3 SF X 6 DP

(2X)

16.66

C

L

(0.6560)

C

L

M3 X 8 DP

(4X)

22.2

(0.875)

(FKM Seals) (-20 to 250°F)

Actuation 0.14 sec

Accuracy ±0.05 mm (±0.002")

Repeatability ±0.03 mm (±0.001")

Valve Required to Actuate 4-way, 2-position

Z

L

LOADING CAPACITY† STATIC DYNAMIC

C

Maximum Tensile T 400 N (90 lbs) 133 N (30 lbs)

Maximum Compressive C 400 N (90 lbs) 133 N (30 lbs)

Maximum Moment Mx 6.8 Nm (60"/lbs) 2.3 Nm (20"/lbs)

Maximum Moment My 9.0 Nm (80"/lbs) 2.8 Nm (25"/lbs)

Maximum Moment Mz 6.8 Nm (60"/lbs) 2.3 Nm (20"/lbs)

†

Capacities are per set of jaws and are not simultaneous

C-41

79

16

To Order Visit omega.com/rpl_series for Pricing and Details

BODY LENGTH BODY HEIGHT BODY DEPTH STROKE GRIP FORCE @ WEIGHT

MODEL NO. mm (inch) mm (inch) mm (inch) mm (inch) 7 BAR (100 psi) kg (lbs)

RPL-1M 44.5 (1.750) 29.5 (1.164) 19.1 (0.750) 6.4 (0.25) 116 (26) 0.07 (0.16)

70

14

62

12

53

- ECROF REGNIF 2/F

10

44

8

35

6

26

4

18

2

9

0

0

001

FAIL SAFE

VALVE OPTION

16 (0.63)

60 (2.36) MIN.

RPL-2M 59.5 (2.344) 29.5 (1.164) 19.1 (0.750) 12.7 (0.50) 116 (26) 0.09 (0.20)

RPL-3M 80 (3.150) 32.6 (1.283) 22.2 (0.875) 19.1 (0.75) 160 (36) 0.15 (0.32)

Ordering Example: RPL-2M mini pneumatic low profile gripper with jaw stoke of 12.7 mm (0.50"). Recommended accessories include

2 sensors and mounting kit, along with a 4-way, 2-position valve. Temperature rating of -35 to 80°C (-30 to 180°F). Temperature range can be

extended to -30 to 120°C (-20 to 250°F) with FKM seals. Add “-V” to the end of the part number for additional cost.

All models come with standard synchronous jaws, if non-synchronous jaws are required consult sales.

Detailed specification and CAD drawings are available at omega.com.

Accessories

ISP 001 ]rab 7[

20 PSI [1.4 bar]

25250375

EFFECTIVE FINGER LENGTH - L

ISP 08 ]rab 5.5[

ISP 06 ]rab 1.4[

ISP 04 ]rab 7.2[

9 (0.36)

GRIP FORCE PER FINGER

lbs.N

18

MODEL NO. QTY/UNIT DESCRIPTION

OSMK-008 1 Sensor mounting kit

OHSN-017 1 or 2 NPN magneto resistive sensor short barrel with quick disconnect fitting

OHSP-017 1 or 2 PNP magneto resistive sensor short barrel with quick disconnect fitting

CABL-010 1 or 2 2 m (6.6') sensor extension cable with quick disconnect fitting

CABL-013 1 or 2 5 m (16') sensor extension cable with quick disconnect fitting

OFSV-001 1 M5 fail safe valve

WARNING!

DO NOT EXCEED

MAXIMUM EFFECTIVE

FINGER LENGTHS

4 in.

102 mm

MAGNETO RESITIVE

SENSOR OPTION

6.4

C

(0.25)

L

6.4

(0.250)

160 N (36 lb)

Z

M

Z

Y

T

F/2

X

MM

(0.25)

3

(0.147"3)

X

F/2

Y

6.4

C

L

M3 X 4 DP

(6X)

Loading...

Loading...