Page 1

User’s Guide

Model PX2088 Pressure Transmitter

http://www.omega.com

e-mail: info@omega.com

Pressure Transmitter

PX2088

Page 2

OMEGAnet® On-Line Service Internet e-mail

http://www.omega.com info@omega.com

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGASM

Customer Service: 1-800-622-2378 / 1-800-622-BESTSM

Engineering Service: 1-800-872-9436 / 1-800-USA-WHENSM

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico and

Latin America: Tel: (95) 800-826-6342 FAX: (95) 203-359-7807

En Espan˜ol: (95) 203-359-7803 e-mail: espanol@omega.com

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Czech Republic: ul. Rude armady 1868, 733 01 Karvina-Hranice

Tel: 420 (69) 6311899 FAX: 420 (69) 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5EX, England

Tel: 44 (161) 777-6611 FAX: 44 (161) 777-6622

Toll Free in the United Kingdom: 0800-488-488

e-mail: info@omega.co.uk

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of

its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

Table of Contents

SECTION 1

Introduction

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Safety Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Models Covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

SECTION 2

Commissioning the Smart Transmitter

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Commission: On the Bench or In the Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Set up the Transmitter and the Communicator . . . . . . . . . . . . . . . . . . . . . 2-2

Review Configuration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Check Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Process Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Output Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Rerange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Detailed Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Meter Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Burst Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Save, Recall, or Clone Configuration Data . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Enable or Disable Local Span and Zero Buttons . . . . . . . . . . . . . . . . . . . . . 2-7

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Calibration Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Sensor Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Output Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Diagnostics and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Multidrop Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

i

Page 4

SECTION 3

Commissioning the Analog Transmitter

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Commission: On the Bench or In the Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Test Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Zero and Span Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Selector Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Potentiometer Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Setting the Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Setting the Span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

SECTION 4

Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Model PX2088 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Wiring Connections PX2088 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Failure Mode and Security Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Failure Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Transmitter Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Zero and Span Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Rerange Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

SECTION 5

Troubleshooting

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

ii

Page 5

SECTION 6

Spare Parts and Ordering

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

SECTION 7

LCD Meter

LCD Meter for Smart Transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Diagnostic Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

LCD Meter for Analog Transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Diagnostic Message Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Positioning the Decimal Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Scaling the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

iii

Page 6

APPENDIX A

Model HC275 HART

Communicator

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Menu Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Fast Key Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

iv

Page 7

SECTION

1

Introduction

OVERVIEW

This section contains general transmitter safety information, a brief description of

each model covered in this manual, and a summary of each of each section.

SAFETY MESSAGES

Procedures and instructions in this manual may require special precautions to

ensure the safety of the personnel performing the operations.

SAFETY NOTICE

The following performance limitations may inhibit efficient or safe operation. Critical

applications should have appropriate diagnostic and backup systems in place.

Pressure transmitters contain an internal fill fluid. It is used to transmit the process pressure

through the isolating diaphragms to the pressure sensing element. In rare cases, oil leak paths

in oil-filled pressure transmitters can be created. Possible causes include: physical damage to

the isolator diaphragms, process fluid freezing, isolator corrosion due to an incompatible

process fluid, etc.

A transmitter with an oil fill fluid leak can continue to perform normally for a period of time.

Sustained oil loss will eventually cause one or more of the operating parameters to exceed

published specifications while a small drift in operating point output continues. Symptoms of

advanced oil loss and other unrelated problems include:

nSustained drift rate in true zero and span or operating point output or both

nSluggish response to increasing or decreasing pressure or both

nLimited output rate or very nonlinear output or both

nChange in output process noise

nNoticeable drift in operating point output

nAbrupt increase in drift rate of true zero or span or both

nUnstable output

nOutput saturated high or low

1-1

Page 8

MODELS COVERED

Model PX2088 Smart and Analog Absolute or Gage Pressure Transmitter

measures absolute or gage pressure ranges from 0–1 to 0–4,000 psi

(0–6.9 to 0–27579 kPa) using a patented piezoresistive silicon sensor.

Mounts directly to the process pipe or to the optional mounting bracket.

USING THIS MANUAL

This manual provides information for the Omega Model PX2088

Pressure Transmitter. It is organized into the following sections:

Section 2 Commissioning the Smart Transmitter

This section provides information on commissioning and operating the Model PX2088

Smart Pressure Transmitter. Information is also included on software functions,

configuration parameters, and on-line variables.

Section 3 Commissioning the Analog Transmitter

This section provides information on commissioning and operating the Model PX2088

Analog Pressure Transmitter.

Section 4 Installation

This section provides installation procedures, wiring diagrams, and information

about transmitter load limitations and power supply requirements.

Section 5 Troubleshooting

This section provides basic troubleshooting suggestions to help solve the most

common operating problems.

Section 6 Reference Data

This section provides reference data including ambient temperature effects, spare

parts, and typical transmitter model structures.

Secton 7 LCD Meter

This section provides installation and operation information for the optional LCD

Meter.

Appendix B HART Communicator

menu tree and fast key sequences for HART Communicator

1-2

Page 9

SECTION

2 Commissioning the Smart

Transmitter

OVERVIEW

This section contains information regarding commissioning the transmitter.

Commissioning involves reviewing configuration data, setting the 4 and 20 mA

points, configuring the transmitter to recognize accessories such as a LCD meter,

and testing the transmitter output.

SAFETY MESSAGES

This section contains procedures that require connecting a communicator to the

transmitter, or making connections in an explosive atmosphere. The following safety

messages apply to all procedures throughout this section requiring cover removal

and communicator connection to the transmitter terminal block. Keep the following

safety messages in mind whenever you perform an operation requiring cover

removal or the connection of a communicator to a measurement loop.

Warnings

Explosions could result in death or serious injury:

nDo not remove the transmitter covers in explosive atmospheres

when the circuit is alive.

nBefore connecting a HART-based communicator in an explosive atmosphe re,

make sure the instruments in the loop are installed in accordance with

intrinsically safe or non-incendive field wiring practices.

nBoth transmitter covers must be fully engaged to meet

explosion-proof requirements.

High voltage that may be present on leads could cause electrical shock:

nAvoid contact with leads and terminals.

2-1

Page 10

COMMISSION: ON THE BENCH OR IN THE LOOP

Commission the Model PX2088 Smart Transmitter before or after installation.

It may be useful to commission the transmitter on the bench before

installation to ensure proper operation, to familiarize yourself with transmitter

functionality, and to avoid exposing the transmitter electronics to the plant

environment. Commissioning consists of reviewing configuration data, setting

output units, setting the 4 and 20 mA points, configuring the transmitter for any

non-standard accessories or functions, and testing the transmitter output.

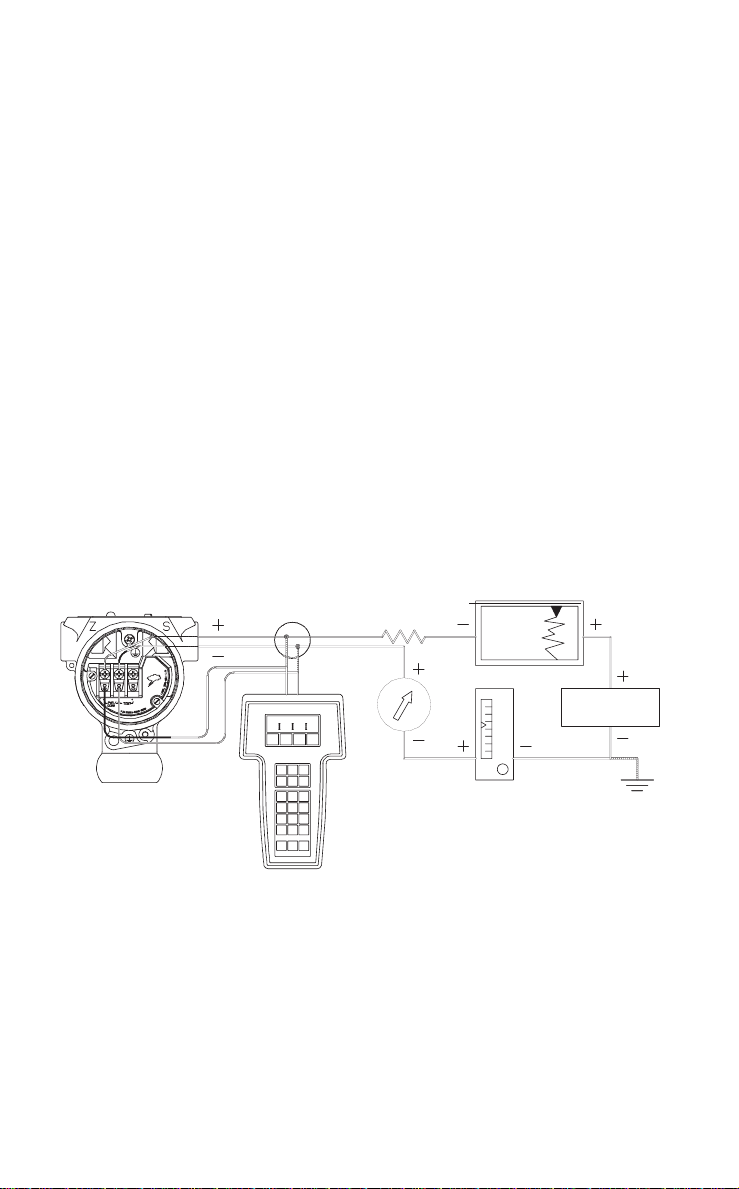

Set up the Transmitter and the Communicator

To configure the transmitter on the bench, connect the transmitter and the

communicator as shown in Figure 2-1. To power the transmitter you will need a

power supply capable of providing 10.5 to 36.0 V dc and a meter to measure output

current. To enable communication, a resistance of at least 250 ohms must be present

between the communicator loop connection and the power supply. You can connect the

communicator leads at any termination point in the signal loop, but it is most

convenient to connect them to the terminals labeled “COMM” on the terminal block.

After you con nec t th e b ench equipm e nt a s s h ow n in Figure 2-1, turn on the

communicator by pressing the ON/OFF key. The communicator will search for a

HART-compatible device and will indicate that the connection is made. If the

connection is not made, the communicator will indicate that no device was found.

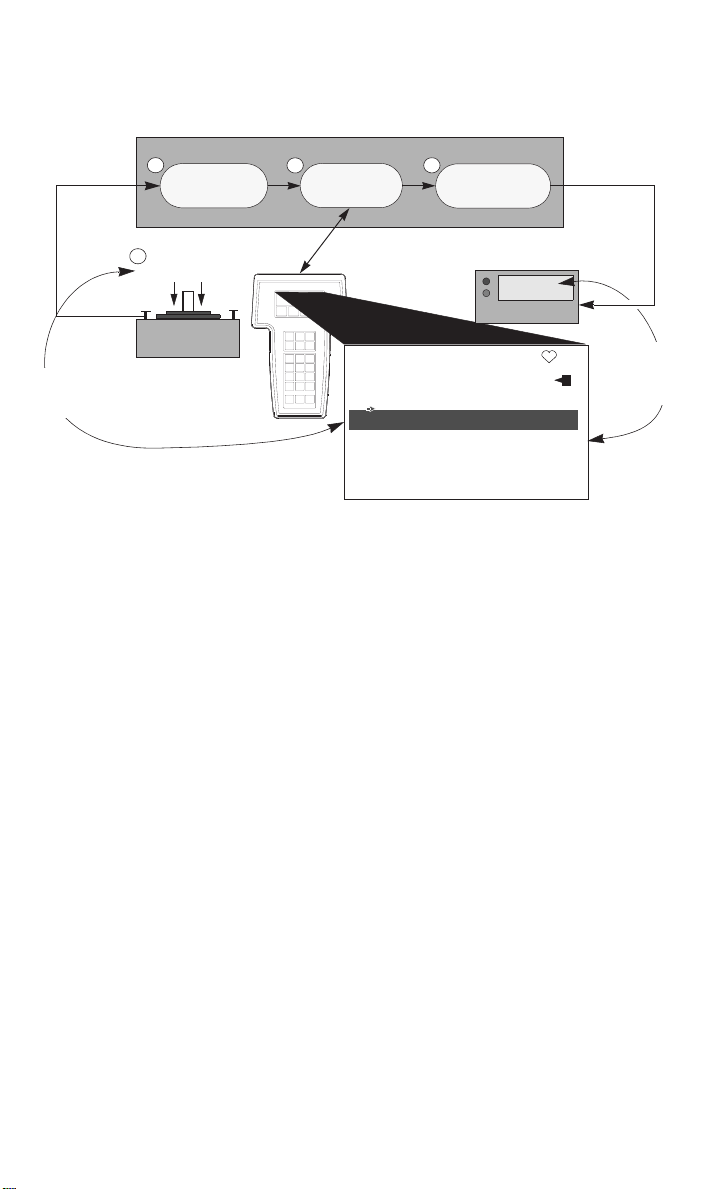

FIGURE 2-1. Connecting a Communicator to a Transmitter Loop

RL≥ 250 V

Power

Supply

The signal loop may be grounded

at any single point in the loop, or

may be left ungrounded

2088S-2088C02C

If the communicator lacks the device driver for the PX2088 Smart, the transmitter will

be identified as “GENERIC” by the communicator. Basic configuration functions are

still possible, but many advanced configuration functions are not possible when the

communicator is in this mode. Contact Omega customers service for assistance

in obtaining the PX2088 Smart device driver for the HART Communicator.

2-2

Page 11

FIGURE 2-2. HART Communicator ScreenWithout Model PX2088 S ma rt De vice Drive r.

Generic

Online

1 Device Setup

2 PV 100.00 inH2O

3 AO 20.00 mA

4 LRV 0.00 inH2O

5 URV 100.00 inH2O

REVIEW CONFIGURATION DATA

Review all of the factory-set configuration data to ensure that is reflects the needs of

your application before operating the transmitter in an actual installation.

Review

HART Fast Keys

Review the transmitter configuration parameters set at the factory to ensure

accuracy and compatibility with your particular application. After activating the

review function, scroll through the data list to check each variable. Refer to “Basic

Setup” in this section of the manual if a change to the transmitter configuration data

is necessary.

1, 5

CHECK OUTPUT

Before performing other transmitter on-line operations, review the digital output

parameters to ensure that the transmitter is operating properly and is configured to

the appropriate process variables.

Process Variables

HART Fast Keys

The process variables for the Model PX2088 Smart provide the transmitter output,

and are continuously updated. The Process Variable menu displays the following

process variables:

nPressure

nPercent Range

nAnalog Output

1, 1

2-3

Page 12

BASIC SETUP

From the Basic Setup menu you can configure the transmitter for certain basic

variables. In many cases, all of these variables are pre-configured at the factory.

Configuration may be required if your transmitter is not configured or if the

configuration variables need revision.

Tag

HART Fast Keys

1, 3, 1

The Tag variable is the easiest way to identify and distinguish between transmitters

in multi-transmitter environments. Use this variable to label transmitters

electronically according to the requirements of your application. The tag you define

is automatically displayed when a HART-based communicator establishes contact

with the transmitter at power-up. The tag may be up to eight characters long and

has no impact on the primary variable readings of the transmitter.

Output Units

HART Fast Keys

The Unit command sets the desired primary variable units. Set the transmitter

output to one of the following engineering units:

ninH

O

2

ninHg

nftH

O

2

nmmH

O

2

npsi

nbar

nmbar

nInH

O @ °4 C

2

NOTE

Output units is the only variable which must be sent separately from all other

variable configurations. After changing units, press SEND (F2) so the

microprocessor will recalculate the associated variables (4–20 mA points, for

example). The Model PX2088 Smart recalculates all variables that depend on units.

After the transmitter recalculates the variables, you may change any of the

remaining parameters.

1, 3, 3

ng/cm

nkg/cm

nPa

nkPa

ntorr

natm

nmmH

2

2

O @ °4 C

2

2-4

Page 13

Rerange

HART Fast Keys

1, 3, 3

The Range Values command sets the 4 and 20 mA points (lower and upper range

values). Setting the range values to the limits of expected readings maximizes

transmitter performance; the transmitter is most accurate when operated within the

expected pressure ranges for your application. In practice, you may reset the

transmitter range values as often as necessary to reflect changing process

conditions.

You may use one of three methods to rerange the transmitter. Each method is

unique; examine all three closely before deciding which method to use.

NOTE

Regardless of the range points, the Model PX2088 Smart will measure and report all

readings within the digital limits of the sensor. For example, if the 4 and 20 mA

points are set to 0 and 10 inH

it digitally outputs the 25 in H

However, there may be up to ±5.0% error associated with output outside of the range

O, and the transmitter detects a pressure of 25 inH2O,

2

O reading and a 250% percent of span reading.

2

points.

Method 1:Rerange Using the Communicator

Reranging using only the communicator is the easiest and most popular way to

rerange the transmitter. This method changes the values of the analog 4 and 20

mA points independently without a pressure input.

To rerange using only the communicator enter the fast-key sequence above, select

1 Keypad input, and follow the on-line instructions. Or enter the values directly

from the HOME screen.

Method 2:Rerange Using the Communicator and a Pressure Source or Process

Pressure

Reranging using the communicator and a pressure source or process pressure is a

way of reranging the transmitter when specific 4 and 20 mA points are not known.

This method changes the values of the analog 4 and 20 mA points. When you set

the 4 mA point the span is maintained; when you set the 20 mA point the span

changes.

To rerange using the communicator and a pressure source or process pressure

enter the fast-key sequence above, select 2 Apply values, and follow the on-line

instructions.

Method 3:Rerange Using the Local Zero and Span Buttons

and a Pressure Source or Process Pressure

Reranging using the local zero and span adjustments and a pressure source is a

way of reranging the transmitter when specific 4 and 20 mA points are not known

or a communicator is not available. When you set the 4 mA point the span is

maintained; when you set the 20 mA point the span changes.

To rerange using the zero and span adjustments, refer to “Rerange Procedure” on

page 4-13.

2-5

Page 14

Damping

HART Fast Keys

The Damping command changes the response time of the transmitter to smooth

variations in output readings caused by rapid changes in input. Determine the

appropriate damping setting based on the necessary response time, signal stability,

and other requirements of the loop dynamics of your system. The default damping

value is 0.50 seconds and can be reset in fixed increments of 0.05, 0.10, 0.20, 0.40,

0.80, 1.60, 3.20, 6.40, 12.8, or 25.6 seconds.

1. 3. 6

DETAILED SETUP

Meter Setup

HART Fast Keys

The Meter Type command allows you to configure the transmitter for use with an

LCD meter. Transmitters shipped without meters are set to “NONE.” Change the

meter settings as often as necessary to reflect changing process or application

conditions. To change the meter settings, and thereby configure the transmitter to

recognize the LCD meter, perform the following procedure.

1.Select 1 Device setup, 4 Detailed setup, 3 Output condition, 4 Meter options to

prepare to change the meter settings.

2.Select the appropriate variable configuration from the Meter options screen,

and press enter.

1, 4, 3, 4

NOTE

Selecting “None” from the meter type screen will disable the meter.

3.Select SEND to download the new meter configuration information to the

transmitter.

For a more detailed description of the LCD meter features and diagnostic messages,

refer to Section 7 LCD Meter.

Burst Mode

HART Fast Keys

Burst Mode sets the transmitter to maintain digital contact with a Digital Control

System that has custom software to support burst mode. When the Model PX2088

Smart is configured for burst mode, it provides faster digital communication from

the transmitter to the control system by eliminating the time required for the control

system to request information from the transmitter.

1, 4, 3, 4, 3

2-6

Page 15

Burst mode is compatible with use of the analog signal. Because HART® protocol

features simultaneous digital and analog data transmission, the analog value can

drive other equipment in the loop while the control system is receiving the digital

information. Burst mode applies only to the transmission of dynamic data (pressure

and temperature in engineering units, pressure in percent of range, and/or analog

output in mA or V), and does not affect the way other transmitter data is accessed.

Access to information other than dynamic transmitter data is obtained through the

normal poll/response method of HART communication. A HART-based

communicator or the control system may request any of the information that is

normally available while the transmitter is in burst mode. Between each message

sent by the transmitter, a short pause allows the HART-based communicator or a

control system to initiate a request. The transmitter will receive the request, process

the response message, and then continue “bursting” the data approximately three

times per second.

Save, Recall, or Clone Configuration Data

HART Fast Keys

Data that was entered off-line can be stored in the communicator memory and

downloaded to other transmitters later. Data also can be copied from a transmitter in

order to be sent to other transmitters in a process known as “cloning”. This is

especially useful if you work with a large number of transmitters that require the

same configuration data.

left arrow, 3 (note)

Enable or Disable Local Span and Zero Buttons

HART Fast Keys

The Local Keys command allows you to enable or disable the local span and zero

buttons. Disabling the local keys will prevent unauthorized reranging using the span

and zero buttons, but will not prevent reranging using the communicator . To prevent

all changes to the configuration data, use the transmitter security jumper (see

“Transmitter Security” on page 4-12).

1, 4, 4, 1, 7

2-7

Page 16

CALIBRATION

Calibrating the transmitter increases the precision of your measurement system.

You may use one or more of a number of trim functions when calibrating.

To understand the trim functions, it is necessary to understand that smart

transmitters operate differently from analog transmitters. An important difference is

that smart transmitters are fa ctory -c haracte rized; they are shipped with a standard

sensor curve stored in the transmitter firmware. In operation, the transmitter uses

this information to produce a process variable output, in engineering units,

dependent on the sensor input. The trim functions allow you to make corrections to

the factory-stored characterization curve by digitally altering the transmitter’s

interpretation of the sensor input.

The trim functions should not be confused with the rerange functions. Although the

rerange command matches a sensor input to a 4–20 mA output—as in conventional

calibration—it does not affect the transmitter’s interpretation of the input.

Calibration Overview

Complete calibration of the Model PX2088 Smart Pressure Transmitter involves one or

more of the following tasks:

Configure the Analog Output Parameters

nSet Process Variable Units (Page 2-3)

nRerange (Page 2-5)

nSet Output Type (Page 2-4)

nSet Damping (Page 2-6)

Calibrate the Sensor

nFull Trim (Page 2-10)

nZero Trim (Page 2-10)

Calibrate the 4–20 mA Output

nDigital to Analog Trim (Page 2-11) or

nScaled Digital to Analog Trim (Page 2-12)

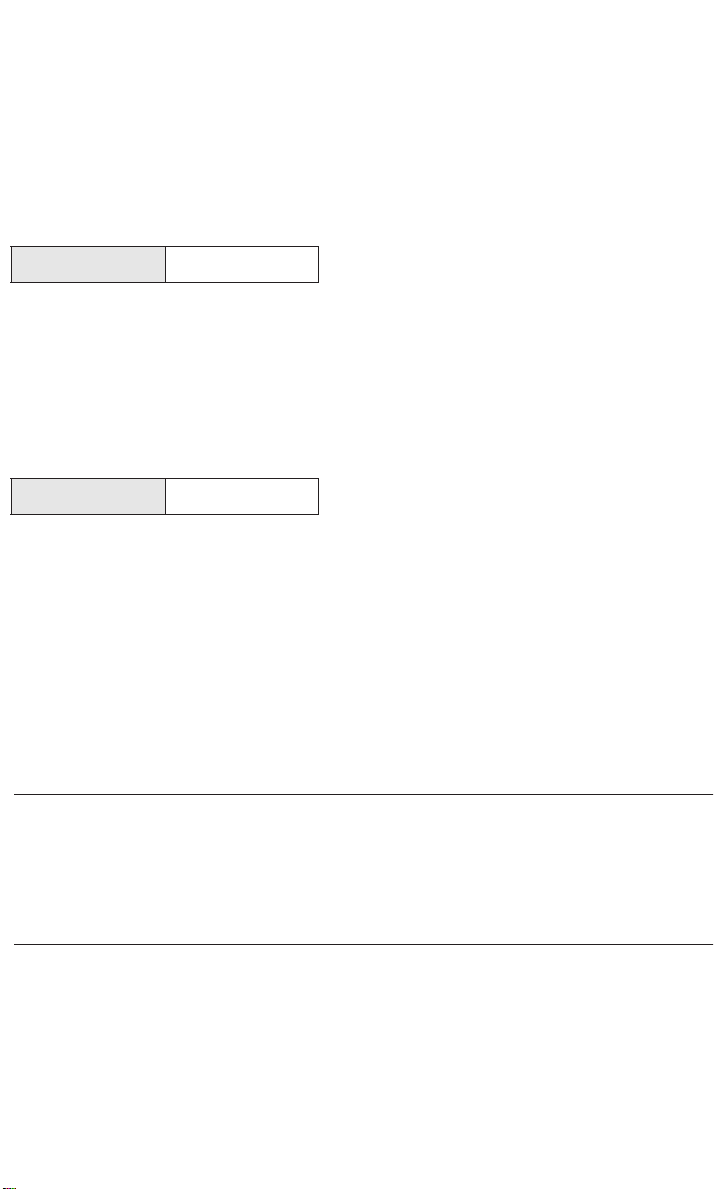

Figure 2-3 illustrates the Model PX2088 Smart transmitter data flow. This data flow

can be summarized in four major steps:

1.A change in pressure is measured by a change in the sensor output (Sensor

Signal).

2.The sensor signal is converted to a digital format that can be understood by

the microprocessor (Analog-to-Digital Signal Conversion).

3.Corrections are performed in the microprocessor to obtain a digital

representation of the process input (Digital PV).

4.The Digital PV is converted to an analog value

(Digital-to-Analog Signal Conversion).

2-8

Page 17

FIGURE 2-3. Transmitter Data Flow

with Calibration Options.

(Transmitter Ranged 0 to 100 inH

2

Transmitter Electronics Module

Analog-to-

Digital Signal

Conversion

3 4

Microprocessor

Digital PV

O)

2

Digital-to-Analog

Signal Conversion

Analog Output

1

100 inH2O

Sensor Signal

Input Device

If readings do not

match perform

sensor trim

NOTES

1)Value on PV line should equal

the input pressure

2)Value on AO line should equal the

output device reading

HART Communications

PX2088S:PT-4763

Online

1 Device Setup

2 PV 100.00 inH2O

3 AO 20.00 mA

4 LRV 0.00 inH2O

5 URV 100.00 inH2O

20.00 mA

Output Device

If readings do

not match

perform

output trim

Deciding Which Trim

Procedure to Use

To decide which trim procedure to use, you must first determine whether the analogto-digital section or the digital-to-analog section of the transmitter electronics is in

need of calibration. To do so, refer to Figure 2-3 and perform the following procedure:

1.Connect a pressure source, a HART communicator, and an output device to

the transmitter.

2.Establish communication between the transmitter and the communicator.

3.Apply the desired 20mA point pressure (100 in H2O, for example).

4.Compare the applied pressure to the Process Variable (PV) line on the

Communicator Online Menu. If the PV reading on the communicator does not

match the applied pressure, and you are certain your test equipment is

accurate, perform a sensor trim.

5.Compare the Analog Output (AO) line on the communicator online menu to

the digital readout device. If the AO reading on the communicator does not

match the digital readout device, and you are certain your test equipment is

accurate, perform an output trim.

Sensor Trim

You can trim the sensor using either the full trim or the zero trim function. The trim

functions vary in complexity, and their use is application-dependent. Both alter the

transmitter’s interpretation of the input signal.

2-9

Page 18

A zero trim is a single-point adjustment. It is useful for compensating for mounting

position effects, and can be performed with the transmitter installed or from the

bench. Since this correction maintains the slope of the characterization curve, it

should not be used in place of a full trim over the full sensor range.

A full trim is a two-point sensor calibration where two end-point pressures are

applied, and all output is linearized between them. Y ou should always adjust the low

trim value first to establish the correct offset. Adjustment of the high trim value

provides a slope correction to the characterization curve based on the low trim value.

The factory-established characterization curve is not changed by this procedure. The

trim values allow you to optimize performance over your specified measuring range

at the calibration temperature.

Zero Trim

HART Fast Keys

1, 2, 3, 3, 1

To calibrate the sensor using the zero trim function, perform the following procedure.

1. Vent the transmitter and attach a communicator to the measurement loop.

2. From the communicator main menu select 1 Device setup,

2 Diagnostics and service, 3 Calibration, 3 Sensor trim, 1 Zero trim to prepare

to adjust the zero trim.

NOTE

The transmitter must be within 3% of true zero (zero based) in order to calibrate

using the zero trim function.

3. Follow the commands provided by the communicator to complete the

adjustment of the zero trim.

Full Trim

HART Fast Keys

1, 2, 3, 3

To calibrate the sensor using the full trim function, perform the following procedure.

1. Assemble and power the entire calibration system including a transmitter,

communicator, power supply, pressure input source, and readout device.

NOTE

Use a pressure input source that is at least three times more accurate than the

transmitter, and allow the input pressure to stabilize for 10 seconds before entering

any values. If remote seals are used allow more time for the input pressure to

stabilize.

2. From the communicator main menu select 1 Device setup,

2 Diagnostics and service, 3 Calibration, 3 Sensor trim, 2 Lower sensor trim to

prepare to adjust the lower trim point.

2-10

Page 19

NOTE

Select pressure input values so that the low and high values are equal to or outside

the 4 and 20 mA points. Do not attempt to obtain reverse output by reversing the

high and low points. The transmitter allows approximately a 5% URL deviation from

the characterized curve established at the factory.

3.Follow the commands provided by the communicator to complete the

adjustment of the lower value.

4.Repeat the procedure for the upper value, replacing 2 Lower sensor trim with

3 Upper sensor trim in Step 2.

Output Trim

The output trim commands allow you to alter the transmitter’s conversion of the

input signal to a 4–20 mA output (see Figure 2-3 on page 2-9). Adjust the analog

output signal at regular intervals to maintain measurement precision. Match the

transmitter output to the output of the digital readout device (ammeter, DCS, etc.).

You can trim the transmitter output using either the digital to analog trim or the

scaled digital to analog trim function.

Digital to Analog Trim

HART Comm.

To perform a digital-to-analog trim, perform the following procedure.

1.From the HOME screen, select 1 Device setup, 2 Diag/Service, 3 Calibration, 4

D/A trim. Select “OK” to after you set the control loop to manual.

2.Connect an accurate reference meter to the transmitter at the “Connect

reference meter” prompt. To do so, connect the meter across the test terminals

in the transmitter terminal compartment, or use the readout device within the

loop.

3.Select “OK” after connecting the reference meter.

4.Select “OK” at the “Setting fld dev output to 4 mA” prompt.

The transmitter outputs 4.00 mA.

5.Record the actual value from the reference meter, and enter it at the “Enter

meter value” prompt.

The communicator prompts you to verify whether or not the output value equals the

value on the reference meter.

6.Select 1 Yes if the reference meter value equals the transmitter output value,

or 2 No if it does not.

If you select 1 Yes, proceed to Step 7.

If you select 2 No, repeat Step 5.

1, 2, 3, 2, 1

1

2-11

Page 20

7.Select “OK” at the “Setting fld dev output to 20 mA” prompt, and repeat Steps

5 and 6 until the reference meter value equals the transmitter output value.

Select “OK” after you return the control loop to automatic control.

Scaled Digital to Analog Trim

HART Comm.

1, 2, 3, 2, 2

The Scaled D/A Trim command matches the 4 and 20 mA points to a user-selectable

reference scale other than 4 and 20 mA (1 to 5 volts if measuring across a 250 ohm

load, or 0 to 100 percent if measuring from a DCS, for example). To perform a scaled

D/A trim, connect an accurate reference meter to the transmitter and trim the

output signal to scale as outlined in the Output Trim procedure.

NOTE

Use a precision resistor for optimum accuracy. If you add a resistor to the loop,

ensure that the power supply is sufficient to power the transmitter to a 20 mA

output with the additional loop resistance.

DIAGNOSTICS AND SERVICE

Test Device

HART Fast Keys

The Test device command initiates a more extensive diagnostic routine than that

performed continuously by the transmitter. If the transmitter test detects a problem,

the communicator displays messages to indicate the source of the problem.

Loop Test

HART Fast Keys

The Loop Test command verifies the output of the transmitter, the integrity of the

loop, and the operations of any recorders or similar devices installed in the loop. To

initiate a loop test, perform the following procedure:

1.From the HOME screen, Select 1 Device Setup, 2 Diagnostics and Service, 2

Loop Test, to prepare to perform a loop test.

2.Select “OK” after you set the control loop to manual.

The communicator displays the loop test menu.

3.Select a discreet milliamp level for the transmitter to output. At the “Choose

analog output” prompt, select 1 4mA, 2 20mA, or select 3 other to manually

input a value between 4 and 20 milliamps.

1, 2, 1, 1

1, 2, 2

2-12

Page 21

4.Check the current meter installed in the test loop to verify that it reads the

value you commanded the transmitter to output. If the readings do not match,

the transmitter requires an output trim or the current meter is

malfunctioning.

After completing the test procedure, the display returns to the loop test screen and

allows you to choose another output value.

MULTIDROP COMMUNICATION

Multidropping transmitters refers to the connection of several transmitters to a

single communications transmission line. Communication between the host and the

transmitters takes place digitally with the analog output of the transmitters

deactivated. Many of the SMART transmitters can be Multidropped.

With the HART smart communications protocol, up to 15 transmitters

can be connected on a single twisted pair of wires or over leased phone lines. Note

that Burst Mode Operation is not compatible with multidrop communications.

The application of a multidrop installation requires consideration of the update rate

necessary from each transmitter, the combination of trans mitter models, and the

length of the transmission line. Multidrop installations are not recommended where

intrinsic safety is a requirement. Communication with the transmitters can be

accomplished with commercially available Bell 202 modems and a host

implementing the HART protocol. Each transmitter is identified by a unique address

(1-15) and responds to the commands defined in the HART protocol.

Figure 2-4 shows a typical multidrop network. This figure is not intended as an

installation diagram.

FIGURE 2-4. Typical Multidrop Network.

Bell 202

RS-232-C

Modem

Power

3051-0087A

HART-based communicators can test, configure, and format a multidropped

transmitter the same way as a transmitter in a standard point-to-point installation.

2-13

Page 22

NOTE

The transmitter is set to address 0 at the factory, allowing it to operate in the

standard point-to-point manner with a 4–20 mA output signal. To activate multidrop

communication, you must change the transmitter address to a number from 1 to 15.

This change deactivates the 4–20 mA analog output, locking it to 4 mA. It also

disables the failure mode alarm signal, which is controlled by the upscale/downscale

jumper position.

Changing a Transmitter Address

HART Fast Keys

1, 4, 3, 4, 1

To change the address of a multidropped transmitter, follow these fast key

sequences. To activate multidrop communication, the transmitter address must be

changed to a number from 1 to 15.

Polling a Multidropped Loop

HART Fast Keys

Left Arrow, 1, 1,

Polling a multidropped loop determines the model, address, and number of

transmitters on the given loop.

NOTE

The Model HC275 HART Communicator requires you to use the Utility Menu to

perform an auto poll. This menu is available from the Main Menu of the HART

Communicator. Press the left arrow to move from the Online Menu to the Main

Menu. Press 4 from the Main Menu to access the Utility Menu. The HART

Communicator will only recognize transmitters with an address of “0” unless polling

is initiated.

2-14

Page 23

SECTION

3 Commissioning the Analog

Transmitter

OVERVIEW

This section contains calibration information for the Models PX2088

Pressure Transmitter. The transmitter can be continuously adjusted to spans

between maximum span and

information is programmed into the microprocessor at the factory; linearity

adjustment is not necessary in the field.

SAFETY MESSAGES

This section contains procedures that require connecting the transmitter, or making

connections in an explosive atmosphere. The following safety messages apply to all

procedures throughout this section requiring cover removal and connection to the

transmitter terminal block. Keep the following safety messages in mind whenever

you perform an operation requiring cover removal or connection to a measurement

loop.

1

/10 of maximum span.Transmitter linearity

Failure to follow safe commissioning guidelines can cause death or serious injury. Please

review the following safety messages before commissioning a Model PX2088

Pressure Transmitter.

■To avoid explosions, do not remove the instrument cover or make electrical connections in

explosive atmospheres when the circuit is alive. Make sure the instrument is installed in

accordance with intrinsically safe or nonincendive field wiring practice.

■To meet explosion proof requirements, make sure that both transmitter covers are fully

engaged.

High voltage that may be present on leads could cause electrical shock:

nAvoid contact with leads and terminals.

1

3-1

Page 24

COMMISSION: ON THE BENCH OR IN THE LOOP

Commission the Model PX2088 Analog transmitter before or after

installation. It may be useful to commission the transmitter on the bench before

installation to ensure proper operation and to avoid exposing the transmitter

electronics to the plant environment. Commissioning consists of applying pressure

and setting the zero and span to the desired values.

FIGURE 3-1. Transmitter Wiring.

TEST TERMINALS

Do not contact meter leads from

either test terminal on the output board to case ground. This can result in the maximum

current from the power supply flowing through the test meter and may blow the test meter

fuse, or damage the test meter or transmitter.

Terminals for connecting an ammeter to the transmitter are provided in both the

terminal and the electronics compartments. To connect an ammeter in the terminal

compartment, connect the positive lead to the terminal marked “+TEST,” and the

negative lead to the terminal marked “–”. To connect an ammeter in the electronics

compartment, attach the positive lead to the terminal marked “+ TEST,” and the

negative lead to the terminal marked “– TEST” (see Figure 3-2).

3-2

Page 25

FIGURE 3-2. Transmitter Terminal and Electronics Compartments.

ELECTRONICS

COMPARTMENT

Potentiometer

Negative Terminal

Test Terminal

TERMINAL

COMPARTMENT

Test

Terminals

Selector

Switch

ZERO AND SPAN ADJUSTMENTS

Adjustment controls for zero and span are located in the transmitter electronics

compartment. Calibrate the transmitter with the three-position switch and the

¾-turn potentiometer (see Figure 3-2).

2088-2088B02H, 2088A02A

Selector Switch

The selector switch is labeled “Z” (Zero), “RUN,” and “S” (Span). The switch is set to

the “RUN” position at the factory, and should remain there under normal operation.

The selector switch must be returned to the “RUN” position after setting the proper

calibration. Failure to return the switch to the “RUN” position will, after 20 minutes, cause

the transmitter to return to the previously set 4–20 mA points. This will result in erroneous

transmitter output.

3-3

Page 26

Potentiometer Adjustment

The procedure for calibrating the Model PX2088 is different from that of any

other pressure transmitters and takes some time to become accustomed to.

However, this method of calibration is considerably faster than other calibration

methods. In addition, there is no interaction between the zero and span adjustments.

An important feature of this design is that the potentiometer is an active part of the

circuit only during calibration. The potentiometer is removed from the active circuit

when the switch is placed in the “RUN” position. This unique design eliminates the

temperature drift and stability shifts often associated with common potentiometers.

The potentiometer is marked “DN” (Down), “FINE,” and “UP.” The coarse

adjustment regions are at each end, and a fine adjustment region is in the center.

The output of the transmitter increases or decreases automatically when the

potentiometer is placed in the coarse adjustment regions. The longer the

potentiometer is held in the coarse adjustment region, the faster the rate of change

in output.

The potentiometer is a ¾-turn device and has a mechanical stop to prevent full rotation. Do

not exert large twisting forces against the mechanical stop or damage will result.

NOTE

When the transmitter output is saturated below 4mA or above 20 mA, the

potentiometer may appear to have no effect on the transmitter calibration because

the microprocessor is adjusting the calibration, but the current-limiting circuitry is

maintaining the output at the saturation levels. Place the potentiometer in the

coarse-adjust region and wait at least 15 seconds for the output to change.

Setting the Zero

Setting the zero point of the transmitter involves applying pressure and adjusting

the potentiometer accordingly. To set the zero point of the transmitter, use the

following procedure:

1.If the transmitter does not have a readout device, attach an ammeter using

the test terminals in either compartment (see Figure 3-2 on Page 3-3).

2.Ensure that the selector switch is in the “RUN” position. Apply the pressure to

which the zero point will be calibrated.

3.Set the selector switch to “Z.”

4.Using the potentiometer, adjust the transmitter output until the readout

device reads the 4 mA.

5.Return the selector switch to the “RUN” position.

3-4

Page 27

The selector switch should not be set to the “Z” position unless the potentiometer will be

adjusted. Failure to adjust the potentiometer while in the “Z” position will result in erroneous

transmitter output during an overpressure event, and a shift in calibration after the

overpressure event. The transmitter can be returned to normal operation by performing

either of the following procedures:

1.Remove power from the transmitter while the selector switch is in the “RUN” position,

and re-apply power. This will reset the former zero calibration.

OR

2.Calibrate the zero point of the transmitter by following the instructions in the section

entitled “Setting the Zero.”

Setting the Span

Setting the span of the transmitter involves applying pressure and adjusting the

potentiometer accordingly. To set the span of the transmitter, use the following

procedure:

1. If the transmitter does not have a readout device, attach an ammeter using

the test terminals in either compartment (see Figure 3-2 on Page 3-3).

2. Ensure that the selector switch is in the “RUN” position. Expose the

transmitter to full scale pressure.

3. Set the selector switch to “S.”

4. Using the potentiometer, adjust the transmitter output until the readout

device reads the 20mA.

5. Return the switch to “RUN.”

3-5

Page 28

3-6

Page 29

SECTION

4

Installation

OVERVIEW

This section contains a flowchart (Figure 4-1 on Page 4-2), installation procedures,

and a wiring diagram (Figure 4-8 on Page 4-10), to guide you to a successful Model

PX2088 installation. Shielded cable should be used for best results in

electrically noisy environments.

Safety Messages

Instructions and procedures in this section may require special precautions to

ensure the safety of the personnel performing the operations. Please read all

warnings before proceding.

nExplosions could result in death or serious injury:

nDo not remove the transmitter cover in explosive atmospheres

when the circuit is alive.

nBefore connecting a HART-based communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

nVerify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

nBoth transmitter covers must be fully engaged to meet explosion-proof requirements.To

avoid output shifts in critical applications, do not plug the low side with a solid plug.

nTo avoid process leaks, install and tighten all four flange bolts before applying

pressure, or process leakage may result. When properly installed, the flange bolts will

protrude through the top of the module housing. Attempting to remove the flange bolts

while the transmitter is in service may cause process fluid leaks.

Failure to follow these installation guidelines could result in death or serious injury:

nMake sure only qualified personnel perform the installation.

4-1

Page 30

High voltage that may be present on leads could cause electrical shock:

• Avoid contact with leads and terminals.

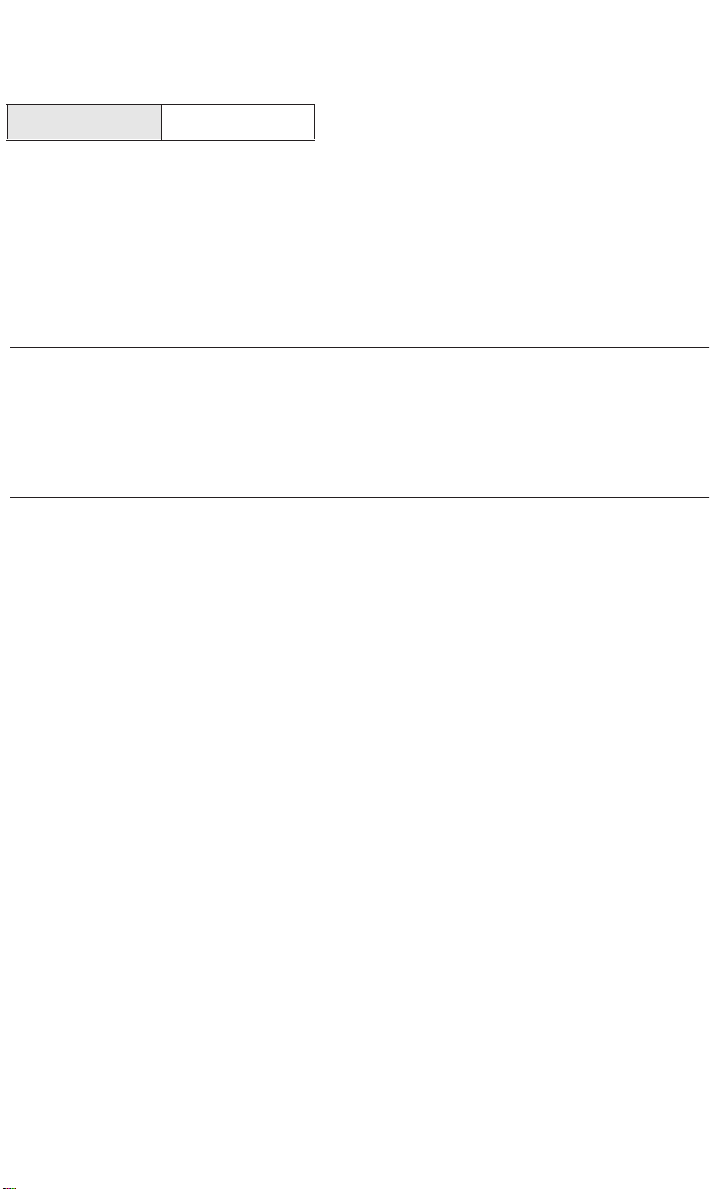

FIGURE 4-1. Installation Flowchart.

START HERE

VERIFY

A

Apply Pressure

Within

Specifications?

No

Refer to

Troubleshooting

Section

Yes

B

Check Configuration

(See Chapter 2)

Within

Specifications?

No

Set Units

(See Chapter 2)

Set Range Points

Set Output Type

Set Damping

Perform Sensor

and/or Output

Trim

A

Smart

Yes

A

Bench

Calibration?

Yes

Check Configuration

Specifications?

No

ADJUST ANALOG

ZERO/SPAN

(See Chapter 3)

Repeat Steps

until

Calibrated

A

No

Analog

(See Chapter 3)

Within

Yes

FIELD

B

INSTALL

Check Jumper

or Switches

(Smart Only)

Mount

Transmitter

Check for Leaks

(Process

Smart

Zero Trim

Connections)

Wire

Transmitter

Power

Transmitter

Analog

Zero

Transmitter

A

Confirm Transmitter

Configuration

Transmitter for

Mounting Effects

4-2

DONE

Page 31

INSTALLATION

Installation consists of attaching the transmitter to the process piping and making

electrical connections.

The Model PX2088 weighs approximately 2.0 pounds (0.9 kg). In many cases, its

compact size and light weight makes it possible to mount the Model PX2088 directly to

the impulse line without using an additional mounting bracket. When this is not

desirable, mount directly to a wall, panel, or two-inch pipe using the optional

mounting bracket (see Figure 4-3).

INSTALLATION PROCEDURES

Model PX2088

Do not apply torque directly to the electronics housing. Rotation between the electronics

housing and the process connection can damage the electronics. To avoid damage, apply

torque only to the hex-shaped process connection.

Electronics

Housing

Process

Connection

Impulse Piping

Impulse piping configurations depend on specific measurement conditions. Use the

following information and Figure 4-2 as a guideline when installing impulse piping.

Liquids: Make the line tap on the side of the pipe to prevent sediment deposits

from plugging the impulse line or transmitter. Mount the transmitter level with or

below the tap so gases vent into the process line.

Gases: Make the line tap on either the top or the side of the process line. Mount the

transmitter level with or above the line tap so liquids drain into the process line.

Steam: Make the line tap in the side of the process line. Mount the transmitter

below the line tap to ensure that the impulse line remains filled with condensate.

4-3

Page 32

FIGURE 4-2. Model PX2088 Mounting Configurations for Liquids, G ases, an d Ste am .

GAS OR LIQUID

SERVICE

LIQUID OR STEAM

SERVICE

GAS

SERVICE

FIGURE 4-3. Model PX2088 Mounting Configurations with Optional Bracket.

5.2

(132)

3.6

(91)

1.25

(32)

2.48

(63)

Hex

5.97

(152)

Mounting bracket ordering

code MB,

and optional block and bleed

valve.

3.10

(79)

2-inch U-Bolt

for Pipe

Mounting

NOTE

Dimensions are in

inches

(millimeters).

4-4

Page 33

nExplosions could result in death or serious injury:

nDo not remove the transmitter cover in explosive atmospheres

when the circuit is alive.

nBefore connecting a HART-based communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

nVerify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

nBoth transmitter covers must be fully engaged to meet explosion-proof requirements.To

avoid output shifts in critical applications, do not plug the low side with a solid plug.

High voltage that may be present on leads could cause electrical shock:

•Avoid contact with leads and terminals.

To power the transmitter, connect the positive power lead to the terminal marked

“SIG +” and the negative power lead to the terminal marked “–” (see Figure 4-8 on

Page 4-10). Tighten the terminal screws to ensure that adequate contact is made. No

additional power wiring is required.

To connect test equipment for monitoring the output of the Model PX2088

during maintenance procedures, connect one lead to the terminal labeled

“TEST+” and the other lead to the terminal labeled “–” (see Figure 4-8 on Page 4-10).

Avoid contact with the leads and the terminals.

Signal wiring may be grounded at any one point on the measurement loop, or it may

be left ungrounded. The negative side of the power supply is a recommended

grounding point. The transmitter case may be grounded or left ungrounded.

Conduit connections at the transmitter should be sealed to prevent moisture

accumulating in the field terminal side of the transmitter housing. Also, install

wiring with a drip loop with the bottom of the drip loop lower than the conduit

connection of the transmitter housing.

4-9

Page 34

FIGURE 4-8. Transmitter Field Wiring.

Ground Terminal

Power

Supply

Positive Terminal

Negative Terminal

Test Terminal

Signal loop may be grounded at

any point or left ungrounded

Power Supply

The dc power supply should provide power to the transmitter with less than one

percent ripple. The total loop resistance load is the sum of the resistance of the signal

wires and the resistance load of the controller, indicator, and other pieces of

equipment in the loop. Note that the resistance of intrinsic safety barriers, if used,

must be included. Figure 4-9 shows the transmitter power supply load limitations.

FIGURE 4-9. Transmitter Load Limitations.

MODEL PX2088

Max. Load = 45.4 (Power Supply Voltage) –10.5

Operating

Load (Ohms)

Power Supply (dc Volts)

(1)For CENELEC EX ia approval, power supply

must not exceed 30 volts.

NOTE

Minimum load impedance for Output Code M

is 100 kilohms.

Region

(1)

4-10

Page 35

FAILURE MODE AND SECURITY JUMPERS

(Security Jumpers are Available with Smart Transmitters Only)

Failure Mode

As part of normal operation, the Model PX2088 Smart continuously monitors its

own operation. This automatic diagnostic routine is a timed series of checks repeated

continuously. If the diagnostic routine detects a failure in the transmitter, the

transmitter drives its output either below or above specific values depending on the

position of the failure mode jumper or switch.

Smart Transmitters

Whether the output is driven high or low when in failure mode is user-selectable by a

jumper on the transmitter. The values to which 4–20 mA transmitters drive their

output in failure mode depend on whether they are factory-configured to standard or

NAMUR-compliant operation. The values for each are as follows:

Standard Operation

linear output:3.9 ≤ I ≤ 20.8 mA

fail low: 3.75 mA

fail high 21.75 mA

NAMUR-Compliant Operation (Option Code C4)

linear output:3.8 ≤ I ≤ 20.8 mA

fail low: 3.6 mA

fail high: 22.5

To determine the failure mode configuration of your transmitter, review the failure

mode options using a Model HC275 HART Communicator.

NOTE

The failure mode configuration, whether standard or NAMUR-compliant, is

configured at the factory and can not be changed in the field.

Failure Mode Jumper Locations

Without a meter installed

The failure mode alarm jumper is located on the front side of the electronics

module just inside the electronics housing cover and is labeled ALARM (See

Figure 4-10). Do not remove the instrument cover in explosive atmospheres when

the circuit is alive. Both transmitter covers must be fully engaged to meet

explosion proof requirements.

With a meter installed

The failure mode alarm jumper is located on the LCD faceplate in the electronics

module side of the transmitter housing and is labeled ALARM (See Figure 4-10).

Do not remove the instrument cover in explosive atmospheres when the circuit is

alive. Both transmitter covers must be fully engaged to meet explosion proof

requirements.

Analog Transmitters

If self diagnostics detect a sensor or microprocessor failure, the analog signal is

driven low to alert the user (I ≤ 3.6 mA or V≤ 1V for output Code M).

4-11

Page 36

Transmitter Security

(Security Jumpers are Available with Smart Transmitters Only)

After commissioning the transmitter, you may wish to protect the configuration data

from unwarranted changes. The transmitter is equipped with a security jumper that

can be positioned to prevent changes to the configuration data. (see Figure 4-10).

Remember that the circuit board is electrostatically sensitive. Be sure to observe

handling precautions for static-sensitive components to avoid damage to the circuit

board.

When the transmitter security jumper is in the “ON” position, the transmitter will

not accept any “writes” to its memory. This means that configuration changes (such

as digital trim and reranging) cannot take place when the transmitter security is on.

The zero and span adjustment buttons are also disabled. To reposition the jumper,

use the following procedure.

1.If the transmitter is installed, secure the loop, and remove power.

2.Remove the housing cover opposite the field terminal side. Do not remove the

instrument cover in explosive atmospheres when the circuit is alive.

3.Reposition the jumper. Avoid contact with the leads and the terminals. Refer

to Figure 4-10 for the location of the jumper and the ON and OFF positions.

4.Reattach the transmitter cover. The cover must be fully engaged to comply

with explosion-proof requirements.

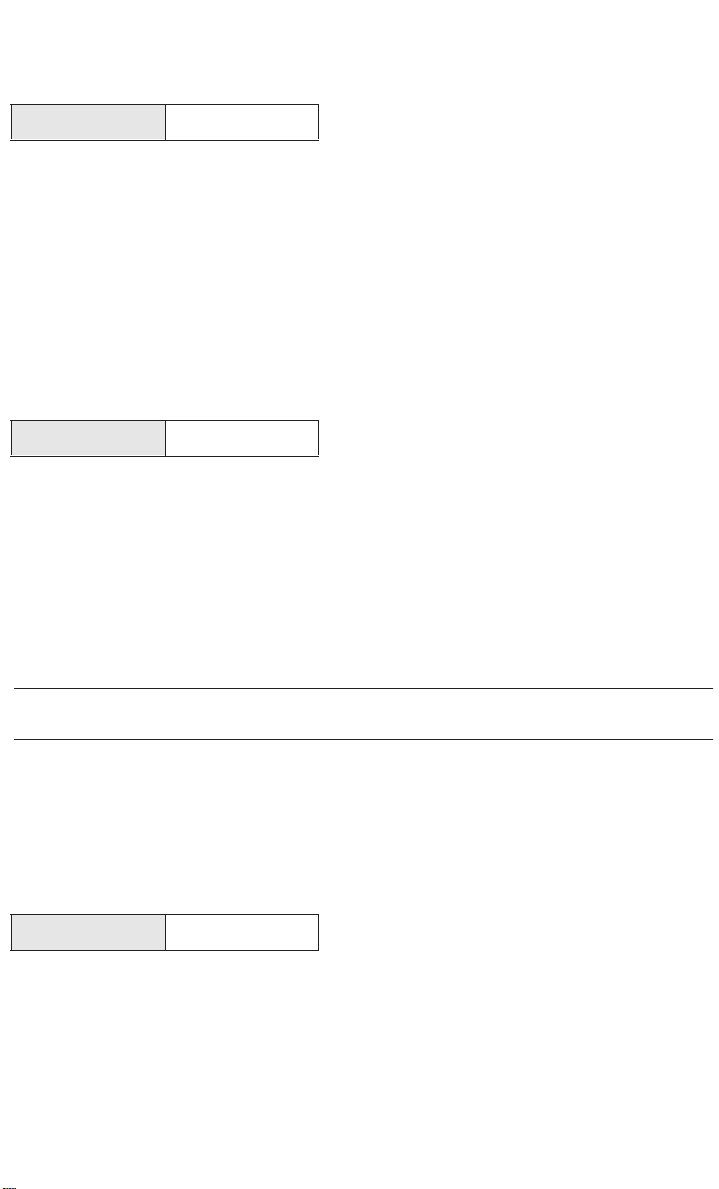

FIGURE 4-10. Transmitter Alarm and Security Jumper Locations.

Alarm and Security Jumpers Without Meter

Alarm

Security

Alarm and Security Jumpers With Meter

Alarm

y

Securit

NOTE

If either the alarm or security jumper is dislodged or removed from its position the

transmitter reverts to default alarm or security settings of:

Alarm: output high

Security: off

ZERO AND SPAN ADJUSTMENTS

Smart

The Model PX2088 Smart is equipped with local zero and span adjustment buttons. The

buttons are located on the top of the transmitter beneath the certifications label. Use

the zero and span adjustments to set the 4 and 20 mA output points.

4-12

Page 37

Rerange Procedure

To rerange the transmitter using the span and zero buttons, perform the following

procedure.

1. Loosen the screw holding the nameplate on top of the transmitter housing and

rotate the nameplate to expose the zero and span buttons (see Figure 4-11).

2. Using a pressure source with an accuracy three to ten times the desired

calibrated accuracy, apply a pressure equivalent to the lower range value.

3. To set the 4 mA point, press and hold the zero button for at least two seconds,

then verify that the output is 4 mA. If a meter is installed, it will display

ZERO PASS.

4. Apply a pressure equivalent to the upper range value.

5. To set the 20 mA point, press and hold the span button for at least two seconds,

then verif y t h at th e ou t pu t i s 2 0 mA . If a meter is installed, it will display

SPAN PASS.

NOTE

If the transmitter security jumper is in the “ON” position, or if the local zero and

span adjustments are disabled through the software, you will not be able to make

adjustments to the zero and span using the local buttons. Refer to Figure 4-10 on

Page 4-12 for the proper placement of the transmitter security jumper.

FIGURE 4-11. Local Zero and Span Adjustments.

Span and Zero Adjustment Buttons

Disabling the Zero and Span Adjustments

After you rerange the transmitter using the span and zero adjustments, you may

wish to disable the adjustments to prevent further reranging. To disable the span

and zero adjustments, either activate the transmitter security jumper (see

“Transmitter Security” on Page 4-12) or use the sofware to disable the zero and span

adjustment buttons (HART fast key sequence 1,4,4,1,7).

NOTE

The transmitter security jumper prevents any changes to the transmitter

configuration data. The software lockout sequence only disables the local span and

zero adjustment buttons.

4-13

Page 38

Analog

If it is necessary to make zero or span adjustments after installation of the

transmitter, use the zero/span selector switch and the potentiometers to rerange the

transmitter

4-14

Page 39

SECTION

5

Troubleshooting

This section provides basic troubleshooting suggestions to help solve the most

common operating problems.

The following performance limitations may inhibit efficient or safe operation. Critical

applications should have appropriate diagnostic and backup systems in place.

Pressure transmitters contain an internal fill fluid. It is used to transmit the process pressure

through the isolating diaphragms to the pressure sensi ng ele ment. In rare cases, oil leak

paths in oil-filled pressure transmitters can be created. Possible causes include: physical

damage to the isolator diaphragms, process fluid freezing, isolator corrosion due to an

incompatible process fluid, etc.

A transmitter with an oil fill fluid leak can continue to perform normally for a period of time.

Sustained oil loss will eventually cause one or more of the operating parameters to exceed

published specifications while a small drift in operating point output continues. Symptoms of

advanced oil loss and other unrelated problems include:

nSustained drift rate in true zero and span or operating point output or both.

nSluggish response to increasing or decreasing pressure or both.

nLimited output rate or very nonlinear output or both.

nChange in output process noise.

nNoticeable drift in operating point output.

nAbrupt increase in drift rate of true zero or span

or both.

nUnstable output.

nOutput saturated high or low.

FIGURE 5-1. Range of Output.

3.9

mA

3.6 for Analog

3.75 for Smart

Fail Low

(1) Failure mode for output code M is

≤1V.

(2) Above Values are for Standard

Failure Mode. NAMUR compliant

values are different than above.

4

(1)

Process Variable

Out of Range

Normal Operating Range

Hardware Alarm

5-1

20

20.8

21.75

Fail High

Smart only

Page 40

TROUBLESHOOTING

TABLE 5-1. Smart Transmitter Troubleshooting and Corrective Actions.

Symptom Potential Source Corrective Action

High Output Impulse Piping, •Check for blockage in the impulse line.

Electronics •Check test equipment.

Power Supply •Check the output voltage of the power supply at the

Other Components •Replace the transmitter.

Erratic Output Impulse Piping •Check for leaks or blockage in the impulse line.

Loop Wiring •Check for adequate voltage to the transmitter.

Electronics •Check for EMF interference.

Other Components •Replace the transmitter.

•Check to ensure that the blocking valve is fully open.

•Check for trapped gas in a liquid line, or trapped liquid

in a gas line.

•Check to ensure that the density of the fluid in the

impulse line is unchanged.

•Check for sediment in the transmitter process

connection. If you find sediment, flush the process

connection clean with water or an appropriate solvent.

Do not attempt to scrape sediment free; doing so

could puncture the thin isolating diaphragm and destroy

the transmitter.

•Check for frozen process fluid in the process connector.

•Perform full sensor trim.

transmitter.

•Check to ensure that the blocking valve is fully open.

•Check for trapped gas in a liquid line, or trapped liquid

in a gas line.

•Check to ensure that the density of the fluid in the

impulse line is unchanged.

•Check for sediment in the transmitter process

connection. If you find sediment, flush the process

connection clean with water or an appropriate solvent.

•Check for frozen process fluid in the process connector.

•Check for trapped gas in a liquid line, or trapped liquid

in a gas line.

•Check for intermittent shorts, open circuits, and multiple

grounds.

•Check damping.

•Replace the output board and recalibrate the

transmitter.

(1)

(1)

5-2

Page 41

TABLE 5-1. (continued).Smart Transmitter Troubleshoot ing and Co rrective Actions.

Symptom Potential Source Corrective Action

Low Output or

No Output

Impulse Piping •Check for leaks or blockage in the impulse line.

•Check to ensure that the blocking valve is fully open.

•Check for trapped gas in a liquid line, or trapped liquid

in a gas line.

•Check to ensure that the density of the fluid in the

impulse line is unchanged.

•Check for sediment in the transmitter process

connection. If you find sediment, flush the process

connection clean with water or an appropriate solvent.

Do not attempt to scrape sediment free; doing so

could puncture the thin isolating diaphragm and destroy

the transmitter.

•Check for frozen process fluid in the process connector.

Loop Wiring •Check test equipment.

•Check for adequate voltage to the transmitter.

•Check the current rating of the power supply against the

total current being drawn by all transmitters being

powered.

•Check for intermittent shorts, open circuits, and multiple

grounds.

•Check for proper polarity at the signal terminals.

•Check the loop impedance.

Electronics •Replace the electronics board and recalibrate the

transmitter.

Other Components •Replace the transmitter.

TABLE 5-2. Analog Transmitter Troubleshooting Symptoms and Corrective Actions.

Symptom Potential Source Corrective Action

High Output Impulse Piping •Check for blockage in the impulse line..

Power Supply •Check the output voltage of the power supply at the

Output Electronics •Replace the output board and recalibrate the transmitter.

Other Components •Replace the transmitter.

•Check to ensure that the blocking valve is fully open.

•Check for trapped gas in a liquid line, or trapped liquid in

a gas line.

•Check to ensure that the density of the fluid in the

impulse line is unchanged.

•Check for sediment in the transmitter process

connection. If you find sediment, flush the process

connection clean with water or an appropriate solvent.

Do not attempt to scrape sediment free; doing so

could puncture the thin isolating diaphragm and destroy

the transmitter.

•Check for frozen process fluid in the process connector.

transmitter.

(1)

5-3

Page 42

TABLE 5-2. (continued).Analog Transmitter Troubleshooting and Co rrect ive Acti ons.

Symptom Potential Source Corrective Action

Erratic Output Impulse Piping •Check for leaks or blockage in the impulse line.

Loop Wiring •Check for adequate voltage to the transmitter.

Output Electronics •Replace the output board and recalibrate the transmitter.

Other Components •Replace the transmitter.

Low Output or

No Output

Impulse Piping •Check for leaks or blockage in the impulse line.

Loop Wiring •Check for adequate voltage to the transmitter.

Output Electronics •Replace the output board and recalibrate the transmitter.

Other Components •Replace the transmitter.

•Check to ensure that the blocking valve is fully open.

•Check for trapped gas in a liquid line, or trapped liquid in

a gas line.

•Check to ensure that the density of the fluid in the

impulse line is unchanged.

•Check for sediment in the transmitter process

connection. If you find sediment, flush the process

connection clean with water or an appropriate solvent.

•Check for frozen process fluid in the process connector.

•Check for trapped gas in a liquid line, or trapped liquid in

a gas line.

•Check for intermittent shorts, open circuits, and multiple

grounds.

•Check to ensure that the blocking valve is fully open.

•Check for trapped gas in a liquid line, or trapped liquid in

a gas line.

•Check to ensure that the density of the fluid in the

impulse line is unchanged.

•Check for sediment in the transmitter process

connection. If you find sediment, flush the process

connection clean with water or an appropriate solvent.

Do not attempt to scrape sediment free; doing so

could puncture the thin isolating diaphragm and destroy

the transmitter.

•Check for frozen process fluid in the process connector.

•Check the current rating of the power supply against the

total current being drawn by all transmitters being

powered.

•Check for intermittent shorts, open circuits, and multiple

grounds.

•Check for proper polarity at the signal terminals.

•Check the loop impedance.

5-4

Page 43

SECTION

6 Spare Parts and Ordering

SPARE PARTS

.

FIGURE 6-1. Model PX2088 Smart Transmitter Exploded View.

1

5

LCD Meter Cover Assembly

includes LCD Cover and Oring

6

8

2

1

Part Description Item No. Part Number Spares Category

Smart Transmitters (Output Code S)

Electronics Cover (with O-ring)

LCD Meter Cover Assembly

Cover O-rings

Electronics Board Kits

S Output (4–20 mA/Digital HART

Protocol)

S Output (NAMUR Compliant

Operation)

Optional Mounting Bracket

(with 2-inch U-Bolt for Pipe

Mounting)

LCD Meter Kit with Cover

LCD Meter Kit without Cover

Local Zero and Span Kit

Standard Terminal Block

Transient Protection BLock

7

1, 2

6

2

3

3

4

5, 6

5

7

8

8

2

03031-0292-0001

03031-0193-0002

03031-0232-0001

02088-0306-0002

02088-0306-0003

02088-0071-0001

03031-0193-0101

03031-0193-0103

3031-0293-0002

3031-0332-0003

3031-0332-0004

3

4

(1)

B

B

A

A

A

A

B

B

(1) One spare part is recommended for every 25 transmitters in category A, and one spare part for

every 50 transmitters in category B.

6-1

Page 44

FIGURE 6-2. Replacement Parts for the Model PX2088.

1

2

4

2088-2088A04B

5

6

LCD Meter Cover Assembly

includes LCD Cover and O-ring

3

2

2090-2088D03A

1

2088-2088A03B

Part Description Item No. Part Number Spares Category

(1)

Analog Transmitters

(Output Codes A and M)

Electronics Cover

LCD Meter Cover Assembly

Cover O-rings

Electronics Board Kits

(2)

A Output (4–20 mA)

M Output (1–5 V)

1

6

2

3

3

02088-0014-0002

02088-0075-0003

02088-0073-0001

02088-0076-0001

02088-0077-0001

B

B

A

A

Transient Protection

A Output (4–20 mA)

M Output (1–5 V)

--

--

02088-0214-0001

02088-0216-0001

A

A

Optional Mounting Bracket

(with 2-inch U-Bolt for Pipe

Mounting)

LCD Meter Kit with Cover

(3)

LCD Meter Kit without Cover

(3)

4

5, 6

5

02088-0071-0001

02088-0075-0001

02088-0075-0002

A

(1) One spare part is recommended for every 25 transmitters in category A, and one spare part for

every 50 transmitters in category B.

(2) Assembly hardware is included.

(3) Engineering Unit Label Provided.

6-2

Page 45

Page 46

SECTION

7 LCD Meter

LCD METER FOR SMART TRANSMITTERS

The LCD meter provides local indication of the output, and abbreviated diagnostic

messages governing transmitter operation. The meter is located on the electronics

module side of the transmitter, maintaining direct access to the signal terminals. An

extended cover is required to accommodate the LCD Meter for Smart Transmitters.

The LCD Meter can be ordered with the transmitter or added at a later time.

The new meter features a two-line display that accommodates five digits for

reporting the process variable on the top line, and six characters for displaying