Page 1

User’s Guide

Shop online at

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

RHB-3 and RHB-4

Dew Point Monitor

Page 2

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

U.S.A.:

ISO 9001 Certified

Canada:

For immediate technical or application assistance:

U.S.A. and Canada:

Servicing North America:

One Omega Drive, P.O. Box 4047

Stamford, CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

®

®

®

Mexico:

Benelux:

Czech Republic:

France:

Germany/Austria:

United Kingdom:

ISO 9002 Certified

En Espan˜ ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

One Omega Drive, River Bend Technology Centre

Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

CONTENTS

TOPIC PAGE

Overview of the RHB-3 and the RHB-4 5

Systems Components 5

Measurement parameters available 6

Available Interfaces 6

ACCUSTAR, self correction feature 6

Theory of Operation 6

Operating from Display 7

Cleaning Mirror 8

Menu Overview 9, 10, 11

Display/Sensor Controls 12

Electrical Connections to Display Module 13

Electrical Connections to the Sensor Chassis 14

RS232 Connection 14, 15

Calibration Analog Outputs 15, 16

Final (NIST) Calibration 16

Page 4

Overview of the RHB-3

The OMEGA® RHB-3 is a chilled mirror monitor and can be used in a wide variety of

applications. It provides accurate and reliable measurements over an extended range for

long periods of time with the new ACCU-Star self-correcting feature.

• Dew/frost point from 22°C to –40°C @ an ambient temperature of 25°C

• Relative humidity from 0.002% to 100%

The RHB-3 offers a remote multifunction display and can display two selectable

measurements simultaneously, while outputting two selectable analog outputs, one

selectable alarm point and any combination of selected measurements on a serial port.

The RHB-3 is a bench top monitor with panel mount capability.

Three sensing configurations of the RHB-3 are available: dew point, temperature and

pressure.

RHB-3 Specifications

Dew Point Range -40°C to 24°C @25°C

Accuracy +/- 0.2°C

Repeatability +/-0.05°C

Hysteresis None

Temperature (optional) 100 Ohm 4 wire PRT 0.00385 Ohm

Pressure (optional) 4-20mA abs. pressure sensor

Analog

RS232

Alarms

Operating Temperature 0 to 60 deg C

Operating Pressure 0-1Mpa

Power 85 to 265Vac 50/60HZ 100W

Weight 5kg

Sensor dimensions

Meter dimensions

Dual 0-5Vdc & 4-20mA

Any parameters

100mA AC/DC Opto-Isolators

360*110*130mm

210*110*30mm

Page 5

Overview of the RHB-4

The Shinyei RHB-4 is a chilled mirror monitor and can be used in a wide

variety of applications. It provides accurate and reliable measurements over an extended

range for long periods of time with the new ACCU-Star self-correcting feature.

• Dew/frost point from 22°C to –60°C @ an ambient temperature of 25°C

• Relative humidity from 0.002% to 100%

The RHB-4 offers a remote multifunction display and can display two selectable

measurements simultaneously, while outputting two selectable analog outputs, one

selectable alarm point and any combination of selected measurements on a serial port.

The RHB-4 is a bench top monitor with panel mount capability.

Three sensing configurations of the RHB-4 are available: dew point, temperature and

pressure.

RHB-4 Specifications

Dew Point Range -55°C to 24°C @25°C

Accuracy +/- 0.2°C

Repeatability +/-0.05°C

Hysteresis None

Temperature (optional) 100 Ohm 4 wire PRT 0.00385 Ohm

Pressure (optional) 4-20mA abs. pressure sensor

Analog

RS232

Alarms

Operating Temperature 0 to 60 deg C

Operating Pressure 0-1Mpa

Power 85 to 265Vac 50/60HZ 100W

Weight 5kg

Sensor dimensions

Meter dimensions

Dual 0-5Vdc & 4-20mA

Any parameters

100mA AC/DC Opto-Isolators

360*110*135mm

210*110*30mm

System Components

The complete system consists of the following items:

• The electronic display

• Dew point sensor

• Interconnecting sensor cable

• AC line cord

• Operators manual

• Certificate of Calibration

• Maintenance Kit

• RS232 cable

Page 6

Measurement parameters available:

Dew Point Degree C or F

Temperature Degree C or F

Pressure kPa, mbar, psia

Relative Humidity %RH

Absolute Humidity PPMv, PPMw, g/m3, grains/lb

Available interfaces are as follows:

• 2 Analog outputs: 0-5V and 4-20mA (all parameters)

• “Analog outputs” may be configured as 0/5 volt and 4/20mA alarms, optional

100mA AC/DC Opto-isolated add-on module available

• Alarm relay: 100mA AC/DC Opto-isolated

• RS-232: Any parameter

• 4-20mA Pressure sensor inputs

• 100 Ohm PRT 4 wire 0.00385 Ohm

Feature:

The ACCU-STAR feature provides automatic contaminations correction allowing

your Dewpoint Monitor to continue providing accurate and reliable measurements over

extended periods of time without having to physically interrupt your measurement

process.

Theory of Operation

Optical condensation hygrometry is a precise technique for determining the water vapor

content in gases by directly measuring dew point or frost temperatures. Using this

technique, a metallic mirror is cooled until it reaches a temperature at which a thin layer

of condensation begins to form on it. The dew layer is detected optically, and the mirror

is held at that temperature. The mirror temperature, measured with a platinum resistance

thermometer, is an accurate indicator of the dew or frost point. Because these

hygrometers are so accurate, they are widely used as a standard in many of the world's

metrology laboratories. The condensate mirror is illuminated with a high-intensity, solid

state, light emitting diode (LED). A photo- detector monitors the LED light reflected

from the mirror. The photo detector is fully illuminated when the mirror is clear of dew,

and it receives less light as dew forms. A separate photo detector is used as a known

reference to compensate for any thermally induced changes in the optical components.

The photo detectors are measured by a microprocessor, the output of the microprocessor

controls the electrical current to the thermoelectric cooler. A high cooler current is sent

when the mirror is dry, causing the mirror to cool toward the dew point. As dew begins to

form on the mirror, less light is reflected, and the current output decreases. A rate

feedback loop within the microprocessor ensures critical response, causing the mirror to

stabilize quickly at a temperature that maintains a thin dew or frost layer on the mirror

surface. A precision thermometer element embedded within the mirror directly monitors

this dew point temperature.

Page 7

Operating from display

Power up

Should read OMEGA Dewpoint system RHB.

Begin power-up Accu-Star

Unit automatically goes into heat mode

Stays in heat until mirror is dry (min 20 sec)

Unit then goes into cool mode until mirror is flooded

Unit heats to clear mirror, and check optics.

Checkpoint: lower right hand of display a star will appear indicating unit is in accustar

mode. If star switches to a DT, clean the mirror.

The ACCU-STAR mode balances the optics, checks the clean mirror condition, if these

two conditions are met unit goes into operate. If the mirror is dirty, it will try to clean it

automatically, if it fails to clean mirror twice the DT letters will appear in the lower left

of the display. After two cycles of cleaning, unit goes into operate mode.

If it is in operate mode and has found a stable dew point, then the letters OK will appear

in the lower left of the display.

Page 8

Cleaning Mirror

Power down

Unscrew sensor cap

Using cotton swab and cleaning solution (provided in the MC Kit), wipe mirror with the

wetted end of the cotton swab, dry mirror with the other end of the cotton swab.

Power unit up and unit will rebalance.

Alternate procedure:

Push heat button,

Using cotton swab and cleaning solution (provided in the MC Kit), wipe mirror with the

wetted end of the cotton swab, dry mirror with the other end of the

swab.

Push * button. Unit will rebalance.

Page 9

Menu

Overview:

To scroll forward through the menu items, press the menu button. To scroll backwards,

press cool. When you see the menu item that you want to change, press select. The

existing setting or units will appear. To scroll forward through the setting or units, press

the menu button. To scroll backwards, press cool. When you see the setting or units that

you want, press select.

To set numbers, scroll up or down using the up or down keys (heat or cool), the

increment can be changed using the incr key (*). In all cases, when the setting is as you

like it, press select.

Main menu choices:

Units Line 1

Selects the Units for top line of display

Units Line 2A

Selects the Units for second line of display

Units Line 2B

Selects the Alternate Units for second line of display, quick switch by

pressing select while the unit is operating.

Units Output 1

Selects the Units for Output channel 1,

Set the LO range (0 volt, 4mA) using the number select procedure.

Set the HI range (5 volt, 20mA) using the number select procedure.

Select Analog or Alarm mode.

Page 10

Units Output 2

Selects the Units for Output channel 2,

Set the LO range (0 volt, 4mA) using the number select procedure.

Set the HI range (5 volt, 20mA) using the number select

procedure.

Select Analog or Alarm mode.

Units Alarm

Selects the Units for the Alarm,

Set the LO range (alarm open) using the number select procedure.

Set the HI range (alarm closed) using the number select

procedure.

Note: Outputs and alarms can be set normal or inverted. When the HI value is lower than

the LO value the analog scaling is inverted. For alarms the range of values between the

HI and LO values is the hysteresis or dead band, for analog outputs it is the linear range.

Units Comm Port

Selects the Units to be output on the COMM port,

Scroll through the Units and press either include or exclude to decide

which units are sent to the COMM port.

Accu* Set up

Set the time interval between automatic ACCU*s.

Select track to have the progress of the ACCU* tracked on the

display and outputs.

Select hold to have the last reading held until the ACCU* is

over.

Scale Pressure

Set the LO range (4mA) of the pressure sensor in kPa, using the number

select procedure.

Set Mol Wt

Set the Molecular weight of the gas you are measuring using the number

select procedure.

Set Average

Set the number of points to average over.

Note: Averaging is only applied when the unit is stable at the dew point.

Non SI Units (Sensor)

Include or exclude Non-SI sensor units from the units scroll.

Set the HI range (20mA) of the pressure sensor in kPa, using the

number select procedure.

Note: pressures are absolute. Also if you do not have a

pressure transducer, you can enter local atmospheric

pressure as the LO and some higher pressure as the HI.

This will then use local pressure in pressure based

calculations.

Page 11

Display/Sensor Controls

When in operation, the second line of the display can be toggled between units 2A and

2B by pressing the select button.

When the Monitor is running, measurements are shown on the left side of lines one and

two of the display. The right hand edge of the display is used for status indication.

Line one status can be clear or show an “A” if the alarm is active.

Line two status can show clear, OK, DT, *, H, C or X

OK shows that the sensor is stable and at the dew point.

DT means that the last ACCU* failed to clean the mirror properly, see mirror cleaning

procedure.

“*“ means that the unit is in ACCU*

H shows that the sensor has been manually placed into heat.

C shows that the sensor has been manually placed in maximum cool.

X shows that the sensor heat pump has been manually turned off.

To manually place the sensor into heat, press the heat button until the word HEAT

appears. This is done to clear the mirror of dew.

To manually place the sensor into cool, press the cool button until the word COOL

appears. This is done to cover the mirror with dew.

To exit either heat or cool, press the same button again.

To manually place the sensor into ACCU* press the star button.

To shut down the heat pump, press heat, until the word HEAT appears, than press cool

until OFF appears.

To reactivate the heat pump, press either heat or cool until ON appears.

Page 12

Electrical connections to the display module

The Cable to the Sensor chassis plugs in here.

To make your own longer cable, connect

with the terminals on the chassis. Make sure that the

Dout (Data out) from the chassis goes to the Din (Data in)

Of the display module, and vice versa.

When the lock pins are shorted together the buttons on the display are active.

If the shorting plug is removed, the module is locked.

Plug into the 9600 Baud RS-232 port here using the 9 pin to stereo adaptor cable

included with RHB-4.

Alarm terminals, 300 V AC/DC, 100 mA max, opto isolated MOSFET relay.

4-20 mA source for channel 1

0-5volt output channel 1

0-5 volt or 4-20 mA return

4-20 mA source for channel 2

0-5volt output channel 2

0-5 volt or 4-20 mA return

The optional output alarm isolator module connects to the I

(out),V(out) and G(nd)

terminals of either output 1 and(or) 2 to provide (an) additional alarm(s).

Page 13

Electrical connections to the sensor chassis

Reserved for future use, do not connect.

The Cable to the Sensor chassis plugs in here.

To make your own longer cable, connect

with the terminals on the chassis. Make sure that the

Dout (Data out) from the chassis goes to the Din (Data in)

Of the display module, and vice versa.

Connect the + terminal of Pressure transducer here, (4-20mA V+)

Connect the - terminal of Pressure transducer here, (4-20mA V-)

Connect pressure transducer and/or Temperature sensor shield

here.

Connect two wires from same side of 100Ohm PRT here.

Connect two wires from other side of 100Ohm PRT here.

RS232 Connection

Connecting and using the Monitor RS-232 output

The Monitor includes an RS-232 output on the Display Module. The RS-232 port is a

3.5mm round connector which can be used with the cable supplied with your unit.

The choice of information transmitted is selected from the menu on the display module,

and can include any combination of humidity, temperature or pressure units available

from the system. In addition the RS-232 port will send a status word including

information about the control status, mirror cleanliness, and any buttons that have been

pressed, and lastly the hours left until the unit enters an ACCU self cleaning cycle. The

data is sent in a CSV format (comma separated variable) which can be imported directly

into many software packages such as Microsoft Excel.

The data is transmitted at 9600 BAUD, 8 Bit, 1 Stop Bit, No flow control, no parity. Any

Microsoft Windows (version 3.11 and up) based system with a serial port can access this

data using a standard program included in Windows called HyperTerminal. This is

generally found in “windows\accessories\communications”. Please refer to your

Page 14

computer help files for the correct configuration of your computer serial port. After your

computer is correctly configured you will see a data stream such as:

C DP= 32.3607 ,PPMw= 32524.1328 ,gr/#= 227.6689 ,00001100 ,24.

C DP= 33.5534 ,PPMw= 34905.6015 ,gr/#= 244.3392 ,00001100 ,24.

C DP= 34.7088 ,PPMw= 37366.4843 ,gr/#= 261.5653 ,00001100 ,24.

C DP= 35.8230 ,PPMw= 39892.1250 ,gr/#= 279.2448 ,00001100 ,24.

C DP= 36.8813 ,PPMw= 42438.3515 ,gr/#= 297.0684 ,00001100 ,24.

C DP= 37.9010 ,PPMw= 45035.6250 ,gr/#= 315.2493 ,00001100 ,24.

C DP= 38.8769 ,PPMw= 47661.3281 ,gr/#= 333.6293 ,00001100 ,24.

C DP= 39.8022 ,PPMw= 50284.4218 ,gr/#= 351.9909 ,00001100 ,24.

C DP= 40.6960 ,PPMw= 52948.1953 ,gr/#= 370.6373 ,00001100 ,24.

C DP= 41.5535 ,PPMw= 55629.8671 ,gr/#= 389.4090 ,00001100 ,24.

C DP= 42.3635 ,PPMw= 58282.5390 ,gr/#= 407.9777 ,00001100 ,24.

The first part of each line transmits the units that you have selected.

The code 00001100 is the status code.

24 is the number of hours left before the next ACCU cycle.

The Status word at the end of the RS-232 string is a Binary word, (BIT7>> 00001100

<<BIT0)

Bit7=ACCU* button pressed,

Bit6=Heatpump OFF

Bit5=COOL ON

Bit4=HEAT ON

Bit3=System is in ACCU*

Bit2=Air Temp PRT OPEN or not Attached

Bit1=System IN CONTROL

Bit0=Dirty Mirror

Calibrating the Monitor analog outputs

The Analog outputs on the Monitor are both 0-5volts and 4-20mA outputs, on adjacent

terminals for each output, (output#1, output#2, etc.). The ranges for the outputs may be

set from the display, using the “SET OUTPUT(X)” menu. The 0-5 volt outputs are

derived from an internal voltage reference and no calibration is necessary or possible.

The 4-20mA outputs are derived from the 0-5volt outputs and may be calibrated at the

4mA and 20mA values.

To calibrate the 4-20mA output(x), first set the output(x) to a range where the output

should be at 4mA such as DP C , LO= -100°C , HI= -120°C , Analog. With these settings

the output should be at 4mA unless the dew point being measured is below –100°C. Then

adjust the 4mA adjustment pot until the output is 4mA.

Next set the output(x) range so that the output should be 20mA, such as LO = -120°C and

HI= -100°C. This should generate 20mA unless the dew point is below –100°C. Then

adjust the 20mA adjustment pot until the output is 20mA.

The output adjustment pots are found on the display module. They are labeled as follows.

Output #1 4mA, R33 Output#1 20mA, R32

Output #2 4mA, R21 Output#2 20mA, R19

The last pot, R1 is used to adjust the display contrast.

Page 15

Final Calibration

Final Calibration is a test for accuracy where the unit under test is compared against a

NIST transfer standard at a number of different dew points/frost points. A dew

point/frost point generator will create a desired dew point/frost point and will provide a

sample flow at 1L/min to the units under test and the transfer standard. Typically, the

units will be connected in series but should be connected in parallel when testing more

than one unit.

A typical set of test points for a 2 stage dew point monitor is: 15°C, 0°C, -20°C,-30°,

-40°C but can be customized to its application.

The only adjustment that can be made during final calibration is the cleaning of the

mirror and the display unit will indicate if the mirror is dirty by blinking the letters ‘DT’.

See the section (page 7) on cleaning the mirror.

Page 16

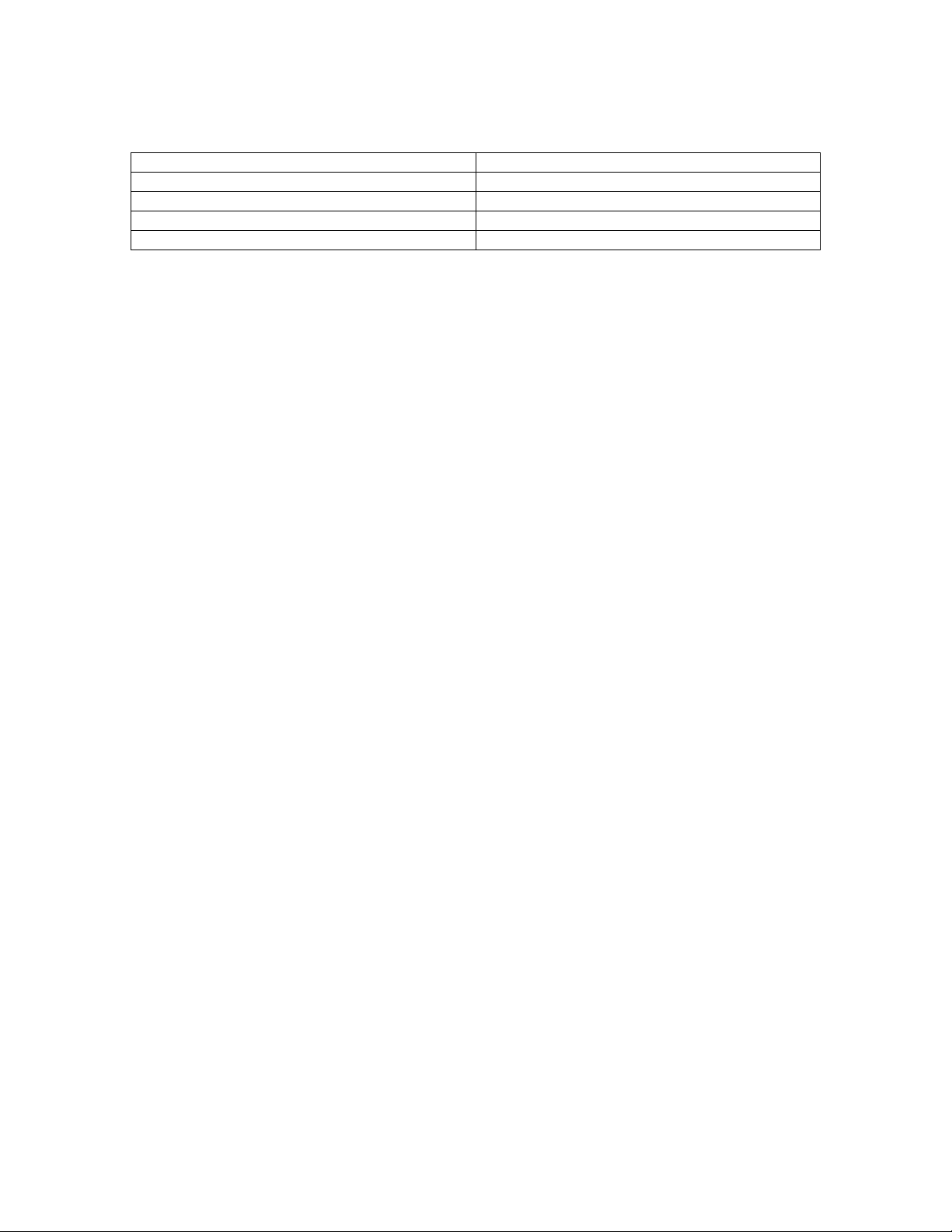

Dry Bulb

2 Stage

3 Stage

20 40 60 80

0

Ambient Temp (°C)

-20

RHB-3 (2-stage) and RHB-4 (3-stage) Measurement Range

80

-20

-40

-60

-80

0

20

40

60

Measurement

-40

-100

Page 17

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

grace period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components in which wear is not warranted, include but are not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by the

company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR W

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

2. Model and serial number of the product under

3. Repair instructions and/or specific problems

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2004 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

ARRANTY RETURNS, please have the

was PURCHASED,

warranty, and

relative to the product.

FOR NON-WARRANTY REPAIRS,

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

consult OMEGA

Page 18

W

here Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

䡺⻬

Transducers & Strain Gages

䡺⻬

Load Cells & Pressure Gages

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters & Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators & Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition & Engineering Software

䡺⻬

Communications-Based Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM & Compatibles

䡺⻬

Datalogging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater Treatment

䡺⻬

pH, Conductivity & Dissolved Oxygen Instruments

M4082/0605

Loading...

Loading...