Page 1

Page 2

Page 3

Page 4

Page 5

Contents

Introduction 1

1 Overview 2

1.1 485 communication interface 2

1.2 Communication protocol 2

2 Communication specifications 2

3 Confirmation and setting method of communication

specification

4 Connection 4

4.1 Precautions during connection 4

4.2 Communication cable 5

4.3 Connection of RS-485 7

5 MODBUS protocol 8

5.1 Transmission mode of message 9

5.2 Data time interval 10

5.3 Message configuration 10

5.4 Method of creating message 16

5.5 Function code 17

5.6 Process during abnormality 21

5.7 Print message function 23

5.8 Reference table 24

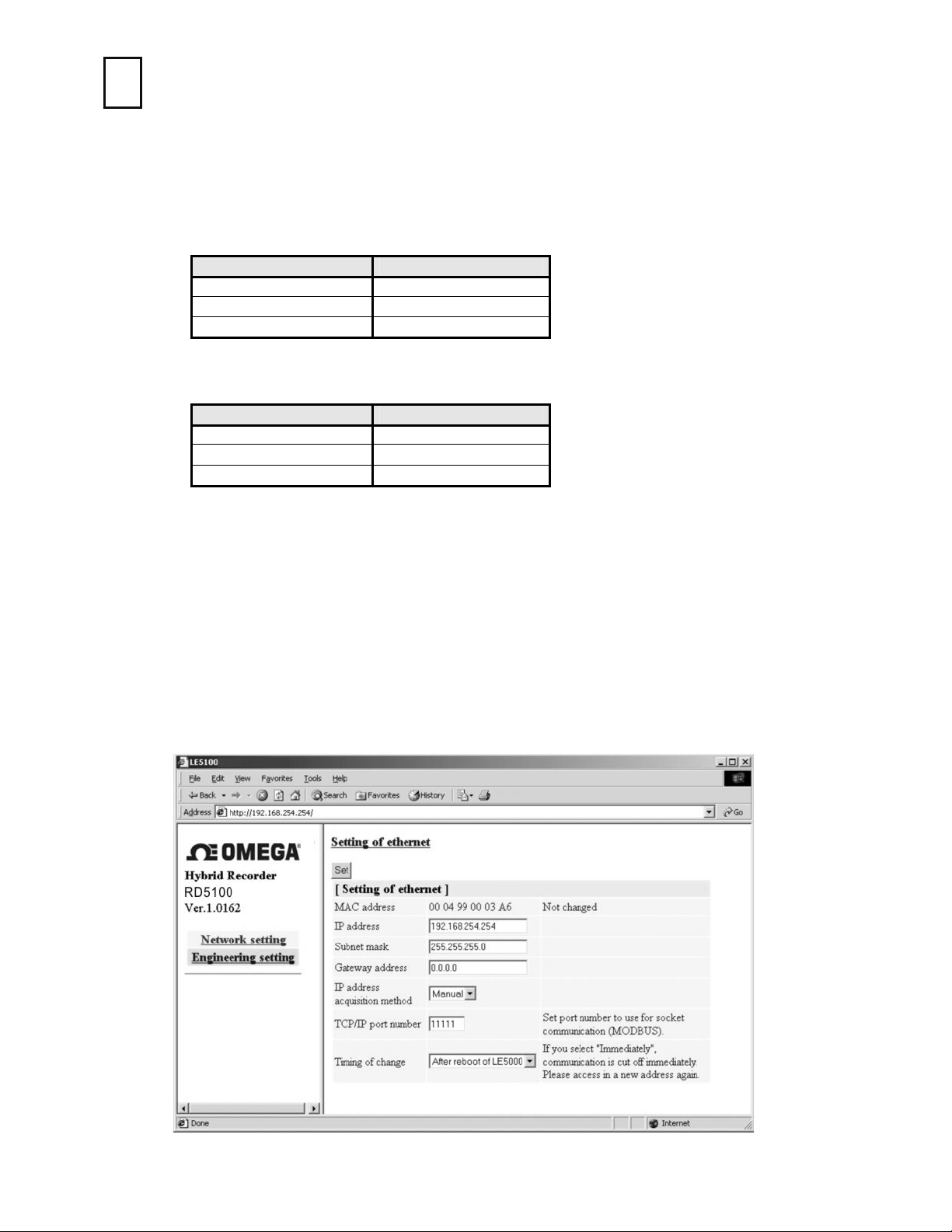

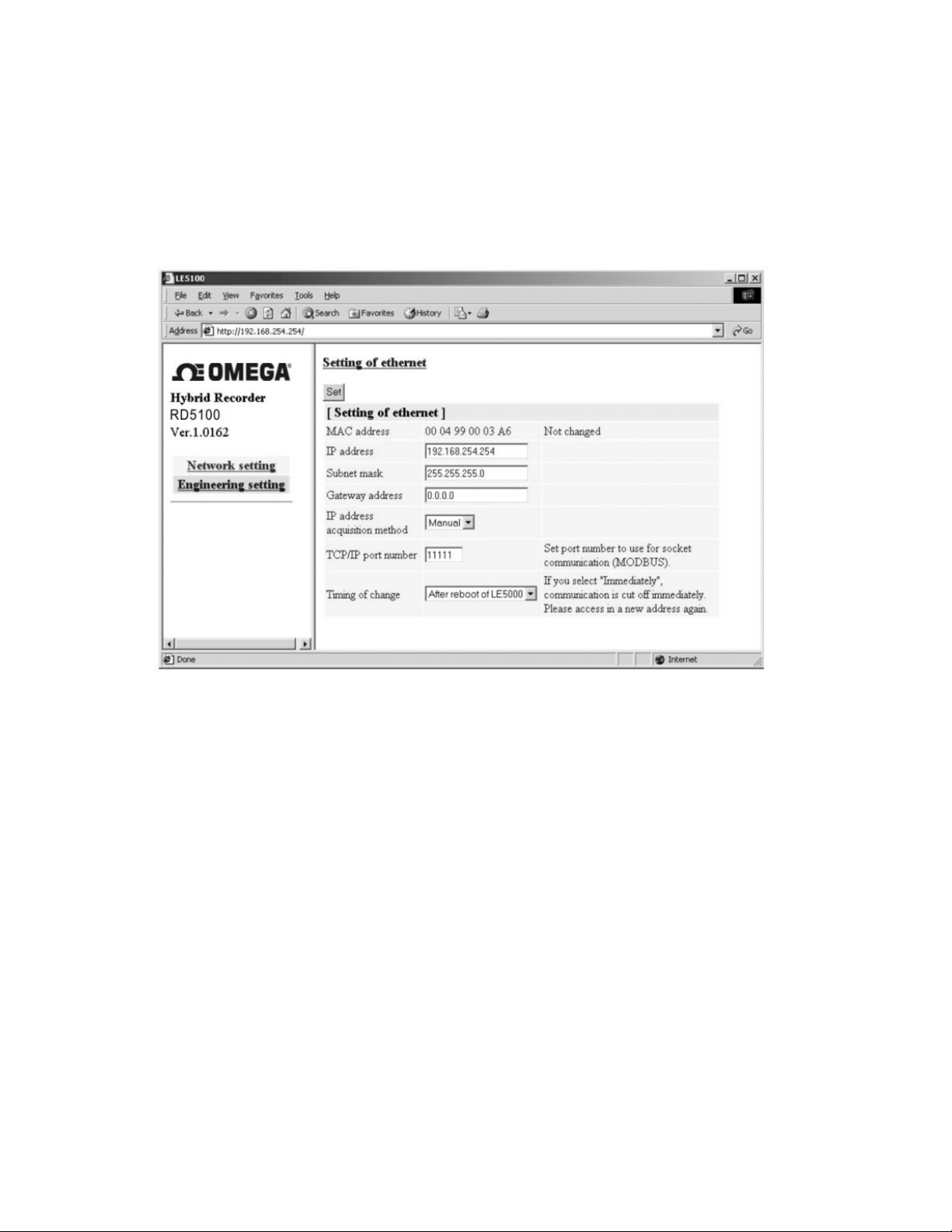

6 Before connecting to the network 81

6.1 Allocation of IP address 82

6.2 Communication error of Ethernet 83

3

Page 6

Introduction

This instruction manual explains the handling and specifications about 3 communication interfaces

( RS-485, USB, Ethernet) in the common communication interface edition of Hybrid recorder RD5100

series. Each individual part is divided into “

collectively explained. Hence read the part that is required.

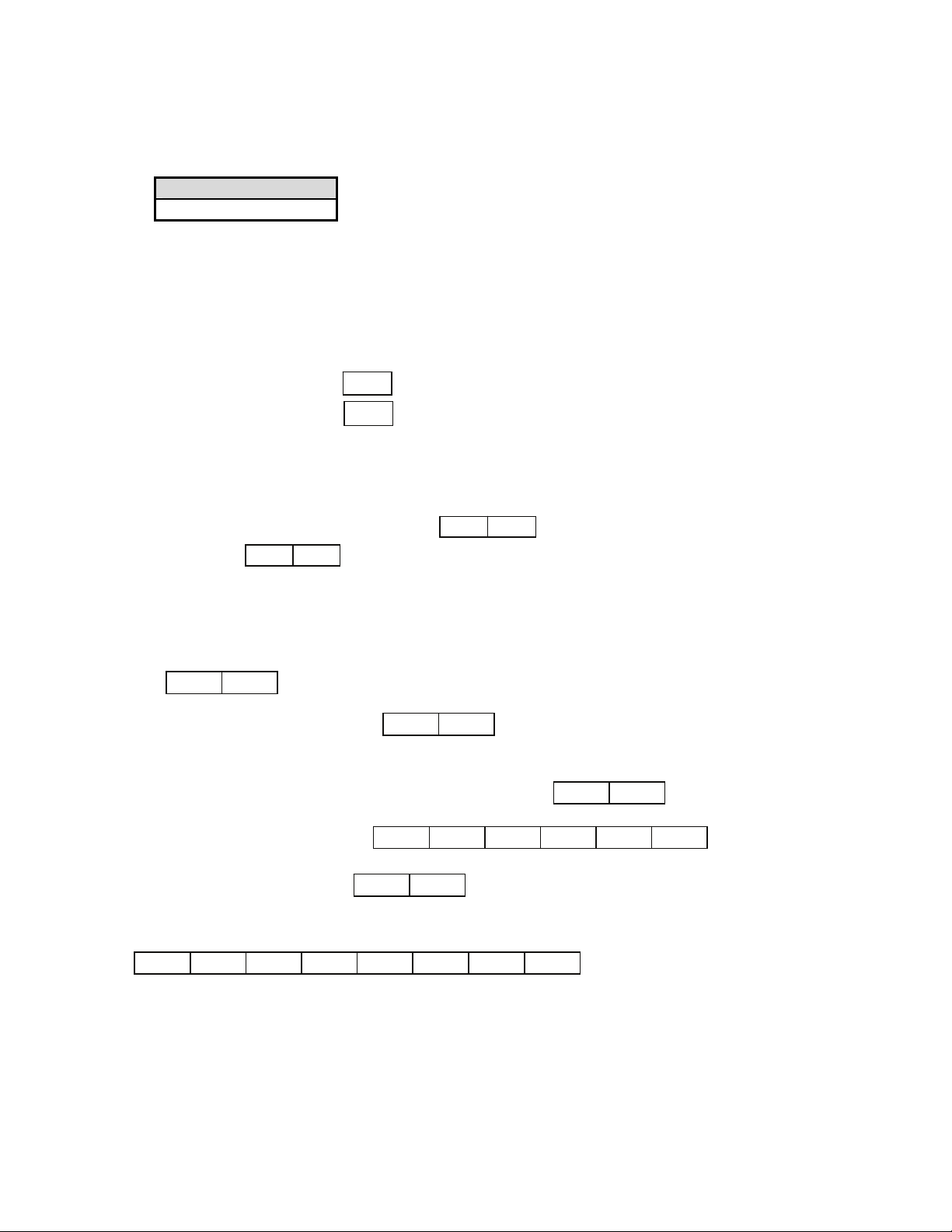

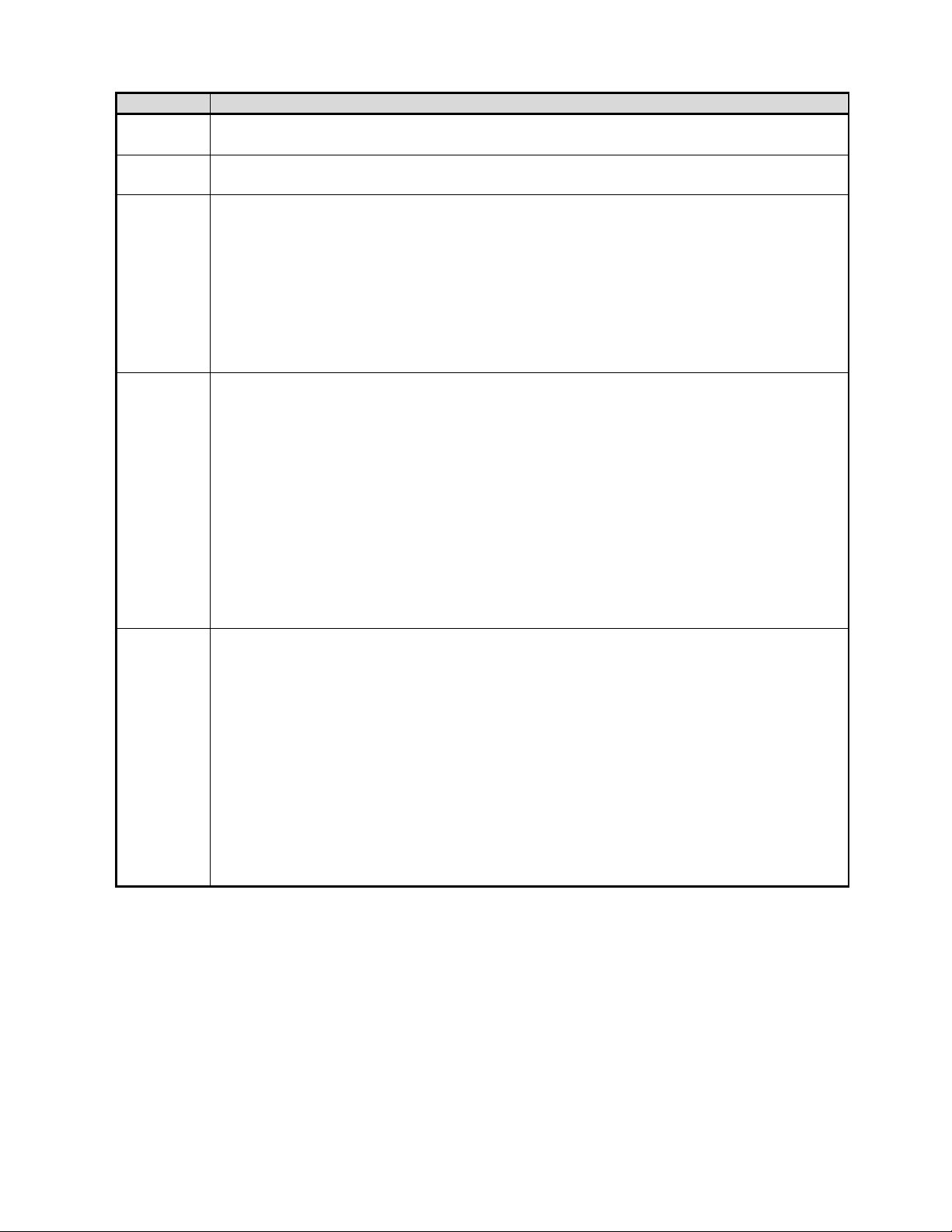

Confirm the communication interface of the purchased RD5100 series by model code.

RD5100 series

RD51-

Communication interface

N: None

1: RS-485+USB+Ethernet+Contact point 1 output (Contact point 1

output mechanical relay ‘a’ contact point output)

1. Other instruction manuals to be referred to

RS485”, “USB”, “Ethernet” and common part is

As this manual gives a limited explanation about the communication interface, refer to the instruction

manual of this instrument itself for the operation methods etc.

ÚFor the PC to be used refer to the instruction manual of that PC.

2. Precaution table Precautions

In between the sentences in this instruction manual there are explanations. It is the description of

things that are to be observed during operation and at the time of handling the communication

interface. If these things are not followed the device may be damaged and the performance will drop

remarkably or operation may not run properly.

Precautions

(1) The contents of this document may be changed without notice in the

future.

(2) All the possible care has been taken while creating this manual.

However if you come across any mistake, or have any doubts or if you

notice any description leakage etc. contact the shop from where you

purchased the product or contact our company's nearest branch office.

(3) Please note that irrespective of (2) we will not be responsible for the

effect of operation result.

-1-

Page 7

1 Overview

In communication interface of RD5100 there are 3 types viz. RS-485, USB, Ethernet available and are

used for communicating with the personal computer (Hereafter referred to as PC). PC can receive

measurement data from RD5100, various parameters can be set and operation commands can be

executed.

Connection count of RD5100 is 1 USB and maximum 31 RS-485.

1.1 RS-485 communication interface

RS-485 communication interface can communicate by connecting in series multiple (maximum 31)

RD5100 series machines through the signal that conforms to RS-485.

Although the number of PCs having RS-485 is less, it can be easily connected by using

RS-232C RS-485 signal converter, as it is a serial communication.

As this company also has line converters for RS-232C RS-485 signal conversion, you can place

an order for them.

1.2 Communication protocol

RD5100 series uses MODBUS protocol (MODBUS is a registered trademark of SCHNEIDER

Company) as communication protocol

MODBUS protocol has 2 modes viz. RTU mode and ASCII mode and they can be toggled using key

settings. MODBUS protocol has operation function and, settings and send function of measurement

data.

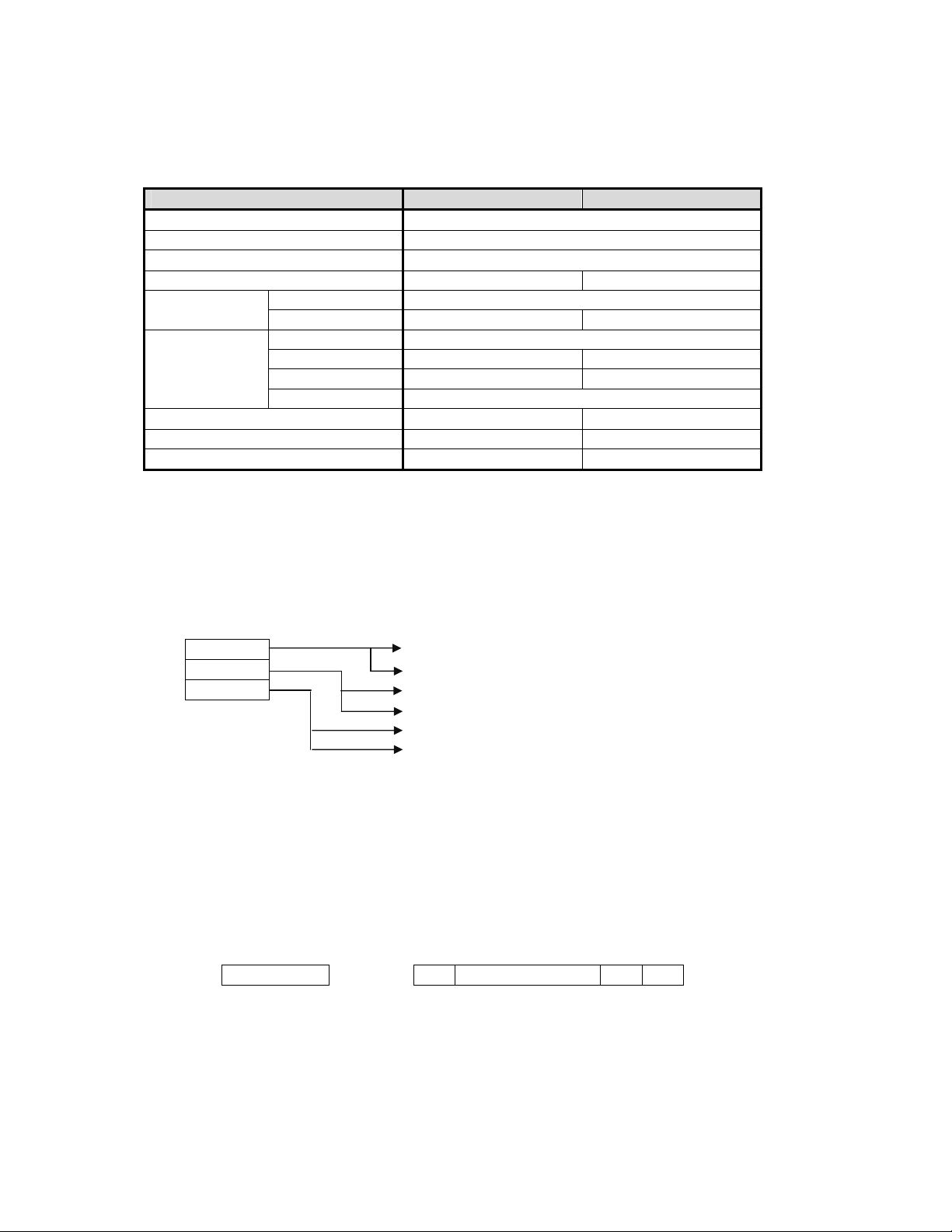

2 Communication specifications

・Asynchronous method

・Half duplex communication method (Polling selecting method)

・Protocol: MODBUS protocol/usual protocol (Compatible with LE1000)

・Transmission speed:19200, 9600, 4800, 2400, 1200 bps switching possible (differs depending on

the protocol)

・Start bit:1 bit

・Data length: 7 bits/8 bits switching is possible

・Parity bit: Even (even parity)/Odd (odd parity)/Non (No parity) switching is possible

・Stop bit: 1 bit/2 bits switching over is possible

・Transmission code: Binary/ASCII (Differs depending on the protocol)

・Error check: Differs depending on the protocol

・External instrument priority communication method

・Data transmission procedure: No procedure

・Usage signal name: Send and receive data only (Without using control signal)

-2-

Page 8

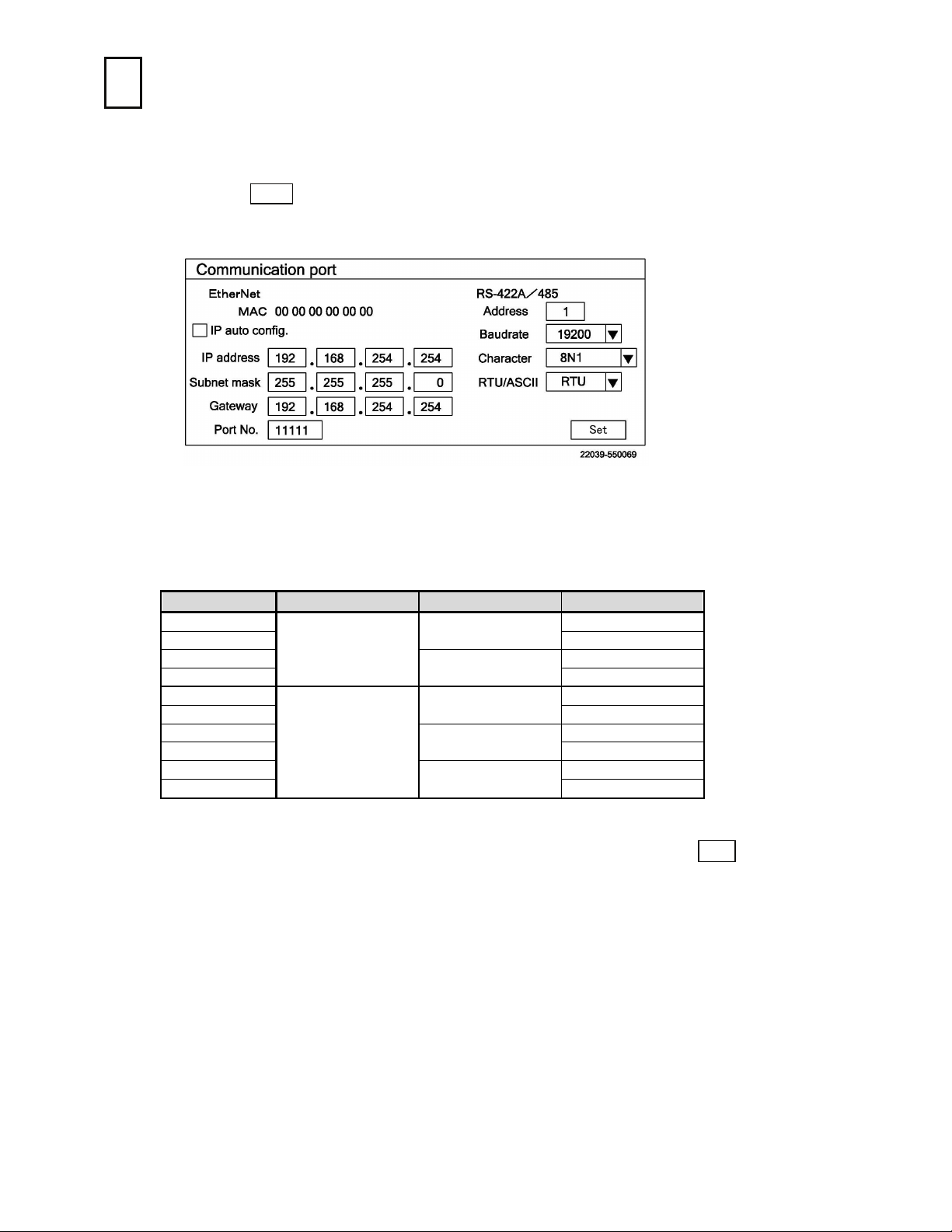

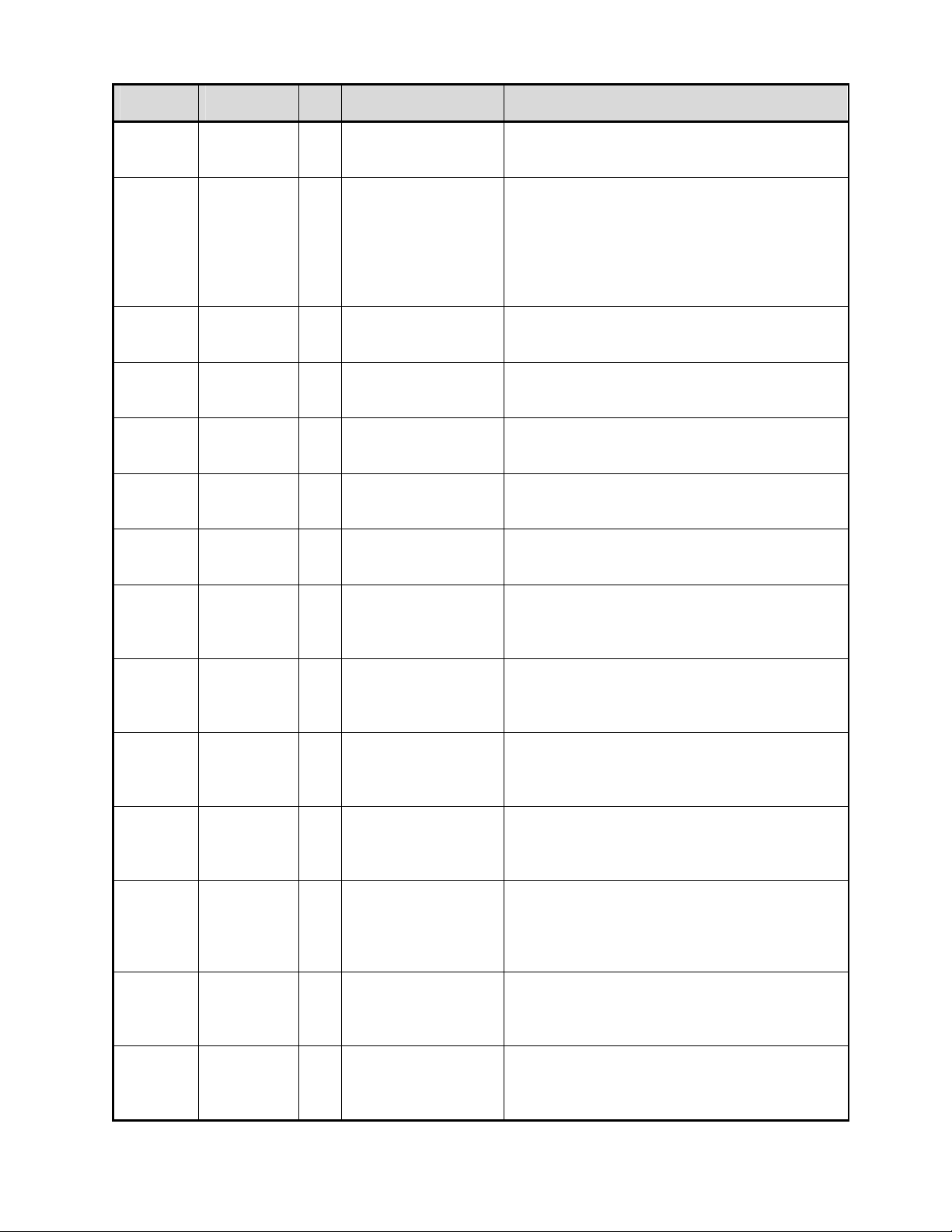

3 Confirmation of communication

specifications, and setting method

Go to the settings display mode by clicking the Menu key. A window opens and a list of setting items is

displayed, select

specifications and do the settings as per the requirement.

・Instrument address: Setting range from 1-99 can be entered directly using the number keys.

・Transmission speed: Select either of 9600,19200bps.

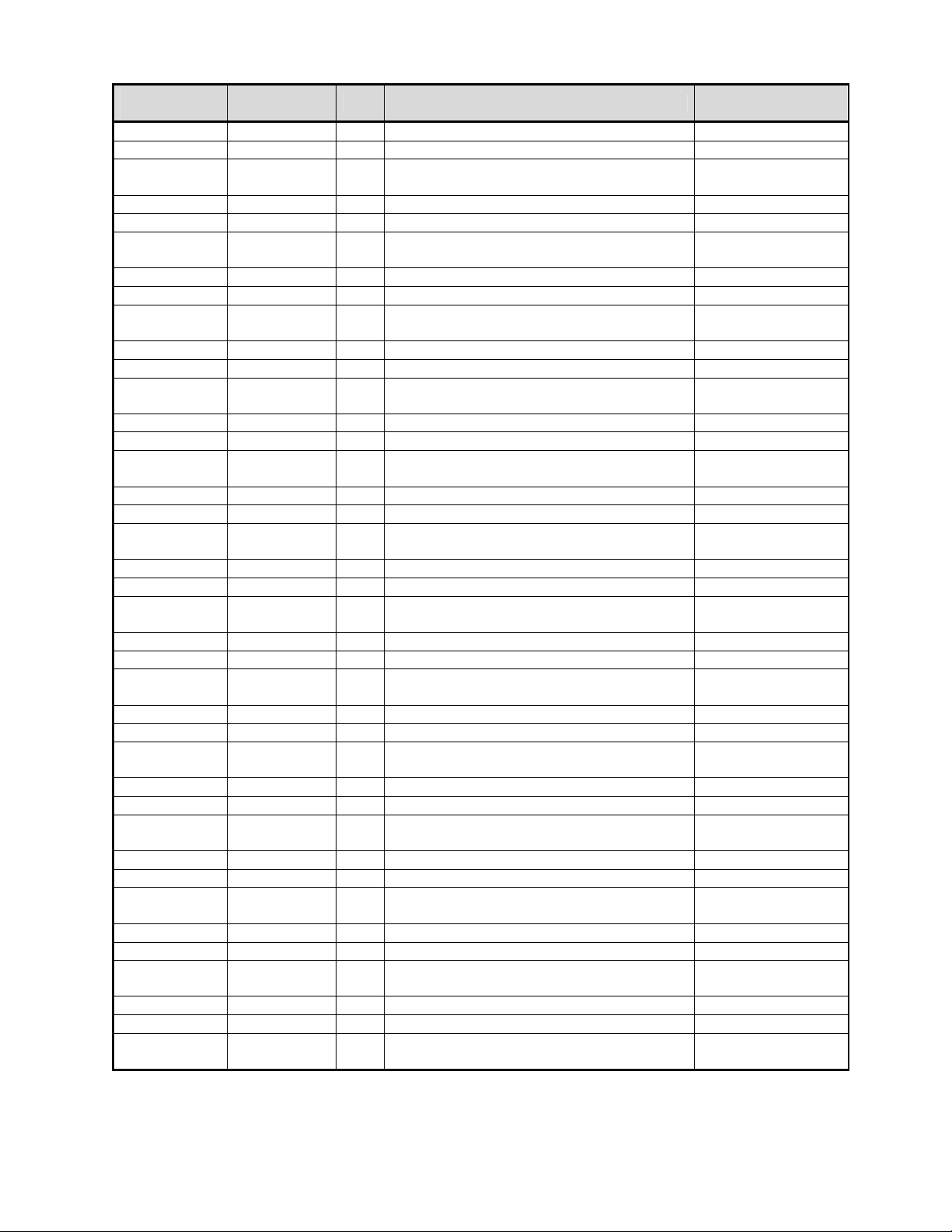

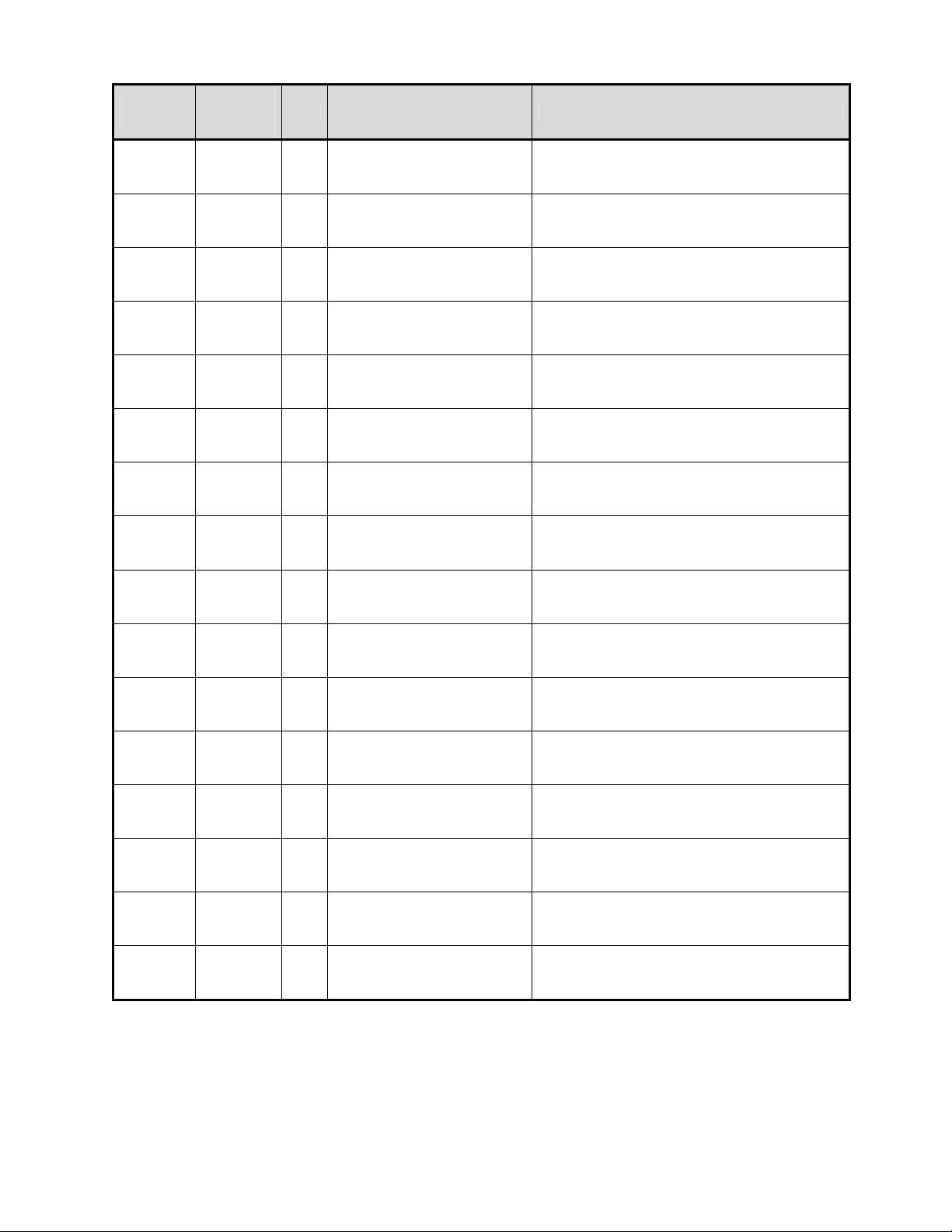

・Character: Select from the code given in the table below.

Code Length of data Parity Stop bit

Ú RTU mode is 8 bits only

・RTU/ASCII: Select either of RTU, ASCII, PRIVATE.

Confirm all the settings or finish all the setting changes then take the cursor to Set button and

end after clicking the Enter key.

.

COM. and click the Enter key. The following settings screen is displayed. Confirm the

7E1

7E2 2

701

702 2

8N1

8N2 2

8E1

8E2 2

801

802 2

7 bits

8 bits

Even

Odd

None

Even

Odd

1

1

1

1

1

-3-

Page 9

4 Connection

4.1 Precautions while doing the connections

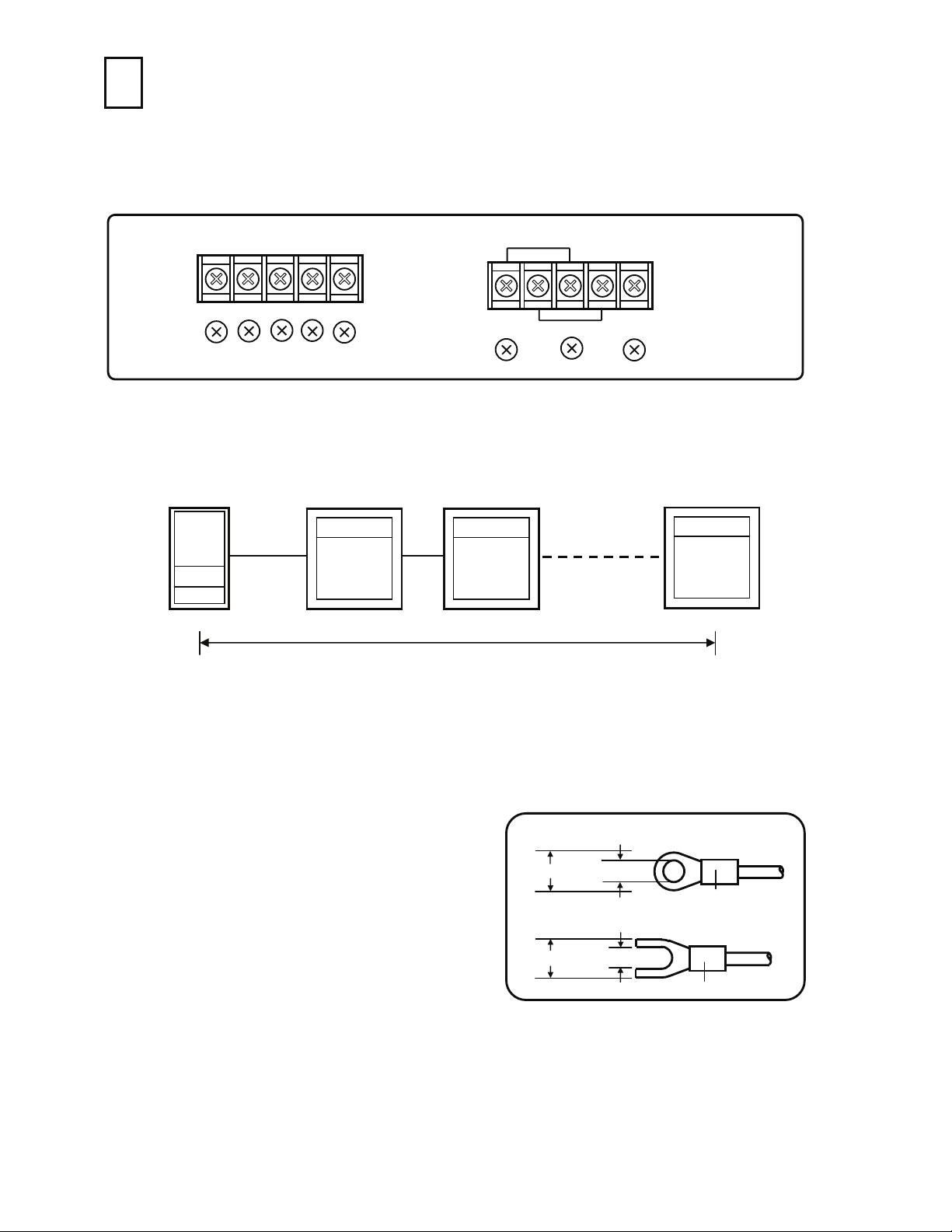

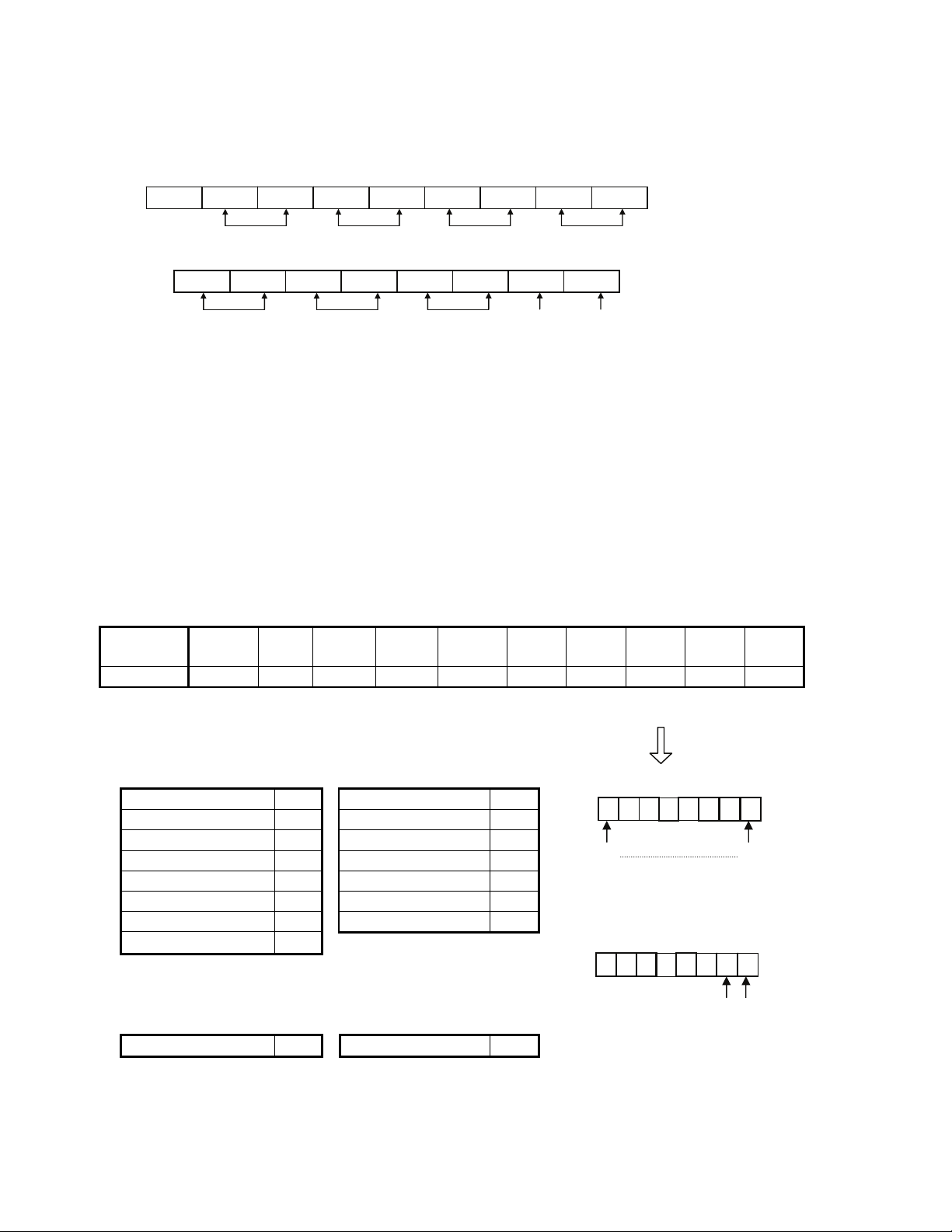

4.1.1 Communication terminal

Terminal layout differs depending on the communication interface that is specified.

RS-422 communication terminal

RS-485 communication terminal

Short circuit SDA and RDA

RS-422A

SDA

SDB

4.1.2 Total extension of RS-422A/485 communication cable is less than 1.2km

Wiring interval between each instrument can be anything but the total extension distance of the cable

is within 1.2 kms.

(Line converter LE5000 of the farthest terminal)

Line converter

RDA

RS-485

SG

RDB

SA

RD5100

Total length of cable less than 1.2 km

SB

Short circuit SDA and RDB

SG

4.1.3 Take prevention measures to prevent noise mixing.

In order to avoid the effect of noise keep a distance of minimum 50cm or more between the power

line and other communication lines.

4.1.4 Always do crimp style terminal processing.

Due to one of the causes of communication defect

the connection is lost. Always process the

communication cable of the terminal using crimp

style terminal with insulated sleeve of O type or Y

type. (Terminal screws of LE5000 line converter are

M3.5mm)

4.1.5 Apply terminating resistance.

In case of using RS-485 communication, apply a resistance of 100Ω to RD5100 to be placed in the

last terminal. (For details refer to 4.3)

(General metal coating resistance will do. It is available in this company, place an order with us.)

O type crimp style terminal

Less than 8

Ytype crimp style terminal

Less than 8

(㎜)

3.7 or more

3.7 or more

Insulated sleeve

Insulated sleeve

4.1.6 Number of connection machines of RD5100

For RS-485

:Maximum 31

-4-

Page 10

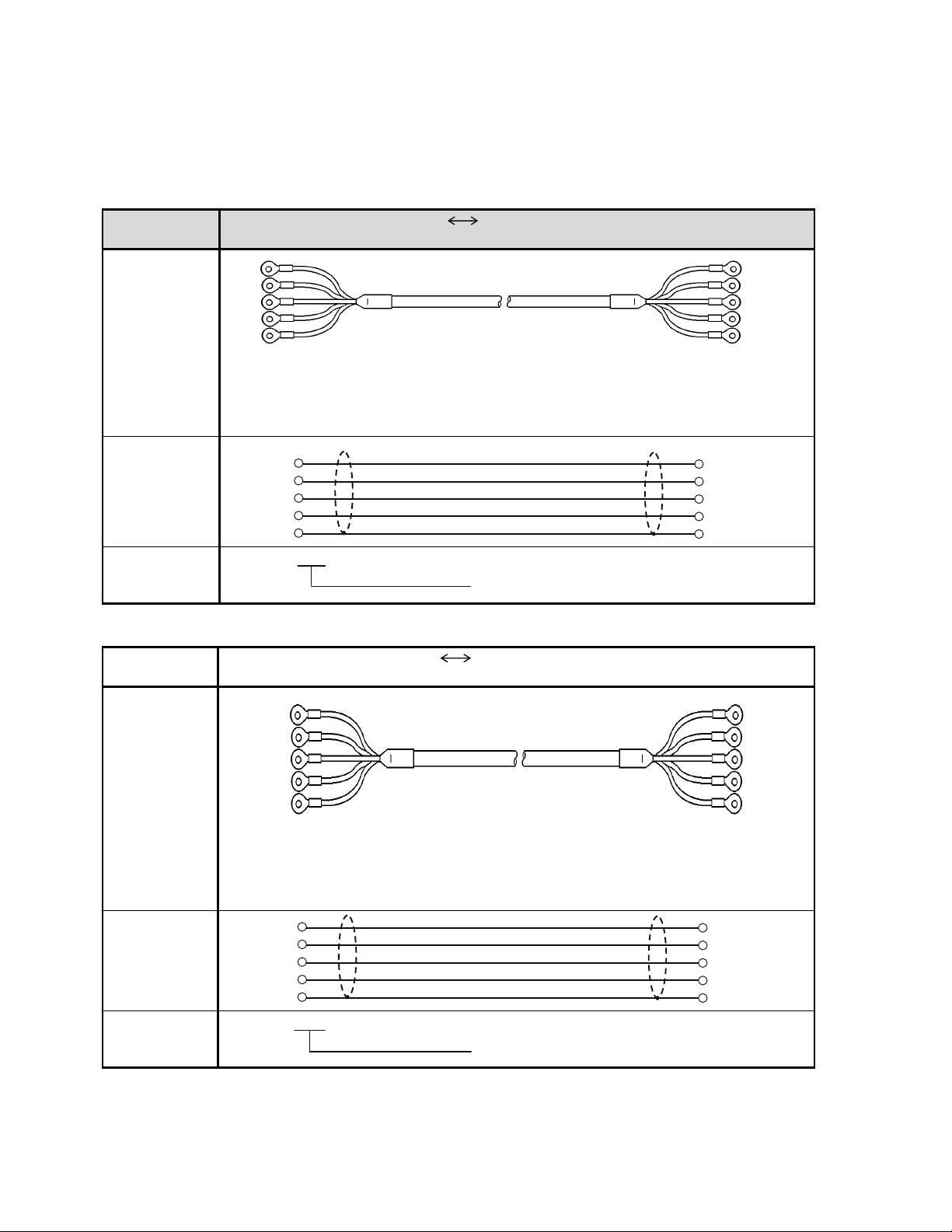

4.2 Cable for communication

ASDA

A

ASDA

A

Before connecting be prepared with cable exclusively for communication. It is available in our company

also; hence you may place an order with us.

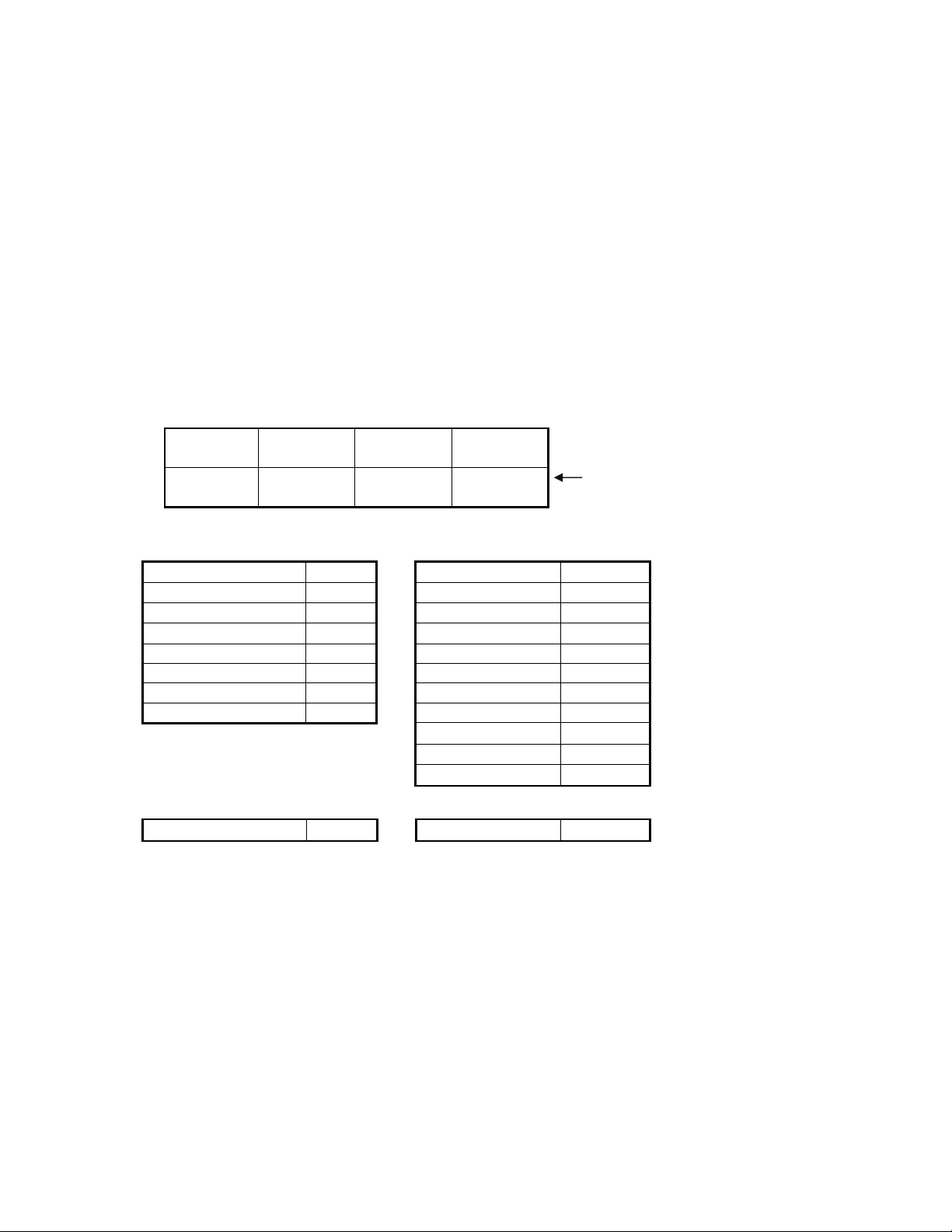

4.2.1 Communication cable for RS-422A

① Connection between line converter and LE5000

Cable

Form

Internal

connection

Format code

O type crimp style terminal O type crimp style terminal RS-422A cable

(For line converter)

RDA

RDB

SDA

SDB

SG

Line converter side

It is a 2 core CVVS wire that is twisted and it is further twisted to 4 core cable and

SG (Signal Grand) wire is available on both sides. As there is no SG converter on

line converter side, use it after disconnecting.

RD

RDB

SDB

SG

RZ-CRA2□□

Cable length 1-99m (specified)

SDA

SDB

RDA

RDB

SG

LE5000 side

RDA

RDB

SD

SDB

SG

② Connection between LE5000s

Cable

O type crimp style terminal O type crimp style terminal RS-422A cable

(For series)

SDA (Black)

SDB (White)

RDA (Red)

RDB (Green)

Form

SG (Blue)

LE5000 side

It is a 2 core VCTF wire that is twisted and it is further twisted to 4 core cable and

SG (Signal Grand) wire is available on both sides.

Internal

connection

SDB

RD

RDB

SG

RZ-CRA1□□

Format code

Cable length 01-99m (specified)

LE5000 side

SD

SDB

RDA

RDB

SG

(Black) SDA

(White) SDB

(Red) RDA

(Green) RDB

(Blue) SG

-5-

Page 11

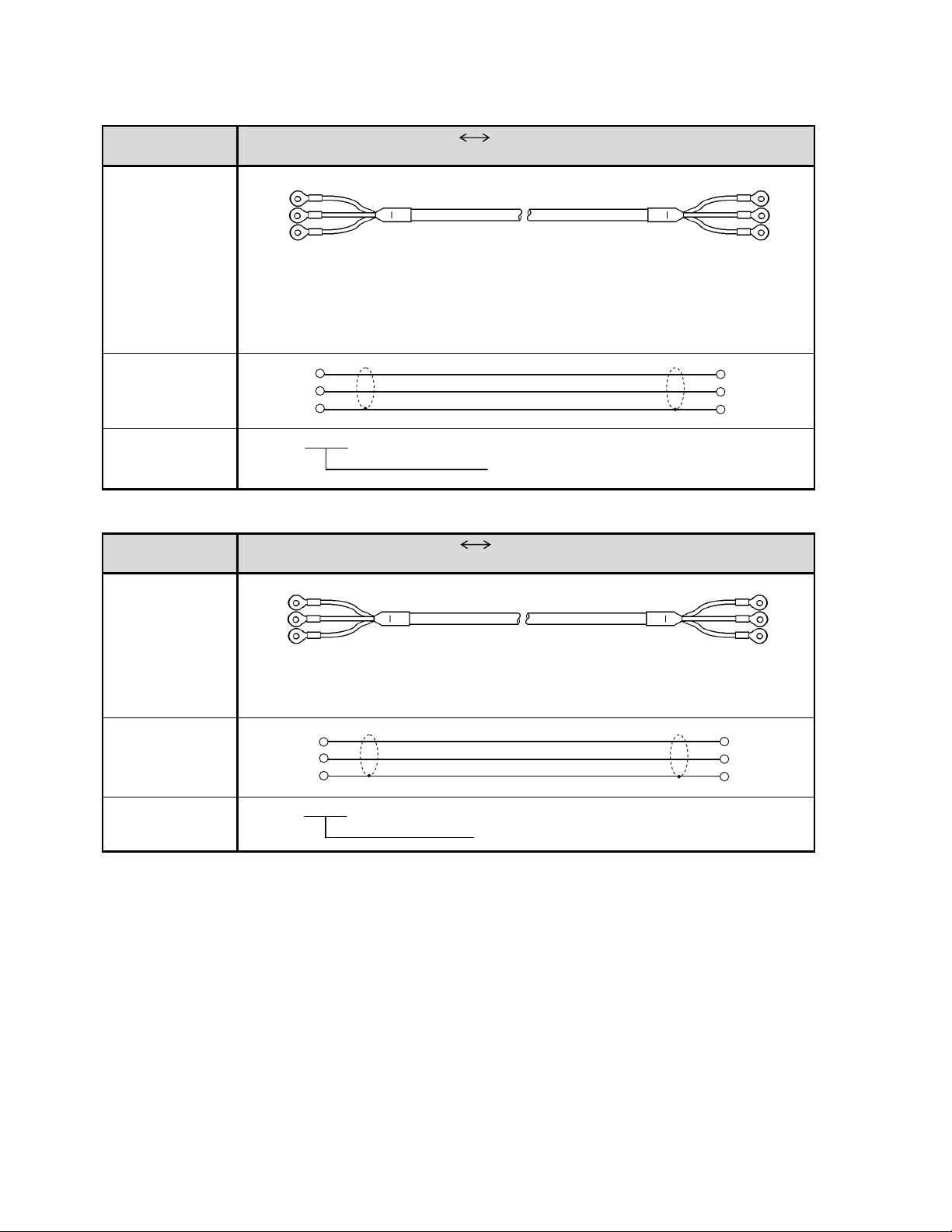

4.2.1 Communication cable for RS-485

(

)

ARDB

G

A

① Connection between line converter and RD5100

Cable

Form

O type crimp style terminal O type crimp style terminalRS-485 cable

(For line converter)

RDB

RD

S

Line converter side

It is a CVVS wire that is twisted to 2 core cable and SG (Signal Grand) wire is

available in both the terminals. As there is no SG converter on line converter

side, use it after disconnecting.

SA

SB

SG

LE5000 side

Internal

connection

Format code

② Connection between RD5100s

Cable

RD

SG

RZ-LEC□□□ (For line converter)

Cable length 1-200m (specified)

O type crimp style terminal O type crimp style terminalRS-485 cable

For series

SA

SB

Form

Internal

connection

Format code

SG

RD5100 side

It is a CVVS wire that is twisted to 2 core cable and SG (Signal Grand) wire is

available in both the terminals.

SA

SB SB

SG

RZ-LEC□□□ (For series)

Cable length 1-200m (specified)

SA

SB

SG

SA

SB

SG

LE5000 side

SA

SG

-6-

Page 12

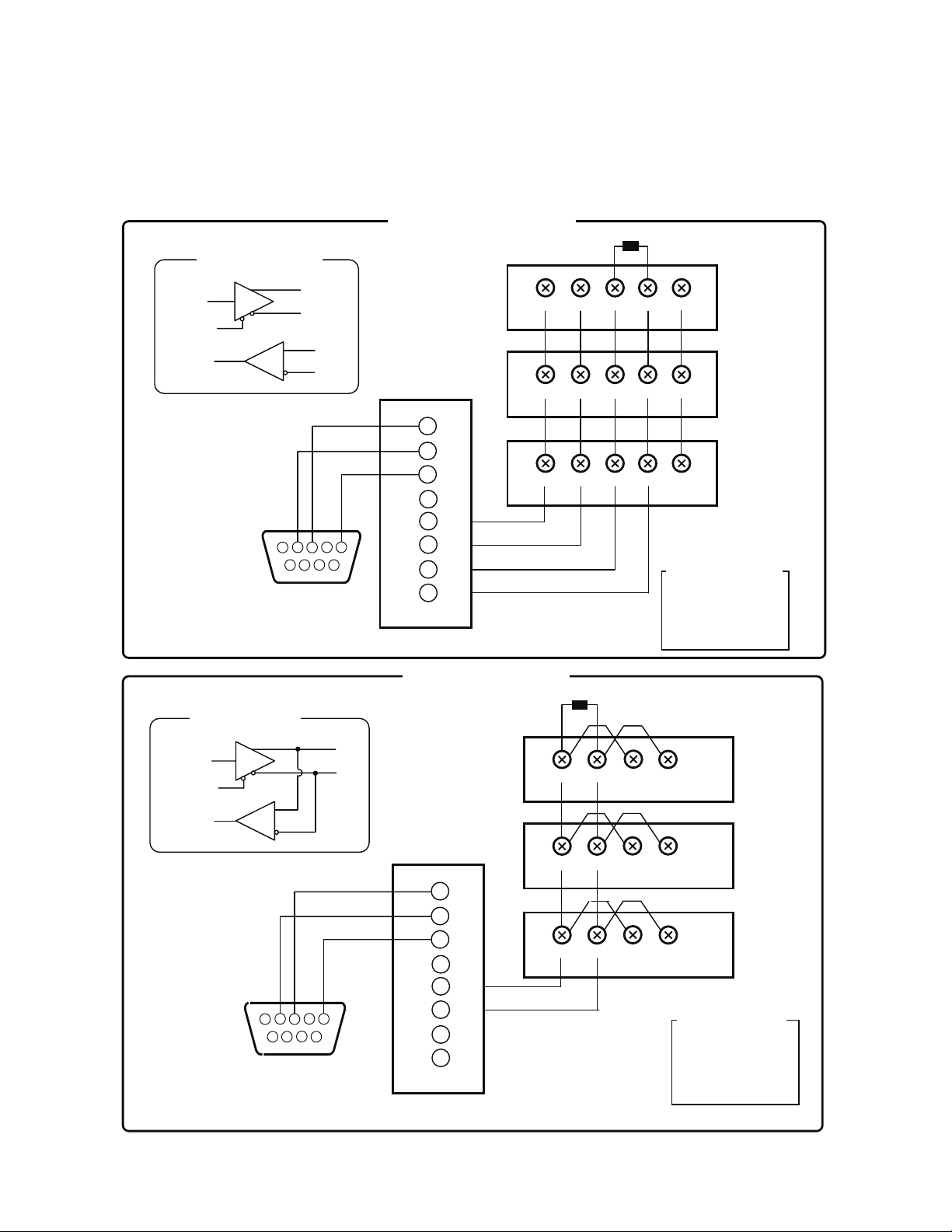

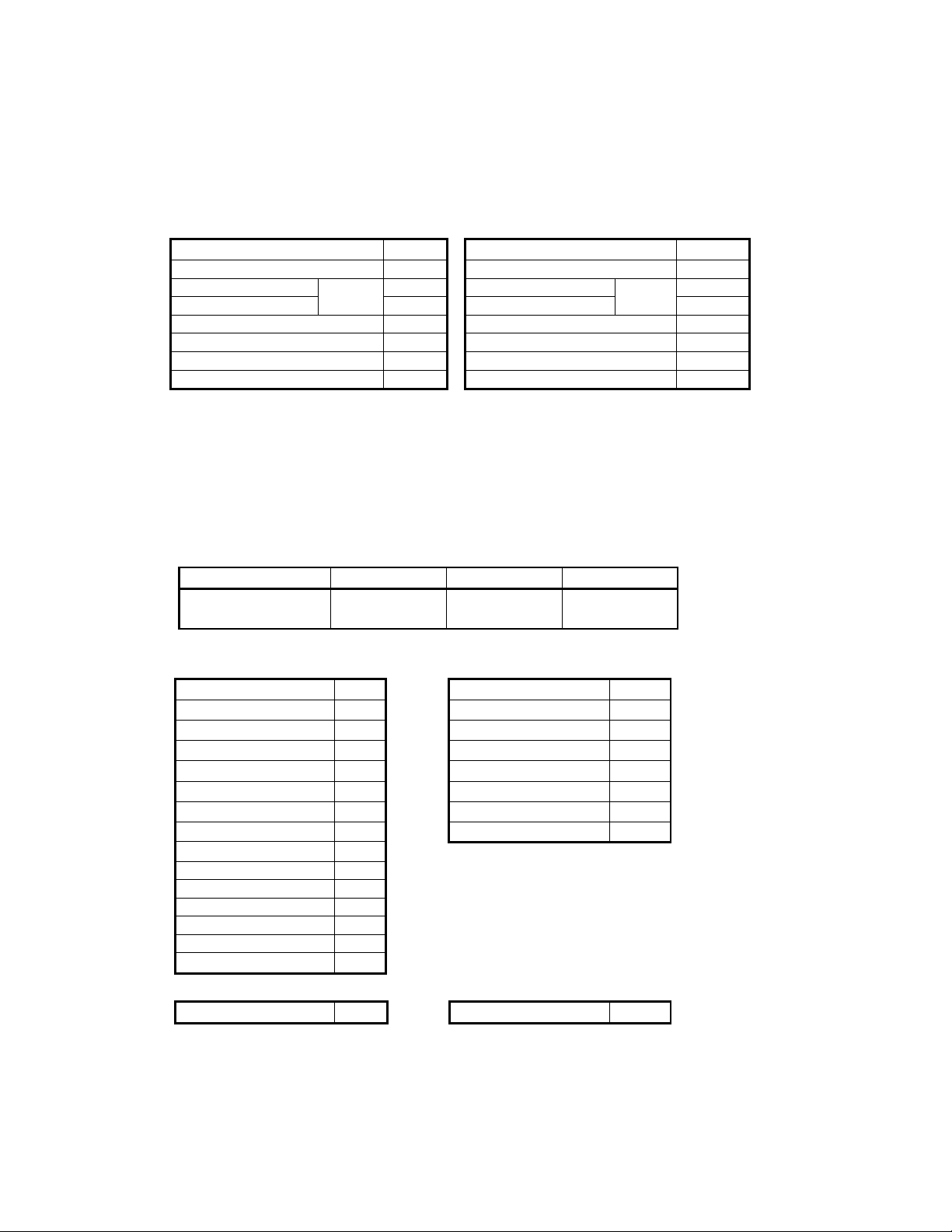

4.3 RS-485 connection

Connect RS-485 communication interface to PC using line converter. As the line converter and PC

use only 3 signals viz. send, receive and signal grand and no other control signal is used, wiring

process in the connector needs to be similar to that of RS-232C connection. (For details refer to line

converter instruction manual.)

Send

data

Receive

data

Communication cable

RZ-CRS6□□

(Wiring process is necessary.)

Internal circuit

Send

data

Receive

data

Communication cable

RZ-CRS6□□

(Wiring process is necessary.)

Internal circuit

SDA

SDB

RDA

RDB

1 2 3

6

5

4

8

9

7

9 pin connecter for PC

SA

SB

1 2 3

6

5

4

8

9

7

9 pin connecter for PC

Communication cable

RS-422A connection

RZ-CRA1□□

1

RD

SD

2

3

SG

4

RDA

5

6

RDB

SDA

7

SDB

8

Line converter

RS-485 connection

Communication cable

RZ-LEC□□□

1

RD

SD

2

3

SG

4

RDA

5

6

RDB

SDA

SDB

7

8

Communication cable

RZ-LEC□□□

Line converter

SDA

SDA

SDA

SDB RDA

SDB RDA

SDB RDA

SDA

SDA

SDA

Terminal resistance 100Ω

RDB SG

RDB SG

RDB SG

Communication cable

RZ-CRA2□□

Caution

Do not connect the SG

wire to the earthing

terminal or FG terminal

of the instrument.

Terminal resistance 100Ω

RDB

RDA

SDB

RDB

RDA

SDB

RDA

SDB

RDB

Caution

Do not connect the SG

wire to the earthing

terminal or FG terminal

of the instrument.

RD5100

RD5100

RD5100

RD5100

RD5100

RD5100

-7-

Page 13

5 MODBUS protocol

Precautions and basic procedure of communication

Caution

1. Error occurs if data is requested immediately after starting the power supply.

RD5100 can be communicated with, any time. Response is output anytime for the data request

from PC.

However at the time of starting the power supply, response is not output normally, until the data of

the channel is gathered. For example, time necessary to gather data of RD5100 36 point analyzer,

is around 20 seconds. If data is requested in that time Error No. 12 (Setting mode error) is

returned.

2. As the control signal wire is not used, consider resending the command.

Serial interface of RD5100 communicates without using control wire. Hence consider resending

the command as reception defect may occur depending on RD5100 status.

3. Do not remove any device or communication cable and do not ON-OFF the

power supply during communication.

If device or cable that makes up the serial interface is removed in between or if power is switched

ON or OFF, operation may stop and error may occur. If this happens reset all the devices that

make up the serial interface and do the process all over again.

4. Send the next command after confirming that the communication drive is

switched OFF.

In RS-485, if multiple instruments are connected in same communication line, then only 1 machine

in which instrument numbers are specified from the PC, drives the communication line. At that time

in order to receive all the characters in the PC for sure, let some time lapse after the last character

is sent and then switch OFF the drive of communication line. If PC sends a command for the next

device before it becomes OFF, then the signal crashes and normal communication is not done

hence take care in case of high speed PCs. This interval is around 5ms.

-8-

Page 14

5.1 Message transmission mode

There are 2 types of modes viz. RTU (Remote Terminal Unit) mode and ASCII mode and they can be

selected by key settings.

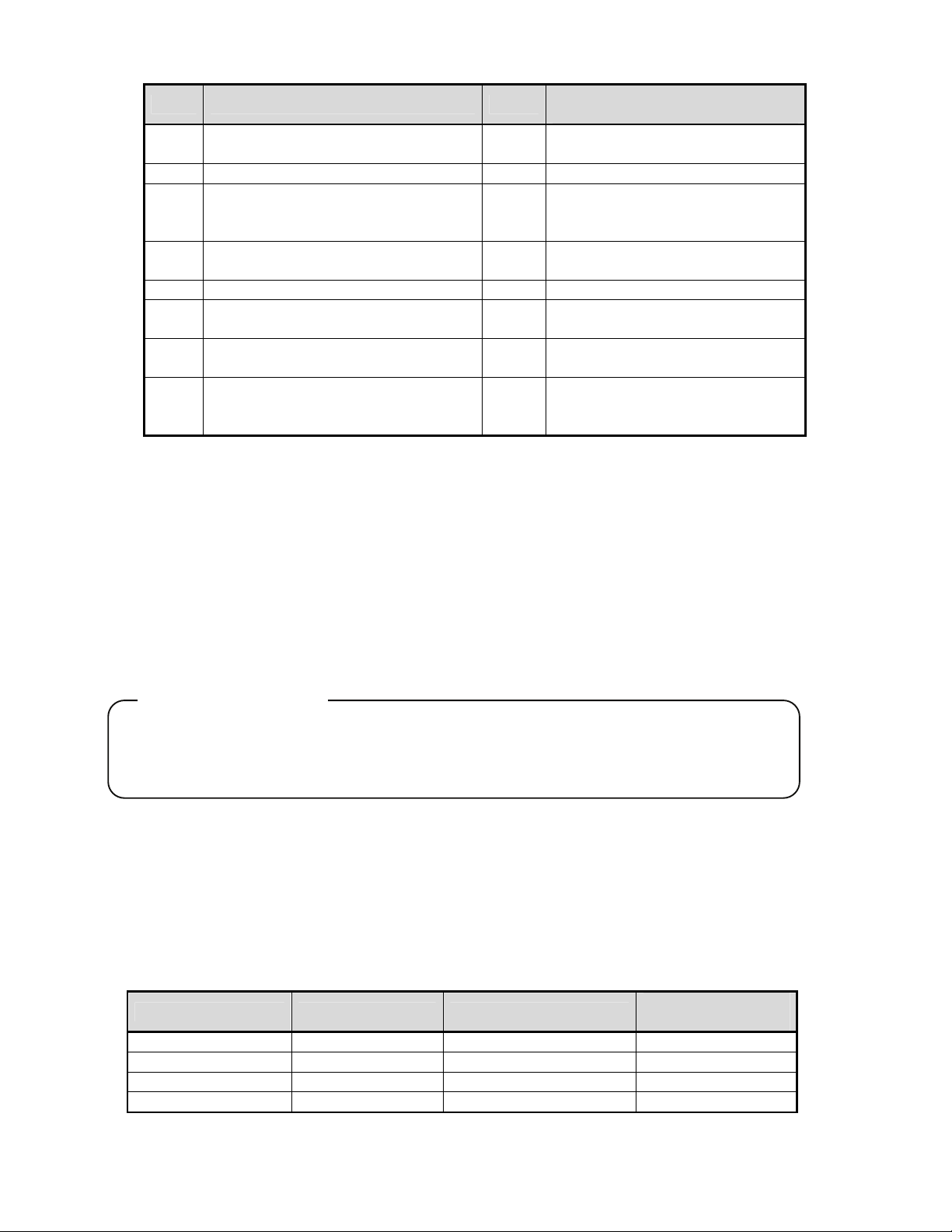

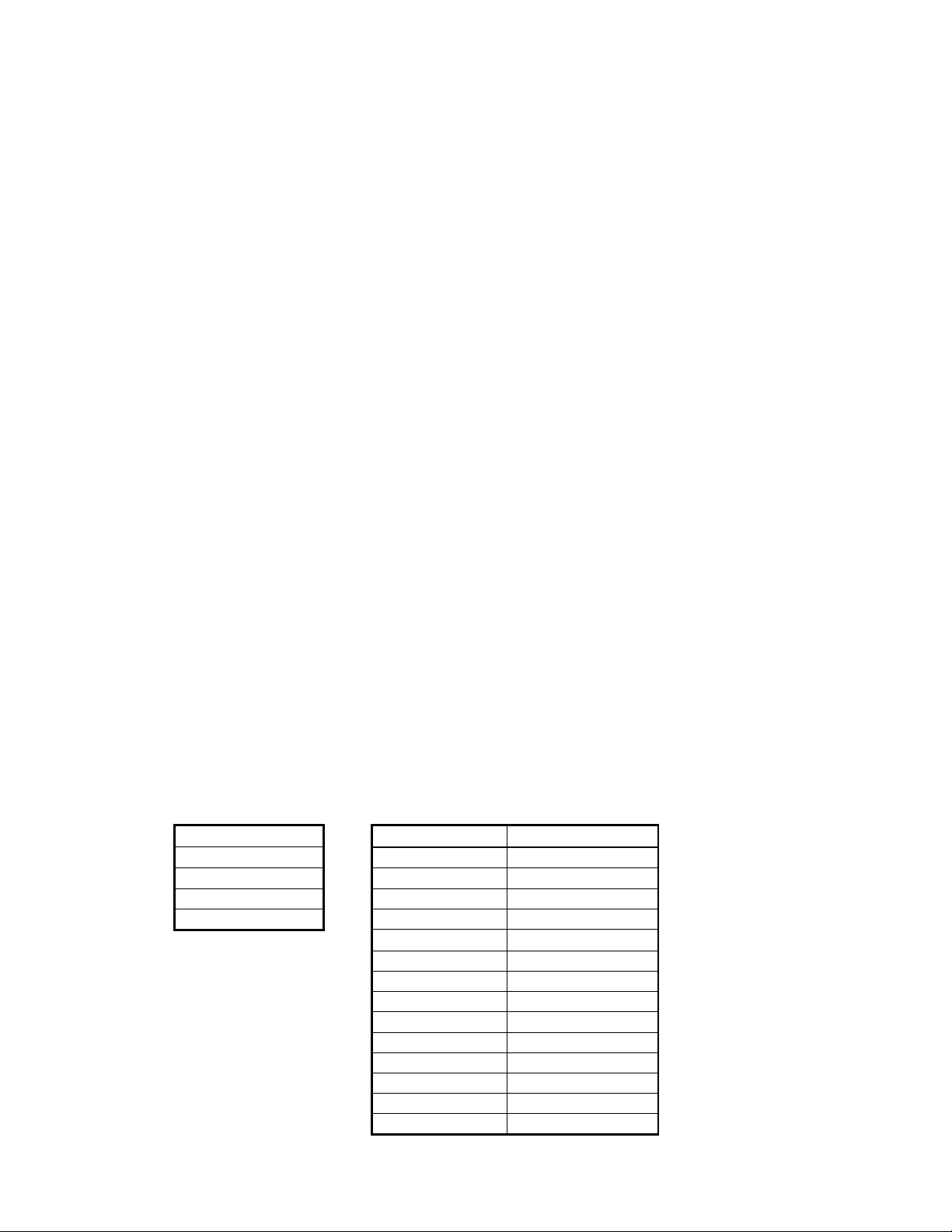

(Table 1. Comparison of RTU mode and ASCII mode)

Items RTU mode ASCII mode

Interface RS-485

Communication method 0 {Half duplex asynchronous method

Communication speed

Transmission code Binary ASCII

Error detection

(Error check)

Character

configuration

Message start code None

Message end code None CR, LF

Data time interval Less than 28 bit hours Less than 1 second

(Note) When data bit is 7 bits, “Parity bit None” is not applicable.

Vertical direction Parity

Average direction CRC-16 LRC

Start bit 1 bit

Data bit 8 bits 7 bits, 8 bits

Parity bit None, odd, even None (Note), odd, even

Stop bit 1, 2 bits

5.1.1 Transmission data

9600,19200bps

:(Colon)

RTU mode is binary transmission. ASCII mode divides 8 bit binary of RTU into high order low order 4

bits and does the respective character conversion (0-9, A-F).

Example) RTU mode ASCII mode

67H

89H

ABH

The message length of the RTU mode is half as compared to the ASCII mode hence the transmission

efficiency is better.

36H (“6”)

37H (“7”)

38H (“*”)

39H (“9”)

41H (“A”)

42H (“B”)

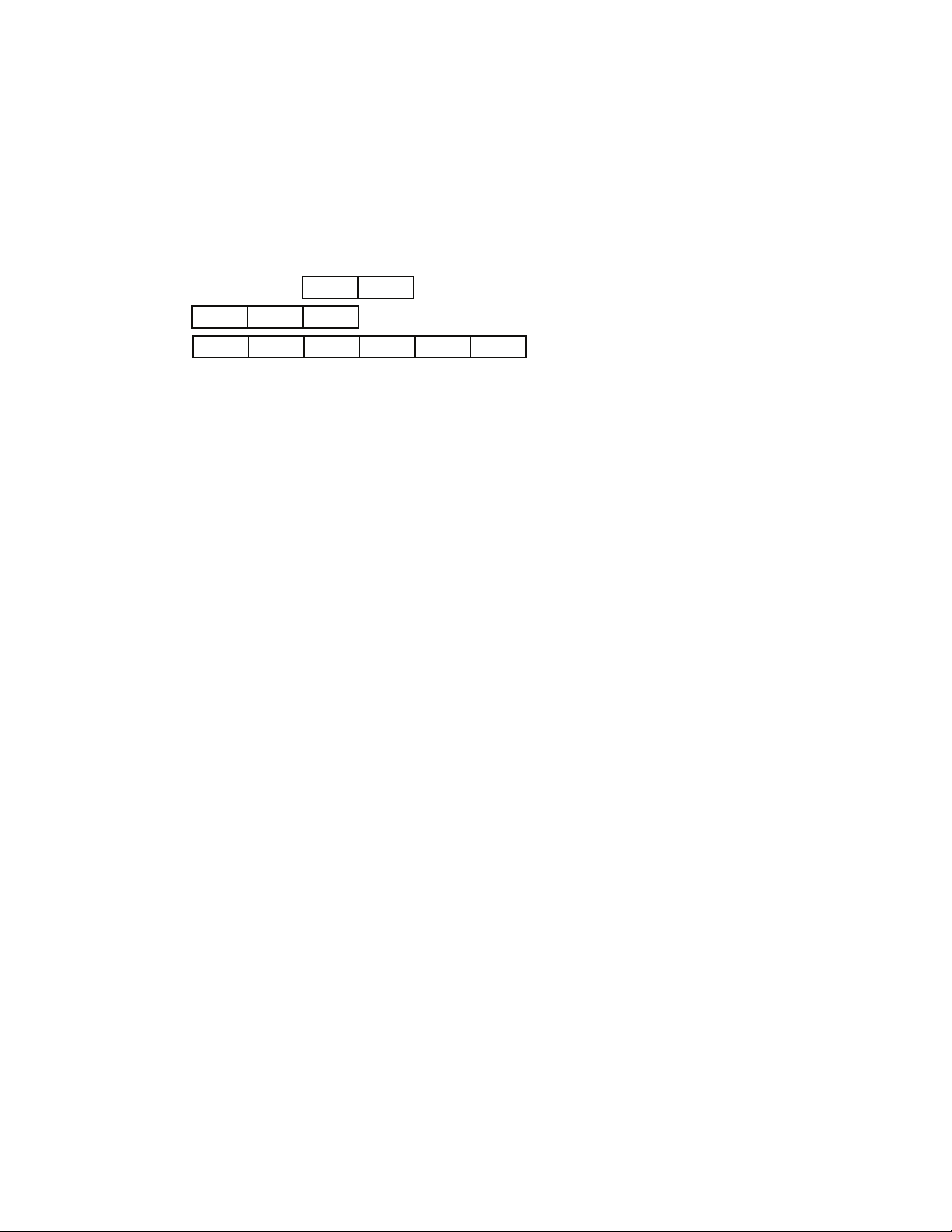

5.1.2 Message frame configuration

RTU mode is made up of message part only.

ASCII mode is made up of beginning character “: (colon, 3AH)”, message and end character “CR

(carriage return, ODH) + LF (Line feed, OAH)”.

RTU mode ASCII

Message : Message CR LF

For the message of ASCII mode, as the beginning character is “ : ”, trouble shooting is easy. This is

an added advantage.

-9-

Page 15

5.2 Data time interval

RTU mode time: Less than 28 bit hours (9600bps time: 2.8msec, 19200nps time: 1.4msec)

ASCII mode time: Less than 1 second

At the time of sending the message, see to it that the time interval of the data that consists of one

message does not exceed the time interval mentioned above. If the time interval mentioned above is

exceeded, the receiving side (this instrument), in order to judge that the sending is finished from the

send side, processes an abnormal message as received data.

In RTU mode message characters should be continuously send however in ASCII mode, as the interval

between the characters is maximum 1 second, even though the process speed of the master (PC) is

comparatively slow, it can be used.

5.3 Message configuration

MODBUS message along with RTU and ASCII mode has the following configuration.

Slave address

Function code

Data

Error check

5.3.1 Slave address

Slave address is set in advance in a range of 1-31 using the key settings. Master usually

communicates with 1 slave. All the devices that are connected receive the message from the master in

common however, only the slave that matches with the slave address in the command message

responds to that message.

Slave address “0” is used in the messages (Broadcast) for all the slaves from the master. In this case

slave does not return response.

5.3.2 Function code

Function code is the code to be executed in the slave and each data is roughly categorized as follows.

For details refer to the reference table.

① Digital settings value:

② Digital input data:

③ Analog settings value:

④ Analog input data:

Recording ON/OFF, data print execution etc. and mainly function

change parameters

Parameters of external contact point input status, input data status,

alarm activation status etc.

Various setting information. Numeric value range is a numeric value

within a range of 16 bits.

-32763 to 32767 (For details refer to reference table).

Measurement data, instrument specification information etc. Numeric

value range outputs a numeric value within a range of 16 bits.

-10-

Page 16

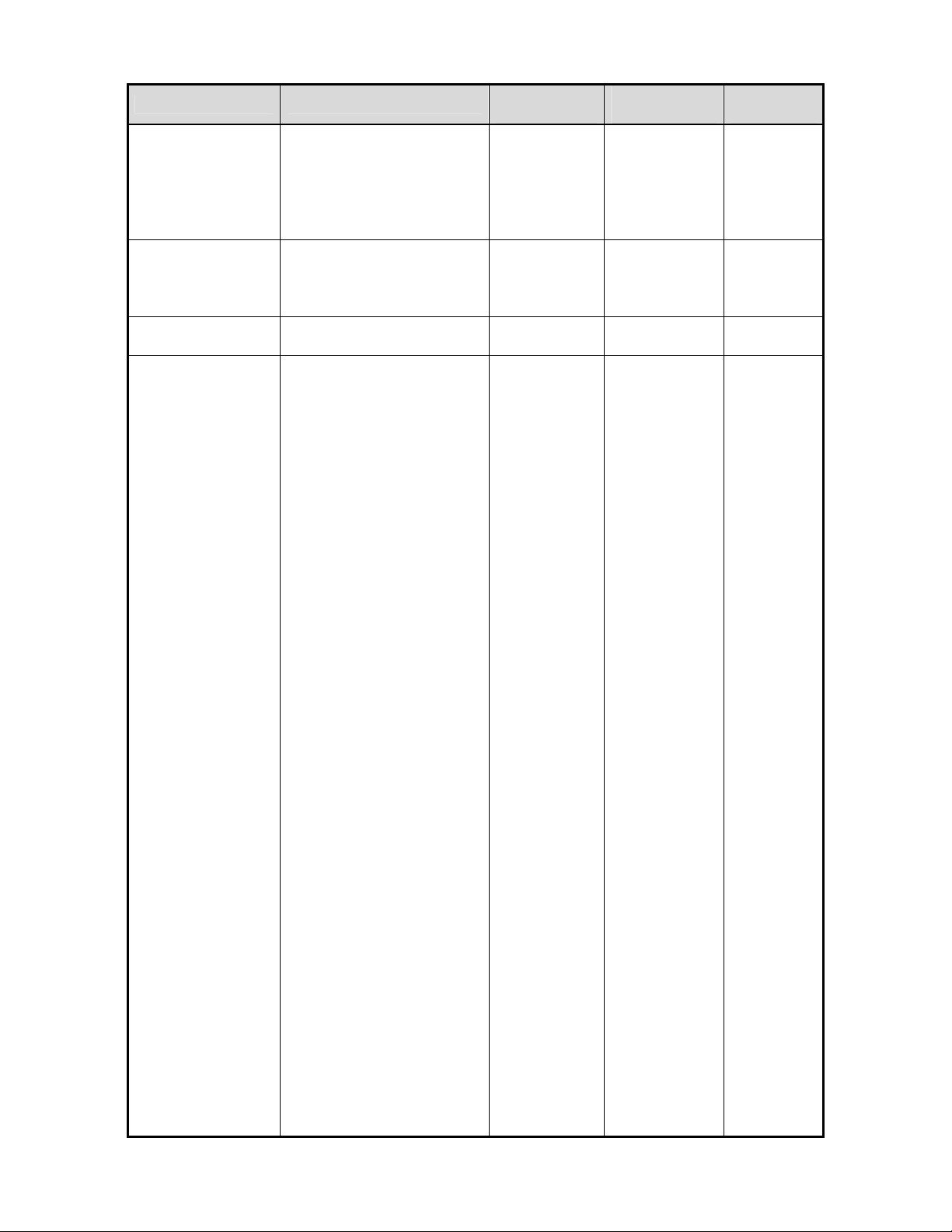

(Table 2. Function code table)

Code Function Unit

01

02 Reading the digital input data 1 bit

03

60

62

04 Reading the analog input data 16 bits

05 Writing digital setting value 1 bit Changing the status of single coil

06 Writing analog setting value 16 bits

08

16

61

63

Reading digital (ON/OFF) settings

value

Reading the analog setting value 16 bits

Sending the reception data (For

examination)

Writing multiple analog setting value

1 bit Reading the status of coil

MODBUS original function

(Reference)

Reading the input relay status

Reading the contents of

maintenance register

Reading the contents of input

register

Writing to single maintenance

register

Loop back test

Writing to multiple maintenance

register

5.3.3 Data part

Data structure differs depending on the function code. In case of requests from the master, it is made

up of, code number (Relative number calculated from reference number mentioned hereafter) of the

target data to be read and data count etc. Response from the slave consists of data etc. that is

requested.

Basic data of MODBUS is on a whole an integer of 16 bits and existence of a mark is decided for each

data. Hence put the decimal point at a different place and make it an integer value or keep the position

of the decimal fixed, and display formally using the upper and lower limit of the scale. In LE5000 there

is a method of assigning a decimal point at a different position.

Caution

In the data part, specific numeric value such as input data is assigned as the error data.

When using this data, first does error decision for the data, then combine the decimal point data.

If you combine the decimal point data first, the error data is mistaken as the normal data.

5.3.4 Reference number

There is a number called “Reference number” assigned to the data in RD5100, and this number is

necessary for reading and writing the data. Data in RD5100 is categorized as “Digital setting value”,

“Digital input data”, “Analog input data” and “Analog setting value” depending on its type. Number

specification in the message is done by “Relative number” that corresponds to the respective reference

number.

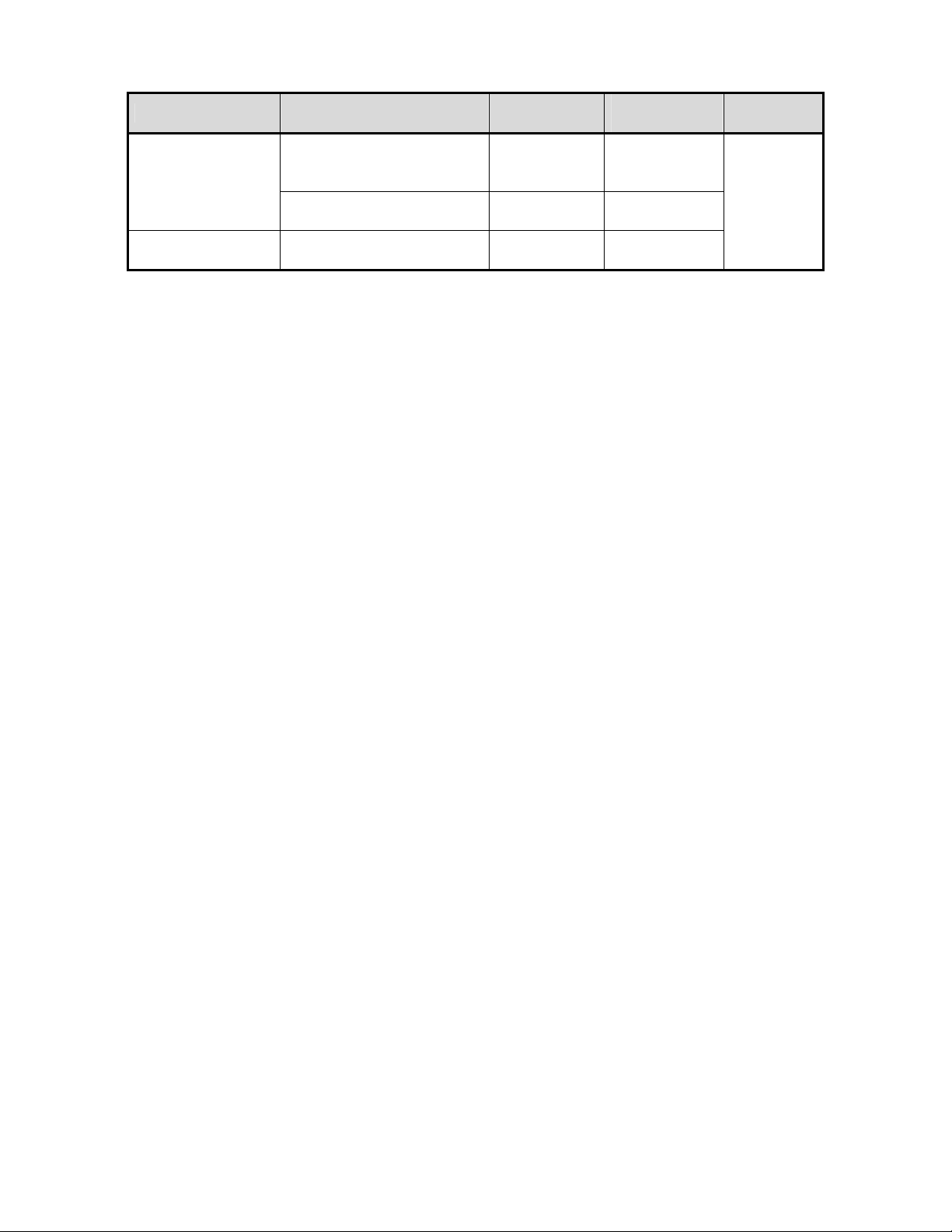

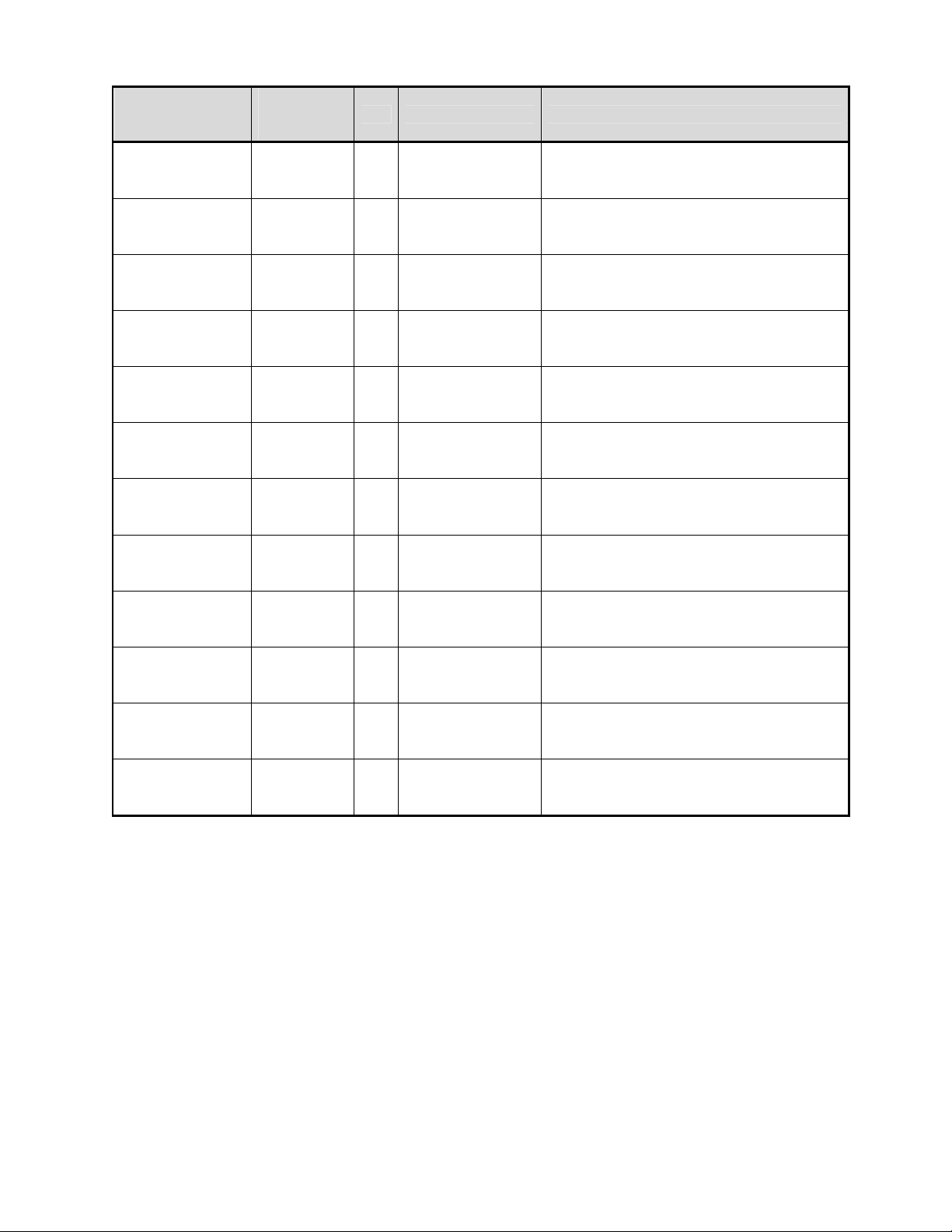

(Table 3. Reference number and relative number)

Data type Reference number Relative number

Digital setting value 1 to 1000 Reference number-1 Coil

Digital input data 10001 to 20000 Reference number-10001 Input relay

Analog input data 30001 to 40000 Reference number-30001 Input register

Analog setting value 40001 to 50000 Reference number-40001 Maintenance register

Example) “100”becomes the relative number of channel 1 data of “Reference number 30101”.

-11-

MODBUS original

(Reference)

Page 17

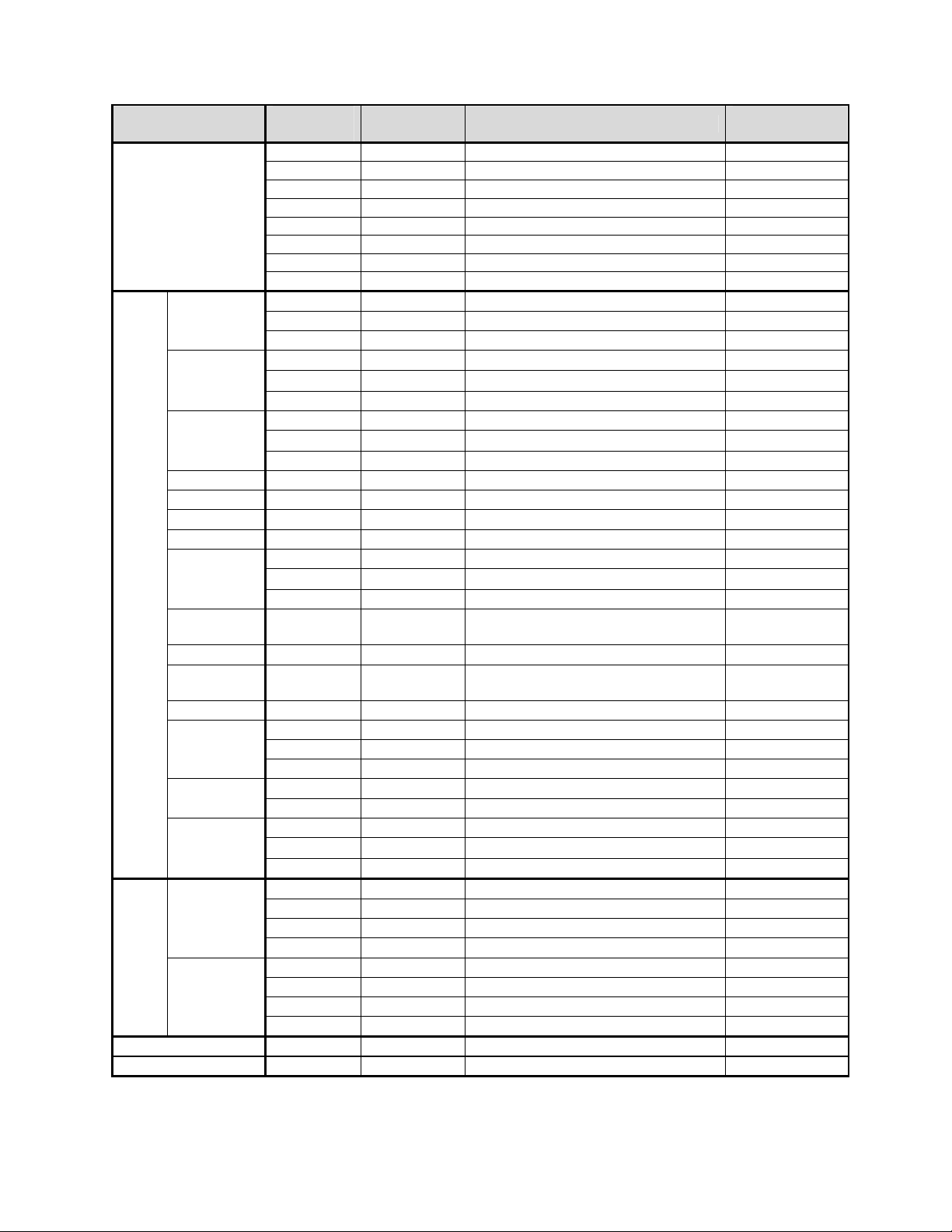

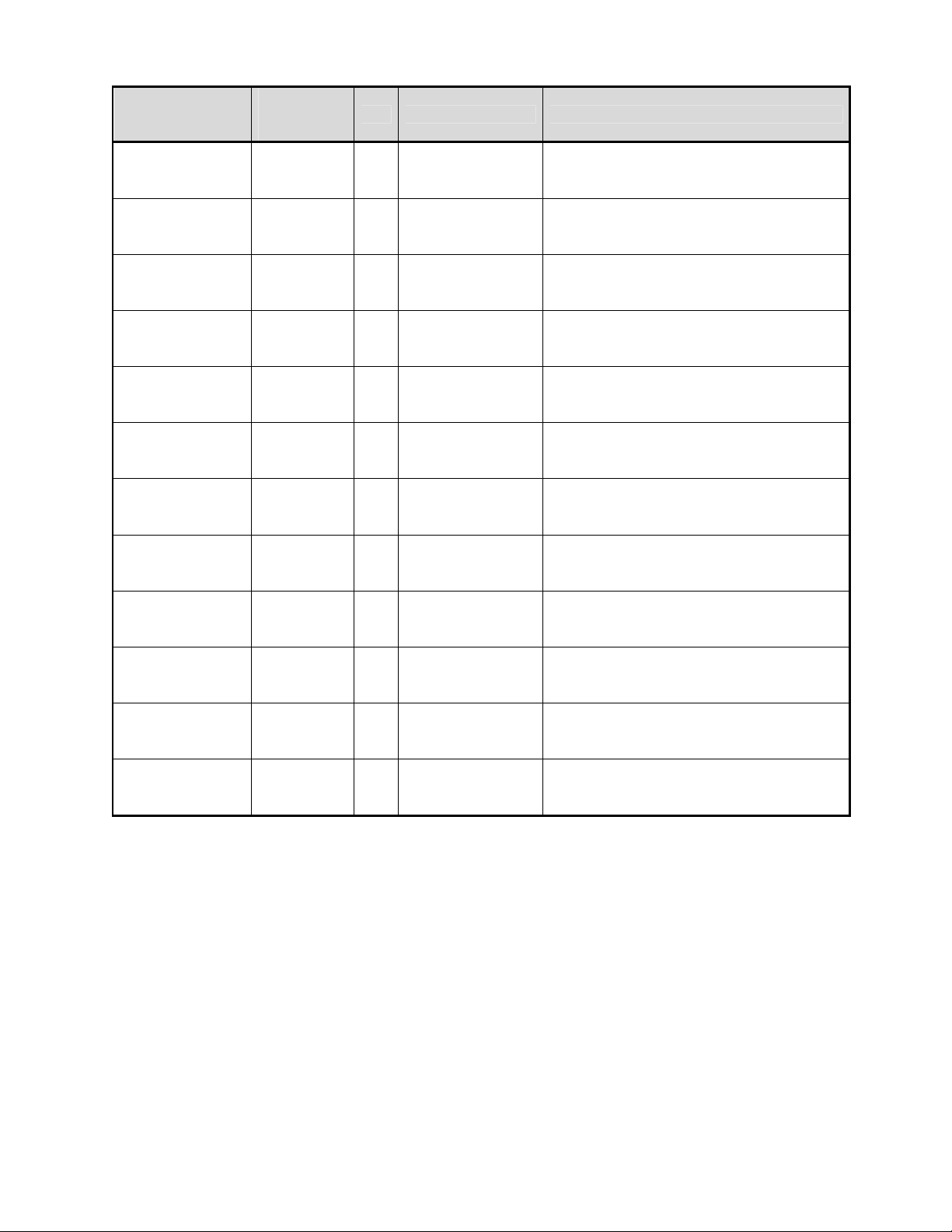

(Table 4. Reference number)

Data type Parameter

Key lock

Recording ON/OFF

Digital setting value

Digital input data

Analog input data

Analog setting value

Feed

Print list

Print message

Data print

External drive status (Contact

point input)

Measurement data status

Alarm status

Function information

Measurement data

Channel common setting 1

Clock setting

External drive functional

settings

Arbitrary intermittent period

setting

Channel speed setting

Data interval recording

setting

Logging recording setting

Data print setting

Select recording format

Parallel pointer scale setting

Alarm dead band setting

Setting for each channel

Range number setting

RJ internal/external setting

Range setting

Scale setting

Burn out setting

Sensor correction

Digital filter

Unit settings

Tag settings

Alarm settings

Calculation settings

Recording scale settings

Calculation constant setting

Difference calculation setting

Partial reduction

magnification recording

Parallel pointer scale

settings

Auto range settings

Each channel settings

Memory card settings

Print communication

Setting for each intermittent

number

Data communications input

Setting common to channels

Reference

number

1 to 50

10001 to 11500 02 (READ) 5.8.2 Clause

30001 to 30050

30101 to 30300

40001 to 40200

40001 to 40008

40009 to 40017

40018

40019 to 40027

40033 to 40037

40038 to 40042

40043

40049

40050 to 40075

40081

40102 to 47300

40102

40103

40104 to 40106

40107 to 40109

40110

40 111

40112

40119 to 40122

40125 to 40128

40133 to 40163

40165

40166 to 40168

40169 to 40176

40177 to 40180

40181 to 40187

40188

40189 to 40194

40202 to 47300

47906 to 47920

48003 to 48050

48101 to 48850

49001 to 49100

49101 to 49150

Corresponding

function code

01 (READ)

05 (WRITE)

04 (READ) 5.8.3 Clause

03 (READ)

06 (WRITE)

16 (WRITE)

Reference

table

5.8.1 Clause

5.8.4 Clause

-12-

Page 18

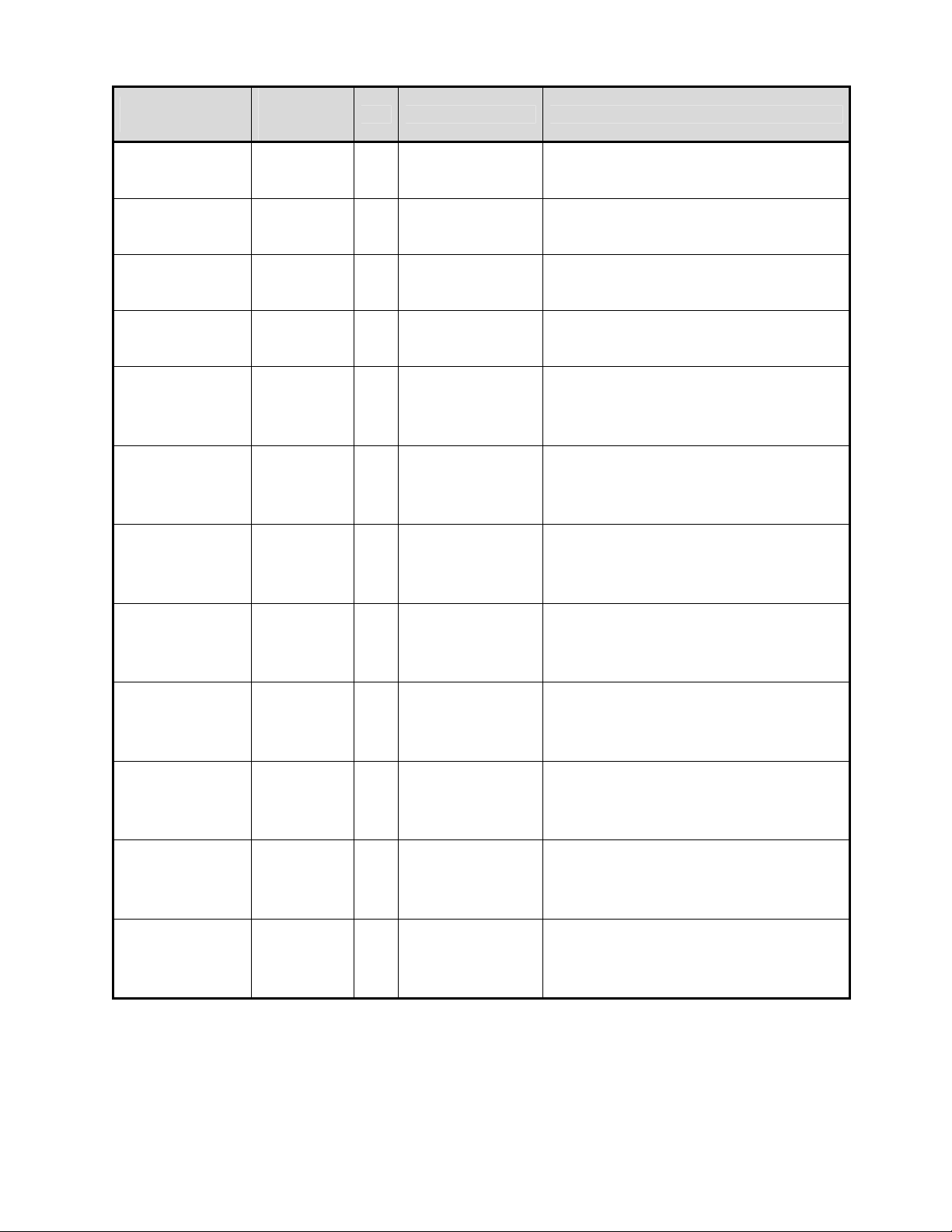

(Table 4. Reference number for RD5200/RD5300)

Data type Parameter

Calculation character string

Analog input setting

value

Analog input data

(RD5200 only)

RD5300 responds with option

Channel parameter of CH101

to CH599 (LE5300 only)

CH73 to CH599

Reading measurement data

Reference

number

23720 to 27250

40101 to 47300

30245 to 31300 04 (READ)

Corresponding

function code

62 (READ)

63 (WRITE)

60 (READ)

61 (WRITE)

Reference

table

5.8.5 Clause

-13-

Page 19

5.3.5 Error check

Error check of transmission frame differs depending on the mode.

RTU mode: CRC-16

ASCII mode: LRC

5.3.5.1 Calculation of CRC-16

CRC method divides using generating polynomials, the information to be sent and sends the rest of the

information by attaching it. Generating polynomials are as follows.

1 + X

Calculate to the target from slave data up to the end of the data by the following procedure.

1) Initialization (=FFFFH) of data of CRC-16 (consider as X)

2) Exclusive logical OR of data 1 and X (EX-OR) → X

3) Shift X 1 bit to the right → X

4) If there is a carry, get A001H and EX-OR else go to 5). → X

5) Repeat 3) and 4) until it shifts 8 times.

6) Following data and EX-OR of X.→ X

7) Same as 3) - 5).

8) Repeat till the last data.

9) Create message in the order, low order and high order of calculated 16 bit data (X).

2

+ X

15

+ X16

Example) When data is 02H 07H , CRC becomes 1241H

hence error check data becomes 41H 12H .

Reference: CRC-16 calculation program

10 D(1) = &H2 : D(2) = &H7 : N = 2

20 GOSUB *CRCMAKE

30 END

40

100 *CRCMAKE

110 CRC = &HFFFF

120 FOR I = 1 TO N

130 CRC = CRC XOR D(I)

140 FOR J = 1 TO 8

150 CY = CRC AND &H1

160 IF CRC < 0 THEN P = &H4000 ELSE

P = 0: GOTO 180

170 CRC = CRC AND &H7FFF

180 CRC = CRC ¥ 2

190 CRC = CRC OR P

200 IF CY = 1 THEN CRC = CRC XOR

&HA001

210 NEXT J

220 NEXT I

230 IF CRC < 0 THEN P = &H80 ELSE

P = 0: GOTO 250

240 CRC = CRC AND &H7FFF

250 C1 = CRC AND &HFF

260 C2 = ( CRC AND &H7F00 ) ¥ 256

270 C2 = C2 OR P

280 D (N+1) = C1 : D(N+2) = C2

290 RETURN

-14-

Page 20

5.3.5.2 LRC calculation method

Calculate to the target from slave data up to the end of the data by the following procedure.

1) Create message in RTU mode.

2) Add from the beginning (slave address) of the data to the end. →X

3) Get the complement (Bit inversion) of X. →X

4) Subtract 1. (X=X+1)

5) Attach X as LRC at the end of the message.

6) Convert everything into ASCII character.

Example) When data is 02H 07H ; LRC becomes F7H hence binary message becomes

02H 07H F7H and ASCII message becomes

30H 32H 30H 37H 46H 37H .

5.3.6 Precautions at the time of data processing

① As the measurement data and decimal point position are assigned to different numbers, it is

necessary to use the information of both at the time of replaying the data.

② As each 1 data can be accessed (changed), precautions are necessary at the time of setting the

associated data. For example, Initialization process etc. of the associated data due to change in

range number. Process contents are mentioned in reference number table.

③ At the time of executing settings by key (in case of setting status by Enter key), settings by

communication cannot be received. To avoid this first do the key lock and then do the settings by

communication.

④ Read and write the data in the range stipulated by the reference number. In case of reading and

writing for reference number that is other than stipulated reference number, instrument operation

may be affected

⑤ Reading and writing to multiple reference numbers that are not in series is also possible but if

reference number that is not stipulated is the starting number then an error (error 02H) occurs.

⑥ At the time of reading multiple reference numbers, the data of the reference number that is not

stipulated becomes “0”.

⑦ In case of writing to multiple reference numbers, if error is detected, all the settings become

disabled.

-15-

Page 21

5.4 Method of creating a message

Message consists of ①Step address, ②Function code, ③Data part, and ④Error check code. (Refer to

5.3)

Message that can be read once is within the following range.

Data count

120 units

Method of creating a message is explained in the following example.

Example) Reading the measurement data of RD5100 “Channel 1” of “Slave address 02”

5.4.1 RTU mode message

① Slave address: 02 ( 02H )

② Function code: 04 ( 04H )

It is “Reads the analog input data (Reading the contents of input register)”. When function code is

“04”; specify the “relative number of data 2 bytes” to be read in data part and “data count 2 byte” to be

read. (Refer to 5.3. Refer to 5.3.2 for “Function code: 04”)

ÚIt is necessary to confirm the number of bytes of data.

③ Data part: Relative number 100 ( 00H 64H ) at the beginning,

count 2 ( 00H 02H )

Measurement data (analog input data) is stored in reference number “30001 to 40000” (Refer to 5.3.4

Table 3). As per the reference table it is understood that integer part of CH1 is stored in “30101”and

decimal point position is stored in "30102". (For reading the measurement data, refer to 5.5.4.)

Relative number of beginning “reference number 30101” is 30101-30001=100, if it is expressed in 2

bytes it becomes

“ 00H 64H ” (Refer to 5.3.4).

Count of data to be read is the integer part CH. 1 and decimal point position “2” and if it is to be

expressed in 2 bytes it becomes “

00H 02H ”.

④ Error check: Calculated by CRC-16 2730H ( 30H 27H )

Error check in RTU mode is done by CRC-16. (Refer to 5.3.5.1)

Data of basic part of message is 02H 04H 00H 64H 00H 02H as per ①-③, and

CRC-16 is 2730H.

Thus the error check data is

30H 27H

⑤ Message: Message is created with the configuration

02H

04H 00H 64H 00H 02H 30H 27H . (Refer to 5.3)

-16-

Page 22

5.4.2 ASCII mode message

R

Error check LRC is calculated from basic part of the message. LRC is 94H. (Refer to 5.3.5.2). Convert

every data of basic part to ASCII code, also convert LRC to ASCII code and attach it to the basic part.

Add the starting character " : " of the message and, “CR”, “LF” at the end.

3AH 30H 32H 30H 34H 30H 30H 36H 34H

30H 30H 30H

[:]

02H 04H 00H

32H 39H 34H 0DH 0AH

00H 02H

94H

LRC

64H

C

LF

5.5 Function code

Response for each function is given below. (Refer to <Table 2 Function code table> in 5.3.2)

Note) Refer to 5.6 for responses at the time of abnormality.

5.5.1 Reading digital settings value (Reading coil status)

[Function code:01 (01H)]

Only the specified count reads “digital (ON/OFF) settings value of series of numbers”, from specified

number. ON/OFF data consists of reply message data wherein 8 units are arranged in numerical order

in 1 data (1 byte). LSB (DO side) of each data is the digital data of young number. When the read count

is not in multiples of 8, the unnecessary bits become 0.

Example) Reading 10 units from digital setting value reference number 17 to 26 of slave 2.

Reference

number

Data ON OFF ON OFF OFF - - - - -

(RTU mode)

Master → Instrument

Slave address 02H

Function code 01H

Starting number (H) 00H

Starting number (L) 10H

Count (H) 00H

Count (L) 0AH CRC (L) 7FH

CRC (L) BDH CRC (H) 6DH

CRC (H) FBH

〈ASCII mode error check〉

Error check CRC (L), CRC (H) parts are as follows.

LRC E3H

Note) Starting number (Relative number) is “Reference number -1”. (Decimal 16 (=17-1) →

Note) Data count is number of bytes of data.

17 18 19 20 21 22 23 24 25 26

Recording

ON

Hexadecimal 10H)

(It differs from request count. In the example request count is 10 units and data count is 2)

Feed

OFF

List

Execute

Instrument → Master (Normal)

Slave address 02H

Function code 01H

Data count 02H

Initial 8 data 05H

Next 8 data 02H

LRC F4H

Title

OFF

Data print

OFF

First 8 data

0 0 0

24 17

Reference number

Next 8 data

0 0 0 0 0 1 0 0

Reference number

0

1 0 0 1

(05H)

(02H)

26 25

-17-

Page 23

5.5.2 Reading the digital input data (Reading the status of input relay)

[Function code: 02(02H)]

Only the specified count reads “digital (ON/OFF) input data of series of numbers”, from specified

number. ON/OFF data consists of reply message data where in 8 units are arranged in numerical order

in 1 data (1 byte). LSB (DO side) of each data is the digital data of the young number. When the read

count is not in multiples of 8, the unnecessary bits become 0.Response example is similar to “Function

code 01”. However starting number (Relative number) is “Reference number - 10001”.

5.5.3 Reading analog settings value (Reading the contents of maintenance

register)

[Function code: 03 (03H)/60 (3CH)/62 (3EH)]

Only the specified count reads “analog settings value (2 bytes:16 bits) data” of series of numbers, from

specified numbers. Data consists of response message data, arranged in numeric order and split into

high order 8 bits and low order 8 bits.

Example) Reading the clock information “Year month date” of slave 2.

(Reading of 3 analog settings value reference number from 40001 to 40003 of slave 2.)

Reference

number

Data

(RTU mode)

Master → Instrument

Slave address 02H

Function code 03H

Starting number (H) 00H

Starting number (L) 00H

Count (H) 00H

Count (L) 03H Data of Month (H) 31H

CRC (L) 05H Data of Month (L) 32H

CRC (H) F8H Data of Date(H) 32H

〈ASCII mode error check〉

LRC F8H

Note) Starting number (Relative number) is “Reference number - 40001”. (Decimal 0 (=40001-40001)

→ Hexadecimal 00H)

Note) When function code is 62, “Reference number - 20001”

Note) Data count is number of bytes of data.

(It differs from request count. In the example Request count is 3 and data count is 6)

Note) There is a limitation on the data count of the message (that this instrument can send) that can

be received at a time.

(Refer to 5.4)

40001 40002 40003

98

(3938H)

12

(3132H)

25

(3235H)

Instrument → Master (Normal)

Slave address 02H

Function code 03H

Data count 06H

Data of Year(H) 39H

Data of Year (L) 38H

Data of Date (L) 35H

CRC (L) EBH

CRC (H) 6DH

LRC BAH

Example)

Data of December 25, 1998

5.5.4 Reading the analog input data (Reading the contents of input register)

[Function code: 04 (04H)]

Only the specified count reads “analog settings value (2 bytes: 16 bits) data” of series of numbers, from

specified numbers. Data consists of response message data arranged in numeric order and split into

high order 8 bits and low order 8 bits. Response example is similar to “Function code 03”. However

starting number (Relative number) is "Reference number - 30001".

-18-

Page 24

5.5.5 Writing digital settings value (Changing the status of single coil)

[Function code: 05 (05H)]

Consider digital settings value of specified number as specified status (ON/OFF).

Example) Executing ‘Print message’ of slave 2. (Switch ON the digital settings value reference number

20 of slave 2.

(RTU mode)

Master → Instrument Instrument → Master (Normal)

Slave address 02H Slave address 02H

Function code 05H Function code 05H

Settings value number (H) 00H Settings value number (H) 00H

Settings value number (L) 13H Settings value number (L) 13H

Settings status (H) FFH Settings status (H) FFH

Settings status (L) 00H Settings status (L) 00H

CRC (L) 7DH CRC (L) 7DH

CRC (H) CCH CRC (H) CCH

〈ASCII mode error check〉

LRC E7H

Note) In case of normal response, response is same as that of command message.

Note) Setting value number (Relative number) is “Reference number -1”. (Decimal 19 (=20-1) →

Hexadecimal 13H)

Note) ”FF00HH” is set at the time of execution. In key lock and recording ON/OFF, “000H” is set in

case of OFF and “FF00H” is set in case of ON.

Note) If slave address is 0 all the slaves execute this command. But no slave address responds.

LRC E7H

5.5.6 Writing analog settings value (Writing to unit maintenance register)

[Function code:06 (06H)]

Analog settings value of specified number is considered to be the specified value.

Example) Alarm dead band of slave 2 is set to 0.5%.

(Consider “5” as analog settings value reference number 40081 of slave 2.)

(RTU mode)

Master → Instrument

Slave address 02H

Function code 06H

Settings value number (H) 00H

Settings value number (L) 50H

Setting data (H) 00H

Setting data (L) 05H

CRC (L) 49H

CRC (H) EBH

〈ASCII mode error check〉

LRC A3H

Note) In case of normal response, response is same as that of command message.

Note) Setting value number (Relative number) is “Reference value -40001”. (Decimal

80(=40081-40001) → Hexadecimal 50H)

Note) If slave address is 0 all the slaves execute this command. But no slave address responds.

Instrument → Master (Normal)

Slave address 02H

Function code 06H

Settings value number (H) 00H

Settings value number (L) 50H

Setting data (H) 00H

Setting data (L) 05H

CRC (L) 49H

CRC (H) EBH

LRC A3H

-19-

Page 25

5.5.7 Loop back test

[Function code: 08 (08H)]

Transmission check is performed between master slaves. Responding is done depending on the

specified diagnosis code. In this instrument “return check to send the received data as it is” is

performed and diagnosis code “0000H” is fixed.

Example) Execute "loop back test" in slave 2

(RTU mode)

Master → Instrument Instrument → Master (Normal)

Slave address 02H Slave address 02H

Function code 08H Function code 08H

Diagnosis code (H)

Diagnosis code (L) 00H Diagnosis code (L) 00H

Optional data * Received data *

Optional data * Received data *

CRC (L) * CRC (L) *

CRC (H) * CRC (H) *

Fixed

00H Diagnosis code (H)

Fixed

00H

5.5.8 Writing multiple analog setting values (Writing to multiple maintenance

register)

[Function code: 16 (10H)/61 (3DH)/63 (3FH)]

Analog settings value of count specified from the specified number, is considered to be the specified

value. Data is split into high order 8 bits and low order 8 bits and arranged in numerical order and then

sent.

Example) Time of slave 2 is set as 15 hours 30 minutes 00 seconds.

(Set 3 analog settings value reference number of slave 2, from 40004 to 40006.)

Reference number 40004 40005 40006

Data

(RTU mode)

Master → Instrument

Slave address 02H

Function code 10H

Starting number (H) 00H

Starting number (L) 03H

Count (H) 00H

Count (L) 03H

Data count 06H

First data (H) 31H

First data (L) 35H

Second data (H) 33H

Second data (L) 30H

Third data (H) 30H

Third data (L) 30H

CRC (L) 80H

CRC (H) 36H

〈ASCII mode error check〉

LRC B9H

Note) Starting number (Relative value) is “Reference number - 40001”. (Decimal 3 (=40004-40001) →

Hexadecimal 03H)

Note) When function code is 63, “Reference number - 20001”

Note) If slave address is 0 all the slaves execute this command. But no slave address responds.

Note) There is a limitation on the data count of the message (that this instrument can receive) that can

be sent at a time. (Refer to 5.4)

15

(3135H)

30

(3330H)

Instrument → Master (Normal)

Slave address 02H

Function code 10H

Starting number (H) 00H

Starting number (L) 03H

Count (H) 00H

Count (L) 03H

CRC (L) 70H

CRC (H) 3BH

LRC E8H

00

(3030H)

-20-

Page 26

5.6 Process during abnormality

Response is as follows when there is an error in the contents of the message from master.

5.6.1 For no response

In the following cases the message is ignored and there is no response.

① When transmission error (over run, framing, parity, CRC or LRC) is detected in the message.

② When the slave address in the message is not one’s own address.

③ When the data interval of the message is long.

RTU mode... 28 bits or more

ASCII mode…1 second or more

④ When transmission parameter does not match.

⑤ When received message exceeds 512 bytes.

Note 1) In write function when slave address is “0”, message is executed if there is no error in the

message, but there is no response. Also there is no response in case of overwriting error in the

message. Hence when slave address is "0", whether normal or abnormal cannot be judged just

by response.

Note 2) When using USB and TCP/IP, respond by using the following formats except with errors at the

physical layer.

Slave address

88H

Error code

CRC(L)

CRC(H)

Error code

99H: CR error

5.6.2 Error message response

In the contents of the message from the master, if following error is detected and not the error in 5.6.1,

code showing those error contents responds as “error message”.

Format of the error message is as follows.

Slave address

Function code+80H

Error code

CRC (L)

CRC (H)

Function code Function code+80H

01 81H

02 82H

03 83H

04 84H

05 85H

06 86H

08 88H

16 90H

60 BCH

61 BDH

62 BEH

63 BFH

70 C6H

71 C7H

-21-

Page 27

Error codes are as follows

Error code Contents

01H

02H

Function code defect

When function code that is not specified is received

Relative number (Reference number) defect

When received starting number or settings value number are other than specified

Data count defect

In case of any of the following

① When received function code and data count do not match

In case of function code “16”, when “data count” is not twice that of “count”

03H

In case of function code “16”, when data count does not match with the “received data

count”.

② When count of the data to be sent in response to the received message exceeds the

specified count

Maximum 120 units

Out of setting value range (Set error)

In case of any of the following

① When month, day, hours, minutes and range no. is other than specified

② When settings value (binary) exceeds the range “-30000 to 30000”

③ When data communication input data (binary) exceeds the range “-32765 to 32765”

However, exceeding binary expression (-32768), data exceeding the range (32767 or

11H

-32767), burn out data (32766), invalid data (-32766) can be received.

④ When decimal point data exceeds the range “0-3”

⑤ When time interval settings of ‘fixed time recording’ cannot be executed due to chart

speed

⑥ When there is a contradiction in the direction of increase and decrease in ‘partial

reduction magnification settings’ and auto range settings

⑦ When RJ internal settings are out of thermocouple input range

Cannot be set

① When message is received in any of the following cases

Immediately after starting the power supply during initialization (When this instrument

is performing initial display)

Pointer scale connection mode

Check mode

12H

② When setting message is received in any of the following cases

At the time of setting, using the front key or at the time of setting confirmation

When ”data print”, “list” command is received during recording OFF status

When parameter settings of multiple channels is received in parameter settings of

each channel

When parameter settings of option function that is not loaded are received

(“0” is sent as response for the read message.)

-22-

Page 28

5.7 Print message function

It is possible to print on the chart of this instrument the optional characters by communication.

(Printing specifications)

Channel specifications exist No channel specifications

Count of characters

to be printed

Type of characters

to be printed

Print color Black

Feed specification

(Procedure)

① Print color, feed specifications, print contents are sent from the master to this instrument.

(Refer to reference number: 48001 to 48050)

② Execution message is sent from master to this instrument.(Reference number:20 Refer to 5.5.5)

Note) If ② is executed without executing ①, the contents printed previously are reprinted. If message

printing is not done even once, nothing is printed.

Maximum 75 characters Maximum 80 characters

English alphanumeric characters (upper case/lower case), symbols, Katakana

(At the time of using Katakana, communication is always done by 8 bit data

length)

It can be specified whether to print after dividing the analog recording or

whether to print on analog recording

-23-

Page 29

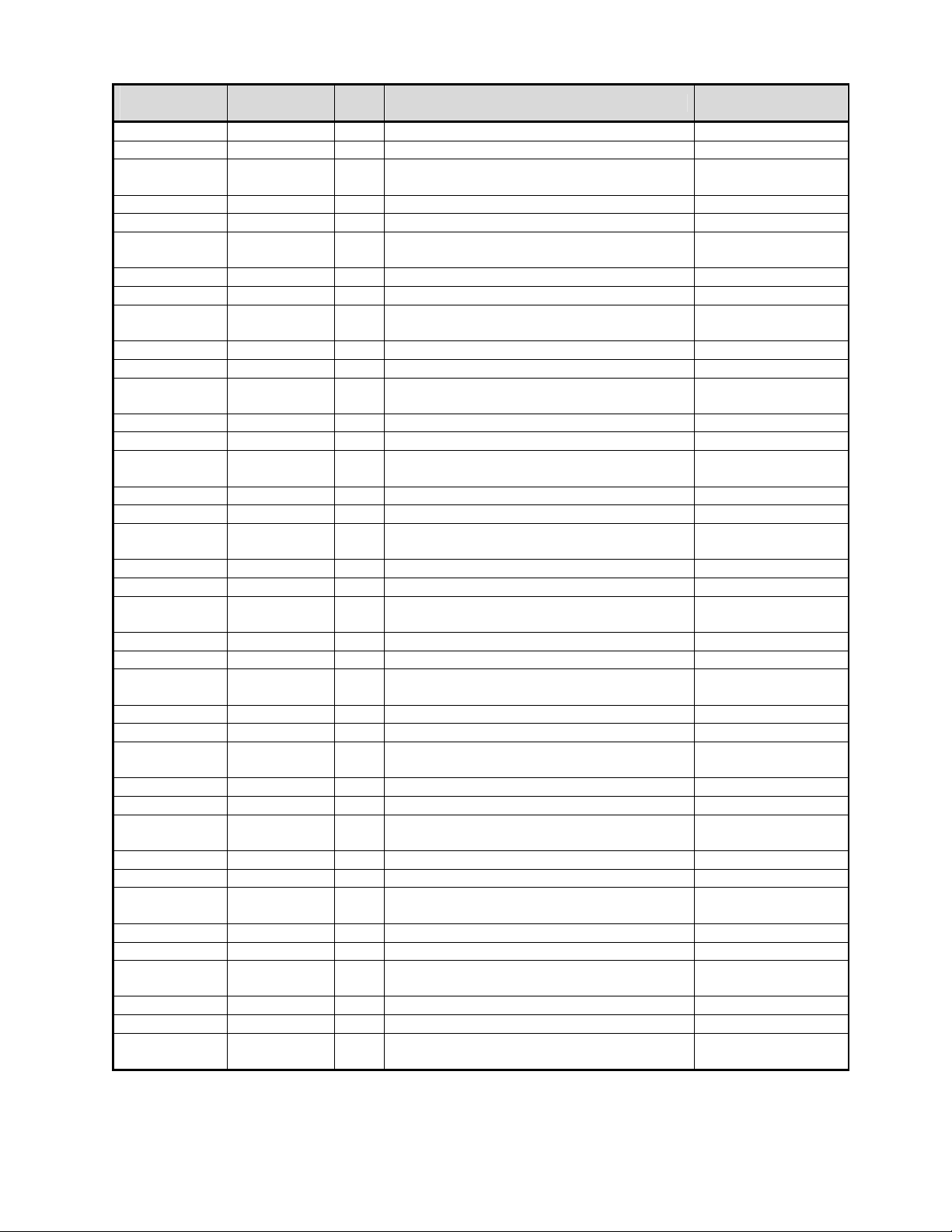

5.8 Reference table

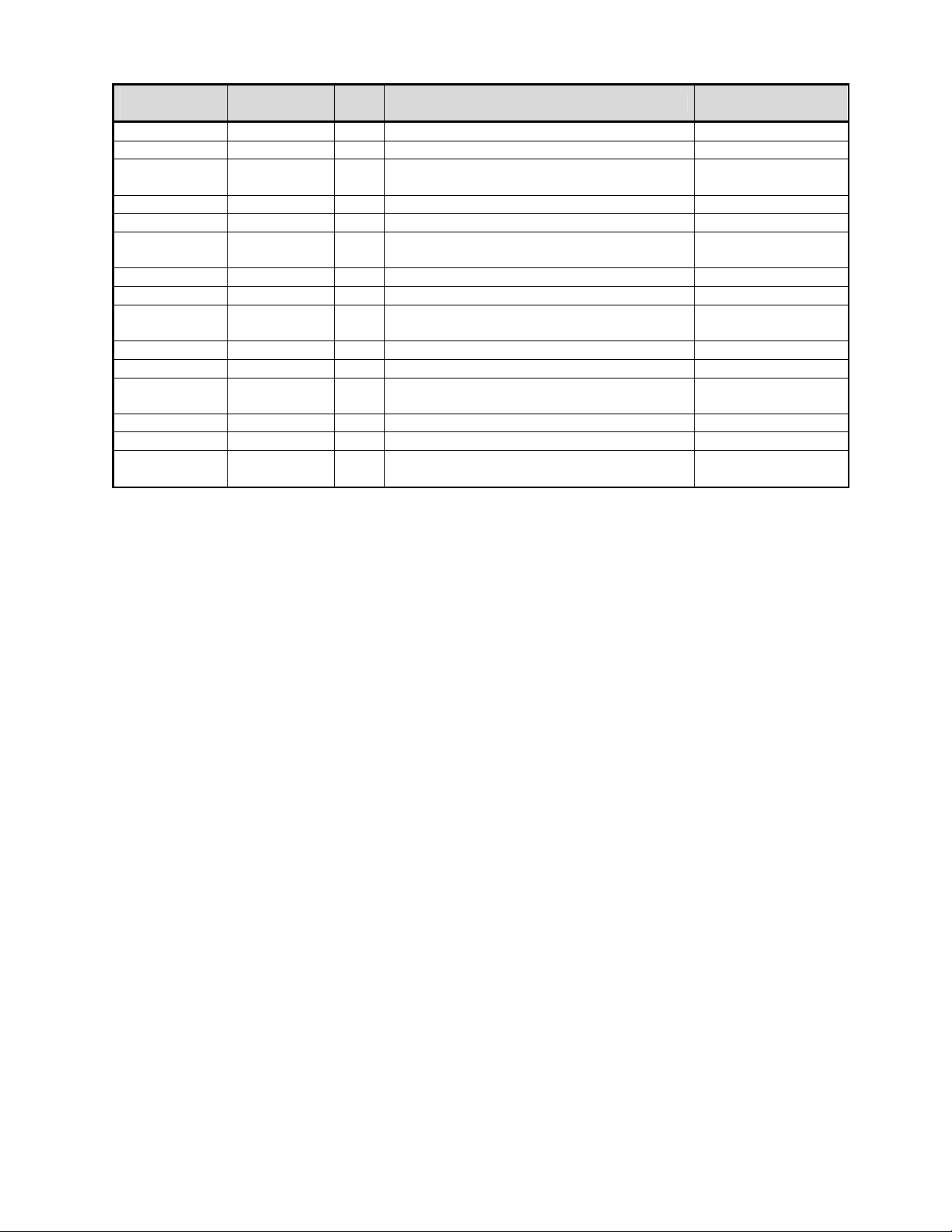

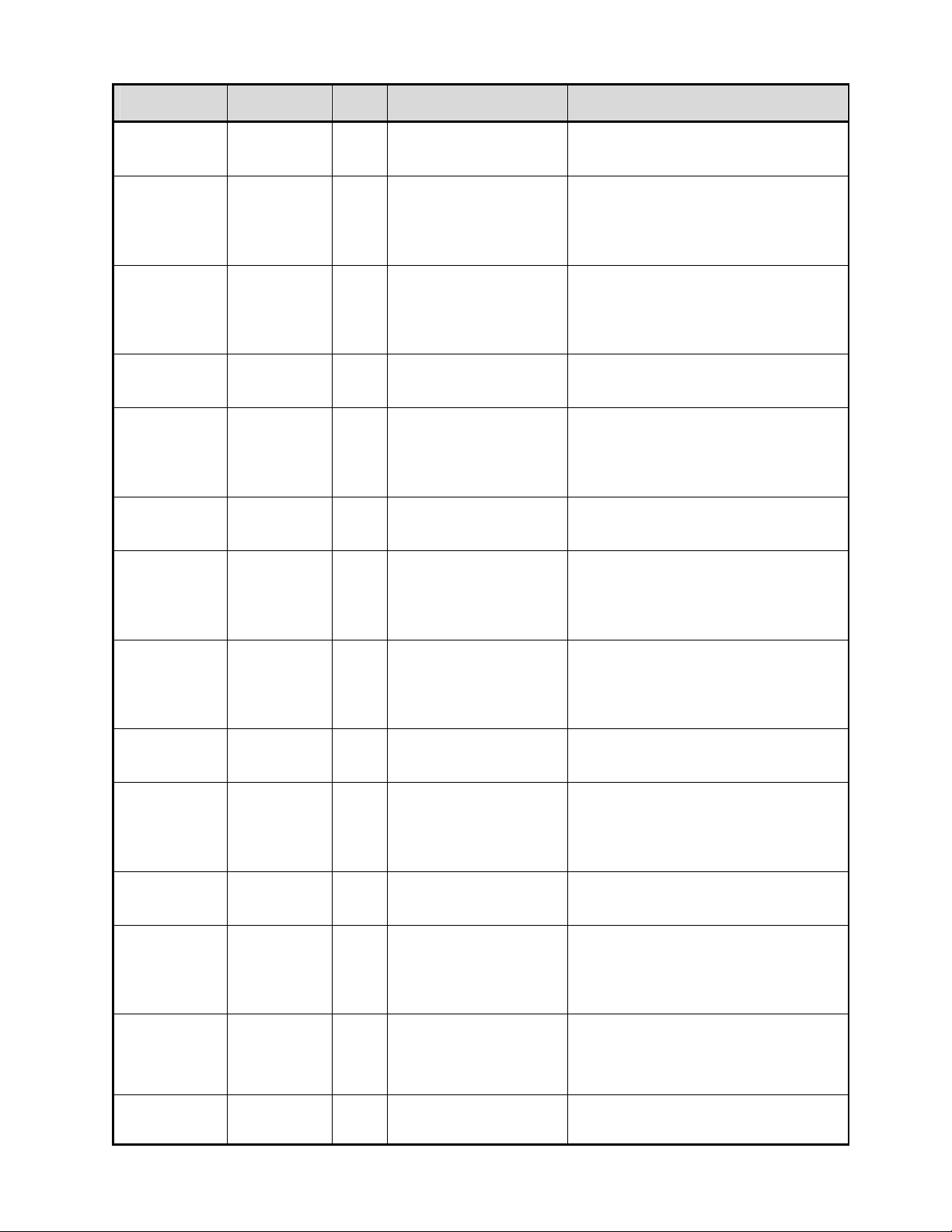

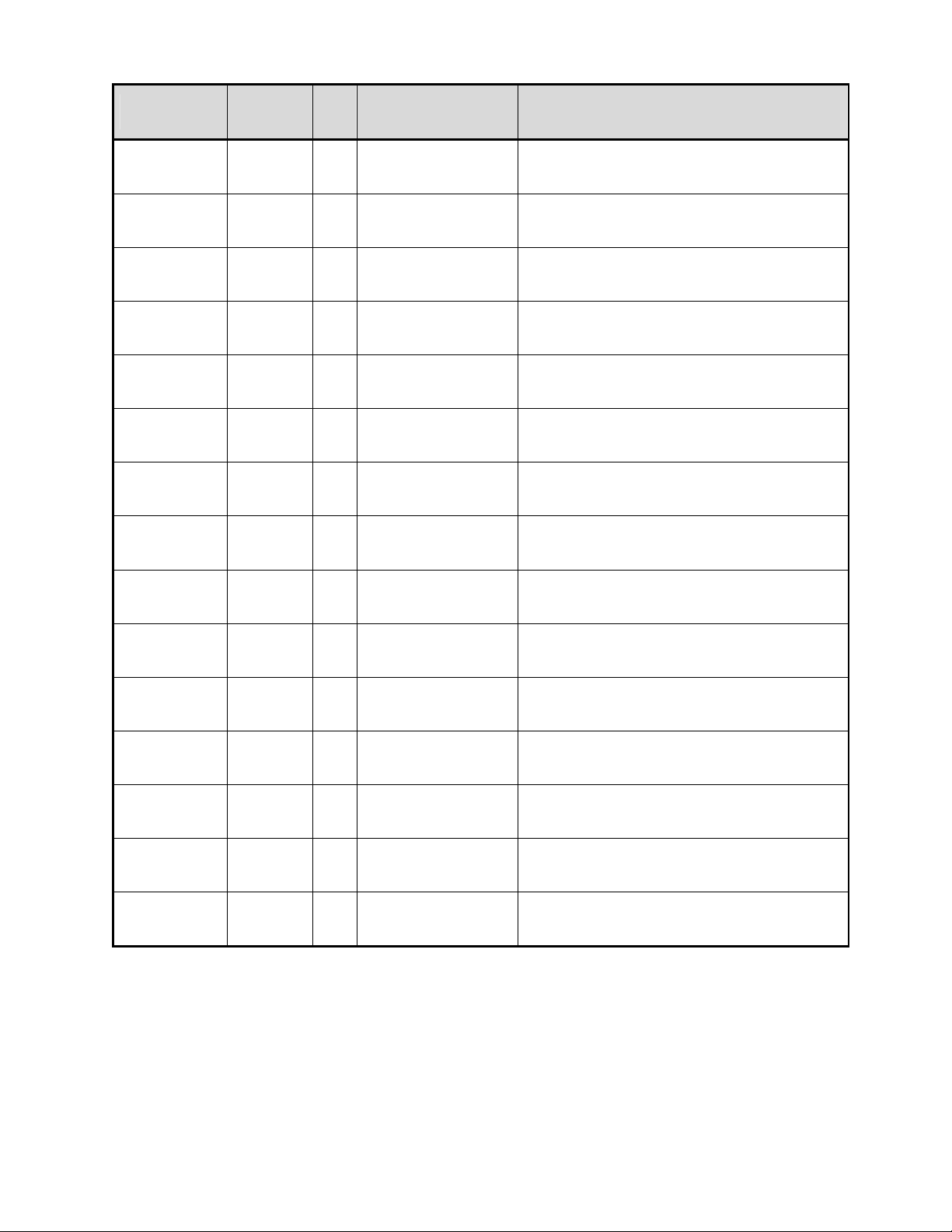

5.8.1 Digital settings value

Reference

Number

01

17

18

19

20

Application

Function code

01

05

01

05

01

05

01

05

01

05

R/W Contents Details

R

W

R

W

R

W

R

W

R W Execute print message

Key lock

Recording ON/OFF

Execute feed

Execute print list

R/W……R: READ,W: WRITE

0 (000h) = Key lock disabled

1 (FF00h) = Key lock enabled

Contents in the ( ) are the contents at the time

of function code 05

Error code: 01H, 02H, 03H, 11H, 12H

0 (000h) = Recording OFF

1 (FF00h) – Recording ON

Contents in the ( ) are the contents at the time

of function code 05

Error code: 01H, 02H, 03H, 11H, 12H

0= Recording non execution (End execution)

1(FF00h)= Recording in process (Start

execution)

Contents in the ( ) are the contents at the time

of function code 05

10mm feed for every execution reception

Error code: 01H, 02H, 03H, 11H, 12H

0= Recording non execution (End execution)

1(FF00h)= Recording being done (Start

execution)

Contents in the ( ) are the contents at the time

of function code 05

Error code: 01H, 02H, 03H, 11H, 12H

0= Recording non execution (End execution)

1(FF00h)= Recording being done (Start

execution)

Contents in the ( ) are the contents at the time

of function code 05

Error code: 01H, 02H, 03H, 11H, 12H

21

22

23

24

25

26

27

01

05

Execute all CH data print

Execute CH001 to

CH099

Execute CH101 to

CH199

R

W

Execute CH201 to

CH299

Execute CH301 to

CH399

Execute CH401 to

CH499

Execute CH501 to

CH599

When function code is 01

0000000= Recording non execution

0000001= Execute all CH

0000010= Execute CH001 to CH099

0000100= Execute CH101 to CH199

0001010= Execute CH201 to CH299

0010000= Execute CH301 to CH399

0100000= Execute CH401 to CH499

1000000= Execute CH501 to CH599

When function code is 05

0= End execution, FF00h= Start execution

Error code: 01H, 02H, 03H, 11H, 12H

-24-

Page 30

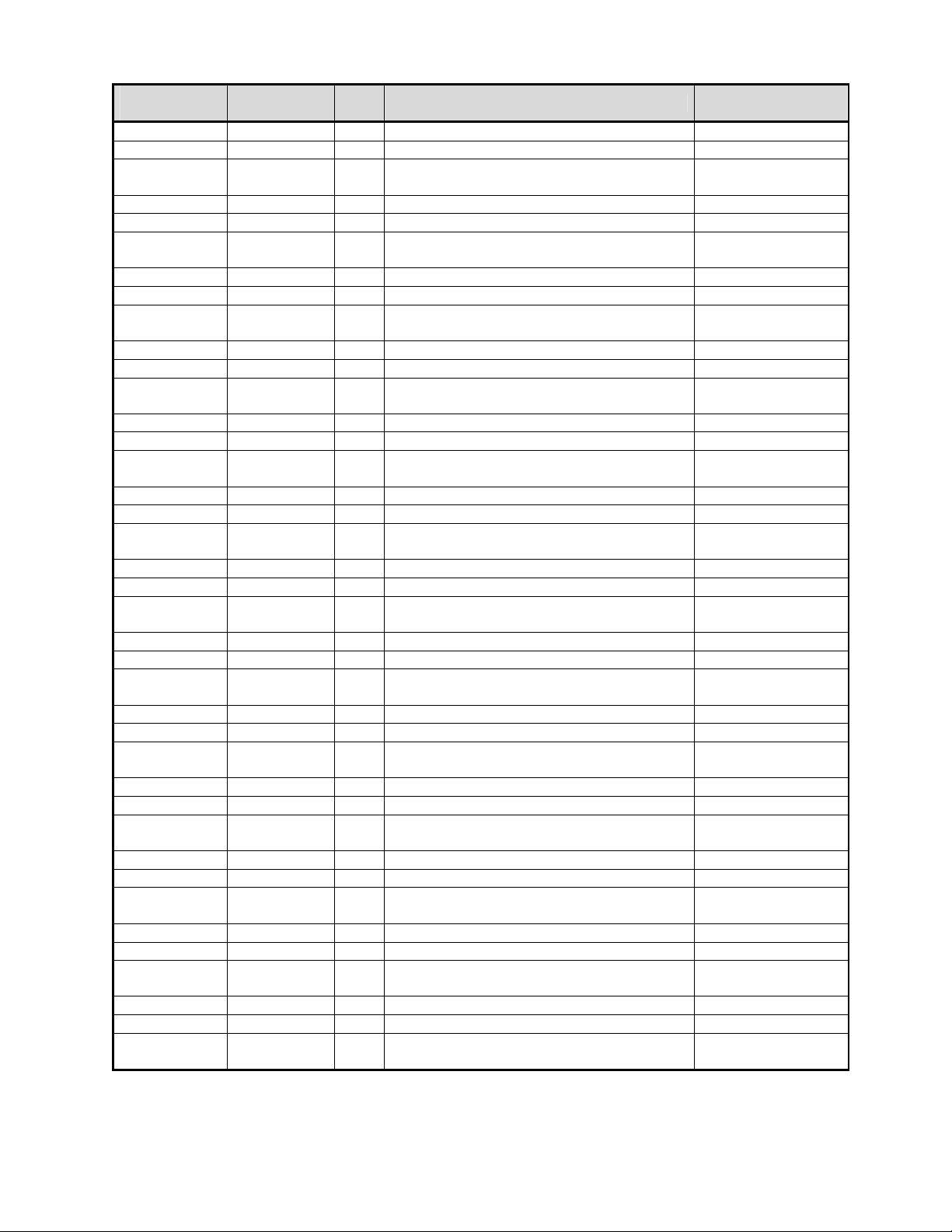

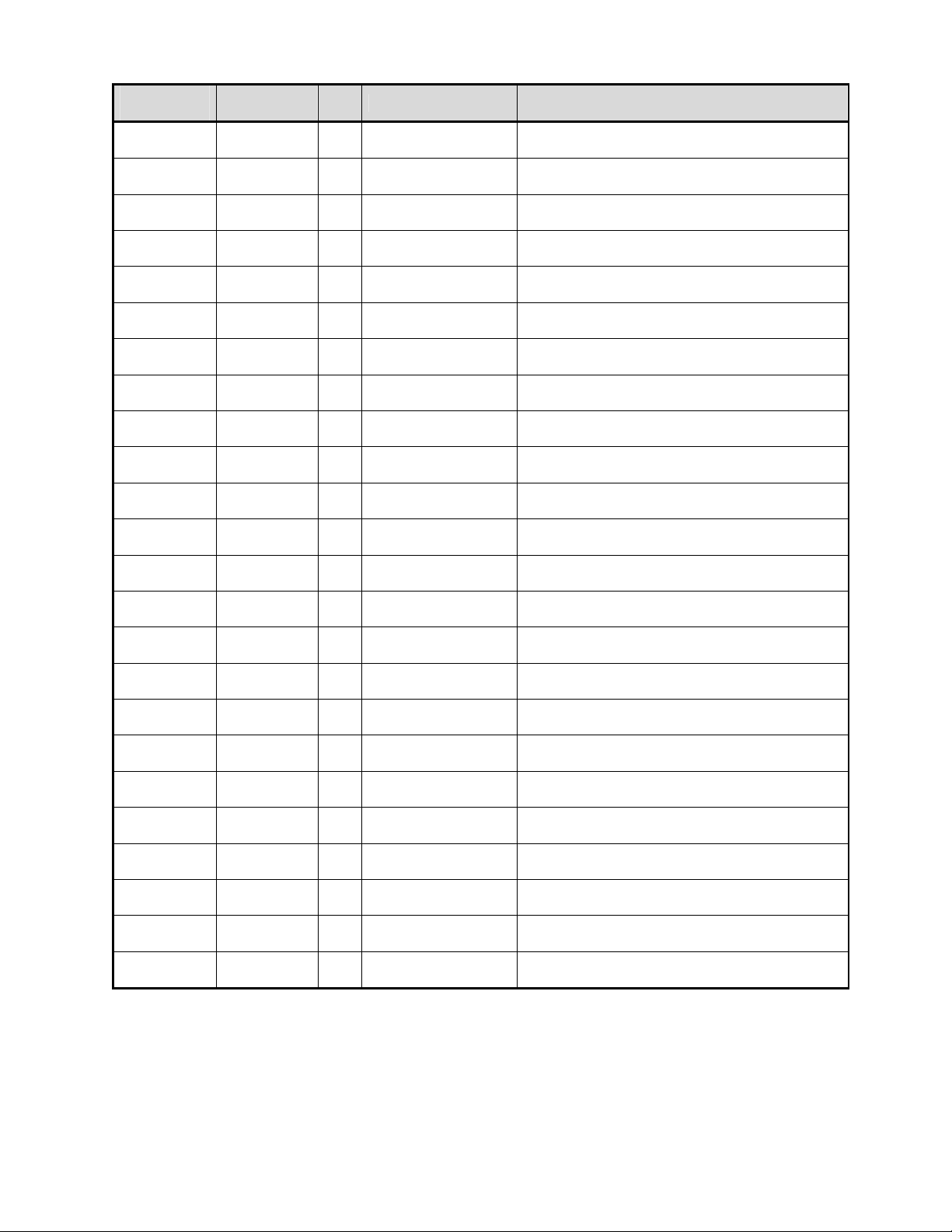

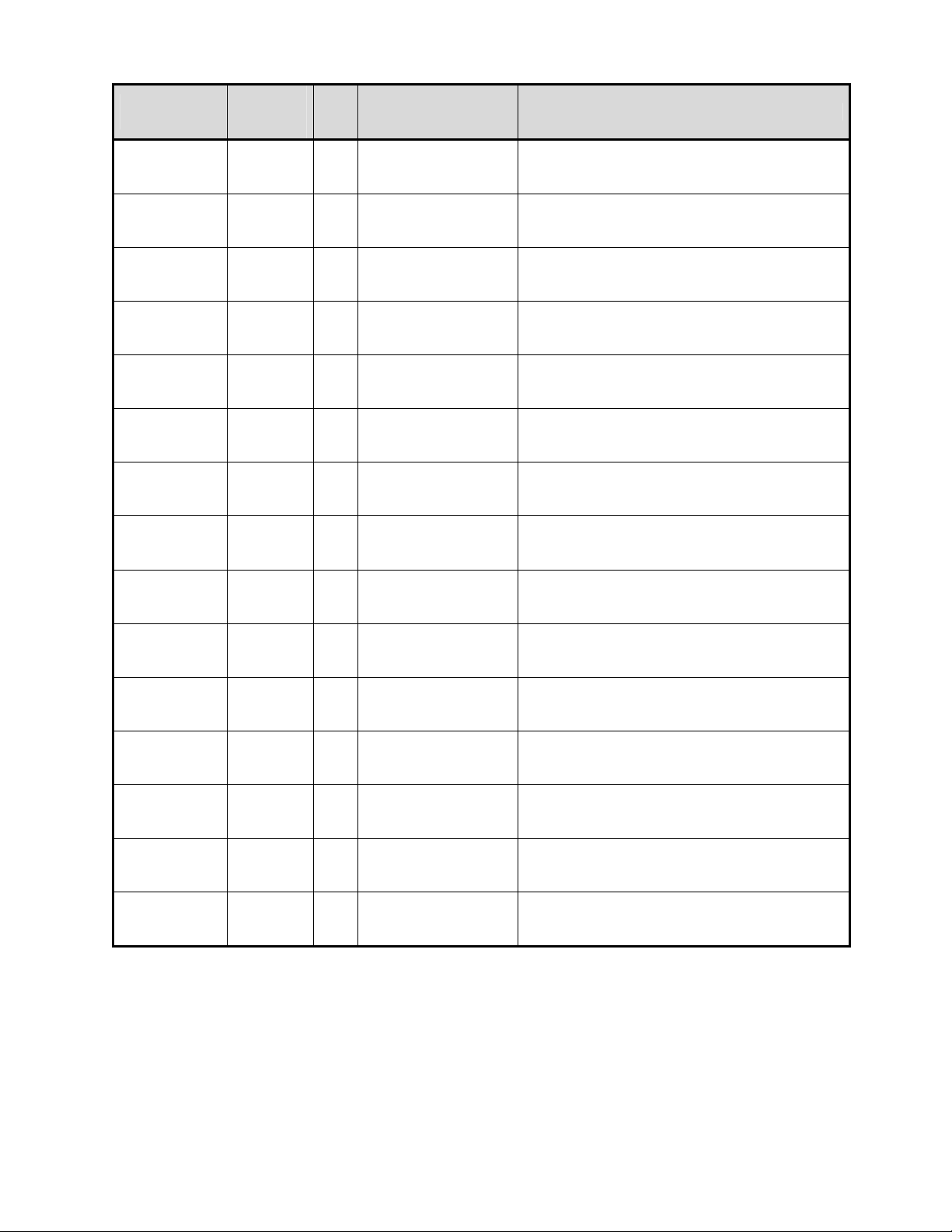

5.8.2 Digital input data

Reference

Number

10009

10010

10011

10012

10101

10102

10105

10106

10107

10108

10109

10110

10111

10112

10117

10118

10121

10122

10123

10124

10125

10126

10127

10128

Application

Function code

02 R

02 R CH1 status 1

02 R CH1 status 2

02 R

02 R CH2 status 1

02 R CH2 status 2

02 R

R/W……R: READ,W: WRITE

R/W Contents Details

Status of external drive 1

Status of external drive 2

Status of external drive 3

Status of external drive 4

CH1 alarm level 1

CH1 alarm level 2

CH1 alarm level 3

CH1 alarm level 4

Activation status

CH2 alarm level 1

CH2 alarm level 2

CH2 alarm level 3

CH2 alarm level 4

Activation status

Status of external drive contact point input

0: OFF

1: ON

Status expression in 2 bits

00: Measurement value

01: Calculation data

10: Communication input data

Error code: 01H, 02H, 03H

Status expression in 4 bits

0000: Normal data

0001: + Over range

0010: - Over range

0100: Burn out

1000: Invalid data (Initializing, acquiring data, no

range settings)

Error code: 01H, 02H, 03H

0: Alarm not activated

1: Alarm activated

Error code: 01H, 02H, 03H

Express status in 2 bits

00: Measurement value

01: Calculation data

10: Communication input data

Error code: 01H, 02H, 03H

Status expression in 4 bits

0000: Normal data

0001: + Over range

0010: - Over range

0011: Burn out

1000: Invalid data (Initializing, acquiring data, no

range settings)

Error code: 01H, 02H, 03H

0: Alarm not activated

1: Alarm activated

Error code: 01H, 02H, 03H

-25-

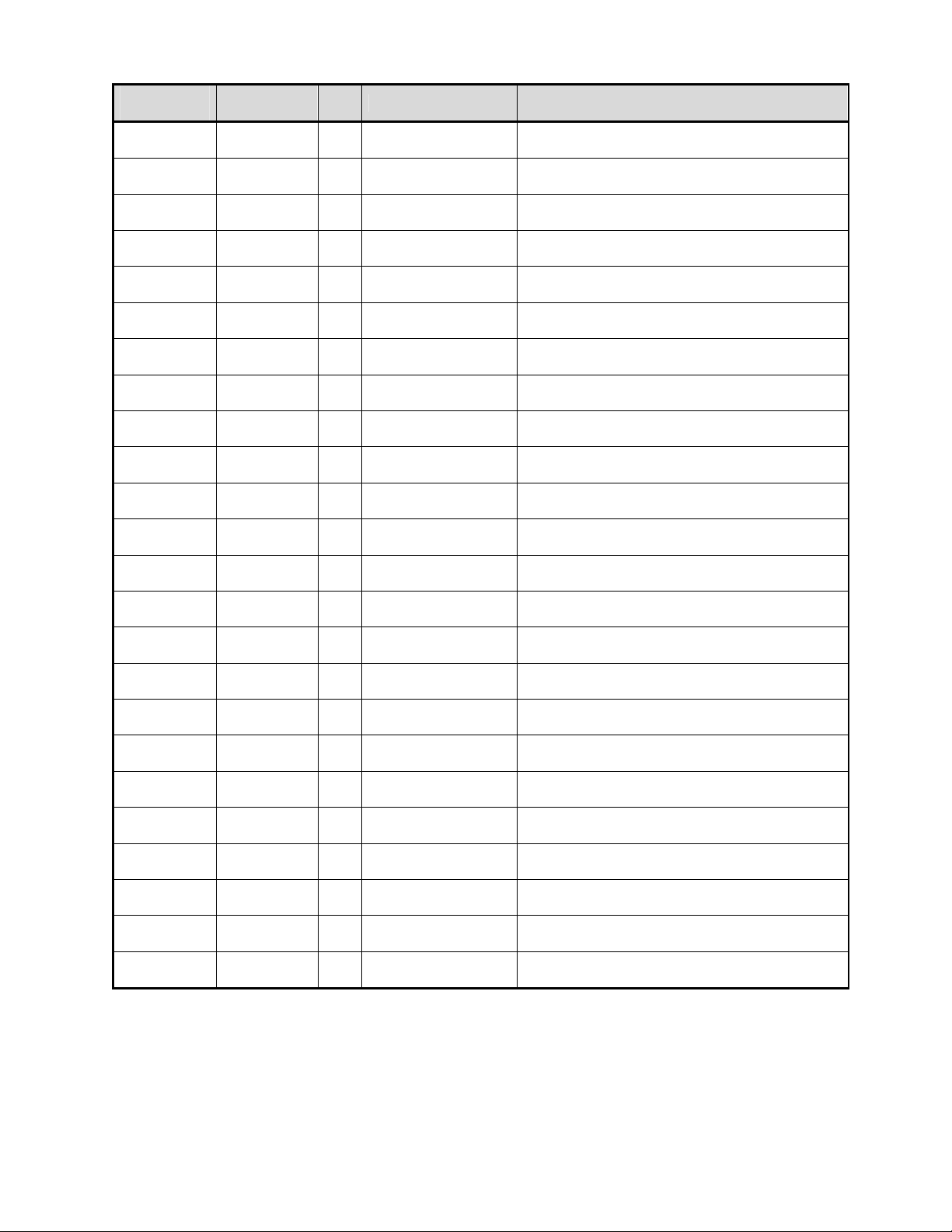

Page 31

R/W……R: READ,W: WRITE

Reference

number

10133 to 10134 02 R CH3 status 1 Similar to CH1

10137 to 10140 02 R CH3 status 2 Similar to CH1

10141 to 10144 02 R

10149 to 10150 02 R CH4 status 1 Similar to CH1

10153 to 10156 02 R CH4 status 2 Similar to CH1

10157 to 10160 02 R

10165 to 10166 02 R CH5 status 1 Similar to CH1

10169 to 10172 02 R CH5 status 2 Similar to CH1

10173 to 10177 02 R

10181 to 10182 02 R CH6 status 1 Similar to CH1

10185 to 10188 02 R CH6 status 2 Similar to CH1

10189 to 10192 02 R

10197 to 10198 02 R CH7 status 1 Similar to CH1

10201 to 10204 02 R CH7 status 2 Similar to CH1

10205 to 10208 02 R

10213 to 10214 02 R CH8 status 1 Similar to CH1

10217 to 10220 02 R CH8 status 2 Similar to CH1

10221 to 10224 02 R

10229 to 10230 02 R CH9 status 1 Similar to CH1

10233 to 10236 02 R CH9 status 2 Similar to CH1

10237 to 10240 02 R

10245 to 10246 02 R CH10 status 1 Similar to CH1

10249 to 10252 02 R CH10 status 2 Similar to CH1

10253 to 10256 02 R

10261 to 10262 02 R CH11 status 1 Similar to CH1

10265 to 10268 02 R CH11 status 2 Similar to CH1

10269 to 10272 02 R

10277 to 10278 02 R CH12 status 1 Similar to CH1

10281 to 10284 02 R CH12 status 2 Similar to CH1

10285 to 10288 02 R

10293 to 10294 02 R CH13 status 1 Similar to CH1

10297 to 10300 02 R CH13 status 2 Similar to CH1

10301 to 10304 02 R

10309 to 10310 02 R CH14 status 1 Similar to CH1

10313 to 10316 02 R CH14 status 2 Similar to CH1

10317 to 10320 02 R

10325 to 10326 02 R CH15 status 1 Similar to CH1

10329 to 10332 02 R CH15 status 2 Similar to CH1

10333 to 10336 02 R

10341 to 10342 02 R CH16 status 1 Similar to CH1

10345 to 10348 02 R CH16 status 2 Similar to CH1

10349 to 10352 02 R

Application

Function code

R/W Contents Details

Activation status of CH3 alarm level 1 to CH3

alarm level 4

Activation status of CH4 alarm level 1 to CH4

alarm level 4

Activation status of CH5 alarm level 1 to CH5

alarm level 4

Activation status of CH6 alarm level 1 to CH6

alarm level 4

Activation status of CH7 alarm level 1 to CH7

alarm level 4

Activation status of CH8 alarm level 1 to CH8

alarm level 4

Activation status of CH9 alarm level 1 to CH9

alarm level 4

Activation status of CH10 alarm level 1 to CH10

alarm level 4

Activation status of CH11 alarm level 1 to CH11

alarm level 4

Activation status of CH12 alarm level 1 to CH12

alarm level 4

Activation status of CH13 alarm level 1 to CH13

alarm level 4

Activation status of CH14 alarm level 1 to CH14

alarm level 4

Activation status of CH15 alarm level 1 to CH15

alarm level 4

Activation status of CH16 alarm level 1 to CH16

alarm level 4

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

-26-

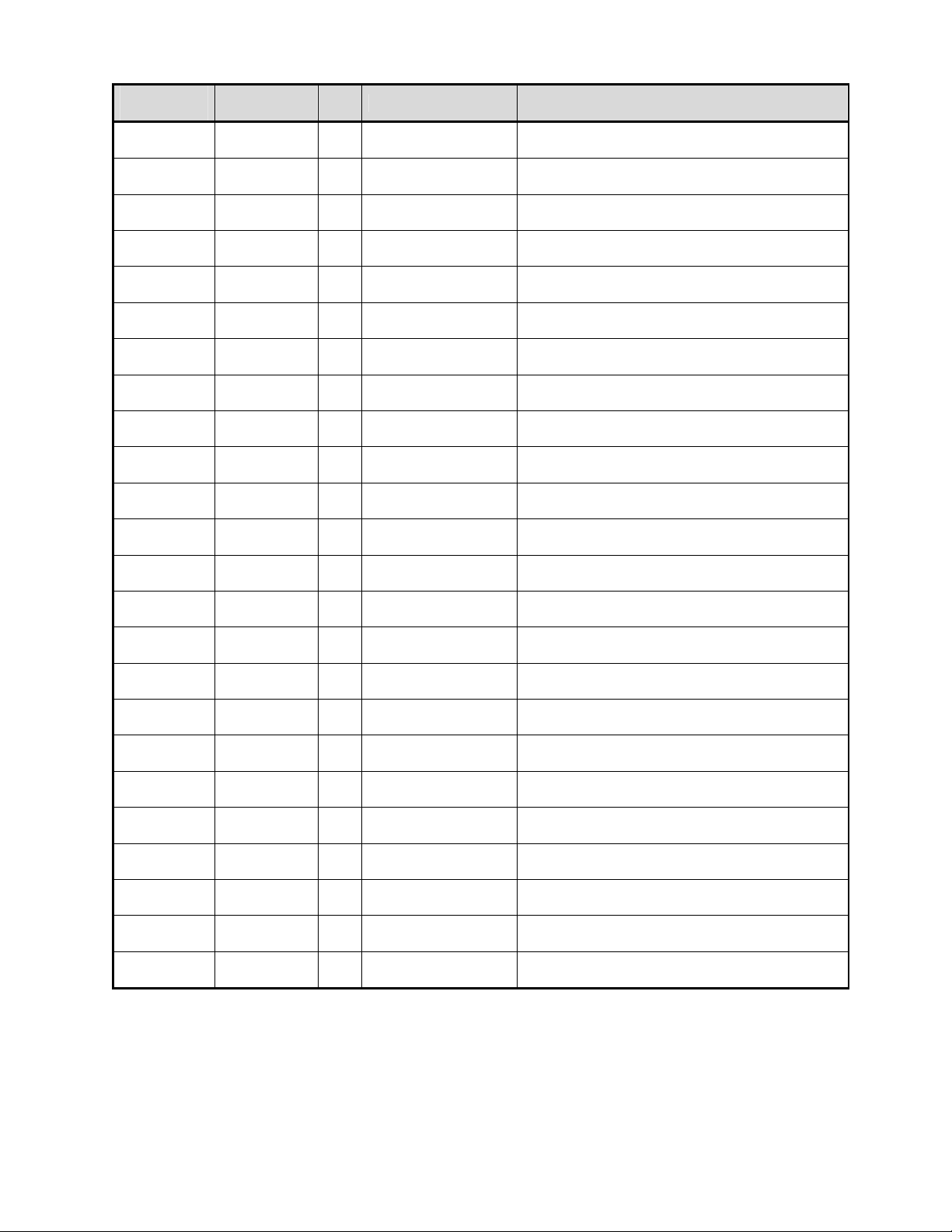

Page 32

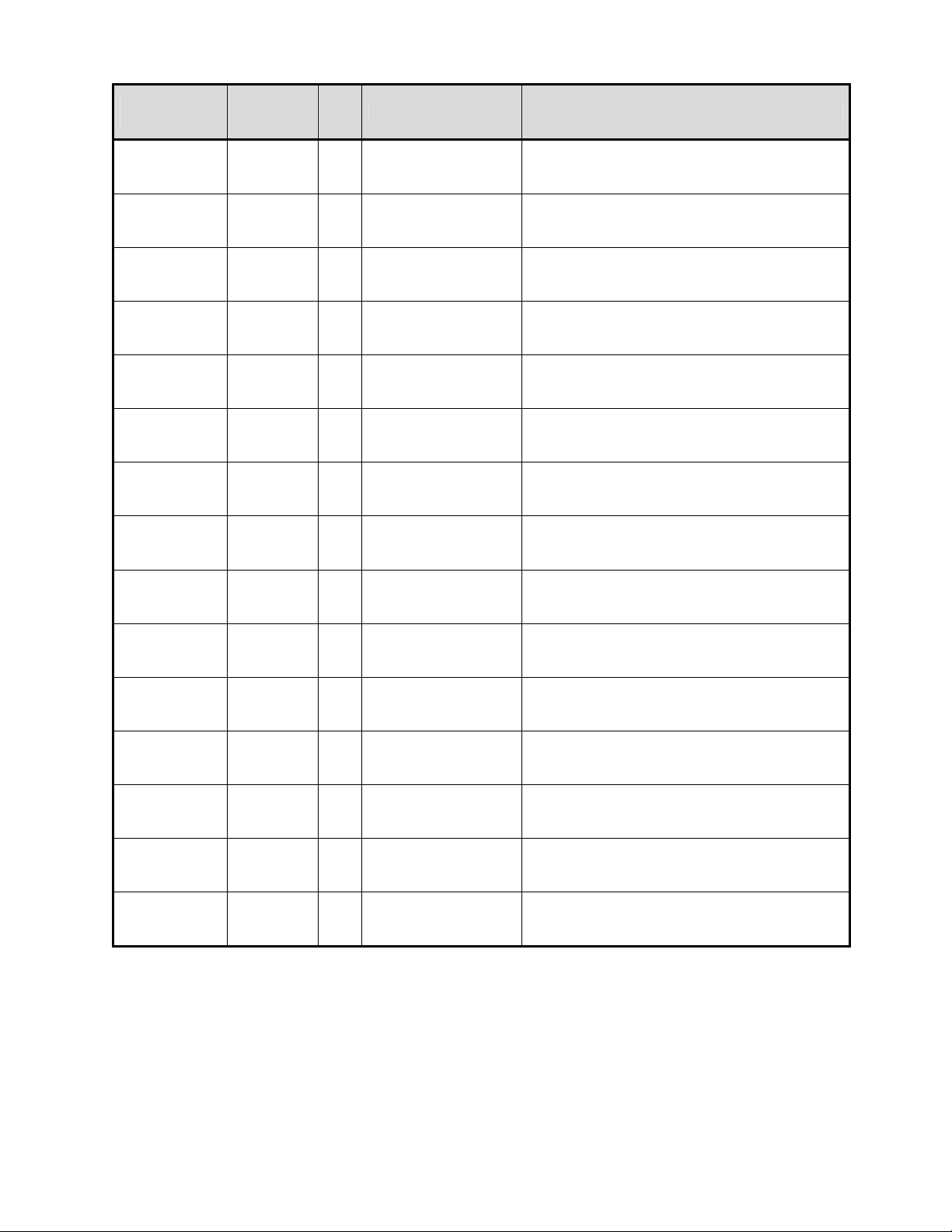

R/W……R: READ,W: WRITE

Reference

number

10357 to 10358 02 R CH17 status 1 Similar to CH1

10361 to 10364 02 R CH17 status 2 Similar to CH1

10365 to 10368 02 R

10373 to 10374 02 R CH18 status 1 Similar to CH1

10377 to 10380 02 R CH18 status 2 Similar to CH1

10381 to 10384 02 R

10389 to 10390 02 R CH19 status 1 Similar to CH1

10393 to 10396 02 R CH19 status 2 Similar to CH1

10397 to 10400 02 R

10405 to 10406 02 R CH20 status 1 Similar to CH1

10409 to 10412 02 R CH20 status 2 Similar to CH1

10413 to 10416 02 R

10421 to 10422 02 R CH21 status 1 Similar to CH1

10425 to 10428 02 R CH21 status 2 Similar to CH1

10429 to 10432 02 R

10437 to 10438 02 R CH22 status 1 Similar to CH1

10441 to 10444 02 R CH22 status 2 Similar to CH1

10445 to 10448 02 R

10453 to 10454 02 R CH23 status 1 Similar to CH1

10457 to 10460 02 R CH23 status 2 Similar to CH1

10461 to 10464 02 R

10469 to 10470 02 R CH24 status 1 Similar to CH1

10473 to 10476 02 R CH24 status 2 Similar to CH1

10477 to 10480 02 R

10485 to 10486 02 R CH25 status 1 Similar to CH1

10489 to 10492 02 R CH25 status 2 Similar to CH1

10493 to 10496 02 R

10501 to 10502 02 R CH26 status 1 Similar to CH1

10505 to 10508 02 R CH26 status 2 Similar to CH1

10509 to 10512 02 R

10517 to 10518 02 R CH27 status 1 Similar to CH1

10521 to 10524 02 R CH27 status 2 Similar to CH1

10525 to 10528 02 R

10533 to 10534 02 R CH28 status 1 Similar to CH1

10537 to 10540 02 R CH28 status 2 Similar to CH1

10541 to 10544 02 R

10549 to 10550 02 R CH29 status 1 Similar to CH1

10553 to 10556 02 R CH29 status 2 Similar to CH1

10557 to 10560 02 R

Application

Function code

R/W Contents Details

Activation status of CH17 alarm level 1 to CH17

alarm level 4

Activation status of CH18 alarm level 1 to CH18

alarm level 4

Activation status of CH19 alarm level 1 to CH19

alarm level 4

Activation status of CH20 alarm level 1 to CH20

alarm level 4

Activation status of CH21 alarm level 1 to CH21

alarm level 4

Activation status of CH22 Alarm level 1 to CH22

Alarm level 4

Activation status of CH23 alarm level 1 to CH23

alarm level 4

Activation status of CH24 alarm level 1 to CH24

alarm level 4

Activation status of CH25 alarm level 1 to CH25

alarm level 4

Activation status of CH26 alarm level 1 to CH26

alarm level 4

Activation status of CH27 alarm level 1 to CH27

alarm level 4

Activation status of CH28 alarm level 1 to CH28

alarm level 4

Activation status of CH29 alarm level 1 to CH29

alarm level 4

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

-27-

Page 33

R/W……R: READ,W: WRITE

Reference

number

10565 to 10566 02 R CH30 status 1 Similar to CH1

10569 to 10572 02 R CH30 status 2 Similar to CH1

10573 to 10576 02 R

10581 to 10582 02 R CH31 status 1 Similar to CH1

10585 to 10588 02 R CH31 status 2 Similar to CH1

10589 to 10592 02 R

10597 to 10598 02 R CH33 status 1 Similar to CH1

10601 to 10604 02 R CH33 status 2 Similar to CH1

10605 to 10608 02 R

10613 to 10614 02 R CH34 status 1 Similar to CH1

10617 to 10620 02 R CH34 status 2 Similar to CH1

10621 to 10624 02 R

10629 to 10630 02 R CH35 status 1 Similar to CH1

10633 to 10636 02 R CH35 status 2 Similar to CH1

10637 to 10640 02 R

10645 to 10646 02 R CH36 status 1 Similar to CH1

10649 to 10652 02 R CH36 status 2 Similar to CH1

10653 to 10656 02 R

10661 to 10662 02 R CH37 status 1 Similar to CH1

10665 to 10668 02 R CH37 status 2 Similar to CH1

10669 to 10672 02 R

10677 to 10678 02 R CH38 status 1 Similar to CH1

10681 to 10684 02 R CH38 status 2 Similar to CH1

10685 to 10688 02 R

10693 to 10694 02 R CH39 status 1 Similar to CH1

10697 to 10700 02 R CH39 status 2 Similar to CH1

10701 to 10704 02 R

10709 to 10710 02 R CH40 status 1 Similar to CH1

10713 to 10716 02 R CH40 status 2 Similar to CH1

10717 to 10720 02 R

10725 to 10726 02 R CH41 status 1 Similar to CH1

10729 to 10732 02 R CH41 status 2 Similar to CH1

10733 to 10736 02 R

10741 to 10742 02 R CH42 status 1 Similar to CH1

10745 to 10748 02 R CH42 status 2 Similar to CH1

10749 to 10752 02 R

10757 to 10758 02 R CH43 status 1 Similar to CH1

10761 to 10764 02 R CH43 status 2 Similar to CH1

10765 to 10768 02 R

Application

Function code

R/W Contents Details

Activation status of CH30 alarm level 1 to CH30

alarm level 4

Activation status of CH32 alarm level 1 to CH32

alarm level 4

Activation status of CH33 alarm level 1 to CH33

alarm level 4

Activation status of CH34 alarm level 1 to CH34

alarm level 4

Activation status of CH35 alarm level 1 to CH35

alarm level 4

Activation status of CH36 alarm level 1 to CH36

alarm level 4

Activation status of CH37 alarm level 1 to CH37

alarm level 4

Activation status of CH38 alarm level 1 to CH38

alarm level 4

Activation status of CH39 alarm level 1 to CH39

alarm level 4

Activation status of CH40 alarm level 1 to CH40

alarm level 4

Activation status of CH41 alarm level 1 to CH41

alarm level 4

Activation status of CH42 alarm level 1 to CH42

alarm level 4

Activation status of CH43 alarm level 1 to CH43

alarm level 4

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

-28-

Page 34

R/W……R: READ,W: WRITE

Reference

number

10773 to 10774 02 R CH44 status 1 Similar to CH1

10777 to 10780 02 R CH44 status 2 Similar to CH1

10781 to 10784 02 R

10789 to 10790 02 R CH45 status 1 Similar to CH1

10793 to 10796 02 R CH45 status 2 Similar to CH1

10797 to 10800 02 R

10805 to 10806 02 R CH46 status 1 Similar to CH1

10809 to 10812 02 R CH46 status 2 Similar to CH1

10813 to 10816 02 R

10821 to 10822 02 R CH47 status 1 Similar to CH1

10825 to 10828 02 R CH47 status 2 Similar to CH1

10829 to 10832 02 R

10837 to 10838 02 R CH48 status 1 Similar to CH1

10841 to 10844 02 R CH48 status 2 Similar to CH1

10845 to 10848 02 R

10853 to 10854 02 R CH49 status 1 Similar to CH1

10857 to 10860 02 R CH49 status 2 Similar to CH1

10861 to 10865 02 R

10870 to 10871 02 R CH50 status 1 Similar to CH1

10874 to 10877 02 R CH50 status 2 Similar to CH1

10878 to 10881 02 R

10886 to 10887 02 R CH51 status 1 Similar to CH1

10890 to 10893 02 R CH51 status 2 Similar to CH1

10894 to 10897 02 R

10902 to 10903 02 R CH52 status 1 Similar to CH1

10906 to 10909 02 R CH52 status 2 Similar to CH1

10910 to 10913 02 R

10918 to 10919 02 R CH53 status 1 Similar to CH1

10922 to 10925 02 R CH53 status 2 Similar to CH1

10926 to 10929 02 R

10934 to 10935 02 R CH54 status 1 Similar to CH1

10938 to 10941 02 R CH54 status 2 Similar to CH1

10942 to 10945 02 R

10950 to 10951 02 R CH55 status 1 Similar to CH1

10954 to 10957 02 R CH55 status 2 Similar to CH1

10958 to 10961 02 R

10966 to 10967 02 R CH56 status 1 Similar to CH1

10970 to 10973 02 R CH56 status 2 Similar to CH1

10974 to 10977 02 R

Application

Function code

R/W Contents Details

Activation status of CH44 alarm level 1 to CH44

alarm level 4

Activation status of CH45 alarm level 1 to CH45

alarm level 4

Activation status of CH46 alarm level 1 to CH46

alarm level 4

Activation status of CH47 alarm level 1 to CH47

alarm level 4

Activation status of CH48 alarm level 1 to CH48

alarm level 4

Activation status of CH49 alarm level 1 to CH49

alarm level 4

Activation status of CH50 alarm level 1 to CH50

alarm level 4

Activation status of CH51 alarm level 1 to CH51

alarm level 4

Activation status of CH52 alarm level 1 to CH52

alarm level 4

Activation status of CH53 alarm level 1 to CH53

alarm level 4

Activation status of CH54 alarm level 1 to CH54

alarm level 4

Activation status of CH55 alarm level 1 to CH55

alarm level 4

Activation status of CH56 alarm level 1 to CH56

alarm level 4

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

-29-

Page 35

R/W……R: READ,W: WRITE

Reference

number

10982 to 10983 02 R CH57 status 1 Similar to CH1

10986 to 10989 02 R CH57 status 2 Similar to CH1

10990 to 10993 02 R

10998 to 10999 02 R CH58 status 1 Similar to CH1

11002 to 11005 02 R CH58 status 2 Similar to CH1

11006 to 11009 02 R

11014 to 11015 02 R CH59 status 1 Similar to CH1

11018 to 11021 02 R CH59 status 2 Similar to CH1

11022 to 11025 02 R

11030 to 11031 02 R CH60 status 1 Similar to CH1

11034 to 11037 02 R CH60 status 2 Similar to CH1

11038 to 11041 02 R

11046 to 11047 02 R CH61 status 1 Similar to CH1

11050 to 11053 02 R CH61 status 2 Similar to CH1

11054 to 11057 02 R

11062 to 11063 02 R CH62 status 1 Similar to CH1

11066 to 11069 02 R CH62 status 2 Similar to CH1

11070 to 11073 02 R

11078 to 11079 02 R CH63 status 1 Similar to CH1

11082 to 11085 02 R CH63 status 2 Similar to CH1

11086 to 11089 02 R

11094 to 11095 02 R CH63 status 1 Similar to CH1

11098 to 11101 02 R CH63 status 2 Similar to CH1

11102 t o 11105 0 2 R

11110 to 11111 02 R CH64 status 1 Similar to CH1

11114 t o 11117 02 R CH6 4 s tatus 2 Si m ilar to CH1

11118 to 11121 02 R

11126 to 11127 02 R CH65 status 1 Similar to CH1

11130 to 11133 02 R CH65 status 2 Similar to CH1

11134 t o 11137 0 2 R

11142 to 11143 02 R CH66 status 1 Similar to CH1

11146 to 11149 02 R CH66 status 2 Similar to CH1

11150 t o 11153 0 2 R

11158 to 11159 02 R CH66 status 1 Similar to CH1

11162 to 11165 02 R CH66 status 2 Similar to CH1

11166 t o 11169 0 2 R

11174 to 11175 02 R CH67 status 1 Similar to CH1

11178 to 11181 02 R CH67 status 2 Similar to CH1

11182 t o 11185 0 2 R

Application

Function code

R/W Contents Details

Activation status of CH57 alarm level 1 to CH57

alarm level 4

Activation status of CH58 alarm level 1 to CH58

alarm level 4

Activation status of CH59 alarm level 1 to CH59

alarm level 4

Activation status of CH60 alarm level 1 to CH60

alarm level 4

Activation status of CH61 alarm level 1 to CH61

alarm level 4

Activation status of CH62 alarm level 1 to CH62

Alarm level 4

Activation status of CH63 Alarm level 1 to CH63

Alarm level 4

Activation status of CH63 Alarm level 1 to CH63

Alarm level 4

Activation status of CH64 Alarm level 1 to CH64

Alarm level 4

Activation status of CH65 Alarm level 1 to CH65

Alarm level 4

Activation status of CH66 Alarm level 1 to CH66

Alarm level 4

Activation status of CH66 Alarm level 1 to CH66

Alarm level 4

Activation status of CH67 Alarm level 1 to CH67

Alarm level 4

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

Similar to CH1

-30-

Page 36

R/W……R: READ,W: WRITE

Reference

number

Application

Function code

R/W Contents Details

11190 to 11191 02 R CH68 status 1 Similar to CH1

11194 to 11197 02 R CH68 status 2 Similar to CH1

11198 to 11201 02 R

Activation status of CH68 Alarm level 1 to CH68

Alarm level 4

Similar to CH1

11206 to 11207 02 R CH69 status 1 Similar to CH1

11210 to 11213 02 R CH69 status 2 Similar to CH1

11214 to 11217 02 R

Activation status of CH69 Alarm level 1 to CH69

Alarm level 4

Similar to CH1

11222 to 11223 02 R CH70 status 1 Similar to CH1

11226 to 11229 02 R CH70 status 2 Similar to CH1

11230 to 11233 02 R

Activation status of CH70 Alarm level 1 to CH70

Alarm level 4

Similar to CH1

11238 to 11239 02 R CH71 status 1 Similar to CH1

11242 to 11245 02 R CH71 status 2 Similar to CH1

11246 to 11249 02 R

Activation status of CH71 Alarm level 1 to CH71

Alarm level 4

Similar to CH1

11254 to 11255 02 R CH72 status 1 Similar to CH1

11258 to 11261 02 R CH72 status 2 Similar to CH1

11262 to 11265 02 R

Activation status of CH72 Alarm level 1 to CH72

Alarm level 4

Similar to CH1

-31-

Page 37

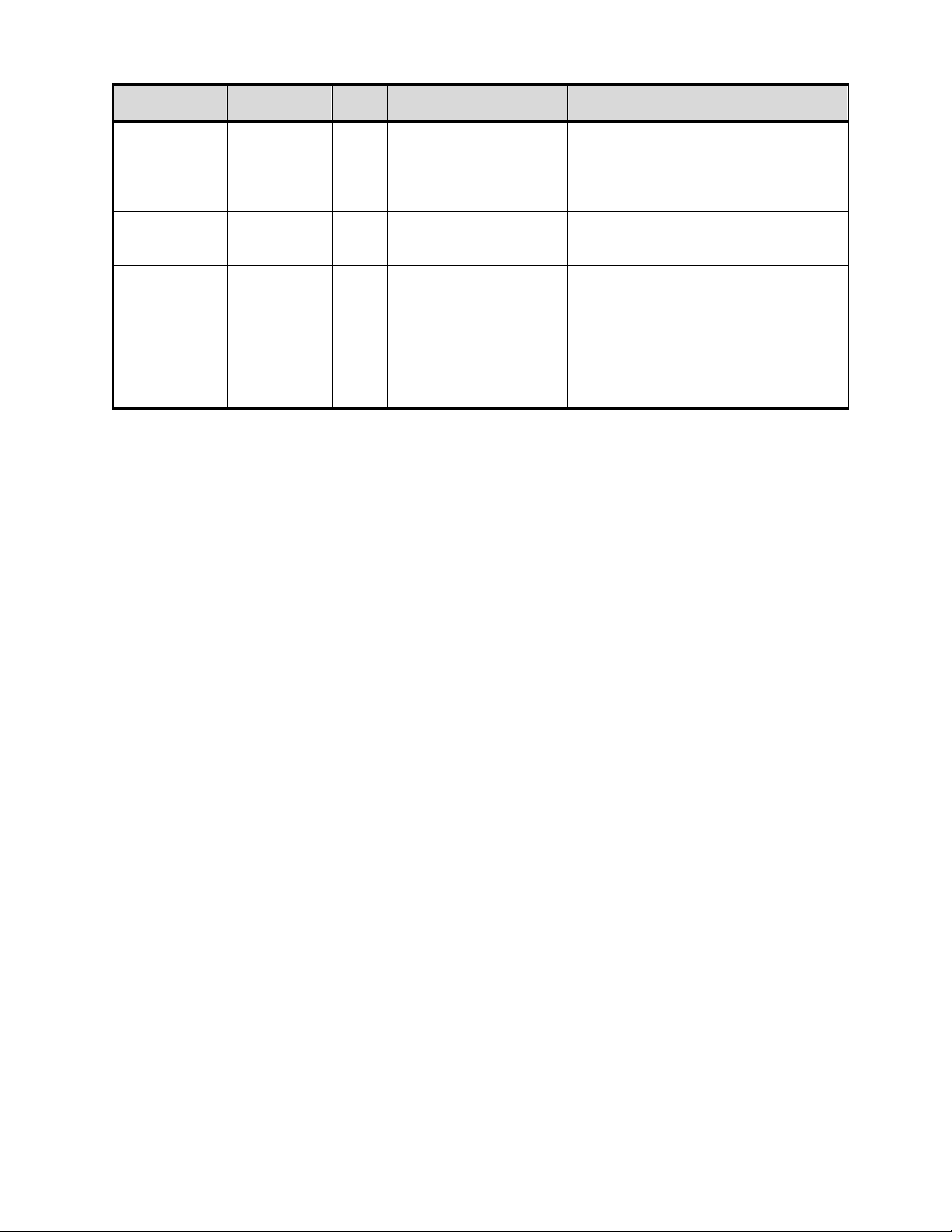

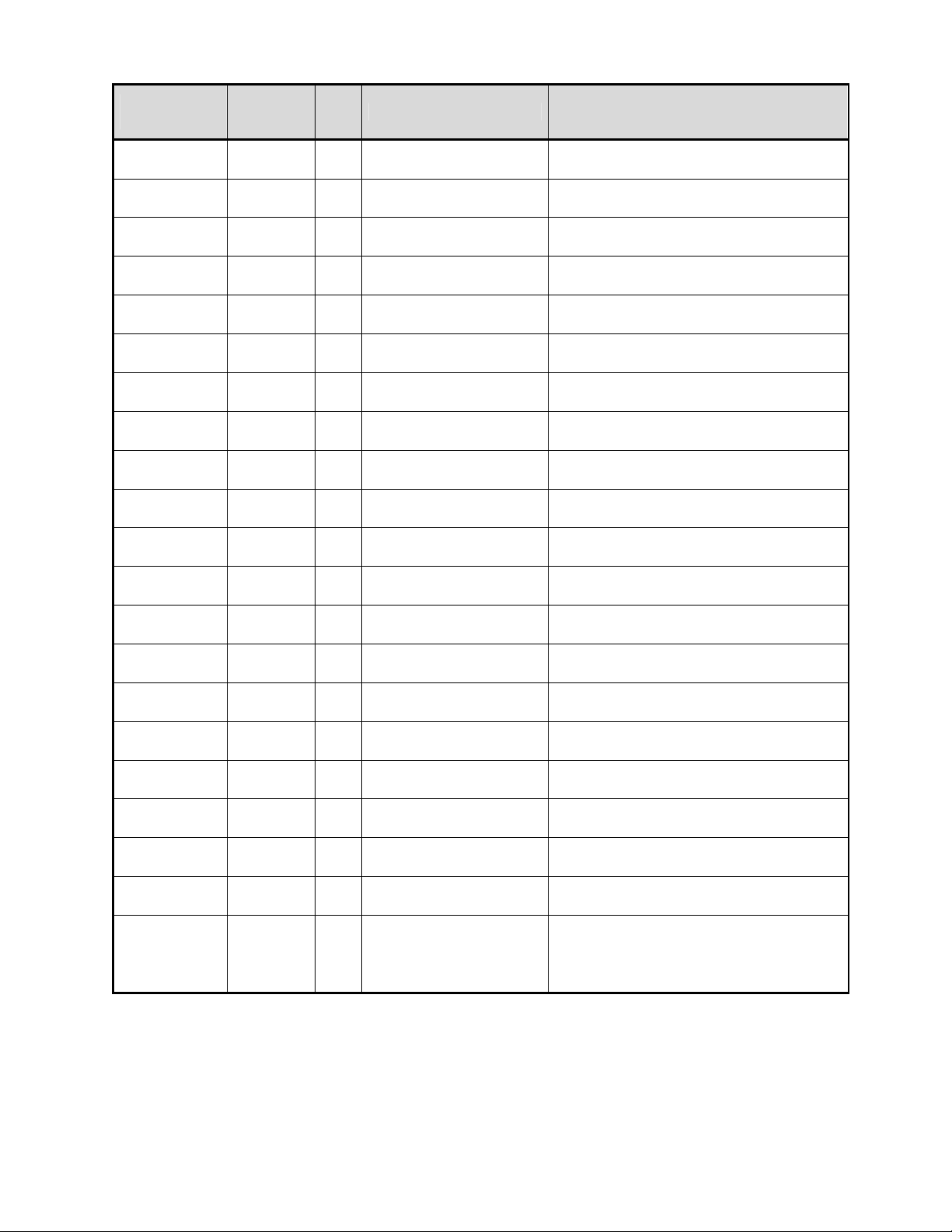

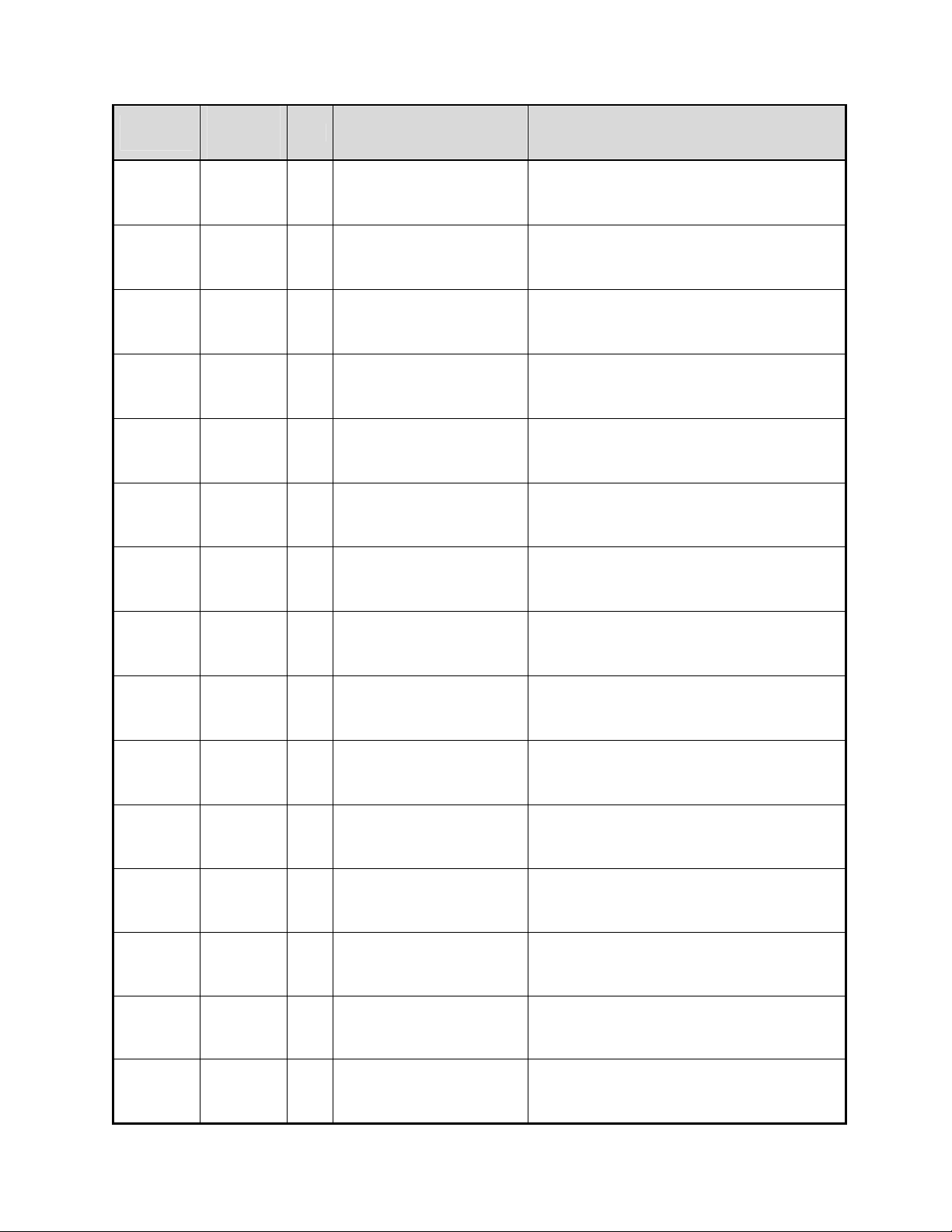

5.8.3 Analog input data

1) Reading instrument specification

Reference

number

30001 04 R

30002 04 R

30003 04 R

30009 04 R

30010 04 R

30011 04 R

30017 04 R Input points

30025 04 R Alarm output points

30026 04 R External drive

30027 04 R Communication type

30028 04 R Option information

2) Reading measurement data

Reference

number

30101 04 R CH1 data

30102 04 R

30103 04 R CH2 data

Application

Function code

Application

function code

R/W Contents Details

Instrument name

character 1,2

Instrument name

character 3,4

Instrument name

character 5,6

ROM version

character 1,2

ROM version

character 3,4

ROM version

character 5,6

R/W Contents Details

CH1 decimal point

status

R/W……R: READ,W: WRITE

ASCII“LE”(Fixed)

Error code: 01H, 02H, 03H, 12H

ASCII“51”or“52”

Error code: 01H, 02H, 03H, 12H

ASCII…1st digit: input, 2nd digit: output

1st digit…0:None, 1: 12 points,

2: 24 points, 3:36 points

2nd digit…0: None, 1: 12 points,

2: 24 points, 3: 36 points

Error code: 01H, 02H, 03H, 12H

ASCII 2 digits

Error code: 01H, 02H, 03H, 12H

ASCII 2 digits

Error code: 01H, 02H, 03H, 12H

ASCII 2 digits

Error code: 01H, 02H, 03H, 12H

0: None, 12, 24, 36

Error code: 01H, 02H, 03H, 12H

0: None, 12, 24, 36

Error code: 01H, 02H, 03H, 12H

0:Does not exist 1: Exists

Error code: 01H, 02H, 03H, 12H

0:None,1: RS-422A, RS-485, USB,

EtherNet

Error code: 01H, 02H, 03H, 12H

0:None,1:Calculation

Error code: 01H, 02H, 03H, 12H

R/W……R: READ,W: WRITE

DATA: -32765 to 32765

-32768: Binary expression exceeded

32767: + Exceeded range

-32767: - Exceeded range

32766: Burn out data

-32766: Invalid data

Error code: 01H, 02H, 03H, 12H

Data status, event status, decimal point

(described later)

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

-32-

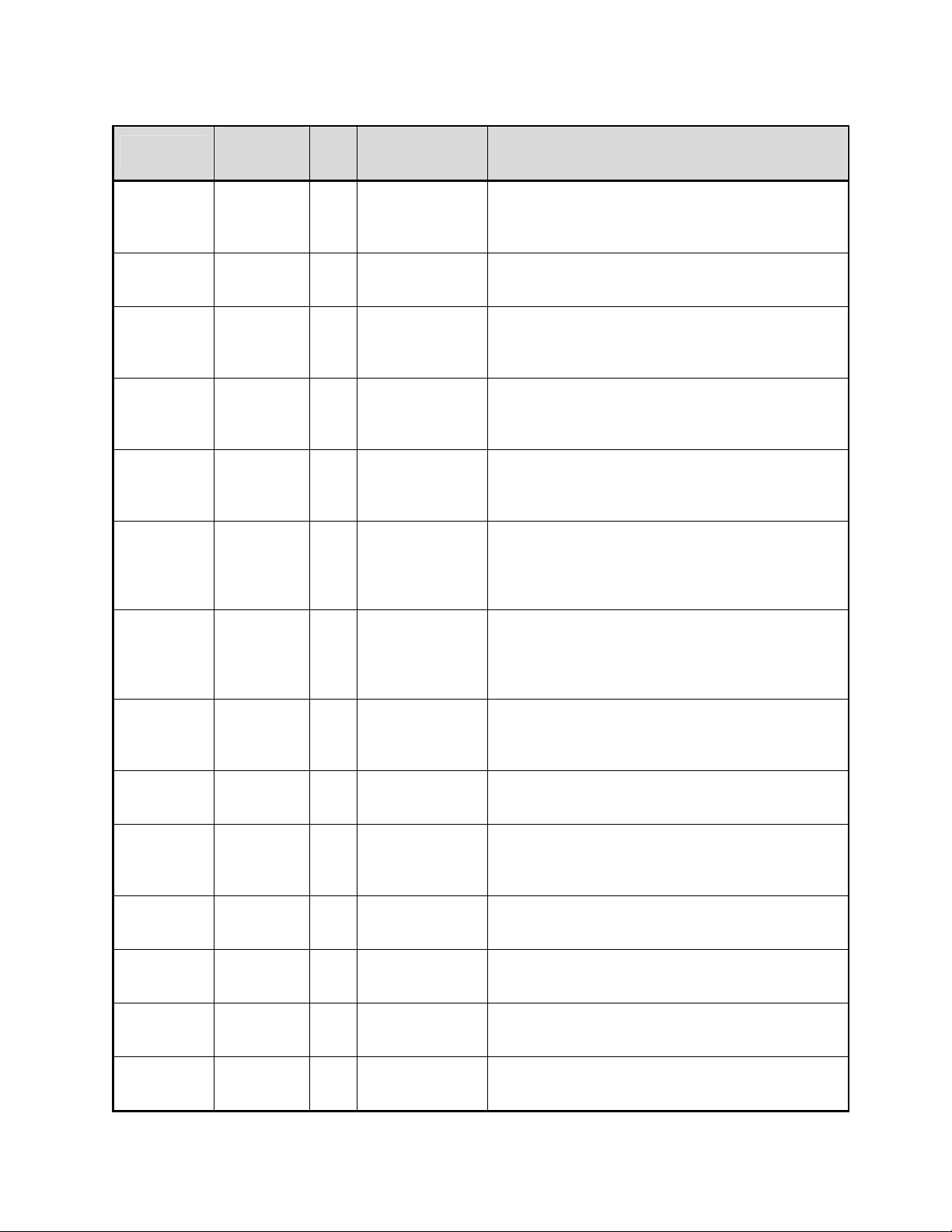

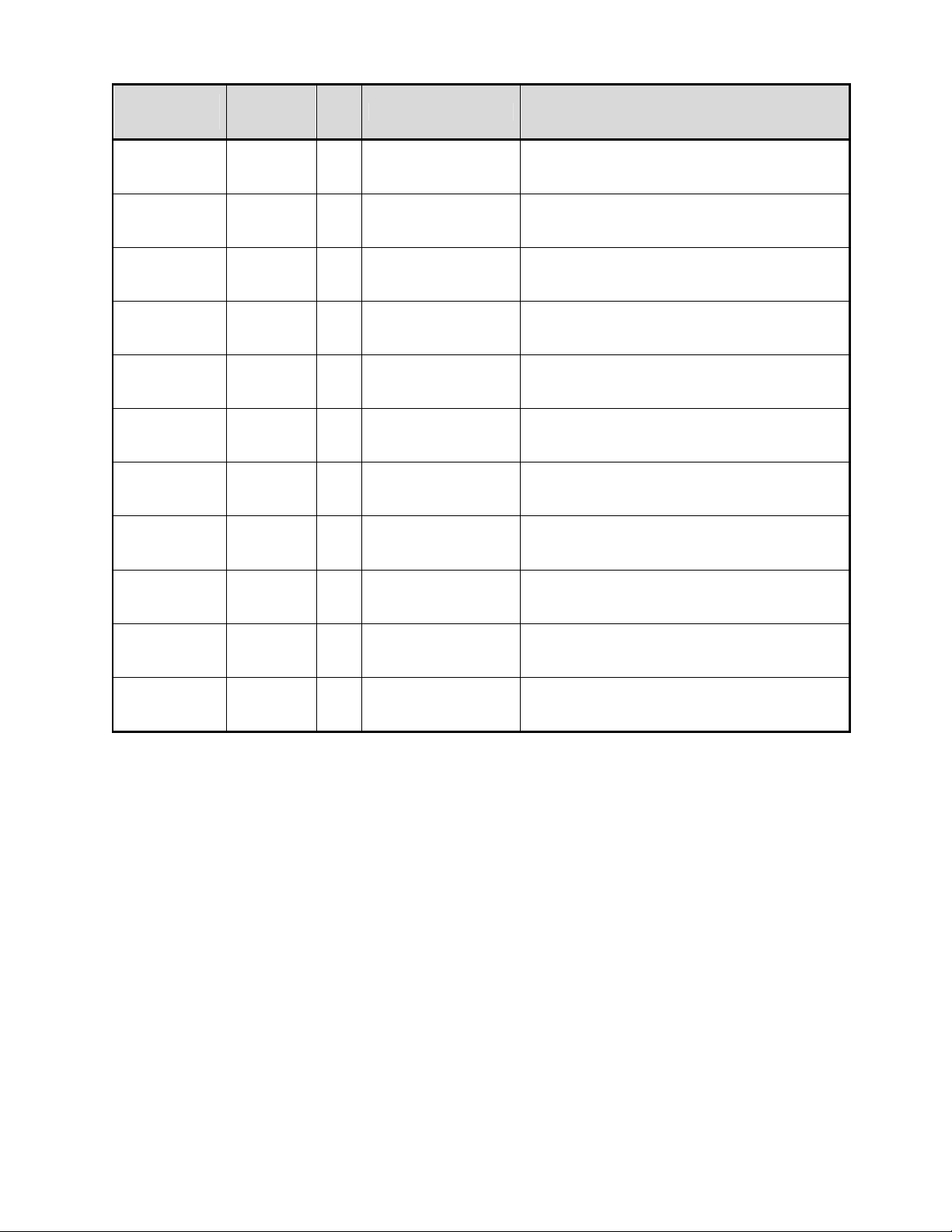

Page 38

Reference

Number

30104 04 R

30105 04 R CH3 data

30106 04 R

30107 04 R CH4 data

30108 04 R

30109 04 R CH5 data

30110 04 R

30111 04 R CH6 data

30112 04 R

30113 04 R CH7 data

30114 04 R

30115 04 R CH8 data

30116 04 R

30117 04 R CH9 data

30118 04 R

30119 04 R CH10 data

30120 04 R

30121 04 R CH11 data

30122 04 R

30123 04 R CH12 data

30124 04 R

30125 04 R CH13 data

30126 04 R

30127 04 R CH14 data

Application

function code

R/W Contents Details

CH2 decimal point

status

CH3 decimal point

status

CH4 decimal point

status

CH5 decimal point

status

CH6 decimal point

status

CH7 decimal point

status

CH8 decimal point

status

CH9 decimal point

status

CH10 decimal point

status

CH11 decimal point

status

CH12 decimal point

status

CH13 decimal point

status

R/W……R: READ,W: WRITE

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

-33-

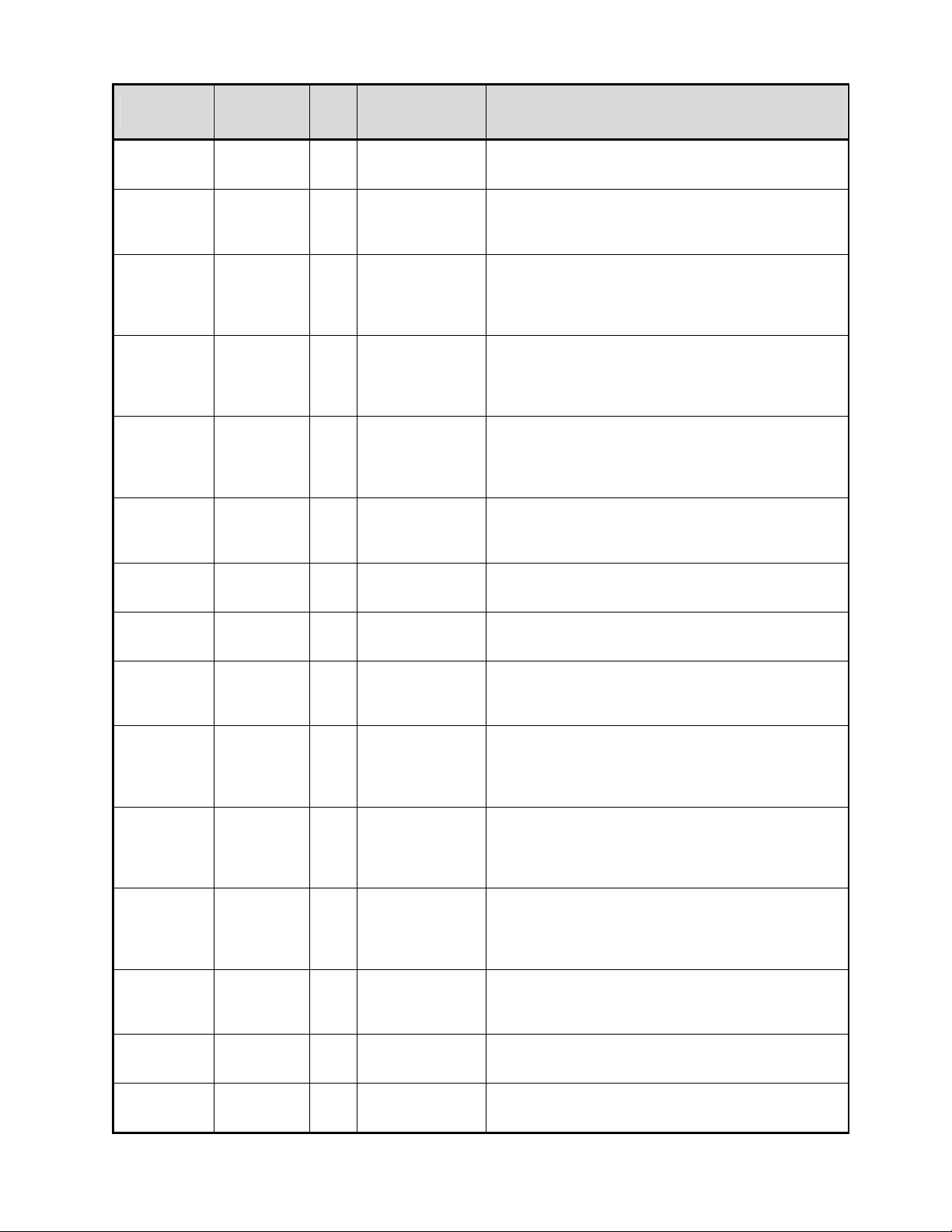

Page 39

Reference

Number

30128 04 R

30129 04 R CH15 data

30130 04 R

30131 04 R CH16 data

30132 04 R

30133 04 R CH17 data

30134 04 R

30135 04 R CH18 data

30136 04 R

30137 04 R CH19 data

30138 04 R

30139 04 R CH20 data

30140 04 R

30141 04 R CH21 data

30142 04 R

30143 04 R CH22 data

30144 04 R

30145 04 R CH23 data

30146 04 R

30147 04 R CH24 data

30148 04 R

30149 04 R CH25 data

30150 04 R

30151 04 R CH26 data

Application

function code

R/W Contents Details

CH14 decimal point

status

CH15 decimal point

status

CH16 decimal point

status

CH17 decimal point

status

CH18 decimal point

status

CH19 decimal point

status

CH20 decimal point

status

CH21 decimal point

status

CH22 decimal point

status

CH23 decimal point

status

CH24 decimal point

status

CH25 decimal point

status

R/W……R: READ,W: WRITE

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

-34-

Page 40

Reference

Number

30152 04 R

30153 04 R CH27 data

30154 04 R

30155 04 R CH28 data

30156 04 R

30157 04 R CH29 data

30158 04 R

30159 04 R CH30 data

30160 04 R

30161 04 R CH31 data

30162 04 R

30163 04 R CH32 data

30164 04 R

30165 04 R CH33 data

30166 04 R

30167 04 R CH34 data

30168 04 R

30169 04 R CH35 data

30170 04 R

30171 04 R CH36 data

30172 04 R

30173 04 R CH37 data

30174 04 R

30175 04 R CH38 data

Application

function code

R/W Contents Details

CH26 decimal point

status

CH27 decimal point

status

CH28 decimal point

status

CH29 decimal point

status

CH30 decimal point

status

CH31 decimal point

status

CH32 decimal point

status

CH33 decimal point

status

CH34 decimal point

status

CH35 decimal point

status

CH36 decimal point

status

CH37 decimal point

status

R/W……R: READ,W: WRITE

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1

Error code: 01H, 02H, 03H, 12H

Similar to CH1