Page 1

K-5

HIGH TEMPERATURE CLOTH-FACED

INFRARED PANEL HEATERS

U Most Popular

U 870°C (1600°F) Maximum

Operating Temperature

U Black Quartz Ceramic

Cloth Face

U Output Wavelength

Between 2.5 and 6

Microns

U No External Reflectors

Required

OMEGALUX®QF Series heaters are

very popular infrared panel heaters

used in a wide variety of applications.

The QF series panel heaters’ radiant

surface is constructed through a

patented process using bonded high

temperature cloth quartz. A black

coating is applied to the face of the

heater for greater emissivity. A 2.5 cm

(1") thick ceramic fiber refractory board

is grooved out to support the precision

resistance coils.

The resistance coil is then housed

into the grooved-out refractory board.

A layer of durable, high temperature,

cement is used to bond the quartz

face to the resistance coils as well

as to the refractory coil support.

The resistance coils used are an

iron/chromium/aluminum alloy which

can operate up to 1315°C (2400°F).

These are then welded to stainless

terminals which are routed to the back

of the heater for external electrical

connections. The welding insures the

best possible electrical path. By

changing to stainless buss bars and

terminals, the conductivity is increased,

insuring less heat buildup in the

terminals. The heater board is then

backed up by a high temperature

insulation to prevent back heat loss.

Finally, this is all packaged in a sturdy

aluminized steel frame.

CHOOSING THE RIGHT IR HEATER

Not all infrared heaters are alike. Here is

a list of some of the most important

questions to answer when determining

which heater to choose.

1. RESPONSE TIME: How quickly do

heaters need to reach operating

temperature? IR heaters can reach

operating temperatures as quickly as

2 seconds or take as long as 1 hour.

Most take between 5 seconds and

10 minutes.

2. POWER REQUIREMENTS: What

watt density (usually referred to as

watts per square inch) is required?

3. ENVIRONMENT: What will the

ambient temperature be? Will there

be any flux, fibers, hazardous

chemicals, or any other matter

disturbing the environment?

From

$

295

Shown with

the CN9000A

Series

Controller,

from $199.

4. CONTROL METHOD: IR heaters can

be controlled one of two ways:1)

having the heaters on a percentage

timer (open loop) and 2) through the

use of a temperature control (closed

loop) method. The temperature

control method is the most accurate

way to control heaters and keep them

at a consistent temperature. If you

choose temperature control, you will

have to decide whether to use a

thermocouple or a pyrometer to

measure temperature.

5. PROCESS NEEDS: Is it a conveyor,

indexing, or a stationary process?

Does the process call for a cleanable

surface on the heater? Are zones in

the individual heaters required?

Compensation?

6. APPLICATION PROCESS: What

exactly is the application? Are you

trying to cure something? Melt

something? Cook something, etc.?

7. SPACE RESTRICTIONS: Is space

limited?

USA

MADE IN

Page 2

K-6

K

Without With

Thermowell Thermowell

Width Length Dim. Weight

cm (in.) cm (in.) Wattage Voltage Phase Model Number Price Model Number Price Reference kg (lb)

10 W/in

2

15 (6) 30 (12) 720 120 1 QF-061210 $295 QF-061210-T $320 Fig. A 1.4 (3)

15 (6) 46 (18) 1080 120/240 1 QF-061810 338 QF-061810-T 355 Fig. B 2.0 (4.5)

15 (6) 61 (24) 1440 120/240 1 QF-062410 363 QF-062410-T 388 Fig. B 2.7 (6)

15 (6) 76 (30) 1800 120/240 1 QF-063010 395 QF-063010-T 420 Fig. B 3.4 (7.5)

15 (6) 91 (36) 2160 240/480 1 QF-063610 395 QF-063610-T 420 Fig. B 4.1(9)

15 (6) 122 (48) 2880 240/480 1 QF-064810 498 QF-064810-T 520 Fig. B 5.0 (11)

30 (12) 30 (12) 1440 240 1 QF-121210 363 QF-121210-T 388 Fig. E 2.7 (6)

30 (12) 46 (18) 2160 240/480 1 QF-121810 430 QF-121810-T 455 Fig. E 3.9 (8.5)

30 (12) 61 (24) 2880 240/480 1 QF-122410 495 QF-122410-T 520 Fig. E 5.0 (11)

30 (12) 76 (30) 3600 240/480 1 QF-123010 563 QF-123010-T 588 Fig. E 6.1 (13.5)

30 (12) 91 (36) 4320 240/480 1 QF-123610 630 QF-123610-T 655 Fig. C 6.8 (15)

30 (12) 122 (48) 5760 240/480 1 QF-124810 630 QF-124810-T 763 Fig. D 9.1 (20)

30 (12) 152 (60) 7200 240 or 480 3 QF-126010/* 900 QF-126010/*-T 925 Fig. D 11.8 (26)

30 (12) 183 (72) 8640 240 or 480 3 QF-127210/* 1030 QF-127210/*-T 1055 Fig. D 14.5 (32)

41 (16) 41 (16) 2560 240/480 1 QF-161610 468 QF-161610-T 493 Fig. F 4.5 (10)

61 (24) 61 (24) 5760 240 or 480 Dual QF-242410/* 763 QF-242410/*-T 788 Fig. G 9.1 (20)

15 W/in

2

15 (6) 30 (12) 1080 120/240 1 QF-061215 295 QF-061215-T 320 Fig. A 1.4 (3)

15 (6) 46 (18) 1620 120/240 1 QF-061815 338 QF-061815-T 355 Fig. B 2.0 (4.5)

15 (6) 61 (24) 2160 240/480 1 QF-062415 363 QF-062415-T 388 Fig. B 2.7 (6)

15 (6) 76 (30) 2700 240/480 1 QF-063015 395 QF-063015-T 420 Fig. B 3.4 (7.5)

15 (6) 91 (36) 3240 240/480 1 QF-063615 430 QF-063615-T 455 Fig. B 4.1(9)

15 (6) 122 (48) 4320 240/480 1 QF-064815 495 QF-064815-T 520 Fig. B 5.0 (11)

30 (12) 30 (12) 2160 240/480 1 QF-121215 363 QF-121215-T 388 Fig. E 2.7 (6)

30 (12) 46 (18) 3240 240/480 1 QF-121815 430 QF-121815-T 455 Fig. E 3.9 (8.5)

30 (12) 61 (24) 4320 240/480 1 QF-122415 495 QF-122415-T 520 Fig. E 5.0 (11)

30 (12) 76 (30) 5400 240/480 1 QF-123015 563 QF-123015-T 588 Fig. E 6.1 (13.5)

30 (12) 91 (36) 6480 240 3 QF-123615/ 630 QF-123615/-T 655 Fig. C 6.8 (15)

30 (12) 122 (48) 8640 240 or 480 3 QF-124815/* 763 QF-124815/*-T 788 Fig. D 9.1 (20)

30 (12) 152 (60) 10800 240 or 480 3 QF-126015/* 900 QF-126015/*-T 925 Fig. D 11.8 (26)

30 (12) 183 (72) 12960 240 or 480 3 QF-127215/* 1030 QF-127215/*-T 1055 Fig. D 14.5 (32)

41 (16) 41 (16) 3840 240/480 1 QF-161615 468 QF-161615-T 493 Fig. F 4.5 (10)

41 (16) 61 (24) 5760 240 or 480 Dual QF-162415/* 585 QF-162415/*-T 610 Fig. F 6.6 (14.5)

61 (24) 61 (24) 8640 480 Dual QF-242415/480 763 QF-242415/480-T 788 Fig. G 9.1 (20)

Comes with mounting hardware and complete operator’s manual

*Specify voltage, i.e. insert 240 for 240 V or 480 for 480 V

Ordering Example: Model QF-061810, 15 x 46 cm (6" x 18") 1080 Watt heater with 10 W/in2Watt density that may be powered by either

120 Vac or 240 Vac single phase, $338.

To Order

(Specify Model Number) Highlighted Models In Stock for Fast Delivery

All Dimensions in mm (inches)

4 (5/32) I.D.Thermowell 127 (5) Deep

Coil Direction

914 (36)

4 (5/32) I.D.Thermowell 127 (5) Deep

Coil Direction

1219 - 1524 - 1829

(48- 60- 72)

305

152 (6)

(12)

16

(5/8)

4

(5/32) I.D.

Thermowell 127 (5) Deep

38

(1-1/2)

152 (6)

152

Radiant Surface

(6)

Aluminized Steel Housing

229 (9)

C

L

102 x 102 (4 x 4)

152 (6)

305 W x 914 mm L

Junction Box with Cover

Figure C

(12'' x 36'')

6 x 508 x 19

(1/4 x 20 x 3/4) Stud [4]

8 (5/16)

Lip - 4 sides

79 (3-1/8)

130 (5-1/8)

305

(12)

16

(5/8)

38

(1-1/2)

102 x 102

(4 x 4)

Junction Box

with Cover

152

Radiant Surface

(6)

4

(5/32) I.D.

Thermowell 127 (5) Deep

229 (9)

C

L

152 (6)

305 W x 1219, 1524 or 1829 mm L

Figure D

(12'' x 48'', 60" or 72")

Aluminized Steel Housing

C

L

8 (5/16)

Lip - 4 sides

79 (3-1/8)

130 (5-1/8)

6 x 508 x 19

(1/4 x 20 x 3/4) Stud [4]

Page 3

K-7

Without With

Thermowell Thermowell

Width Length Dim. Weight

cm (in.) cm (in.) Wattage Voltage Phase Model Number Price Model Number Price Reference kg (lb)

20 W/in

2

15 (6) 30 (12) 1440 120/240 1 QF-061220 $295 QF-061220-T $320 Fig. A 1.4 (3)

15 (6) 46 (18) 2160 240/480 1 QF-061820 338 QF-061820-T 355 Fig. B 2.0 (4.5)

15 (6) 61 (24) 2880 240/480 1 QF-062420 363 QF-062420-T 388 Fig. B 2.7 (6)

15 (6) 76 (30) 3600 240/480 1 QF-063020 395 QF-063020-T 420 Fig. B 3.4 (7.5)

15 (6) 91 (36) 4320 240/480 1 QF-063620 430 QF-063620-T 455 Fig. B 4.1(9)

15 (6) 122 (48) 5760 240/480 1 QF-064820 495 QF-064820-T 520 Fig. B 5.0 (11)

30 (12) 30 (12) 2880 240/480 1 QF-121220 363 QF-121220-T 388 Fig. E 2.7 (6)

30 (12) 46 (18) 4320 240/480 1 QF-121820 430 QF-121820-T 455 Fig. E 3.9 (8.5)

30 (12) 61 (24) 5760 240/480 1 QF-122420 495 QF-122420-T 520 Fig. E 5.0 (11)

30 (12) 76 (30) 7200 240 or 480 3 QF-123020/* 563 QF-123020/*-T 588 Fig. E 6.1 (13.5)

30 (12) 91 (36) 8640 240 or 480 3 QF-123620/* 630 QF-123620/*-T 655 Fig. C 6.8 (15)

30 (12) 122 (48) 11520 240 or 480 3 QF-124820/* 763 QF-124820/*-T 788 Fig. D 9.1 (20)

30 (12) 152 (60) 14400 240 or 480 3 QF-126020/* 900 QF-126020/*-T 925 Fig. D 11.8 (26)

30 (12) 183 (72) 17280 240 or 480 3 QF-127220/* 1030 QF-127220/*-T 1055 Fig. D 14.5 (32)

41 (16) 41 (16) 5120 240 or 480 Dual QF-161620/* 468 QF-161620/*-T 493 Fig. F 4.5 (10)

41 (16) 61 (24) 7680 480 Dual QF-162420/480 585 QF-162420/480-T 610 Fig. F 6.6 (14.5)

61 (24) 61 (24) 11520 480 Dual QF-242420/480 763 QF-242420/480-T 788 Fig. G 9.1 (20)

25 W/in

2

15 (6) 30 (12) 1800 120/240 1 QF-061225 295 QF-061225-T 320 Fig. A 1.4 (3)

15 (6) 46 (18) 2700 240/480 1 QF-061825 338 QF-061825-T 355 Fig. B 2.0 (4.5)

15 (6) 61 (24) 3600 240/480 1 QF-062425 363 QF-062425-T 388 Fig. B 2.7 (6)

15 (6) 76 (30) 4500 240/480 1 QF-063025 395 QF-063025-T 420 Fig. B 3.4 (7.5)

15 (6) 91 (36) 5400 240/480 1 QF-063625 430 QF-063625-T 455 Fig. B 4.1(9)

15 (6) 122 (48) 7200 240/480 1 QF-064825 495 QF-064825-T 520 Fig. B 5.0 (11)

30 (12) 30 (12) 3600 240/480 1 QF-121225 363 QF-121225-T 388 Fig. E 2.7 (6)

30 (12) 46 (18) 5400 240/480 1 QF-121825 430 QF-121825-T 455 Fig. E 3.9 (8.5)

30 (12) 61 (24) 7200 240 or 480 3 QF-122425/* 495 QF-122425/*-T 520 Fig. E 5.0 (11)

30 (12) 76 (30) 9000 240 or 480 3 QF-123025/* 563 QF-123025/*-T 588 Fig. E 6.1 (13.5)

30 (12) 91 (36) 10800 240 or 480 3 QF-123625/* 630 QF-123625/*-T 655 Fig. C 6.8 (15)

30 (12) 122 (48) 14400 240 or 480 3 QF-124825/* 763 QF-124825/*-T 788 Fig. D 9.1 (20)

30 (12) 152 (60) 18000 240 or 480 3 QF-126025/* 900 QF-126025/*-T 925 Fig. D 11.8 (26)

30 (12) 183 (72) 21600 240 or 480 3 QF-127225/*

†

1030 QF-127225/*-T 1055 Fig. D 14.5 (32)

41 (16) 41 (16) 6400 240 or 480 Dual QF-161625/* 468 QF-161625/*-T 493 Fig. F 4.5 (10)

41 (16) 61 (24) 9600 480 Dual QF-162425/480 585 QF-162425/480-T 610 Fig. F 6.6 (14.5)

61 (24) 61 (24) 14400 480 Dual QF-242425/480 763 QF-242425/480-T 788 Fig. G 9.1 (20)

Comes with mounting hardware and complete operator’s manual

*Specify voltage, i.e. insert 240 for 240 V or 480 for 480 V

†

This heater has two junction boxes at opposite ends of the panel

Ordering Example: Model QF-123625/240, 30 x 91 cm (12" x 36") 10800 Watt 3-phase heater with 25 W/in2Watt density, 240 Vac, $655.

To Order

(Specify Model Number) Highlighted Models In Stock for Fast Delivery

All Dimensions in mm (inches)

4 (5/32) I.D. Thermowell 127 (5) Deep

Coil Direction

Length

305

(12)

152

(6)

8 (5/16) Lip

- 4 sides

79 (3-1/8)

130 (5-1/8)

6 x 508 x 19

(1/4 x 20 x 3/4)

Stud [4]

16

(5/8)

4

(5/32) I.D.

Thermowell

127 (5) Deep

38 (1-1/2)

38

(1-1/2)

C

L

152 (6)

Radiant Surface

Aluminized Steel Housing

4 (5/32) I.D. Thermowell 127 (5) Deep

Coil Direction Coil Direction

Length

406 (16)

203

(8)

152 (6

)

16

(5/8)

4

(5/32) I.D.

Thermowell

127 (5) Deep

38

(1-1/2)

C

L

38 (1-1/2)

Radiant Surface

Aluminized Steel Housing

4 (5/32) I.D. Thermowell 127 (5) Deep

610 (24)

610 (24)

305

(12)

8 (5/16) Lip

- 4 sides

79 (3-1/8)

130 (5-1/8) 130 (5-1/8)

6 x 508 x 19

(1/4 x 20 x 3/4)

Stud [4]

4

(5/32) I.D.

Thermowell

127 (5) Deep

38 (1-1/2)

16

(5/8)

152 (6)

38 (1-1/2)

C

L

Aluminized Steel Housing

8 (5/16) Lip

- 4 sides

Radiant Surface

79 (3-1/8)

6 x 508 x 19

(1/4 x 20 x 3/4)

Stud [4]

152 (6)

305 W x 305, 457, 610 or 762 mm L

(12" W x 12", 18", 24" or 30")

Figure E

102 x 102 (4 x 4)

Junction Box

with Cover

102 x 102 (4 x 4)

152 (6)

406 W x 406 or 610 mm L

(16" W x 16" or 24")

Junction Box with Cover

Figure F

152 (6)

Figure G

610 W x 610 mm L

(24" W x 24" L)

102 x 102 (4 x 4)

Junction Box with Cover

Page 4

K-8

K

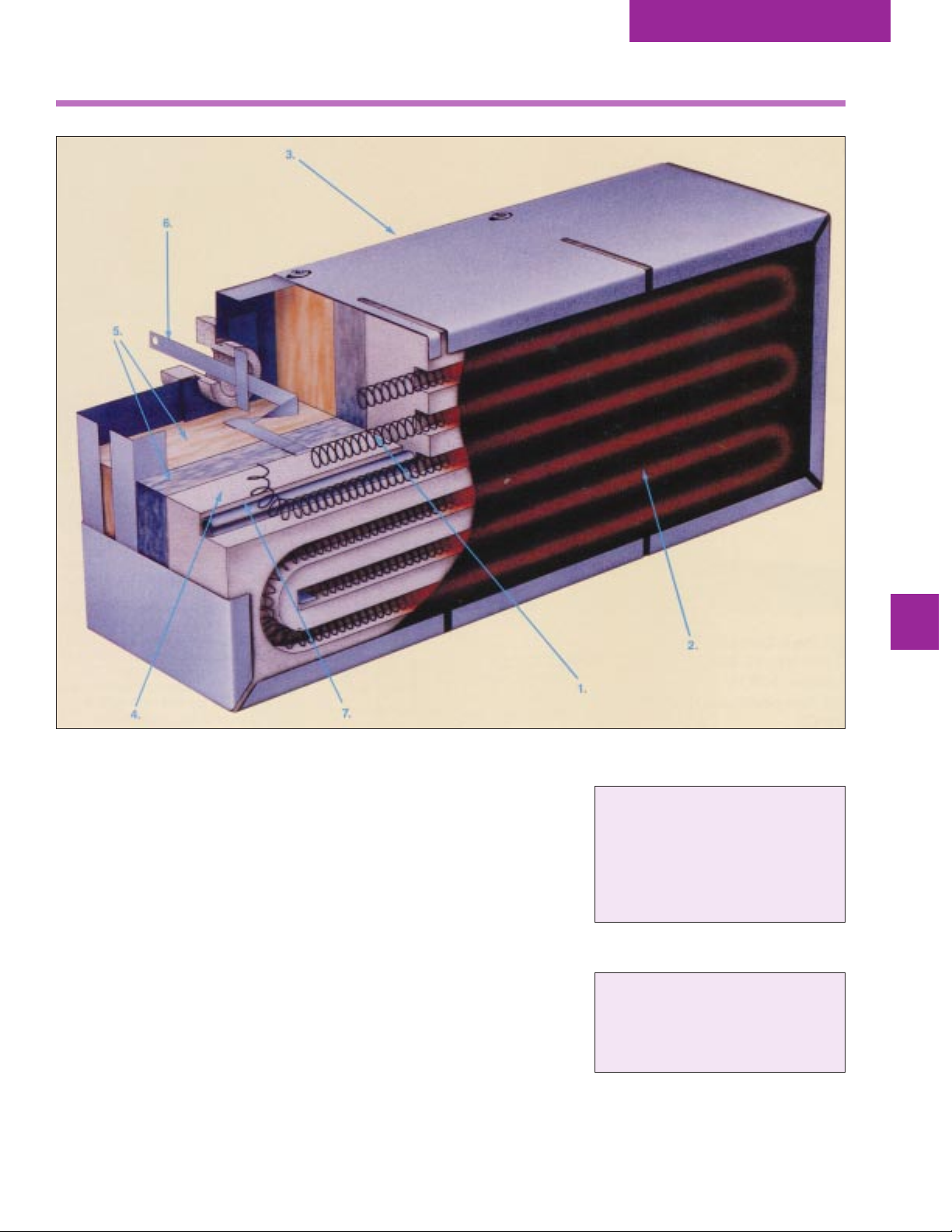

QF SERIES INFRARED PANEL HEATERS

CONSTRUCTION

1. Heater Element: precision

iron/chrome/ aluminum resistance

wire, designed for uniform emission

over entire heating surface and

extended life.

2. Surface: rugged black woven ceramic

cloth for high radiant energy transfer.

3. Frame: heat resistant, heavy gauge

aluminized steel.

4. Heater Element Support: grooved

ceramic fiber refractory board is used

to support precision coil resistance

wire. This helps to insulate the heater

as well as reflect the infrared energy

onto the application.

5. High Temperature Insulation:

to minimize heat loss from the back

of the heater.

6. Stainless Steel Terminals: all welded

construction, for easy power

connection.

7. Optional Quartz Thermowell: high

temperature 4 mm (

5

/32'') diameter

127 mm (5'') long quartz thermowell,

with strain relief.

APPLICATIONS

U Paint Drying

U Plastic Forming

U Wave Soldering

U Silk Screening

U Laminating

U Moisture Removal

U Thermo Forming

SPECIFICATIONS

Maximum Temperature Emitter

Face: 870°C (1600°F)

Power: 120, 240, 480 Vac single and

dual voltage, 1 phase, 3 phase and

dual phase

Wattage: 720-21,600 watts

Watt Density: 10, 15, 20, and 25 W/in

2

Enclosure: Heavy gauge

aluminized steel

CAUTION AND WARNING!

Fire and electrical shock may

result if products are used

improperly or installed or used

by non-qualified personnel.

Note:

QF series heaters are

intended for “radiant” heat. Never

let material to be heated come into

direct contact with the face of the

heater. It is recommended that

overtemperature control be used to

prevent overheating.

Patented

Page 5

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...