Page 1

MADE IN

User’s Guide

Shop online at

www.omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

RD8300

Recorder

Page 2

OMEGAneOMEGAne

OMEGAne

OMEGAneOMEGAne

http://www.omega.comhttp://www.omega.com

http://www.omega.com

http://www.omega.comhttp://www.omega.com

tt

On-Line Service On-Line Service

t

On-Line Service

tt

On-Line Service On-Line Service

®

Internet e-mailInternet e-mail

Internet e-mail

Internet e-mailInternet e-mail

info@omega.cominfo@omega.com

info@omega.com

info@omega.cominfo@omega.com

Servicing North America:

USA:USA:

USA: One Omega Drive, Box 4047

USA:USA:

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada:Canada:

Canada:

Canada:Canada:

976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada:USA and Canada:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGASM

USA and Canada:USA and Canada:

Customer Service: 1-800-622-2378 / 1-800-622-BESTSM

Engineering Service: 1-800-872-9436 / 1-800-USA-WHENSM

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico andMexico and

Mexico and

Mexico andMexico and

Latin America:Latin America:

Latin America: Tel: (001) 800-826-6342 FAX: (95) 203-359-7807

Latin America:Latin America:

En Español: (95) 203-359-7803 e-mail: espanol@omega.com

Servicing Europe:

Benelux:Benelux:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Benelux:Benelux:

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic:Czech Republic:

Czech Republic: ul. Rude armady 1868, 733 01 Karvina-Hranice

Czech Republic:Czech Republic:

Tel: 420 (69) 6311899 FAX: 420 (69) 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France:France:

France: 9, rue Denis Papin, 78190 Trappes

France:France:

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria:Germany/Austria:

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Germany/Austria:Germany/Austria:

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: info@omega.de

United Kingdom:United Kingdom:

United Kingdom: One Omega Drive, River Bend Technology Centre

United Kingdom:United Kingdom:

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5EX, United Kingdom

Tel: 44 (161) 777-6611 FAX: 44 (161) 777-6622

Toll Free in United Kingdom: 0800-488-488

e-mail: info@omega.co.uk

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts no

liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: WARNING:

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

WARNING: WARNING:

Page 3

1.0 TABLE OF CONTENTS:

1.0 Table of Contents: ........................................................... i

Warning and Safety Notice .................................................... v

2.0 Overview ......................................................................... 1

2.1 General Description ............................................................................................... 1

2.2 System Overview ................................................................................................... 2

2.3 Recorder Front ....................................................................................................... 4

2.3.1 Display Area ..................................................................................................................................... 4

2.3.2 Media Door ....................................................................................................................................... 5

2.3.3 Status Indicator ................................................................................................................................. 5

2.3.4 IR COMM Port .................................................................................................................................. 5

2.3.5 Stylus ................................................................................................................................................ 5

2.4 Recorder Rear Panel .............................................................................................. 6

2.4.1 Power Supply.................................................................................................................................... 6

2.4.2 Analog Inputs .................................................................................................................................... 6

2.4.3 Input/Output Module ......................................................................................................................... 7

2.4.4 Computer Interface ........................................................................................................................... 7

2.5 Files ......................................................................................................................... 8

2.5.1 Configuration Files ............................................................................................................................ 8

2.5.2 Data Files .......................................................................................................................................... 9

2.5.3 Activity Files ...................................................................................................................................... 9

2.5.4 Miscellaneous Files .......................................................................................................................... 9

2.6 Exhibitor Software ................................................................................................. 9

2.7 QUICK START GUIDE .......................................................................................... 10

2.8 Keyboarding ......................................................................................................... 11

2.9 Help ....................................................................................................................... 11

2.10 Activity Lights ...................................................................................................... 11

2.11 Security ................................................................................................................. 11

2.11.1 User Levels ..................................................................................................................................... 12

2.11.2 Remote Access Passwords ............................................................................................................ 12

3.0 Installation .................................................................... 13

3.1 Equipment Handling ............................................................................................ 13

3.1.1 Initial Inspection .............................................................................................................................. 13

3.1.2 Unpacking Procedure ..................................................................................................................... 13

3.1.3 Detected Damage ........................................................................................................................... 13

Page i

Page 4

Section 1.0 Table of Contents

3.1.4 Equipment Return ........................................................................................................................... 13

3.1.5 Storage ........................................................................................................................................... 13

3.2 Environment and Location .................................................................................. 13

3.3 Installation ............................................................................................................ 14

3.3.1 Panel Mounting ............................................................................................................................... 15

3.4 Wiring Specifications and Procedures ............................................................... 17

3.4.1 Power Requirements ...................................................................................................................... 17

3.4.2 Power Connections ........................................................................................................................ 17

3.4.3 Signal Input Wiring ......................................................................................................................... 18

3.4.3.1 Analog Inputs ....................................................................................................................................................... 19

3.4.3.2 Thermocouple Inputs ........................................................................................................................................... 19

3.4.3.3 Resistance Temperature Detector (RTD) Inputs ................................................................................................... 19

3.4.3.4 Linear Inputs ........................................................................................................................................................ 19

3.4.3.5 Potential Free Contacts ........................................................................................................................................ 20

3.4.3.6 Frequency ............................................................................................................................................................ 20

3.4.4 Relay Output, Contact Input ........................................................................................................... 21

3.5 Ethernet................................................................................................................. 21

3.6 USB Connection ................................................................................................... 22

3.7 Audio Connection ................................................................................................ 22

3.8 Mouse and Keyboard Connection ...................................................................... 22

3.9 24Vdc Isolated Output (Option) .......................................................................... 23

3.10 Isolated Serial Interface (Option) ........................................................................ 23

4.0 Fuctional Description .................................................. 24

4.1 Display Elements ................................................................................................. 24

4.1.1 Live Display Area ............................................................................................................................ 24

4.1.2 Task Bar ......................................................................................................................................... 24

4.2 Utility Setup Menu ................................................................................................ 25

4.3 Alarm, Event and Activity Logs .......................................................................... 27

4.4 Record Session .................................................................................................... 27

4.5 Configuration Manager ........................................................................................ 28

4.6 Sending Email ...................................................................................................... 29

4.7 User Login ............................................................................................................ 30

4.8 Display Utilities .................................................................................................... 30

4.8.1 Display Brightness .......................................................................................................................... 30

4.8.2 Background Color ........................................................................................................................... 31

Page ii 09/11/2008 REV 0.99

Page 5

Section 1.0 Table of Contents

4.9 Timer/Totalizer Reset ........................................................................................... 31

4.10 Special Events ...................................................................................................... 31

4.10.1 Record on Alarm ............................................................................................................................. 31

4.10.2 Record on External Event ............................................................................................................... 31

4.10.3 Email on Alarm Event ..................................................................................................................... 32

4.11 Turning the unit off .............................................................................................. 32

4.12 Annotating Trends ............................................................................................... 33

4.12.1 Drawing on the Screen ................................................................................................................... 33

4.12.2 Adding a Text Message .................................................................................................................. 34

4.13 Browsing Historic Data ........................................................................................ 34

4.13.1 Zoom and Compress Data ............................................................................................................. 35

4.13.2 View Memos and Bitmaps .............................................................................................................. 36

4.13.3 Using the Cursor ............................................................................................................................. 36

4.13.4 Using Browser Jump To ................................................................................................................. 37

4.14 Browsing Annotations ......................................................................................... 37

5.0 Recorder Setup ............................................................ 38

5.1 Input Channels ..................................................................................................... 38

5.1.1 Master Channel Setup .................................................................................................................... 38

5.1.2 Channel Setup ................................................................................................................................ 39

5.1.3 Channel Type Setup ....................................................................................................................... 40

5.1.3.1 Linear Input .......................................................................................................................................................... 40

5.1.3.2 Resistance Input .................................................................................................................................................. 40

5.1.3.3 Industrial Square Root Extraction ......................................................................................................................... 41

5.1.3.4 Thermocouples and RTDs ................................................................................................................................... 41

5.1.3.5 Calculated Input ................................................................ ................................................................................... 42

5.1.3.6 Conditional Input .................................................................................................................................................. 44

5.1.3.7 Gated Timer ......................................................................................................................................................... 44

5.1.3.8 Totalizer ............................................................................................................................................................... 45

5.1.3.9 Frequency/Pulse Count ........................................................................................................................................ 46

5.2 Display Builder ..................................................................................................... 49

5.2.1 Building the Display ........................................................................................................................ 49

5.2.2 Editing ............................................................................................................................................. 50

5.2.3 Rotate List ....................................................................................................................................... 51

5.3 Widgets ................................................................................................................. 52

5.3.1 Digital Displays ............................................................................................................................... 52

5.3.1.1 Digital Display Setup ............................................................................................................................................ 52

5.3.1.2 Displaying Min, Max or Average Values ............................................................................................................... 53

Page iii 09/11/2008 REV 0.99

Page 6

Section 1.0 Table of Contents

5.3.2 Bar Graphs ..................................................................................................................................... 54

5.3.2.1 Bar Graph Setup .................................................................................................................................................. 54

5.3.2.2 Trend Setup ......................................................................................................................................................... 57

5.3.2.3 Trend Setup Window ............................................................................................................................................ 57

5.4 Alarms ................................................................................................................... 59

5.4.1 Alarm Master Setup ........................................................................................................................ 60

5.4.1.1 Alarm Setup ......................................................................................................................................................... 61

5.5 Digital Input/Output .............................................................................................. 62

5.5.1 Digital Output Setup ....................................................................................................................... 63

5.5.2 Digital Input Setup .......................................................................................................................... 64

5.6 Record Setup ........................................................................................................ 66

5.6.1 Select Channels ............................................................................................................................. 66

5.6.2 Media and Filename ....................................................................................................................... 67

5.6.3 Record Rate.................................................................................................................................... 67

5.6.4 What to Record ............................................................................................................................... 67

5.6.4.1 Point type – Max Min Average. ............................................................................................................................. 67

5.6.5 Timed Record ................................................................................................................................. 68

5.6.6 Split Files ........................................................................................................................................ 68

5.6.7 Triggered Record ............................................................................................................................ 68

5.6.8 Media Alarm.................................................................................................................................... 69

5.7 System Administrative Menu .............................................................................. 70

5.7.1 Temperature Compensation ........................................................................................................... 72

5.7.2 System Setup ................................................................................................................................. 72

5.7.2.1 NTP Time Server ................................................................................................................................................. 72

5.7.2.2 Modbus Settings .................................................................................................................................................. 73

5.7.2.3 Mouse Pointer Enable .......................................................................................................................................... 73

5.7.2.4 Config Auto Save ................................................................................................................................................. 73

5.7.2.5 Menu Timeout ...................................................................................................................................................... 73

5.7.2.6 50/60 Hz Filter ...................................................................................................................................................... 73

5.7.2.7 Unit Tag ............................................................................................................................................................... 73

5.7.3 Date/Time Setting ........................................................................................................................... 73

5.7.4 User Setup (Password Management) ............................................................................................ 74

5.7.5 File Explorer.................................................................................................................................... 75

5.7.6 Network Settings ............................................................................................................................ 76

5.7.7 Web User Manager ........................................................................................................................ 76

5.7.8 SMTP Email Settings ...................................................................................................................... 77

5.7.9 Set ActiveSync Password ............................................................................................................... 77

5.7.10 Registry ........................................................................................................................................... 78

Page iv 09/11/2008 REV 0.99

Page 7

Section 1.0 Table of Contents

5.7.11 Languages ...................................................................................................................................... 79

5.7.12 System ReFlash ............................................................................................................................. 79

6.0 Communication ............................................................ 81

6.1 World Wide Web ................................................................................................... 81

6.2 Web Based FTP Manager .................................................................................... 83

6.3 Ethernet Protocols ............................................................................................... 86

6.3.1 OPC Server .................................................................................................................................... 86

6.3.2 Modbus Server ............................................................................................................................... 87

6.3.2.1 Modbus Status Registers ..................................................................................................................................... 87

6.3.2.2 Modbus Data Registers ........................................................................................................................................ 87

6.4 USB Connections ................................................................................................. 89

6.5 Utility Programs ................................................................................................... 90

6.5.1 FTP Manager .................................................................................................................................. 90

6.5.2 Remote Control .............................................................................................................................. 93

6.5.2.1 Remote Display .................................................................................................................................................... 93

6.5.2.2 Remote Manager ................................................................................................................................................. 94

7.0 Instrument Care and Maintentance ............................ 95

7.1 Touch Screen ....................................................................................................... 95

7.2 Cleaning Instructions........................................................................................... 95

7.3 Calibration ............................................................................................................ 95

7.3.1 Calibrating Linear Voltage Inputs: .................................................................................................. 96

7.3.1.1 Set Channel ........................................................................................................................................................ 96

7.3.1.2 Zero Cal .............................................................................................................................................................. 96

7.3.1.3 Full Cal ................................................................................................................................................................ 96

7.3.1.4 Store Cal ............................................................................................................................................................. 97

7.3.2 Calibrating the RTD Current Source .............................................................................................. 97

7.3.2.1 Zero Cal RTD ....................................................................................................................................................... 97

7.3.2.2 Current Cal RTD .................................................................................................................................................. 97

7.3.3 Calibrating Frequency: ................................................................................................................... 97

Appendix A – Technical Specifications ............................. 99

Appendix B – Digital Input Voltage Adjustment .............. 102

B.1 ANALOG MODULE: ............................................................................................ 102

B.2 DIGITAL IO MODULE: ........................................................................................ 103

Page v 09/11/2008 REV 0.99

Page 8

Warnings and Safety Precautions

Refer to manual for instructions

Caution - Risk of electric shock

Earth (ground) terminal

Directive 2002/96/EC WEEE: Waste Electrical and Electronic Equipment

NOTE

The contents of this manual are correct at the time of issue. The contents may change at any time without prior

notification. This is due to continuous developments to the recorder and its functionality.

Trademarks

Microsoft, MS-DOS, Windows, Windows 2000, Windows XP and Windows CE are all registered trademarks

of Microsoft Corporation.

CompactFlash™ and CF (logo) are trademarks of the Compact Flash Association (CFA).

For the purpose of the manual the ™ and ® symbols will not follow their own trademark names or registered

trademark names.

Company names and Product names mentioned in this manual are trademarks or registered trademarks of

their individual owners.

Symbols

One or more of the following symbols may appear on the recorder labeling.

Page iv 09/11/2008 REV 0.99

Page 9

Warnings and Safety Precautions

WARNING AND SAFETY NOTICE

This Safety Notice has been included to emphasize the DANGER OF HAZARDOUS VOLTAGES on

the REAR TERMINAL PANEL of your instrument. USE EXTREME CAUTION WHEN INSTALLING

OR SERVICING your instrument. Please read the entire contents of Section 2 - Installation and

Wiring within this manual before attempting to install or service your instrument.

1. Before any connections are made to the recorder, ensure the protective earth terminal is connected to a

protective conductor.

WARNING

Any interruption of the protective conductor inside or outside the recorder, or disconnection of the

protective earth terminal is likely to make the recorder dangerous under some fault conditions.

Intentional interruption is prohibited.

NOTE: In order to comply with the requirements of safety standard EN61010, the recorder must have one of the

following as a disconnecting device, located within easy reach of the operator, and be labeled as the

disconnecting safety device:

A switch or circuit breaker which complies with the requirements of IEC 60947-1 and IEC 60947-3

A separable coupler which can be disconnected without the use of a tool

A separable plug, without a locking device, to mate with a socket outlet in the building

2. The protective earth terminal must remain connected (even if the recorder is isolated from the mains supply) if

any of the measuring, communications, or relay terminals are connected to hazardous voltages.

3. Whenever it is likely that protection has been impaired, the recorder should be made inoperative and secured

against operation. Contact the factory for assistance.

4. Any adjustment, maintenance and repair of the opened recorder under voltage should be avoided as far as

possible and, if inevitable, should be carried out only by a skilled person who is aware of the hazard involved.

All repairs should be carried out only by authorized service personnel or returned to an authorized repair

center.

5. Where conductive pollution such as condensation or conductive dust is present, adequate air conditioning,

filtering and/or sealing must be installed.

6. Signal and supply voltage wiring should be kept separate from one another. Where this is impractical,

shielded cables should be used for the signal wiring.

7. If the equipment is used in a manner not specified by the manufacturer, the protection provided by the

equipment might be impaired or inadequate.

Page v 09/11/2008 REV 0.99

Page 10

Section 2 - Overview

2.0 OVERVIEW

This manual applies to Firmware version 1.0 and above. This section gives a system overview of the recorder and

the basic elements involved.

2.1 General Description

The recorder is an 18 channel unit capable of measuring 6 or 12 live inputs which can be a combination of linear

inputs – voltage or current, thermocouples, RTDs, or Frequency. Those channels not associated with live inputs can

be assigned as gated timers, totalizers, calculated or conditional inputs which are referred to as virtual channels. The

recorder is extremely versatile and can be configured in many different ways to suit the user‟s environment. The

user can also install an optional digital input/output module providing up to 12 potential free contact closures and up

to 6 opto-isolated digital inputs that can be set to silence alarms, reset contacts and start recordings.

The recorder‟s firmware is based on the Windows CE embedded operating system providing advanced

connectivity and features. The system is Ethernet aware and runs as a secure web server providing browser

accessibility via web pages and as an ftp server. It also runs an OPC (Open Connectivity) server allowing

connectivity to a large selection of third party Data Access Specification compliant software and the companion

Exhibitor Software, providing real time data update over Ethernet and off line data analysis. The recorder can be

set up to send emails in the event of an alarm. See Section 4.10.3 Email on Alarm Event for more details.

The recorder can save data, alarms and events to a number of sources. The primary storage medium is to

compact flash card that can be locked in the unit. Alternatively the unit can record to internal memory. Data is

saved in an ADO (ActiveX Data Objects) database and is encrypted for security purposes. Internal memory can

be expanded using a Secure Digital (SD) Card that plugs into the rear of the device.

The recorder is security enabled. If password protection is turned on, the unit requires the user to log in to

operate. There are three classes of operators with different access rights – administrator, manager and user. All

operations are logged to the alarm and event log and user privileges can be set to expire by date. The unit can be

set to automatically log users out after a preset time.

In order to use the recorder the user has to set up various parameters to customize the unit to the environment.

This set up is referred to as the configuration. Once configured, the settings can be saved to a configuration file. A

number of default configurations are provided and any of these can be loaded as a default.

2.2

Page 1 09/11/2008 REV 0.99

Page 11

Section 2 - Overview

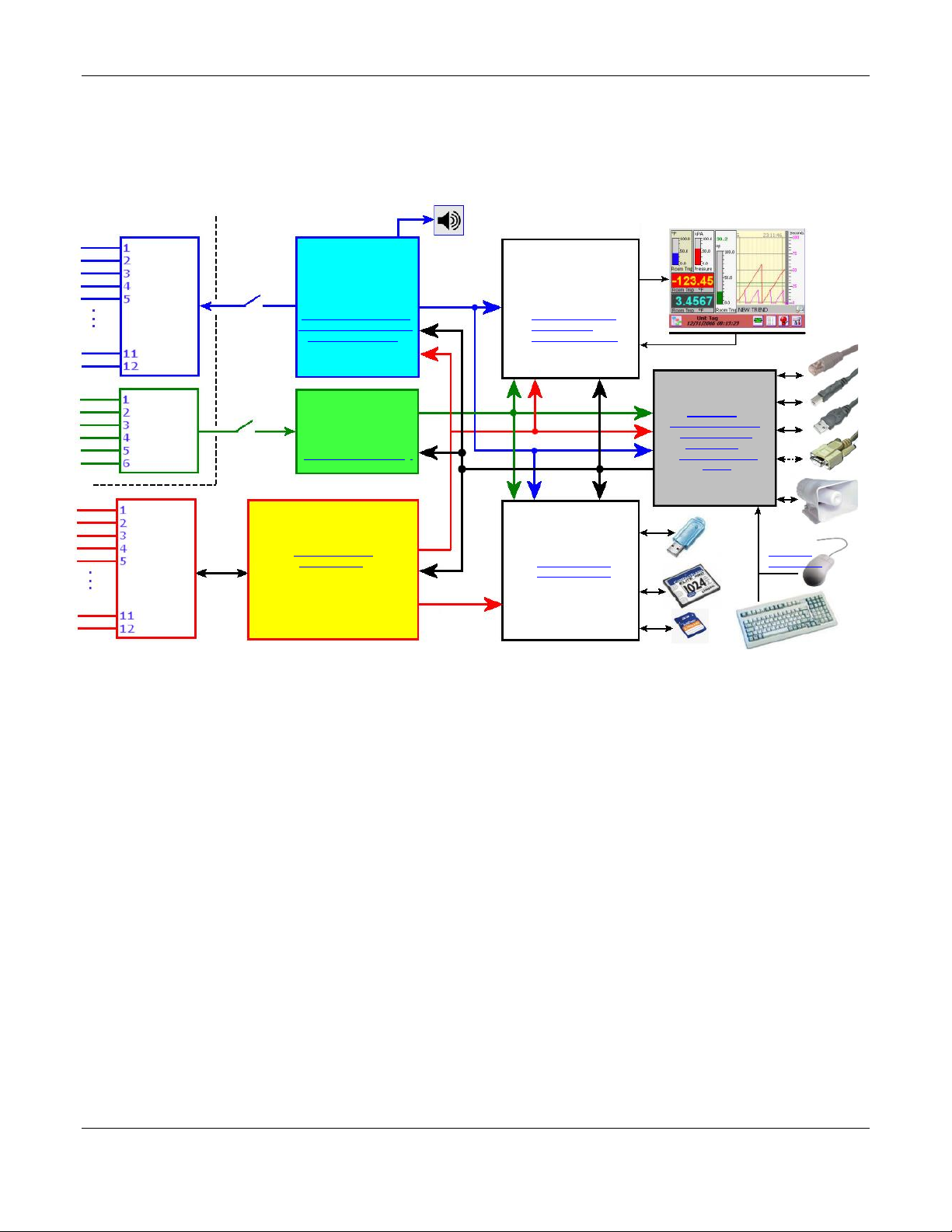

Figure 2-1 System Overview

DIGITAL

INPUTS

ANALOG

INPUTS

RELAY

OUTPUTS

MASTER

ENABLE

MASTER

ENABLE

DATA

MANAGER

DIGITAL

INPUT

MANAGER

ALARM

EVENT

MANAGER

DISPLAY &

KEYBOARD

MANAGER

DATA

STORAGE

MANAGER

SYSTEM

MANAGER

USB A/B

RS232/485

AUDIO IO

System Overview

Refer to the figure below:

ALARM MASTER SETUP DISPLAY BUILDER

DIGITAL OUTPUT SETUP ROTATE LIST

ALARM EVENT LOG WIDGET CONTROL

SYSTEM SETUP

LANGUAGE

SYSTEM SECURITY

EMAIL

DIGITAL INPUT SETUP … .. CONFIGURATION

CHANNEL SETUP MOUSE &

CALIBRATION RECORD SETUP KEYBOARD

FILE EXPLORER

The recorder block diagram shows the major elements of the unit.

The Analog Inputs module scans the live inputs (6 or 12 channel) at a rate of 10 times per second per channel,

converting the analog inputs to digital values and applying a time stamp to the digitized data. The Data Manager

collects this data at a rate of 120 samples per second from the Analog Inputs module and processes it in real

time applying any scaling or linearization as required by user programming, and holds it in a buffer for use by the

rest of the system. This process has the highest priority and runs irrespective of whatever other activity is going

on in the recorder. Data is fed on demand to the following:

Data Storage Manager receives data at a rate set by the user for recording to the media. The media is selected

by the user – compact flash, USB device or internal memory (SD card). The data is buffered till there is a suitable

amount and is then flushed to the selected media.

Display & Keyboard Manager receives data at a rate to satisfy the displays setup by the user, trends, digital or

bar graphs.

Alarm Event Manager receives all data required to do comparison to any user set up alarm. If any alarm is

exceeded the Alarm Event Manager will perform the required user set action, including sounding the alarm,

closing any contacts, updating the display, initiating an email and making an entry in the log.

System Manager receives all data required to keep the various communications servers up to date. This includes

the web, Modbus and OPC servers, and ftp data files.

ETHERNET

Page 2 09/11/2008 REV 0.99

Page 12

Section 2 - Overview

The Data Manager is also controls the Analog Inputs calibration process. This is a privileged operation and

allows an administrator to recalibrate the conversion factors and offsets on the various inputs and their associated

ranges. All units are shipped fully calibrated with a default set of calibration parameters stored in non-volatile

memory which may be recalled at any time.

The Data Storage Manager is used to set up the recording parameters required by the user. Recordings can be

started by the user or can be triggered to start as a result of an external event, an alarm condition or at a preset

time, once or on a daily basis. There is also a File Explorer. This is a privileged operation which enables an

administrator to rename, copy or delete files and move files between the various media.

The Alarm Event Manager is used to set up the various alarms on the channels and route events to the

(optional) relay outputs. Various alarm types can be set. The operation of the (optional) relay contacts are also

defined here. This module processes data in real time checking it against the preset alarm conditions and reacting

accordingly as described above. There is a (soft) master enable switch which allows the user to configure alarms

without affecting the actual (optional) relay contacts.

The Digital Input Manager is used to define the operation of the (optional) isolated digital inputs and process

these inputs according to the user set conditions when they occur. Digital inputs can be used to reset timers or

totalizers, acknowledge and reset alarms, force events or start recording. There is a (soft) Master enable switch

which allows the user to configure the (optional) digital inputs without affecting the actual operation of the

recorder.

The Display & Keyboard Manager controls the content of the graphic display and interprets the input on the

display touch screen and passes this information to where it is required. The user can create an infinite number of

visual screens using a combination of widgets – bar graphs, trends or digital displays. All the other modules

communicate with the Display Manager to provide status information to the user.

The System Manager controls the overall operation of the recorder and prioritizes events as required. It also

manages system security and handles the administrative tasks such as importing or exporting configurations. It

services external requests (via the communication ports), controls the email and configures the unit at startup. It

also deals with any peripherals and routes the information accordingly.

Page 3 09/11/2008 REV 0.99

Page 13

Section 2 - Overview

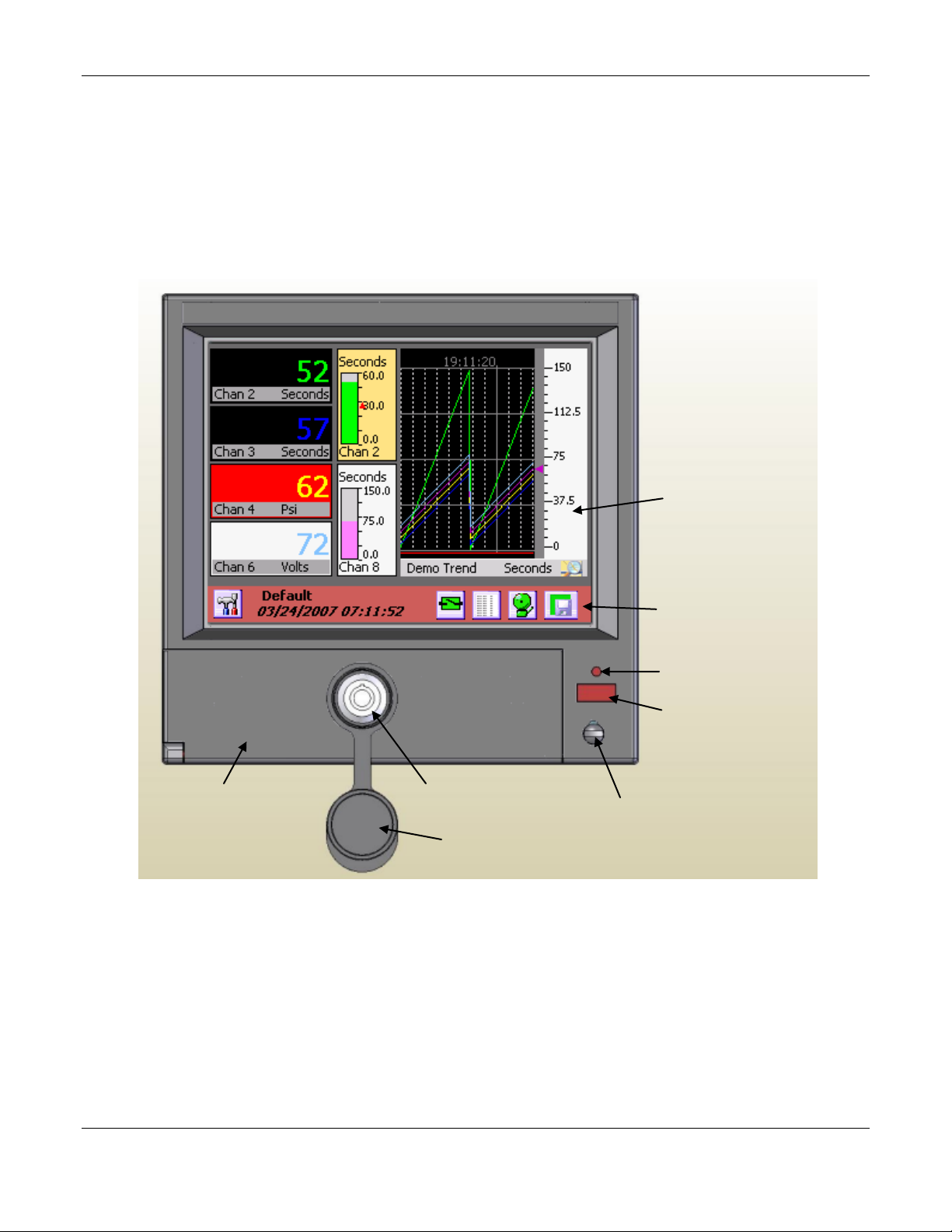

Figure 2-2 Recorder Front View

DISPLAY AREA

STATUS

INDICATOR

IR COMM PORT

STYLUS

MEDIA DOOR

LOCK

WATERPROOF

LOCK COVER

TASK BAR

2.3 Recorder Front

Figure 2-2 shows the front view of the recorder. The recorder has a ¼ VGA color display with touch screen.

Below the display are a lockable media door, status indicator, IR COMM port and stylus used for data entry on the

display.

The recorder is intended to be panel mounted and if mounted correctly using the supplied gasket, the unit is

waterproof to IP65 when the media door is closed and the waterproof lock cover is in place.

Page 4 09/11/2008 REV 0.99

2.3.1 Display Area

The recorder has a ¼ VGA color display (320 x 240 pixels) and can display 24 million colors. The display has

a touch screen over it and is fully interactive. The screen consists of two distinct areas – the task bar with

icons along the bottom of the screen and the live display which is that area above the task bar showing the

live data in either trend, bar graph or digital display widgets. A full description of this is given in Section 3.0.

Page 14

Section 2 - Overview

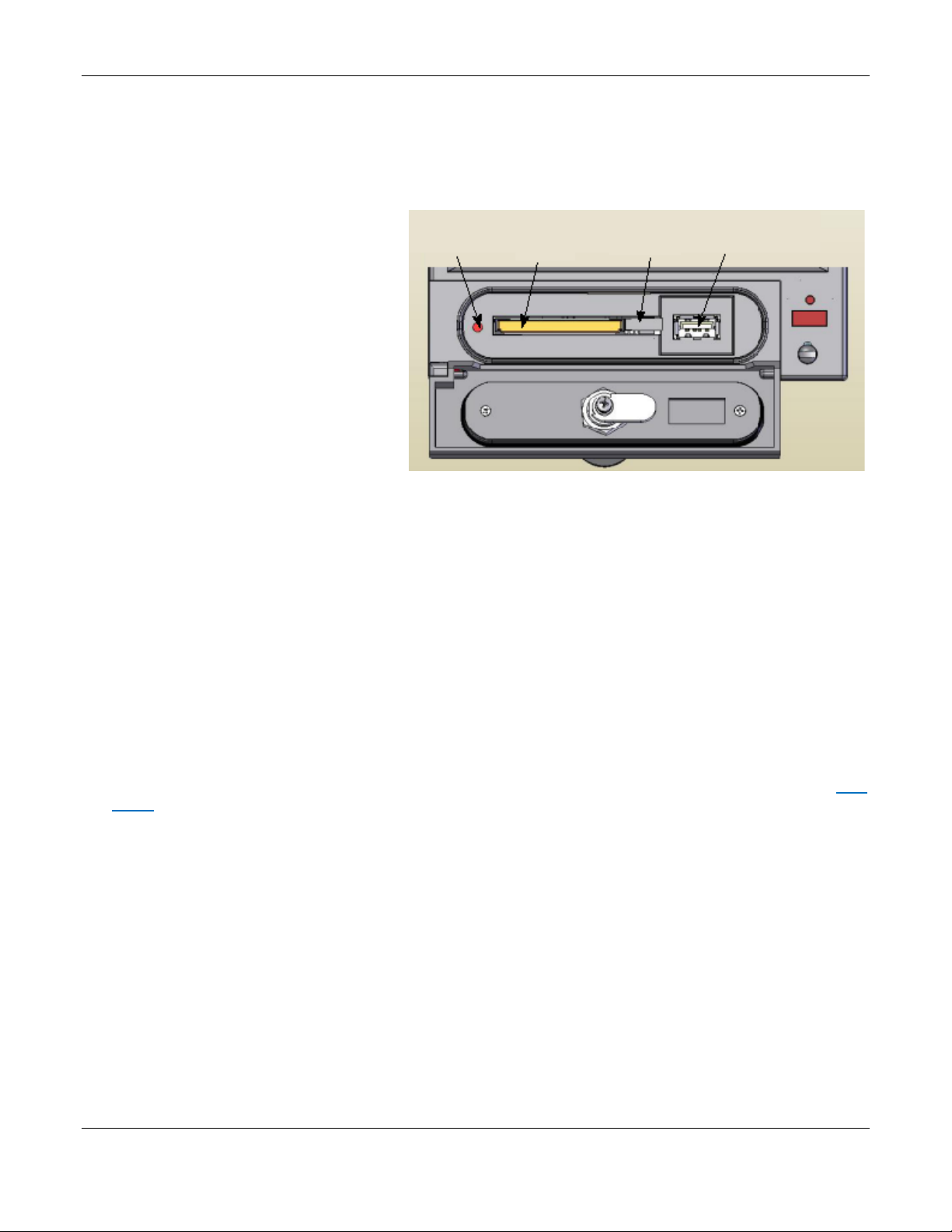

Figure 2-3 Media Door Contents

RESET

BUTTON

COMPACT

FLASH CARD

CARD EJECT

BUTTON

USB A

SOCKET

2.3.2 Media Door

The media door is opened by turning the key in the lock ¼ turn clockwise and pulling the door out and down.

Note that in order to meet the water resistance specification (IP65) the door must be closed and locked and

the waterproof lock cover must be snapped over the lock.

Opening the media door exposes the

compact flash card socket and the USB

port. The compact flash card is intended

as the principal recording media,

however the unit will record to a USB

device or to internal memory.

The compact flash card fits into the

socket as shown right. The card eject

button must fold over to the right once

the card is in place. To eject the card, lift

the eject button, press it to pop the card

out then fold it back over. Grab the card

along the left and right edges between

the thumb and forefinger and remove.

To the left of the card slot is a small

opening. Set back behind this opening is the system reset button. Under normal operation there should be no

need to use this. Using this button may cause loss of data.

2.3.3 Status Indicator

The status indicator is lit when the unit is powered on and blinks during shut down or when the unit is running

off the internal batteries. The internal batteries allow the unit to survive short power interruptions (< 15

seconds) or brown outs, during which time the display blanks and the status indicator blinks.

2.3.4 IR COMM Port

The IR COMM port is an Infrared send/receive port which allows connection to compatible Infrared devices.

Future Option.

2.3.5 Stylus

The stylus is used to do data entry on the touch screen. It is stored in the bottom right of the recorder front

panel. To remove it, depress the exposed top and turn ¼ turn counter clockwise. The stylus is sprung loaded

and will pop out of its docking location. CAUTION: Control removal of the stylus as it is spring loaded.

To return it to its docking location, insert the pointer end into the hole, fully depress it and give it a ¼ turn

clockwise.

Page 5 09/11/2008 REV 0.99

Page 15

Section 2 - Overview

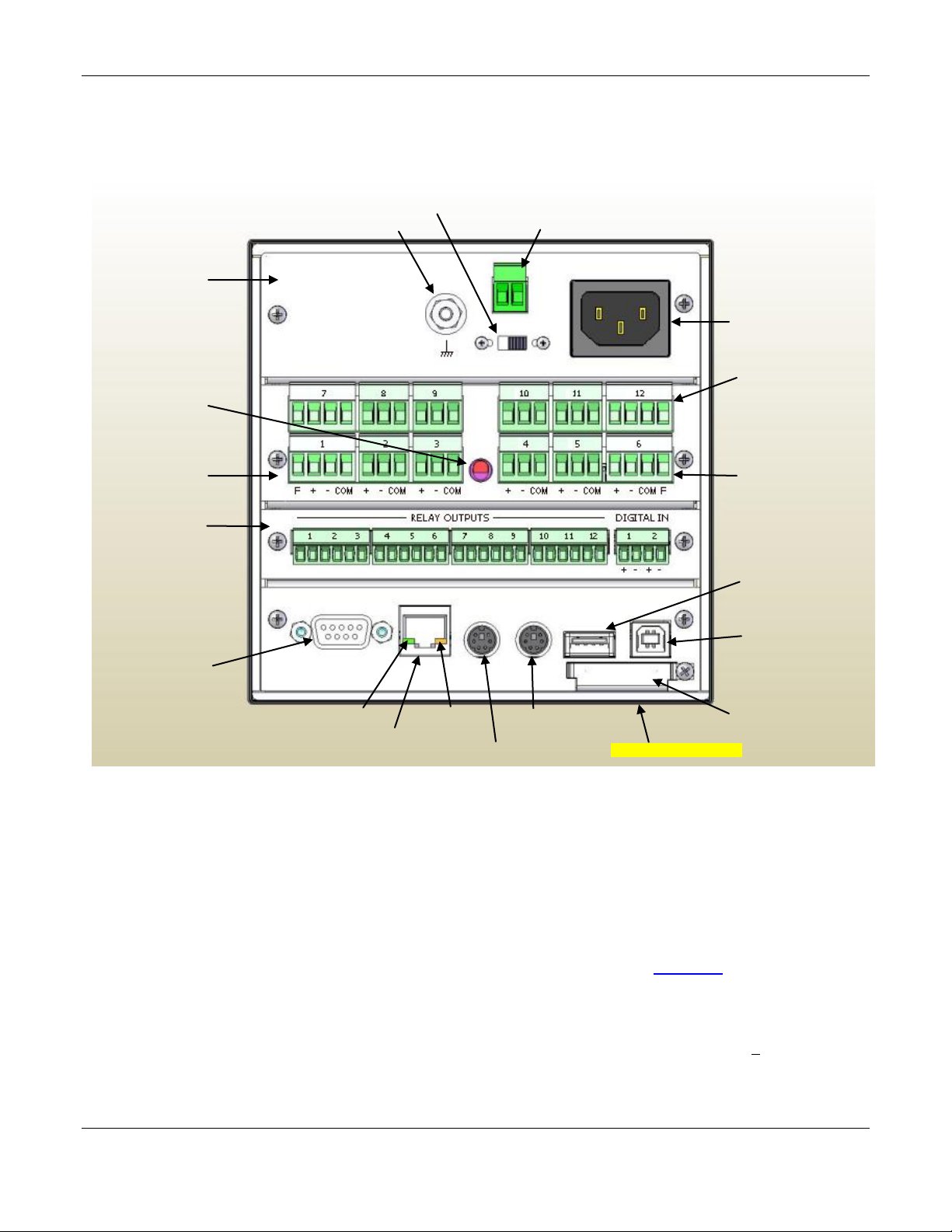

AC POWER

INPUT

24 VDC OUTPUT OPTION

SYSTEM GROUND LUG

BATTERY DISCONNECT

ANALOG INPUTS

CHANNELS 7 – 12

(OPTIONAL)

ANALOG INPUTS

CHANNELS 1 – 6

INPUT/OUTPUT

MODULE

(OPTIONAL)

USB TYPE A

(MASTER)

USB TYPE B

(SLAVE)

MEMORY

EXPANSION SLOT

MOUSE/KEYBOARD

CONNECTOR

USB SELECT SWITCH (UNDER)

AUDIO CONNECTOR

SPEED LED

ETHERNET RJ-45

CONNECTOR

ACTIVITY LED

RS-232/RS-485

DB9 CONNECTOR

(OPTIONAL)

AMBIENT

TEMPERATURE

SENSOR

ANALOG INPUT

MODULE

POWER SUPPLY

MODULE

OFF ON

BATTERY BACKUP

POWER SUPPLY

MODULE

Figure 2-4 Recorder Rear Panel

2.4 Recorder Rear Panel

The rear panel of the recorder is shown below:

2.4.1 Power Supply

The power supply module is at the top of the recorder rear panel. The rear panel of the universal AC version

is shown in above. On the right is the AC power input socket that takes a standard IEC connector. Screw

terminals are available as an option, as is a DC power supply module. To the left is the optional 24 Volt dc

output option which provides isolated voltage to power external sensors (100mA). Below this is the battery

disconnect switch. The battery is used to enable the system to shut down correctly and survive short power

outages or brown outs. It should be disconnected for storage or shipping purposes. The system-grounding

lug is used to properly ground the recorder on installation. NOTE: See Section 3 for installation and

connection details.

2.4.2 Analog Inputs

The analog input module is available with either 6 or 12 inputs and accepts dc inputs up to +25 volts. These

inputs are isolated from each other and ground and are truly differential. In addition channels 1, 6, 7 and 12

Page 6 09/11/2008 REV 0.99

USB SWITCH

Page 16

Section 2 - Overview

have an isolated frequency inputs which allows the unit to measure frequency to 10,000 Hz. Between the

terminal blocks is the ambient temperature sensor for thermocouple compensation.

2.4.3 Input/Output Module

The input/output module is optional and provides potential free relay contacts and isolated digital inputs.

2.4.4 Computer Interface

The bottom of the rear panel is the computer interface. At the bottom right hand corner is a small cover

secured by a screw. This is the internal memory expansion slot – it takes standard secure digital memory

cards.

Above this are the two USB ports – the type A port (to the left) is a master port and the type B port is a slave

port. These are mutually exclusive ports and the user needs to select which port will be active. This is done by

using the small slide switch on the underside of the unit – indicated but not shown in Figure 2-4 above. Slide

the switch toward whichever connector is being used. The Type of port selected, A or B depends on what is to

be connected to it.

To the left of these connectors are two mini-din style connectors. The mouse / keyboard connector allows the

use of an external PS2 PC style mouse directly or a PS2 PC style keyboard using an available adapter board

which will accommodate both mouse and keyboard together. The audio connector is to the left and allows the

audio output from the unit to be fed to an external amplifier.

The Ethernet connector is the standard RJ45 type and allows a 100 Mbps (megabits per second) connection

to be made to the network. There are two indicator LEDs, the one on the right shows connection speed either

10 Mbps unlit or 100 Mbps when lit. The led on the left is the activity led and it blinks when the link is active

and data is being transmitted.

On the left is the optional RS232/RS485 legacy connector. This is a factory installed option. Normally there is

a blanking panel over the opening.

Page 7 09/11/2008 REV 0.99

Page 17

Section 2 - Overview

2.5 Files

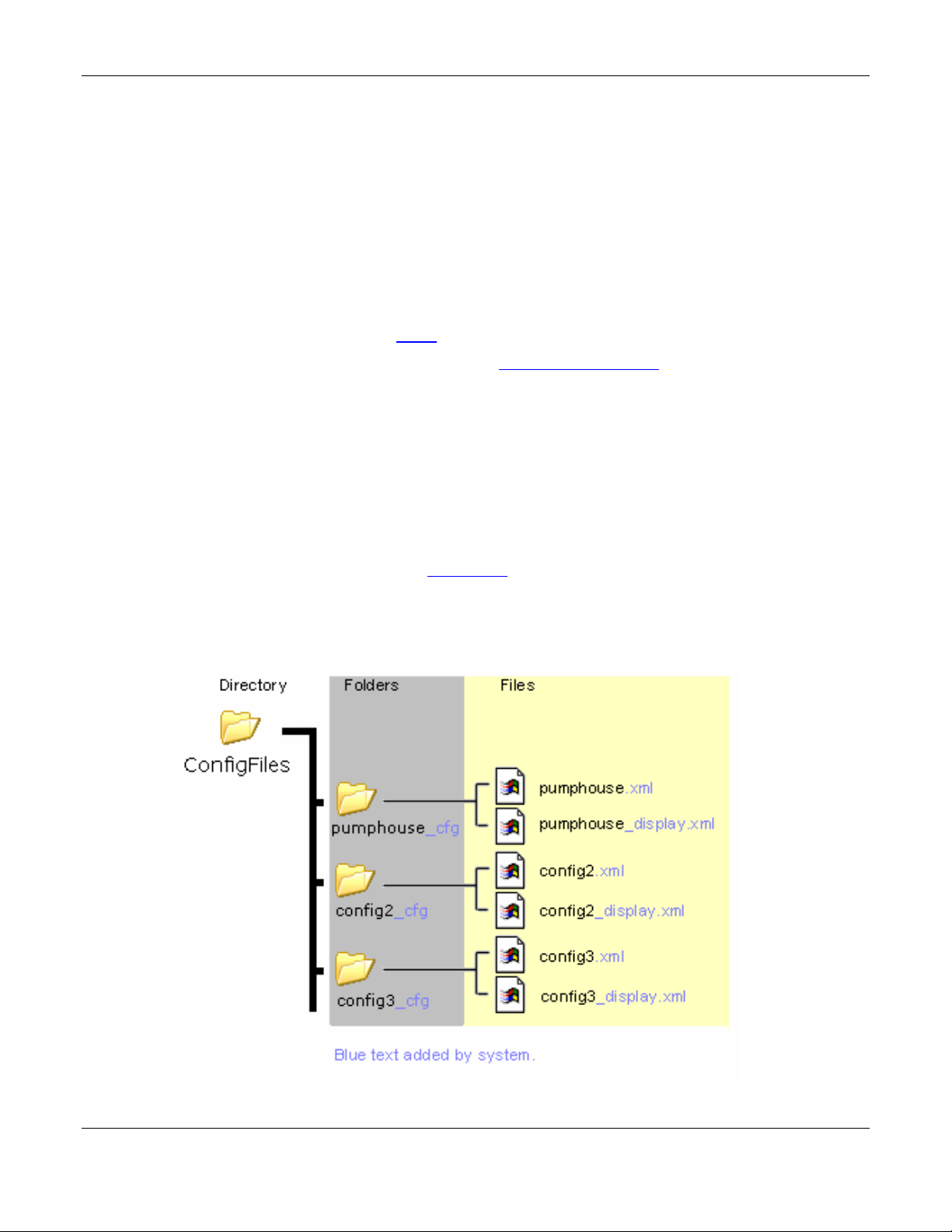

2.5.1 Configuration Files

The recorder has hundreds of options and settings that need to be set up by the user. Things like input types,

point tags, displays, record information and so-on. Once set up, this information is saved in the internal

memory (SD Card) as a user named configuration file in a special directory called ConfigFiles. Each unique

configuration is stored in a sub-folder within the ConfigFiles directory. The system appends “_cfg” to each

folder name created which in turn contains the actual configuration files. The files are in an xml format and

bear the extension “.xml”. Currently there are two independent but related files – one for the physical settings

of the recorder – input types, record setup, alarms and so on and has the filename given by the user with the

file type “.xml” and one for the displays as set up by the user which has the filename given by the user but has

“_display.xml” added by the system. See below.

When a user saves or loads a configuration using the Configuration Manager the system takes care of the

details and defaults to the ConfigFiles directory.

When saving the configuration, the user enters a filename and accepts the entry – for example the filename

could be “pumphouse”. The Recorder will then create a folder in the ConfigFiles directory called

“pumphouse_cfg” and in this folder it will create the two configuration files, “pumphouse.xml” for the physical

settings and “pumphouse_displays.xml” for the display information.

When loading a configuration, the Configuration Manager will show a list of all the subfolders (Configurations)

in the ConfigFiles directory (without the “_cfg” adder) so the user can recognize the configuration files. When

a configuration is selected, the system loads the two files from this subfolder.

At the recorder, this folder and split file structure is totally transparent and configurations can be loaded using

names assigned by the user. When using the file explorer to move configuration files it is important to note

that you need to move, save or copy the subfolder in the ConfigFiles directory. This will keep all associated

file with that configuration together.

The structure is as follows:

.

Page 8 09/11/2008 REV 0.99

Page 18

Section 2 - Overview

Eg: To copy the “pumphouse” configuration to a different media you need to go to the ConfigFiles directory

and copy the FOLDER “pumphouse_cfg”.

In the root of the internal memory (SD card) are two files – config.xml and displays.xml. These are the default

configuration files used by the system. When you quick-save a configuration, this is where it saves to. You

should not transport these files but rather save the configuration as mentioned above.

2.5.2 Data Files

When data is recorded, the unit creates a folder in the root directory of the selected media with the name

given in the Record Setup menu. This folder contains all files generated during the record session. The

primary data file is in this folder and has the extension “.dat”. So if you set up to record to the compact flash

card and name the file “session1” the recorder will create a folder on the compact flash card (CF CARD)

named “session1”. In this folder will be a file “session1.dat” which is an ActiveX Data Object File (ADO) and is

the primary database containing all the recorded channel data as well as alarm and event data for the record

session if this has been enabled. The file size is dynamic and depends on how many channels are being

recorded, the record rate (samples/second) and how active the data is (static data results in reduced file size.

It is not unusual for active data recorded at high speeds to result in large files. Any annotations should be

saved in this folder (they save as “.bmp” files) to keep all record session information together. The “.dat” files

can be transported or moved using the FTP manager, and can be analyzed on the PC using the Exhibitor

software.

2.5.3 Activity Files

The activity files are saved when the Activity Log check box is checked in the User Setup Menu. The Activity

Logs are stored in the Activity Folder in internal memory (SD Card). These files are used for FDA 21 CFR

Part 11 compliance. The files are created whenever a user logs on or logs off. Using the Exhibitor software an

administrator can print out a report of all changes made by that user during the time they were logged into the

recorder. The files created are in the form: user-date-sequence-“start config” and user-date-sequence-“end

config” and are xml types.

The Administrator should purge these files periodically to free up space.

2.5.4 Miscellaneous Files

The recorder saves alarm and event information in the root of the internal memory (SD Card) in log files

AlarmFile.Log and EventFile.log. These files are encrypted and can be decrypted and printed using the

Exhibitor program running on the PC.

2.6 Exhibitor Software

The Exhibitor software is a program that runs on the PC that allows a user to plot and print data recorded on

the recorder. This data may be retrieved remotely, displayed in graphic or tabular format or be exported in

various formats including ExcelTM format. Additionally it allows a user to view Event and Alarm Logs and

analyse data, search for highlights and parse data for minimums or maximums. It can also be used to gather

data in real time from remote recorders, create real time widget displays, print reports and configure remote

recorders. A lite version of the software is provided with each recorder and can be upgraded to various

capabilities.

Page 9 09/11/2008 REV 0.99

Page 19

Section 2 - Overview

Okay or

Accept

Cancel

Exit

Reset or

Refresh

Setup

Edit

Color

(Foreground)

Background

Color

2.7 QUICK START GUIDE

The recorder ships in a fully functional mode, but may not be set up the way you would want to use it and needs

to be configured before it is used.

There are several areas that need to be configured to customize the unit to the user‟s needs. This unique

combination of settings is referred to as the system configuration and is saved in a file called the configuration

file which is physically named config.xml. This file is reasonably human readable and is in XML (Extensible

Markup Language) format. This file resides in the recorder‟s internal memory and is portable. On start-up the

recorder loads this file and configures itself accordingly. There can be numerous configuration files in the

recorder, however only one can be called config.xml. See the Configuration Manager on page 28. If no

configuration file is present at startup, the unit will create one which will have minimal functionality.

The most basic setup needs to define the inputs, create a display and set up a recording. You may need to set

the time and calibrate the touch screen. The setup can then be extended to include alarms, contact outputs

(requires an optional digital I/O module), digital inputs, various display options, and conditional events (like

recording on alarm or sending emails).

The first thing to do is to browse this manual to get some idea of the features of the unit. The following will steer

you to various sections based on a quick set up. Help is available at each screen and you should see the section

on keyboarding before you start anything.

Naming the Recorder: You should give the recorder a unique name to identify it such as “Soap Plant Boiler”.

This is known as the Unit Tag and is entered in the System Setup window.

Analog Setup: You will then need to set up the analog inputs to meet the requirements of the signals you will be

measuring. The recorder has universal inputs capable of measuring a variety of signals from millivolts to Volts,

Current, Resistance, Thermocouples, RTDs and on some channels, Frequency. All channels can also be

assigned as virtual channels, that is they do not have a direct live inputs, but can be Calculated channels, Timers,

Totalizers or Conditional. The analog inputs are set up in the Master Channel Setup menu. Each channel can be

uniquely programmed and has a Channel Tag to identify the channel, eg. “Pump 6”. These settings will apply to

any display objects or widgets that use this channel.

Display Creation: Once the inputs are set up you need some way of displaying the data. This is done on the live

display. To appreciate what this entails check out the section on Display Elements and Widgets. Then use the

Display Builder to create the actual display. This builder allows you to place the widgets on the screen and

customize each and give the display a name. In order to have the display come up on the screen you need to

move it to the Rotate List.

Recording Data: To record data you need to use the Record Setup dialog to select which channels to record,

what to record, at what rate and where to save it. Data can be saved to internal memory, compact flash card or

USB flash drive.

At this point you are ready to connect your signals, watch the data live and record it.

To record the data you must have set up the recorder as mentioned above.

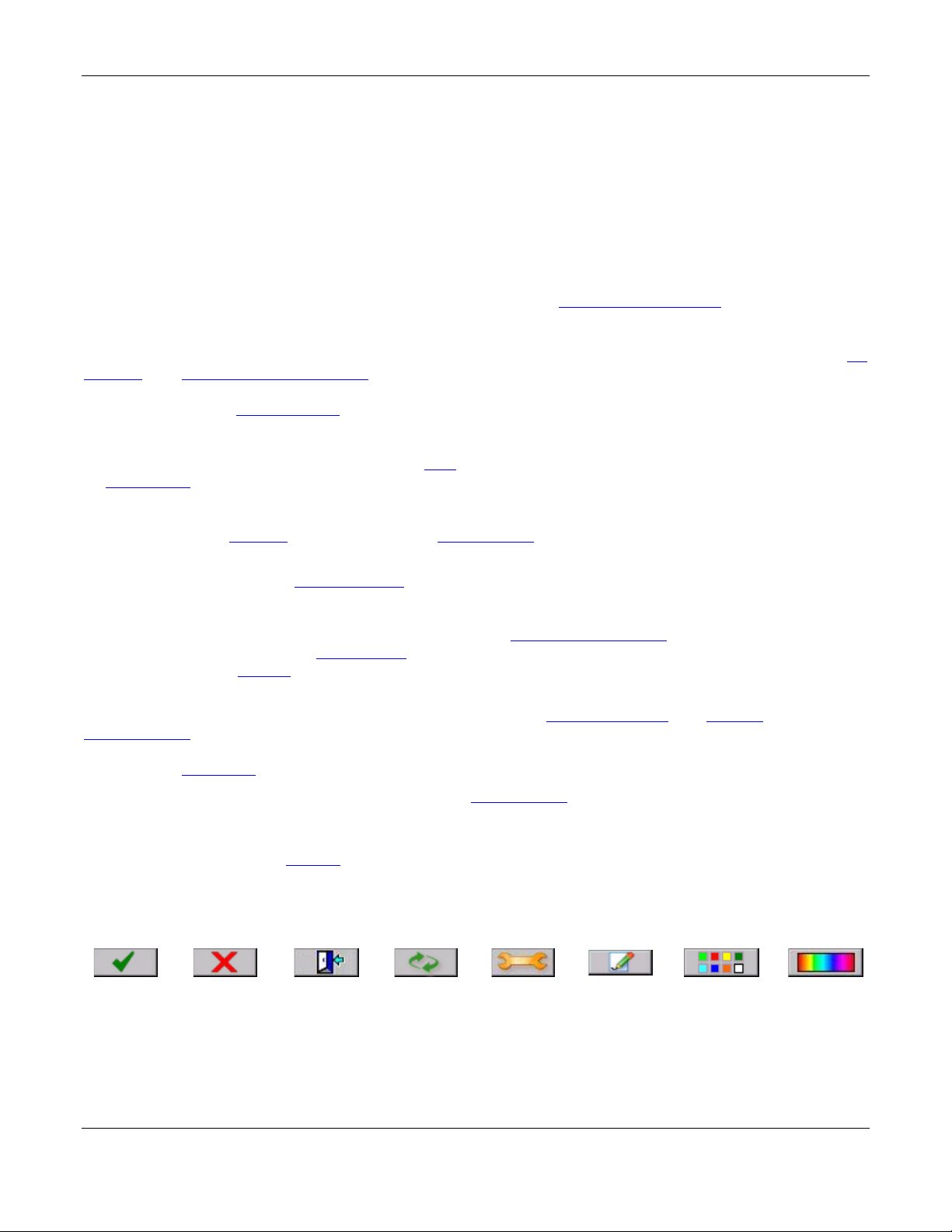

Icon Buttons: There are several buttons with icons used on the recorder. Specific ones are described in the

respective sections. Generic ones are shown below.

Page 10 09/11/2008 REV 0.99

Page 20

Section 2 - Overview

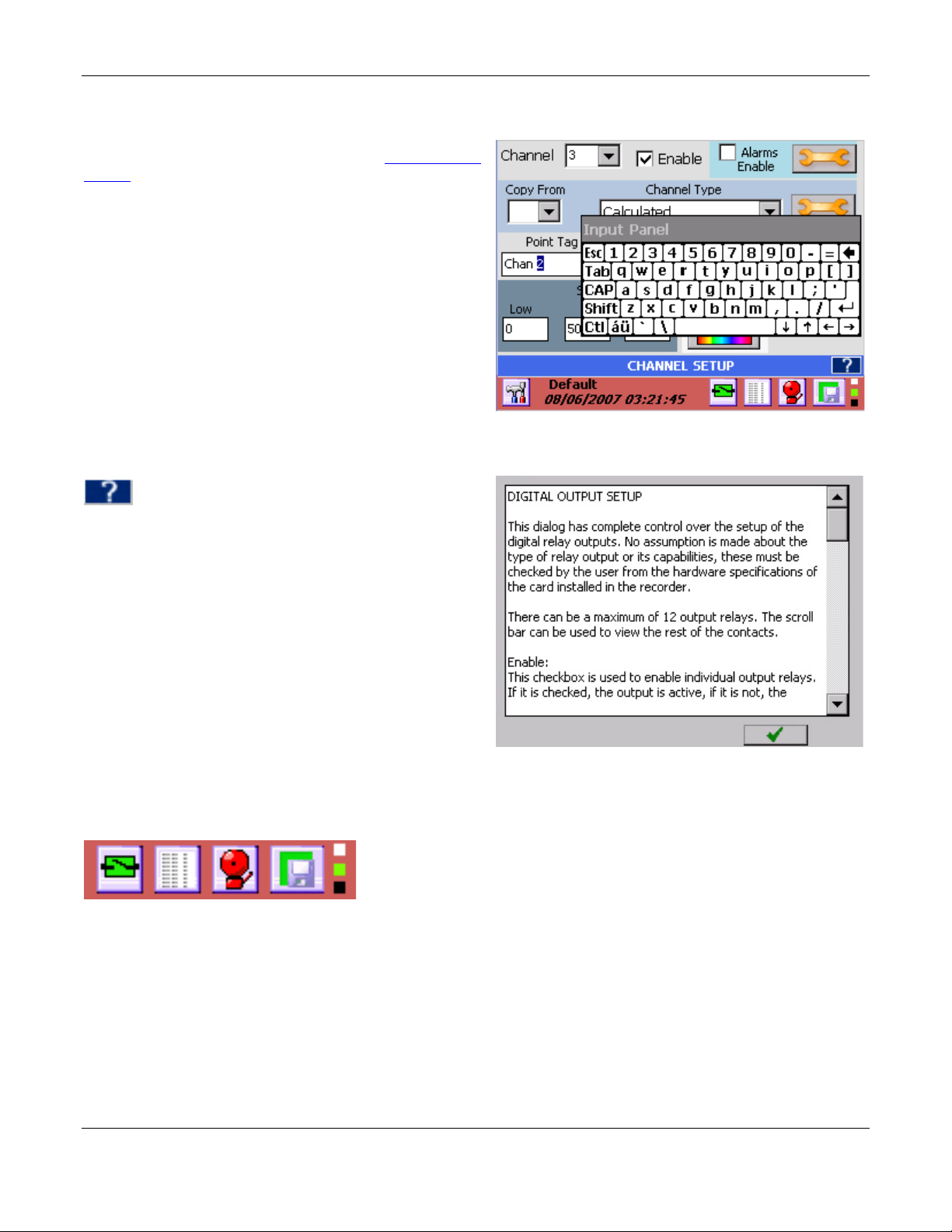

Figure 2-5 On-screen Keyboard

Figure 2-6 On-screen Help

Figure 2-7 Activity Lights

2.8 Keyboarding

While it is possible to connect a standard keyboard and

mouse to the recorder, one may not be readily available

in which case data is entered using the pop-up keyboard

as shown right.

When you enter a recorder setup screen where it is

necessary to type in data, the instant you tap the input

field box the keyboard pops up. Entry is made by tapping

the keys firmly with the stylus. As each key is pressed it

inverts its color. The Shift key allows a one time

uppercase letter to be entered and pressing the CAP key

will lock the keyboard in uppercase. The keyboard can be

moved by pressing in the gray area where it says Input

Panel and dragging it out the way in the event you need

to access an entry point behind the current location.

2.9 Help

Help is available on most set up screens by

tapping the help icon (shown left) on the right of

the blue name bar near the bottom of the screen – see

Figure 2-5 above. This will bring up a help text file which

deals specifically with the subject at hand.

The scroll bar at the right of the screen can be used

to browse through the file.

Tap the DONE button to exit.

2.10 Activity Lights

At the bottom right of the display are three small square activity „lights‟, the top one being white, the middle green

and the bottom black.

These have no purpose for the user other than “feel good” indicators to

indicate everything is working internally. The white block is the analog

subsystem activity and blinks at around 3 Hz. The green block indicates

internal data execution and the black block is the internal watchdog and

blinks at a rate around once every 3 seconds.

2.11 Security

The recorder has several levels of password to protect the various functions and prevent unauthorized access to

the unit. Access can also to limited access and control who can make changes, who can access and who can

administer the unit.

Page 11 09/11/2008 REV 0.99

Page 21

Section 2 - Overview

2.11.1 User Levels

There are three user levels for gaining direct access to the recorder. User levels are only active if security is

enabled. The three levels are

Administrator: Has access to all levels of the recorder menus and systems.

Manager: Has restricted access. A Manager cannot set up any base level parameters, but can use

existing setups to create alarms, displays and the like.

User: Can use the recorder only as set up by the Administrator or Manager. A User cannot

change any parameters. A User needs to log in to accept alarms.

User management is an Administrative only function and is controlled in the System Administrative Menu.

Here the Administrator can set usernames and passwords, disable users, set user expiry times and force a

user to be logged out after a specific time. The number of log in attempts can also be set before the current

user is disabled.

All users need to log in to the unit to perform any functions. At each log in the recorder makes a note of the

time and user name and will also log any failed attempts at login. Each user has a unique username and

password. Users may change their passwords at any time at the log in screen.

The unit also saves a copy of the configuration file when the user logs in and when the user logs out. This

way a complete activity log can be generated (by the accompanying Exhibitor software comparing the two

configuration files) and all parameters changed can be reported.

2.11.2 Remote Access Passwords

The user can access the recorder remotely using various methods. Each method is protected by a unique

password. The passwords need to be set up by the Administrator in the System Administrative Menu as

follows:

USB Access: Password optional. When accessing the unit via the USB Connection using ActiveSyncTM or

VistaTM Mobile Manager the Administrator can set an optional password which needs to be entered from the

remote computer before access is allowed. This password is set in the Set ActiveSync Password menu.

HTTP Access: Password required. When accessing the web server using the Ethernet and a browser the

user has to provide a password. There are two levels of password Admin and User. Users can view the web

pages but only Admin can perform remote functions. These passwords are set in the Web User Manager and

the Administrator user name HAS to be Admin.

FTP Access: Password Required. This is the same Admin password used for HTTP Access. No User access

is permitted.

Remote Control over Ethernet: Password Required. These are the same user names and passwords set for

recorder front panel access through the User management option described above.

All access user names and passwords can be set to be the same provided the administrator user name is

Admin. However you do have to set these up at the various locations referred to above.

Page 12 09/11/2008 REV 0.99

Page 22

Section 3 – Installation

3.0 INSTALLATION

This section provides information and procedures on installing and wiring the recorder. Included are handling

procedures, installation and wiring specifications, and instructions for both standard and optional equipment.

3.1 Equipment Handling

3.1.1 Initial Inspection

Exercise care when unpacking the instrument from the shipping carton. The instrument is packed in a

shockproof foam retainer to prevent damage during normal transit. If damage to the shipping carton is

evident, ask the carrier‟s representative to be present when the instrument is unpacked.

3.1.2 Unpacking Procedure

To unpack your recorder, first remove the foam retainer and instrument from the shipping carton. Then,

carefully remove the instrument from the foam retainer.

3.1.3 Detected Damage

If damage is detected after unpacking the instrument, re-pack the instrument and return it to the factory as

described in the following section.

3.1.4 Equipment Return

Before returning a damaged or malfunctioning instrument to the factory for repairs, contact the sales

organization from which you purchased the instrument. A Return Merchandise Authorization number must be

obtained from the factory before returning an instrument for any reason.

3.1.5 Storage

For prolonged storage before installation, re-pack the recorder in the shipping container. Cushion the

recorder with foam molding or an equivalent and store in a cool, dry area. It is not recommended to store the

recorder for more than one year. If longer storage time is required, contact the factory for additional storage

information.

3.2 Environment and Location

The instrument is intended to operate in the following environment:

Indoor Use Only

Installation Category II per IEC 664

Pollution Degree Level II per UL3111-1 / IEC61010-1

Altitude up to 2,000 m

Temperature -10 °C to +50 °C operating per UL3111-1 / IEC61010-1

Humidity Maximum relative humidity 80% for temperatures up to

31°C decreasing linearly to 50% relative humidity at 40°C

AC Mains Supply 100 - 240 Vac ~ 50/60 Hz 35 Vac ±10%

Page 13 09/11/2008 REV 0.99

Page 23

Section 3 – Installation

NOTE: The recorder is designed to be panel mounted and as such should be considered as

permanently connected. Disconnection from the supply must be possible via a customer

supplied switch or circuit breaker. This disconnection device must be included in the panel

installation and should be clearly marked, in close proximity to the Recorder and easily

accessible to the operator.

3.3 Installation

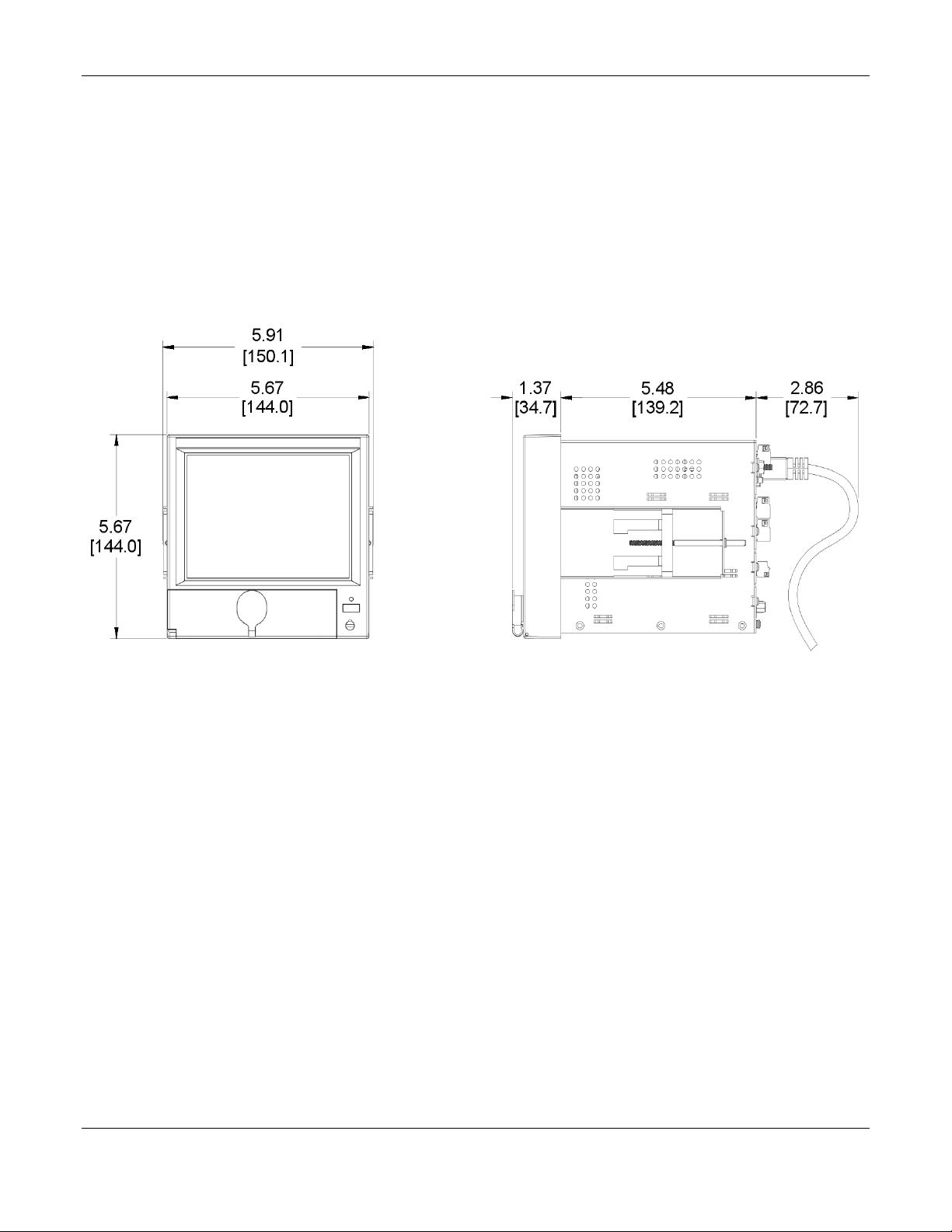

The recorder is sized to fit in a standard DIN panel cutout of 5.43” x 5.43” [138 mm x 138 mm] and requires a

minimum of 6.5” [188.2 mm] behind panel depth not including power and input source cable space needed.

Actual dimensions are shown below.

Figure 3-1 Recorder Dimensions in Inches [mm]

WARNING: Do not use this instrument in any manner inconsistent with these operating instructions or

under any conditions that exceed the environmental specifications stated.

Page 14 09/11/2008 REV 0.99

Page 24

Section 3 – Installation

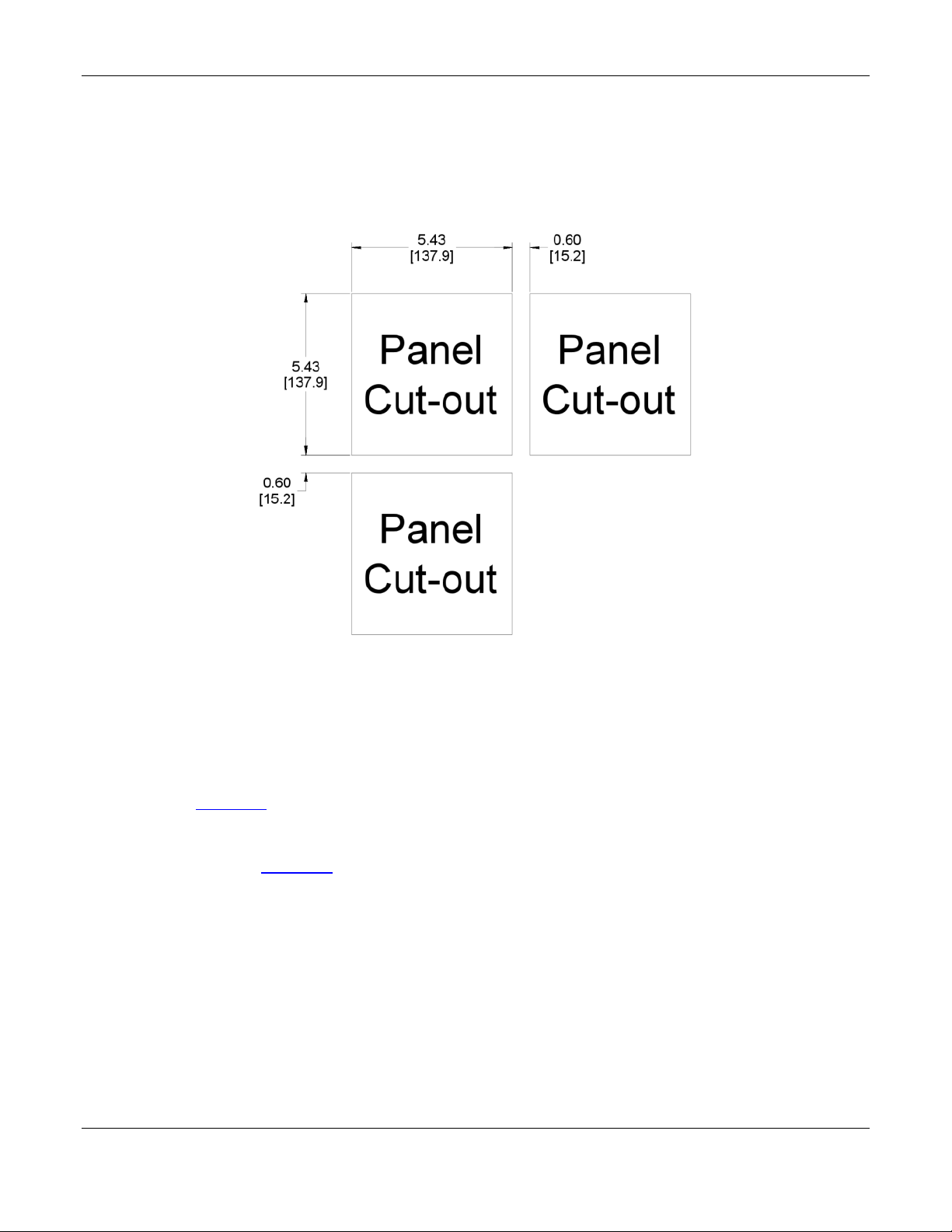

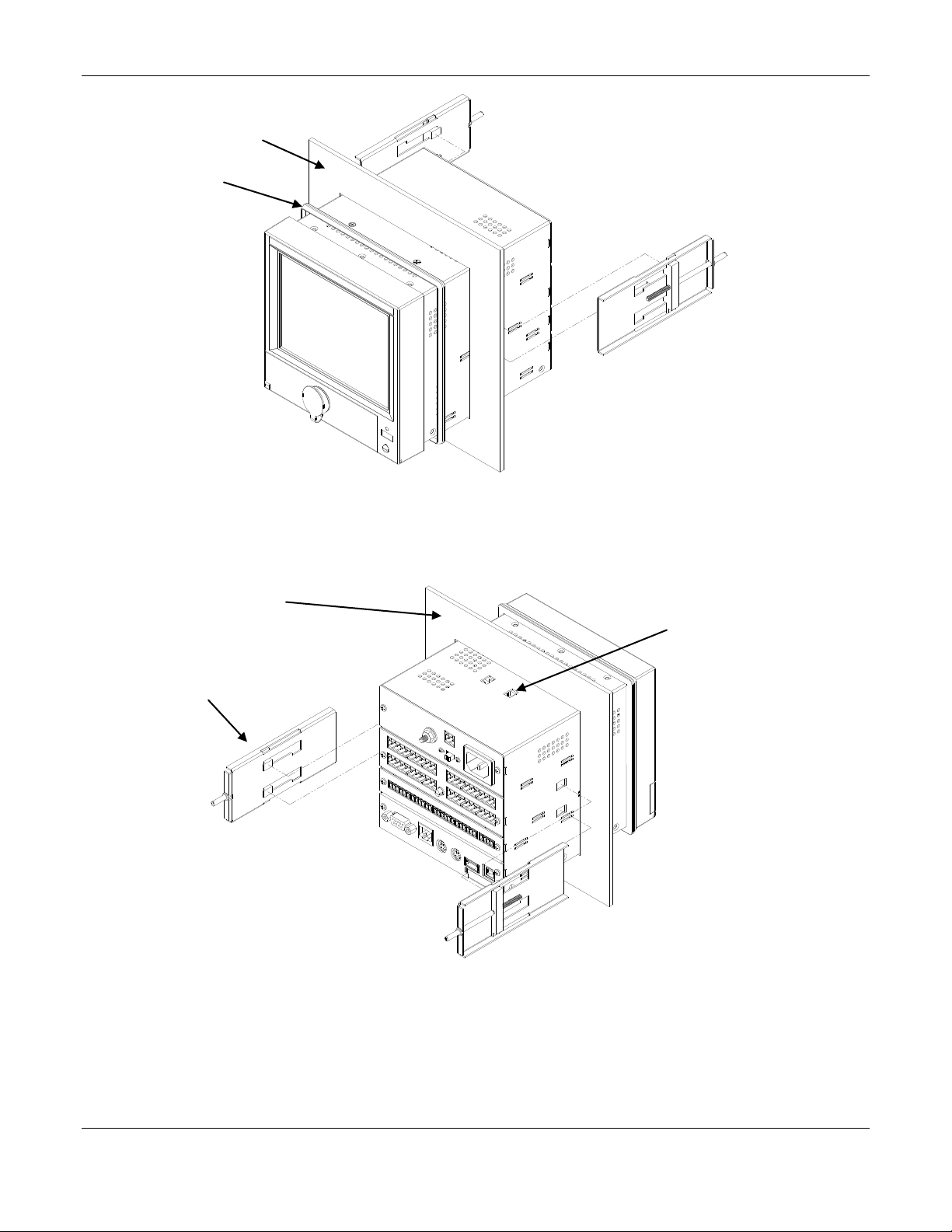

3.3.1 Panel Mounting

The recorder should be mounted in a vertical panel to ensure proper operation. Note that the locking bars can

be used on the sides or top and bottom of the unit depending on available space. Ensure you have the proper

clearances and proceed as follows:

3.3.1.1 Cut a panel opening 5.43” x 5.43” [138 mm x 138 mm]. Units can be mounted as close as 0.6”

[15.2mm] between opening cutouts

Figure 3-2 Front Panel Cut Out

3.3.1.2 Remove any packaging material from the recorder. Always handle the unit carefully to avoid

damaging the LCD display or scratching the display surface.

3.3.1.3 Remove the locking bars from the recorder enclosure and ensure the gasket is not twisted on the

enclosure.

3.3.1.4 Insert the recorder rear end first, into the panel opening from the front of the panel as shown in

Figure 3-3. Ensure that the gasket is between the front bezel of the recorder and the front panel.

3.3.1.5 With the recorder held firmly in place against the panel, install one of the locking bar assemblies

by sliding the locking bar notch into the slot on the side (or top) of the recorder enclosure as

shown in Figure 3-4.

3.3.1.6 Using a slotted screwdriver, tighten the screw until the locking bar is just pressing against the

panel.

3.3.1.7 Install the other locking bar assembly into the slot on the opposite side (or bottom) of the recorder

enclosure and tighten as before.

3.3.1.8 Using the screwdriver, tighten both screws so that the recorder is held firmly in place. Do not over

tighten.

3.3.1.9 Use the supplied silver “stickers” to seal the unused locking bar slots on the top and bottom or

sides of the unit

Page 15 09/11/2008 REV 0.99

Page 25

Section 3 – Installation

Figure 3-3 Front Panel Insertion

Figure 3-4 Rear View Panel Insertion

Panel Back

Locking Bar Assembly

Seal unused slots

Panel Front

Gasket

Page 16 09/11/2008 REV 0.99

Page 26

Section 3 – Installation

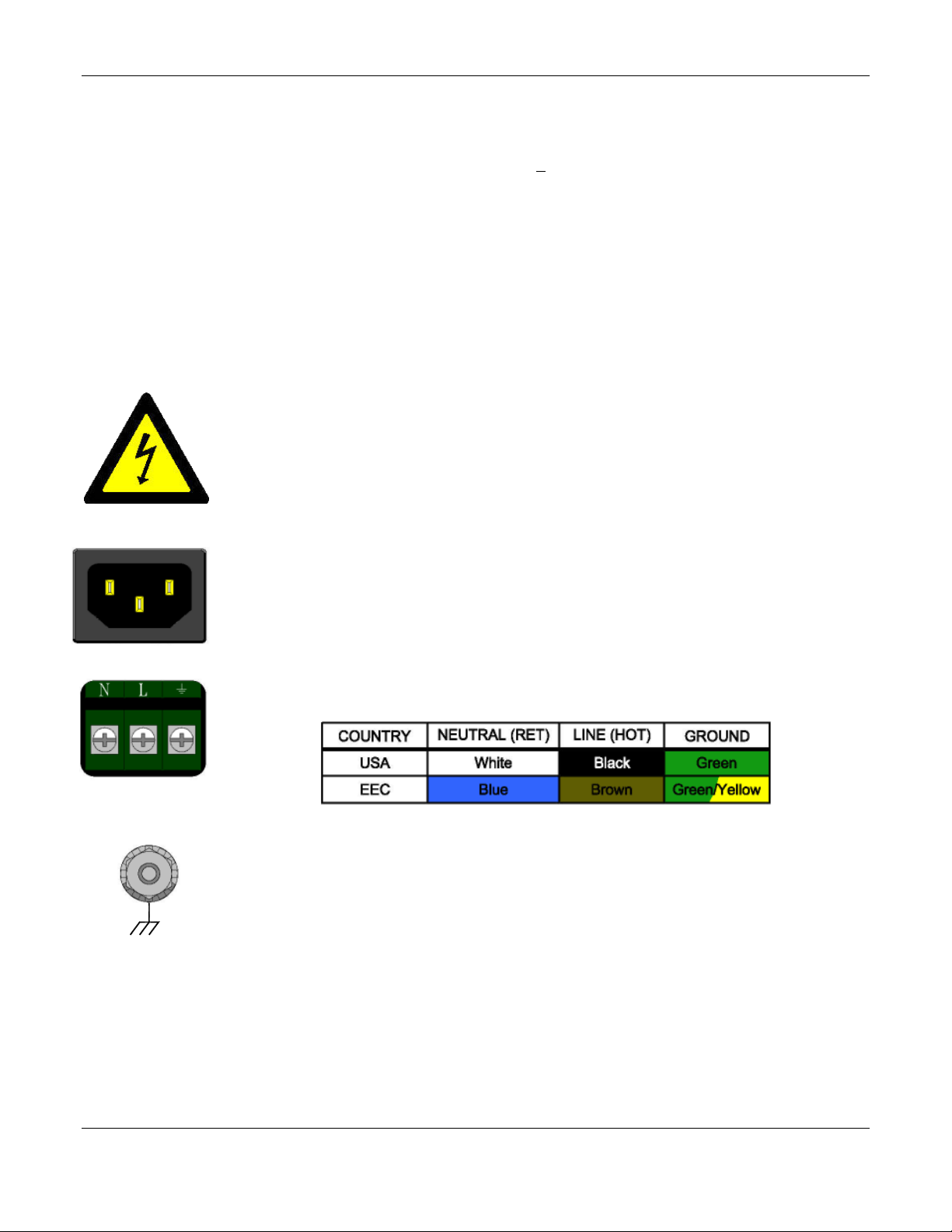

Figure 3-5

Figure 3-6

Figure 3-7

3.4 Wiring Specifications and Procedures

3.4.1 Power Requirements

The recorder operates on any voltage from 100 to 240 Vac +10%, 50/60 Hz enabling it to be used in most

countries. The maximum apparent power required by the unit is 35 VA.

3.4.2 Power Connections

NOTE: The recorder is designed to be panel mounted and as such should be considered as permanently

connected. Disconnection from the supply must be possible via a customer supplied switch or

circuit breaker. This disconnection device must be included in the panel installation and should be

clearly marked, in close proximity to the recorder and easily accessible to the operator.

All connections to the recorder are made to the Rear Terminal Panel. Any wiring carrying hazardous voltages

must conform to all applicable local and national safety codes. AC Mains connection is via an internationally

accepted IEC 320 AC mains connector or screw terminal (Figure 3-5 and Figure 3-6).

WARNING Ensure all mains power is turned off before proceeding with

installation. This unit is provided with a mating connector for the ac power socket or

with a compatible three wire grounded cable which may be terminated with a plug.

Always ensure the ground wire (green or green and yellow) or ground pin of the plug,

is connected to a low impedance safety ground (earth) within the ac power distribution

system you are using. Always use the recommended mating connector and an

approved three wire cable to connect this unit to the ac mains. Always provide a low

impedance safety ground wire to the ground lug on the rear panel marked.

Figure 3-5 shows the IEC 320 AC mains connector on the rear of the recorder. The center

pin is the ground termination. If a mating plug is provided, it will be marked with the Ground,

LINE (L) or hot, and NEUTRAL (N) or return. In the United States, an approved cable with

integral plug (NEMA 5-15 P) is provided. In some instances, a cable with no plug may be

provided. In this instance, the user must connect an approved plug to the cable prior to

connecting to the AC source.

Figure 3-6 shows the screw terminal power connections on the rear of the recorder. The right

terminal is ground, the center terminal is LINE (L) or hot and the left terminal is NEUTRAL (N)

or return. The wire color codes are as follows:

Figure 3-7 shows the ground lug on the rear panel. This screw terminal must be connected to

an earth wire which in turn is connected to the ground or earth of the AC power distribution

system.

This unit is equipped with an AC mains fuse internally. If this fuse should blow, it generally

indicates a serious problem with the recorder. THE FUSE SHOULD NOT BE REPLACED

BY AN OPERATOR. The fuse is a quick acting 5 x 20mm type - 2.0 Amps 250 VAC (~).

Page 17 09/11/2008 REV 0.99

Page 27

Section 3 – Installation

COMIN-IN+

CHAN 9

COMIN-IN+

CHAN 8

COMIN-IN+FIN

CHAN 7

CHAN 3CHAN 2CHAN 1

IN+ IN- COMIN+ IN- COMFIN IN+ IN- COM

CHAN 12

IN+ IN- COM FINCOMIN-IN+

CHAN 11CHAN 10

IN+ IN- COM

FINCOMIN-IN+

CHAN 6CHAN 5

IN+ IN- COMCOMIN-IN+

CHAN 4

24VDC OUT

+

-

ON

OFF

BATTERY BACKUP

RELAY 1RELAY

2

RELAY

3

RELAY

4

RELAY 5RELAY

6

RELAY

7

RELAY 8RELAY 9RELAY

10

RELAY 11RELAY

12

DIGITAL 1 DIGITAL 2

+ +

-

-

RS232/485

ETHERNET

AUDIO

OUT

KEYBOARD /

MOUSE

90 - 240 VAC 35 VA

USB

MASTER A

USB

SLAVE B

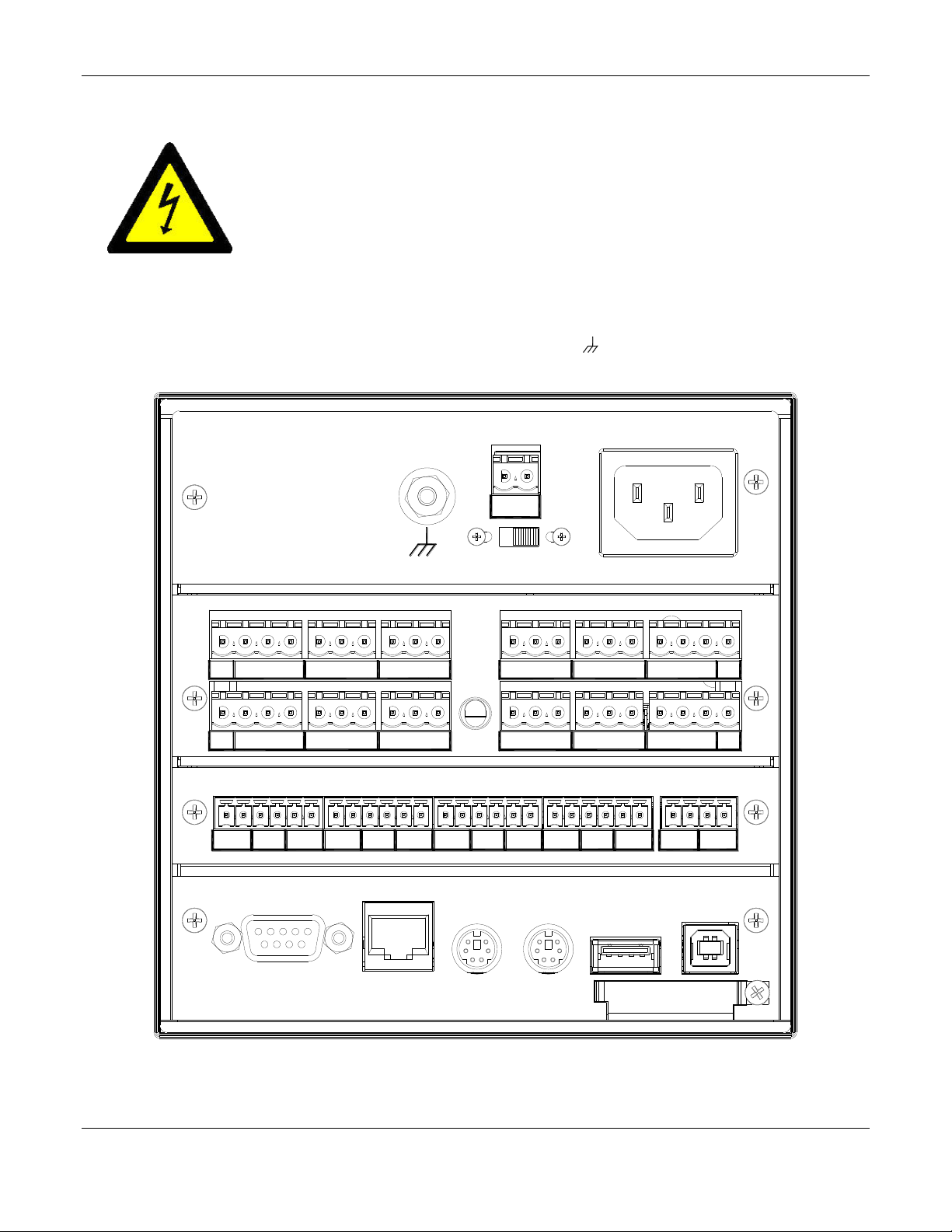

Figure 3.8 – Rear Panel

3.4.3 Signal Input Wiring

Signal input connections. Hazardous potentials may exist on signal input terminals

which are floating with respect to case ground. These hazardous potentials may be

on the rear terminal panel of your instrument. Any voltage potential at the signal

source will exist on the instrument’s respective signal input terminal (i.e. power

generator stator winding). The analog inputs can sustain up to 2000 Volts with

respect to the chassis ground.

The recorder accepts up to twelve direct inputs. Input connection is via plug in screw terminal connectors on

the rear panel. Inputs can be mixed in any combination of thermocouple, RTD, milliamps, millivolts, volts or

contact inputs. In addition, channels 1 and 6 (and optionally 7 and 12) can accept frequency inputs via an

additional terminal. There is a common ground lug marked with a for connection of signal cable shields

or screens.

Page 18 09/11/2008 REV 0.99

Page 28

Section 3 – Installation

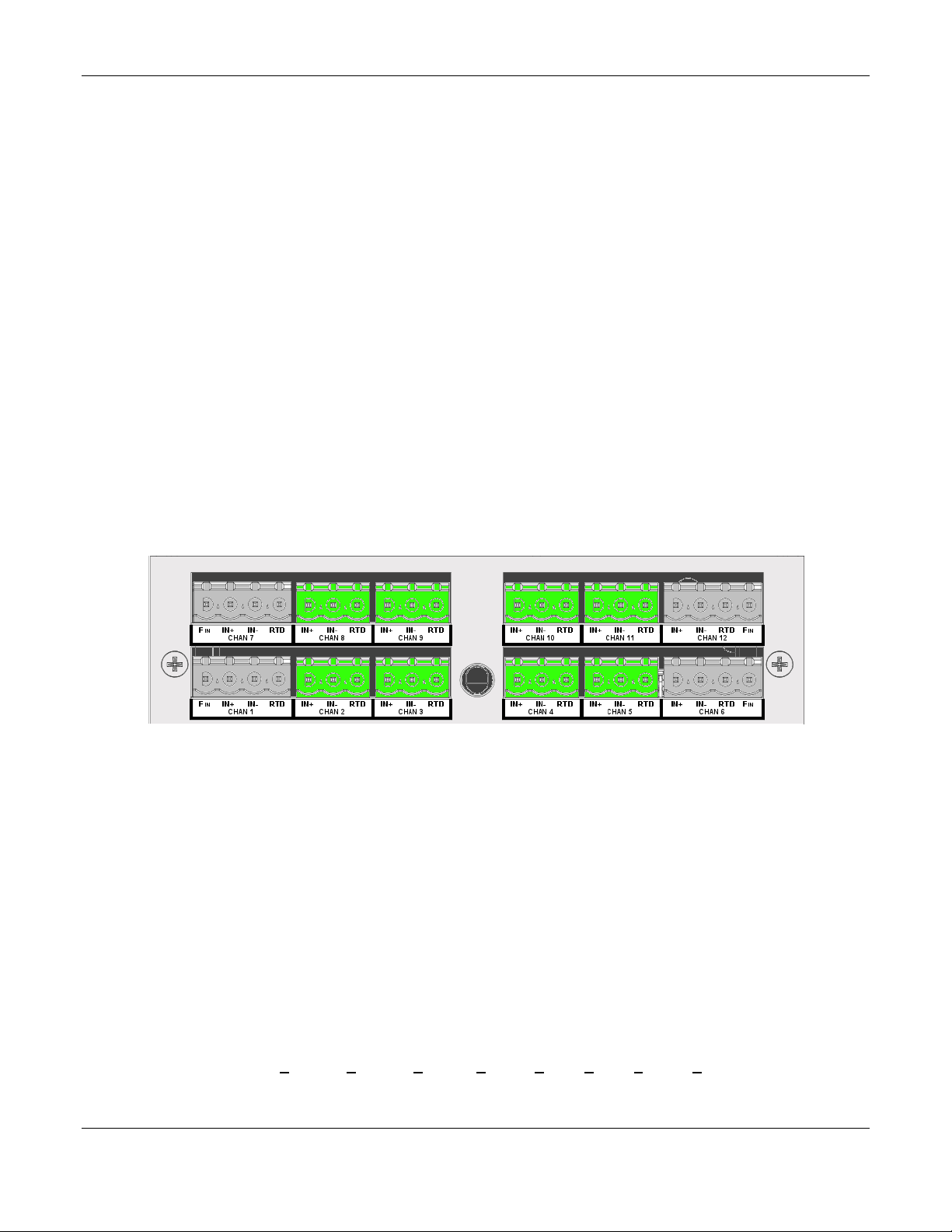

Figure 3-9 Analog Input Module (12 Channels shown)

Read the following procedures prior to connecting inputs to the terminals.

WARNING: Ensure the power is off before connecting signal inputs to the unit.

The plug in screw terminal connectors are of the clamping screw variety, putting even pressure on the signal

wire. It is therefore not necessary to terminate the wires with lugs, however you may do so if you wish. The

maximum gauge wire that can be accommodated is 14 AWG or 2.5 mm². You will need a small screwdriver

and a pair of wire cutters and strippers. The use of shielded twisted lead wire is recommended to minimize

electromagnetically induced noise.

WARNING: All unused inputs must have + and - contacts commoned together.

CAUTION: Never run signal and power or control wiring together in the same conduit. This is to

prevent possible recording error due to induced signals between lines. If running cables

is inevitable, use shielded cable where possible and properly ground the shield. Route

signal wires away from power wires at the rear panel.

NOTE: Ground cable shields at one end only to eliminate the possibility of interference due to

ground loop currents. When grounded transducers are used, the shield should be

grounded at the sensor end only.

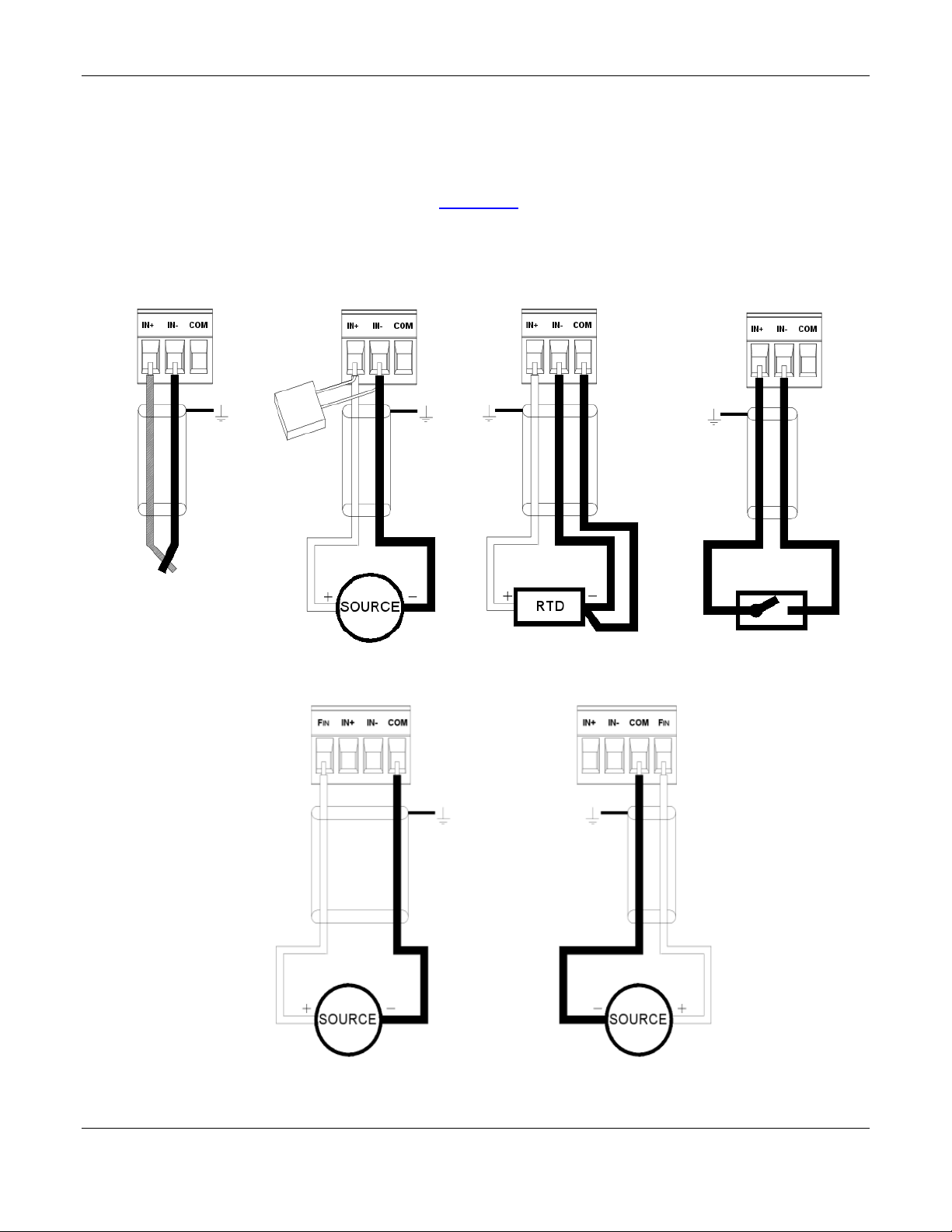

3.4.3.1 Analog Inputs

The Analog Input board can have 6 or 12 channels (12 shown below). Each Input is truly differential and

has a positive (IN+) and negative (IN-) input and an RTD Common (COM) for RTD current return and

Frequency input Common ONLY. Channels 1 and 6 (and optionally 7 and 12) have a Frequency Input

(FIN) which is common with the COMmon input. All inputs are isolated to 350 Vac from each other and

2,000 Vac from the chassis ground.

3.4.3.2 Thermocouple Inputs

Thermocouple Input connections are made as shown in Figure 3-10 T/Cs. The ambient temperature

compensator is between inputs 3 and 4.

3.4.3.3 Resistance Temperature Detector (RTD) Inputs

Two or three wire RTDs may be used for connection with cable compensation of up to ±50 ohms. The

“COM” Terminal is the common current return (Wire 3). Four wire RTDs can be used – simply do not

connect the second + wire. Two wire RTDs require a jumper between (IN-) and (COM). Refer to Figure

3-10

3.4.3.4 Linear Inputs

Linear Inputs are divided into two types:

Current inputs: 4-20 milliamps, 0-20 milliamps and 10-50 milliamps, using an external 50 ohm

shunt (0.1% 0.5W).

Voltage inputs: +125mV, +250mV, +500mV +1.00V, +3.0V, +6.0V, +12.0V, +24.0V DC.

Page 19 09/11/2008 REV 0.99

Page 29

Section 3 – Installation

Figure 3-10 Analog Inputs - Wiring Detail

CHAN 1, 7 FREQUENCY/PULSE INPUT CHAN 6, 12 FREQUENCY/PULSE INPUT

THERMOCOUPLE VOLTAGE AND CURRENT RTDs CONTACTS

NOTE: RESISTOR FOR CURRENT ONLY

50 Ω 0.1%

0.5W

3.4.3.5 Potential Free Contacts

Normally open/closed contact inputs.

3.4.3.6 Frequency

Available on channels 1, 6, 7 and 12 only. Default input is for 12 to 24V DC @ 20mA max. The inputs can

be jumpered internally for 5 to 12V dc. See Appendix B for details.

Page 20 09/11/2008 REV 0.99

Page 30

Section 3 – Installation

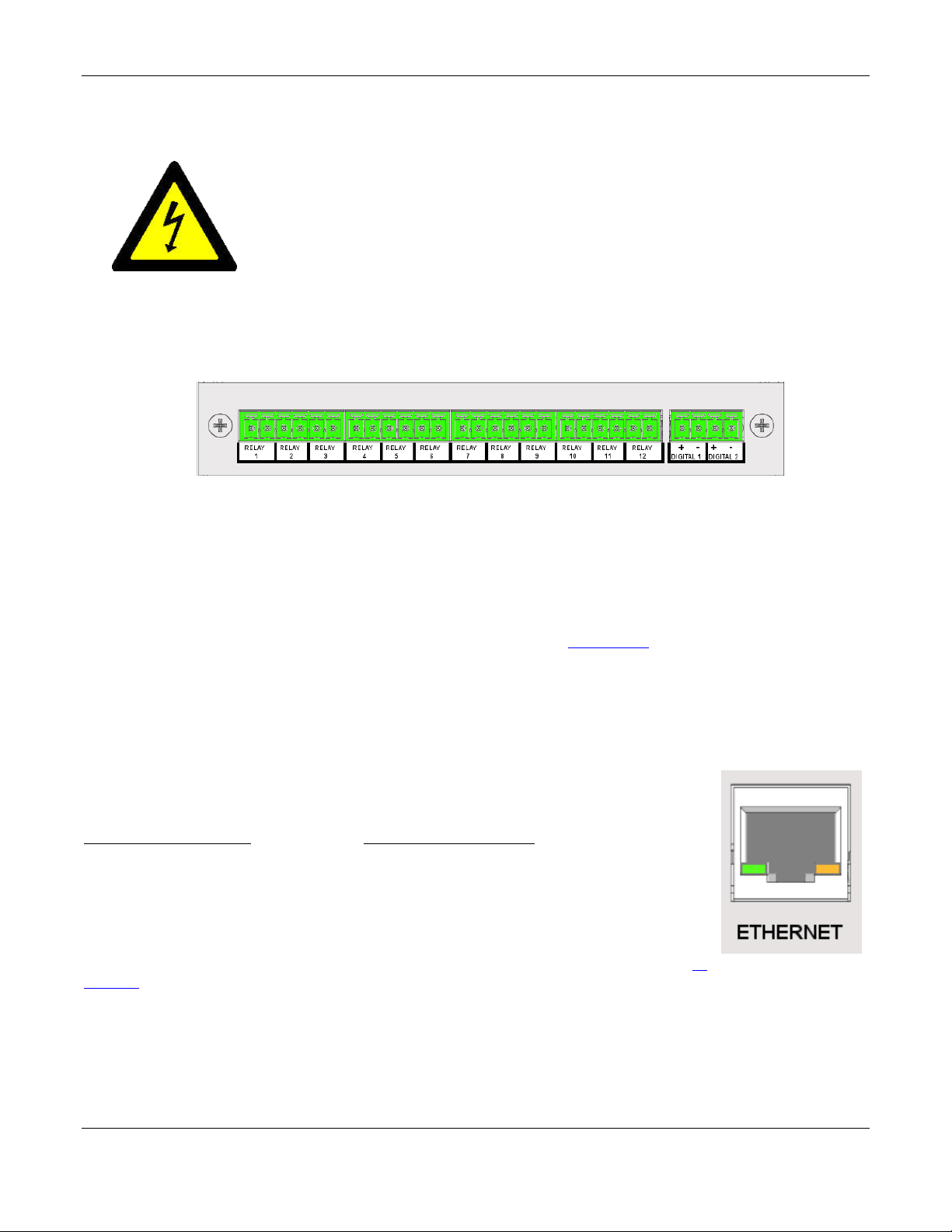

Figure 3-11 Digital I/O Module 12 Contacts Out, 2 In

Figure 3-12

3.4.4 Relay Output, Contact Input

WARNING

To prevent the possibility of electrical shock, use extreme caution when wiring

contact output connections. Hazardous potentials may exist on contact output