Page 1

User’s Guide

http://www.omega.com

e-mail: info@omega.com

RD260 RECORDER

Technical Manual

Page 2

OMEGAne t®On-Line Service Internet e-mail

h t t p : / / w w w.omega.com i n f o @ o m e g a . c o m

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico and

Latin America: Tel: (001) 800-826-6342 FAX: (001) 203-359-7807

En Espan˜ol: (001) 203-359-7803 e-mail: espanol@omega.com

SM

SM

SM

Servicing Europe:

Benelux: Postbus 8034, 1180 LAAmstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: ul. Rude armady 1868, 733 01 Karvina-Hranice

Tel: 420 (69) 6311 8 9 9 FAX: 420 (69) 631111 4

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Cert i f i e d Northbank, Irlam, Manchester

M44 5EX, United Kingdom

Tel: +44 (0) 161 777-6611 FAX: +44 (0) 161 777-6622

Toll Free in United Kingdom: 0800-488-488

e-mail: info@omega.co.uk

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

a p p l y. OMEGA is constantly pursuing certification of its products to the European New Appro a c h

D i rectives. OMEGA will add the CE mark to every appropriate device upon cert i f i c a t i o n .

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

All Rights Reserved, Copyright © 1988

Notes

• The contents of this manual are subject to change without prior notice as a result of

improvements in the instrument’s performance and functions. Display contents

illustrated in this manual may differ slightly from what actually appears on your screen.

• Every effort has been made in the preparation of this manual to ensure the accuracy

of its contents. However, should you have any questions or find any errors, please

contact OMEGA Engineering.

i

Page 4

SAFETY PRECAUTIONS

This recorder is developed to satisfy and to be used under the following conditions:

• It is a component type instrument to be installed on an instrumentation panel or

rack.

• It complies with the IEC class II safety standard.

• It complies with the EN61010-1 safety standard.

• It complies with the CSA1010-1 safety standard.

• It is based on EN55011 (EMI) Group 1, Class A (for commercial and industrial use).

• It complies with the EN50082-2 (EMS) safety standard.

General definitions of safety symbols used on the recorder and in this manual:

Make sure to comply with the following safety precautions. Not complying might result in

injury, death of personnel, or cause damage to the instrument. We assume no liability for

customer’s failure to comply with these requirements.

Where this mark is found on the In-position of bistable push control

recorder there is danger of injury

or death.

Please check the manual carefully

Power ON Alternating current

Out-position of bistable push control

Power OFF Functional earth terminal (This

terminal should not be used as a

Equipment protected throughout by “Protective earth terminal”.)

double insulation or reinforced insulation

(Class II)

WARNING

Power Supply

Ensure the source voltage matches the voltage of the power supply before turning

ON the power.

Grounding

Make sure to ground the recorder before turning on the power.

Necessity of Grounding

Grounding is necessary to prevent noise interference.

Do not Operate in an Explosive Atmosphere

Do not operate the recorder in the presence of flammable liquids or vapors.

Operation of any electrical instrument in such an environment constitutes a safety

hazard.

Keep Away from Live Circuits

Inside this recorder there are areas of high voltage; therefore, never touch the

interior when the power supply is connected. The recorder has replacable parts

and subassemblies; however, the replacement must be carried out only by our

service personnel.

External Connection

Before connecting to measurement and control unit, connect the grounding wire.

ii

Page 5

Using the Technical Manual

This manual contains information about the instrument’s functions and operating

procedures as well as precautions that should be observed during use. To ensure

proper use of the instrument, please read this manual thoroughly before operating it.

Keep the manual in a safe place for quick reference whenever a question arises.

Two manuals are provided with the instrument, including this Technical Manual.

Manual Name Description

User’s Manual Basic information for recorder operators.

Technical Manual Detailed technical manual for recorder engineers,

Structure of this Manual

This Manual is intended for technicians in charge with installing, and wiring, and with the

making of the recorder settings.

The additional User’s Manual is intended for simple daily operation of the recorder.

including mounting, wiring and setting

information.

Read this manual first.

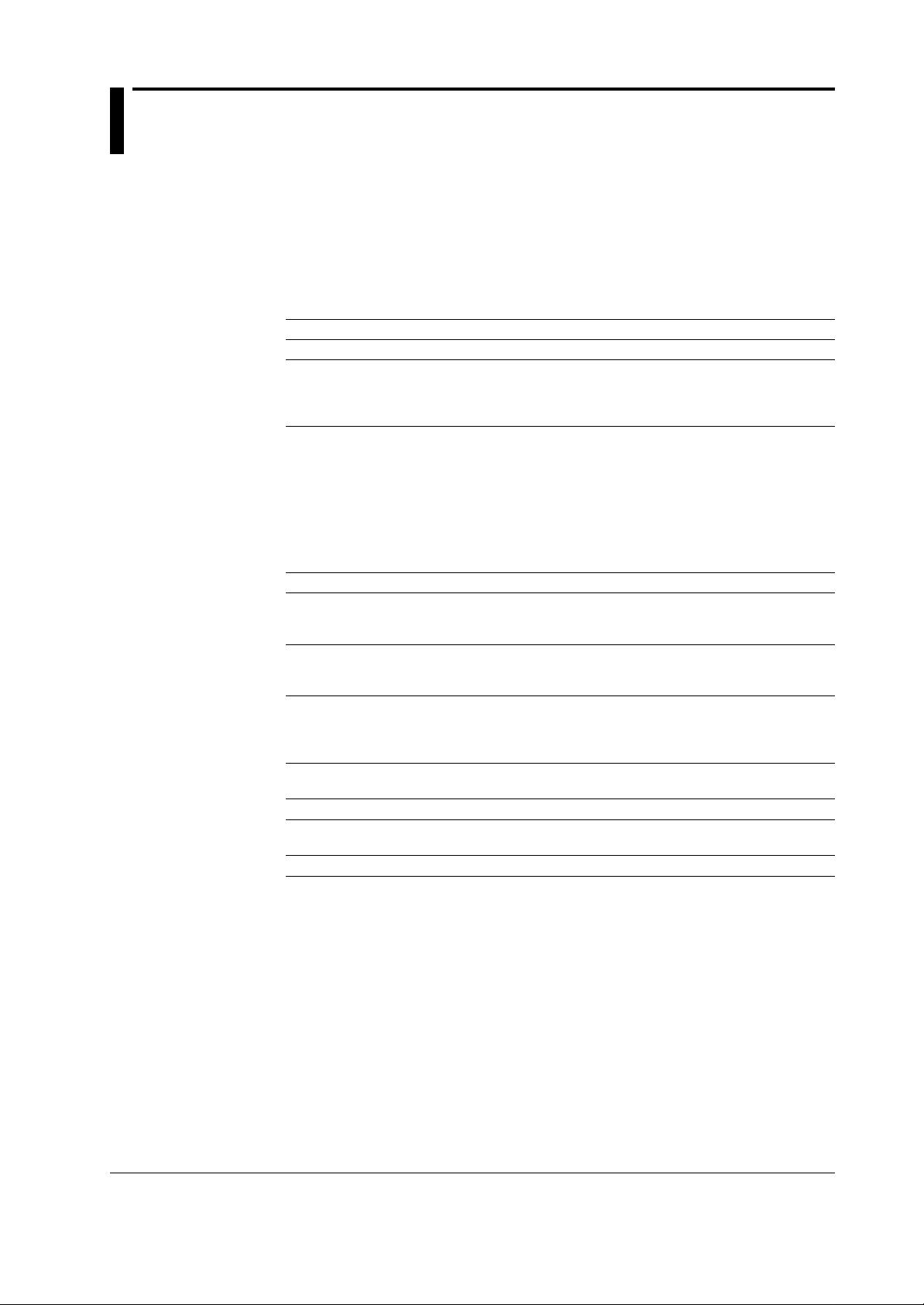

Chapter Title Content

1 Preparation Read this before unpacking the recorder. List of accesories

2 Regular Settings Explains the Regular Setting mode mode, in which daily-

3 Basic (SETUP) Settings Explains the Basic (SETUP) Setting Mode, for the

4 Calibration and Explains how to calibrate the recorder and how to

Adjustment adjust pen, dot and ribbon posiions.

5 Periodic Inspection About periodic maintenance and cleaning of the recorder.

6 Troubleshooting Explains the meaning of error messages on recorder

Index

and explanation of the basic functions and display. Also

describes the mounting and wiring required before use.

used settings such as input range, recording span, alarm

setpoints, and chart feed speed are made.

adjustment of a whole range of detailed settings such as

the pen’s position, dot printing postion and color, the noise

input filter, a remote trigger settings.

display and a troubleshooting check list.

iii

Page 6

Using the Technical Manual

Conventions Used in this Manual

Displayed characters

Bold alphanumeric characters enclosed with [ ] refer to characters or setting values that

are displayed on the screen.

Symbols

The following symbol marks are used to attract the operator’s attention.

Affixed to the instrument. Indicates danger to personnel or

instrument and the operator must refer to the User’s Manual.

ThinUser’s Manual to indicate the reference.

WARNING

CAUTION

Note

Describes precautions that should be observed to prevent injury or

death to the user.

Describes precautions that should be observed to prevent minor or

moderate injury, or damage to the instrument.

Provides important information for the proper operation of the

instrument.

iv

Page 7

1

2

3

4

5

6

Index

Contents

SAFETY PRECAUTIONS ................................................................................................................ ii

Using the Technical Manual ......................................................................................................... iii

Chapter 1 Preparation........................................................................................................................... 1-1

1.1 Checking Accessories and Appearance ............................................................................... 1-1

1.2 Removing Packings.............................................................................................................. 1-2

1.3 Checking Model Codes ........................................................................................................1-3

1.4 Front/Rear Panels: Functions and Display ........................................................................... 1-4

1.5 Handling Precautions ...........................................................................................................1-6

1.6 Mounting............................................................................................................................... 1-7

1.7 Wiring .................................................................................................................................1-10

Chapter 2 Regular Settings .................................................................................................................. 2-1

2.1 Introduction to Regular Settings ........................................................................................... 2-1

2.2 Setting Input Range and Recording Span ............................................................................ 2-3

2.3 Setting Alarm Functions........................................................................................................ 2-8

2.4 Adjusting the Chart Speed..................................................................................................2-10

2.5 Setting the Dot Printing Interval (Dot Model) ...................................................................... 2-11

2.6 Setting the Key-Lock ..........................................................................................................2-12

Chapter 3 Basic (SETUP) Settings ...................................................................................................... 3-1

3.1 Introduction to Basic (SETUP) Settings................................................................................3-1

3.2 Setting Relay for post-Alarm (de-)Energizing ....................................................................... 3-4

3.3 Setting Alarm Hysteresis ...................................................................................................... 3-5

3.4 Selecting A/D Integration Time (Pen Model).........................................................................3-6

3.5 TC Burnout Registration Method ..........................................................................................3-7

3.6 Setting the Noise Input Filter (Pen Model)............................................................................3-8

3.7 Setting Moving Average Calculation (Dot Model) ................................................................. 3-9

3.8 Offset Values ......................................................................................................................3-10

3.9 Assigning Channel Printing Colors (Dot Model) ................................................................. 3-12

3.10 Selecting Celsius or Fahrenheit..........................................................................................3-13

3.11 Remote Trigger for Recording or Chart Speed................................................................... 3-14

Chapter 4 Calibration and Adjustment................................................................................................ 4-1

3.12 Protecting Settings .............................................................................................................3-15

3.13 Initializing Settings..............................................................................................................3-16

4.1 Calibration ............................................................................................................................4-1

4.2 Re-adjusting the Pen-Position (Pen Model) ........................................................................4-3

4.3 Re-adjusting the Dot-Position (Dot Model) .......................................................................... 4-5

Chapter 5 Periodic Inspection ............................................................................................................. 5-1

5.1 Periodic Inspection ............................................................................................................... 5-1

Chapter 6 Troubleshooting .................................................................................................................. 6-1

6.1 Error Messages .................................................................................................................... 6-1

6.2 Troubleshooting.................................................................................................................... 6-2

Index ................................................................................................................................ Index-1

v

Page 8

1

Chapter 1 Preparation

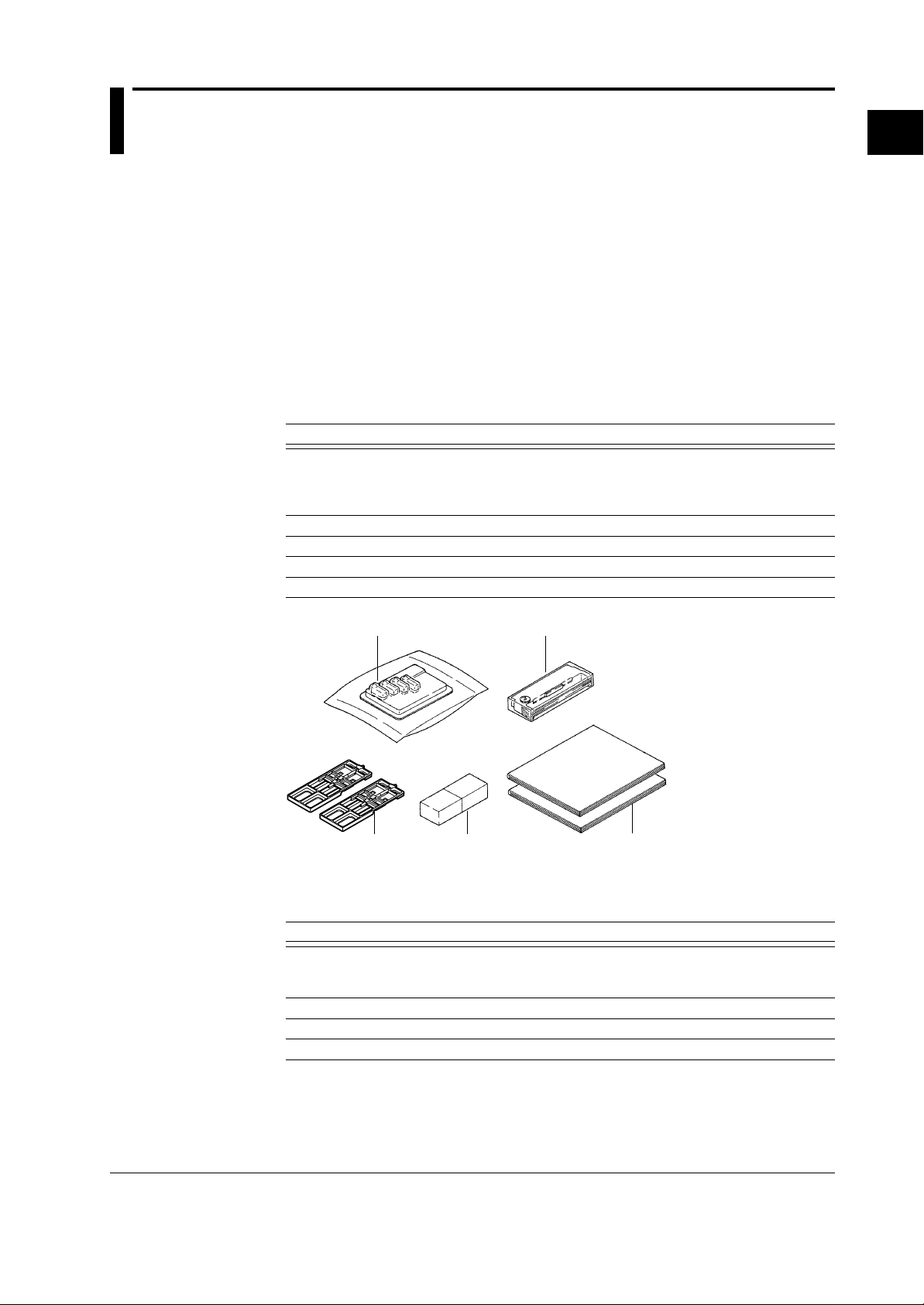

1.1 Checking Accessories and Appearance

Checking and Unpacking

This recorder has been thoroughly inspected before shipment; however, when you

receive the recorder, check that all accessories are present and in the correct quantities.

Also check the external appearance of the recorder to ascertain that no damage has

occurred.

Checking Accessories and Appearance

The recorder should be accompanied by the accessories indicated below. Check that all

are present in the correct quantities. Also check the external appearance of the recorder

to ascertain that no damage has occurred.

Accessories

No. Name Quantity Remarks

1 Disposable felt pen Only for pen models

1-pen model 1 Red

2-pen model 2 Red, green

3-pen model 3 Red, green, blue

2 Ribbon cassette 1 Only for dot model

3 Mounting brackets 2

4 Z-folded chart paper 1 Approx. 16 meter

5 Instruction manuals 2 1 User’s Manual & 1 Technical Manual

Preparation

1

34

Spare Parts

Name Part No. Quantity* Remarks

Disposable felt pen (red) RD260-01 3 Only for pen models

Disposable felt pen (green RD260-02 3 Only for pen models

Disposable felt pen (blue) RD260-03 3 Only for pen models

Ribon cassette RD260-RC 1 Only for dot model

Mounting brackets B9962CG 2

Z-folded chart paper RD260ZFP 10 Approx. 16 meter

*The amount of items per ordered Part No.

2

5

1-1

Page 9

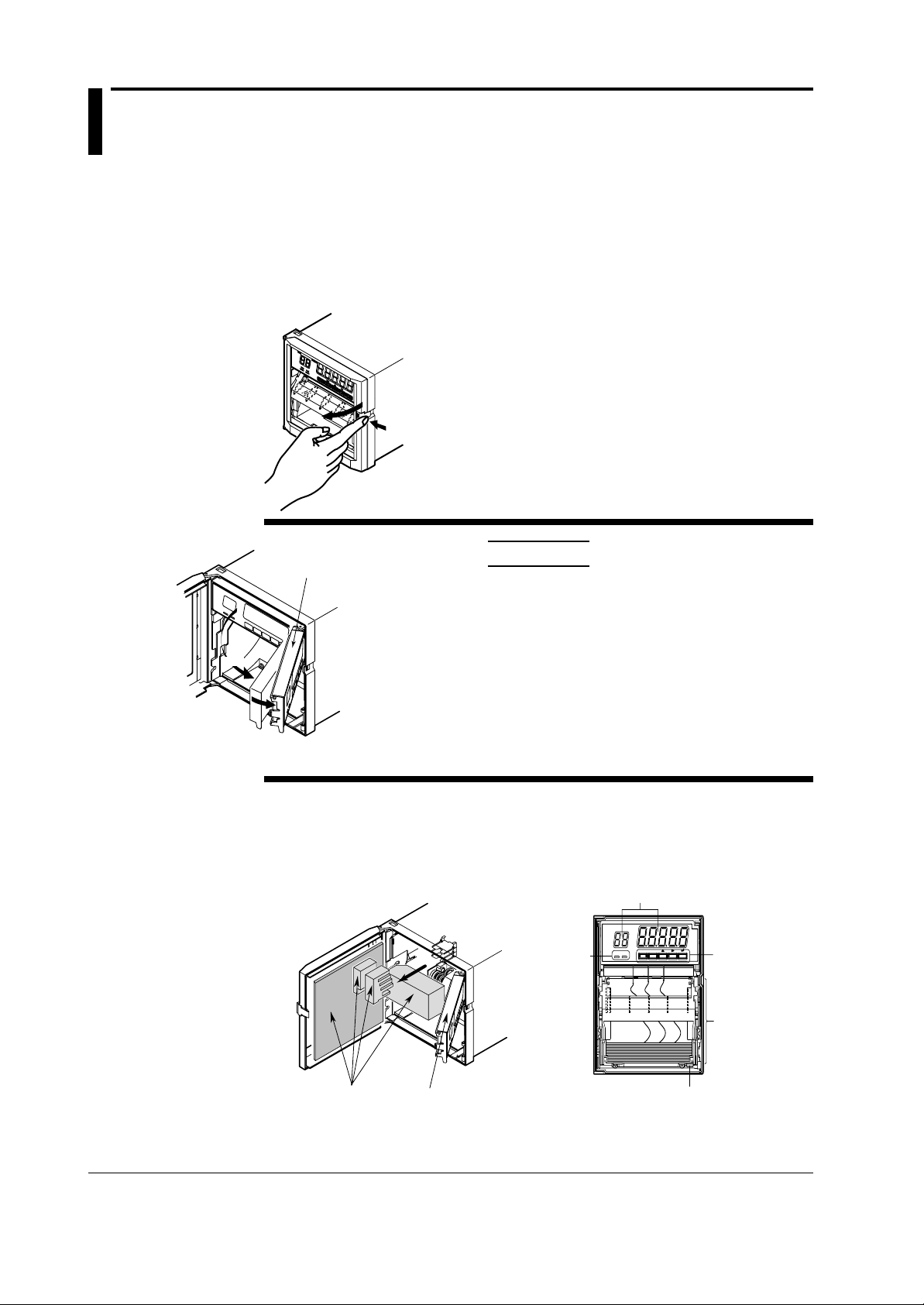

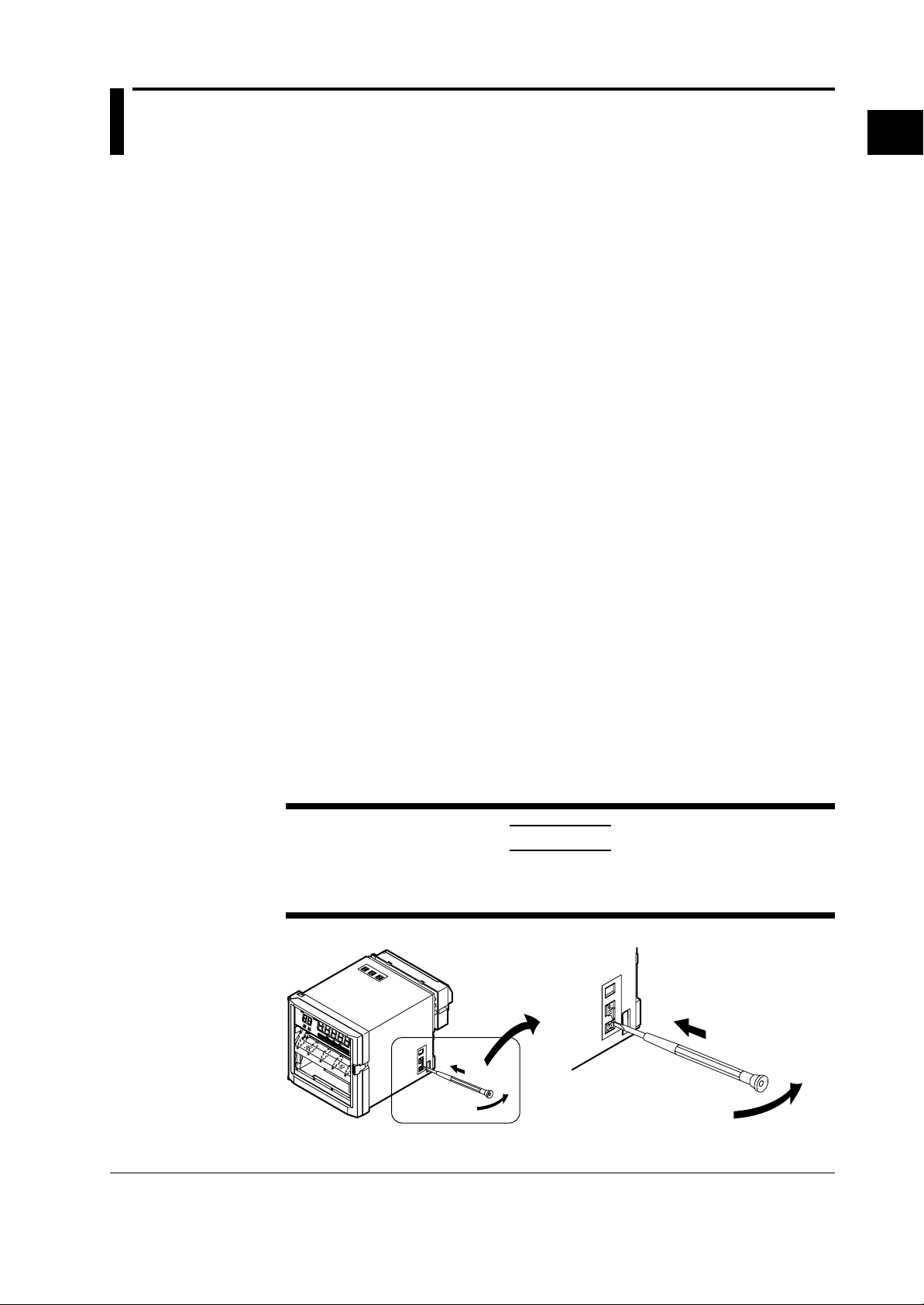

1.2 Removing Packings

The internal assembly is secured in position by packings to safeguard against damages

during transit. Before you unpack the recorder please read the following.

Opening the front door

Open the front door by pushing and then puling the clip on the right, as shown below,

and open the display by pulling its left end after removing the adhesive tape.

Do not push the display bar

further after you feel a click.

CAUTION

• Please take care not to apply any undue pressure in an

upward or downward direction to the display.

This might cause a strain on the hinges.

100°

• When you open the display further than about

100 degrees you will feel a clicking resistance which

marks the largest possible opening for the display. Do

not try to open the display further than upto that point

as it may break.

Removing Protective Lock Screw and Packings

Pen model Dot model

Packing material

Display

4 Status display

CH DATA

RCD ALM

5 Display

ESC

RCD CH UPFEEDMENU

2 Key panel

3 Chart cassette

1 Power switch

1-2

Page 10

1

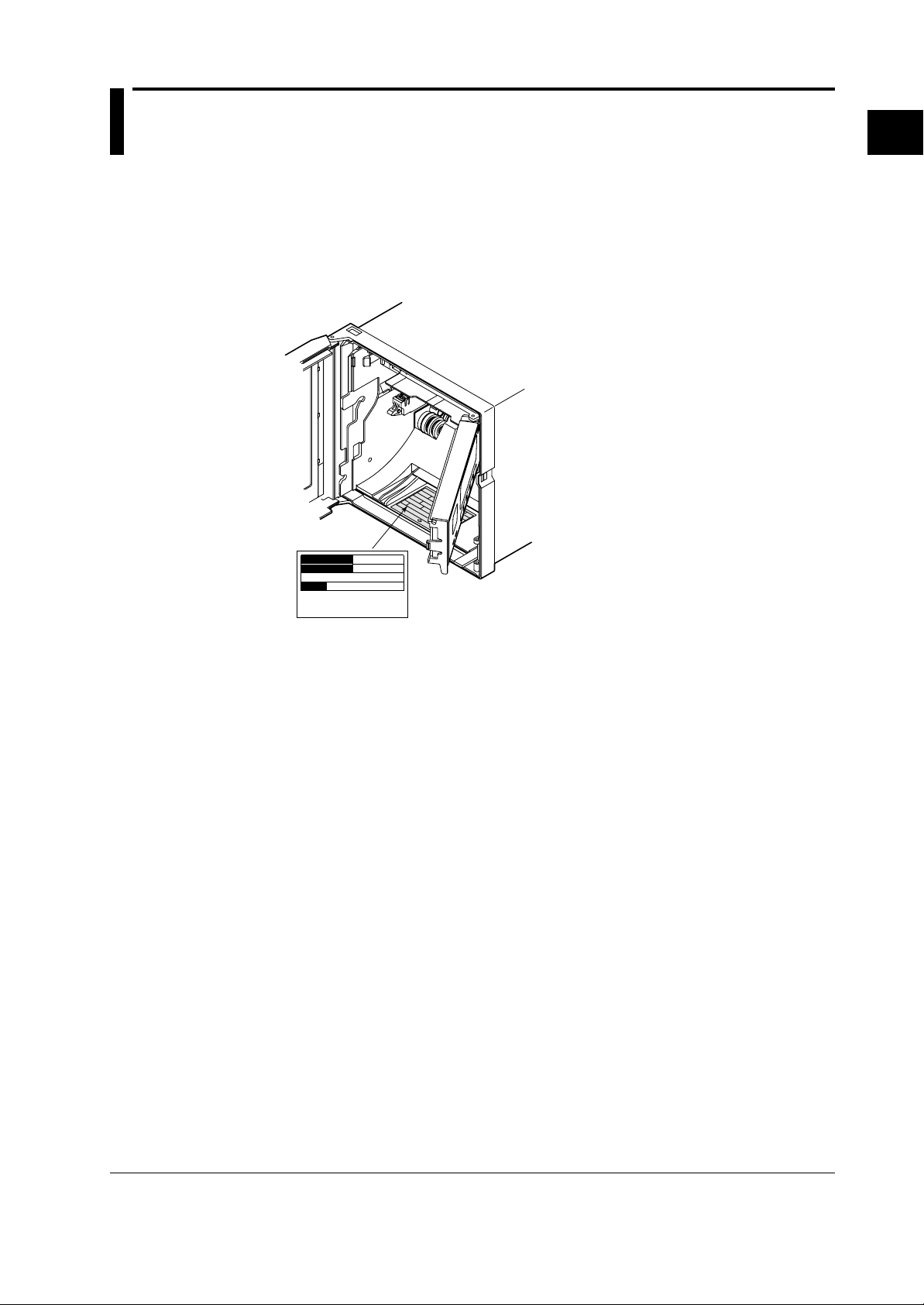

1.3 Checking Model Codes

MODEL

SUFFIX

NO.

Check the model codes on the nameplate to make sure they are as specified by your

order.

The nameplate is visible after you removed the chart cassette and is as shown in the

figure below. When you contact Omega, inform the model code (MODEL) and the serial

number (No.).

MODEL

SUFFIX

NO.

OMEGA

Made in Japan

Nameplate

Preparation

1-3

Page 11

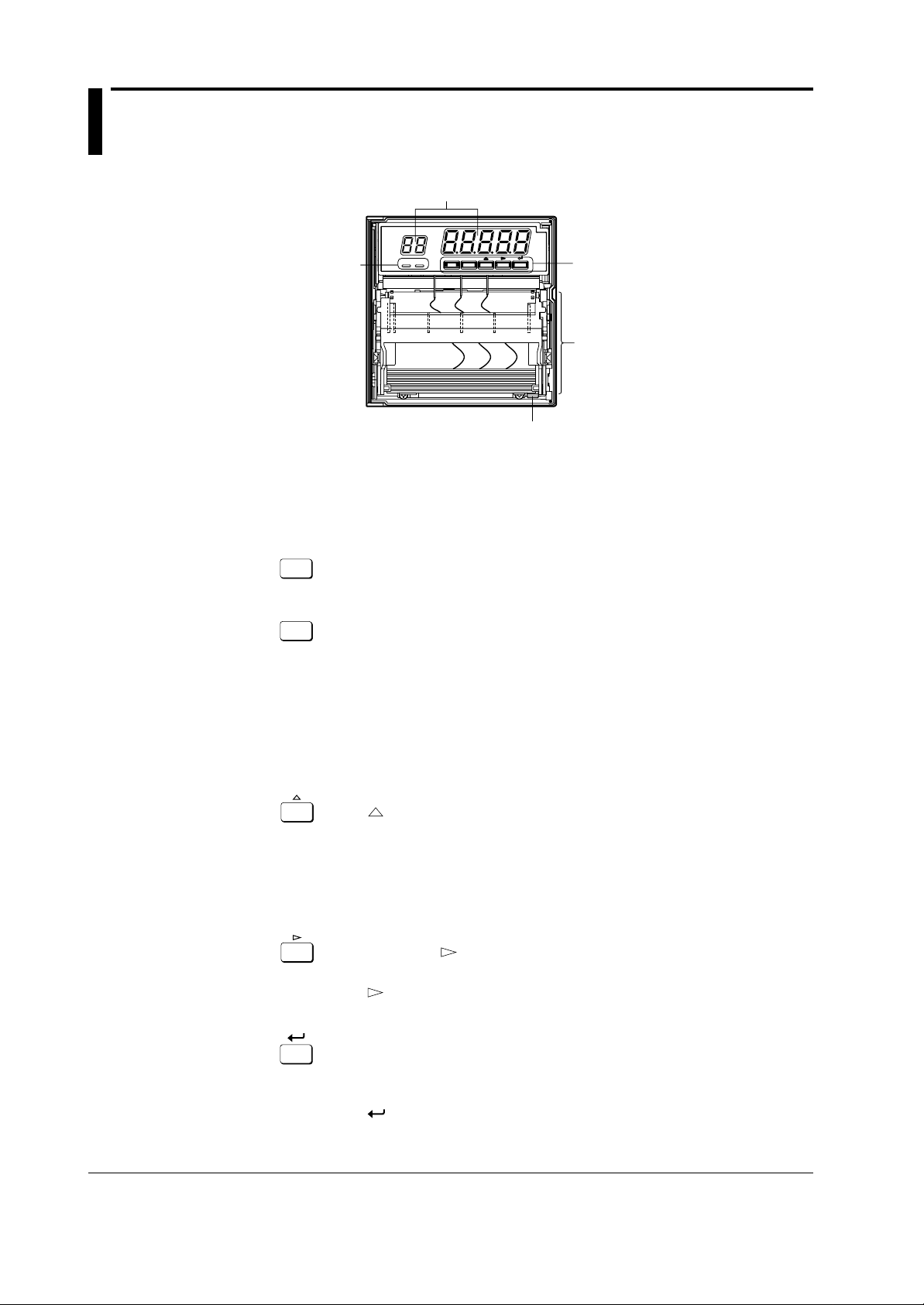

1.4 Front/Rear Panels: Functions and Display

Front Panel

5 Display

CH DATA

RCD CH UPFEEDMENU

ESC

2 Key panel

3 Chart cassette

1 Power switch

4 Status display

RCD ALM

1.Power switch (push-button type)

Pressing the switch turns the power ON and OFF.

2.Key panel (push-key type)

The panel contains the follwing five keys:

RCD

ESC

DISP

FEED

RCD key

Pressing the key starts or stops the recording.

DISP key, ESC key

DISP function: Cycles through the modes of display in the order of

AUTO, MANUAL, and OFF. Also selects between the Regular Setting

mode and Operation mode (see Section 2.1).

If this key is pressed for three seconds, the recorder enters the Regular

Setting Mode.

ESC function: Exits from the menu in the middle of setting or selecting

procedures.

key

Selects setting parameters (numerics or command codes). Selecting

step is upward circulation.

If the recorder is a pen model, pressing this key for three seconds in

operation mode causes the recorder to enter the pen-replacement

mode.

FEED key, key

FEED function: The chart is fed as long as this key is being pressed.

key function: Changes the number of digits for setting numeric

values. The digit moves from high to low.

1-4

CH UP

CH UP key , ENT key

CH UP function: Selects a channel for which the display shows the

screen in the MANUAL display mode.

function: Makes a parameter entry or executes a function after

selecting parameters (numerals or command codes). Pressing the key

executes the settings.

Page 12

1

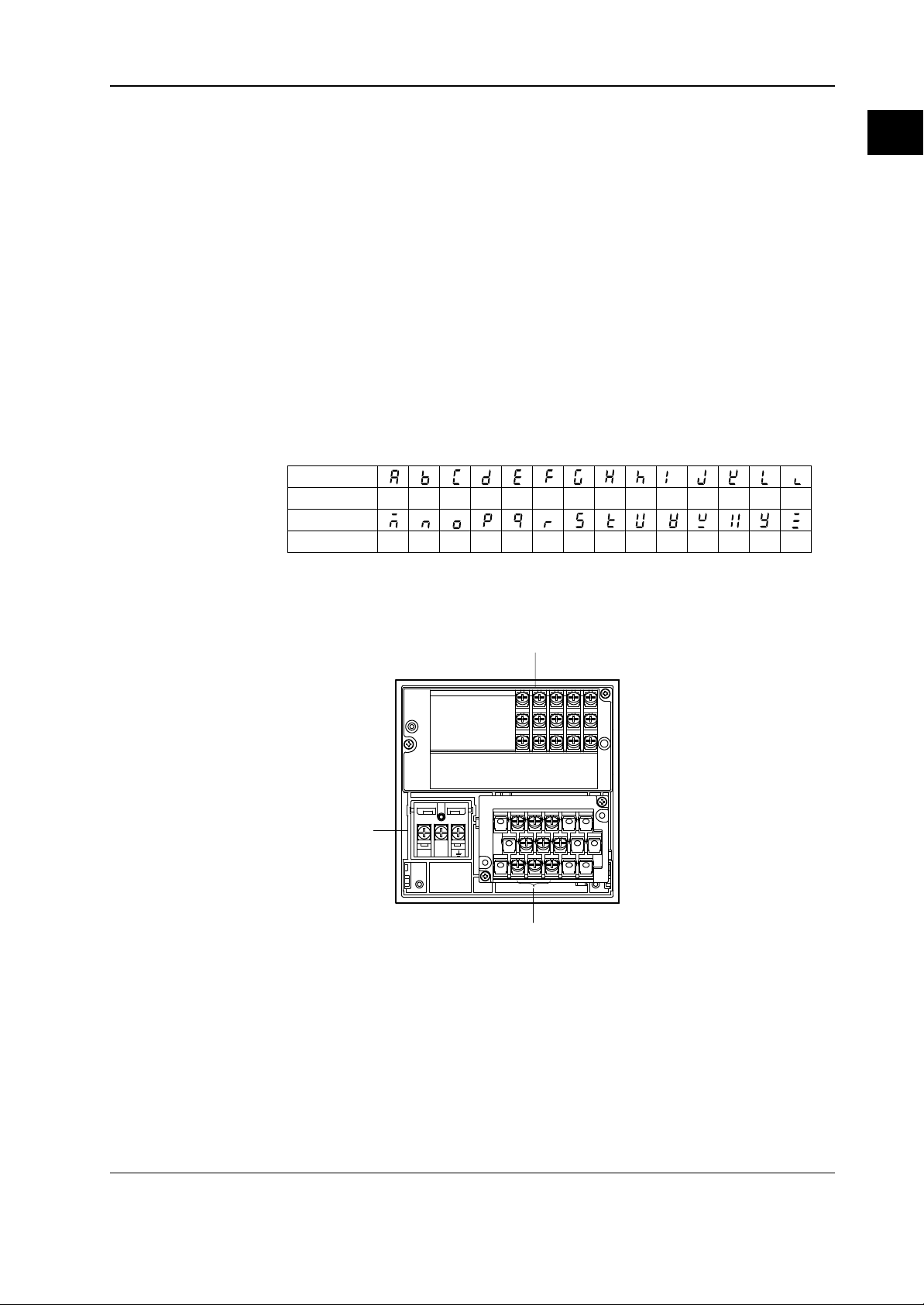

Characters on Display

The display consists of seven segments, and therefore characters exist which are

difficult to display.

Characters are presented on the display as shown in the following table.

Front/Rear Panels: Functions and Display

3.Chart cassette

Contains a Z-fold chart (width: 100 mm, length: 16 m).

4.Status Display

RCD indicator: Illuminated when recording of measurement values is in progress.

ALM indicator:Will illuminate when an alarm occurs.

5.Seven-segment character display

Used to display data, setting screen, etc.

• Data display: Displays channel No., type of alarms, and measured data.

• Setting screen: Displays various settings of the recorder.

Display

Alphabet

Display

Alphabet

A

BCDEFGHhI JKLl

MN OP QR S TUVWXY Z

Preparation

Rear Panel

Below, the rear panel of the dot model reorder, for more details and the rear of the pen

model recorder see Section 1.7,

Power terminal

L

N

Wiring

.

Optional terminals

Input terminals

1-5

Page 13

1.5 Handling Precautions

Safety precautions

• Before you use this recorder make sure to read the Safety Precautions on page 2 of

this manual.

• Do not touch the interior of this recorder. For the replacement of parts, please

contact OMEGA Engineering.

• Turn the recorder power switch off as soon as any symptoms of malfunction such as

unusual sound, smell, or smoke yield from the recorder. Also turn the main power

switch off. If a malfunction occurs, contact OMEGA Engineering.

General handling precautions

• The recorder contains many plastic parts. To clean, use a soft, dry cloth. Do not

use chemicals such as benzene or thinner, since these may cause discoloration or

damage.

• Do not bring any objects charged with static electricity near the signal terminals.

This might cause malfunction.

• Do not allow any volatile substances to the front or key panel. Do not allow rubber

or vinyl to remain in contact with the recorder for long periods.

• Whenever the recorder is not used, turn the power switch OFF.

1-6

Page 14

1

1.6 Mounting

Before mounting the recorder make sure to read this chapter carefully.

Installation Site

Panel and rack mounting

• The recorder is designed to be installed on an instrumentation panel or rack.

Well ventilated location

• Install the recorder in a well ventilated site to prevent internal overheating.

Avoid mechanical vibration

• To install the recorder in a location susceptible to mechanical vibration will adversely

Horizontal installation

• The recorder must be installed horizontally from left to right. Backward or forward

Avoid direct sunshine or heater radiation.

• The recorder will be adversely affected if the unit is exposed to direct sunlight or

Keep out of soot, steam, moisture, dust, corrosive gases

• The recorder will be damaged if exposed to soot, steam, moisture, dust, corrosive

Avoid electro-magnetic fields

• To use the recorder within strong electro-magnetic fields may cause malfunction.

Preparation

affect the mechanical parts and the quality of recording. Please choose an installation site with minimal mechanical vibration.

mounting may slant 0˚ to 30˚.

installed near a heater. Choose a location near room temperature (23˚C) with

minimal temperature fluctuation.

gases, etc.,

Please avoid installing near electro-magnetic objects.

Mounting Methods

1 The recorder has three small square windows lined on the right, left, bottom and top

of the recorder to apply mouting brackets. Remove the plastic inside frames of the

square windows ,as shown in the below illustration, by flipping them out with a

small screwdriver. Don’t let the frames fall inside.

CAUTION

• Take care not to damage the interior of the recorder when flipping the plastic

frames out of the windows. Don’t insert the driver too far.

2 Insert the recorder into the panel-front face (continued on next page).

1-7

Page 15

Mounting

3 Mount the recorder on a steel panel which thickness is at least 2 mm (and up to 26

mm).

Fix the recorder to the panel using the mounting brackets as shown in below.

Adequate screw tightening torque is approximately 3 to x kg-cm. A pair of mounting

brackets can be applied to the recorder’s top and bottom, or to both side faces.

CAUTION

• A tightening torque exceeding the above-mentioned adequate values may cause

deformation of the recorder case or brackets.

Mounting bracket

1-8

Page 16

1

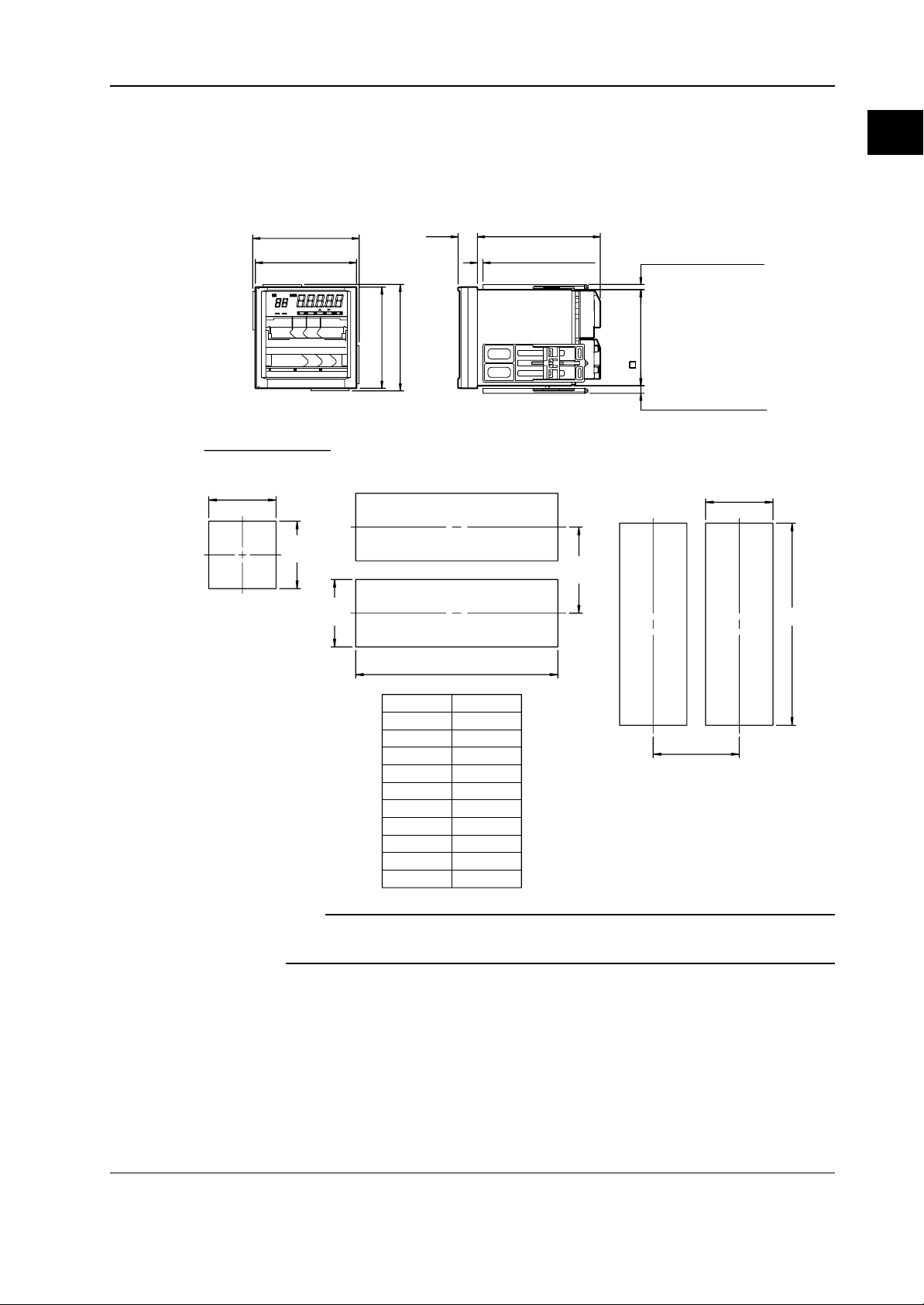

External Dimensions

Panel Cutout and External Dimensions (including Mounting Brackets).

Unit : mm (approx. inch)

If not specified, the tolerance is ± 3%. When less than 10 mm, however, tolerance is ± 3 mm.

151.5 (5.96)

144 (5.67)

Panel Cutout & Spacing

Single-Unit Mounting

+2

137

0

(5.39)

27.5

144 (5.67)

(1.08)

151.5 (5.96)

175

2 to 26 (panel thickness)

Side-by-Side Mounting (horizontally)

(6.89)

Mounting

(min. space for mounting )

(0.3)

0

+0.2

(5.37)

136.5

(dimension after mounting )

11 7.5

(0.43)

Side-by-Side Mounting (vertically, max. 3 units)

+2

137

0

(5.39)

Preparation

+2

137

0

(5.39)

137

(5.39)

+2

0

+2

L

0

+2

(mm)

Units

L

0

175 MIN

(6.89)

2 282

3 426

4 570

5 714

175 MIN

(6.89)

6 858

7 1002

8 1146

9 1290

10 1434

n

(144xn)-6

Note

• A pair of mounting brackets should be used on the top and bottom, or on both sides of the

recorder.

+2

L

0

1-9

Page 17

1.7 Wiring

Wiring should be done only after you have read this section. The section consists of the

following subsections:

page:

1-10 Rear Panel Terminal Arrangement

1-11 Power Supply Wiring

1-12 Input Signal Wiring

1-14 Alarm Output Wiring

1-15 Remote Control Wiring

• Make sure to fasten the wiring at the rear wall of the mounting panel and

employ some kind of strain relief between the rear wall and the recorder to

prevent an electric shock.

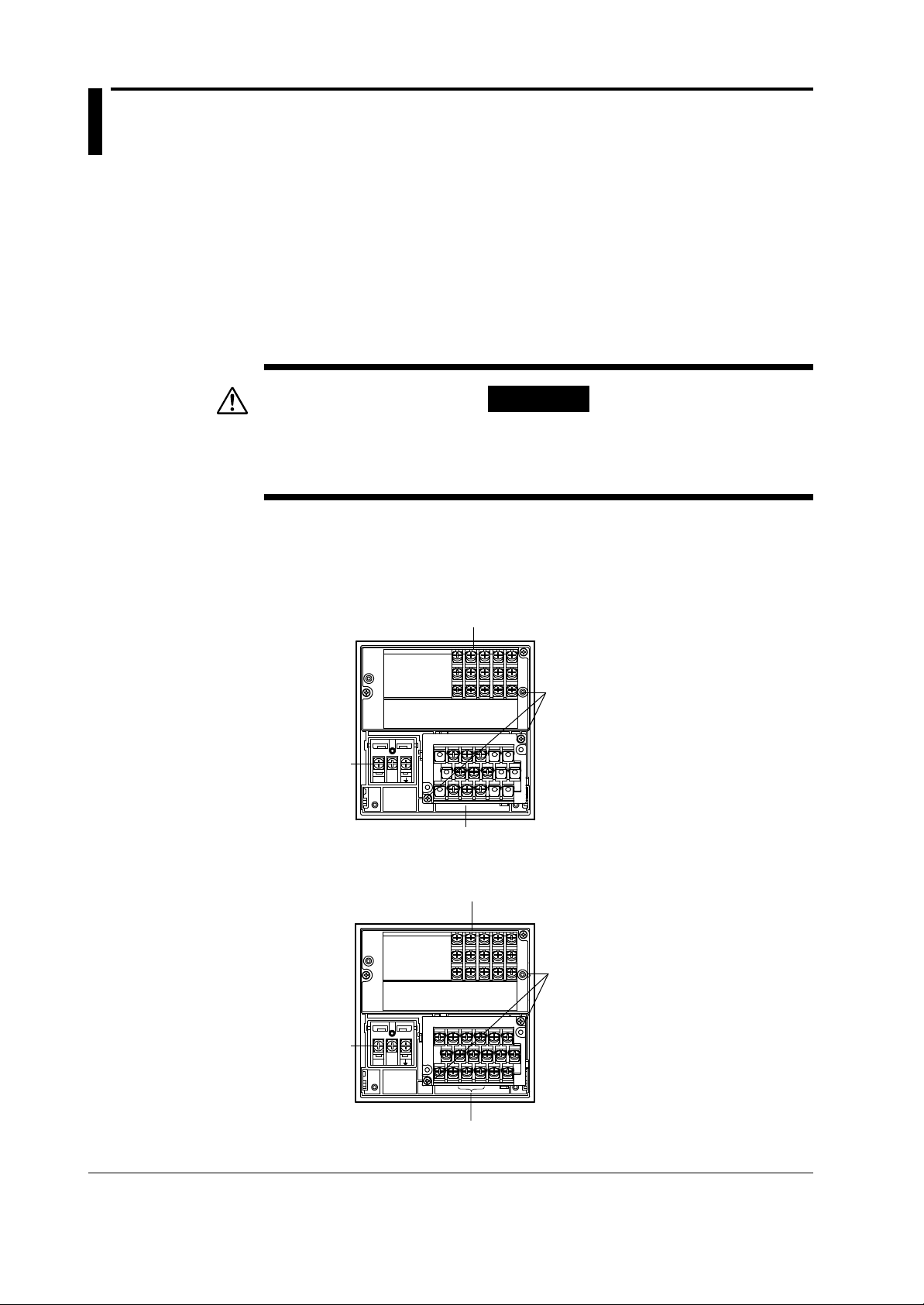

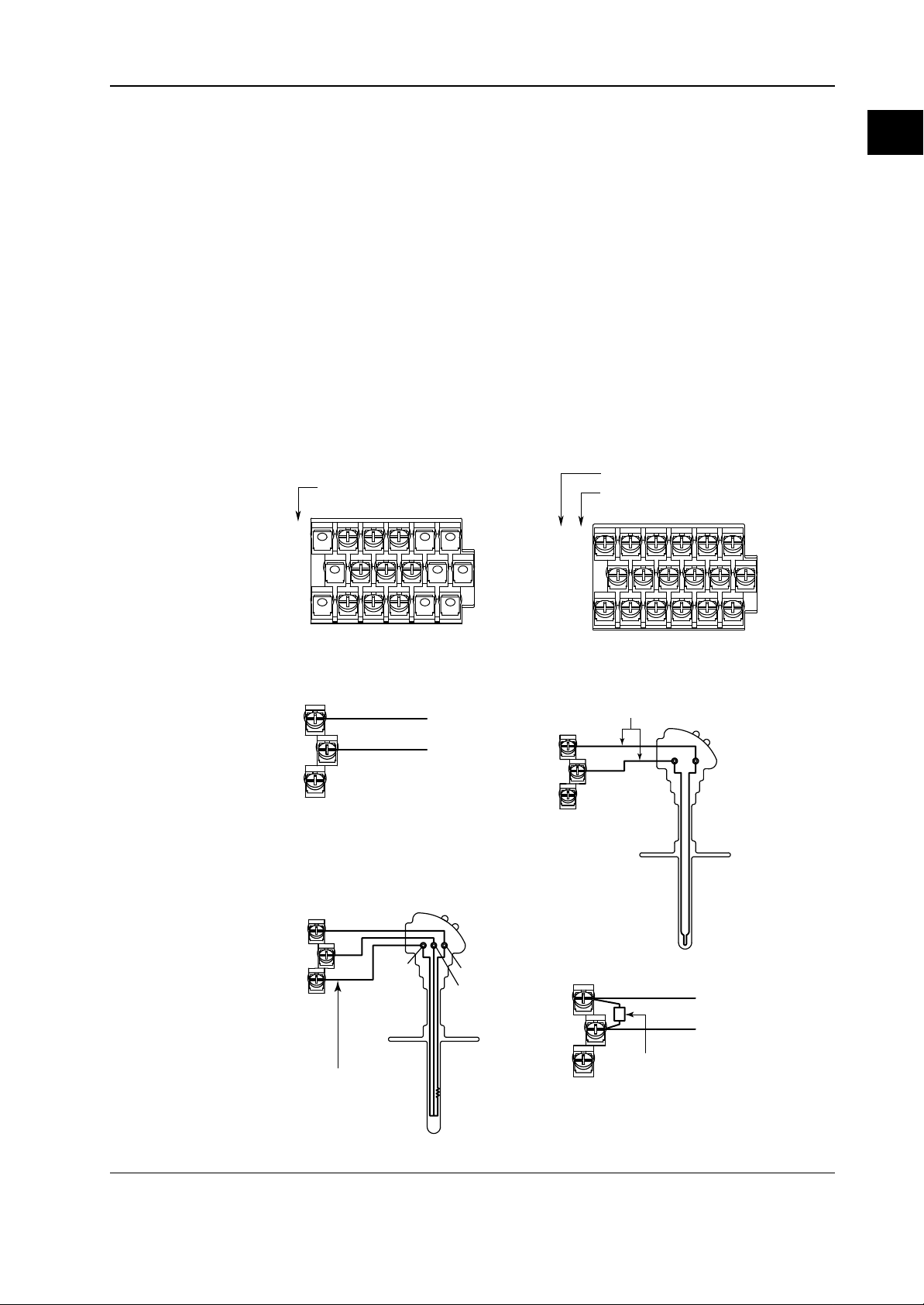

Rear Panel Terminal Arrangement

WARNING

Pen Model

Power terminal

Dot-Printing Model

Power terminal

Optional terminals

Terminal screws: ISO M4,

nominal length 6 mm

The terminal blocks can be

detached from the case by removing

these screws for easy wiring.

Tighten the terminal screws

L

N

Input terminals

Optional terminals

L

N

properly to ensure proper contact.

Terminal screws: ISO M4,

nominal length 6 mm

The terminal blocks can be

detached from the case by removing

these screws for easy wiring.

Tighten the terminal screws

properly to ensure proper contact.

1-10

Input terminals

Page 18

1

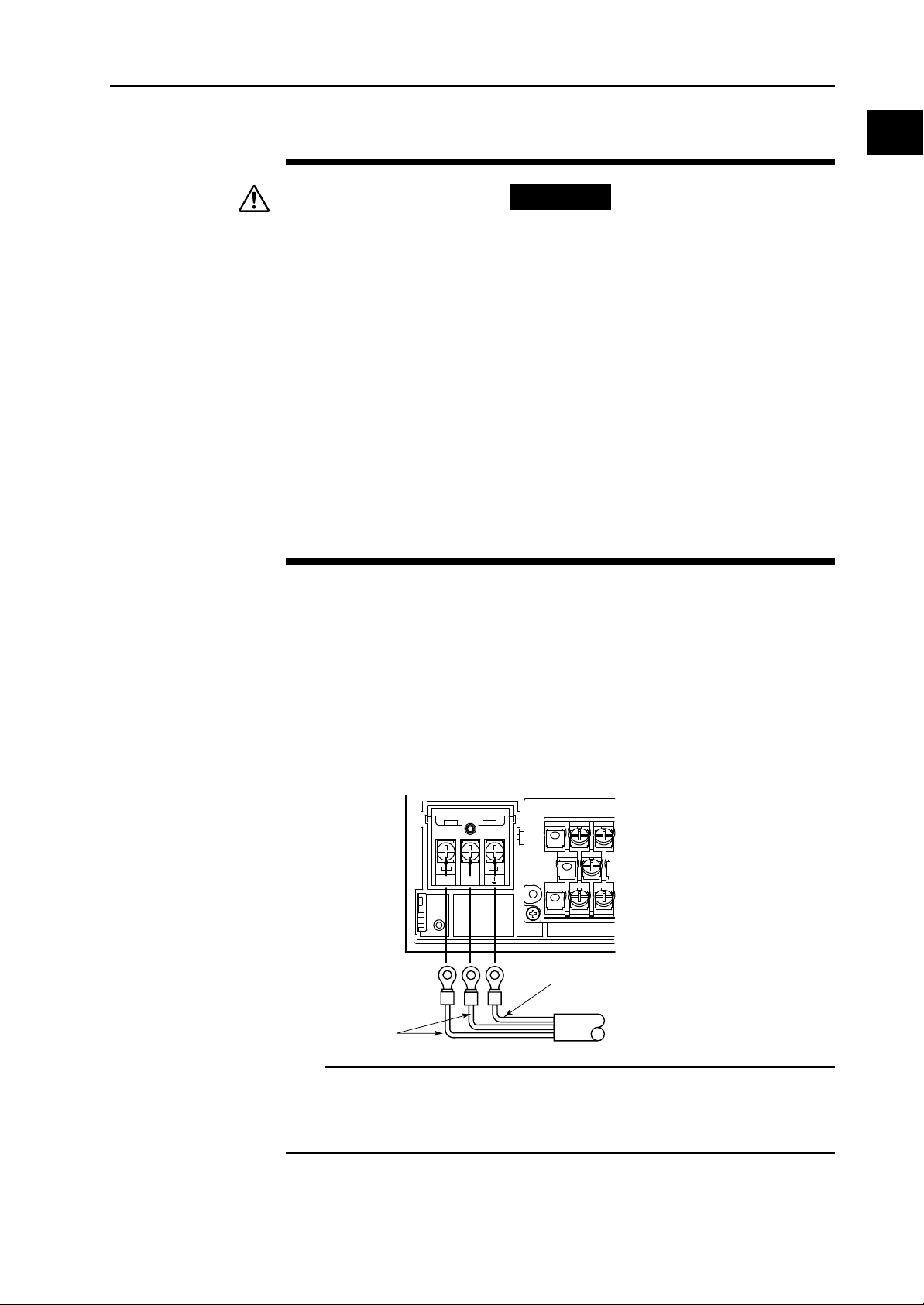

Power Supply Wiring

Wiring

Preparation

WARNING

• To prevent an electric shock, ensure the main power supply is turned off before

wiring.

• To prevent fire, use 600 V PVC insulated wire (AWG18) for power and ground

wiring (cross sectional area of 0.83 mm2 or thicker, anti-galvanic corrosion finish,

insulation thickness should be more than 0.8 mm, insulation resistance ahould

be more than 50 M Km at 20˚C, approved EN60 320 (VDE0625) ), or

equivalent cables.

• Connect the protective grounding wire to the earth through grounding resistance

less than 100 before turning on the power .

• Use crimp on lugs (for 4 mm screws) with insulation sleeves.

• To prevent an electric shock, cover the power terminals certainly with the

transparent cover.

• Make sure to apply a power switch with the following characteristic:

rated power current > 1A

rated rush current > 60A

fuse(s) of 2 to 15A

Wiring method

1 The rated power supply voltage for the recorder is 100 to 240 V AC.

2 Turn the recorder’s power switch OFF.

3 Open the transparent cover of the power terminal after releasing the cover screw.

4 Connect the power supply wires and the protective ground wire to the terminal. To

prevent an emission of electromagnetic disturbances, separate the input wires from

the other wires at least 0.1 m. Over 0.5 m is recommended.

5 Cover the terminals with the transparent cover, and secure the screw.

Power Supply Wiring

LN

Functional earthing cord

Power supply wires

Note

• Do not apply a power supply in the range from 132 V to 180 V AC. Doing so might affect the

measuring accuracy.

• To prevent emission of electromagnetic disturbances, separate the power supply wires from the

other wires at least 0.1 m. Over 0.5 m is recommended.

1-11

Page 19

Wiring

Input Signal Wiring

WARNING

To prevent an electric shock, ensure the main power switch is turned off when wiring.

CAUTION

Do not apply inputs exceeding the rated range as follows to prevent the recorder

from damage:

• Maximum input voltage

±10 V DC for TC, and for the voltage range of 2 V DC or less

±30 V DC for the voltage range of 6 to 20 V DC

• Maximum common mode voltage

250 V AC rms (50/60 Hz)

• This instrument complies with Installation Category II.

1 Turn off the recorder power switch.

2 Remove the transparent cover for the input signal terminals.

3 Connect the input signal wires to the terminals. To prevent an emission of electro-

magnetic disturbances, separate the input wires from the other wires at least 0.1 m.

Over 0.5 m is recommended.

4 Attach the cover on the terminals, and secure the screws.

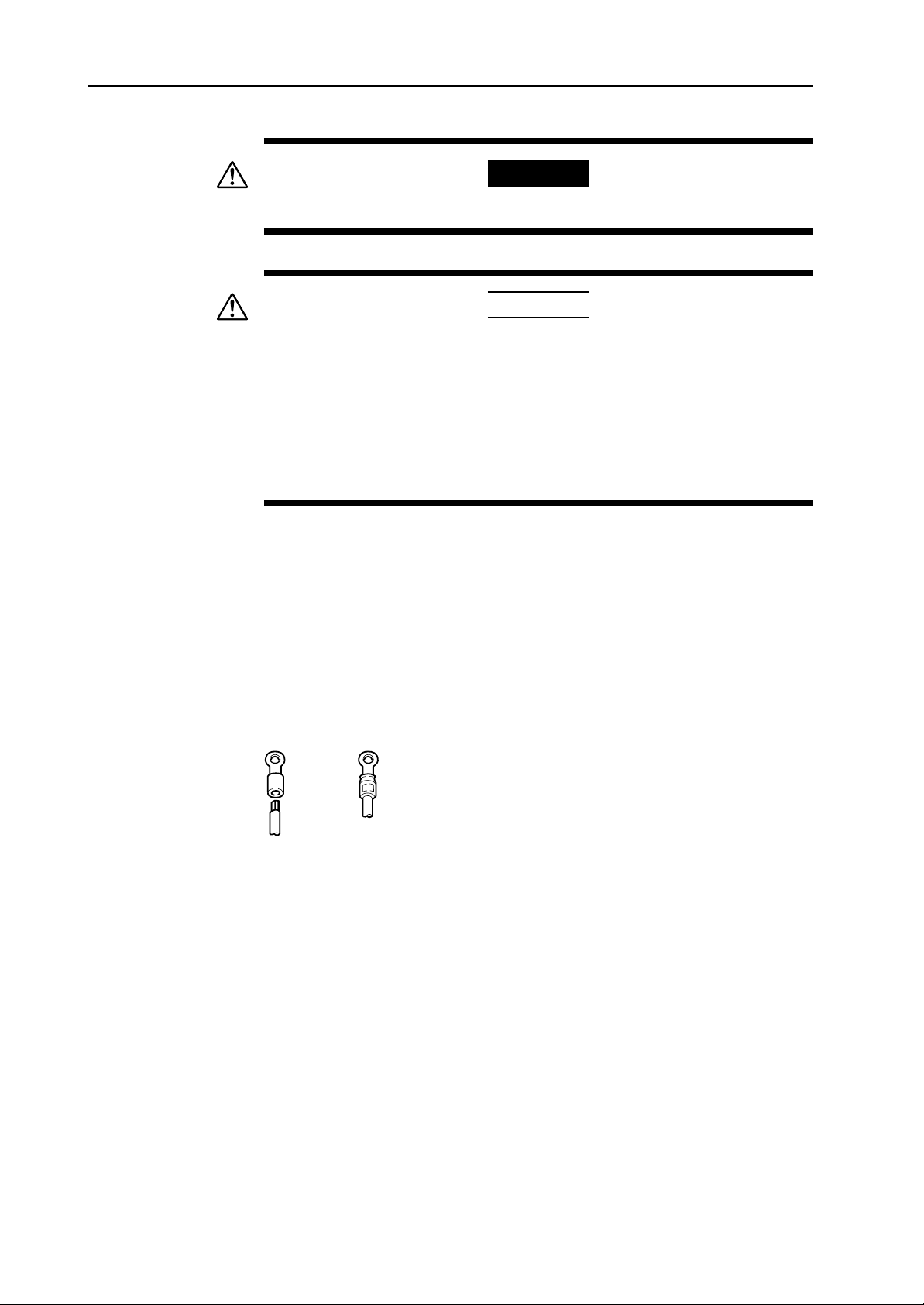

It is recommended to use the crimp-on lugs (for 4 mm screws) with insulation sleeves for

lead wire ends, but they are not required for thermocouples (TC) .

Crimp-On Lugs

Suggestions to minimize noise pickup:

• Separate the measuring-signal wires from power lines and grounding lines.

• It is desirable that the measuring object is not a noise source; if not, insulate it from

the measuring signal wires and ground the object.

• It is recommended to use shielded wires to minimize noise pickup from an electrostatic induction source. The shields are connected to the recorder’s grounding

terminal, if necessary. In that case, avoid two-point grounding.

• To minimize the noize from an electrostatic induction noise, twist the measuring

wires (a pair of wires) in short and equal intervals.

• The grounding line must have low resistance.

1-12

Page 20

1

Wiring

For TC (thermocouple) inputs the ambient temperature around the recorder’s terminal

board should be kept as stable as possible.

• Cover the input terminals with the transparent cover.

• Do not use a large-diameter wire (cross sectional area of more than 0.5 mm

because it has a large radiation rate.

• Keep the ambient temperature as stable as possible; start/stop of a nearby fan can

considerably affect the temperature.

If input signal wires are connected to two or more receivers with parallel connection,

measured values sometimes affect each other. The following notes should be observed

for parallel connection:

• Ground each receiver at the same point.

• Do not turn on/off the power of a receiver while other receivers are in measuring

operation.

• A resistance temperature sensor (RTD) cannot be used essentially in parallel

connection.

Terminal Board (Pen Model) Terminal Board (Dot Model)

DC Voltage, TC

1 ch 2 ch 3 ch

RTD

DC Voltage, TC

1 ch 2 ch 3 ch 4ch 5 ch 6 ch

2

)

Preparation

+

_

Input terminal

Wiring for Input Terminals

DC voltage Inputs

+

--

RTD input (for dot model only)

A

B

b

+

DC voltage Input

B

A

b

A

+

_

B

b

Input terminals

TC input

Extension wires

+

-

DC current input

+

-

+

DC current input

-

Wire resistance per

one line: 10 Ω or less

Three wires should

have the same

resistamce values

Example: The shunt resistor rating

is 250 Ω ± 0.1% for the current input

of 4 to 20 mA.

Shunt resistor

1-13

Page 21

Wiring

Alarm Output Wiring (optional)

To prevent an electric shock, ensure the power switch is turned off before wiring.

Depending on the type (the number of outputs) of alarm relay options, the terminal

arrangement changes as shown in the following:

Alarm Output Terminal Arrangements

NO

NC

ALARM

1

C

NO

NC

WARNING

2

C

-A2 Option

(2 outputs)

1234

NO

NC

NO

C

NC

NO

C

NC

NO

C

NC

C

-A4 Option

(4 outputs)

Contact characteristics

Output type : Relay transfer contacts

Output capacity : 250 V AC (50/60 Hz), 3 A. 250 V DC, 0.1 A (resistive load)

Dielectric strength : 1500 V AC (50/60 Hz) for one minute between output

terminals and grounding terminals

Wiring method

1 Turn the power switch off.

2 Remove the transparent cover of the optional terminals.

3 Connect the alarm output wires to the optional terminals.

To prevent an emission of electromagnetic disturbances, separate the alarm output

wires from the power supply and input wires at least 0.1 m. Over 0.5 m is recommended.

4 Cover the terminals with the transparent cover and secure the screws.

ALARM

1-14

Page 22

1

Remote Control Wiring (optional)

To prevent an electric shock, ensure the power switch is turned off before wiring.

Remote Control Terminals Arrangements:

Input characteristics

Input signal:

Dry contact, open-collector (TTL or transistor) signal.

Control functions and signal types:

(1) Recording start/stop level

(2) Chart speed change level

Signal characteristics:

ON voltage 0.5 V or less (30 mA DC)

Leakage current in OFF state 0.25 mA or less

Signal duration 250 ms or more

Input types:

Photocoupler isolation (one line common).

Internal isolated power source (5 V ±5%).

Dielectric strength:

500 V DC for one minute between input terminals and grounding terminal.

Wiring

Preparation

WARNING

REMOTE

1

2

C

Wiring method

1 Turn the power switch off to revent an electric shock.

2 Remove the transparent cover of the optional terminals.

3 Connect the wires for remote control to the optional terminals. The C is the terminal

common to other 1 to 2. To prevent an emission of electromagnetic disturbances,

separate the input wires from the other wires at least 0.1 m. Over 0.5 m is recommended.

4 Cover the terminals with the transparent cover and secure the screws.

Note

• Use shielded cables for remote control signals to prevent noise pickup. The shield should be

grounded at the recorder’s terminal.

1-15

Page 23

2

Chapter 2 Regular Settings

2.1 Introduction to Regular Settings

Three Recorder Modes

Operation Mode

This is the mode for daily operation, described in the ; when the power turns on, the

recorder automatically enters this mode.

Select from the following functions by pressing the appropriate keys on the key panel.

key Replacement of pens (pen model only). See

RCD key Starting/stopping the recording.

FEED key Feeding the chart. See

DISP key Selection from the modes on display. See

Regular Setting Mode

In the Regular Setting mode, described in this Chapter, daily-used settings such as input

range, recording span, alarm setpoints, and chart feed speed are made. Pressing the

DISP key three seconds in the operation mode changes the mode to the Regular Setting

mode.

Basic (SETUP) Setting Mode (see Section 3)

In the Basic (SETUP) Setting Mode, you can adjust a whole range of detailed settings

such as the pen’s position, dot printing postion and color, the noise input filter, and

remote trigger settings. Enter this mode by turning the power ON while pressing the CH

UP(ENT) key.

User’s Manual

User’s Manual

Section 2.1.

User’s Manual

Regular Settings

Section 2.5.

Section 1.1.

Note

While in the Basic (SETUP) mode, measurement, recording, and alarm detection are not carried

out.

Using the settings protection function, you can protect your settings by defining a password when

you enter the Regular or Basic (SETUP) mode.

Turning the Recorder Modes ON

Power ON while pressing

Power ON

Operation

mode

Mode changes to the other by pressing

the DISP key for three seconds.

Regular

Setting mode

Turning the Recorder Modes OFF

Power ON

the CH UP (ENT) key.

Basic

SET UP mode

Leaving the Basic SET UP

mode is done by the

SET UP END procedure.

Power ON while pressing

the CH UP (ENT) key.

SET UPQUIT

Password

Operation

mode

*1

*1 Mode changes to the other by pressing

the DISP key for three seconds.

*1

Password

Regular

Setting mode

Leaving the Basic SET UP

mode is done by SET UP

END procedure.

Basic

SET UP mode

2-1

Page 24

Introduction to Regular Settings

Flow Chart Regular Setting Mode

Range

Type

Type

Span (L)

Span (L)

Span (L)

Span (R)

Span (R)

Span (R)

2.2 Voltage input

setting and span

2.2 TC input setting

and span setting

2.2 RTD input setting

and span setting

3.8 Offsets (when offset

settings protection function

is ON only)

2.3 Alarm functions

2.4 Chart feed speed

Range

Channel No.

Channel No.

Contact output

Relay No.

Span (L)

Scale (L)

Offset

Alarm level

Span (R)

Scale (R)

Alarm on/off

2.6 Scaling setting

2.2 No measurement,

recording, or display

of unused channel

Alarm

Type of alarm

point

2.5 Dot-printing interval in

analog records (dot model)

2.6 Key lock

2-2

First/second speed

Chart feed speed

: Numeric value input

Page 25

2

2.2 Setting Input Range and Recording Span

Setting Input Range and Recording Span

One of the following parameters can be set for every channel:

SKIP Prevents the specified channel from being measured, recorded and displayed .

VOLT Measures and records DC-voltage.

TC Measures and records temperatures using Thermocouple.

RTD Measures and records temperatures using Resistance Temperature Detector .

SCL Performs scaling on voltage measurements.

Scaling results in appending a different scale to the measured values.

Restrictions apply to the measurable types of input depending on the type of recorder

used. Check your recorder type as indicated on the nameplate (see Section 1.3 for

details on the nameplate), and then refer to the following table:

Model Code Measurable Type of Input

RD260 Voltage (VOLT), thermocouple (TC), SCL

RD266-RTD Resistance temperature detector (RTD, dot–models only)

SKIP Setting

Unused channels can be skipped, which means that these channels will not be measured, recorded or displayed.

Regular Settings

Setting Procedures

ESC

DISP

3 sec

CH UP

CH UP

CH UP

CH UP

or

ESC

DISP

3 sec

Press the DISP key for three seconds to enter the Regular

Setting mode.

Select the [Range] display by using the key.

Then press the ENT key .

.

.

.

.

.

.

Use the key to select the desired channel.

Press the ENT key.

Use the key to select [Skip].

Press the ENT key.

[Range] is displayed and the setting is completed.

Press the ENT key to set another channel; or press the

DISP key for three seconds to return to the Operation mode.

2-3

Page 26

Setting Input Range and Recording Span

Voltage Measurement Setting (VOLT Setting)

If the measured signal is a DC-voltage, the range can be set as follows:

Setting Procedures

ESC

DISP

CH UP

CH UP

CH UP

CH UP

3 sec

Press the DISP key for three seconds to enter the Regular

Setting mode.

Select the [Range] display by using the key.

Then press the ENT key .

.

.

.

Use the key to select the desired channel.

Press the ENT key.

Use the key to select [Volt].

Press the ENT key.

.

.

.

Select the desired range using the keys and press the

ENT key.

Display

Range

–20.00 to 20.00mV

–60.00 to 60.00mV

–200.0 to 200.0mV

–2.000 to 2.000V

–6.000 to 6.000V

–20.00 to 20.00V

CH UP

CH UP

CH UP

FEED

FEED

or

ESC

DISP

3 sec

Select the minimum value of the recording span (SPAN L)

using the

and keys. Then press the ENT key.

The display which appears will allow you to enter the

maximum value of the recording span (SPAN R). Select it

the same way as for the minimum value and press the ENT

key.

The recording span cannot be beyond the input range, nor

can SPAN L be equal to SPAN R.

[Range] is displayed and the setting is completed.

Press the ENT key to set another channel; or press the

DISP key for three seconds to return to the Operation mode.

2-4

Page 27

2

Setting Input Range and Recording Span

Setting Thermocouple and Resistance Temperature Detector (dot model only)

In the case that the measured signal is a TC (Thermocouple), or -for dot models onlyRTD (Resistance Temperature Detector), the range can be set the same way as if it were

a DC-voltage.

Setting Procedures

ESC

DISP

3 sec

CH UP

CH UP

CH UP

CH UP

Regular Settings

Press the DISP key for three seconds to enter the Regular

Setting mode.

Select the [Range] display by using the key.

Then press the ENT key .

.

.

.

Use the key to select the desired channel.

Press the ENT key.

Use the key to select [TC], or [RTD].

.

.

.

Press the ENT key.

Select the desired type (R, S, B, K, E, J, T, N, W, L, U in

.

.

.

case of TC, or PT, JPT in case of RTD) using the

and press the ENT key.

key

TC Type Description and RTD Type Description

CH UP

CH UP

FEED

or

ESC

DISP

3 sec

( Type R )

( Type S )

( Type B )

( Type K )

( Type E )

( Type J )

( Type T )

( Type N )

( Type W )

( Fe-CuNi )

( Cu-CuNi )

TC Type Description

0.0 to 1760.0°C

0.0 to 1760.0°C

0.0 to 1820.0°C

–200.0 to 1370.0°C

–200.0 to 800.0°C

–200.0 to 1100.0°C

–200.0 to 400.0°C

0.0 to 1300.0°C

0.0 to 2315.0°C

–200.0 to 900.0°C

–200.0 to 400.0°C

RTD Type Description

(pt 100 Ω)

(jpt 100 Ω)

–200.0 to 600.0°C

–200.0 to 550.0°C

Range

32 to 3200°F

32 to 3200°F

32 to 3308°F

–328 to 2498.0°F

–328.0 to 1472.0°F

–328.0 to 2012.0°F

–328.0 to 752.0°F

32 to 2372°F

32 to 4199°F

–328.0 to 1652.0°F

–328.0 to 752.0°F

Range

–328.0 to 1112.0°F

–328.0 to 1022.0°F

Select the desired minimum value (SPAN L) and maximum

value of the recording span (SPAN R) in the same way as

described under ‘VOLT setting’.

The recording span cannot be beyond the input range, nor

can SPAN L be equal to SPAN R.

[Range] is displayed and the setting is completed.

Press the ENT key to set another channel; or press the

DISP key for three seconds to return to the Operation mode.

2-5

Page 28

Setting Input Range and Recording Span

Scale Setting (SCL Setting)

To assign a different scale to the measured data, the range can be set as described

below. Note that the measured data which can get a different scale must be of the

voltage (VOLT).

Setting Procedures

ESC

DISP

3 sec

CH UP

Press the DISP key for three seconds to enter the Regular

Setting mode.

Select the [Range] display by using the key.

Then press the ENT key .

CH UP

CH UP

CH UP

CH UP

FEED

.

.

.

.

.

.

.

.

.

Use the key to select the desired channel.

Press the ENT key.

Use the key to select [SCL].

Press the ENT key.

Select the desired range using the key and press the

ENT key.

VOLT Input Ranges

Display

The display which appears will allow you to enter the

minimum value of the recording span. Select the desired

minimum value using the and keys. Then press the

ENT key.

Range

–20.00 to 20.00mV

–60.00 to 60.00mV

–200.0 to 200.0mV

–2.000 to 2.000V

–6.000 to 6.000V

–20.00 to 20.00V

2-6

CH UP

CH UP

FEED

FEED

The display which appears will allow you to enter the

maximum value of the recording span. Select it the same

way as the minimum value and press the ENT key .

The recording span cannot be beyond the input range, nor

can SPAN L be equal to SPAN R.

This display allows you to enter the minimum value of the

scale corresponding to the minimum value of the recording

span. Select it using the and the keys. The position of

the decimal point can be moved using the

is flashing. Note that the allowable range is –19999 to

20000. Then press the ENT key.

key in case [t]

Page 29

2

Setting Input Range and Recording Span

CH UP

CH UP

FEED

or

ESC

DISP

3 sec

This display allows you to enter the desired maximum value

of the scale corresponding to the maximum value of the

recording span. Select it the same way as the minimum

value. Then press the ENT key. Note that the decimal point

will be in the same position as for SCL L. SCL L and SCL R

cannot be same.

In this example, 0.000V input will be scaled to –100.0.

2.000V input will be scaled to 100.0.

[Range] is displayed and the setting is completed.Press the

ENT key to set another channel; or press the DISP key for

three seconds to return to the Operation mode.

Regular Settings

2-7

Page 30

2.3 Setting Alarm Functions

Alarms can be set on the measured data of any channel.

Up to two alarms (i.e. two levels) can be set on one channel.

After an alarm is set, and the measured value reaches the setpoint, the ALM LED will be illuminated.

Alarms can be used on models with the alarm output relay option (-A2, -A4) only.

[H]: High alarm Occurs when a measuring value is on or over the alarm setpoint.

[L]: Low alarm Occurs when a measuring value is under the alarm setpoint.

Setting Procedures

ESC

DISP

CH UP

3 sec

.

.

.

.

.

.

Press the DISP key for three seconds to enter the Regular

Setting mode.

Select [Alarm] by pressing the key, and press the ENT

key.

Select a channel by the key, and press the ENT key.

CH UP

CH UP

CH UP

CH UP

CH UP

FEED

Select an alarm level by the key, and press the ENT key.

Up to two levels can be set.

Select ON/OFF of the alarm settings by the key, and

press the ENT key . Setting [Off] shows [Alarm] and ends

this setting.

Select a type of alarms by the key, and press the ENT

key.

The display which appears will allow you to enter the alarm

value.

Set the alarm value using the and keys. After setting,

press the ENT key .

The decimal point is predetermined by the input range.

Relationship between Input Range and Decimal Points

DC Voltage

Type of Input

–20.00 to 20.00 mV

-60.00 to 60.00 mV

–200.0 to 200.0 mV

–2.000 to 2.000 V

–6.000 to 6.000 V

–20.00 to 20.00 V

Thermocouple/RTD

Position of Decimal Point

XXX. XX

XXX. XX

XXXX. X

XX. XXX

XX. XXX

XXX. XX

XXXX. X

2-8

Page 31

2

Relay Option Alarm Settings

Setting Alarm Functions

The following settings are available only for the model with

relay options (-A2, -A4). For models without these options,

the alarm setting ends by pressing the ENT key until

[Alarm] appears.

CH UP

CH UP

CH UP

Determines whether the relay outputs a signal or not when

an alarm occurs.

Select ON/OFF by the key, and press the ENT key.

Sets the number of the relay after the alarm output ON is

.

.

.

ESC

DISP

or

3 sec

selected. A numeric to be set is selected from I01 to I04 by

the key. Then press the ENT key.

If a number larger than the available number of output

relays is selected, the alarm output will not implemented.

The setting ends with the [Alarm] indication.

When you want to set alarm settings for other channels

continuously, press the ENT key to return to the channel

setting.

In order to return to the operation mode, press the DISP key

for three seconds.

Regular Settings

Note

As a merged function, a combination of remote control option (-R) and alarm output relay option

is available to change the chart speed when an alarm occurs.

2-9

Page 32

2.4 Adjusting the Chart Speed

Relationships between chart speeds and their code numbers are shown below.

Chart Speed (unit: mm/h)

10 15 20 25 30 40 50 60 75 80

90 100 120 150 200 300 600 1200 1500 3000

6000

The data for a dot model (10 mm/h to 1200 mm/h) are shown within the bold border.

Setting Procedures

ESC

DISP

CH UP

CH UP

3 sec

Press the DISP key for three seconds to enter the Regular

Setting mode. Then press the ENT key.

Select [Chart] by pressing the

.

.

.

key.

Using the key, select one of the two kinds of chart speed,

the No.1 and No.2 chart speeds. Then press the ENT key.

The No.2 chart speed identifies the chart speed which takes

effect in case the speed is changed by remote control

(optional function).

For models without the remote control function, the setting

of the No.2 chart speed is invalid.

Select a numeric code referring to the table above using the

key and press the ENT key.

The setting ends with the [Chart] indication.

When you want to continue to set another chart speed ,

press the ENT key. In order to return to the operation mode,

press the DISP key for three seconds.

key, and press the ENT

2-10

Page 33

2

2.5 Setting the Dot Printing Interval (Dot Model)

This recorder prints in FIX or AUTO mode.

In FIX mode, dot printing is performed with a constant interval regardless of the chart

speed (approx. 30 sec).

AUTO mode is provided to prevent the chart from being damaged during repetitive dot

printing. This mode is useful for low chart speeds. The chart is protected from damage

because the printout timing changes with the chart speed (approx. 30 to 90 sec).

Single printout

(0.5mm dia.)

Repetitive dot

printing

FIX AUTO

The initial value is ‘AUTO’. To set the trend recording mode, proceed as follows:

Regular Settings

Setting Procedures

ESC

DISP

3 sec

CH UP

CH UP

ESC

3 sec

DISP

Press the DISP key for three seconds to enter the Regular

Setting mode. Then press the ENT key.

.

.

.

Select the [Trend] display using the key, and press the

ENT key.

Specify [Auto] or [Fix] using the key. Then press the

ENT key.

[Trend] is displayed and the setting is completed. Press the

DISP key for three seconds to return to the Operation mode.

2-11

Page 34

2.6 Setting the Key-Lock

The key-lock can be set to be either ON or OFF for each key separately. Keys which

can be locked are the RCD, and FEED keys.

Setting Procedures

ESC

DISP

CH UP

CH UP

CH UP

CH UP

3 sec

or

ESC

DISP

3 sec

Press the DISP key for three seconds to enter the Regular

Setting mode. Then press the ENT key.

.

.

.

Select the [Key] display using the key, and press the

ENT key.

Select a key to be locked using the key and press the

ENT key.

Select [Lock] to turn the key-lock on or select [Free] to turn

it off, using the

key and press the ENT key.

[Key] is displayed and setting is completed. Press the ENT

key to set another key; Press the CH UP (ESC) key or the

DISP key for three seconds to return to the Operation mode.

2-12

Page 35

3

Chapter 3 Basic (SETUP) Settings

3.1 Introduction to Basic (SETUP) Settings

Three Recorder Modes

OperationMode

This is the mode for daily operation, described in the

turns on, the recorder automatically enters this mode.

Select from the following functions by pressing the appropriate keys on the key panel.

key Replacement of pens (pen model only). See

RCD key Starting/stopping the recording.

FEED key Feeding the chart. See

User’s Manual

DISP key Selection from the modes on display. See

Regular Setting Mode, (see Section 2)

In the Regular Setting mode daily-used settings such as input range, recording span,

alarm setpoints, and chart feed speed are made. Pressing the DISP key three seconds

in the operation mode changes the mode to the Regular Setting mode.

Basic (SETUP) Setting Mode

In the Basic (SETUP) Setting Mode, described in this Chapter,you can adjust a whole

range of detailed settings such as the pen’s position, dot printing postion and color, the

noise input filter, a remote trigger settings. Enter this mode by turning the power on

while pressing the CH UP(ENT) key.

User’s Manual

User’s Manual

Section 2.1.

User’s Manual

; when the power

Section 2.5.

Basic (SETUP) Settings

Section 1.1.

Note

While in the Basic (SETUP) mode, measurement, recording, and alarm detection are not carried

out.

Using the settings protection function, you can protect your settings by defining a password when

you enter the Regular or Basic (SETUP) mode.

Turning the Recorder Modes ON

Power ON while pressing

Power ON

Operation

mode

Mode changes to the other by pressing

the DISP key for three seconds.

Regular

Setting mode

Turning the Recorder Modes OFF

Power ON

the CH UP (ENT) key.

Basic

SET UP mode

Leaving the Regular

Setting mode is done by

the SET UP END procedure.

Power ON while pressing

the CH UP (ENT) key.

SET UPQUIT

Password

Operation

mode

*1

*1 Mode changes to the other by pressing

the DISP key for three seconds.

*1

Password

Regular

Setting mode

Leaving the Basic SET UP

mode is done by SET UP

END procedure.

Basic

SET UP mode

3-1

Page 36

Introduction to Basic (SETUP) Settings

Flow Chart Basic (SETUP) Settings

3.2 Relay for post

alarm (de-)energizing

3.3 Alarm hysteresis

3.4 A/D integration time

(pen model only)

3.5 TC burnout

registration method

3.5 TC burnout on/off

3.6 Noise input filter

(pen model only)

Channel No.

3.7 Moving average calculation (dot model only)

3.8 Offset settings

protection

3.9 Channel printing

colors (dot model only)

3.10 Selecting Celcius

or Fahrenheit

3.11 Remote trigger

setting

Channel No.

Channel No.

Channel No.

3-2

3.12 Protecting settings

(key lock)

Password

Page 37

3

4.2/4.3 Pen/dot position

adjustment

Introduction to Basic (SETUP) Settings

Pen-ZERO adjustment

(pen model only)

Dot-ZERO adjustment

(dot model only)

Pen-FULL adjustment

(pen model only))

Dot-FULL adjustment

(dot model only)

3.13 Initialization of settings

Explanations for these

settings are not in this

manual.Consult your

purchasing source.

Termination of SETUP mode

Basic (SETUP) Settings

: Numeric value input

3-3

Page 38

3.2 Setting Relay for post-Alarm (de-)Energizing

The alarm output relays can be selected to be energizing or de-energizing on alarm.

Using de-energizing, alarm output relay is activated either when an alarm occurs, or

when power off occurs (common for all relays). This enables simple monitoring of power

supply.

The initial value is ‘ENERG’.

Setting Procedure

CH UP

CH UP

CH UP

Energize

De-energize

Press

power switch

NO C NC NO C NC

NO C NC NO C NC NO C NC

Power OFF

Enter the Basic SET UP Mode by turning ‘ON’ the power

while pressing and holding the CH UP (ENT) key until the

SET UP display appears.

Use the key to select the display [Alarm]. Press the ENT

key.

Press the key until the display [Relay] appears. Press

the ENT key .

Use the

ENT key. The display [Alarm] appears.

Alarm OFF

key to select [Energ] or [De_En]. Press the

NO C NC

Alarm ON

3-4

CH UP

CH UP

CH UP

Before leaving the Basic SET UP Mode, you have to store

.

.

.

your new settings. Use the

display, and press the ENT key.

Select [Store] to keep your new settings or [Abort] to abort

the settings, and press the ENT key. After a few seconds,

the Operation Mode will appear.

key to select the [End]

Page 39

3

3.3 Setting Alarm Hysteresis

The alarm hysteresis is the difference between the levels of alarm occurrence and reset.

You can choose between two levels of hysteresis: 0% (=OFF) and approx. 0.5% of the

recording span (=ON) (common for all alarms).

The initial value is ON.

High Limit Alarm (H)

Alarm generated

Alarm setting value

Basic (SETUP) Settings

Setting Procedure

CH UP

CH UP

1V

Measured value

Low Limit Alarm (L)

1V

Alarm generated

Press

power switch

Measured value

- - Hysteresis (approx. 0.5%)

Alarm release

Alarm release

- - Hysteresis (approx. 0.5%)

Alarm setting value

Enter the SET UP Mode by turning the power ON while

pressing and holding the CH UP (ENT) key until the Basic

SET UP display appears.

Use the key to select the display [Alarm]. Press the ENT

key.

CH UP

CH UP

CH UP

CH UP

Press the key until the display [Hys] appears. Press the

ENT key.

Use the key to select the [On], or [Off]. Press the ENT

key . The display [Alarm] appears.

Before leaving the Basic SET UP Mode, you have to store

.

.

.

your new settings. Use the

display, and press the ENT key.

Select [Store] to keep your new settings or [Abort] to abort

the settings, and press the ENT key. After a few seconds,

the Operation Mode will appear.

key to select the [End]

3-5

Page 40

3.4 Selecting A/D Integration Time (Pen Model)

Setting 50-60Hz A/D Integration Time

The purpose of the following setting is to specify which A/D integration time will be used.

Depending on the power supply, the integration time will affect the ability of noise

rejection and therefore the recording.

If the power supply of the recorder and of the measuring object are the same, the effect

of noise will be automatically minimized and the (initial) value of AUTO is the recommended one.

If the power supplies are different, you should select from 50Hz or 60Hz integration time.

The choice depends on the power supply of the instrument with the highest noise level.

There are three possibilities:

• AUTO: integration time depends on the power supply of the recorder. AUTO is the

initial value.

• 50 Hz.

• 60 Hz.

Setting Procedure

CH UP

CH UP

CH UP

CH UP

CH UP

Press

power switch

Enter the SET UP Mode by turning ON the power while

pressing and holding the CH UP (ENT) key until the Basic

SETUP display appears.

.

.

.

.

.

.

Use the key to select the display [Intg]. Press the ENT

key.

Select AUTO, 50Hz or 60Hz according to your situation

using the

[Intg] appears.

Before leaving the Basic SET UP Mode, you have to store

your new settings. Use the

display, and press the ENT key.

Select [Store] to keep your new settings or [Abort] to abort

the settings, and press the ENT key. After a few seconds,

the Operation Mode will appear.

key. Then press the ENT key. The display

key to select the [End]

3-6

Page 41

3

3.5 TC Burnout Registration Method

The purpose of the following setting is to specify where the pens will move in the case of

a TC-burnout. You can choose from moving to the right (UP) or to the left (DOWN).

This is common for every channel. You can select ON or OFF for each channel.

The initial value is [UP], and [OFF] for every channel.

Setting Procedure

CH UP

Press

power switch

.

.

.

Enter the Basic SET UP Mode by turning the power ON

while pressing and holding the CH UP (ENT) key until the

SET UP display appears.

Use the key to select the display [B_Out]. Press the CH

UP (ENT) key.

Basic (SETUP) Settings

CH UP

CH UP

CH UP

CH UP

CH UP

CH UP

CH UP

Use the key to select the display [Mode]. Press the CH

UP (ENT) key.

Select [UP] or [DOWN] using the key. Press the ENT

key.

The display [B_Out] appears.Press the ENT key.

Note that this burnout processing is ON/OFF selectable per

.

.

.

.

.

.

channel.

Use the key to select the display [B_Set]. Press the

[ENT] key.

Select the channel No. using the key for which you want

to specify this burnout processing. Then press the ENT key.

Select [ON] or [OFF]. Then press the ENT key. The display

[B_Out] appears.

CH UP

CH UP

.

.

.

Before leaving the Basic SET UP Mode, you have to store

your new settings. Use the

display, and press the ENT key.

Select [Store] to keep your new settings or [Abort] to abort

the settings, and press the ENT key. After a few seconds,

the Operation Mode will appear.

key to select the [End]

3-7

Page 42

3.6 Setting the Noise Input Filter (Pen Model)

Configuring the Input Filter

Noise in the measured signal can be suppressed in the final measurement by using an

input filter. The purpose of this setting is to select for each channel whether or not to use

a filter, and if so, to select a time constant of damping.

A filter works as follows:

Setting Procedure

CH UP

CH UP

Input

Meas.

values

2, 5 or 10 sec.

when input filter is in use

If a filter is used, the response time can be selected from 2, 5 or 10 seconds. The initial

value is ‘OFF’.

Press

power switch

.

.

.

.

.

.

Response curve

(Filter OFF)

63.2%

Response curve

(Filter ON)

Enter the Basic SET UP Mode by turning ON the power

while pressing and holding the CH UP (ENT) key until the

SET UP display appears.

Use the key to select the display [Filtr]. Press the ENT

key.

Select the channel No. using the key for which you want

to specify a filter. Then press the ENT key.

3-8

CH UP

CH UP

CH UP

CH UP

Use the key to select the type of filter you want to use.

You can choose from no filter (OFF), 2 seconds, 5 seconds

or 10 seconds. Press the ENT key. The display [Filtr] will

appear.

Press the ENT key to continue the setting for other channels.

.

.

.

The filter setting has been completed, but has not been

stored yet. Before leaving the Basic SET UP Mode, you

have to store your new settings. Use the key to select

the [End] display, and press the ENT key.

Select [Store] to keep your new settings or [Abort] to abort

the settings, and press the ENT key. After a few seconds,

the Operation Mode will appear.

Page 43

3

3.7 Setting Moving Average Calculation (Dot Model)

Noise in the measured signal can be suppressed in the final measurement by computing

a moving average. It is possible to record a moving average calculated over the previous

X samples, selectable from the previous 2 to 16 samples. The purpose of the following

setting is to select for each channel whether or not to compute a moving average, and if

so, over how many samples.

One sampling period is 10 seconds. The initial value is ‘OFF.’

Example: (assuming a moving average over 5 samples is selected)

Buffer data for

sample n

1

10.0mV

2

5.0mV

3

0.0mV

4

–5.0mV

5

–10.0mV erased

new data new data

Buffer data for

sample (n+1)

15.0mV

10.0mV

5.0mV

0.0mV

–5.0mV

erased

Buffer data for

sample (n+2)

10.0mV

15.0mV

10.0mV

5.0mV

0.0mV

Basic (SETUP) Settings

Setting Procedure

CH UP

CH UP

CH UP

CH UP

CH UP

Moving

average

Press

power switch

.

.

.

.

.

.

.

.

.

.

.

.

0.0mV

5.0mV

Enter the Basic SET UP Mode by turning ON the power

while pressing and holding the CH UP (ENT) key until the

SET UP display appears.

Use the key to select the display [M_Ave]. Press the

ENT key.

Select the channel No. using the key for which you want

to compute a moving average. Then press the ENT key.

Use the key to select the number of samples. You can

choose from OFF, 2 samples, 3 samples, ... up to 16

samples. Of course you can also select OFF. Press the ENT

key . The display [M_Ave] will appear.

Press the [ENT] key to continue the setting for other

channels.

The moving average setting has been completed, but has

not been stored yet. Before leaving the Basic SET UP

Mode, you have to store your new settings. Use the key

to select the [End] display and press the ENT key.

8.0mV

Select [Store] to keep your new settings or [Abort] to abort

the settings, and press the ENT key. After a few seconds,

CH UP

the Operation Mode will appear.

3-9

Page 44

3.8 Offset Values

Offset Value Security Lock

Configure the recorder so changes can (ON) or cannot (OFF) be made to the Offset

settings in the Regular Setting mode.

When protection is turned on, you can set an offset value in the SET mode.

The initial value is [OFF].

Setting Procedure

CH UP

CH UP

CH UP

CH UP

CH UP

Press

power switch

Enter the SET UP Mode by turning ON the power while

pressing and holding the CH UP (ENT) key until the Basic

SET UP display appears.

.

.

.

.

.

.

Use the key to select the display [Offst]. Press the ENT

key.

Use the key, select either [ON] or [OFF] and then press

the ENT key. The display [Offst] will appear. The setting is

then complete.

Before leaving the Basic SETUP mode, you have to store

your new settings. Use the

press the ENT key .

Select [Store] to keep your new settings or [Abort] to abort

the settings, and press the ENT key. After a few seconds,

the Operation Mode will appear.

key to select [End] and

3-10

Page 45

3

Setting Offsets (Regular Setting)

When recording and showing data using the current input as the reference, measured

values can be corrected within 10% of the span. For example, assume the reading is

1.998 V for the current level of input. If you want to change the reading to 2.000 V, set

0.002 V as the offset. This menu opens only when offset settings protection is turned on

in the SETUP mode.

Setting Procedures

Offset Values

ESC

DISP

CH UP

CH UP

CH UP

CH UP

3 sec

FEED

or

ESC

DISP

3 sec

Press the DISP key for three seconds to enter the SET

mode. Using the

CH UP (ENT) key.

.

.

.

Using the key, select the channel to be configured and

.

.

.

then press the ENT key. Configurable channels are those

whose measuring range is VOLT, TC, RTD or SCL.

Type the value of offset. Use the key to move through

the digits and the

is complete, press the ENT key . Set the offset within 10% of

the recording span.

[Offst] appears and the setting is then complete. To

continue, press the ENT key and start again with channel

selection. Pressing the ESC key while making settings

returns to the screen showing [Offst]. To return to the

OPERA TION mode, hold down the DISP key for 3 seconds.

key, select [Offset] and then press the

key to select a numeral. When setting

Basic (SETUP) Settings

3-11

Page 46

3.9 Assigning Channel Printing Colors (Dot Model)

You can assign any of the six provided colors to any channel. The initial setting is as

follows:

ch.1 = purple

ch.2 = red

ch.3 = green

ch.4 = blue

ch.5 = brown

ch.6 = black

Setting Procedure

CH UP

CH UP

Press

power switch

.

.

.

Enter the SET UP Mode by turning ON the power while

pressing and holding the CH UP (ENT) key until the Basic

SET UP display appears.

Use the key to select the display [Color]. Press the ENT

key.

CH UP

CH UP

CH UP

CH UP

.

.

.

.

.

.

.

.

.

Select the channel No. for which you want to change a

color. Then press the ENT key.

Select the color. Then press the ENT key. The display

[Color] will appear.

Before leaving the Basic SET UP Mode, you have to store

your new settings. Use the

display and press the ENT key.

Select [Store] to keep your new settings or [Abort] to abort

the settings, and press the ENT key. After a few seconds,

the Operation Mode will appear.

key to select the [End]

3-12

Page 47

3

3.10 Selecting Celsius or Fahrenheit

You can set the standard unit of temperature to either Celsius or Fahrenheit.

The default setting for recorders is Celsius.

Setting Procedure

Enter the SET UP Mode by turning ON the power while

pressing and holding the CH UP (ENT) key until the Basic

SET UP display appears.

Use the key to select the display [Rem]. Press the ENT

key.

Choose the standard unit of temperature from[Deg_C]

(degrees Celsius), or [Deg_F] (degrees Fahrenheit). Press

the ENT key . The display [Temp] appears.

CH UP

CH UP

CH UP

Press

power switch

.

.

.

Basic (SETUP) Settings

CH UP

CH UP

.

.

.

Before leaving the Basic SET UP Mode, you have to store

your new settings. Use the

display, and press the ENT key.

Select [Store] to keep your new settings or [Abort] to abort

the settings, and press the ENT key. After a few seconds,

the Operation Mode will appear.

key to select the [End]

3-13

Page 48

3.11 Remote Trigger for Recording or Chart Speed

This paragraph describes the way to change default settings for REMOTE operation.

The settings concerning the REMOTE option are always accessible, and data entry will

be ignored if your instrument is not equipped with this option.

The -R option allows you to execute functions on this instrument by a remote trigger

(contact input).

The functions which can be executed by a remote trigger are:

• start/stop the recording

• change the chart speed to a preset second chart speed

However, the -R terminal has only two terminals, which means that only two functions

can be triggered.

Initially the functions are assigned to the terminals as follows:

1: start/stop the recording [RCD] (Record)

2: change the chart speed to a preset second chart speed [C_Spd] (Chart Speed)

Setting Procedure

CH UP

CH UP

Press

power switch

.

.

.

Enter the SET UP Mode by turning ON the power while

pressing and holding the CH UP (ENT) key until the Basic

SET UP display appears.

Use the key to select the display [Rem]. Press the ENT

key.

CH UP

CH UP

CH UP

CH UP

Select the terminal No. [Rem1] or [Rem2] ( /R1 has two

terminals.) Press the ENT key .

Select the function which you want to assign to that terminal. You can choose from [RCD] (start/stop recording), or

[C_Spd] (second chart speed). Press the ENT key. The

display [Rem] appears.

.

.

.

Before leaving the Basic SET UP Mode, you have to store

your new settings. Use the

display, and press the ENT key.

Select [Store] to keep your new settings or [Abort] to abort

the settings, and press the ENT key. After a few seconds,

the Operation Mode will appear.

key to select the [End]

Note

If you select ‘start/stop recording,’ recording stops if the remote input terminal is open and starts if

the terminal is closed. If you press the RCD key during the startup of remote-controlled recording, recording stops. In contrast, if you press the RCD key during the shutdown of remotecontrolled recording, recording starts. You can start/stop remote-controlled recording even during

the start/stop sequence of recording based on the RCD key.

3-14

Page 49

3

3.12 Protecting Settings

You can protect your settings made in the Regular Setting or Basic SETUP modes using

a password.

• If you select [OFF]:

the choice does not affect operation in any mode.

• If you select [ON]:

You must type in a password to enter the Regular Setting or Basic SETUP modes. The

password discussed here is one you set in the following procedure.

The initial value is [OFF].

Setting Procedure

Basic (SETUP) Settings

CH UP

CH UP

CH UP

CH UP

CH UP

CH UP

Press

power switch

.

.

.

.

.

.

Enter the SET UP Mode by turning ‘ON’ the power while

pressing and holding the CH UP (ENT) key until the Basic

SET UP display appears.

Use the key to select the display [Lock]. Press the ENT

key.

Select [ON] or [OFF]. Press the ENT key. In the case you

selected Off, the setting is completed.

Select a password composed of four digits. After setting is

finished, press the ENT key. The display [Lock] appears.

Before leaving the SET UP Mode, you have to store your

new settings. Use the

press the ENT key .

Select [Store] to keep your new settings or [Abort] to abort

the settings, and press the ENT key. After a few seconds,

the Operation Mode will appear.

key to select the [End] display and

3-15

Page 50

3.13 Initializing Settings

The settings which can be initialized concern the settings done in the Regular setting

Mode only. This initialization does not affect any settings in the Basic SET UP Mode.

Setting Procedure

CH UP

CH UP

CH UP

CH UP

CH UP

Press

power switch

.

.

.

Enter the Basic SET UP Mode by turning ON the power

while pressing and holding the CH UP (ENT) key until the

SET UP display appears.