Page 1

Page 2

Page 3

Page 4

Page 5

Table of Contents

Preface

For safe use

Main features and functions

2 1 2

Checking model and attachments

3

3.1 Model check

3.2 Checking attachments

Installation

4

4.1 Mounting location

4.2 External dimensions

4.3 Method of mounting the panel

Connections

5

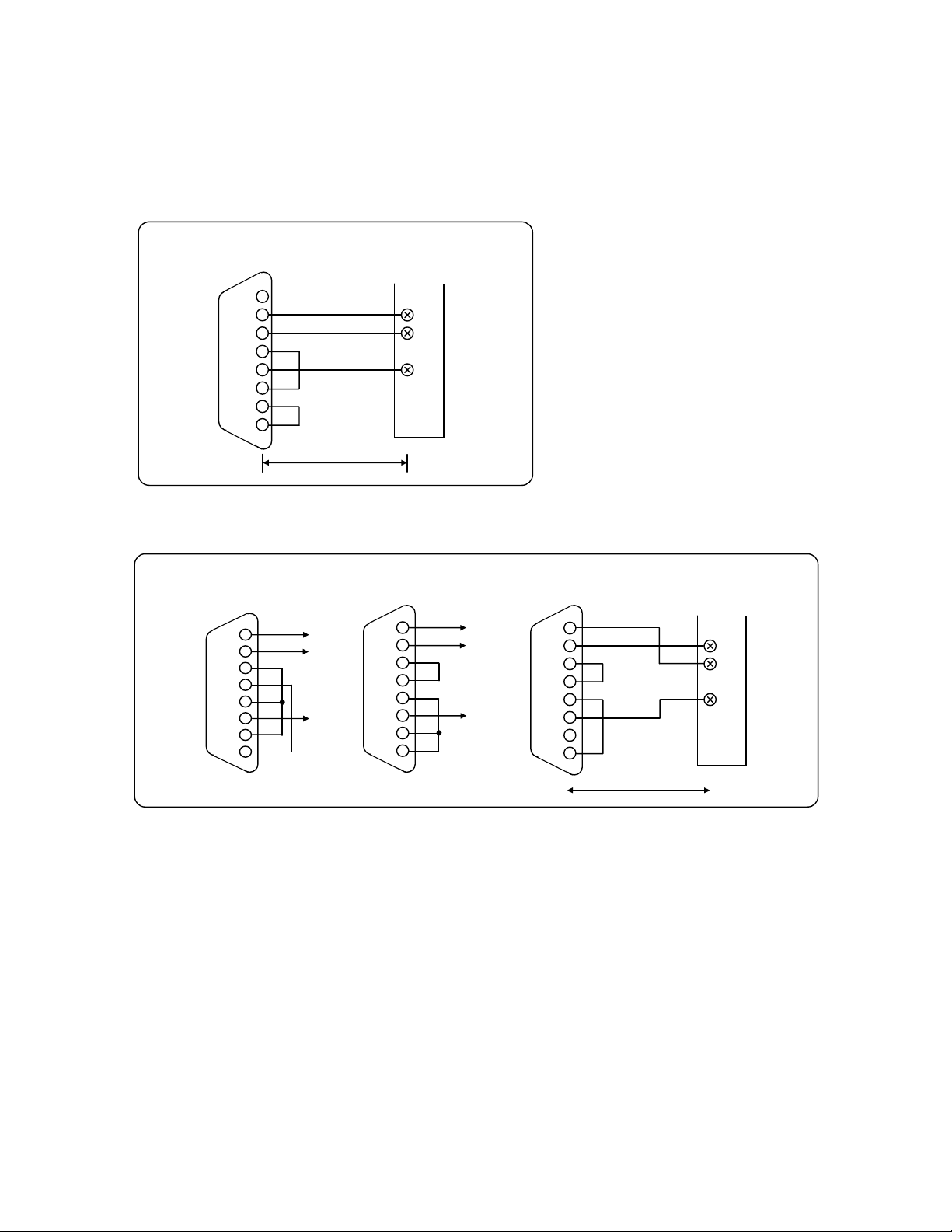

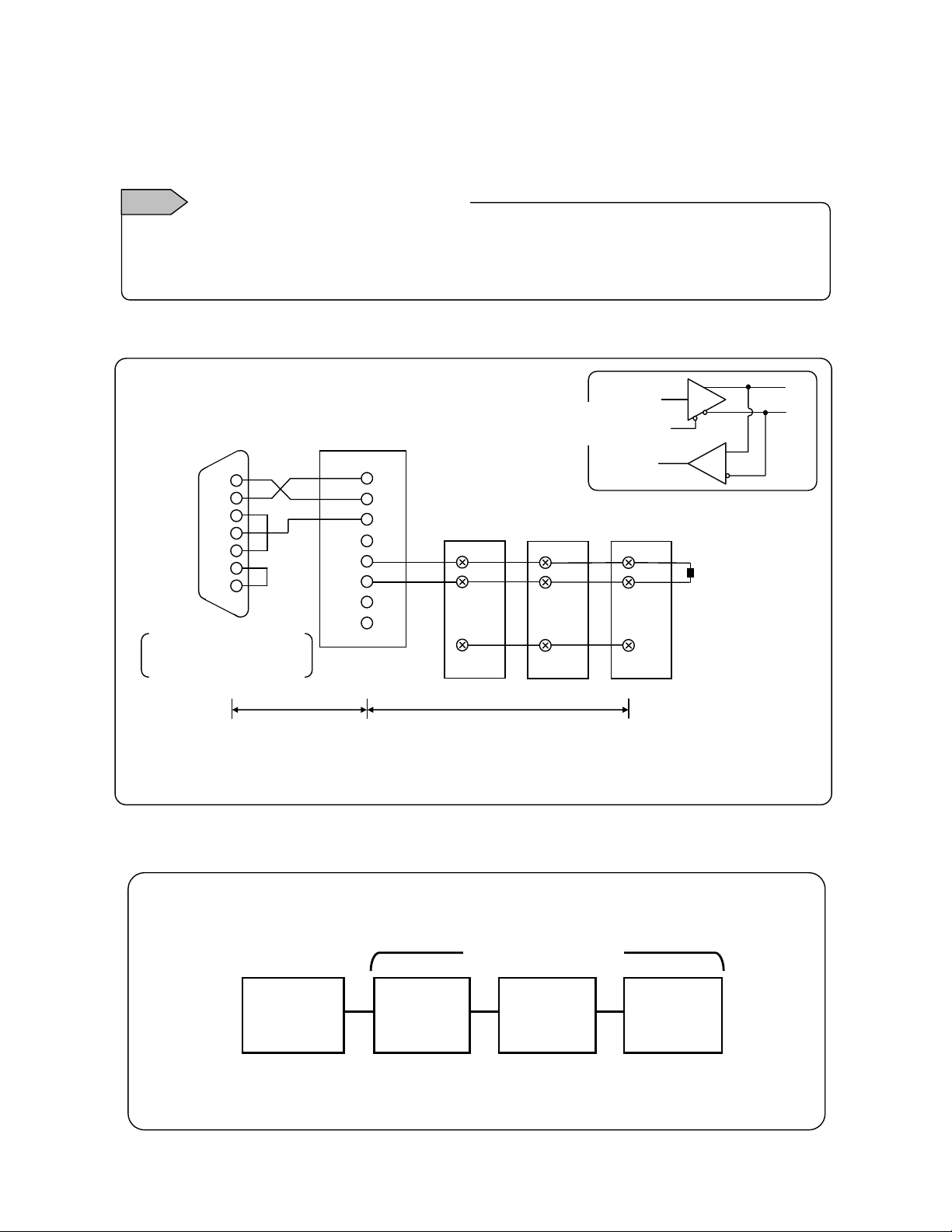

5.1 Terminal board arrangement

5.2 Precautions while connecting

5.3 Connections of power and protective

conductor terminals

5.4 Connection of measuring input

terminal

5.5 Connection of alarm output terminal

(Option)

5.6 Connection of digital input and

operation selection (Option)

5.7 Connection of communication I/F terminal

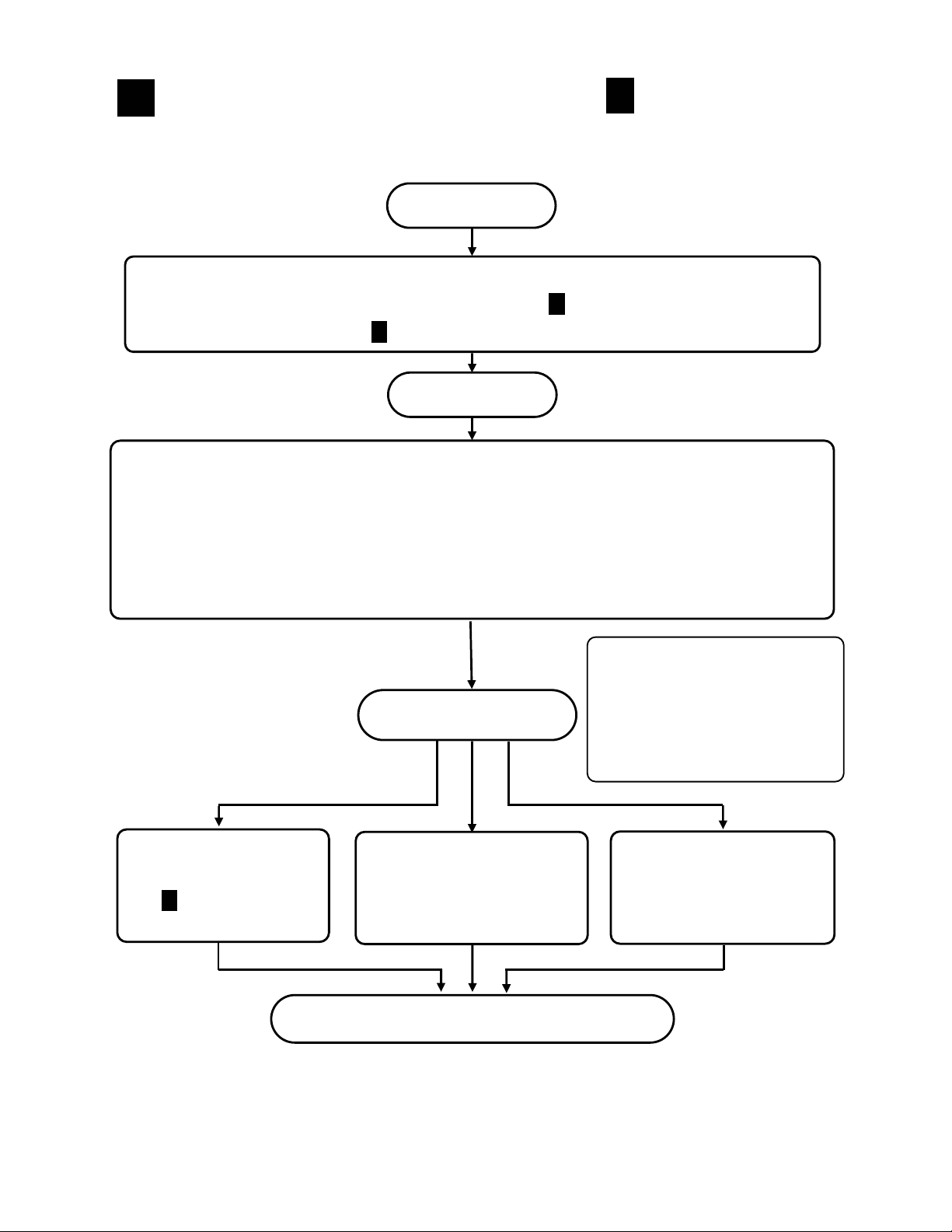

Operation

6

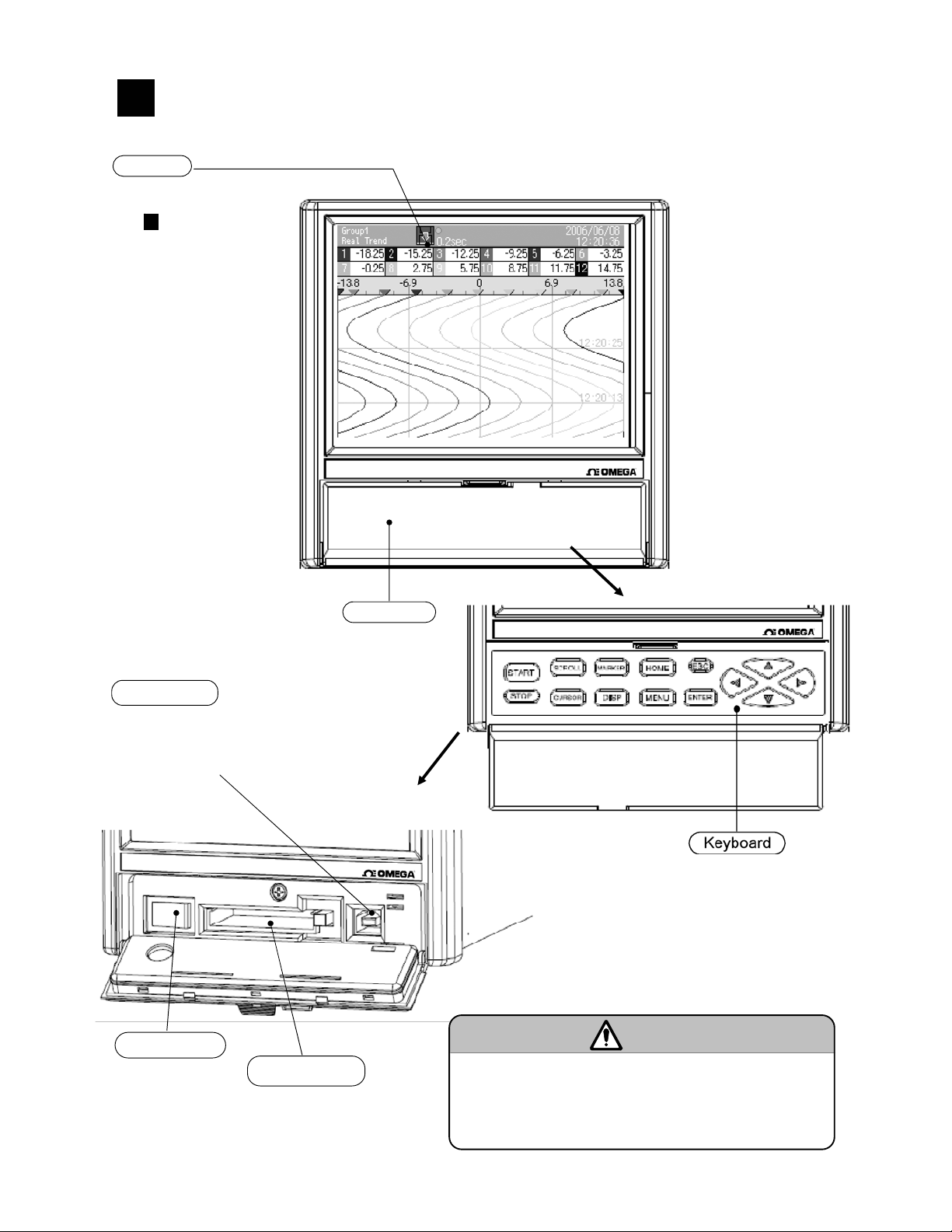

Name of component part

7

7.1 Name of front panel and its major

functions

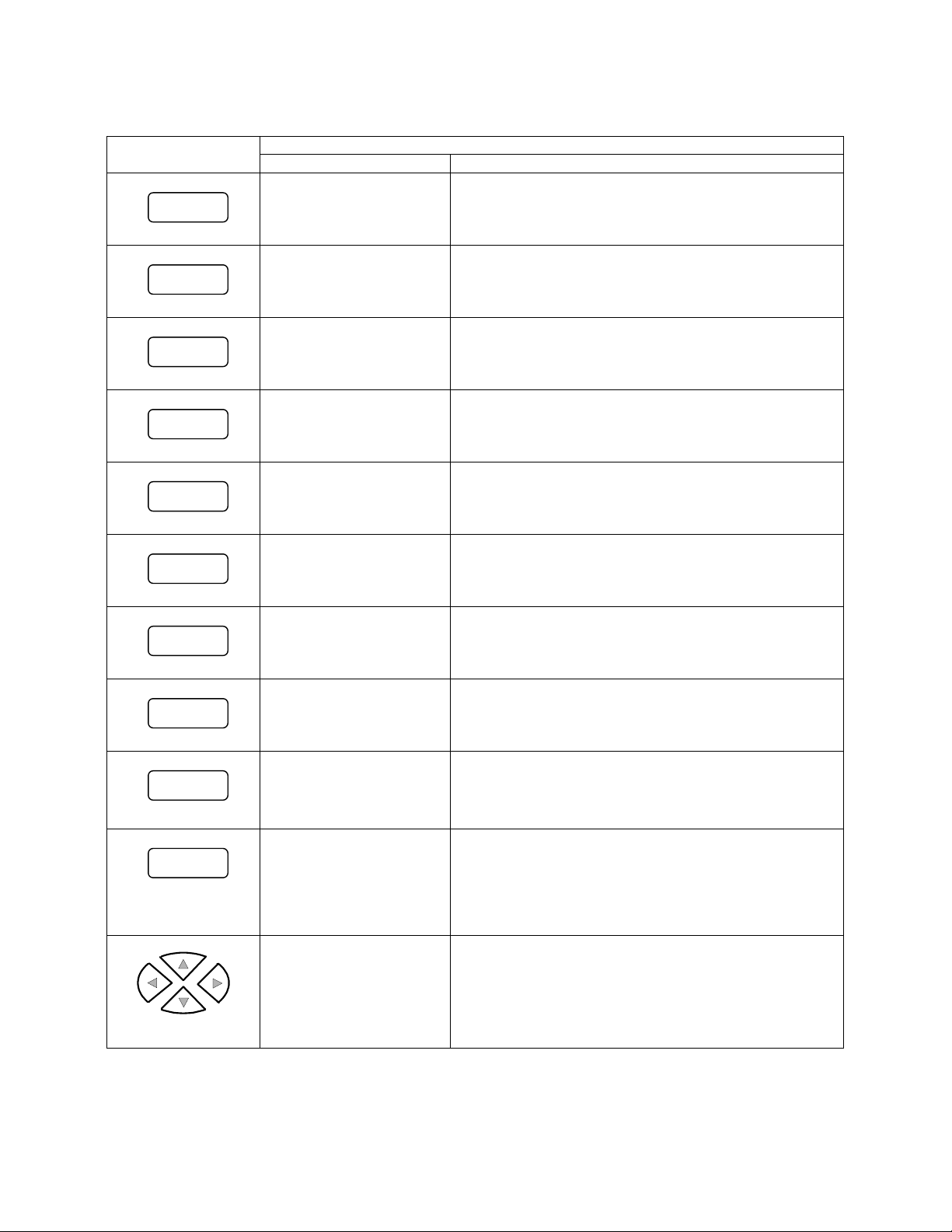

7.2 Name of the key and its functions

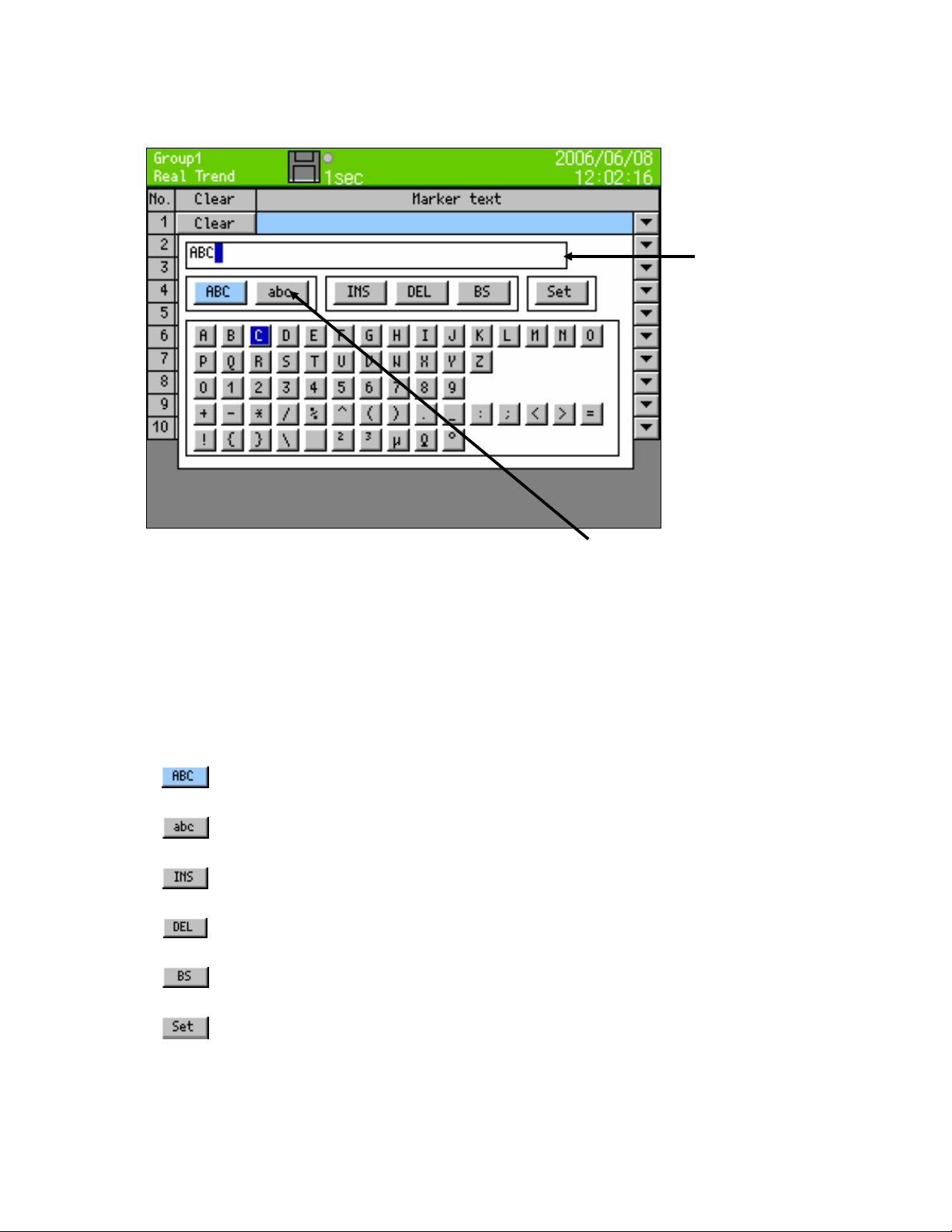

7.3 Method of inputting the characters

Screen switching method

8

Name and functions of operation screen

9

9.1 Common operations of operation screen

9.2 Status bar

9.3 Real time trend screen

9.4 Bar graph screen

9.5 Data screen

9.6 Historical trend screen

9.7 Dual trend screen

9.8 Alarm display screen

9.9 Internal memory screen

9.10 Card file screen

9.11 Marker list screen

10

Initial settings

1

2

4

5

5

5

6

6

6

7

8

8

10

11

12

13

15

16

20

21

21

22

23

25

27

27

28

29

30

30

31

32

32

33

34

34

35

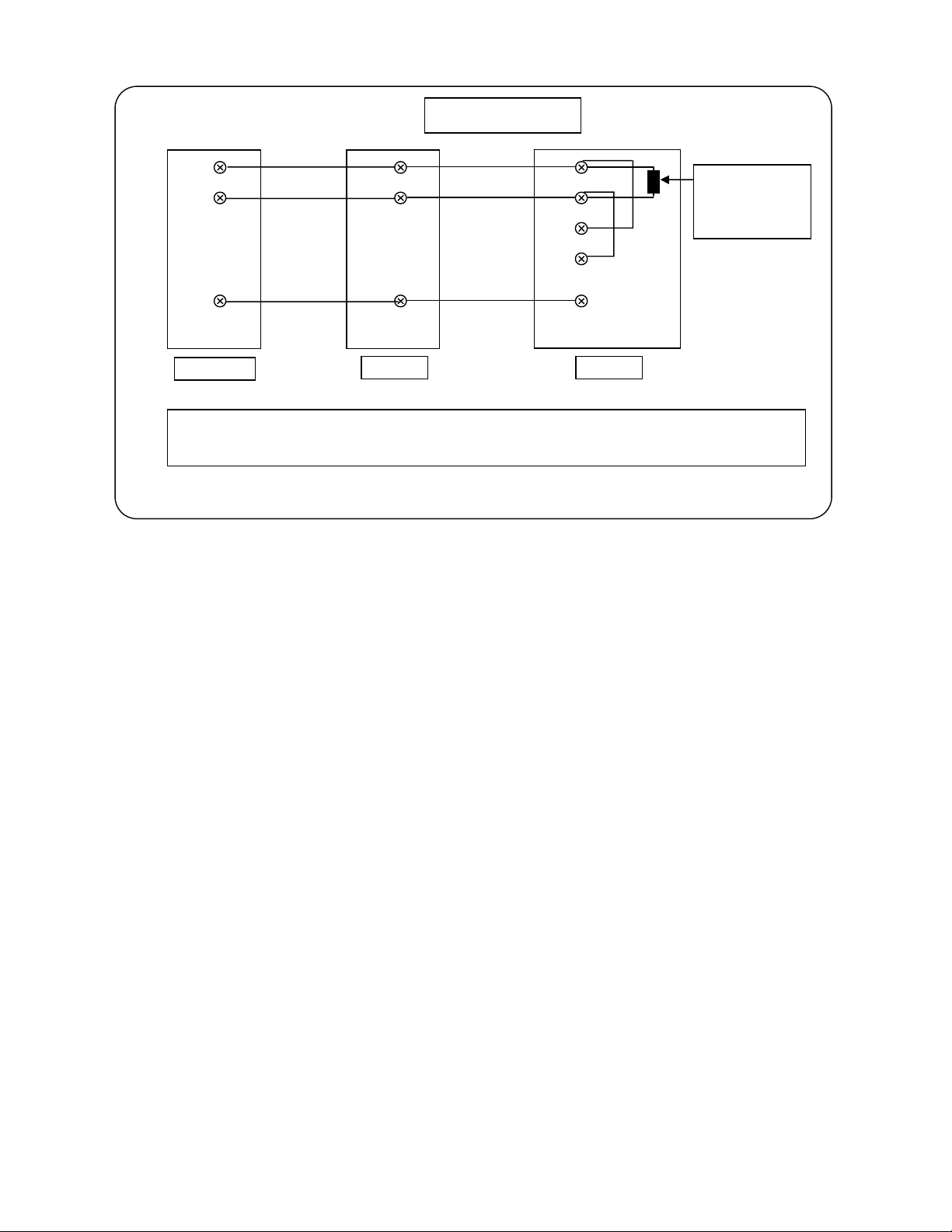

Flow chart of HOME settings &

11

MENU settings

HOME settings

12

12.1 Setting HOME settings

12.2 Confirming the specifications using

13

14

15

16

17

HOME settings screen

MENU settings

13.1 Setting MENU screen

13.2 Input operation settings

13.3 Display settings

13.4 Alarm settings

13.5 File settings

13.6 Totalizer reset settings

13.7 Schedule settings

13.8 Marker text settings

13.9 Memory operation

13.10 Network settings

13.11 System settings

Setting/Displaying in WEB screen

14.1 Display and settings of Web screen

Read the recorded data using USB

15.1.Outline

15.2.Operation environment

15.3.Access to data file

Adjustment

16.1 Adjustment

16.2 Adjustment environment

16.3 Preparation

16.4 Connections

16.5 Zero and span adjustment

Recommended parts replacement

interval

17.1 Operation conditions

17.2 Reference of parts replacement intervals

Specifications

18

Appendix A. Report application (Sample)

A-1 Operation environment

A-2 Installation method

A-3 Uninstallation method

A-4 Operation method

A-5 Edit report sheet

39

41

41

43

44

44

48

54

60

62

64

65

66

67

68

74

78

78

85

85

85

85

87

87

87

87

88

89

93

93

93

94

97

97

97

97

97

105

Page 6

PREFACE

Thank you for purchasing the RD9900 series graphic recorder.

Before using your new recorder, please be sure to read this instruction manual which will advise you

on how to use the instrument correctly and safely and how to prevent problems.

1. Separate instruction manuals

The present instruction manual describes the optional specifications of alarm output and report

application of appendix as well as the operation of standard specifications. When the instrument is

provided with the higher order or low order serial communications interface (option), the instruction

manual for communications interface is attached as a separate manual. For other options for which you

need to have instructions, their instruction manuals are attached respectively. Please read these

instruction manuals together with this manual.

2. Request

● Request to instrumentation engineers, constructors, and sale agents

Make sure to deliver this instruction to the operator of this instrument.

● Request to the operator of this instrument

This instruction manual is necessary for maintenance, too. Keep this manual with care until the

instrument is discarded.

- 1 -

Page 7

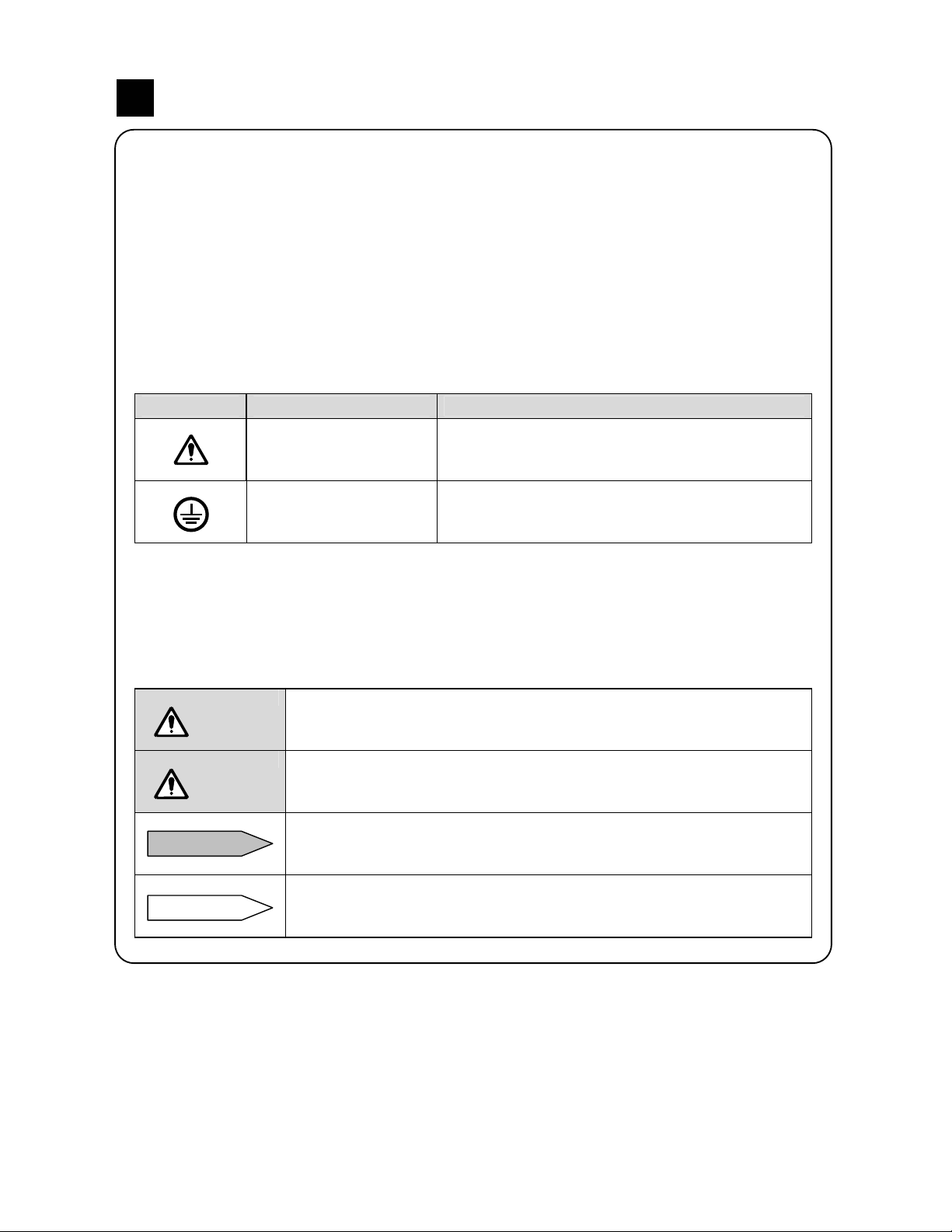

For safe use

1

This section ”FOR SAFE USE” has been compiled to promote the correct use of the instrument in

order to prevent human injury or damage to property before they occur. Please read the following

information carefully and be sure to observe the warnings and cautions in it.

1. Preconditions for use

This instrument is designed for indoor use by mounting it on an indoor instrumentation panel.

2. Labels on this instrument

The following labels are used for safe use.

Label Name Meaning

Alert symbol mark

Protective conductor

terminal

Indicates the location which should refer to the

manual in order to prevent an electric shock and

injury.

A terminal is provided for connection to the

protective conductor of the power supply facility for

the prevention of an electric shock.

3. Symbols in this manual

The cautions to be observed for preventing the damage of this instrument and unexpected

accidents are sorted by the following symbols according to their importance degrees for enabling

operators to use this instrument safely.

Warning

Caution

Remarks

Reference

The nonobservance of information under this symbol may result in

hazardous, critical or serious injury to the user.

The nonobservance of information under this symbol may result in a

hazardous situation or a light injury to the user or in physical damage to

the property.

This symbol shows a caution when the instrument dose not function as

specified or when such a possibility exists.

This reference servers as a supplement for handling and operation, and it

may be convenient for the user.

- 2 -

Page 8

L N

This paragraph covers important warning for safety to be observed before reading the instructions.

Fully understand the following warning before reading this manual. These warnings are important for

preventing the damage to human bodies as well as accidents.

WARNINGS

1. Switch and overcurrent protective device

The RD9900 series graphic recorder in not

provided with a replaceable overcurrent protective

device. Prepare the switch and the overcurrent

protective device for the power supply (circuit

breakers, circuit protectors or the like) within 3m

of this instrument in a location where the operator

can reach instrument in a location where the

operator can reach them handily. Use a switch

and an overcurrent protective device conforming

to IEC947-1 and IEC947-3.

Overcurrent

protective

device

(250V 3A)

Switch

Power/protective

conductor

terminals

To the protective

conductor of power

supply facility

Power supply

2. Be sure to ground the RD9900 series graphic recorder

Before turning the power on, connect the

protective conductor terminal of the RD9900

series graphic recorder to the protective

conductor of the power supply facility. In order to

prevent an accident by electric shock, do not

disconnect an instrument in use.

3. Before turning on the power supply

In order to ensure safety, before turning on the

external power switch make sure that the power

voltage is within the range indicated on the power

supply label.

Reference

Fuse in the power supply

The following fuse is mounted in the power supply

unit of RD9900 series graphic recorder for safety

use. However, this fuse is not replaceable.

Manufacturer:Nippon Seisen Cable., Ltd.

Model:FCT 250V 3A 8H02

Power terminal

Protective conductor terminal

100-240V AC

50/60Hz 50VA MAX

Power

supply label

4. Don’t repair or modify this instrument

Make sure that any persons other than service

engineers approved by ONEGA ENGINEERING

INC. do not repair or modify this instrument by

replacing parts. Otherwise it may be damaged or

will not function normally or an accident such as

electric shock may occur. For ordinary operation,

it is not necessary to open the internal unit.

5. Use this instrument in accordance

with this instruction manual

Use the RD9900 series graphic recorder correctly and safely by following this instruction manual.

ONEGA ENGINEERING INC. will not be responsible for any injury, damage, lost profit or any other

claim, which may result from its wrong use.

6. Turn off the power supply if an abnormal symptom occurs

Turn off the power supply immediately and contact your local OMEGA sales agent if any abnormal

odor noise or any smoke occurs, or if the RD9900 series graphic recorder generates heat that is

too hot to be touched.

- 3 -

Page 9

Main features and functions

2

Besides displaying in various formats like real time trend graph/bar graph/numeric value etc. in 5.6 inch

TFT color LCD and measuring various industrial quantities and temperature of multi channels, this

instrument can as per the requirement, record the data of internal memory and memory card (CF card)

and replay it. Stored data can be used using commercial software like excel etc. Exclusive analysis

software is also available.

Management of

measurement

result is easy

Compliance with

international

standards

Various screen

displays

Various memory

functions

Analog recorder

sensation

Marker function

MODBUS

communication

Measurement result is displayed in various screen formats and monitoring is easy.

The old data stored in CF card can also be read. The stored data can also be

managed using commercial software like EXCEL (Registered trademark of

Microsoft Ltd.) etc.

(Planning to get CE marking compliance)

Real time trend, bar graph, data display (table format) and composite displays like

real time trend and bar graph, real time trend and numeric value display, real time

trend and historical trend can be arbitrarily selected and maximum screens can be

monitored as per requirement. Alarm display screen and marker list screen to

display past alarm activation status collectively, are also available.

Other than maximum 5 groups can be displayed switching over of that screen can

be done by simple operation.

Start/stop of data storage can be done by arbitrary condition settings like key

operation, alarm, time setting etc. and up to 5 files can be stored at a time. During

normal operations, data is stored in internal memory and can be saved on CF

memory card.

As trend screen displays the data on the chart by using scale plate and pointer,

monitoring can be done by analog recorder sensation.

Marker and marker text (alphanumeric characters, maximum 31 characters) can

be written on the trend screen. Marker text is written arbitrarily and also there are

50 types of marker texts that are already registered. This marker text can also be

written in historical trend screen (replay). 'No marker text' marking only, is also

possible.

Parameter settings, data acquisition and operation can be done using high order

communication of option. As communication protocol uses MODBUS it is possible

to communicate with program indicator equipped with MODBUS protocol, even

without creating communication software and building a system is easy.

(MODBUS: Registered trademark of SCHNEIDER Ltd.)

Consumables are

not required

Set up is easy

Software package

is available

Consumables like chart, pen and ink as used in strip chart recorders are not

necessary, thereby making the system cleaner and less time consuming.

Each parameter setting is done by selecting the setting item from menu screen,

using key operation. A window is opened and the method of setting is interactive.

Hence set up is easy.

Also operation can be done easily using the required parameter settings

operation, in ‘Simple settings (HOME)’ screen

Data analysis can be done easily on the PC as software package for exclusive

analysis is available.

● Software for analysis : (Windows98,Me,2000,XP version)

- 4 -

Page 10

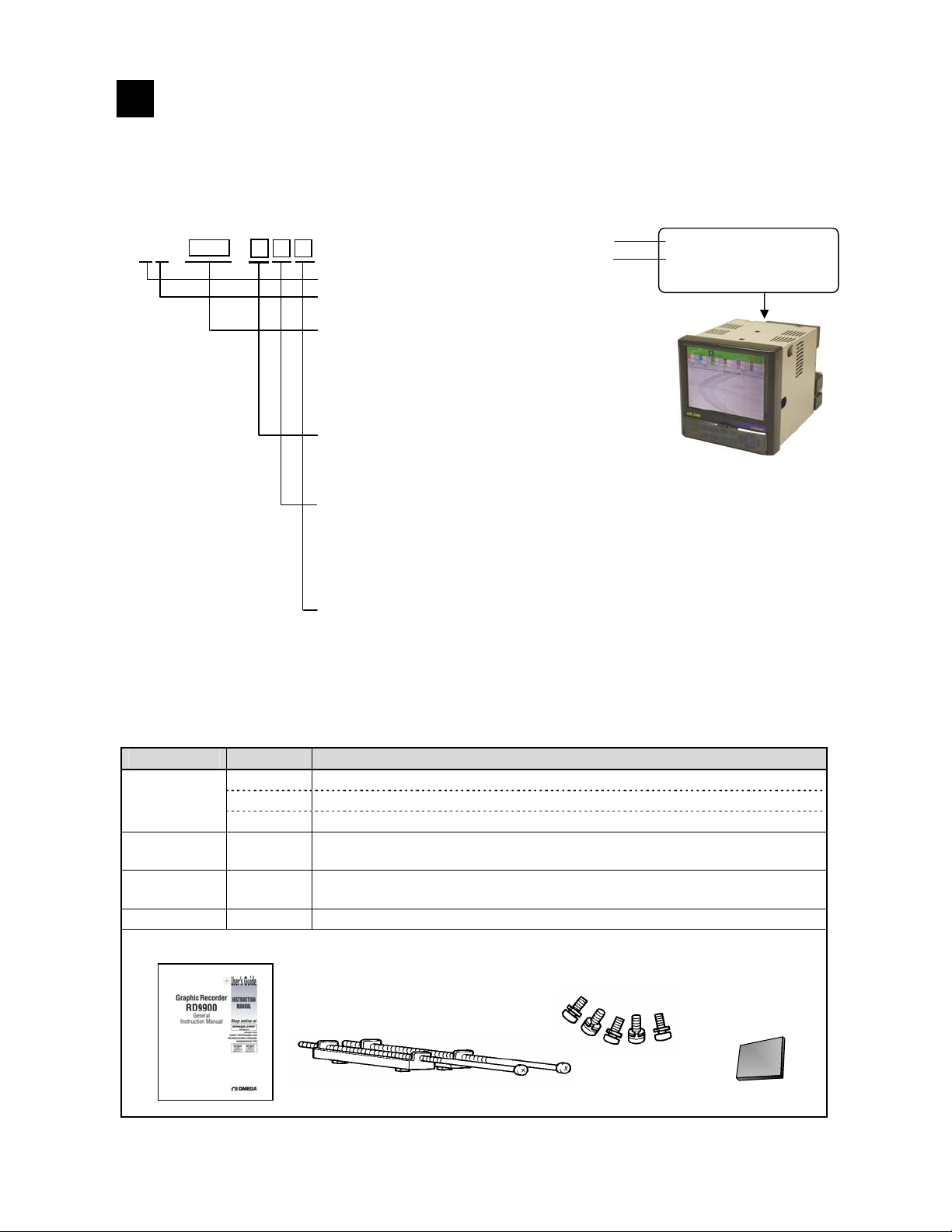

Checking model and attachments

3

Model check

3.1

The model No. and serial No. of the RD9900 series graphic recorder can be confirmed by the label on the

upper face of the case.

Please check the model of your instrument from the model code, before use.

■Model code

RD99 -

Model (Check with model code)

Serial No.

Type (Fixed as 2): 2 types

Input type (Fixed as 1): Universal input

(DC voltage, thermocouple, resistor thermometer)

Measurement points/Sampling rate

00: No input

60: 6-point input /100ms

20: 12 point input /100ms

61: 6 point input /1s

21: 12-point input /1s

Communication interface (Option)

N: None

C-24: High order:RS232C(High order)/RS485 (High order) switchable

Low order: RS485

Alarm output, contact input, Power output for transmitter (Option)

0: None

AC-12: Alarm relay output (12 points)

Power supply,

A: Standard power supply

RD99**-***

RD*********

MADE IN JAPAN

3.2 Checking attachments

Package contains the following attachments. Please confirm.

Parts name Quantity Remarks

①Operation

manual

②Mounting

bracket

③Terminal

screw

④CF card

① Operation manual

1

(1 copy)

1

2 For use in panel mounting

5

1 RZ-CMC128 (128MB)

INE-365□ (For RD9900 series graphic recorder) CD-ROM

INE-366□ (Connection/mounting edition) A4 18 pages

RZMC-01-□ (CF card)

For M3.5, input terminal and alarm (digital input) terminal (Spare in case

of loss)

③ Terminal screws

② Mounting bracket

④ CF card

- 5 -

Page 11

Installation

4

4.1 Mounting location

In order to avoid unfavorable effects on measurement accuracy and recording operation, mount the RD

9900 series graphic recorder at the following locations.

1) Industrial environment

Select a place away from electric field and magnetic field and away from mechanical vibrations/shock.

●Over voltage category……Ⅱ

●Pollution degree…………...2 ●Place of use……Indoor

●Altitude…………2000m or less

2) Ambient temperature/humidity

Keep away from direct sunlight and to avoid increase in temperature do no keep the RD9900 series

graphic recorder in a very closed place.

● Place with stable ambient temperature of around 23°C and humidity 50%RH

● Place not exposed to hot drafts (50°C or more), in order to avoid deformation of front panel

● Place where there is no source of heat near the terminal. This is to avoid, measurement errors.

3) Atmosphere

● For safety reasons avoid place where there is inflammable gas.

● Avoid places with dust, smoke, vapors etc.

4) Mounting angle

● Lateral tilting…0°

● Longitudinal tilting…Forward tilting: 0°, Backward tilting: 0-20°

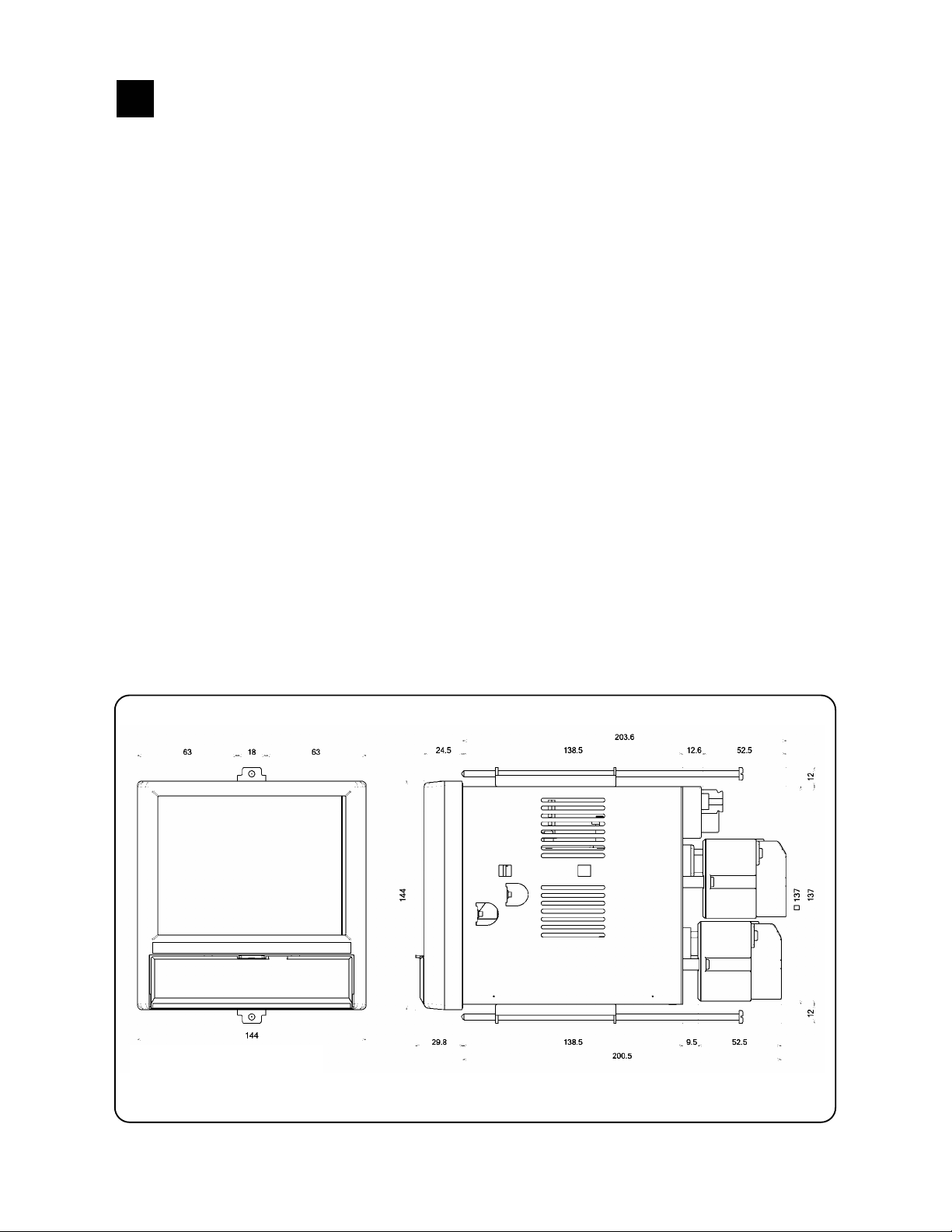

4.2 External dimensions

Following figure shows the dimensions of RD9900 series graphic recorder together with its mounting

brackets.

Unit : mm

- 6 -

Page 12

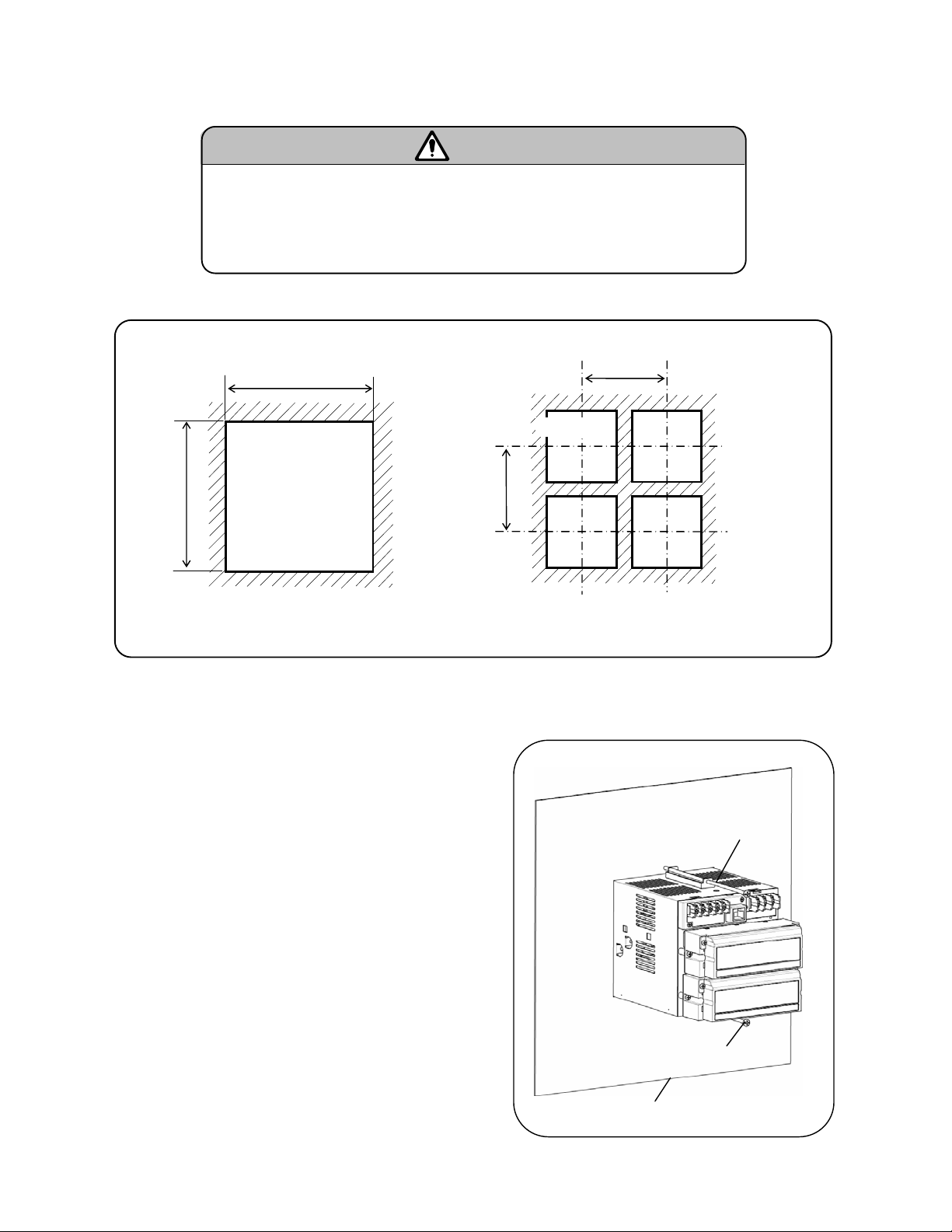

4.3 Method of mounting the panel

1) Panel cut size

2) Mounting method

① Insert the RD9900 series graphic recorder in the

panel cutout from the front of the panel.

② Fixed the RD9900 series graphic recorder using

mounting brackets (Screw tightening torque: 1.0

N・m). Mounting brackets are fixed on the top and

bottom.

■ Mount on the panel and use

① The RD9900 series graphic recorder has been designed to be mounted

on an indoor instrumentation panel.

② Use a panel made of a steel plate of 2mm to 6mm in thickness.

●Minimum interval for installation of multiple instruments

+1

138

0

+1

0

138

パネルカット

(mm)

Warning

200

Panel cut

200

(mm)

Mounting bracket

Mounting bracket

Panel thickness (2 to 6 mm)

- 7 -

Page 13

,mV(-)

,

(B)

)

g

)

3

4

5

6

8

9

0

(

)

A

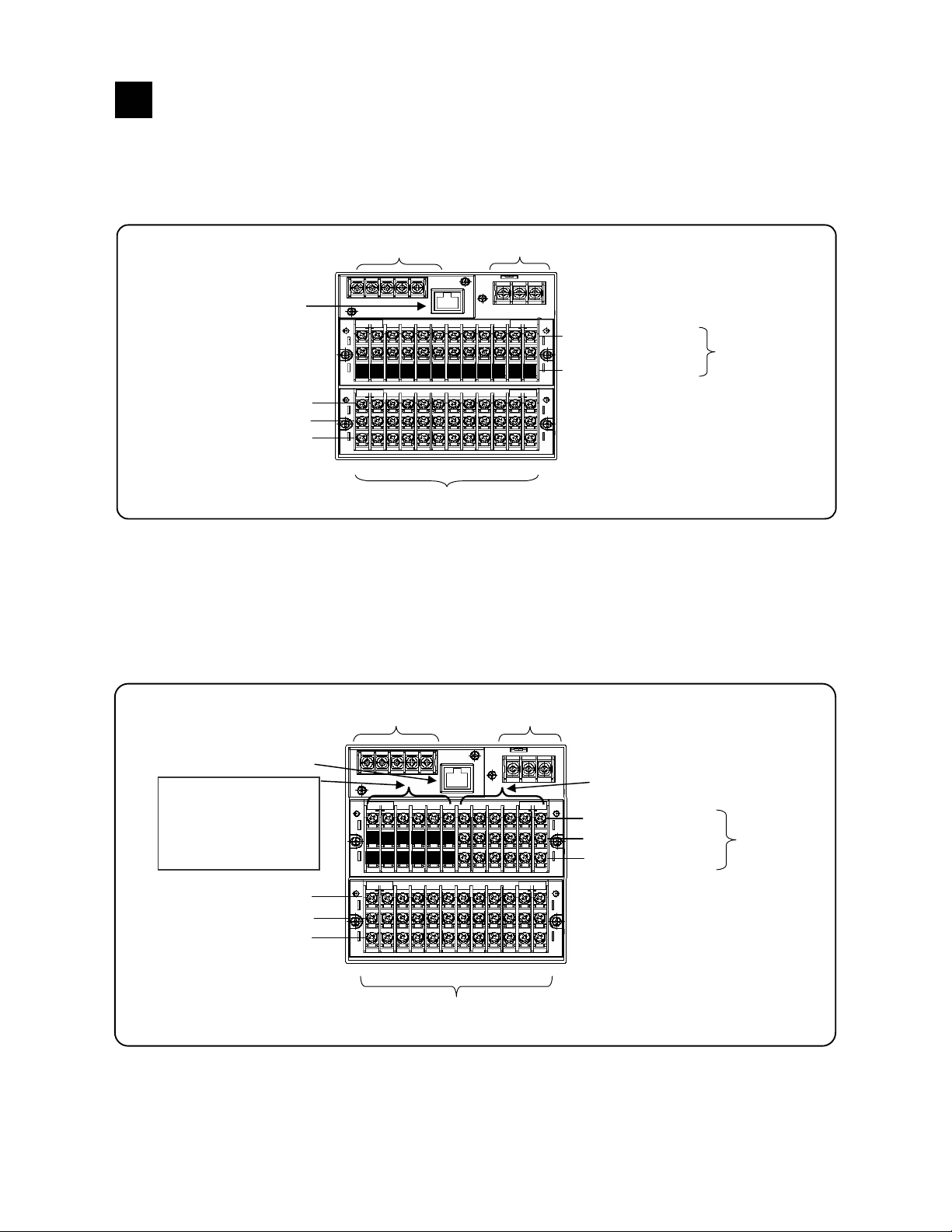

Connections

5

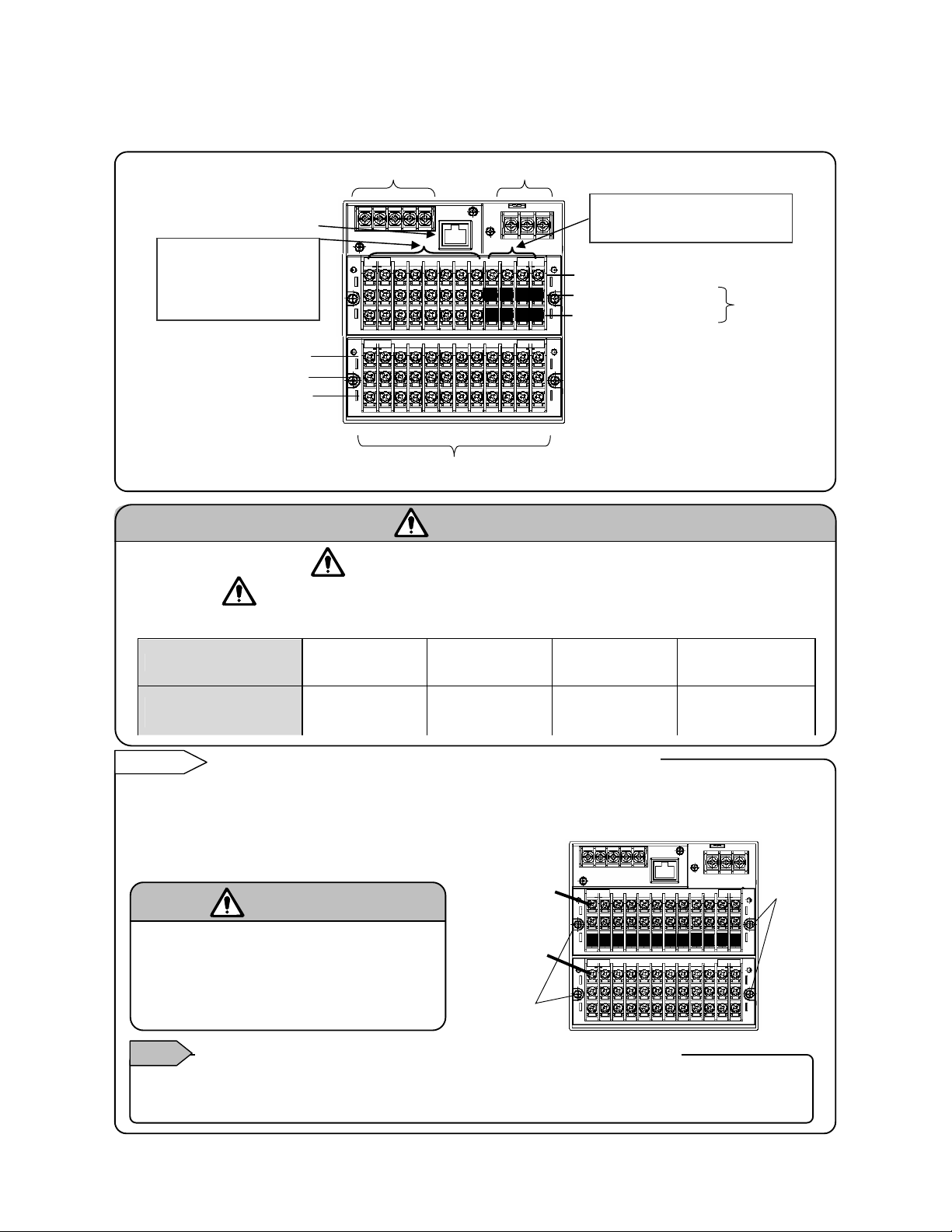

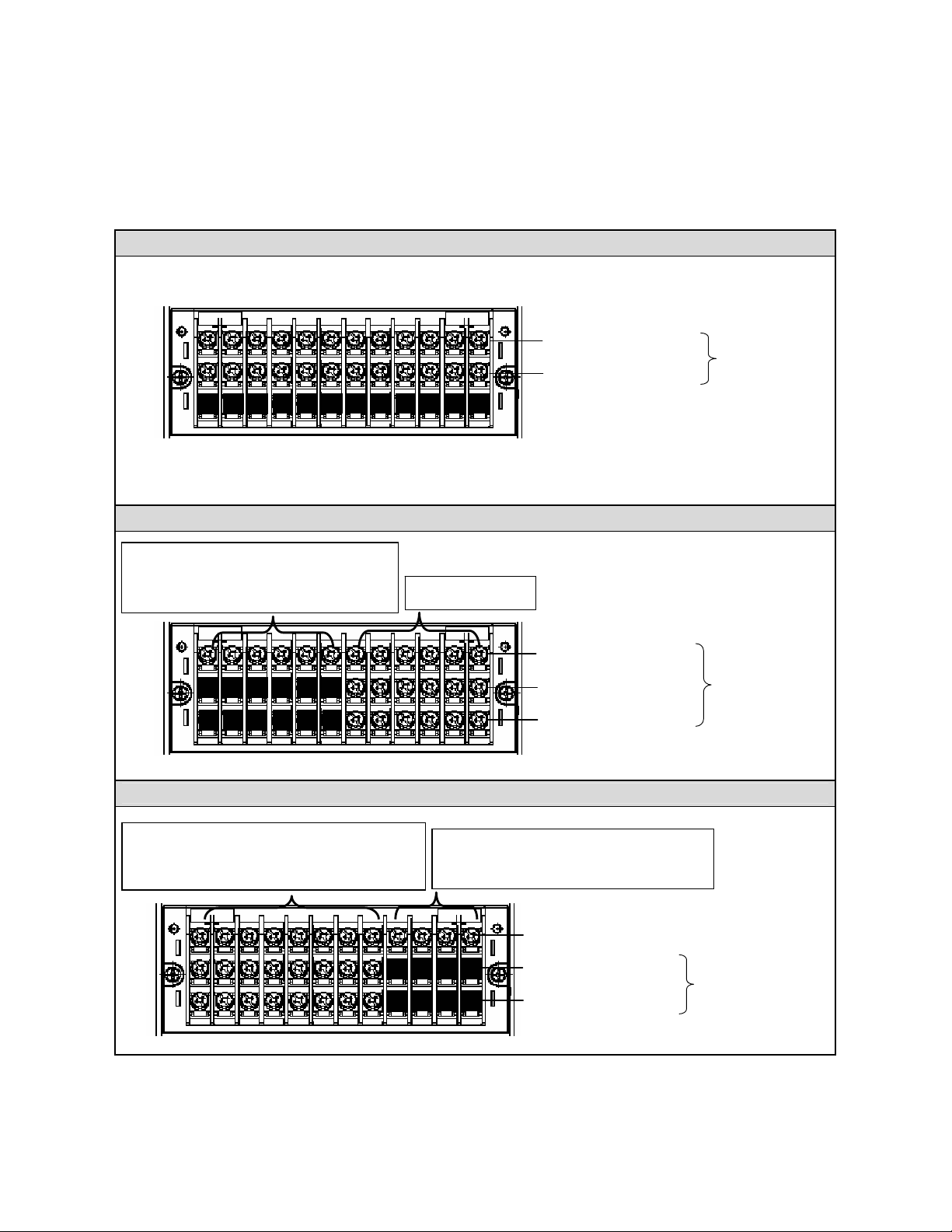

5.1 Terminal board arrangement

The following diagram shows the terminal board arrangement in which option (Alarm relay output [12

points], communication interface) are mounted. Connecter for Ethernet is a standard mounting.

Communications terminal (M4) (for options)

Connector for Ethernet

TC,mV(+), RTD(A) terminal

TC

RTD(B) terminal

RTD

terminal

2

1

Measurin

Following figure is terminal board diagram for option (24VDC transmitter power supply, alarm relay output

[6 points] in RD9900, equipped with communication interface. Connecter for Ethernet is a standard

mounting.

TC,mV(+), RTD(A)

TC,mV(-), RTD(B)

Communications terminal (M4)(option)

Connector for Ethernet

24VDC Power supply

output for transmitter

(From left)

CH1 CH2 CH3

+ - + - + -

terminal

terminal

RTD(B)

terminal

1

2

34

Measuring input terminals

Power/protective conductor terminal (M4)

ø For the connection of communication terminal,

refer to the separate “Communication interface

instruction manual”.

N.O terminal(M 3.5) Alarm relay

terminal(M3.5

COM

(Note) Alarm output in the diagram

is mechanical relay “a”

contact point specification.

7

input terminals(M3.5

7

56

M3.5

11

1

Power/protective conductor terminals(M4)

9

8

10

11

(Note) Measurement input in the

12

12

diagram is 12 points model.

larm output

terminal (M3.5)

N.O

COM

terminal(M3.5)

terminal(M3.5)

N.O

(Note) Alarm output in the diagram is

mechanical relay “C”

connection point specification.

(Note) Measurement input in the

diagram is 12 points model.

output

(12 points)

Alarm relay

output

(6 points)

- 8 -

Page 14

p

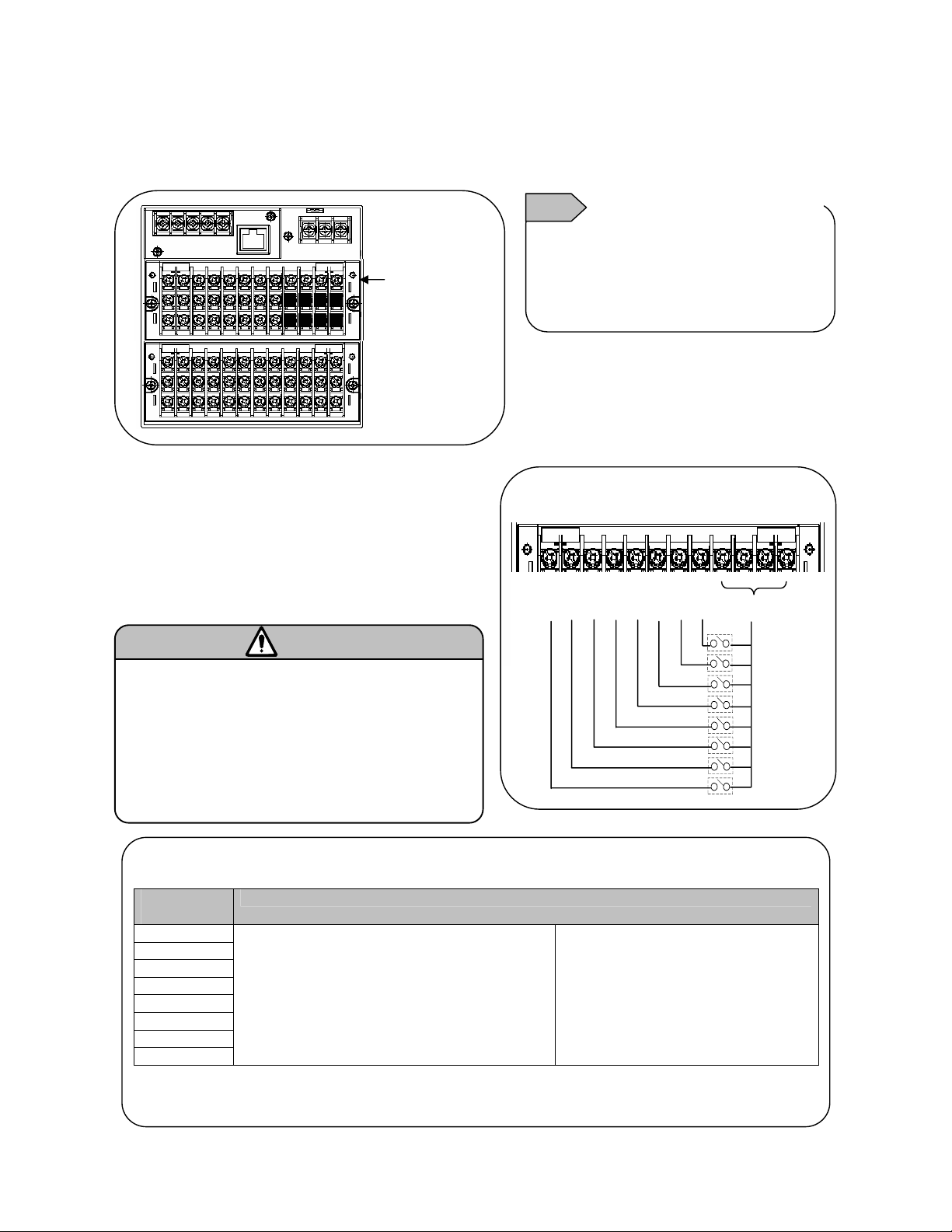

Following figure is terminal board diagram for option (digital input [8 points] + alarm MOS relay output [8

points]) in RD9900, equipped with communication interface. Connecter for Ethernet is a standard

mounting.

TC,mV(+), RTD(A)terminal

TC,mV(-), RTD(B)

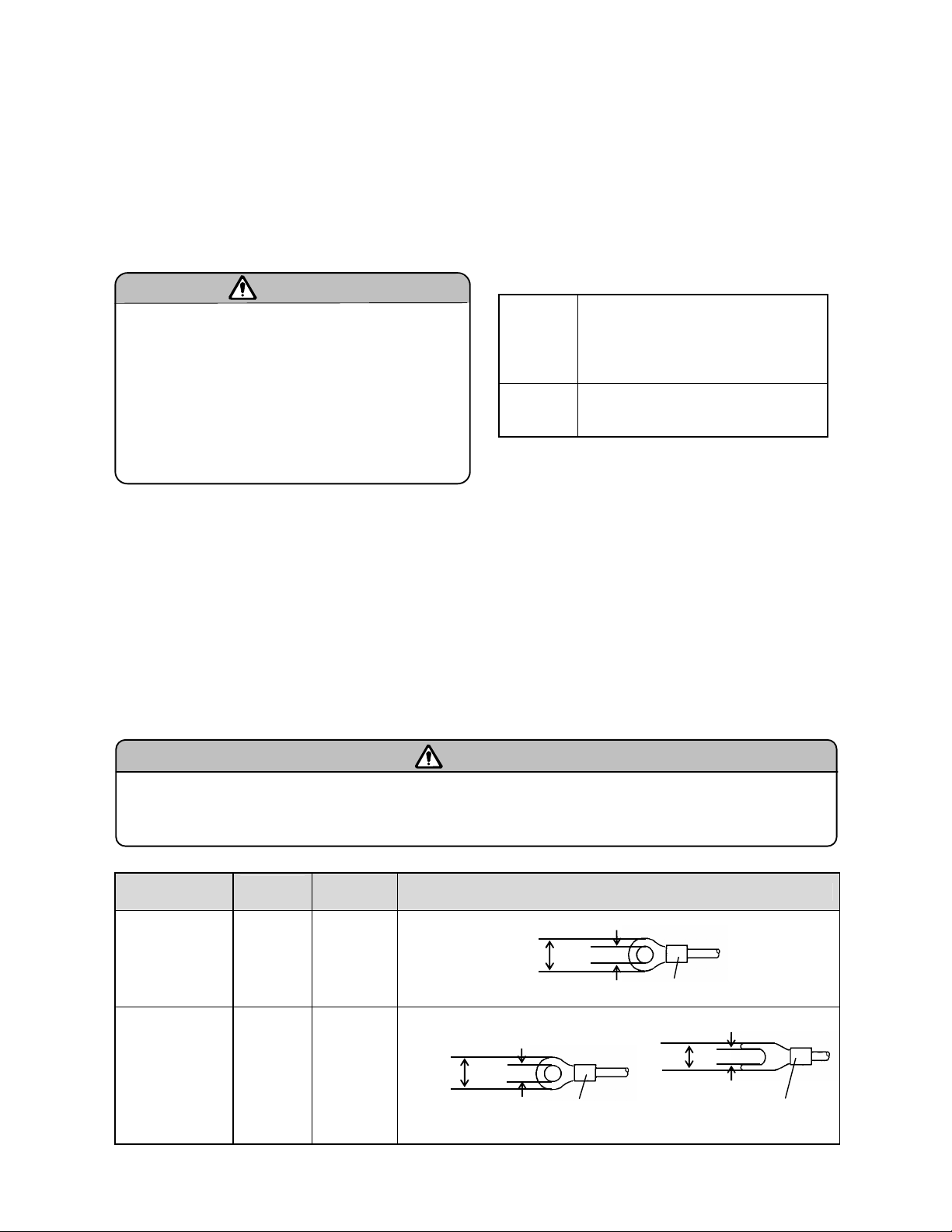

■Alert symbol marks ( )and places

Remarks

Notes

Communications terminal (M4) (options)

Connector for Ethernet

No voltage contact point

input 8 points input

(From left)

CH1,CH2,CH3-CH8

terminal

RTD(B)

terminal

345

1

2

Measuring input terminals

Alert mark is pasted at places where there is a possibility of getting an electric shock on

touching

Place where the alert

(See the following table).

Terminal name

mark is put

Power supply

terminal

On the lower left of

power supply

terminal

Input terminal and alarm terminal blocks are removable

In order to facilitate connection, the input terminal block and alarm terminal block (including the digital

input terminal block) are removable.

It can be removed by removing to mounting screws along with each terminal block

Each terminal block is connected to the instrument

Turn off the power supply in advance

■

For mounting or dismounting the terminal block,

turn off the external power switch to prevent the

electric circuits from being damaged.

Replacement of thermocouple input terminal block

Caution

Thermocouple input terminal block cannot be replaced by terminal block of any other instrument.

If re

laced measurement error occurs.

Power/protective conductor terminal (M4)

No voltage contact point input

(4 points common)

No voltage contact point input (8 point

input)

COM terminal (M3.5)

terminal (M3.5)

N.O

(Note) Alarm output in the diagram is

MOS relay ‘a’ contact point

specification.

6

8

7

(M3.5)

91011

12

(Note) Measurement input in the

diagram is 12 points model.

Warning

Measurement

input terminal

On the upper left

of terminal cover

Alarm terminal

block

Input terminal

block

Mounting

screw

Mechanical relay

‘c’ contact alarm

terminal

On the upper left

of terminal cover

COM

Alarm MOS

relay output

(8 points)

MOS relay, mechanical

relay ‘a’ contact alarm

terminal

Adjacent to alarm

terminal

Mounting

screw

- 9 -

Page 15

5.2 Precautions while connecting

Points to be taken care of before connecting are given below. Please abide by them for safety and

reliability.

1) Source of power supply

In order to avoid mistake in operations, the power

supplied to RD9900 series graphic recorder

should be single-phase power supply with stable

voltage and without waveform distortion.

① Switch and over current protective device

Add a switch and an over current protective device

(3A) to the power supply in order to avoid an electric

shock. This instrument is not provided with

replaceable fuse.

② Turn off the power supply before connection

Be sure to turn OFF the power supply during

input/output connection and power supply, in order to

prevent electric shock.

Warning

2) Away from strong electrical circuits

Avoid placing the input/output cables near or

besides strong electrical circuits like power line

etc. In case of placing it near or besides strong

electrical circuits, they should be separated by at

least 50cm.

3) Thermocouple input should be away from

source of heat

In order to reduce reference junction

compensation error, place thermocouple input,

especially the terminal part away from source of

heat (objects generating heat). Also avoid the

radiations due to direct sunlight.

■

Secure the connected cables properly

Secure the connected cables so that they are not hooked by a person or a substance,

otherwise the connections may be cut and that may cause an electric shock .

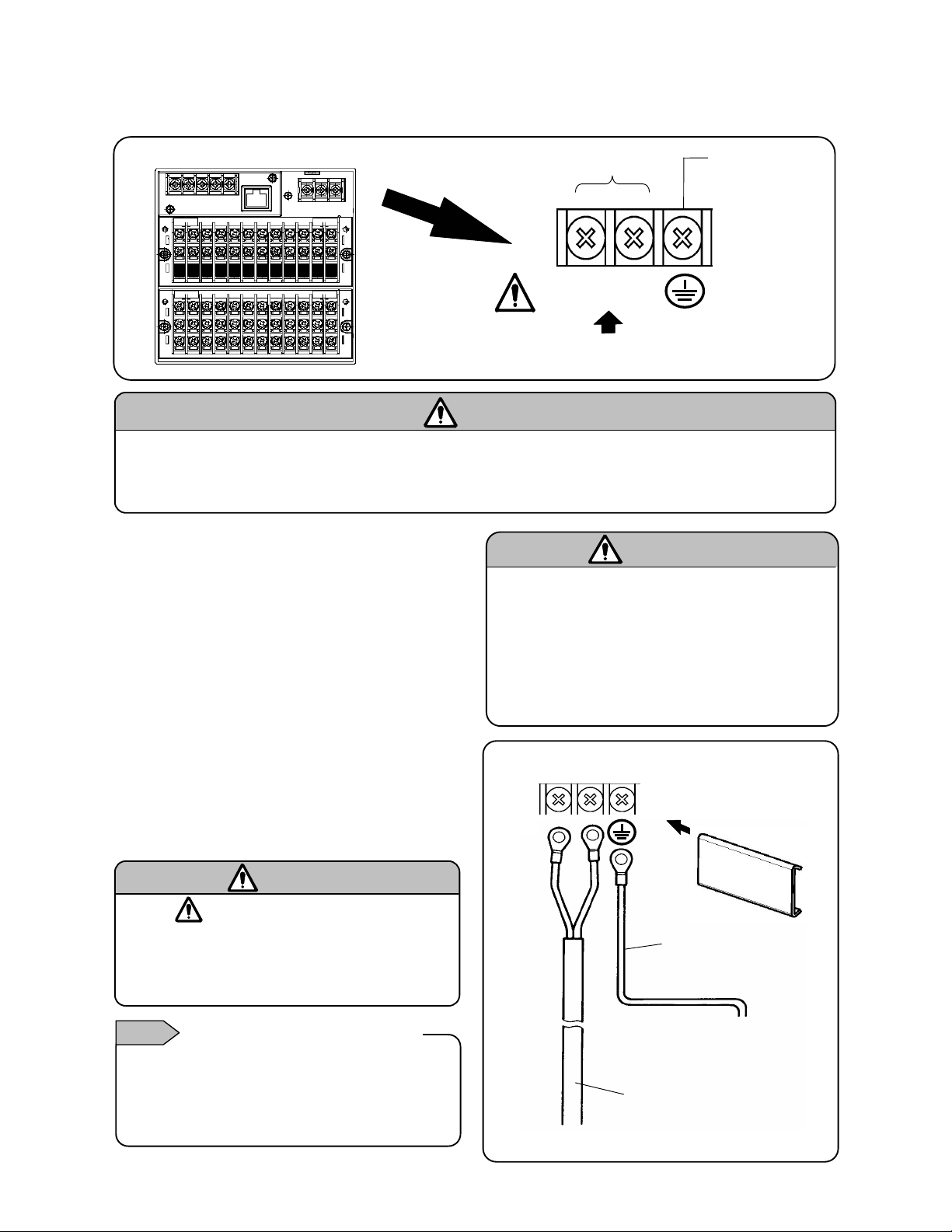

Kinds of terminals and terminal process

Terminal block

Power and

protective

conductor and

communication

terminal

Terminal other

than the above

Screw

diameter

M4 1.2N.m

M3.5 0.8N.m

Tightening

torque

Type O

Type O Type Y

Less than 8

øAs far as possible use TypeO.

4) Keep away from noises

Keep it away from the sources generating noise.

Otherwise unexpected malfunctioning may occur.

In case it is not possible to keep it away from

noise source, take the following

countermeasures.

Major

noise

sources

Counter

measures

●Electromagnetic switch, etc.

●Power line having waveform

distortion

●Inverter

●Thyristor regulator

Insert noise filters between power

supply and input/output terminals.

A CR filter is often used.

5) Use crimp style terminals

① Use crimp style terminal as connection code

terminal to avoid loose or disconnected

terminals and to prevent short circuit between

the terminals.

② Use crimp style terminals with insulating

sleeve to prevent electric shock.

6) Unused terminals

Do not use any unused terminals for relaying,

otherwise electric circuits may get damaged.

.

Warning

Terminal process (Unit: mm)

Less than 8.5

t:0.8

More than 3.7

With an insulation sleeve

More than 4.3

With an insulation sleeve

Less than 8

With an insulation sleeve

t:0.8

More than 3.7

t:0.8

- 10 -

Page 16

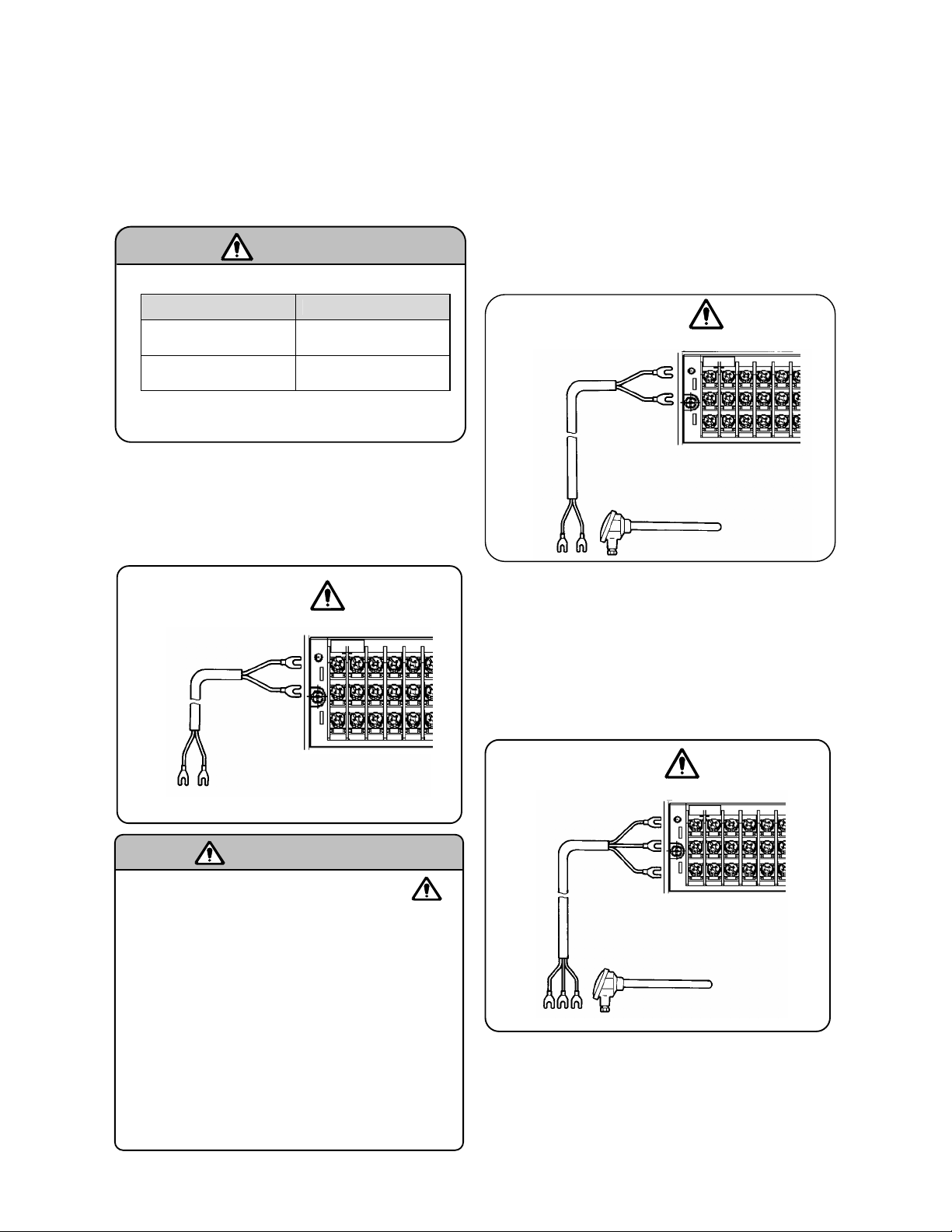

5.3 Connection of power and protective conductor terminals

1) Power and protective conductor terminals

Power supply (voltage, frequency, power consumption)

■Turn off the power supply

Be sure to turn off the power supply before connecting the power supply and protective

conductor terminals to prevent an electric shock.

Warning

2) Connection of power terminals

Power cable used is 600V vinyl insulated cable and

terminal is connected by processing crimp style

terminal with insulated sleeve.

Note: Use the cords with the following standards.

① IEC 227-3

② ANSI/UL817,

③CSA C22.2 No. 21/49

■Be careful with the power voltage and noise

3) Connection of protective conductor

terminal

Be sure to connect to the protective conductor of

the power supply facility. Connection is done after

processing insulating sleeve crimp style terminal.

・ Grounding wire: Copper wire 2mm

(Green/yellow)

■ Mark at power terminal block

A voltage of 100 to 240 V AC is applied to the power

terminals, after connection. Be sure to mount the

power terminal cover after connection, to prevent an

electric shock.

L/N indication of power terminal Notes

It is an indication that conforms to CSA standards

CANADA. Live side of single-phase alternating

current power is L indication and neutral side is N

indication. To get satisfactory performance

maintain the connection of L and N.

2

or more

Warning

Power terminals

L

100-240V AC

50/60Hz 50VA MAX

N

Caution

The power voltage of this instrument is indicated on

the power terminal part. Don’t apply any voltage other

than indicated, otherwise a malfunction or an

accident may result. If there is noise in the power

supply, take countermeasures like installing noise

reduction transformer.

L

Power supply

N

Be sure to connect to the

protective conductor of

the power supply facility.

600 V vinyl insulated cable

Protective

conductor

terminal

Mount the terminal cover

after connections.

A copper wire with 2 mm

or more (green/yellow)

2

-

11 -

Page 17

A

(+)

5.4 Connection of measuring input terminal

1) Measuring input terminal

Connect after switching off the power supply to

prevent electric shock.

● In input terminal, do the connections using crimp

style connection with insulated sleeve.

■Allowable input voltage

ø Channel in which setting are done in a

Input type Allowable input voltage

Voltage,

thermocouple input

Resistance

thermometer input

range of ±5V or higher is ±60VDC

Caution

±10VDCø

± 6VDC

2) Connection of DC voltage (current) input

In order to suppress noise, use twisted cable as

input cable for instrumentation. Connect the current

input after connecting current input shunt resistor to

the channel to be measured.

●DC voltage (DC) input

DC voltage input

Twisted cable

for

instrumentation

(-)

Warning

■Mark on measuring input terminal block

High voltage can be applied to measuring input

terminal, using common mode. The allowable noise

value is lower than 30 V AC or lower than 60 V DC.

Make sure that the noises are lower than the allowable

values. Mount the terminal cover after connection to

prevent electric shock and to protect the input wires. In

the case of thermocouple input, the mounting of the

terminal cover reduces the reference junction

compensation error.

1 2 3 4 5 6

3) Connection of thermocouple (TC) input

Always connect by thermocouple wire (or extension

wire) up to the input terminal of KR 2000 series

recorder. If copper wire is used for connection in

between, noticeable error occurs in measurement.

Avoid using pair of thermocouple wires for

connection in parallel with other instrument

(controller etc) as malfunctioning may occur.

4) Connection of resistance thermometer

In order to avoid measurement errors, use 3-core

input cable, where the resistance value of each

cable is equal.

One resistance thermometer cannot be connected

in parallel with other instrument (controller etc.)

●Resistance

●Thermocouple

(TC) input

Red (+)

White (-)

Compensation

lead wire

(RTD) input

thermometer input

3 core cable

(Same diameter, same length)

Note: The resistance of each cable is

less than 10 Ω. All the 3 wires should be

of the same resistance value.

Resistance thermometer

1 2 3 4 5 6

Thermocouple

1 2 3 4 5 6

B

B

-

12 -

Page 18

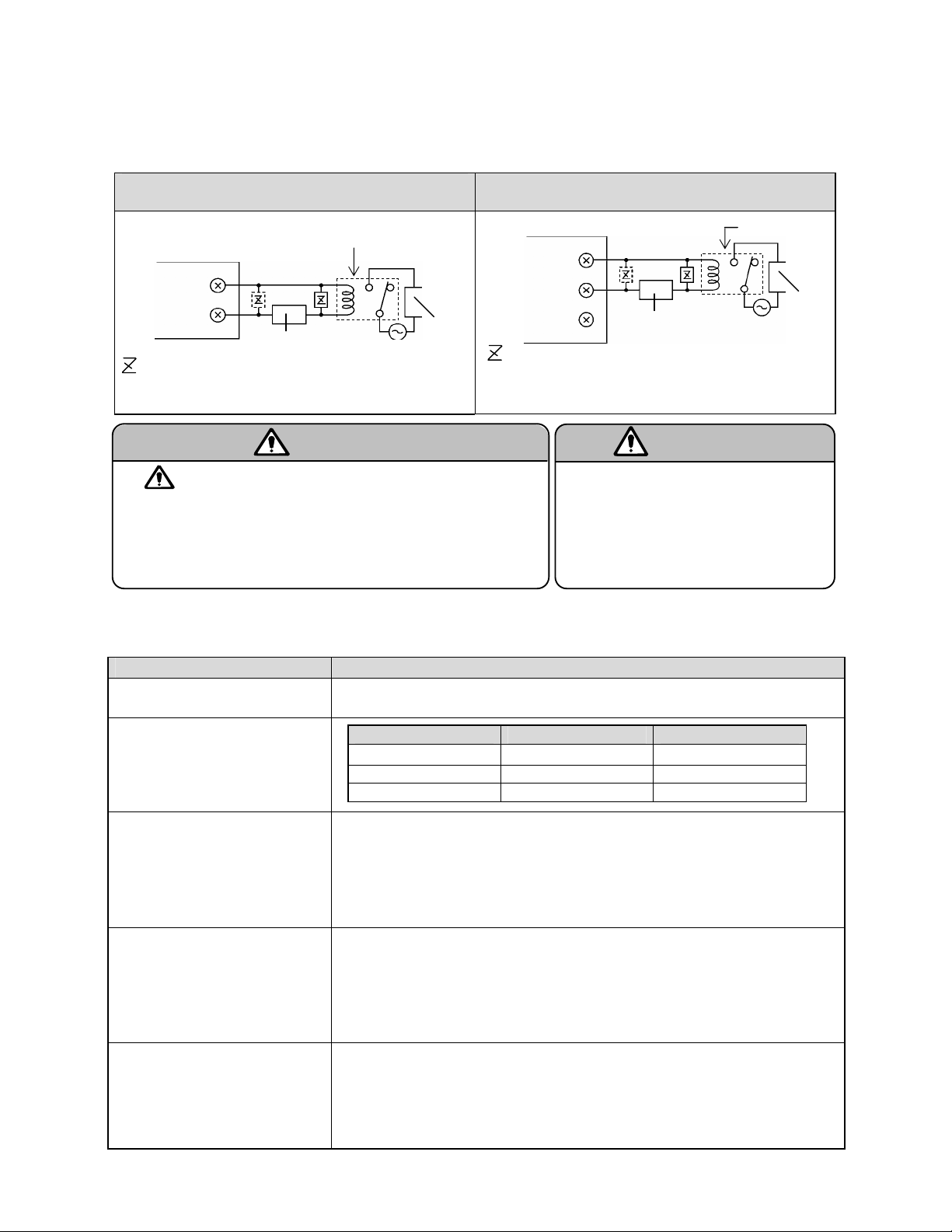

5.5 Connection of alarm output terminal (Option)

Following connections apply only to RD9900 series graphic recorder with alarm output (option).

1) Alarm output terminal

Terminal configuration varies depending on the output specifications.

Alarm relay output (1a)

24VDC Power supply output for transmitter

(From left)

CH1

+ -

CH2 CH3

+ - + -

N.O terminal (M 3.5)

COM terminal (M 3.5)

Alarm relay output (1c)

Alarm relay output

N.O terminal (M 3.5)

COM terminal (M 3.5)

N.C terminal (M 3.5)

Alarm relay

output

(12 points)

Alarm relay

output

(6 points)

(From left)

Digital input (8 points)

DI 1,DI 2,DI 3 - DI 8

Alarm MOS relay output (1a)

Digital input DI COM

(4 points common)

No voltage contact point input 8 point input

COM terminal (M 3.5)

N.O terminal (M 3.5)

-

13 -

Alarm MOS relay

output

(8 points)

Page 19

r

2) Connection

In order to prevent an electric shock, turn off the power supply and buffer relay power supply before

doing the connections.

① Connect to load via buffer relay.

② Connect to alarm output terminal using crimp style terminal with insulated sleeve.

Example of MOS relay and mechanical relay ‘a’

contact output

RD9900 series

graphic recorder

N.O

COM

: Contact point protective element (It is recommended to

mount this element on the a side)

■ mark on alarm output part

Connect a load which does not exceed the specified contact

capacity, to the alarm output terminal. A buffer relay power

supply is applied to the alarm output terminal after connecting.

Hence do not touch this terminal one may get a shock.

Be sure to mount the terminal cover after connections.

Buffer relay

Power

a

Load

b

Warning

Example of mechanical relay ‘c’ contact output

RD9900 series graphic recorde

※ N.C terminal as against N.O terminal is released at

N. O

COM

N. C

※

: Contact protective element (It is recommended to

mount this element on the a side)

the time of alarm activation.

b

Power

a

Caution

Buffer relay

■Take safety measures

Output malfunction may occur in this

instrument due to erroneous

operation/failure, abnormal input etc.

Take safety measures against this as

per the requirement, before using.

3) Precautions for connection

Following are the precautions to be taken during connection.

Item Contents

Contact capacity of MOS relay

output specifications

Contact capacity of mechanical

relay output specifications

(a contact, c contact common)

●Maximum voltage…240V (AC,DC)

●Maximum current…50mA (AC,DC)

Power supply Resistance load Induction load

* Irrespective of load types

100 V AC 0.5 A 0.2 A

240 V AC 0.2 A 0.1 A

30 V DC 0.3 A 0.1 A

Load

Mounting of contact protective

element Z

Selection of buffer relay

Selection of contact protective

element

●Mount the contact protective element that conforms to buffer relay.

MOS relay is broken, if a signal exceeding the contact capacity is

applied even momentarily.

●The mounting position is on coil side (diagram ‘a' of clause 2

‘Connection’ of section 5.5) of the buffer relay that effectively lightens

the load and thus prevents malfunctioning.

(1) Coil rating … Within the contact capacity of output terminals

(2) Contact rating ... Two times or more than the load current

A coil surge absorption element built-in type relay is recommended.

Mount an additional buffer relay if a buffer relay satisfying the load rating

is not available.

Mount this element when buffer relay of surge absorption element built-in

type is not available.

This element is generally composed of C·R (condenser + resistor).

Reference value of C·R

C:0.01µF (Rating around 1KV)

R:100 to 150Ω (Rating around 1W)

-

14 -

Page 20

5.6 Connection of digital input and operation selection (Option)

Following connections apply only to RD9900 series graphic recorder with digital input (option).

1) Digital input terminal

Upper step

Digital input

terminal

●Voltage when the contact point is

●

2) Connection

In order to prevent electric shock, turn off the

power supply before connection.

① Apply a no-voltage contact signal to digital input

terminals.

② Connect to digital input terminal using

crimp style terminal with insulated sleeve.

■No voltage contact input

For the contact to be connected to the digital

input terminal, use a switch or relay driven

at lower than 30 V AC or lower than 60 V

DC, or use manual contact supporting very

light loads.

■Function of the terminal

Te rm i na l

name

DI 1

DI 2

DI 3

DI 4

DI 5

DI 6

DI 7

DI 8

●Each function requires a short circuit of 0.1 seconds or more between COM terminal and

each terminal.

Warning

① Digital Input

To be used as contact input

② Pulse Input

To be used as pulse input

③ Integration Reset

Resets integration operation

■Connection example

DI 1 2 3 4 5 6 7 8 COM

Function

Features of digital input terminal Notes

open : Approximately 5 V

Current in case of contact point short

circuit : Approximately 2 mA

④ Marker

Displays marker

⑤ File Drive

Executes recording start/stop of

data file of internal memory

-

15 -

Page 21

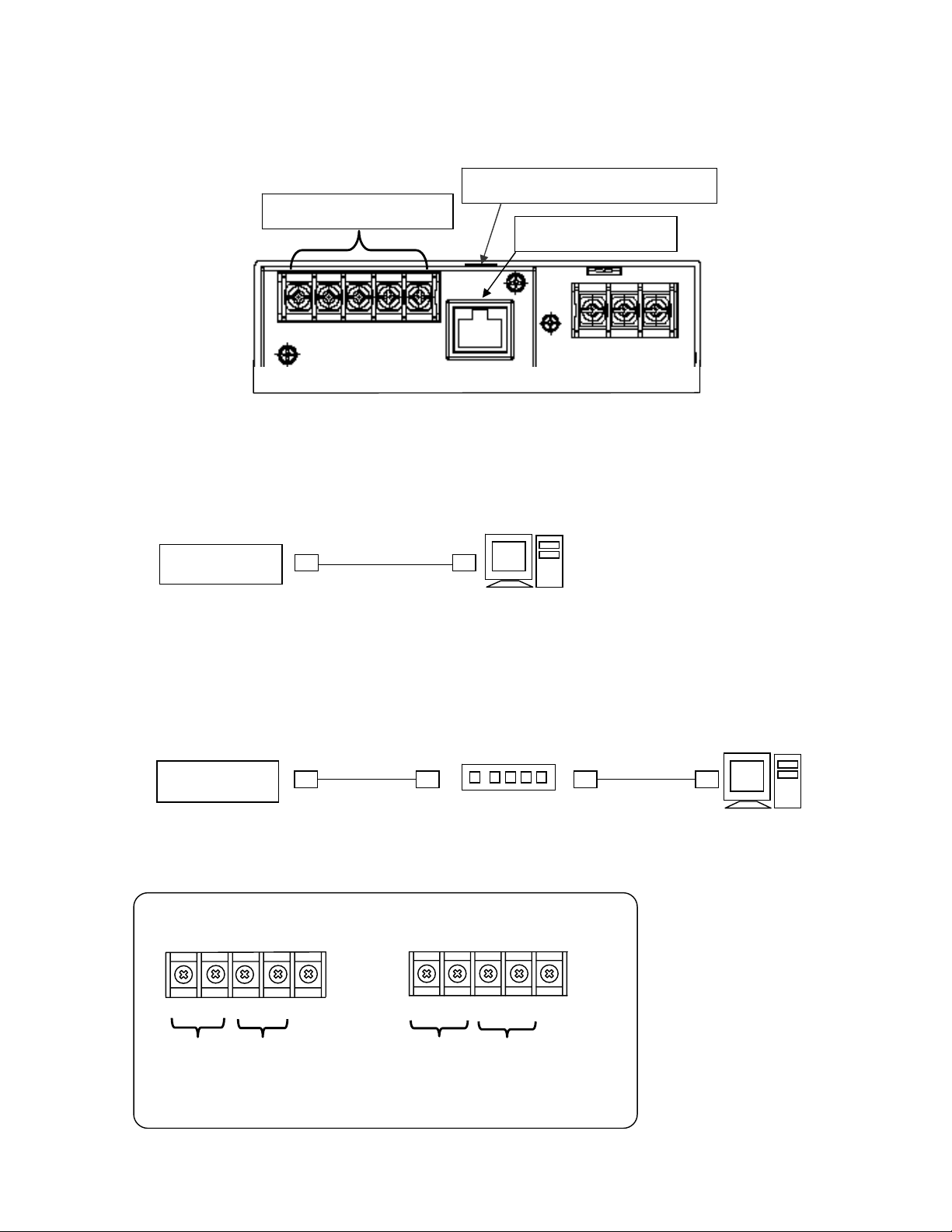

5.7 Connection of communication I/F terminal

The RD9900 communicates with high order instruments via Ethernet and RS232C/RS485, and with low

order instrument via RS485.

RS485/232C terminal

1) When carrying out high order communication using Ethernet

[In case of 1 is to 1 connection with PC]

In case of connecting PC and Ethernet IF as 1 is to 1, use cross type STP cable.

RD9900

STP cross

cable

[In case of N is to N connection with PC]

In case of connecting to existing LAN or a number of PCs, use straight type STP between hub and

Ethernet unit, using switching hub.

RD9900

STP straight

cable

2) Kind of communication terminal

RS485/232C change over switch

Ethernet connector

PC

(With LAN function)

Twist pair

Straight cable

Hub

PC

(With LAN function)

● RS485 + 232C

SA

Low order

*SG is common

SB

RD SD

SG

High order

● RS485 + 485

SB

-

16 -

SA2

SB2

SA1

Low order High order

SG

Page 22

7 8

7

8

7

8

3) High order communication for RS232

There are only 3 communication terminals of this instrument viz. SD,RD and SG and control signal is not

used. General PC uses control signal. The wiring of the control signal in the connector differs depending

on how the PC uses control signal, hence read the operation manual of the PC to be used.

① Example of 9 pin connector

Personal computer

RD9900 series

graphic recorder

1

CD

2

RD

SD

ER

SG

DR

RS

CS

3

4

5

6

7

8

Within 15m

② Example of 25 pin connector

Personal computer

(Example 3)

Personal computer

(Example 2)

2

SD

3

RD

RS

CS

DR

4

5

6

SG

ER

20

RD

SD

SG SG

SD

RD

RS

CS

DR

SG

CD

ER

SD

RD

SG

Personal computer

(Example 1)

2

3

4

5

6

RD

SD

SD

RD

RS

CS

DR

2

3

4

5

6

RD9900 series

graphic recorder

SD

RD

SG

SG

CD

20

ER

20

Within 15m

-

17 -

Page 23

(9-p

7

8

7 8

4) Connection of RS232C/485

Connect to the PC using protocol converter (our model:SC8-10).There are only 3 signals viz. SD, RD

and SG between protocol converter and PC and control signal is not used. Wiring process of connector

similar to “(3) High order communication for RS-232” on the previous page, is necessary.

Installing termination resistance

Notes

To ensure the transmission of communication data of RS232C or RS485, termination resistance is

installed in both the terminals of transmission route. When protocol converter (SC8-10) takes both the

terminals of transmission circuit, short ④ and ⑤. By doing this termination resistance is inserted.

① High order communication for RS485

Sent

data

Received

data

Personal computer

Above figure

is an example

of 9 pin connector.

in or 25-pin)ø

2

RD

3

SD

4

ER

5

SG

6

DR

RS

CS

Within 15m

Protocol converter

(SC8-10)

1

RD

2

SD

3

SG

graphic recorder

RDA

RDB

SDA

SDB

4

5

6

Within a total length of 1.2Km (max 31 recorders)

485+485

RD9900 series

SA2

SB2

SG

Internal

circuit

232+485

RD9900 series

graphic recorder 2

1

SA

SB

SG

For wiring process of connector, refer to “3) High order communication for RS-232”.

ø

RD9900 series

graphic recorder 3

SA

SB

Termination resistance

SG

SA

SB

100Ω 1/4W

② Low order communication for RS-485

《Connection example》

RD9900

(High order

instrument)

Low order instrument

RD200

(Low order

instrument)

(Low order

instrument)

RD2800

(Low order

instrument)

SE3000

- 18 -

Page 24

Connection example

SA2

SB2

SA

SB

SDA

SDB

RDA

RDB

SG

SG

SG

RD9900

RD200/2800

SE3000

For details of low order connection instrument, input points and connections of various

instruments, refer to “Communication interface edition”.

Termination

resistance

100Ω・1/4W

- 19 -

Page 25

P

Operation (Be sure to read section to ensure safety.)

6

Initial setting values are set in RD9900 series graphic recorder at the time of shipping them from the

factory Always do the following settings during actual operation.

Start

Preparation

① Mount RD9900 series graphic recorder to the panel. ( Installation)

② Finish the connections. ( Connection)

① Initial settings at the time of power supply (10 Initial settings…It is necessary to do these settings)

② Do batch setting by HOME settings mode screen (12.1 Set using HOME settings) or, do individual

settings of each channel by the following sections.

③ Input system settings (13.2 Input, calculation settings)

④ Display system settings(13.3 Display settings)

⑤ Recording system settings (13.5 File settings)

5

Do the following parameter settings.

Start operation

Operation screen

switching

Screen switching

8

method

Start/end operations

of recording

13.5 File settings

ower ON

Settings

4

1

This instrument temporarily stores

the measurement/calculation data

etc. on the inbuilt RAM and does

the data processing, display etc.

In case of saving the data, set the

file and save the data on external

CF card.

Storing the data in

the memory card

13.5 File settings

● On a part of LCD some of the images may always be lit and some may not be lit.

However as a characteristic of LCD there is an uneven brightness and it is not a

malfunction.

End operation Power OFF

- 20 -

Page 26

Name of component part

7

7.1 Name of the front panel and its major functions

Display

5.6 inch TFT color LCD

Operation screen: Refer

to

9

Key cover

USB port

File on the CF card can be accessed

by connecting to the PC.

Key case raised

Key cover raised

Power switch

CF card drive

■Front glass

The front of display part is made by glass. To avoid injuries

due to broken glass, do not blow the glass hard.

- 21 -

Caution

Page 27

7.2 Name of the key and its functions

Functions and methods of using the key differs depending on operation screen and setting screen.

Key

Recording starts Not used

START

Recording stops Not used

STOP

Key of each screen and their major functions and methods of using

Operation screen Setting screen

Used for switching of

SCROLL

scroll mode and for

moving to historical trend

Used for switching the

CURSOR

cursor mode in historical

trend

Performs marker writing

MARKER

to trend

Not used

Not used

Not used

Displays DISP menu Snapshot is taken by pressing for a long time

DISP

Displays HOME setting

HOME

MENU

ESC

screen

Displays MENU setting

screen

Used for canceling the

menu or for returning to

the previous screen

Exits HOME screen

Returns to the previous screen

Clicked for returning from setting screen to operation

screen and for returning to the previous screen.

ENTER

Direction key

Decides the menu item

and also displays the

ENTER menu

Used for opening the menu that is selected by the

cursor and for deciding the numeric value or character

selected by the cursor.

Used for returning from setting screen to operation

screen and for storing parameters.

Selects menu item and

also changes the display

group and channel

Used for moving the cursor to the left, right, up and

down

- 22 -

Page 28

7.3 Method of inputting the characters

Used for inputting/setting the password, setting marker text string, setting tag name etc.

By taking the focus (blue) to upper case English

characters, lower case English characters and Kana,

the input character list underneath, changes.

When character input screen is displayed, if down key of the direction key is clicked, after taking the

focus (blue) to upper case English characters and kana etc. the focus moves to the below column.

When the focus (blue) moves to the below column, move the focus using the arrow key up to the

character to be entered and the click the ENTER key. Selected character is displayed in the character

display column.

Upper case alphabets, symbols and numbers can be entered.

Lower case alphabets, symbols and numbers can be entered.

Insert/overwrite is selected.

(Insert/overwrite toggles at the time of selecting.)

Characters selected in the character input column are deleted.

The character that is one position before the selected character, in the character input

column, is deleted.

Entered character is decided. Similar is the case when ENTER key is

clicked after moving the focus to character input column.

Character display

column

- 23 -

Page 29

MEMO

- 24 -

Page 30

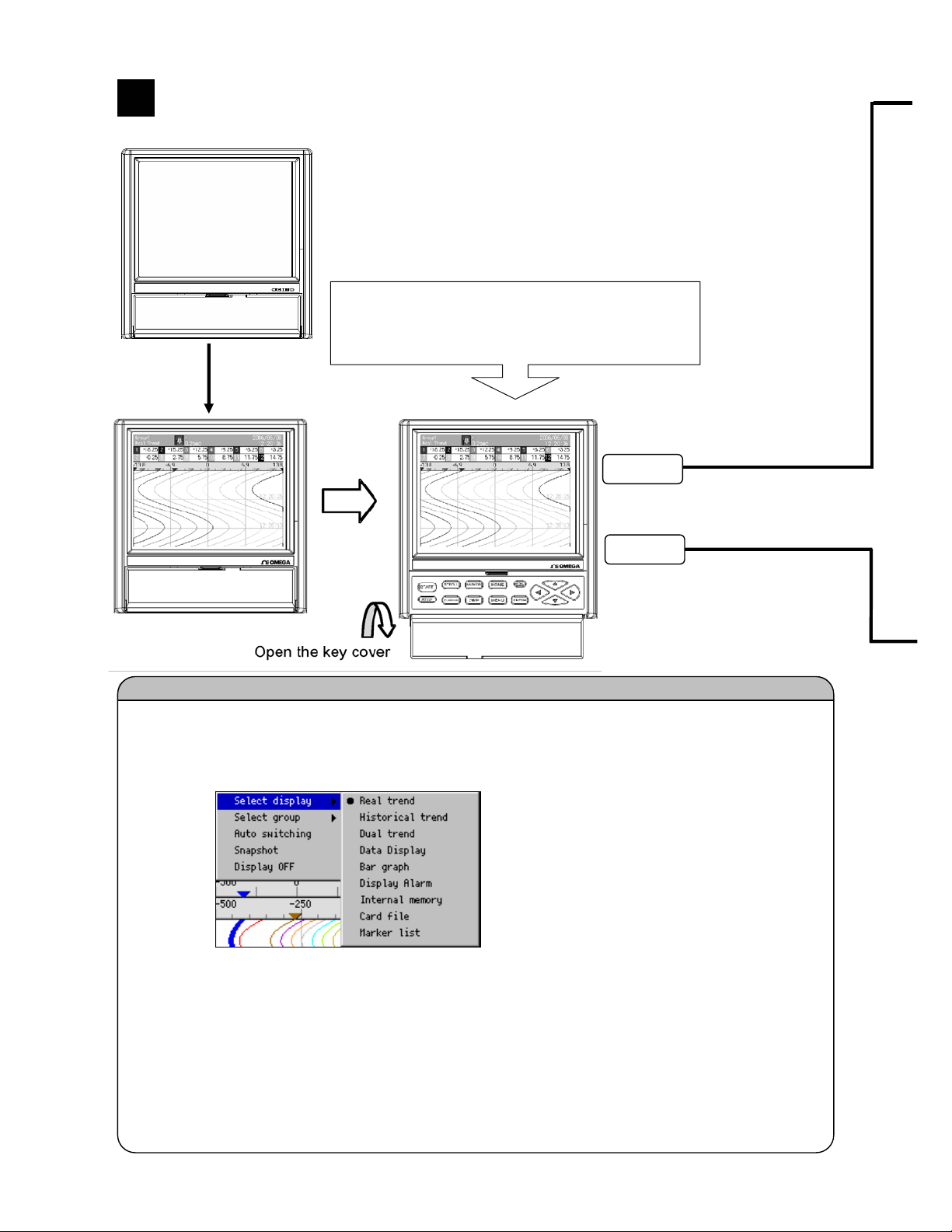

Screen switching method

8

When the power is turned on, operation screen is displayed after

performing the initial operation for about 10 seconds. (Settings at the time

Initial operation

screen

Approximately

Switching of operation screen is done by selecting the DISP menu. Switch over to the desired

screen by doing the following operations.

① DISP menu is displayed by clicking the DISP key.

② Select the menu by using the direction key and on clicking the ENTER key, selected

ø If “auto switching” is selected (status is checked) display group is automatically switched at a

fixed interval.

10 seconds

screen is displayed.

・ Display selection: Display type (Real time trend, data value display etc.) of the

screen can be changed.

・ Group selection: Group to be displayed can be changed.

of shipping from the factory: Real trend screen).When the power supply

was turned ON after changing the operation screen, “Operation screen

that was selected when the power supply was OFF” is displayed.

If the key mentioned on the right is clicked from the

operation screen, one switched over to settings

screen and each parameter can be set.

Switching to settings screen

HOME

MENU

Method of switching of operation screen

- 25 -

Page 31

<HOME settings>

Used in order to facilitate identical settings of all channels. Only some items can be set.

Items being recorded cannot be used.

<MENU settings>

Used for normal settings. All the items can be set. Even while recording, all the settings can be seen

however there are items for which partial setting cannot be done. Items that cannot be set are

displayed in gray.

- 26 -

Page 32

Name and functions of operation screen

9

9.1 Common operations of operation screen

(Method of using each key)

START

STOP

DISP

HOME MENU

ENTER

ESC

(Display data)

Measurement data displayed in each screen

Measurement

data

(Numeric value) Displayed based on display scale settings of each channel

BURN

OVER

UNDER

CAL ER

RJ ERR

Data display is updated every 0.1sec irrespective of the recording interval and excluding historical data

display part of historical trend and dual trend. In order to slow down the updating speed, change “Date

display update interval” (Refer to chapter 13.3.3)

Start the recording. Record in the internal memory the data of the group for which

recording conditions are formed. Group for which recording conditions are not formed is in

waiting status, and recording starts at the time of forming. If recording conditions are not

formed, the status is waiting status.

Storing into CF card is automatically done during save interval and at the time of file

completion.

Stop the recording. Change the recording status of all the groups to stop status. File that is

being recorded is completed and stored into CF card.

Display DISP menu

Menu item Operation contents

Display selection Changes the kind of operation screen.

Select group Changes the display group

Auto switching Automatic switching of group and channels to ON/OFF. When the

Snapshot Saves the hardcopy of the screen to CF card (SNAPSHOT folder).

Display OFF Turns OFF the LCD display. It is redisplayed if some other key is

Displays ENTER menu. Contents of menu differ depending on the screens.

Return to the previous screen. Returns only for real time trend, bar graph and numeric

display.

For vertical trend,

Change the display group using the up and down keys and change the display channel

using left and right keys.

For horizontal trend,

Change the display group using the left and right keys and change the display channel

using up and down keys.

Contents

The upper and lower limits of display scale are displayed as decimal digits.

When kind is “Exponent”, it is displayed in exponential format like “1.2E+3”. In this

case, the significand part after the decimal can be set up to 2 digits however due to

the screen only 1 digit is displayed.

Open circuit the terminal

Value exceeding the upper limit value that can be measured, is measured

Value less than the lower limit value that can be measured, is measured

Calculation error

Instrument is abnormal

.

checkbox is checked the status is ON. Invalid when auto switching

time is set as 0.

clicked.

Each setting screen is displayed.(Refer to chapter 7.2)

- 27 -

Page 33

9.2 Status bar

Status bar is always displayed on the top part of the screen. Displays the status etc. of the instrument.

Normally the back color is green but when the schedule (refer to 13.7) is set, it becomes gray for period

other than the schedule period.

Screen type and group

name that is currently

selected

Back color displays recording status of the group that is currently displayed.

Back color Status

Green Recording. The arrow moves.

Green blinking START key is clicked however, the recording is in wait status as the

Gray

Yellow Remaining capacity of the CF card is less than 10%.

Red CF card capacity is nil.

When X is displayed on the disk mark, it indicates that CF card is not inserted.

Circular stamp on the upper right of the icon shows the access status of CF card. If CF card is

removed when the color is red, one may lose the data. Remove the CF card when the circular

stamp is gray.

Color Status

Gray Not accessing the CF card.

Yellow Writing in the CF card within approximately 5 seconds.

Red Accessing the CF card

Shows the activation status and confirmation status of the icon. Confirmation (ACK) of alarm is done

using the ENTER menu in the operation screen.

Alarm iconø

Icon status Alarm status Confirmation (ACK)

Lit ON Completed

Icon internal blinking ON Incomplete

Icon blinking OFF Incomplete

Hide OFF

Disk icon showing

recording status

etc.ø

Displayed when there are channels that are not

displayed on the screen even though they are

registered in the current group. If the direction

key that the arrow indicates is clicked, the

hidden channels are displayed. AUTO is

displayed in case of auto switching mode.

Recording interval of the group that is currently

displayed and estimate of remaining recordable

time are displayed alternately.

Disk icon

recording condition is not formed

START key is not clicked.(Stopped using the STOP key)

Alarm icon

status

-

Current time

- 28 -

Page 34

9.3 Real time trend screen

Trend of measurement values can be seen by analog recorder sensation. Pen is displayed in the position

of scale plate that corresponds to “Display position” parameter value of each channel. When multiple

channels set the same “display position”, display pen, trend and scale plate in the contents of display

scale of the smallest channel number in the group.

Measurement data of

alarm activation channel

is displayed in red

Marker

display

ENTER menu function

Magnify/reduce Reduce and display the trend time axis.(Same magnification-1/64)

Key operations other than the common operations (9.1)

SCROLL

Displays historical trend (or dual trend) screen. Operation is the same as the operation of selecting the

historical trend (or dual trend) from DISP menu. If historical trend is selected from DISP menu then

historical trend is displayed after that and when dual trend is selected dual trend is displayed.

MARKER

Marker write dialog box is displayed. Recording cannot be stopped.

Marker text registered before hand in MENU settings is selected and

marker is inserted on the trend by clicking the enter key.

When “Input text” is selected, keyboard screen is displayed and

arbitrary text can be inserted.

Can be selected from

data display

(With/without tag), bar

graph and none

- 29 -

Page 35

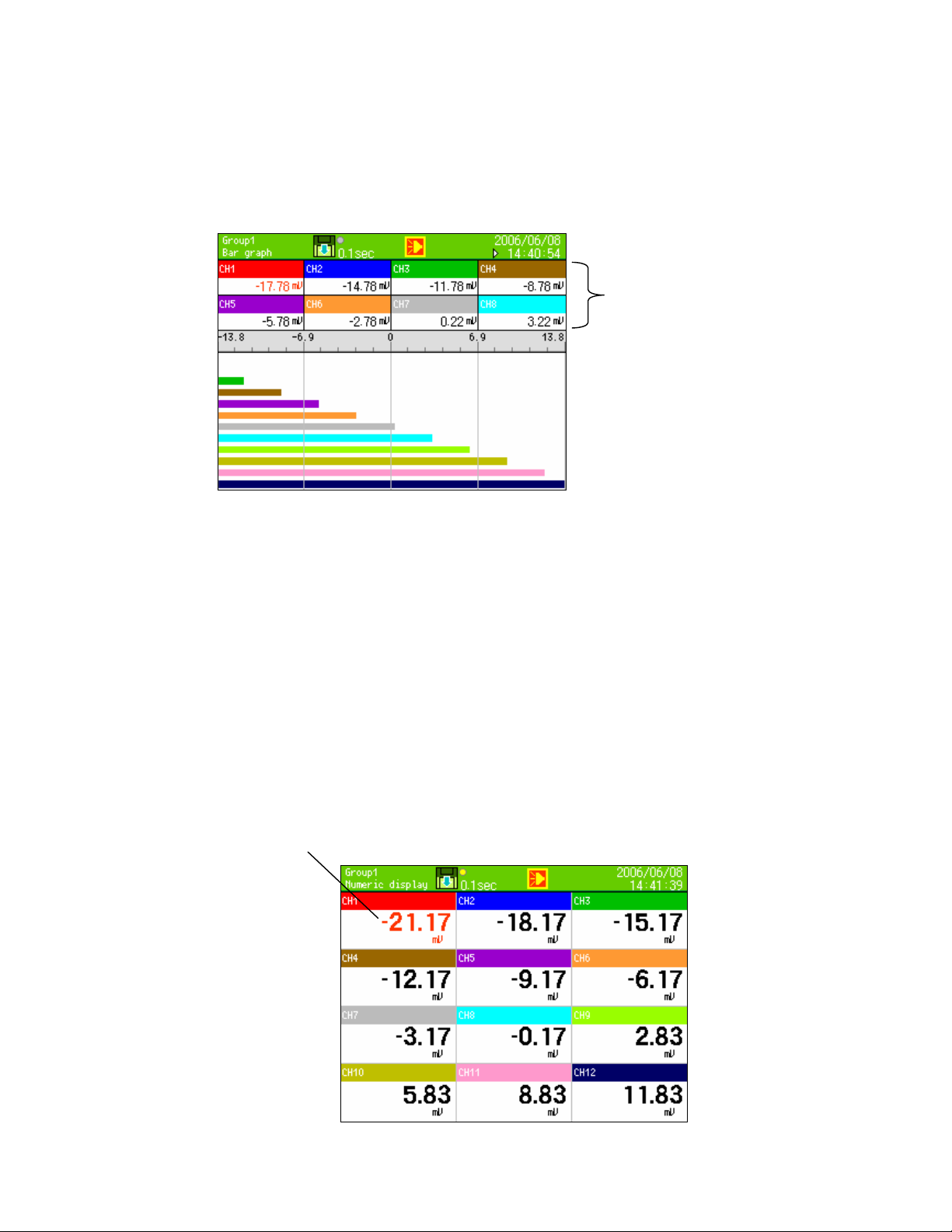

9.4 Bar graph screen

Measurement value is displayed in real time as bar graph and measurement value of each channel can be

seen visually.

The length of the bars and scale plate is displayed in the contents of display scale with smallest channel

number in the group.

Can be selected from data

display (With/without tag) and

none

ENTER menu function

None

Key operations other than the common operations (9.1)

None

9.5 Numeric display

“Measurement data of each channel” and “Alarm activation status” is displayed.

Depending on the “Data display frame count” or number of registration points of the group, data of

channel 1/4/6/12/21/44 is displayed.

Measurement data of

alarm activation channel is

displayed in red

- 30 -

Page 36

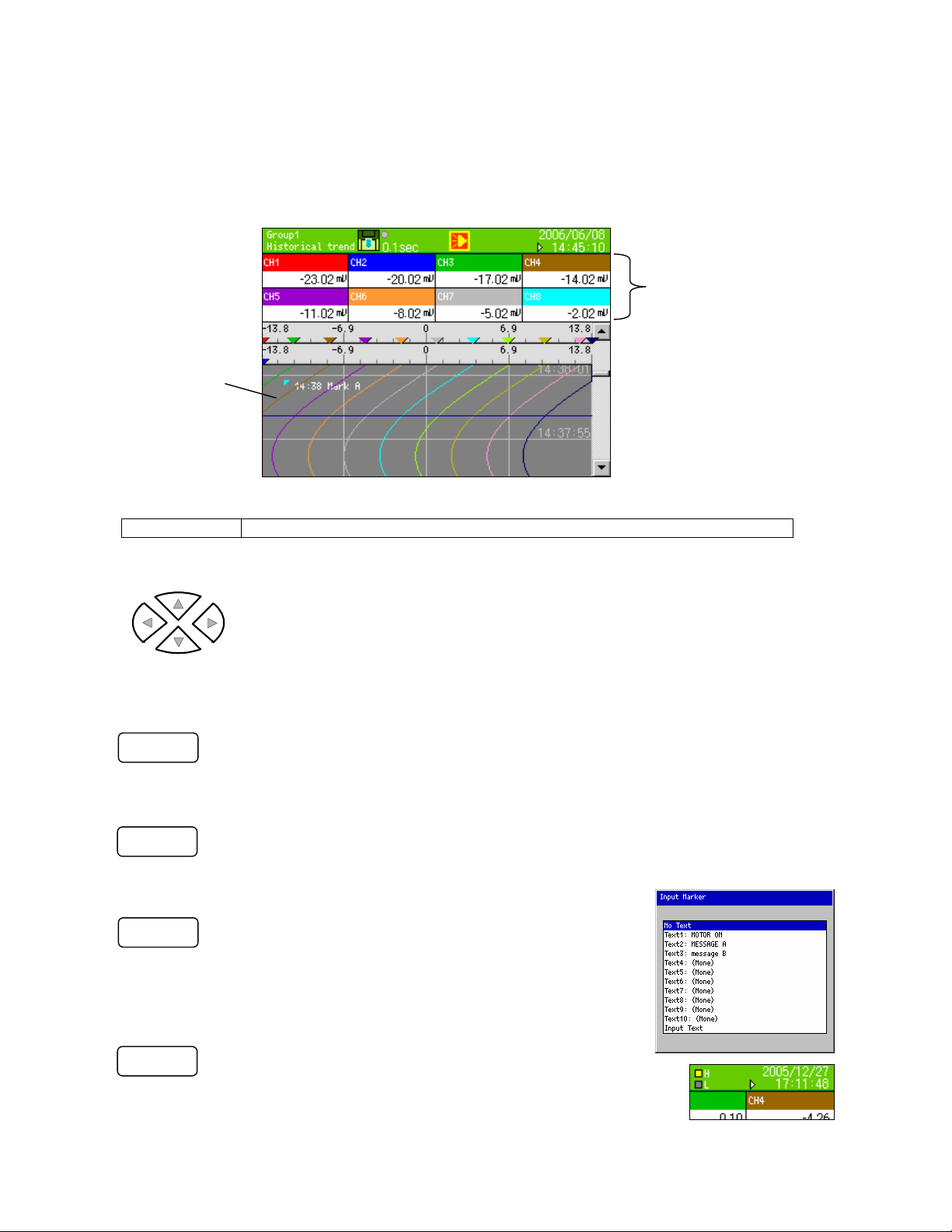

9.6 Historical trend screen

Replays the recorded data and displays it as trend. When “Historical trend” in DISP menu is selected (or

when “SCROLL” key from real trend is clicked), data in the internal memory is displayed. When file is

selected from “internal memory” screen and “card file” screen, data of the target file is displayed.

Historical trend operation method for all the files is the same.

Display method of position of scale plate, trend and pen is same as real time trend.

Market

display

ENTER menu function

Magnify/reduce Reduces and displays the trend time axis.(Same magnification-1/64)

Key operations other than the common operations (9.1)

For vertical trend

Left and right key: Changing the display channel

Up and down key: Moving the cursor when cursor mode is ON and at the time of scrolling the trend

For horizontal trend

Up and down key: Changing the display channel

Left and right key: Moving the cursor when cursor mode is ON and at the time of scrolling the

SCROLL

Scroll mode is switched. When clicked once, scroll bar is enclosed in a yellow frame and

scroll mode becomes ON. In this status if direction key is clicked, screens are scrolled one

by one. When clicked again, scroll mode becomes OFF, and dots are scrolled one by one

using the direction key.

CURSOR

Cursor mode is switched. When clicked once, cursor line is displayed in yellow color and

the cursor mode becomes OFF. In this status if direction key is clicked, scrolling is not done

but cursor line moves. And the data where the cursor is placed is reflected in data display

(or bar).

MARKER

Marker write dialog box is displayed.

Marker text registered before hand in MENU settings is

selected and by clicking the enter key, marker is written in the

position where the cursor is placed.

When “Input text” is selected, keyboard screen is displayed

and arbitrary text can be written.

HOME

When the “data format” of the file to be displayed is

“Maximum/Minimum”, the value to be displayed in data display

(or bar) switches between Maximum/minimum. Other operations

are same as that of HOME key.

Either of the current display is shown in H, L display in the status bar.

Cursor position data display

trend

- 31 -

Page 37

9.7 Dual trend screen

“Real time trend” and “Historical trend” can be split and displayed above and below. Thus the current and

the past data can be compared. Also the data display displays the current value/value of the cursor

position of historical trend by splitting it into above (up) and below (down).

Method of displaying the position of trend and pen is same as that of real time trend however, in case of

settings such as ‘displaying multiple scale plate’, 1 scale plate is displayed, and the numeric value on the

scale plate is not displayed.

Operation method is the same as that of historical trend.

Up: Current measurement value

Down: Historical cursor position data display

ENTER menu function

Magnify/reduce Reduces and displays the trend time axis.(Same magnification-1/64)

Key operations other than the common operations (9.1)

Same as historical trend. (Refer to 9.6)

9.8 Alarm display screen

List of alarms that are activated is displayed. Activation date and time, cancel date and time (cancelled

alarms only), channel (tag name) and kind of alarm are displayed in new order (latest on the top).

Irrespective of the groups all the alarms activated in this instrument are displayed.

Maximum storage count is 1000.If that number is exceeded the oldest ones are deleted.

Selected row is displayed in

yellow color

ENTER menu function

Trend

display

Jumps to the trend of activated date and time of the selected row.

Cannot jump when file not found or when not recorded in activation time.

In this case, the file search is carried out in the order internal memory → CF card.

Key operations other than the common operations (9.1)

SCROLL

Up and down key: Moving the selected row

Left and right key: Not used

Scroll mode is switched. When clicked once, scroll bar is enclosed in a yellow frame and

scroll mode becomes ON. In this status if direction key is clicked, screens are scrolled one

by one. When clicked again, scroll mode becomes OFF, and rows are scrolled one by one

using the direction key.

- 32 -

Page 38

9.9 Internal memory screen

Files recorded in internal memory are displayed

as list. Start date and time, end date (item being

recorded is the latest data time) and time and

data count are displayed. Files are displayed in

new order (Latest on the top).All the files only of

the selected group are selected.

ENTER menu function

Trend display Files of the selected row are displayed as trend.

Key operations other than the common operations (9.1)

Selected row is displayed in

yellow color

Up and down key: Moving the selected row

Left and right key: Not used

SCROLL

This instrument records all the data in the internal memory as a file. This file is copied to the CF card

at the time of file completion and at every ‘save interval’ that is set.

<Limitations of internal memory>

(File capacity)

Approximately 256KB (Excluding header and marker) is taken as one file. File size can be calculated

as follows.

Data volume x Number of channels x recording count

(Usually data volume is 4 bytes, when data format is “Maximum/minimum” it is 6 bytes)

Before reaching 256KB if recording is stopped due to non formation of recording condition, due to

STOP key or due to power off etc, the file is completed at that point of time.

(Number of files)

Maximum number of files that can be saved in internal memory are 250 (In group unit, “250 ÷ Number of

groups used” [Fraction is rounded down]).

(Volume of all files)

Total volume of files that can be saved in internal memory is 64KB X (63÷(Number of groups used) -

2). If it is exceeded files starting from the oldest file are deleted.

Scroll mode is switched. When clicked once, scroll bar is enclosed in a yellow frame and

scroll mode becomes ON. In this status if direction key is clicked, screens are scrolled one

by one. When clicked again, scroll mode becomes OFF, and rows are scrolled one by one

using the direction key.

Internal memory

- 33 -

Page 39

9.10 Card file screen

Files recorded in CF card are displayed as list.

Start date and time, end date (item being

recorded is the latest data time) and time and

data count are displayed. Files are displayed in

new order (Latest on the top).All the files only of

the selected group are selected.

Selected row is

displayed in yellow

ENTER menu function

Trend display Files of the selected row are displayed as trend.

Key operations other than the common operations (9.1)

Up and down key: Moving the selected row

Left and right key: Not used

SCROLL

Scroll mode is switched. When clicked once, scroll bar is enclosed in a yellow frame and

scroll mode becomes ON. In this status if direction key is clicked, screens are scrolled one

by one. When clicked again, scroll mode becomes OFF, and rows are scrolled one by one

using the direction key.

9.11 Marker list screen

Marker recorded on the trend is displayed as list.

Recording date and time and text is displayed in

new order (Latest on the top). Marker, recorded

in the group that is selected, is displayed.

Maximum storage count is 200.If that number is

exceeded the oldest ones are deleted.

Selected row is displayed in

yellow color

ENTER menu function

Trend display

Jumps to the trend position of marker of the selected row.

Cannot jump when file is not found.

Key operations other than the common operations (9.1)

SCROLL

Up and down key: Moving the selected row

Left and right key: Not used

Scroll mode is switched. When clicked once, scroll bar is enclosed in a yellow frame and

scroll mode becomes ON. In this status if direction key is clicked, screens are scrolled one

by one. When clicked again, scroll mode becomes OFF, and rows are scrolled one by one

using the direction key.

- 34 -

Page 40

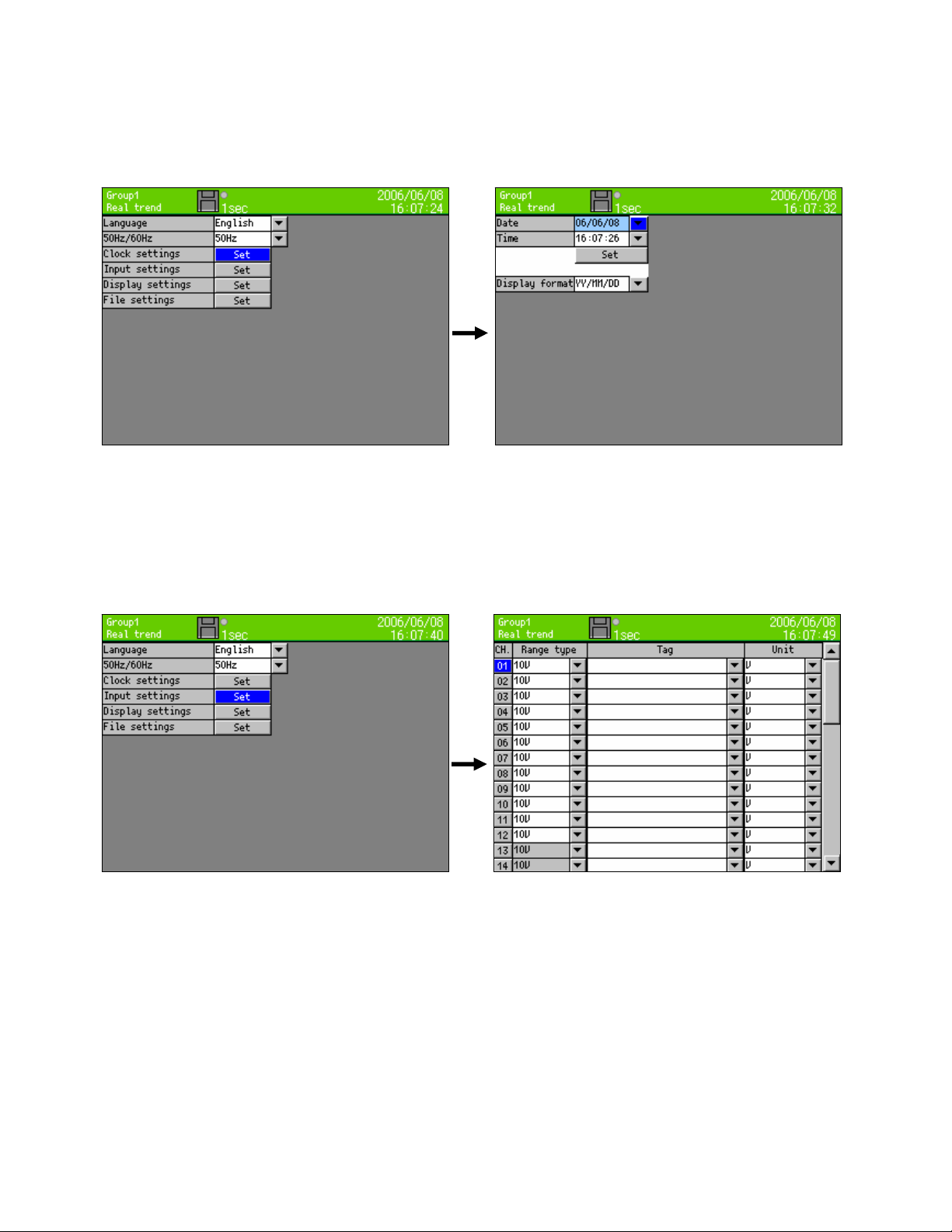

Initial settings

10

When power supply is switched ON at the time of receipt or when settings are initialized, initial settings

screen is displayed. Please set the minimum required parameters from below.

One can exit without setting other items except power supply frequency. At that time operation is done

with the settings at the time of shipping.

・ Power supply frequency 50Hz/60Hz

・ Clock settings

・ Input settings

・ Display settings

・ File settings

When ENTER key is clicked message is erased and the settings can be done.

① Setting power frequency

When cursor is brought to the item of 50Hz/60Hz using arrow key and ENTER key is clicked, pulldown

menu is displayed.

Move the cursor to the selected frequency using the direction key and then clicking ENTER button.

Confirm the power frequency to be used and set it.

- 35 -

Page 41

② Setting the clock

Move the cursor to the clock setting item using the direction key and click the ENTER key, the following

clock settings screen is displayed.

øFor detailed settings refer to “13.11.1 Clock settings”

③ Input settings

Move the cursor to the input setting item using the direction key and click the ENTER key, the following

input settings screen is displayed.

øFor detailed settings refer to “13.2 Input operation settings”

- 36 -

Page 42

④ Display settings

Move the cursor to the display setting item using the direction key and click the ENTER key, the following

display settings screen is displayed.

øFor detailed settings refer to “13.3.1 Channel parameters”.

⑤ File settings

Move the cursor to the file setting item using the direction key and click the ENTER key, the following file

settings screen is displayed.

øFor detailed settings refer to “13.5 File settings”.

- 37 -

Page 43

MEMO

- 38 -

Page 44

A

11

Flow chart of HOME settings & MENU settings

Operation

screen

HOME settings screen (HOME key)

MENU settings menu screen (MENU key)

Settings screen

Input operation settings

Display settings

larm settings

File settings

Totalizer reset settings

Schedule settings

Marker text settings

Memory operation

Network settings

System settings

- 39 -

Page 45

Input parameter settings

Recording interval settings

Specification confirmation

List

Channel parameters

Group parameters

Common parameters

LCD settings

Detail settings

ON/OFF settings

Detail settings

Detail settings

Detail settings

Writing the settings to the card

Read the settings from the card

Initializing the settings

Writing the internal memory to the card

Instrument specifications display

Detail settings

Settings of display

Settings of group

Parameter settings of

operation screen

Detail settings

Detail settings

Detail settings

Save settings

Read settings

OK/Cancel settings

OK/Cancel settings

Clearing the internal memory data

Format card

Ethernet settings

FTP server settings

E-MAIL settings

DNS settings

Clock settings

Key lock

Password settings

Other settings

OK/Cancel settings

OK/Cancel settings

Detail settings

Detail settings

Forward address

Transmission condition

Interval transmission channel

Account

Detail settings

Detail settings

ON/OFF settings

Detail settings

Detail settings

Detail settings

Detail settings

Detail settings

Detail settings

- 40 -

Page 46

12

HOME settings

12.1 Set using HOME settings

When “HOME settings” is used, input setting of all channel batch and setting of recording interval can be

done. This facilitates the input/recording confirmation.

□Operation screen

HOME

□Home settings screen

・ Move the focus (blue) to the setting item using direction key.

・ It is decided by clicking the “Enter” key for the item to be set.

■Setting range type

DC voltage

Thermocouple

Resistance

thermometer

■Setting the range

・ Set the scope of range.(It is decided by range type.)

Click

In case of settings for HOME settings, if

HOME key in the operation screen is clicked,

one moves to the screen for doing the

settings. Each of the settings to be done by

the direction key can be done by moving the

cursor (blue) to the desired item and clicking

the ENTER key due to which the selected

screen gets displayed.

13.8mV,27.6mV,69mV,200mV,500mV,2V,5V,10V,20V,50V

K,E,J,T,R,S,B,N,W-Wre26,PR40-20,NiM0-Ni,CR-AuFe,Platinel2,

U,L

Pt100, JPt100,Pt50,Pt-Co

- 41 -

Page 47

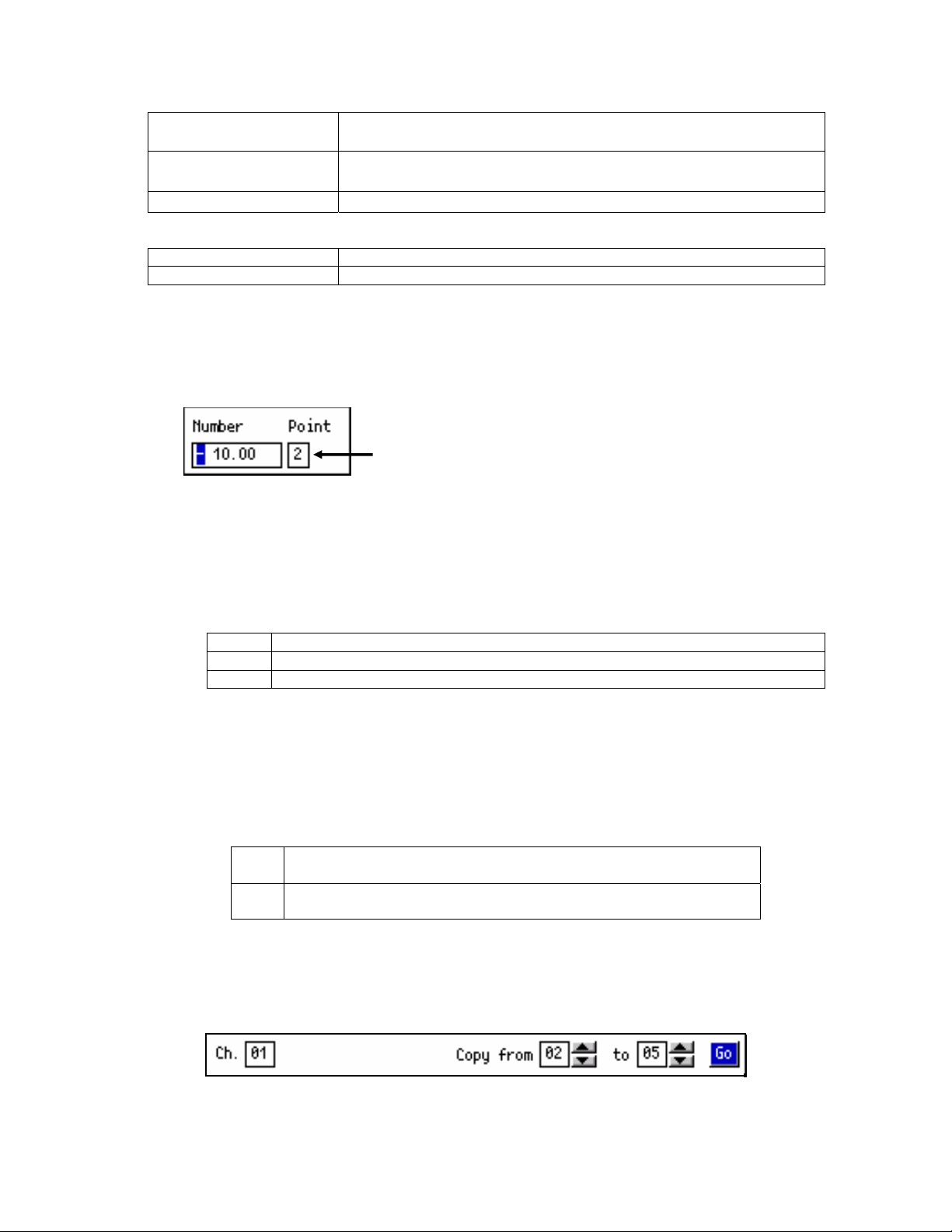

■Setting the scale

・ Set the scope of range. (It is decided by range type.)

This numeric value decides the position of the decimal point.

■RJ (Reference junction compensation) is set

・ Whether RJ is internal or external, is set.

■Setting burnout

None Burnout function is not used.

UP Set as upper limit burnout.

DOWN Set as lower limit burnout.

■Set the recording interval

Seconds 0.1 second, 0.2 seconds, 0.5 seconds, 1 second, 2 seconds, 3 seconds, 5

seconds, 10 seconds, 15 seconds, 20 seconds, 30 seconds

Minutes 1 minute, 2 minutes, 3 minutes, 5 minutes, 10 minutes, 15 minutes, 20

minutes, 30 minutes, 60 minutes

- 42 -

Page 48

12.2 Confirming the specifications using HOME settings screen

・ Specification information of the instrument can be confirmed.

・ For queries please contact after confirming this screen.

□Operation screen

□Home settings screen

□Specifications confirmation screen

HOME

ENTER

Click

Click

Select: Move the focus to “Specifications

confirmation using “↓”.

In specifications confirmation screen following

can be confirmed,

・ Model

・ Serial number

・ Software version

・ MAC address.

- 43 -

Page 49

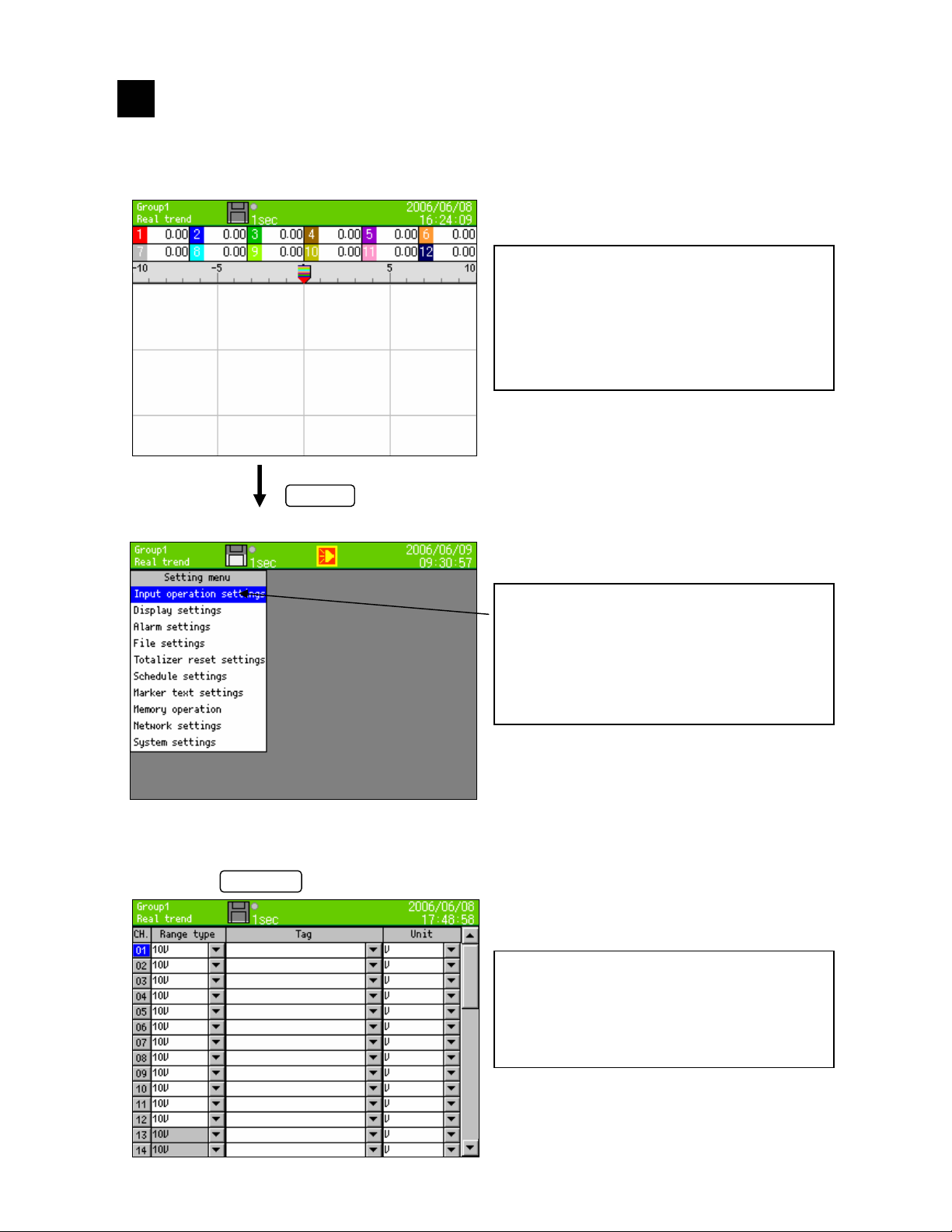

p

MENU settings

13

13.1 Setting MENU screen

□Operation screen

□Settings menu screen

□“In

ut operation settings” screen

Select “Input operation settings”

ENTER

MENU

Click

Click

For setting parameter, if MENU key in the

operation screen is clicked, parameter items

that can be set are displayed.

Items to be set are selected by the direction

key and on clicking the ENTER key, one

moves to the screen in which each parameter

is set.

As list box of the parameters is displayed,

select the parameter by moving the cursor to

the parameter to be set using the up and down

keys. The selected items are as shown on the

left. (Example, at the time of selection of input

operation settings)

Input operation settings

Refer to “13.2 Input operation settings”.

- 44 -

Page 50

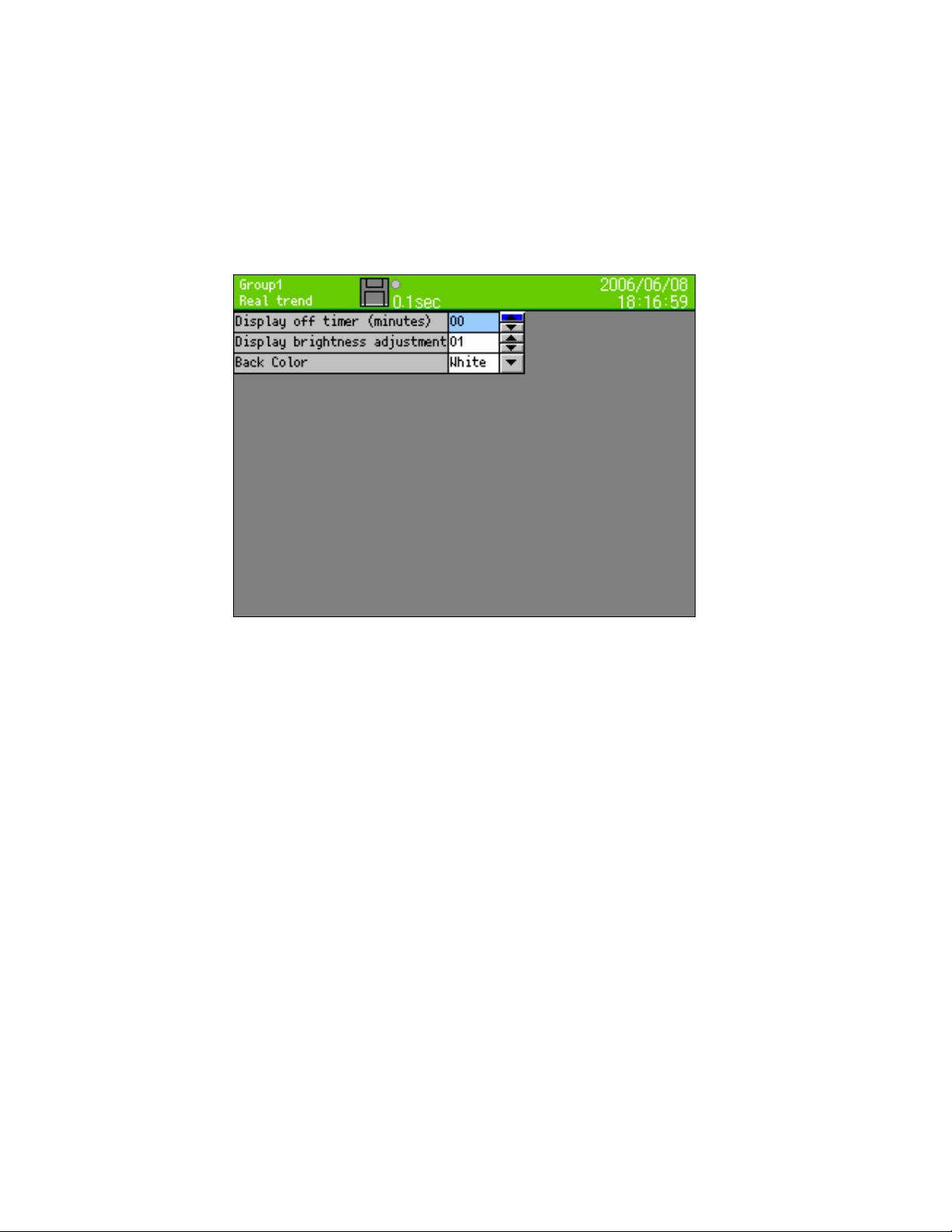

□Display settings screen

Selecting “Display settings”

□Alarm settings screen

Select “Alarm settings”

□File settings screen

Select “File settings”

ENTER

ENTER Click

ENTER

Click

Click

Display settings

Refer to “13.3 Display settings”.

Alarm settings

Refer to “13.4

Alarm settings”.

File settings

Refer to “13.5 File settings”.

- 45 -

Page 51

□Totalizer reset settings screen

Select “To t al iz e r reset ”

□Schedule settings screen

Select “Schedule settings”

□Marker text settings screen

Select “Marker text settings”

ENTER

ENTER

ENTER

Click

Click

Click

Totalizer reset settings

Refer to “13.6 Totalizer reset settings”.

Schedule settings

Refer to “13.7 Schedule settings”.

Marker text settings

Refer to “13.8 Marker text settings”.

- 46 -

Page 52

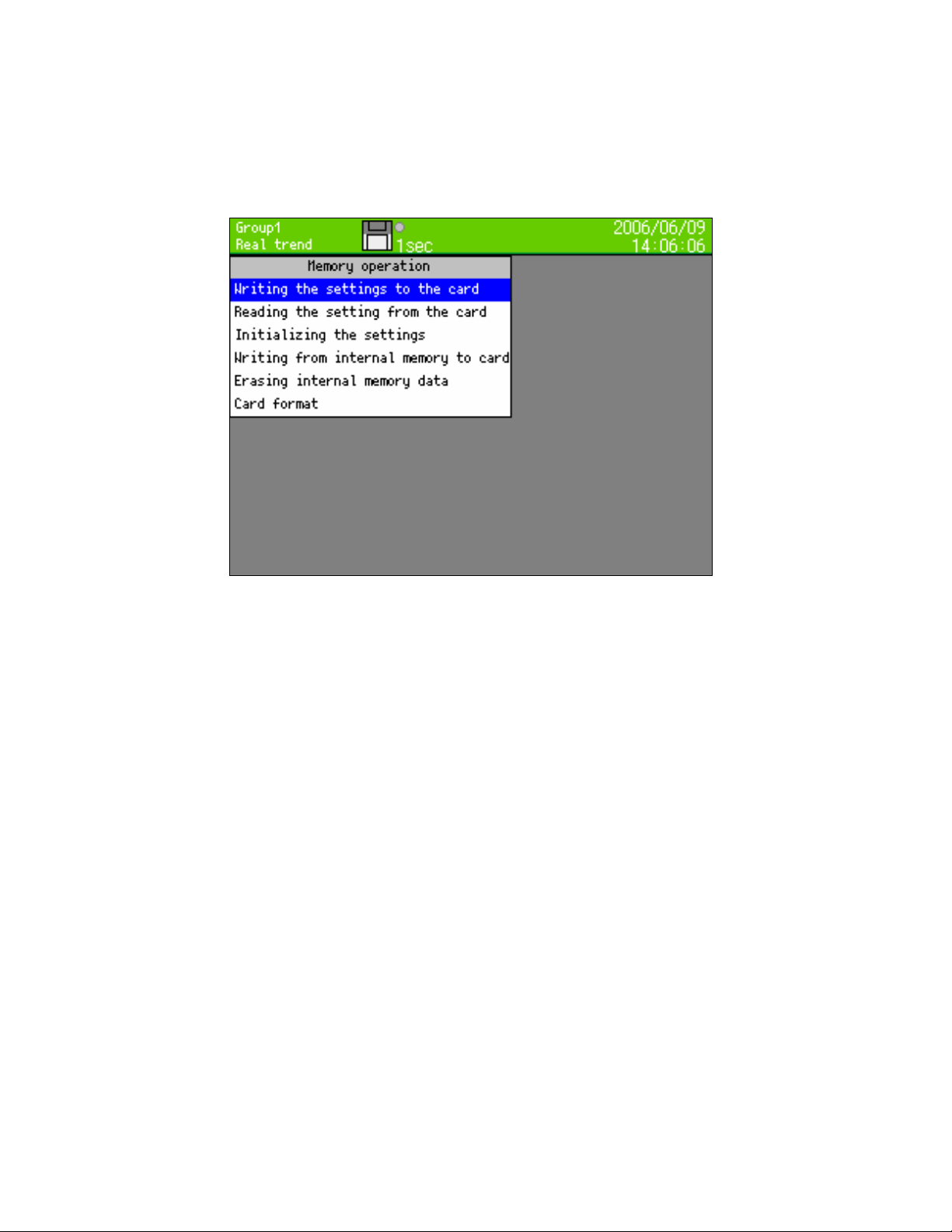

□Memory operation

Select “Memory operation”

□Network settings

Select “Network settings”

□System settings

Select “System settings”

ENTER

ENTER

ENTER

Click

Memory operation

Refer to “13.9. Memory operation”.

Click

Network settings

Refer to “13.10. Network settings

Click

System settings

Refer to “13.11. System settings

”.

”.

- 47 -

Page 53

13.2 Input operation settings

13.2.1 Setting contents

・ Operation is done using MENU settings

・ Move the focus to the setting item using direction key.

・ When ENTER key is clicked for the item to be set one move to the input screen.

Following screen is displayed on selecting “Input operation settings” of settings menu screen.

When focus is on Ch number and when “ENTER” is clicked, detail setting screen of that Ch is displayed.

- 48 -

Page 54

■Setting range type

(Analog input) KR2120: CH1-12, KR2160: CH1-6

DC voltage

13.8mV,27.6mV,69mV,200mV,500mV,2V,5V,10V,20V,

50V

Thermocouple

Resistance thermometer

K,E,J,T,R,S,B,N,W-WRe26,WRe5-WRe26,PR40-20,

NiMo-Ni,CR-AuFe,Platinel2,U,L

Pt100,JPt100,Pt50,Pt-Co

(Digital input) *At the time of digital input option selected CH37-44

Digital input DI

Pulse input Pulse(+), Pulse(-)

■Setting the range scope

・ Setting the scope of range. (It is decided by range type.)

■Setting the scale

・ Set the scope of range. (It is decided by range type.)

This numeric value decides the position of the decimal point.

■Setting sensor correction

・ Setting the addition value to input value (shift value)

■RJ (Reference junction compensation) is set

・ Whether RJ is internal or external is set.

■Setting burn out

None Burnout is not used.

UP Setting upper burnout.

DOWN Setting lower burnout.

■Setting the tag

• Setting the tag name (Setting for displaying the tag name instead of channel no.)

■Setting the unit

・ Unit of that Ch is set.

■Set the usage of computation

None Displays and records the input data as the measurement data of

that channel.

Yes Displays and records the process result of calculation that is set in

arithmetic expression, as the measurement data of that channel.

■Setting the arithmetic expression

・ When computation usage is set to yes, the arithmetic expression of that Ch is set.

■Copying the parameter using copy function

In the above screen the setting is, copying Ch01 from Ch02 to Ch05. On selecting Go and clicking the

ENTER key, the parameter of Ch01 is copied from Ch02 to Ch05.

- 49 -

Page 55

13.2.2 Setting method of computation

1) Computation types

Mathematical calculation

Four arithmetic operations

are performed.

Comparison calculation

Perform the comparison

operation and result is

1 (during formation) or

0 (during non formation)

Logical operation

Logical operations for 1 or

0 are performed and

result is returned as 1 or

0.

øX, Y indicate the arithmetic expression or numeric value. Express X and Y as 0 or 1.

General calculation function

Function calculation is

performed.

Symbol Example Remarks

Totalizer +

Subtraction - X–Y

Multiplication *

Division /

Reminder %

Exponential ^

Equal value ==

Unequal value !=

Greater than >>

Less than <<

Equal or greater than >=

Equal or less than <=

Symbol Example Remarks

Logical AND AND

Logical OR OR XORY

Exclusive OR XOR

Negation NOT

Round up after the decimal CEL

Round down after the decimal FLR

Common logarithm (bottom is 10) LOG10

Absolute value ABS

Square root SQR

Power of e EXP

Natural logarithm (base is e) LOG

X+Y

X*Y

X/Y

X%Y

X^Y

øX, Y indicate the arithmetic expression or numeric value.

Symbol Example Remarks

X==Y

X!=Y

X>>Y

X<<Y

X>=Y

X<=Y

øX, Y indicate the arithmetic expression or numeric value.

XANDY

XXORY

NOT(X)

Put the object that is a

negation in brackets

Symbol Example Remarks

CEL(X)

FLR(X)

ABS(X)

SQR(X)

EXP(X)

LOG(X)

LOG10(X)

øX indicates the arithmetic expression or numeric value.

- 50 -

Page 56

Channel data calculation function

Function calculation is

performed.

When error data

(OVER,UNDER etc.) is

included in measurement

data it becomes “CAL

ER”.

* Channel data calculation uses calculation result of specification destination when calculation is carried

out using settings of channel number specification destination. When channel no. doing the calculation