Page 1

User’s Guide

Shop online at

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

RD1800B

Programmable Recorder

Page 2

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

Servicing North America:

U.S.A.: One Omega Drive, P.O. Box 4047

ISO 9001 Cer

tified

Stamford, CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

®

®

Mexico: En Espan˜ ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LAAmstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfr

TEL: +49 (0)7056 9398-0

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

onn, Germany

AX: +49 (0)7056 9398-29

F

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

Foreword

Notes

Thank you for purchasing the OMEGA RD1800B Recorder.

This manual describes the functions (excluding the communication functions), installation

and wiring procedures, operating procedures, and lists the handling precautions of the

RD100B0 Recorder. To ensure correct use, please read this manual thoroughly before

beginning operation.

The following three manuals including this manual are available for the RD1800B

Recorder.

• Electronic Manuals Provided on the Accompanying CD-ROM

Manual Title Manual No. Description

RD1800B Recorder M-4242 This manual.

User’s Guide

RD100B/RD1800B M-4233 Explains the communication functions of the

Communication Interface RD1800B Recorder using Ethernet interface and

User’s Guide the RS-422A/485 communication interface.

• Paper Manual

Manual Title Manual No. Description

RD1800B Recorder M-4243 Explains concisely the operations of the

Operation Guide RD1800B Recorder.

• The contents of this manual are subject to change without prior notice as a result of

continuing improvements to the instrument’s performance and functions.

• Every effort has been made in the preparation of this manual to ensure the accuracy

of its contents. However, should you have any questions or find any errors, please

contact OMEGA as listed on the back cover of this manual.

• Copying or reproducing all or any part of the contents of this manual without the

permission of OMEGA is strictly prohibited.

• The TCP/IP software of this product and the document concerning the TCP/IP

software have been developed/created based on the BSD Networking Software,

Release 1 that has been licensed from the University of California.

Trademarks

Revisions

Microsoft, MS-DOS, Windows, Windows NT, and Windows XP are either registered

trademarks or trademarks of Microsoft Corporation in the United States and/or other

countries.

• Adobe, Acrobat, and PostScript are trademarks of Adobe Systems incorporated.

• For purposes of this manual, the TM and ® symbols do not accompany their

respective trademark names or registered trademark names.

• Company and product names that appear in this manual are trademarks or registered

trademarks of their respective holders.

1st Edition August 2005

i

Page 4

Safety Precautions

The general safety precautions described here must be observed during all phases of operation.

Safety Standards and EMC Standards

This recorder conforms to IEC safety class I (provided with terminal for protective grounding), Installation Category

II, Measurement Category II (CAT II), and EN61326-1 (EMC standard), class A (use in a commercial, industrial, or

business environment). This recorder is designed for indoor use.

About This Manual

• This manual should be read by the end user.

• Read this manual thoroughly and have a clear understanding of the product before operation.

• This manual explains the functions of the product. OMEGA does not guarantee that the product will suit a

particular purpose of the user.

• Under absolutely no circumstances may the contents of this manual be transcribed or copied, in part or in

whole, without permission.

• The contents of this manual are subject to change without prior notice.

• Every effort has been made in the preparation of this manual to ensure the accuracy of its contents. However,

should you have any questions or find any errors or omissions, please contact OMEGA.

Precautions Related to the Protection, Safety, and Alteration of the Product

• The following safety symbols are used on the product and in this manual.

“Handle with care.” To avoid injury and damage to the instrument, the operator must refer to the

explanation in the manual.

Protective ground terminal

AC

“High temperature.” To avoid injury caused by hot surface, do not touch locations where this

symbol appears.

• For the protection and safe use of the product and the system controlled by it, be sure to follow the instructions

and precautions on safety that are stated in this manual whenever you handle the product. Take special note

that if you handle the product in a manner that violate these instructions, the protection functionality of the

product may be damaged or impaired. In such cases, OMEGA does not guarantee the quality, performance,

function, and safety of the product.

• When installing protection and/or safety circuits such as lightning protection devices and equipment for the

product and control system or designing or installing separate protection and/or safety circuits for fool-proof

design and fail-safe design of the processes and lines that use the product and the control system, the user

should implement these using additional devices and equipment.

• If you are replacing parts or consumable items of the product, make sure to use parts specified by OMEGA.

• This product is not designed or manufactured to be used in critical applications that directly affect or threaten

human lives. Such applications include nuclear power equipment, devices using radioactivity, railway facilities,

aviation equipment, air navigation facilities, aviation facilities, and medical equipment. If so used, it is the user’s

responsibility to include in the system additional equipment and devices that ensure personnel safety.

• Do not modify this product.

ii

Page 5

Safety Precautions

WARNING

• Power Supply

Ensure that the source voltage matches the voltage of the power supply before turning ON the power.

• Protective Grounding

Make sure to connect the protective grounding to prevent electric shock before turning ON the power.

• Necessity of Protective Grounding

Never cut off the internal or external protective earth wire or disconnect the wiring of the protective earth

terminal. Doing so invalidates the protective functions of the instrument and poses a potential shock

hazard.

• Defect of Protective Grounding

Do not operate the instrument if the protective earth or fuse might be defective. Make sure to check

them before operation.

• Do Not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable liquids or vapors. Operation in such

environments constitutes a safety hazard.

• Do Not Remove Covers

The cover should be removed by OMEGA’s qualified personnel only. Opening the cover is dangerous,

because some areas inside the instrument have high voltages.

• External Connection

Connect the protective grounding before connecting to the item under measurement or to an external

control unit.

• Damage to the Protective Structure

Operating the recorder in a manner not described in this manual may damage its protective structure.

Exemption from Responsibility

• OMEGA makes no warranties regarding the product except those stated in the WARRANTY that is provided

separately.

• OMEGA assumes no liability to any party for any loss or damage, direct or indirect, caused by the user or any

unpredictable defect of the product.

Handling Precautions of the Software

• OMEGA makes no warranties regarding the software accompanying this product except those stated in the

WARRANTY that is provided separately.

• Use the software on a single PC.

• You must purchase another copy of the software, if you are to use the software on another PC.

• Copying the software for any purposes other than backup is strictly prohibited.

• Please store the original media containing the software in a safe place.

• Reverse engineering, such as decompiling of the software, is strictly prohibited.

• No portion of the software supplied by OMEGA may be transferred, exchanged, sublet, or leased for use by any

third party without prior permission by OMEGA.

iii

Page 6

Checking the Contents of the Package

Unpack the box and check the contents before operating the recorder. If some of the

contents are not correct or missing or if there is physical damage, contact the dealer

from which you purchased them.

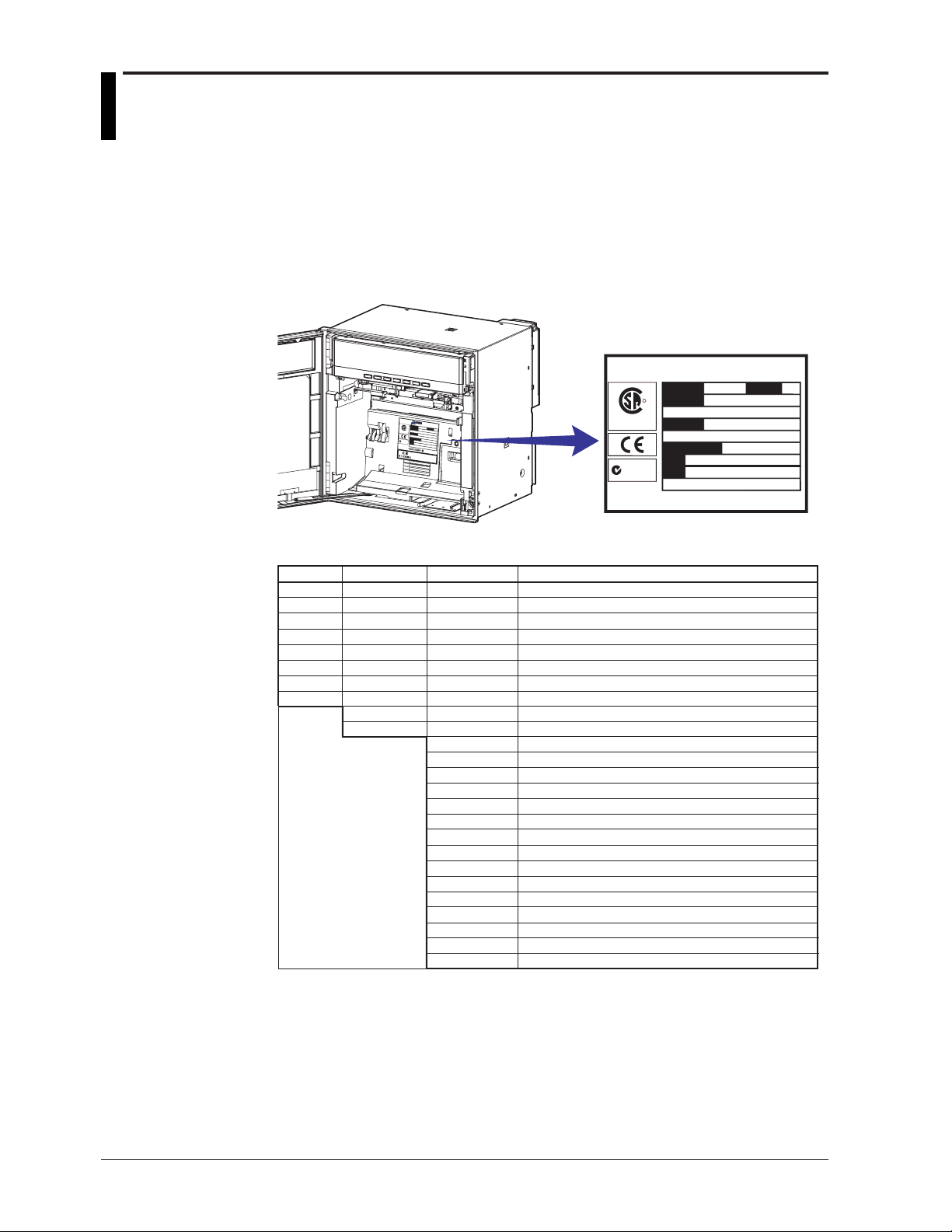

Checking the Model

A name plate is affixed to the recorder. Check that the model name and suffix code

given on the name plate on the rear panel match those on your order.

C

RECORDER

MO

DE

L

R

SUFFIX

STYLE

C

U

S

LR999

88

S

UPPLY

FREQUENCY

MAC

N200

NO.

M

ade in C

hin

a

Do not apply oil

TA

G

NO.

TA

G

NO.

TA

G

NO.

TA

G

NO.

LR99988

N200

R

US

MODEL

SUFFIX

SUPPLY

FREQUENCY

MAC

NO.

RECORDER

STYLE

OMEGA

Made in China

MODEL and SUFFIX Code

Model

Suffix Code

RD1801B

RD1802B

RD1803B

RD1804B

RD1806B

RD1812B

RD1818B

RD1824B

-1

-2

1 /A1, /A2, /A3, /A4, and /A5 cannot be specified simultaneously. /A5 is valid on the dot models.

2 /A5 and /F1 cannot be specified simultaneously on the dot models.

/A4 and /F1 cannot be specified simultaneously on the pen models.

3 /C3 and /C7 cannot be specified simultaneously.

4 /H2 and /N2 cannot be specified simultaneously.

5 Valid only on the dot models.

6 14 types of input including Pt50 RTD, PR40-20, and Platinel TC

Optional Code

/A1

/A2

/A3

/A4

/A5

/C3

/C7

/F1

/H2

/H3

/M1

/N1

/N2

/N3

/R1

Description

µR20000 1 pen recorder

µR20000 2 pen recorder

µR20000 3 pen recorder

µR20000 4 pen recorder

µR20000 6 dot recorder

µR20000 12 dot recorder

µR20000 18 dot recorder

µR20000 24 dot recorder

Japanese

English & deg F / DST

Alarm output relay 2 points

Alarm output relay 4 points

Alarm output relay 6 points

Alarm output relay 12 points

Alarm output relay 24 points

RS-422A/485 interface

Ethernet (10BASE-T) interface

1

1

1

1,2

1,2

3

3

Fail/Chart end detection and output

Clamped input terminal

4

Non-glare door glass

Mathematical function

Cu10, Cu25 RTD input

3 legs isolated RTD

Expansion inputs

4,5

6

Remote control 5 points

2

iv

Page 7

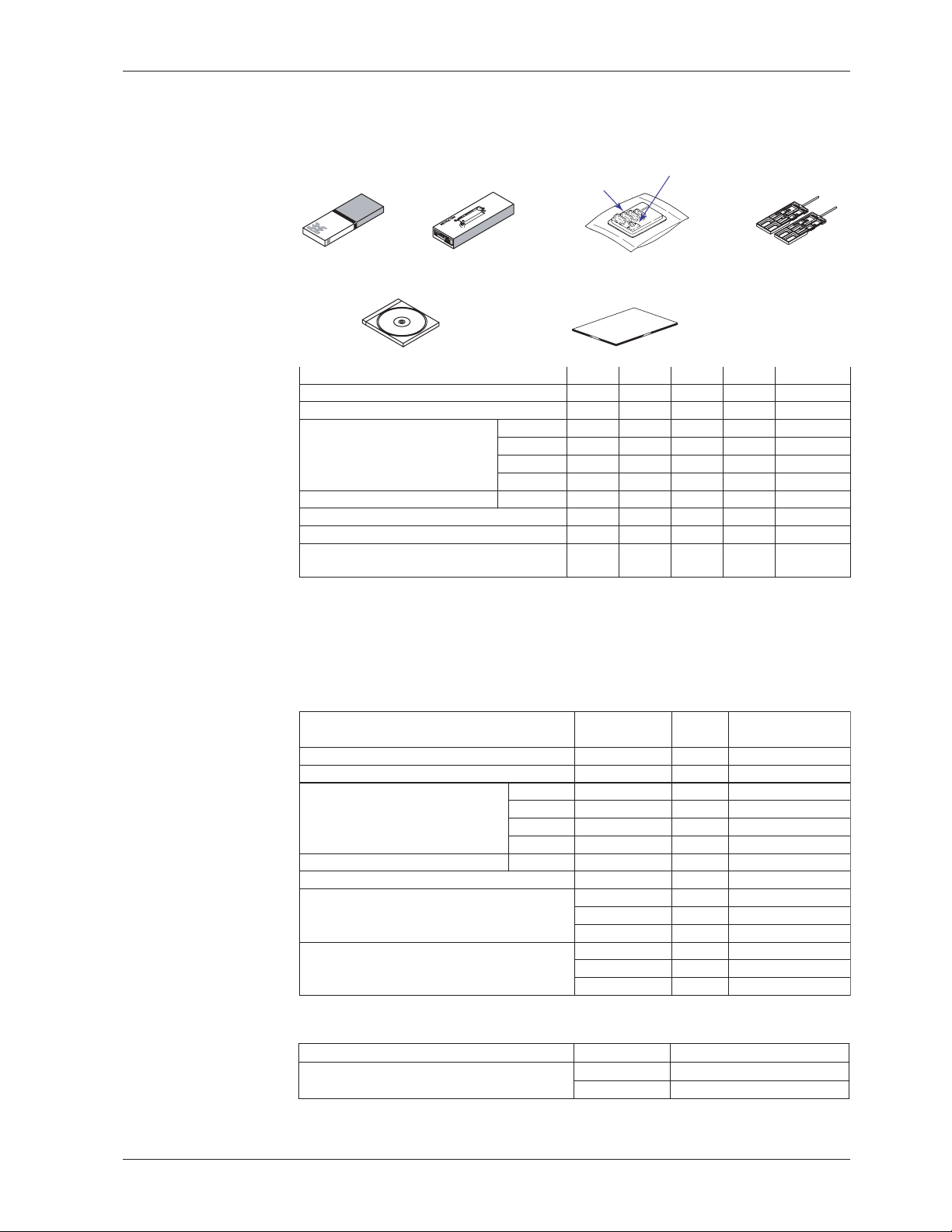

Standard Accessories

t

The standard accessories below are supplied with the recorder. Check that all contents

are present and undamaged.

Checking the Contents of the Package

Z-fold chart paper Ribbon cassette Disposable

Recording

Chart

Recording Chart

KOKUSAI

CHART

KOKUSAI

CHART

Manuals for the µR10000/µR20000

(CD-ROM)

Item 1-Pen 2-Pen 3-Pen 4-Pen Dot Printing

Z-fold chart paper 1 1 1 1 1

Ribbon cassette

Disposable felt pen

Plotter pen

Mounting bracket

Manuals for the µR10000/µR20000 (CD-ROM)

µR20000 Recorder Operation Guide

IM 04P02B01-02E

Optional Accessories (Sold Separately)

The optional accessories below are available for purchase separately. If you make an

order, make sure that all contents are present and undamaged.

For information about ordering accessories, contact the dealer from which you

purchased the recorder.

felt pen

Plotter pen Mounting bracke

µR20000 Recorder Operation Guide

IM 04P02B01-02E

---- 1

Red

Green

Blue

Violet

Purple

1111 -

-111 -

--11 -

---1 -

1111 2222 2

1111 1

1111 1

Z-fold chart paper

Ribbon cassette

Disposable felt pen

Plotter pen

Mounting bracket

Shunt resistor

for the screw terminal (standard)

Shunt resistor

for the clamped input terminal (/H2)

Software (Sold Separately, Planned)

Item

Configuration software

Item

Red

Green

Blue

Violet

Purple

Model

(Part Number)

RD110-ZFP 1

RD110-RC

RD100A-01

RD100A-02

RD100A-03

RD100A-04

RD100A-11

B9900BX

415920

415921

415922

438920

438921

438922

Model

RD100B-SW1

RD100B-SW2 With interface unit

1

1

1

1

1

1

2

1

1

1

1

1

1

NoteQuantity

10 pcs.

3 pcs.

3 pcs.

3 pcs.

3 pcs.

3 pcs.

250 Ω ± 0.1%

100 Ω ± 0.1%

10 Ω ± 0.1%

250 Ω ± 0.1%

100 Ω ± 0.1%

10 Ω ± 0.1%

Note

v

Page 8

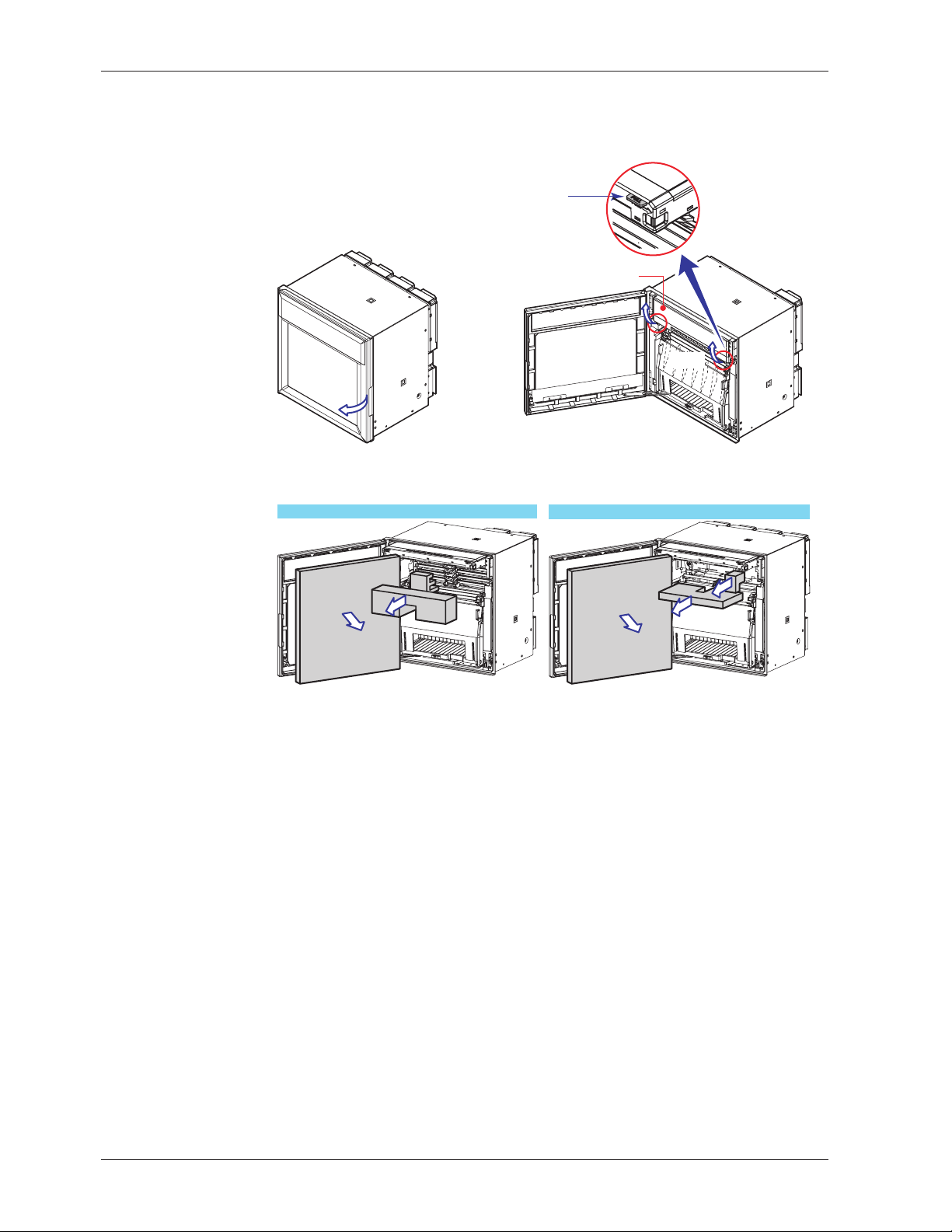

Checking the Contents of the Package

Removing the Packing Materials

Open the door, hold the left and right tabs and pull the display and key panel section

toward you. The section opens upward.

Open

Remove all packing materials.

• Pen Model • Dot Model

Pen model

Tab on the display

Display

Open

Dot model

Return the display and key panel section to its original position by pressing the section

downward.

vi

Page 9

How to Use This Manual

This user’s manual consists of the following sections.

For details on communication functions, see the RD100B/RD1800B Communication

Interface User’s Guide (M-4233) on the CD-ROM.

Chapter Title and Description

1 Functional Description

2 Before Using the Recorder

3 Names of Parts and Run Operations

4 Common Operations for Setting Functions and Setup Guide

5 Frequently Used Setup Operations (Setting Mode)

6 Setup Operations for Convenient Functions (Setting Mode)

7 Setup Operations for Changing/Adding Functions (Basic Setting Mode)

8 Setup Operations for Changing the Displayed Contents

9 Operations Related to the Computation Function (/M1 Option)

10 Troubleshooting

11 Maintenance

12 Specifications

Appendix Describes the printout contents.

Index

Describes the functions of the Recorder. Refer to this chapter when you are unsure

of the details of the function that you are operating.

Describes the installation and wiring procedures.

Describes the names of each part of the recorder and the daily operations.

Describes the execution modes of the recorder, basic setup operations using keys,

and provides a function setup guide.

Describes how to change the input range, alarms, chart speed, etc.

Describes the setup operations for convenient functions such as how to assign tags

to channels and how to set message strings that are to be printed.

Describes the setup operations for changing or adding functions such as setting the

recorder to detect sensor burnouts and changing the contents that are printed on the

chart paper.

Describes how to select the display type suitable for the application.

Describes all operations related to the computation function.

Describes error message and troubleshooting measures of the Recorder.

Describes periodic inspection, calibration, pen adjustment/printer carriage

adjustment, and recommended replacement period for worn parts.

Gives the specifications of the Recorder.

Note

• This user’s manual covers information regarding the recorders with English as the display/

recording language (suffix code “2”).

• For the procedure of setting the display/recording language, see section 7.14, “Changing the

Display/Recording Language.”

vii

Page 10

How to Use This Manual

Conventions Used in This Manual

Unit

K ........ Denotes 1024. Example: 768 KB (file size)

k ........ Denotes 1000.

Safety Markings

The following markings are used in this manual.

Improper handling or use can lead to injury to the user or

damage to the instrument. This symbol appears on the

instrument to indicate that the user must refer to the user’s

manual for special instructions. The same symbol appears in

the corresponding place in the user’s manual to identify those

instructions. In the manual, the symbol is used in conjunction

with the word “WARNING” or “CAUTION.”

WARNING

CAUTION

Note

Subheadings

On pages that describe the operating procedures in Chapter 3 through 9, the following

symbols are used to distinguish the procedures from their explanations.

Bold characters denote keys or character strings that are displayed on the screen.

Example: Range, Unit

Procedure

Explanation

Calls attention to actions or conditions that could cause serious

or fatal injury to the user, and precautions that can be taken to

prevent such occurrences.

Calls attentions to actions or conditions that could cause light

injury to the user or damage to the instrument or user’s data,

and precautions that can be taken to prevent such occurrences.

Calls attention to information that is important for proper

operation of the instrument.

Follow the numbered steps. All procedures are written with

inexperienced users in mind; depending on the operation, not

all steps need to be taken.

This subsection describes the setting parameters and the

limitations on the procedures. It does not give a detailed

explanation of the function. For details on the function, see

chapter 1.

viii

Page 11

Contents

1

Foreword ......................................................................................................................................... i

Safety Precautions ..........................................................................................................................ii

Checking the Contents of the Package ..........................................................................................iv

How to Use This Manual ............................................................................................................... vii

Chapter 1 Functional Description

1.1 Overview of the Recorder ................................................................................................ 1-1

1.2 Measuring Input Section .................................................................................................. 1-2

1.3 Alarms .............................................................................................................................. 1-7

1.4 Recording ....................................................................................................................... 1-13

1.5 Display ........................................................................................................................... 1-22

1.6 Computation Function (/M1 Option) ............................................................................... 1-24

1.7 FAIL/Chart End Detection and Output Function (/F1 Option) ........................................ 1-27

1.8 Remote Control Function (/R1 Option) .......................................................................... 1-28

1.9 Other Functions ............................................................................................................. 1-30

Chapter 2 Before Using the Recorder

2.1 Handling Precautions ....................................................................................................... 2-1

2.2 Installation ........................................................................................................................ 2-2

2.3 Input Signal Wiring ........................................................................................................... 2-5

2.4 Optional Terminal Wiring .................................................................................................. 2-9

2.5 Power Supply Wiring ...................................................................................................... 2-13

2.6 Turning ON/OFF the Power Switch................................................................................ 2-15

Chapter 3 Names of Parts and Run Operations

3.1 Names of Parts ................................................................................................................ 3-1

3.2 Installing or Replacing the Chart Paper ........................................................................... 3-4

3.3 Installing/Replacing Felt Pens or Plotter Pen (Pen Model) .............................................. 3-7

3.4 Installing/Replacing the Ribbon Cassette (Dot Model) .................................................... 3-9

3.5 Starting/Stopping the Recording .................................................................................... 3-11

3.6 Switching the Display Screen ........................................................................................ 3-12

3.7 Printing Measured Values (Manual Printout) ................................................................. 3-13

3.8 Printing the Recorder Settings ....................................................................................... 3-14

3.9 Clearing the Alarm Printout Buffer ................................................................................. 3-15

3.10 Printing Messages ......................................................................................................... 3-16

3.11 Resetting the Report Data of the Periodic Printout ........................................................ 3-17

3.12 Releasing the Alarm Output (Alarm ACK Operation) ..................................................... 3-18

3.13 Activating/Releasing the Key Lock ................................................................................. 3-19

Chapter 4 Common Operations for Setting Functions and Setup Guide

4.1 Run Modes ....................................................................................................................... 4-1

4.2 Key Operations ................................................................................................................ 4-2

4.3 Menu Structure, Settings, and List of Default Values ....................................................... 4-5

4.4 Function Setup Guide .................................................................................................... 4-14

2

3

4

5

6

7

8

9

10

11

12

App

Chapter 5 Frequently Used Setup Operations (Setting Mode)

5.1 Setting the Input Range ................................................................................................... 5-1

5.2 Setting the Alarm .............................................................................................................. 5-9

5.3 Setting the Unit on Scaled Channels ............................................................................. 5-12

Index

ix

Page 12

Contents

5.4 Changing the Chart Speed ............................................................................................ 5-13

5.5 Setting the Date/Time .................................................................................................... 5-14

Chapter 6 Setup Operations for Convenient Functions (Setting Mode)

6.1 Setting the Dot Printing Interval (Dot Model). .................................................................. 6-1

6.2 Setting the Filter (Pen Model) .......................................................................................... 6-2

6.3 Setting the Moving Average (Dot Model) ......................................................................... 6-3

6.4 Setting Recording Zones for Each Channel (Zone Recording) ........................................ 6-4

6.5 Setting the Partial Expanded Recording .......................................................................... 6-5

6.6 Turning Trend Recording (Dot Model) and Periodic Printout ON/OFF for Each Channel 6-6

6.7 Setting Tags on Channels ................................................................................................ 6-7

6.8 Setting the Message String .............................................................................................. 6-8

6.9 Setting the Secondary Chart Speed (Remote Control Function, /R1) ............................. 6-9

6.10 Setting the Alarm Delay Duration ................................................................................... 6-10

6.11 Setting the Brightness of the Display and Internal Light ................................................ 6-11

6.12 Applying a Bias on the Measuring Input Signal ............................................................. 6-12

6.13 Setting the Date/Time When Switching between Standard Time and DST ................... 6-13

Chapter 7 Setup Operations for Changing/Adding Functions (Basic Setting

Mode)

7.1 Changing the Auxiliary Alarm Function ............................................................................ 7-1

7.2 Changing the Integration Time of the A/D Converter ....................................................... 7-4

7.3 Setting the Burnout Detection Function of Thermocouples ............................................. 7-5

7.4 Setting the RJC Function on Channels Set to TC Input................................................... 7-6

7.5 Changing the Channel Recording Color (Dot Model) ...................................................... 7-8

7.6 Recording by Compensating for the Pen Offset along the Time Axis (Pen Model) .......... 7-9

7.7 Turning Printouts ON/OFF.............................................................................................. 7-10

7.8 Setting the Periodic Printout Interval and the Type of Measured Values to Be Printed . 7-12

7.9 Setting the Bar Graph Display Mode ............................................................................. 7-15

7.10 Setting the Key Lock Function ....................................................................................... 7-16

7.11 Enabling the Moving Average Function (Dot Model)...................................................... 7-19

7.12 Enabling the Filter Function (Pen Model) ....................................................................... 7-20

7.13 Enabling the Partial Expanded Recording Function ...................................................... 7-21

7.14 Changing the Display/Recording Language .................................................................. 7-22

7.15 Enabling the Bias Function, Low-Cut Function, and Alarm Delay Function ................... 7-23

7.16 Changing the Time Printout Format ............................................................................... 7-25

7.17 Initializing the Settings ................................................................................................... 7-27

7.18 Assigning Functions to the Remote Control Input Terminals (/R1 Option) ..................... 7-28

7.19 Changing the Printout/Display Format of the Date ........................................................ 7-30

7.20 Changing the Temperature Unit ..................................................................................... 7-31

Chapter 8 Setup Operations for Changing the Displayed Contents

8.1 Key Operations for Changing the Displayed Information ................................................. 8-1

8.2 Changing the Displayed Information ................................................................................ 8-3

Chapter 9 Operations Related to the Computation Function (/M1 Option)

9.1 Starting/Stopping/Resetting the Computation .................................................................. 9-1

9.2 Setting the Computing Equation ...................................................................................... 9-2

9.3 Setting the Unit ................................................................................................................ 9-9

9.4 Setting the Constants Used in Equations ...................................................................... 9-10

9.5 Setting the Alarm............................................................................................................ 9-11

9.6 Specifying the Timer Used in Statistical Calculations (TLOG) ....................................... 9-13

9.7 Setting Recording Zones for Each Channel (Zone Recording) ...................................... 9-15

x

Page 13

Contents

9.8 Setting the Partial Expanded Recording ........................................................................ 9-16

9.9 Turning Trend Recording (Dot Model) and Periodic Printout ON/OFF

for Each Channel ................................................................................................ 9-17

9.10 Setting Tags on Channels .............................................................................................. 9-18

9.11 Setting the Alarm Delay Duration ................................................................................... 9-19

9.12 Setting the Timer Used in TLOG Computation and Periodic Printout ............................ 9-20

9.13 Changing the Channel Recording Color (Dot Model) .................................................... 9-23

9.14 Changing the Channel Assignments of Recording Pens (Pen Model)........................... 9-24

9.15 Changing the Type of Report Data Printed in Periodic Printout ..................................... 9-25

9.16 Setting the Bar Graph Display Mode ............................................................................. 9-27

9.17 Setting the Procedure Taken When the Computed Result Is in Error ............................ 9-28

Chapter 10 Troubleshooting

10.1 A List of Error Messages ................................................................................................ 10-1

10.2 Troubleshooting Flow Charts ......................................................................................... 10-4

Chapter 11 Maintenance

11.1 Periodic Inspection ......................................................................................................... 11-1

11.2 Cleaning the Recorder ................................................................................................... 11-2

11.3 Replacing the Internal Light LED ................................................................................... 11-3

11.4 Calibrating the Recorder ................................................................................................ 11-4

11.5 Adjusting the Pen Position (Pen Model) ........................................................................ 11-6

11.6 Adjusting the Dot Printing Position (Dot Model) ............................................................. 11-7

11.7 Recommended Replacement Periods for Worn Parts ................................................... 11-9

1

2

3

4

5

6

7

Chapter 12 Specifications

12.1 Input Specifications ........................................................................................................ 12-1

12.2 Alarm Function Specifications ........................................................................................ 12-3

12.3 Recording Function Specifications ................................................................................. 12-4

12.4 Display Function Specifications ..................................................................................... 12-7

12.5 Specifications of Optional Functions ............................................................................ 12-13

12.6 General Specifications ................................................................................................. 12-17

12.7 Dimensional Drawings ................................................................................................. 12-21

Appendix

Appendix 1 Periodic Printout and Printout Using the TLOG Timer (/M1 Option) ................. App-1

Index

8

9

10

11

12

App

Index

xi

Page 14

Chapter 1 Functional Description

1.1 Overview of the Recorder

The RD1800B Recorder (hereafter referred to as the recorder) can be used to assign DC

voltage, 1-5V, thermocouple, RTD, and contact or voltage ON/OFF signal to channels for

measurement. The measured results are recorded with pens or dots on a chart paper

that is fed at a constant speed. The pen model can record up to 4 channels; the dot

model can record up to 24 channels.

Alarms

For each channel, various alarms such as high limit alarm and low limit alarm can be

assigned to monitor the measured values. Alarm output relays can be used to output

contact signals when alarms occur (/A1, /A2, /A3, /A4, and /A5 options).

Recording

The measured results are recorded with pens or dots on a chart paper (trend recording).

The chart speed can be selected from 5 to 12000 mm/h on the pen model and 1 to 1500

mm/h on the dot model.

In addition to trend recording, various types of information can be printed or recorded on

the chart paper such as numeric measured values, alarm occurrence/release, and

predefined messages.

Also, the recorder settings can be printed.

1

Functional Description

Internal Light

A light is provided for easier viewing of the recording area of the chart paper.

Display

Measured values can be displayed numerically or using bar graphs on the large display.

Also, alarm status and chart speed can be displayed.

Communication Function

Using the Ethernet communication interface (/C7 option) or the RS-422A/485

communication interface (/C3 option), the measured values on the recorder can be

output to a PC or a PC can be used to control the recorder.

This manual does not cover the communication functions. For details on communication

functions, see the RD100B0/RD1800B Communication Interface User’s Manual (IM

04P01B01-17E) on the CD-ROM.

Other Main Functions

The computation function (/M1 option) can be used to perform various computations from

four arithmetic operations to statistical calculations on 8 and 24 computation channels on

the pen model and dot model, respectively. The computed results can be recorded.

The remote control function (/R1 option) can be used to control the start/stop and other

operations of the recorder by applying contact signals to the dedicated terminals.

The FAIL/chart end detection and output function (/F1 option) can be used to output

contact signals when errors are detected on the recorder or when the chart paper runs

out.

1-1

Page 15

1.2 Measuring Input Section

Input Section

Number of Measurement Channels and Scan Interval

The recorder samples the input signals on the measurement channels at the scan

interval to obtain the measured values.

Model Num. of Ch. Scan Interval

1-pen model 1 125 ms

2-pen model 2 125 ms

3-pen model 3 125 ms

4-pen model 4 125 ms

6-dot model 6 1 s (2.5 s when the integration time of the A/D converter is 100 ms.)

12-dot model 12 2.5 s (5 s when the integration time of the A/D converter is 100 ms.)

18-dot model 18 2.5 s (10 s when the integration time of the A/D converter is 100 ms.)

24-dot model 24 2.5 s (10 s when the integration time of the A/D converter is 100 ms.)

Input Type, Measurable Range, and Computation

The recorder can measure the following types of inputs.

Input Type Measurable Range

DC voltage DC voltage in the range of ±20 mV to ± 50 V

1-5V See “1-5V” below.

Thermocouple Temperature range corresponding to each type: R, S, B, K, E, J, T, N, W, L, U,

RTD Temperature range corresponding to each type: Pt100Ω and JPt100Ω

ON/OFF input Contact input: Open contact is OFF (0). Closed contact is ON (1).

and WRe

Voltage input: Less than 2.4 V is OFF (0). Greater than or equal to 2.4 V is ON (1)

• 1-5V

1-5V is scaled to values in the appropriate unit to be used as measured values. Also,

the low-cut function (input less than 0% is fixed to 0 (scale left value)) can be used.

• Current Input

A shunt resistor is attached to the input terminal. The current signal is converted to a

voltage signal and measured. The measurable range is the range equivalent to the

“DC voltage” range indicated above after converting the current to the voltage signal.

Note

Three types of shunt resistors (250 Ω, 100 Ω, and 10 Ω) are available for current input (see

“Optional Accessories (Sold Separately)” on page v). For example, a 250-Ω shunt resistor is

used to convert the signal to the range of 1 to 5 V for 4 to 20 mA input.

• Range Type, Measurable Range, and Recording Span

Various “range type” are available for the different types of inputs (for example

thermocouple R). Each range type has a preset measurable range (0.0 to 1760.0°C

for thermocouple R). Measurement can be made by specifying an arbitrary range

within the measurable range as the input range. The measured values in the input

range are recorded on the chart paper. The range of measured values that are

recorded is called the recording span.

Measurable range

(Thermocouple R example)

1760.0°C

Input range or

recording span

1500.0°C (rightmost value of span)

1-2

300.0°C (leftmost value of span)

0.0°C

<Related Topics>

Setting the input range: Section 5.1

Page 16

1.2 Measuring Input Section

• Delta Computation

The value obtained by subtracting the measured value of another channel (called the

reference channel) from the input value of the channel set to delta computation is used

as the measured value of that channel. The reference channel must be assigned to a

channel whose channel number is less than that of the channel on which delta

computation is specified. The channel on which delta computation is specified is

automatically set to the same range type as the reference channel.

Channel set to delta computation

Input

value

–

Measured value on the reference channel

DC voltage

Measured value

Note

A channel whose input type is set to DC voltage, TC, or RTD can be designated as a

reference channel. However, channels set to scaling or square root computation cannot be

designated.

• Scaling

The input values are scaled to values in the appropriate unit to be used as measured

values.

Measured valueInput value

10 V

300.0°C

1

Functional Description

0 V −100.0°C

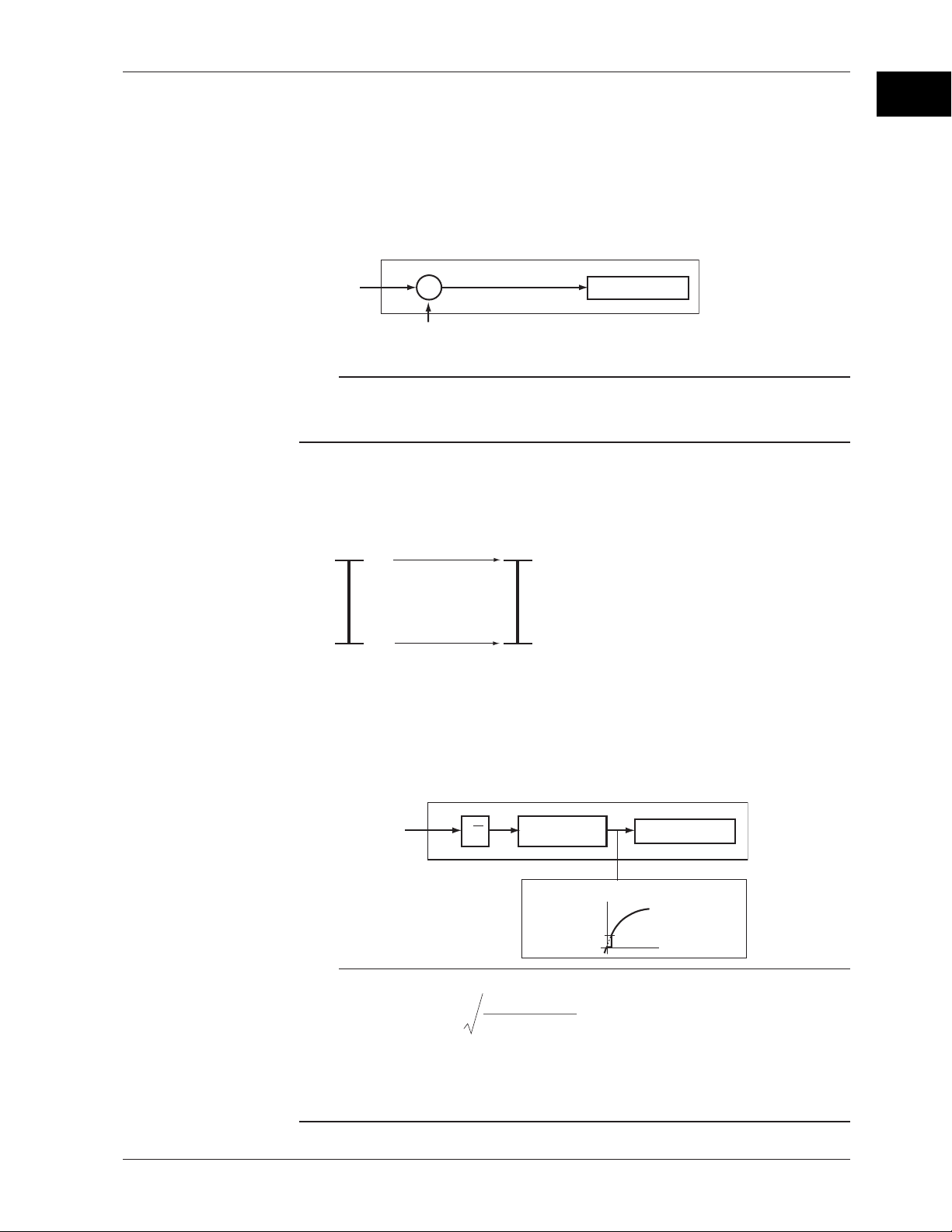

• Square Root Computation

When the input type is DC voltage, the square root of the input value is calculated, the

result is scaled to a value in the appropriate unit, and used as the measured value of

the channel. Also, the low-cut function (input less than a given measured value is

fixed to 0 (scale left value)) can be used.

Channel set to square root computation

Input value

√

Scaling

Measured value

Low-cut value

Measured value

Result of square

root computation

Note

The square root computation on the recorder uses the following formula.

min

V - V

F = ( F - F )

x

max

min min

where Vmin (leftmost value of span) < Vmax (rightmost value of span)

Fmin (leftmost value of scale after scaling) < Fmax (rightmost value of scale after

scaling)

Vx is the input voltage and Fx is the scaled value

x

max min

V - V

+ F

1-3

Page 17

1.2 Measuring Input Section

Bias

A given value (bias value) is added to the input value and used as the measured value of

that channel.

Biased channel

Input value

<Related Topics>

Setting the bias: Section 7.15 and 6.12

Burnout Detection of Thermocouples

This function makes the recording go off the scale to the right or left when the

thermocouple burns out while measuring temperature with a thermocouple. This

function can also be used on 1-5V. The burnout detection function can be set for each

channel.

By default, this function is disabled.

Note

For 1-5V, a burnout occurs when the input value is less than or equal to 0.2 V.

+

Measured value

+

Bias value

<Related Topics>

Setting the burnout detection function: Section 7.3

Reference Junction Compensation of Thermocouple Input

When measuring the temperature using a thermocouple, the reference junction

compensation on the recorder can be used. When using external reference junction

compensation, you can set the reference voltage. The reference junction compensation

can be set for each channel.

By default, the recorder is configured to use the internal reference junction compensation

function.

Note

When using external reference junction compensation, set an appropriate reference junction

compensation voltage. For example, if the reference junction temperature of the external

reference compensation is T0 °C, set the reference compensation junction voltage to the

thermoelectromotive force of the 0°C reference of T0 °C.

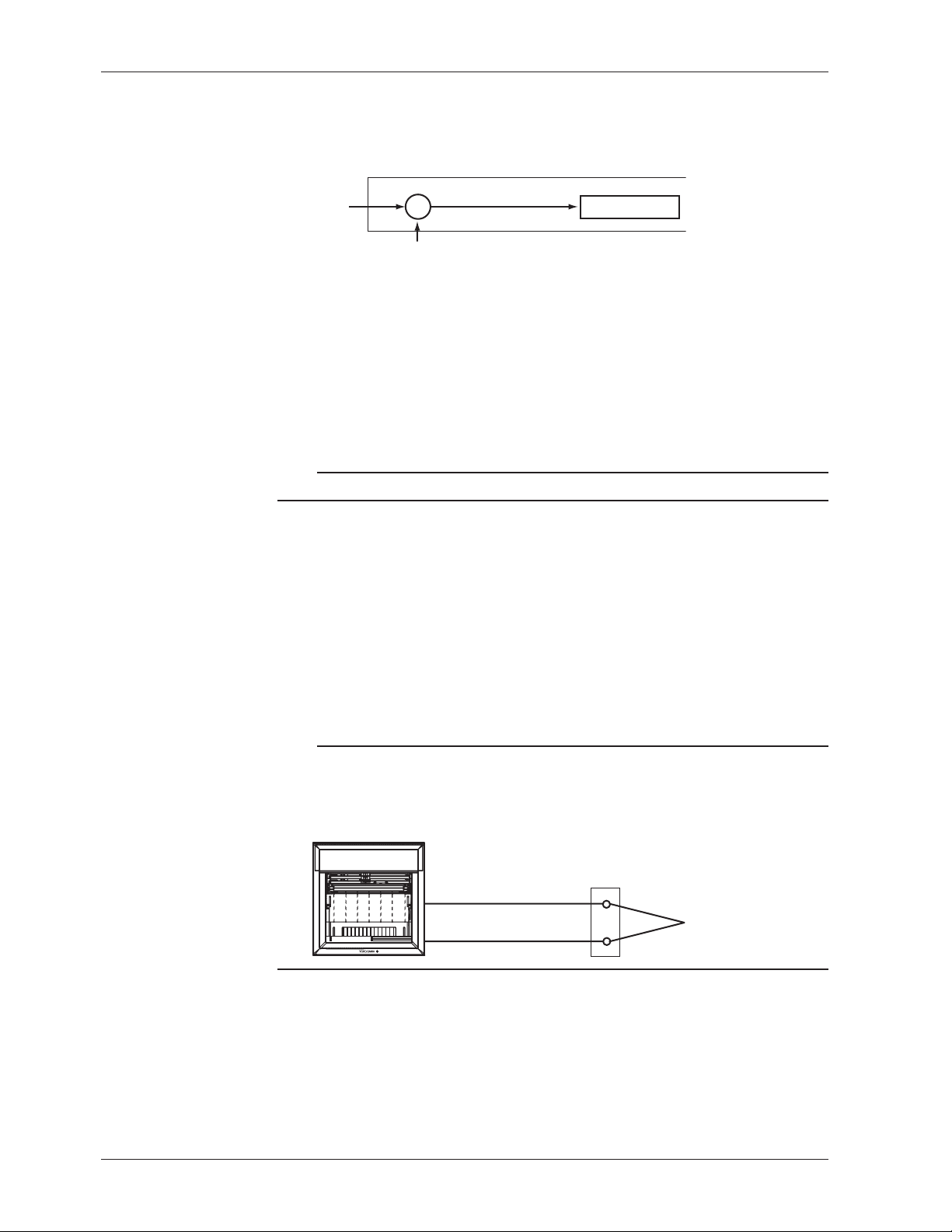

Recorder

1

3

2

4

External reference junction compensation

(Hold the contact point of the thermocouple

and copper wire at T

Copper wire

0

°C)

Thermocouple

1-4

<Related Topics>

Setting the reference junction compensation function: Section 7.4

Page 18

1.2 Measuring Input Section

Noise Elimination from Input Signals

Filter and Moving Average

This function used to suppress the effects of noise that is riding on the signal. The pen

model and dot model are equipped with a filter function and a moving average function,

respectively. The function can be set for each measurement channel. However, it does

not operate on channels set to ON/OFF input.

• Filter (Pen Model)

The filter is a low-pass filter. The time constant can be set to 2 s, 5 s, or 10 s.

Filter result (output for a step input)

Input

2, 5, 10 s (time constant, the time it takes

to reach 63.2% of the output value)

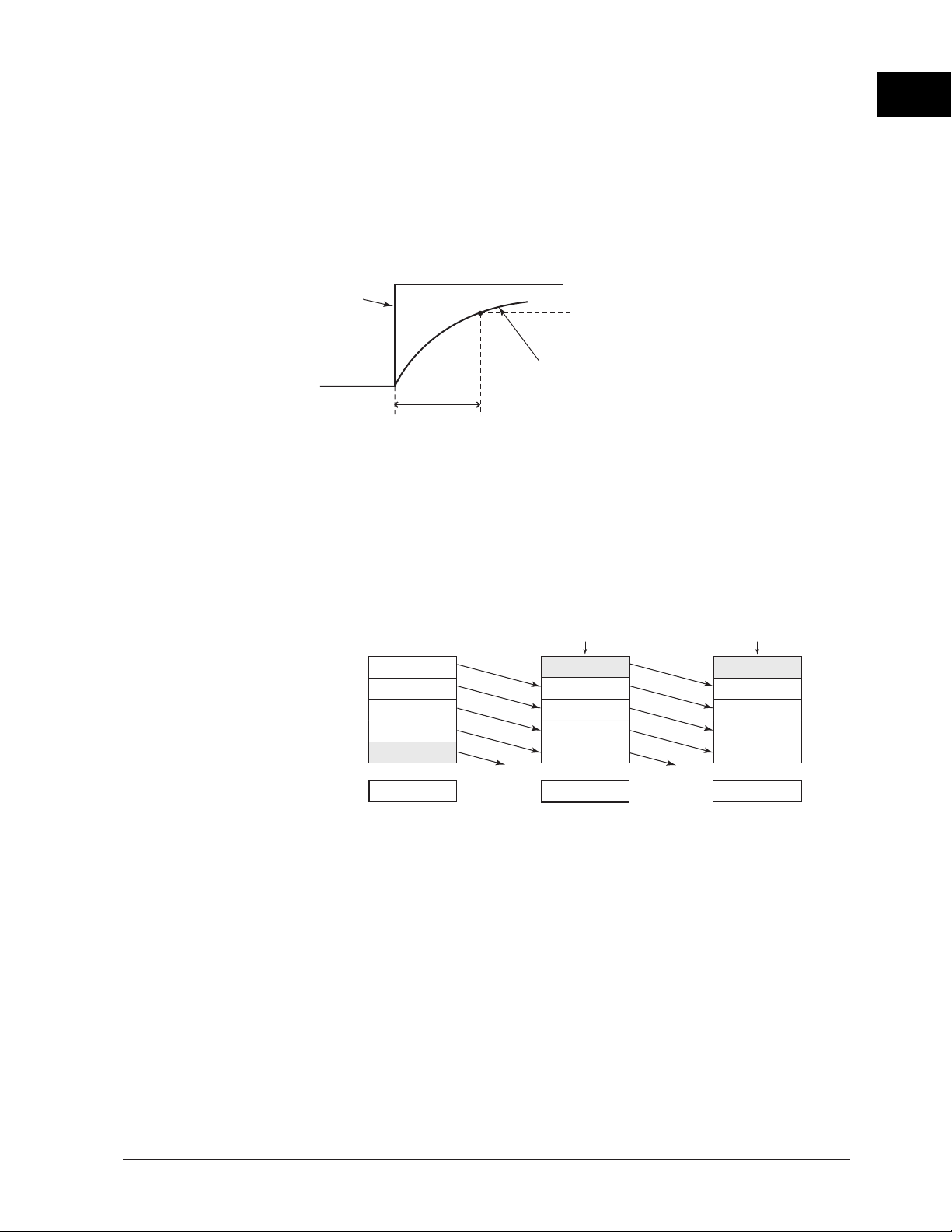

• Moving Average (Dot Model)

The average value of the m most recent values acquired at the scan interval is used

as the measured value of the channel. The number of moving-averaged data points

(m) can be set in the range 2 to 16. The figure below shows an example indicating

the operation of the buffer for the moving average computation when the number of

moving averaged data points is set to 5.

1

Functional Description

63.2% of the output value

Output response curve

(when using the filter)

Moving

average

Buffer data for the

nth sampling time

10.0 mV

1

5.0 mV

2

0.0 mV

3

–5.0 mV

4

–10.0 mV

5

0.0 mV

Buffer data for the

n+1th sampling time

Most recent data Most recent data

15.0 mV

10.0 mV

5.0 mV

0.0 mV

–5.0 mV

Deleted

5.0 mV

<Related Topics>

Setting the filter: Section 7.12 and 6.2

Setting the moving average: Section 7.11 and 6.3

Buffer data for the

n+2th sampling time

10.0 mV

15.0 mV

10.0 mV

5.0 mV

0.0 mV

Deleted

8.0 mV

1-5

Page 19

1.2 Measuring Input Section

Integration Time of the A/D Converter

The recorder uses an A/D converter to convert the sampled analog signal to a digital

signal. By setting the integration time of the A/D converter to match the time period

corresponding to one cycle of the power supply or an integer multiple of one cycle, the

power supply frequency noise can be effectively suppressed.

The integration time of the A/D converter is selected according to the model from the

table below.

Model Integration Time of the A/D Converter

Pen model Select 16.7 ms (60 Hz), 20 ms (50 Hz), or Auto

Dot model Select 16.7 ms (60 Hz), 20 ms (50 Hz), 100 ms or Auto

• If Auto is selected, the recorder detects the power supply frequency and automatically

selects 16.7 ms or 20 ms.

• Because 100 ms is an integer multiple of 16.7 ms and 20 ms, this setting can be used

to suppress the power frequency noise for either frequency, 50 Hz or 60 Hz.

• The scan interval on the dot model varies depending on the integration time setting

(see page 1-2).

<Related Topics>

Setting the A/D integration time: Section 7.2

1-6

Page 20

1.3 Alarms

This function generates an alarm when the measured data meets a certain condition.

The alarm occurrence/release can be recorded on the chart paper. The alarm status can

be displayed on the screen.

Also, alarm output relays can be used to output contact signals when alarms occur (/A1,

/A2, /A3, /A4, and /A5 options).

Alarm Types

Number of Alarm Point Marks

Up to four alarms can be set for each channel.

Alarm Conditions

The eight conditions below are available. The character inside the parentheses is the

symbol used to denote each alarm on the recorder.

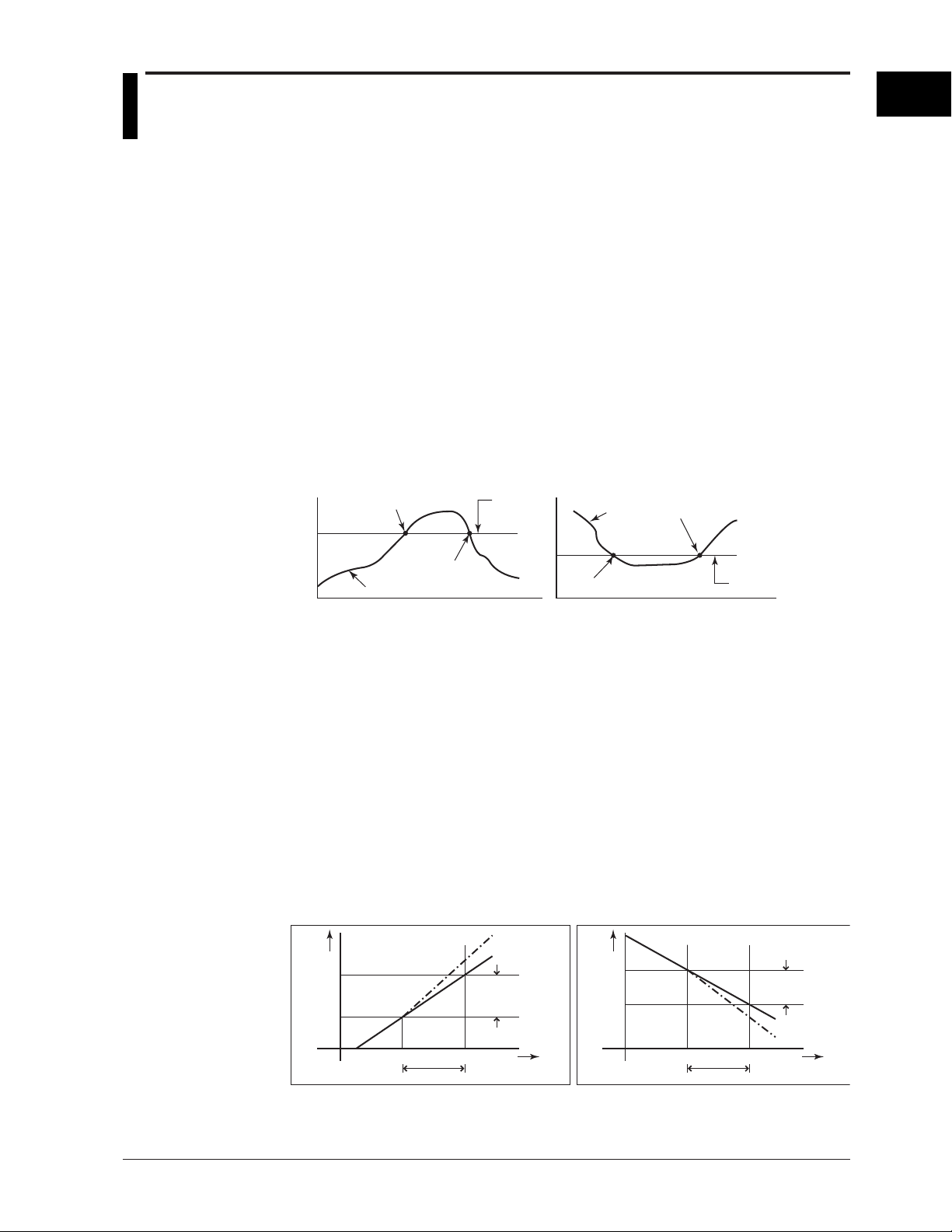

• High Limit Alarm (H)

• Low Limit Alarm (L)

An alarm occurs when the input value exceeds the alarm value.

An alarm occurs when the input value falls below the alarm value.

High limit alarm

Alarm occurrence

Alarm

value

Low limit alarm

Measured

value

Alarm release

1

Functional Description

Alarm release

Measured value

Alarm occurrence

Alarm value

• Difference High Limit Alarm (h)*

An alarm occurs when the difference in the input values of two channels is greater

than or equal to the specified value.

• Difference Low Limit Alarm (l)*

An alarm occurs when the difference in the input values of two channels is less than

or equal to the specified value.

* Can be specified on channels set to delta computation.

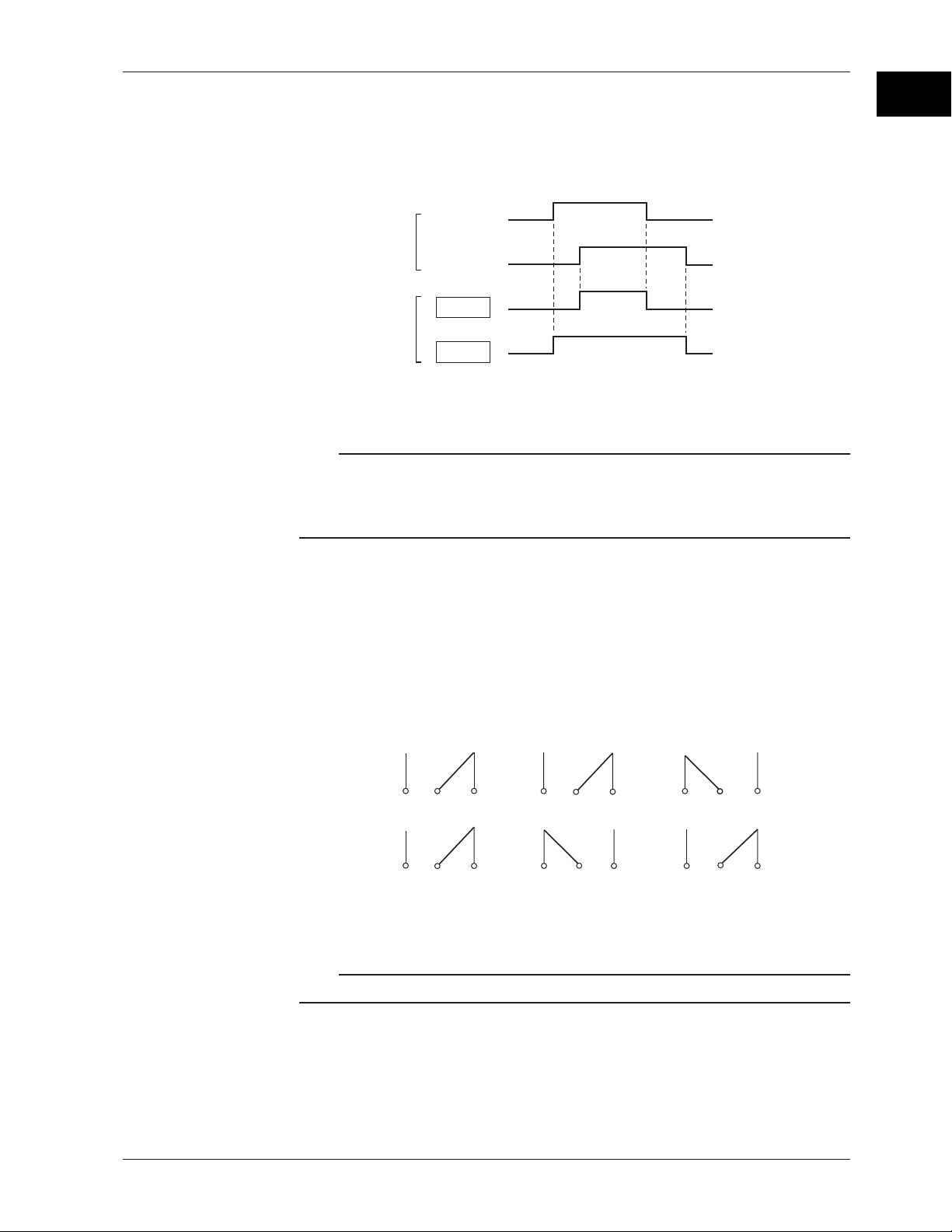

• High Limit on Rate-of-Change Alarm (R)

The rate-of-change of the measured values is checked over a certain time (interval).

An alarm occurs if the rate-of-change of the measured value in the rising direction is

greater than or equal to the specified value.

• Low Limit on Rate-of-Change Alarm (r)

The rate-of-change of the measured values is checked over a certain time (interval).

An alarm occurs if the rate-of-change of the measured value in the falling direction is

greater than or equal to the specified value.

High limit on rate-of-change alarm Low limit on rate-of-change alarm

Change in the

Measured

value

T

2

T

1

t

1

t2−t

1

Interval

measured value

Amount of change

in the setting

T2−T

||

1

t

Time

2

Measured

value

T

1

T

2

t

1

t2−t

Interval

Amount of change

in the setting

T2−T

|

t

2

1

Change in the

measured value

Time

|

1

The alarm value of the rate-of-change alarm is set using an absolute value. The

interval is derived using the following equation and set using the number of samples.

Interval = the scan interval × the number of samples

1-7

Page 21

1.3 Alarms

• Delay High Limit Alarm (T)

An alarm occurs when the measured value remains above the alarm value for a

specified time period (alarm delay period).

• Delay Low Limit Alarm (t)

An alarm occurs when the measured value remains below the alarm value for a

specified time period (alarm delay period).

Delay High Limit Alarm Example (T is the specified delay)

Measured value

X1 X2 X3 X4

Alarm value

T1

T

Alarm releaseAlarm occurrence

• Alarm does not occur at T1, because the time period is shorter than the specified

alarm delay period (T).

• The measured value exceeds the alarm value at time X2, and the alarm occurs at

time X3 at which the specified alarm delay period elapses (the time when the alarm

occurs is the time at X3).

• The measured value falls below the alarm value at time X4, and the alarm is

released.

Note

• The alarm detection operation is reset when a power failure occurs. The operation

restarts after the power recovers.

• If the alarm value is changed while a delay alarm is occurring, the alarm is released if the

new alarm value does not meet the alarm condition.

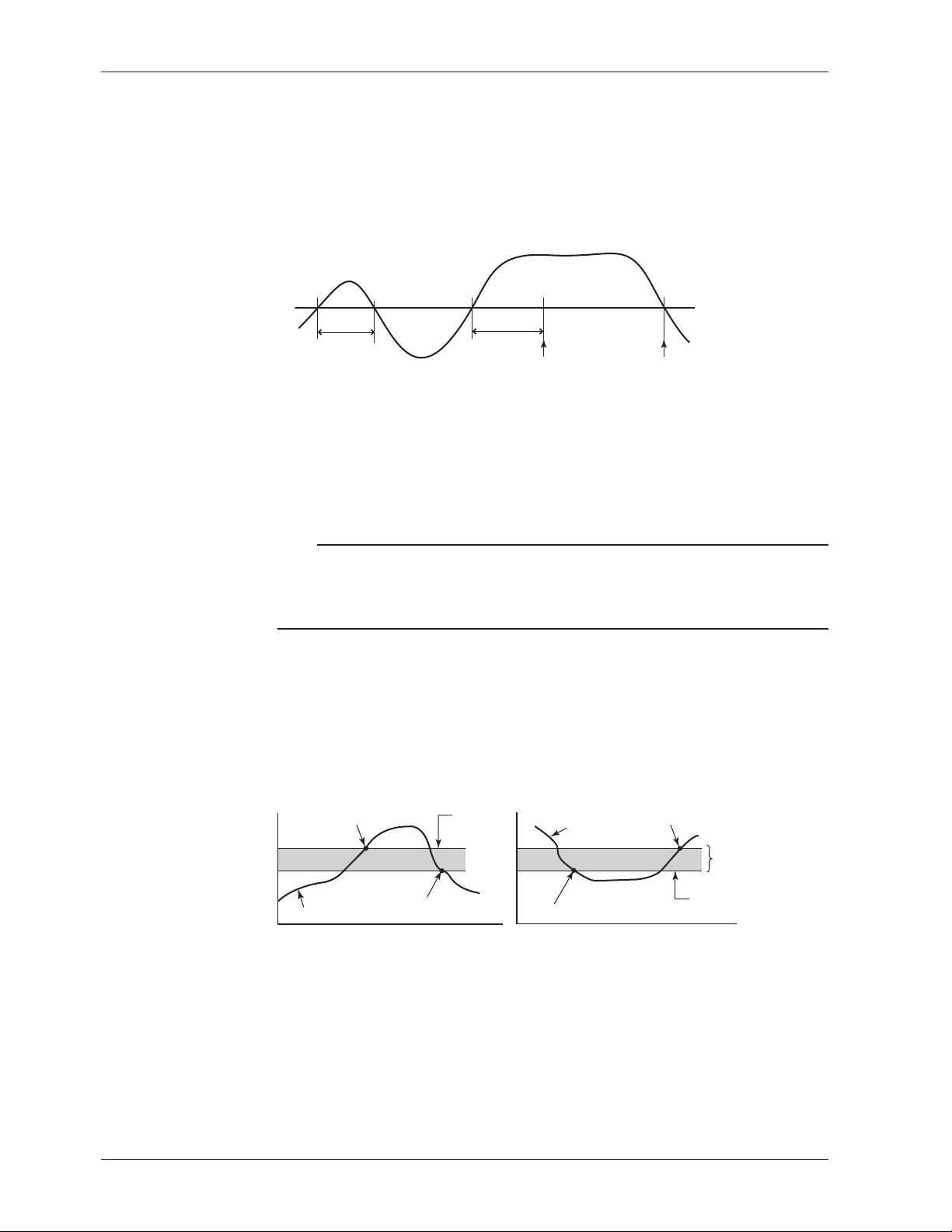

Alarm Hysteresis

Hysteresis can be specified to the values for activating and releasing the alarm. The

hysteresis applies only to high limit alarm (H) and low limit alarm (L). The hysteresis

width can be set in the range of 0.0% (Off) to 1.0% of the recording span in 0.1 steps.

The setting applies to all high limit alarms and low limit alarms. By default, the hysteresis

width is set to 0.5%.

High limit alarm

Alarm occurrence

Measured value

Alarm release

Alarm

value

<Related Topics>

Setting alarms: Section 5.2

Setting the alarm delay function: Section 7.15 and 6.10

Setting the alarm hysteresis: Section 7.1

Low limit alarm

Measured

value

Alarm occurrence

Alarm release

Hysteresis

(1% or less)

Alarm value

1-8

Page 22

1.3 Alarms

Alarm Indication

Alarm Recording

The alarm status can be displayed on the screen. For details on the display, see section

1.5.

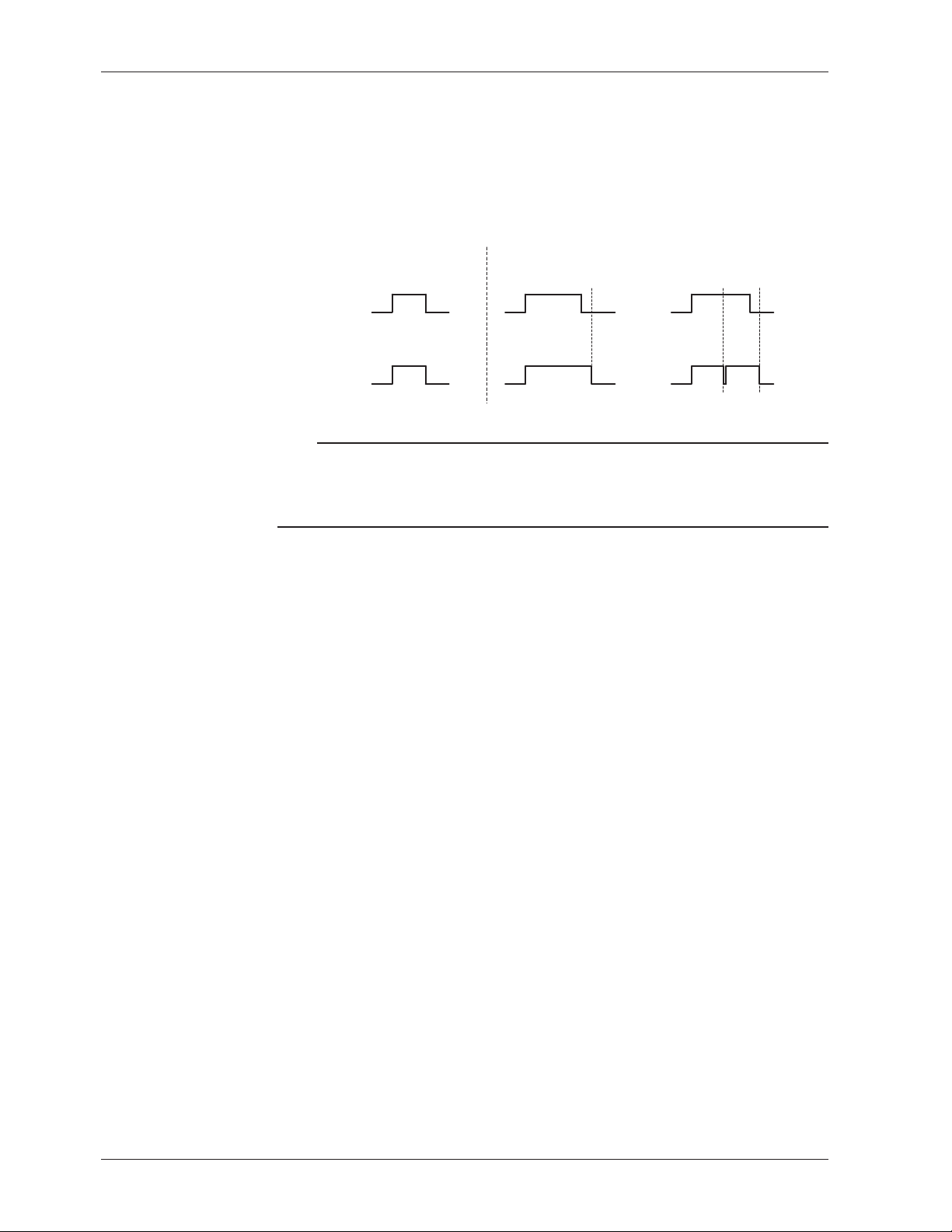

Non-Hold/Hold Operation of the Alarm Indication

The alarm indication can be set to operate in the following fashion when the alarm

condition is no longer met.

• Clear the alarm indication (non-hold).

• Hold the alarm indication until the alarm ACK operation is executed (hold).

The default setting is non-hold.

HoldNon-hold

Alarm ACK Alarm ACK

or

Blinking

or

Blinking

OFF

ON

Alarm

Alarm

indication

Alarm occurrence

Alarm release

ON

OFF

OFF

<Related Topics>

Setting the non-hold/hold operation of the alarm indicator: Section 7.1

The alarm occurrence/release can be recorded on the chart paper. See section 1.4.

1

Functional Description

Alarm Output Relay (/A1, /A2, /A3, /A4, and /A5 Options)

Contact signals can be generated from alarm output relays when alarms occur. The

number of output relays is 2 (/A1), 4 (/A2), 6 (/A3), 12 (/A4), or 24 (/A5). The alarm

output relays are denoted as I01 to I06, I11 to I16, I21 to I26, and I31 to I36 on the

recorder.

The following functions can be assigned to the alarm output relay.

Diagnosis Output

The diagnosis output can be assigned to alarm output relay I01.

The relay is activated when there is an error in the plotter operation on the pen model,

when a burnout is detected, or when there is an error in the A/D converter. Output relay

I01 is normally energized and de-energizes when an error is detected (de-energized

operation and non-hold operation).

NO C NC

Normal

NO: Normally Opened, C: Common, NC: Normally Closed

Note

If diagnosis output is enabled, I01 becomes a relay dedicated to diagnosis output.

<Related Topics>

Setting the diagnosis output: Section 7.1

NO C NC

Malfunction

NO C NC

Power-OFF

1-9

Page 23

1.3 Alarms

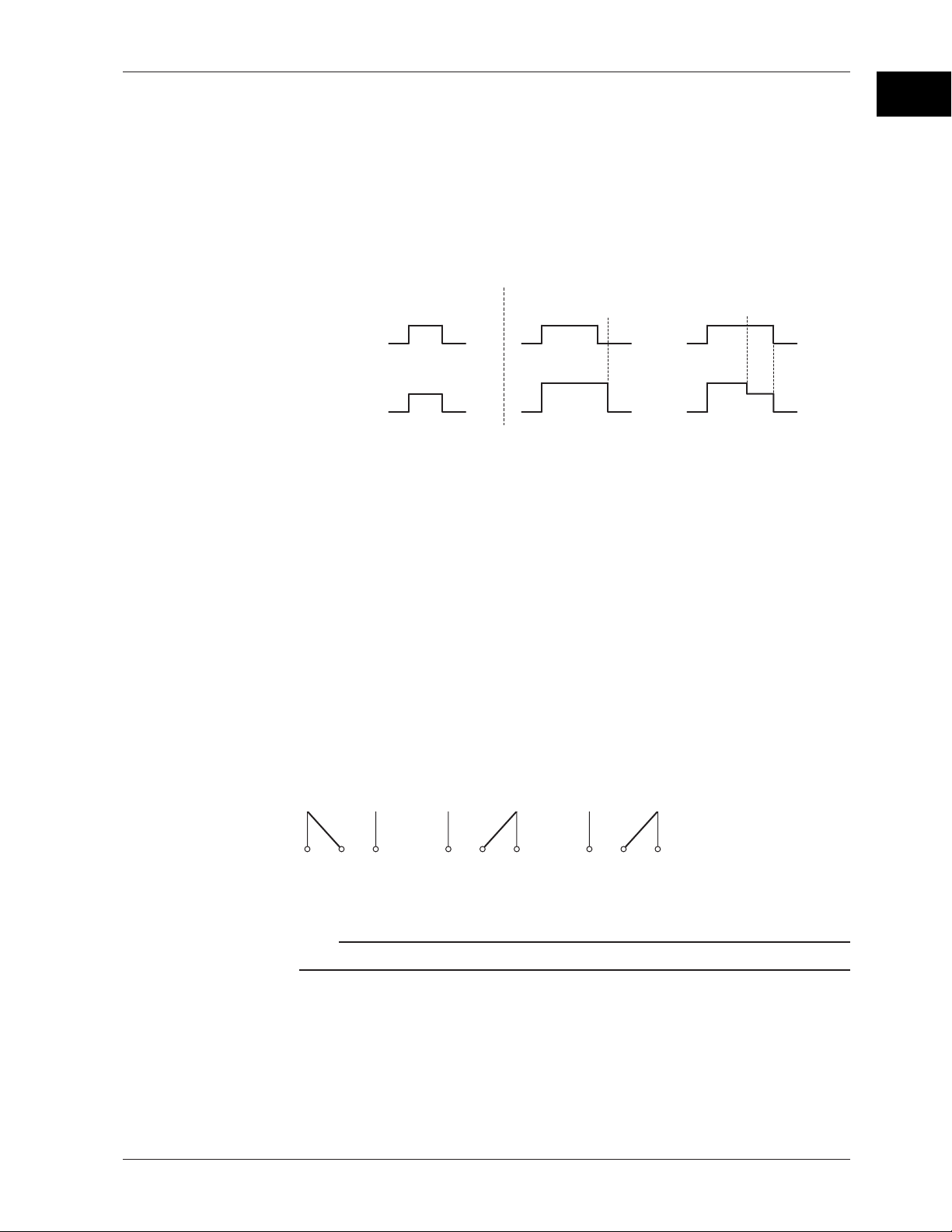

Reflash Alarm

When multiple alarms are assigned to one alarm output relay, this function notifies the

occurrence of subsequent alarms after the relay is activated by the first alarm. When

subsequent alarms occur, the output relay is released temporarily (approximately 500

ms).

The reflash alarm function is set to three output relays (I01, I02, and I03 (I01 and I02 for

the /A1 option)).

By default, the reflash alarm is disabled.

Alarm

Alarm output relay

(Reflash alarm ON)

Alarm output relay

(Reflash alarm OFF)

Channel 1

Channel 2

Channel 3

Approx. 500 ms Approx. 500 ms

Note

• If the reflash alarm is enabled, I01 to I03 are set to reflash alarm operation. In this case, I01

to I03 are set to OR operation and non-hold operation regardless of the settings specified in

“AND/OR Operation of Alarm Output Relays” and “Non-Hold/Hold Operation of Alarm Output

Relays” described below.

• If diagnosis output is enabled, I01 is set to diagnosis output.

<Related Topics>

Setting the reflash alarm: Section 7.1

1-10

Page 24

1.3 Alarms

AND/OR Operation of Alarm Output Relays

When multiple alarms are assigned to one alarm output relay, the condition for activating

the alarm output relay can be selected from the following:

• AND: Activated when all assigned alarms are occurring simultaneously.

• OR: Activated when any of the specified alarms is occurring.

Channel 01

Alarm

Channel 02

AND

Alarm output relay

OR

The alarm output relays assigned to AND operation are specified as follows: “I01 (first

relay) to Ixx (where xx is the relay number).”

The default setting is “no AND relay.”

Note

• If the reflash alarm is enabled, I01 to I03 are fixed to OR operation. Specifying AND

produces no effect.

• If diagnosis output is enabled, I01 is set to diagnosis output. Specifying AND produces no

effect.

1

Functional Description

<Related Topics>

Setting the AND operation: Section 7.1

Energized/De-energized Operation of Alarm Output Relays

You can select whether the alarm output relay is energized or de-energized when an

alarm occurs. If de-energized is selected, the status of the alarm output relay when an

alarm occurs is the same as the status that results when the power is shut down. The

setting applies to all alarm output relays.

The default setting is energized.

NO

Energize

De-energize

NO : Normally Opened, C : Common, NC : Normally Closed

C NC NO C NC NO C NC

NC

When power is

shut down

NO C NC NO C NCNO C

When alarm is

not occurring

When alarm is

occurring

Note

If diagnosis output is enabled, I01 is fixed to de-energized operation.

<Related Topics>

Setting the energized/de-energized operation of alarm output relays: Section 7.1

1-11

Page 25

1.3 Alarms

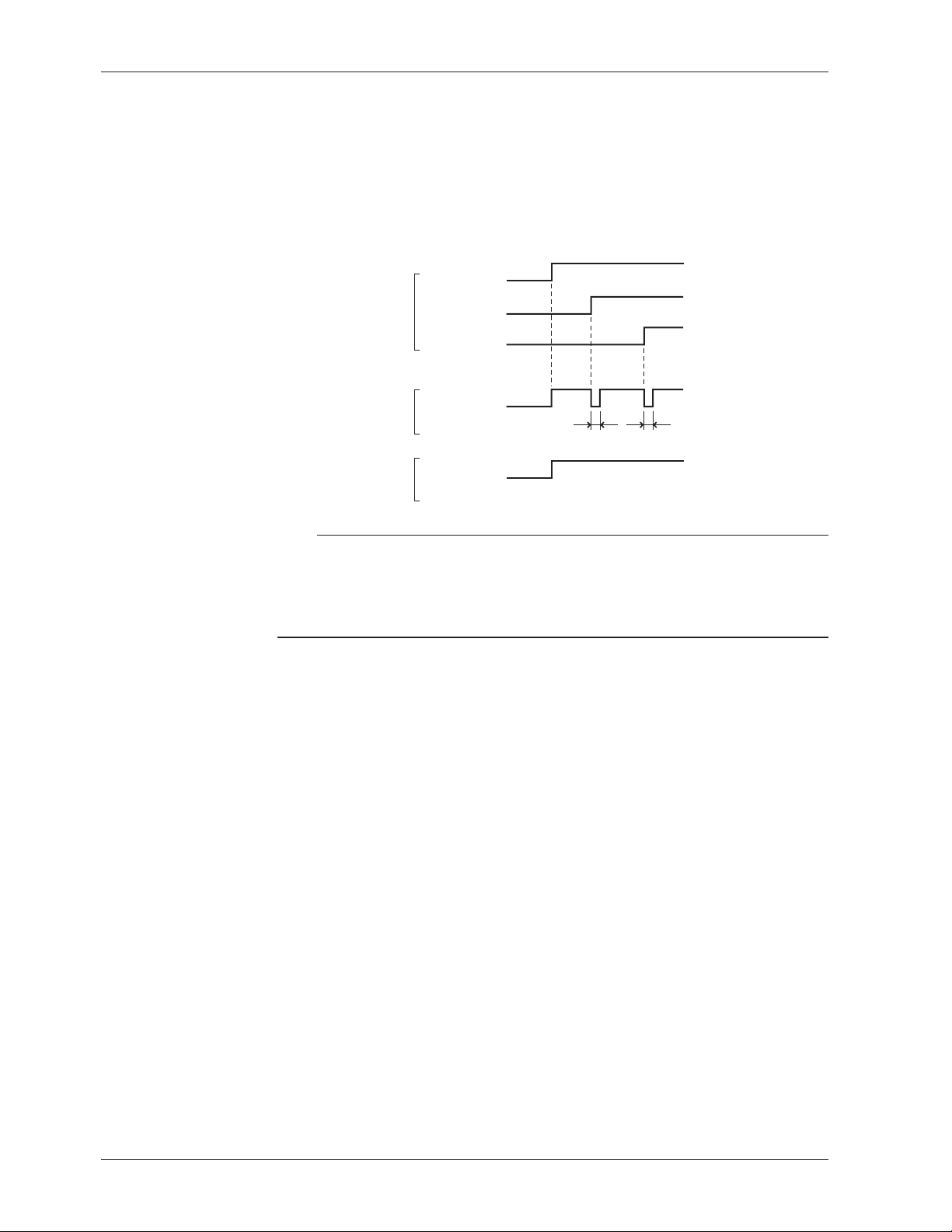

Non-Hold/Hold Operation of Alarm Output Relays

The alarm output relay can be set to operate in the following fashion when the alarm

condition is no longer met.

• Turn off the relay output (non-hold).

• Hold the relay output until the alarm ACK operation is executed (hold).

The setting applies to all alarm output relays.

The default setting is non-hold.

HoldNon-hold

Alarm occurrence

Alarm

ACK

Alarm

ACK

Alarm

ACK

Alarm

Alarm output

relay

Note

<Related Topics>

Setting the non-hold/hold operation of alarm output relays: Section 7.1

Alarm ACK Operation

The alarm acknowledge (alarm ACK) operation releases all alarm indications and relay

outputs (/A1, /A2, /A3, /A4, and /A5 options) that are activated when the alarm indication

or alarm output relay is set to hold operation. This operation can be executed from the

front panel key.

<Related Topics>

Alarm ACK operation: Section 3.12

Alarm release

Activated

Released

• If the reflash alarm is enabled, I01 to I03 are fixed to non-hold operation. Specifying Hold

produces no effect.

• If diagnosis output is enabled, I01 is fixed to non-hold operation. Specifying Hold produces

no effect.

or

or

1-12

Page 26

1.4 Recording

The recorder is capable of recording the measured values with pens or dots (trend

recording) as well as various other types of information.

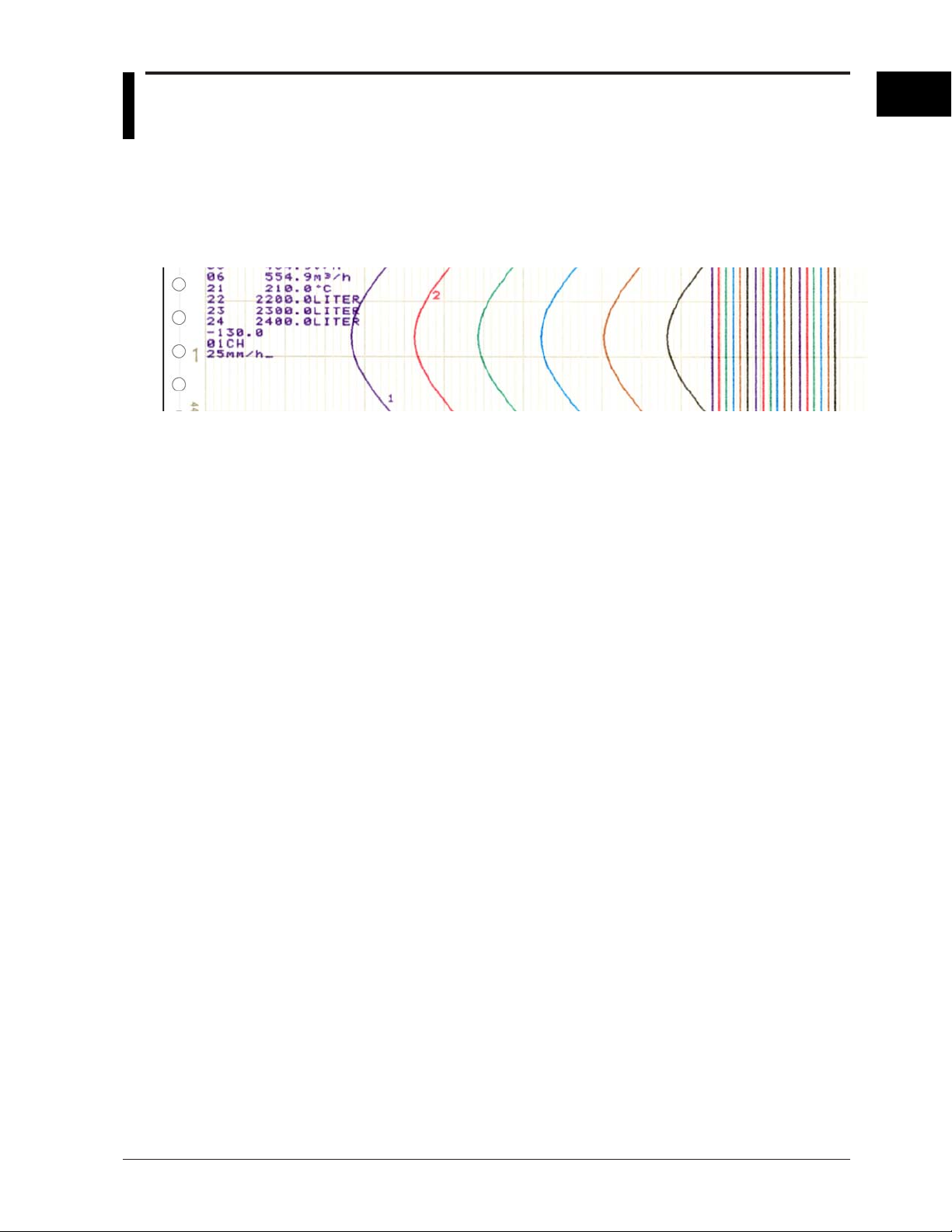

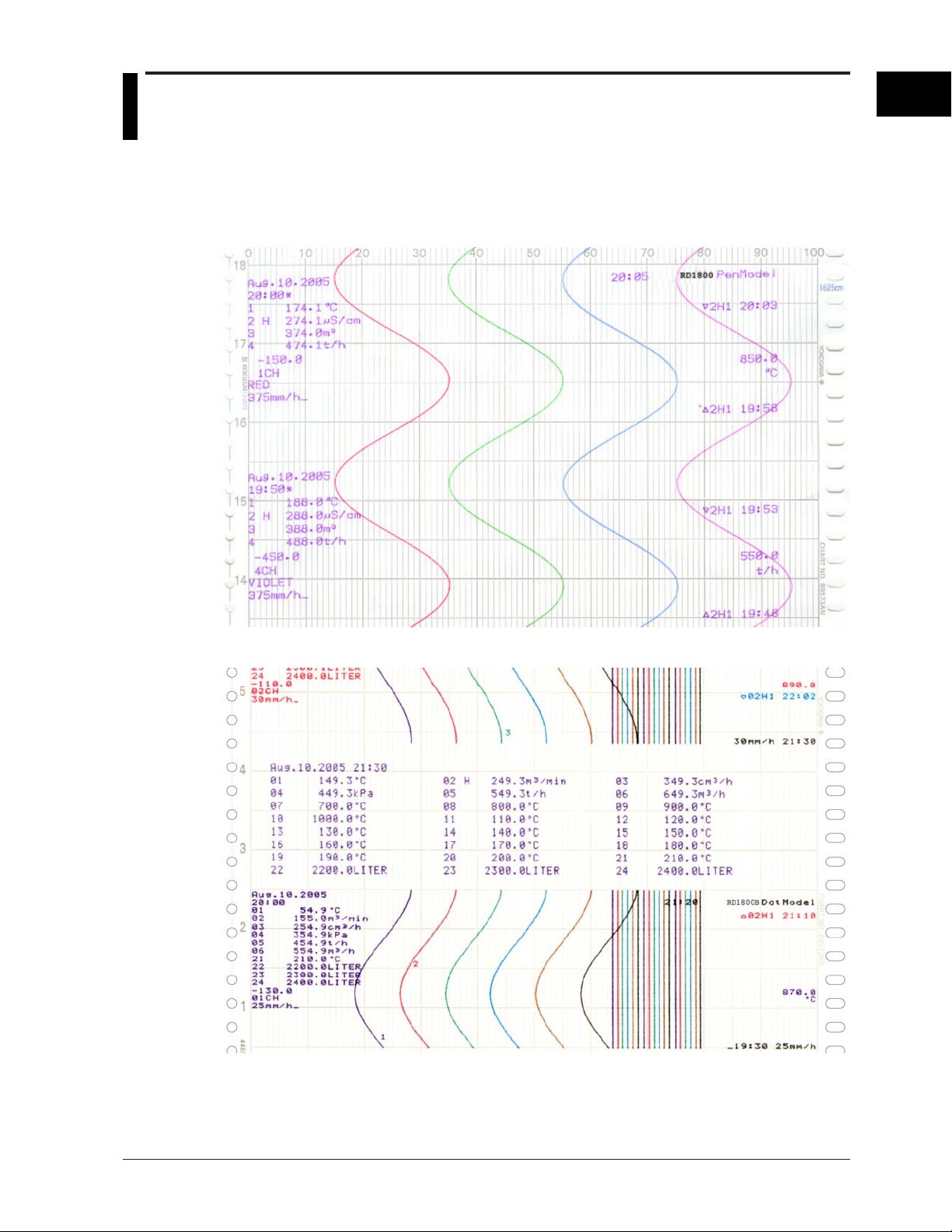

Recording Example on the Pen Model

1

Functional Description

Recording Example on the Dot Model

The recording examples may appear differently from the actual recording as a result of functional

improvements made on the recorder after this manual was written.

<Related Topics>

Starting/Stopping recording: Section 3.5

1-13

Page 27

1.4 Recording

Trend Recording

The measured values are printed within a width of 100 mm.

Recording Method (Pen Model)

• The measured value is updated every scan interval and continuously recorded.

• The recording colors in order from channel 01 are red, green, blue, and violet.

Recording Method (Dot Model)

• The most recent measured value is recorded with a dot every dot printing interval.

The dot printing interval is in the range of 10 s to 90 s. There are two recording

methods from which you can select. One method automatically adjusts the dot

printing interval according to the chart speed so that the dots do not overlap. The

other method records at the fastest dot printing interval at all times.

• The recording colors are assigned to each set (channels 01-06, 07-12, 13-18, and 19-

24) of six channels in ascending order as follows: purple, red, green, blue, brown, and

black. The recording color of each channel can be changed among these six colors.

• For each channel, trend recording can be enabled or disabled.

<Related Topics>

Setting the dot printing interval: Section 6.1

Changing the recording color: Section 7.5

Enabling/Disabling trend recording for each channel: Section 6.6

Chart Speed

On the pen model, the chart speed can be selected from 82 settings in the range of 5 to

12000 mm/h.

On the dot model, the chart speed can be set in the range of 1 to 1500 mm/h in 1-mm

steps.

The default setting is 25 mm/h.

<Related Topics>

Setting the chart speed: Section 5.4

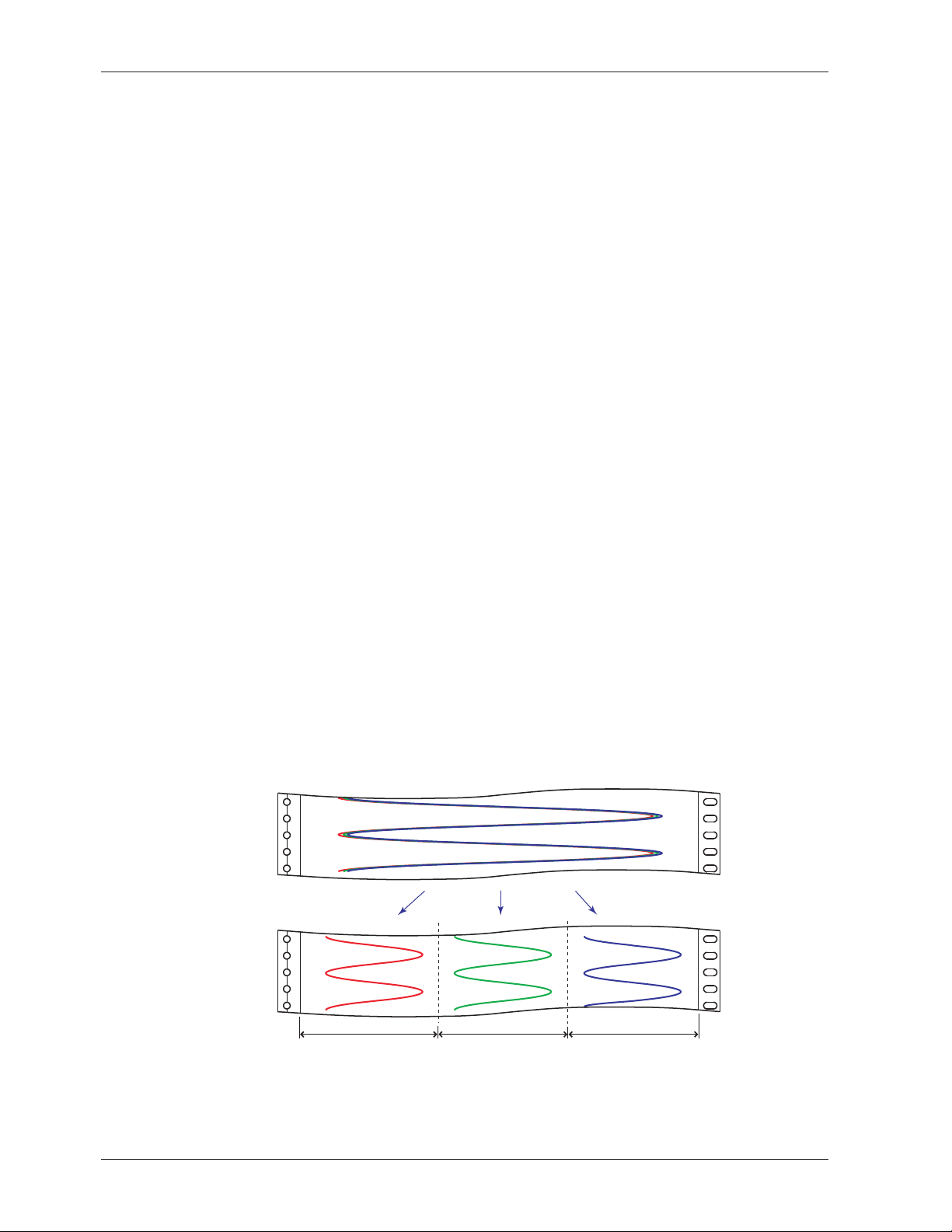

Zone Recording

A recording zone is assigned to each channel.

1-14

Zone 1 Zone 2 Zone 3

<Related Topics>

Setting the zone recording: Section 6.4

Page 28

1.4 Recording

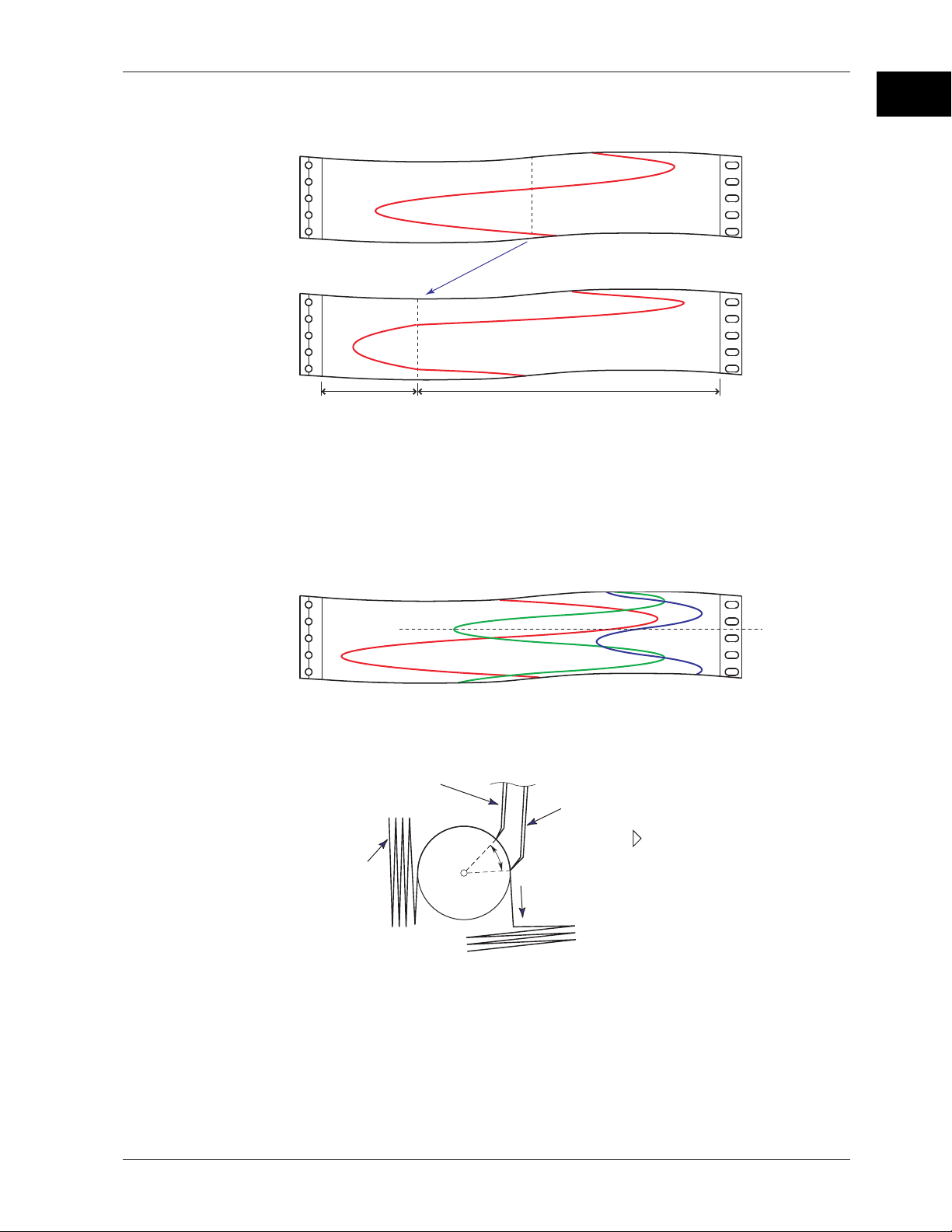

Partial Expanded Recording

This function expands a section of the recording range. By default, partial expanded

recording is disabled.

Compressed Expanded

<Related Topics>

Setting the partial expanded recording: Section 7.13 and 6.5

Pen Offset Compensation (Pen Model)

This function compensates for the pen offset (phase difference) along the time axis.

On 2-pen, 3-pen, and 4-pen recorders, there are offsets along the time axis (phase

difference) between the pens. This offset is corrected when pen offset compensation is

used.

1

Functional Description

Same time

Below is an explanation for the 2-pen model.

The recording of these two pens are offset by an amount of phase P. If pen offset

compensation is enabled, the measured values of pen 1 are stored in the memory, and

recorded when the chart paper is fed by an amount corresponding to P.

Reference pen (pen 2)

Pen 1

Recorder front panel

Chart paper

P

Chart feeding direction

By default, this function is disabled.

<Related Topics>

Setting the pen offset compensation: Section 7.6

1-15

Page 29

1.4 Recording

Printout

The figure below is used to explain the printout contents. The actual printout and font

are different from those illustrated in the figure. The printout positions are also slightly

different.

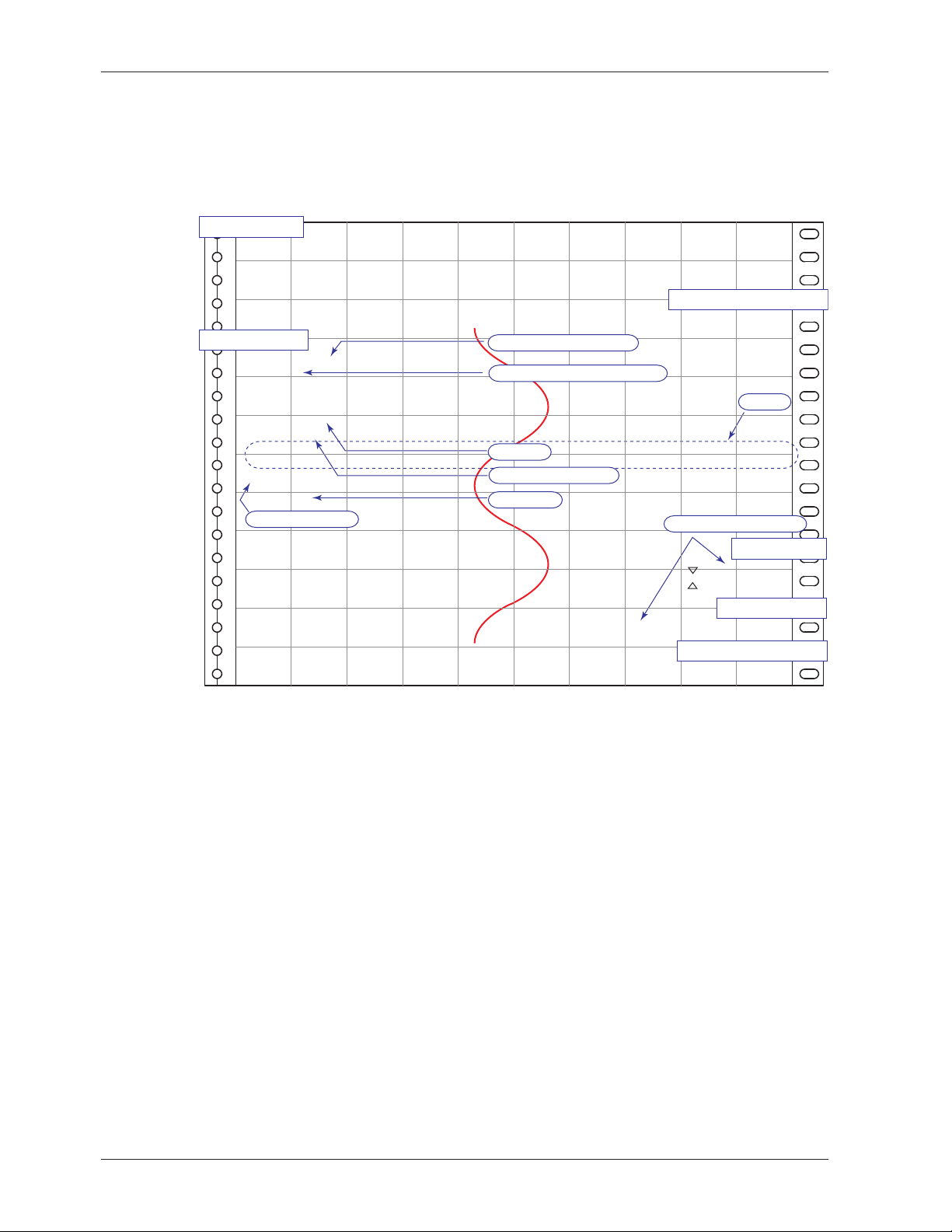

Printout Example on the Pen Model

Manual printout

Nov.09.04 15:00

1 223.5mg/cm

3 H 591.6˚C 4 −0.222V

Periodic printout

Nov.09.04!

13:50*

1 218.7mg/cm

2 390.6µS/cm

3 H 598.4˚C

4 d −0.222V

0.0 500.0

1CH mg/cm

RED

50mm/h_

Recording color

3

2 437.2µS/cm

Time tick cancel mark

3

Offset compensation mark

Alarm

Delta computation

Time tick

New chart speed printout

50mm/h*14:55

Scale

3

Buffer overflow mark

Alarm printout

1H3*10:09

1H3 10:05

Message printout

09:52*START#205 ABCDEF

Recording start printout

08:00*25mm/h

Time tick

The time ticks are marks that indicate the positions of the date/time on the chart paper.

Time tick cancel mark

An exclamation point (!) is printed when the periodic printout time tick was not printed at the

correct position.

<Related Topics>

Setting the channel printout (dot model)/pen color printout (pen model): Section 7.7

Setting the alarm printout, new chart speed printout, and recording start printout:

Section 7.7 and 7.16

Clearing the alarm printout buffer: Section 3.9

Setting the periodic printout: Section 6.6, 7.7, and 7.8

Executing manual print: Section 3.7

Printing messages: Section 6.8 and 3.10

Printing settings: Section 3.8

1-16

Page 30

1.4 Recording

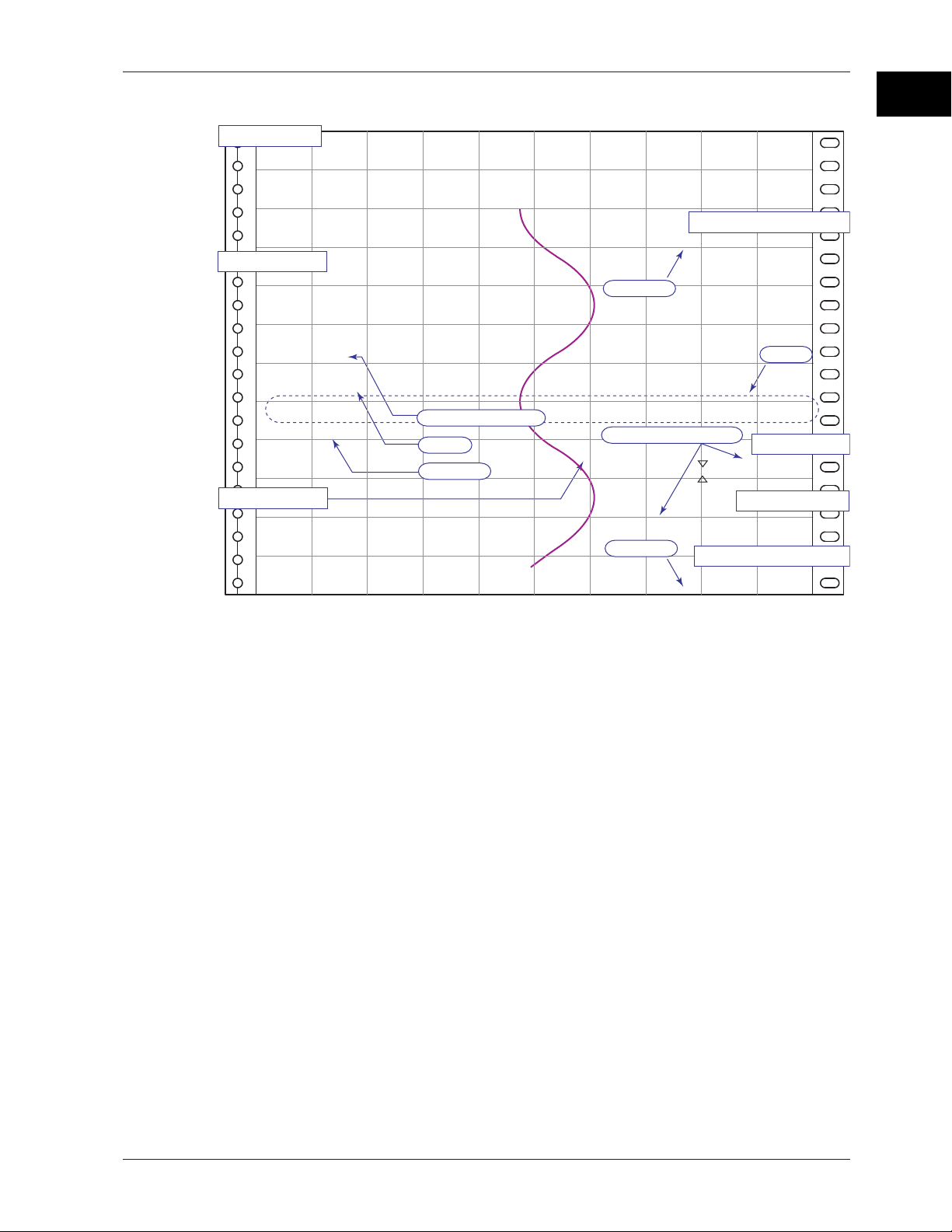

Printout Example on the Dot Model

Manual printout

Nov.09.04 16:00

01 223.5mg/cm

03 H 591.6˚C 04 −0.222V

05 −0.665V 06 L −0.448V

Periodic printout

Nov.09.04

13:50

01 218.7mg/cm

02 390.6µS/cm

03 H 598.4˚C

04 d −0.222V

05 −0.995V

06 L −0.448V

0.0 500.0

01CH mg/cm

50mm/h_

Channel printout

3

02 437.2µS/cm

1

3

1

Delta computation

Alarm

Time tick

1

1

New chart speed printout

_50mm/h*14:55

Time tick

Buffer overflow mark

01H3*10:09

01H3 10:05

09:52*START#205 ABCDEF

Time tick

Recording start printout

_08:00*25mm/h

Alarm printout

Message printout

1

Functional Description

Scale

3

Channel Printout (Dot Model Only)

Prints the channel No. or tag by the trend recording. The channel No. or tag is printed

every approximately 25 mm on the chart paper. The channel printout can be enabled or

disabled. By default, the channel printout is enabled.

1-17

Page 31

1.4 Recording

Alarm Printout

Alarm information is printed when an alarm occurs or releases.

Time of alarm occurrence/release

Indicates that there are alarms that are not

printed because the alarm printout buffer is full.

Level number

Alarm type

Channel No. or tag

: Alarm occurrence, : Alarm release

• The print condition can be set to (1) print when alarms occur and release, (2) print

only when alarms occur, or (3) do not print.

• Alarms that occur while an alarm printout is in progress are temporarily saved to the

buffer memory in a printout-wait condition. Alarms are cleared from the buffer

memory when they are printed.

• The number alarms that can be stored in the buffer is 8 and 24 on the pen model and

dot model, respectively. Alarms that occur while the buffer is full are not printed. A

buffer overflow mark is printed when there are alarms that cannot be printed because

the buffer is full.

• The time printout format can be selected.

Type

Hour:Minute

Month:Day:

Hour:Minute

Year:Month:Day:

Hour:Minute:Second

* The format of year, month, and day varies depending on the setting (see the next page).

Printout format Type Printout format

10 : 00

Nov. 09

10 : 00

Nov. 09. 2004

10 : 00 : 00

Hour:Minute:Second

Month:Day:

Hour:Minute:Second

10 : 00 : 00

Nov. 09

00 : 00 : 00

Periodic Printout

Measured values and other items are printed at the preset interval.

• Printout Contents (for details, see appendix 1)

• Date/time, time ticks (marks that indicate the positions of the date/time on the chart

paper); measured values, alarm status, scale (leftmost and rightmost values of

span) and recording color (pen model) for each channel; and chart speed can be

printed. When pen offset is being executed on the pen model, the pen offset marks

are printed. On the pen model, if a time tick is not printed at the correct position, a

time tick cancel mark (!) is printed.

• Printout of measured values and alarm status can be enabled or disabled for each

channel.

• Printout of the scale and recording colors (pen model) can be enabled or disabled.

The scale can be printed when the recording zone is greater than or equal to 40 mm.

• The measured values for each channel can be selected from the following data types.

Instantaneous value (measured value at the time of periodic printout)

Average value (average of the measured values over an interval)

Minimum value (minimum value of the measured values over an interval)

Maximum value (maximum value of the measured values over an interval)

Minimum value, maximum value, and average value

Sum value (summed value of the measured values over an interval)

• Interval

The printout interval can be set by specifying the value or set automatically in sync

with the chart speed. Periodic printout is disabled at the following chart speeds.

Pen model: Less than or equal to 9 mm/h or greater than or equal to 1600 mm/h

Dot model: 9 mm/h or less, 51 mm/h or greater (18-dot and 24-dot models), and

101 mm/h or greater (6-dot and 12-dot models)

1-18

Page 32

1.4 Recording

• Turning ON/OFF the Periodic Printout

Periodic printout can be turn ON/OFF. By default, periodic printout is enabled with the

interval synchronized to the chart speed. Also, the measured values that are printed

are the instantaneous values.

Manual Printout

Measured values and alarm status can be printed manually using the keys. When

manual printout is executed, trend recording stops and restarts when manual printout is

complete.

Message Printout

Preset messages can be printed on the chart paper using the keys. Five messages,

each within 16 characters, can be registered in advance.

• If message printout is executed while another message is being printed, the most

recent message is temporarily stored to the buffer memory in a printout-wait condition.

Messages are cleared from the buffer memory when they are printed.

• The number of messages that can be stored in the buffer is 5. If message printout is

executed when the buffer is full, the message is not printed. A buffer overflow mark is

printed when there are messages that cannot be printed because the buffer is full.

• The time printout format can be selected.

New Chart Speed Printout

• When the chart speed is changed, the time tick (dot model), the date/time of change,

and the new chart speed are printed. An asterisk (*) shows there are messages that

cannot be printed.

• The time printout format can be selected.

1

Functional Description

Recording Start Printout

When recording is started, the time tick (dot model), the time, and the chart speed can

be printed. An asterisk (*) shows there are messages that cannot be printed.

• The recording start printout can be enabled or disabled. By default, the recording

start printout is disabled.

• The time printout format can be selected.

Printout/Display Format of the Date

The printout/display format of the date can be selected from the list below. The setting

applies to all dates printed and shown on the display.

Type Printout/Display Format

Y/M/D 2005/08/31

M/D/Y 08/31/2005

D/M/Y 31/08/2005

D.M.Y 31.08.2005

M.D.Y Aug.31.2005

<Related Topics>

Setting the printout/display format of the date: Section 7.19

1-19

Page 33

1.4 Recording

Setting Printout

List or Setup List can be printed. When setting printout is executed, trend recording

stops and restarts when the printout is complete.

List contains settings such as the input range and alarm for each channel.

Setup List contains settings of basic specifications such as the alarm output relay

operation and printout method.

• Printout Example of List on the Pen Model

1-20

The printout examples may appear differently from the actual printout as a result of functional

improvements made on the recorder after this manual was written.

Page 34

1.4 Recording

• Printout Example of List on the Dot Model

1

Functional Description

The printout examples may appear differently from the actual printout as a result of functional

improvements made on the recorder after this manual was written.

1-21

Page 35

1.5 Display

y

Displayed Information

Main Display

The recorder is capable of displaying measured values, alarm information, and so on the

VFD (Vacuum Fluorescent Display). Using normal fonts, 30 characters × 2 lines can be

displayed. Using large fonts, 20 characters can be displayed.

Main display

RECORD KEYLOCK MATH CHARTEND ALARM

There are 22 display types available. Also, different displays can be assigned to the top

and bottom sections of the main display. These display types can be registered to

screens 1 to 15 and switched during operation using the keys.

Status Display

A status display is available at the bottom of the main display. The indicators below turn

ON/OFF.

• RECORD

This indicator turns ON when recording is started and turns OFF when stopped.

• ALARM 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

The numbers correspond to measurement channel numbers. The indicator turns ON

when an alarm occurs and turns OFF when the alarm is released.

If the alarm indication is set to hold operation, the indicator blinks when an alarm

occurs. When alarm ACK operation is performed, the indicator turns ON or OFF.

• MATH

This indicator turns ON when computation on the computation function (/M1 option) is

started and turns OFF when stopped.

• KEYLOCK

This indicator turns ON when key lock is enabled and turns OFF when disabled.

• CHART END

This indicator turns ON when the remaining amount of chart paper falls to

approximately 2 cm on models with the FAIL/chart end function (/F1 option).

242322212019181716151413121110987654321

Status displa

Display Types

1-22

The following display types are available.

• Displays that show measured values

Measured values can be displayed numerically or using bar graphs. The channels

that are displayed can be switched automatically at constant intervals.

The bar graph displays 0 to 100% using 181 points.

0% 100%

• Displays that show alarms

• Displays that show the date/time and chart speed

• Displays that show the remote control input and alarm output relay statuses

• Displays that show the status

• System display

Different display types can be assigned to the top and bottom sections of the main display.

181 dots

Page 36

1.5 Display

Several display examples are shown below. For details on the display types, see

“Display Function Specifications” in section 12.4.

1 Channel Digital + 1 Bar Graph Display

Channel No.

Alarm status

Measured value

Unit

01 H -200.0mV

Bar graph

Flag Display

Alarm Status Display

Symbol indicating an alarm

Measurement channel

:123456 789

:ABCDEF GJ P

Alarm point mark

Flag (the number indicates the channel No.)

... ...... ......

012 345678 901234

...... ......

ABCDEF GJKMNP

Scale

Scale

.....

1

Functional Description

Computation

channel

Channel on which an alarm is occurring

Channel on which an alarm is not occurring

Channel on which an alarm is not set

Date/Time and Chart Speed

The date format can be specified.

Date Tme Chart speed

Aug.31.2005 11:26:37 12000mm/h

Status Display

Alarm status

Remaining amount of chart paper is less than approx. 2 cm (/F1 option)

<Related Topics>

Assigning display types to screens: Chapter 8

Switching displays: Section 3.6

Setting the bar graph display mode: Section 7.9

Changing the date format: Section 7.19

Setting the display brightness: Section 6.11

Displaying measured values: Section 12.4.

1-23

Page 37

1.6 Computation Function (/M1 Option)

Computation Function

Computing equations can be set up using measured values and other computed values

as variables in computation-dedicated channels, and the computation can be executed.

The computed result can be recorded. Computation is performed every scan interval.

Channels Dedicated to Computations

The computation-dedicated channels below can be used.

Model Number of Channels Channel Names

Pen model 8 0A, 0B, 0C, 0D, 0E, 0F, 0G, and 0J

Dot model 24 0A, 0B, 0C, 0D, 0E, 0F, 0G, 0J, 0K, 0M, 0N, and 0P

Types of Computations

In the table below, y represents the computed result. X and n represent the measured

value, a constant, etc.

Type Syntax in the Equation Description